Abstract

This paper addresses the highly topical issue of the digitalisation of the port community through the development of advanced port communication systems (PCSs). The efficient and sustainable operation of container terminals (CTs) plays a key role in global trade and in ensuring the sustainable functioning of transport chains. While larger container terminals utilise PCSs, smaller container terminals often face challenges when implementing similar systems due to resource constraints and unique operational characteristics. This research analyses the impact of PCSs on the operational processes and information exchange between the smaller CT in the Port of Koper and the local port community. The aim of this study is to identify the possibilities of upgrading PCSs with modern information technologies, such as artificial intelligence (AI), blockchains, internet-of-things (IoT), etc., that will lead to more efficient execution of operational processes, reduced congestion and a lower carbon footprint for the port community as a whole. The paper provides guidelines for the possible coordinated development of PCSs in the Northern Adriatic to ensure the most harmonised operation of stakeholders in different ports or CTs.

1. Introduction

A container terminal (CT) is an important part of the logistics chain where various operational processes are carried out to ensure the handling and temporary storage of containers [1]. The main operational processes of a CT take place on the sea side of the terminal, on the surface of the terminal and on the land side of the container terminal [2]. The coordination between the operational processes ensures efficient operation of the entire system, which also has a positive effect on the operation of intermodal transport chains [3]. The growth in container traffic, which is expected to increase by 12% per year until 2028, places an increasing technical and technological burden on CTs [4]. This increased burden has a direct impact on the environment. In particular, the proportion of CO2 emissions caused by the means of transport used to handle and transport containers is increasing [5]. The container ships remain in the system for longer, further impacting the environment through greenhouse gas (GHG) emissions, noise and light pollution. The European Emissions Reduction Directive also obliges the transport sector to comply with the directive and the measures it contains to reduce its carbon footprint [6].

The operation of CT depends on the functioning of the port system, which is composed of different stakeholders such as shipowners, freight forwarders, land carriers, public institutions, terminals, insurance companies, shipping agents, etc. Depending on the requirements of the process and the roles of the parties involved, information relevant to the movement of goods through the port system is exchanged between the parties [7]. In the age of digitalisation, port systems use an IT solution for the exchange of information that ensures the electronic exchange of data between stakeholders in real time. The rapid exchange of information is reflected in the efficiency of operational processes within the port system and increases the competitive advantage of the system in terms of the speed at which a container can move through the system [8]. Modern digital technologies are enabling the development of advanced port communication systems (PCSs) that allow stakeholders to exchange data paperless and in real time, even if they use different information systems. This is a development phase based on smart processes, which makes it possible to lay the foundations for the introduction of automation and business analytics to support decision-making and business optimisation [9].

In smaller CTs, the degree of automation of operational processes is lower. Such systems also have difficulties in obtaining timely information, which is essential for planning operations at the berth, in the marshalling yard and on the transhipment tracks. The timeliness of data delivery depends on how communication between stakeholders is handled, in particular whether it is supported by a regulated channel via a single communication point or whether stakeholders exchange data directly with each other [10,11].

The scope of the research concerns the PCS used in the North Adriatic port of Koper. Luka Koper Ltd. operates a multipurpose port with a gravitational area of about 750 km. CT in the Port of Koper handles 1 million of twenty-foot equivalent unit (TEU) per year and is the leading terminal in the Adriatic in terms of throughput [12]. The port and CT are part of a larger port system consisting of logistics terminals in the port area, logistics companies, freight forwarders, car carriers, shipping agents and authorities. Data is exchanged between these parties via PCSs, which were developed with the aim of integrating data from various IT solutions. In this context, the digitalisation of port logistics processes is being driven forward [13]. This study therefore examines the current PCS architecture and the possibilities for improving PCSs in order to optimise the operational processes of CTs and to make the operation of the entire port community more sustainable. The aim of the study is to show the possibilities of upgrading PCSs through the use of modern information technologies (e.g., active communication with the infrastructure) in order to transform the terminal into a smart CT. The research results provide a scientific and professional understanding of the needs and opportunities for the transition of port systems to smart business and thus complement the knowledge for the implementation of solutions at smaller container terminals. Due to the smaller scale of operations, limited research resources and levels of investment, such systems are less likely, and especially slower, to embrace digital and green transformation and sustainable development. The research pursued the basic hypothesis, H1: The current architecture of the PCS in the Port of Koper does not allow the easier and faster implementation of modern IT technologies, and hypothesis H2: The use of blockchain and IoT technologies can significantly improve communication protocols between PCS stakeholders and have a positive impact on the sustainability of the port community.

The paper consists of the following five sections. The second section of the paper presents the theoretical background for the development of PCSs and guidelines for further development through the development of digital tools. The third section describes the research approach, and the fourth section outlines the functionalities of PCSs in the Port of Koper. The fifth section addresses the results of the PCSs’ architecture and emphasises recommendations for further development and transition to smart CTs, which include technical adjustments to achieve higher operational efficiency and sustainable operation. Finally, the sixth section summarises the research contributions and describes future research directions.

2. Theoretical Background

Venus [14] defines that the green management of CTs consists of three main elements, such as cooperation with supply chain partners—stakeholders, environmentally friendly operation, and internal management support. The introduction of digitalisation in ports, with a focus on data exchange, is helping to improve the performance of operations, as noted by Haraldson [15], who also highlights the impact on reducing environmental impact. Greener operational practises have a positive influence on green behaviour and green performance [16]. Tsolakis et al. [17] state that new technologies in CTs lead to greater automation and increase environmental sustainability.

The process of digitalisation in ports has gone through various phases and has constantly evolved with the emergence of new technologies [9]. Moreover, the authors note that digitalisation can be divided into three phases. The first phase aimed to introduce paperless processes through the use of electronic data interchange (EDI). The first port community systems (PCSs) were created, which focus on data exchange among stakeholders. The second phase involved the development of Terminal operating systems (TOSs), which ensure the introduction of automation of container terminals by providing data storage. Such systems are operated with the help of autonomous guided vehicles (AGVs), satellite-based location identification systems (GPS) and digital tag recognition with OCR technology. The third and current phase involves the development of smart ports and container terminals that extend the two previous phases. This includes more advanced data processing, business analyses, communication with infrastructure, situation prediction models, etc. Consequently, ports, port authorities and the port administration can be expected to play a crucial role in the development of PCSs, as also stated by Tijan et al. [18].

Keceli et al. [19] state that the implemented functionalities of PCSs depend on the requirements of the port community stakeholders and are independent of the size of the port. All port stakeholders experience positive effects of PCSs, particularly in terms of connectivity and information exchange, speed, efficiency and quality of service execution, as well as accessibility, security and information quality [20]. In this context, the IT system for port communication consists of three levels: hardware, application components and communication links [21]. Caldeirinha et al. [7] emphasise the role of PCSs in data exchange between the port and port community stakeholders to achieve terminal automation. Providing operational processes with important input information is key to optimising the outputs of the process or functionality, which ultimately enables the optimal operation of the port and CTs.

Carlan et al. [22] examine the cost impact of PCSs on port operations and highlight the increased competitiveness of all parties involved when PCSs is used. In addition to process and cost efficiency, it also makes sense to consider the financial aspect. Anwar et al. [23] emphasise that the digitalisation of CTs requires considerable investment in infrastructure and equipment as well as adjustments to operational processes. Nevertheless, the benefits of developing PCSs outweigh the costs, especially due to efficiency improvement. Zerbino et al. [24] have analysed this in a smaller Mediterranean port. Tijan et al. [25] come to similar conclusions, as the cost efficiency is reflected in the exchange of information, in the possibilities to increase planning efficiency, in the processing of large amounts of data in a short time and in the improvement of cooperation between the players in the port system. In addition to the positive financial effects, Kaup et al. [26] state that the use of systemic solutions to connect different stakeholders ensures faster and more secure execution of business processes. These solutions include process mining (PM), which in combination with PCSs can improve and monitor the execution of operational processes at the berth.

Industry 4.0 also has an impact on the digitalisation of port and CT operations, and De la Pena et al. [27] point out that integration is possible and necessary, especially when integrating Industry 4.0 elements with the TOS. The positive effects of introducing modern technologies such as IoT in ports can also be seen in cross-border effects, as emphasised by Beškovnik and Bajec [28]. Such a development can have an impact on coordinated urbanisation, mobility and business development. Namely, the use of IoT technologies improves the acquisition of real-time data and optimises operations [29]. Furthermore, Heikkila et al. [30] state that the transformation of a port into a Smart Port 4.0 is reflected in higher levels of automation, environmental aspects and connectivity of port community stakeholders. The green transition and sustainable development are therefore also based on the digitalisation of processes within the port community. This is also highlighted by Madkhali et al. [31], as information technologies in combination with advanced analytical tools, artificial intelligence (AI), blockchain and the Internet of Things (IoT) have a significant impact on achieving environmental goals. The technology ensures the efficient use of resources and contributes to a more efficient organisation of business processes and the assessment of environmental risks.

For stakeholder connectivity, blockchain technology is particularly important, but Alahmadi et al. [32] note that blockchain technology is not as widely used for sharing information across the supply chain, which includes CT. Despite the recognised benefits such as impact on efficiency, privacy, speed, traceability, transparency, etc., one of the reasons for limited adoption is mistrust in data storage and processing.

Research into the development and implementation of PCSs is increasing, but there are gaps in the development of PCSs and the concept of the smart port in smaller CTs. These CTs have adapted IT solutions to the growing scale of their activities through their own business development and the parallel development of key players in the port system. Such systems face major challenges in data collection, communication via PCSs and integration with TOS. The introduction of new technologies such as AI, IoT and blockchain technology is an even greater challenge for them.

3. Materials and Methods

The research on the PCSs in the port of Koper was carried out after the introduction of the EdiCenter 2 (EC2) IT solution for CTs in the port of Koper between July and November 2022. The survey data was obtained from the IT company that provides the IT support for the port’s operations. The data contains information about the stakeholders of the port community, which functionalities they use and the architecture of the PCSs Luka Koper system.

The EC2 solution for CTs and PCSs in the Port of Koper represents a significant breakthrough in data exchange between stakeholders and CTs. The EC2 represents an adaptation of the way in which data is exchanged between stakeholders and CT, as the structure and architecture of the information is changing. Since the introduction of this new digital solution, CTs have been focused on an updated platform that serves as an intermediate solution for communication between shipping companies and CTs. The solution was implemented in cooperation with CTs, the port community and a local IT company with the aim of introducing the EDIFACT standard [33] and simplifying the process of announcing the arrival of containers at the CT. Furthermore, the EC2 solution is an additional IT solution to the already implemented Vehicle Booking System (VBS) for the arrival of trucks in the port and in CTs. With this programme, CT plans free slots for entry into the system on a daily basis. The trucking company selects a free slot for entry and CTs can use this to plan the loading or unloading operation.

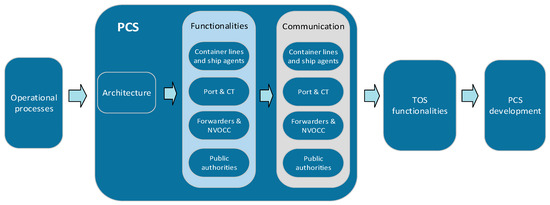

In the first part of the study, the architecture and functionalities of the PCSs in the port of Koper and the main stakeholders in the port community are identified (Figure 1). The stakeholders are categorised into four groups: port and CT, container lines and their ship agents, Non-Vessel Operating Common Carriers (NVOCC) and port forwarders, and public authorities. For each group, the functions are identified and how they are utilised by the PCSs. The next step is to analyse the impact of the existing functionalities on operational processes. The focus here is on reviewing the information solutions for each stakeholder, the type of communication or data exchange with the PCSs and the impact on the flow of operational processes.

Figure 1.

Methodological approach of PCSs research. Source: Authors.

When analysing the port and CT, the degree of integration between the PCSs and the TOS as well as the way information is exchanged and its impact on the execution of operational processes is determined. The activities of container lines and/or shipping agents have a direct and pronounced influence on the operation of CTs. Their decisions regarding the estimated time of arrival (E.T.A) and departure (E.T.D), the stowage plan and the completion of loading operations directly affect CT processes. The activities of NVOCCs and port forwarders are carried out outside the port or CT. Their impact on the TOS is indirect but significant. Instructions and requirements are communicated via the information provided in the PCSs. The role of the third group of stakeholders or government institutions is primarily to monitor cargo flows through the port. The exchange of information also takes place via the PCSs, but the influence of this stakeholder group on the TOS processes is less pronounced. The main focus is on forwarding cargo data to government agencies such as the Maritime Transport Authority, the police, customs and phytosanitary inspections.

Based on the results, the final step is to identify opportunities for changes and improvements in the architecture of PCSs that will have a positive impact on TOS processes and terminal processes, and will indirectly impact the development of sustainable CT operations and the entire port community.

4. PCSs Functionalities

4.1. Port of Koper and Container Terminal

The Port of Koper is a complex port system comprising 12 different terminals, all of which are operated by the company Luka Koper Ltd. (Koper, Slovenia). These terminals are divided into 5 profit centres based on their operational and technological characteristics. Technically, technologically and developmentally, CTs stands out the most. It is one of the largest and most important CTs in the Adriatic, although it is considered relatively small on a global scale. The terminal’s infrastructure on the seaside includes an operational berth with a length of 694.5 m and a maximum permissible draught of 14.5 m. This enables the berthing and handling of container ships with a capacity of up to 15,500 TEU. The terminal’s storage area covers 270,000 square metres. Access to the terminal from the hinterland is ensured via three truck entrances and 1.27 km of rail handling tracks. The terminal’s superstructure for loading and unloading containers on the seaside consists of Super Post-Panamax cranes (4 units), post-Panamax cranes (4 units) and Panamax cranes (3 units). The equipment on the land side of the terminal consists of Rubber-Tired Gantry (RMG) cranes (4 cranes), transtainers (27 cranes) and container handlers (40 cranes) [12].

The CT co-operates with all major container shipping lines such as Maersk, MSC, Evergreen, CMA-CGM, etc., which call at the port regularly with weekly services. The terminal has established regular direct services with a weekly frequency to the Far and Middle East, the Red Sea and feeder services to the major Mediterranean hub ports. An integral part of the logistics hub are logistics and forwarding companies that are part of the port community and co-operate with CTs, especially with regard to the administrative representation of cargo owners.

In the last twenty years, the CT has increased its annual container throughput from 0.12 million TEU to 1 million TEU. Approximately 50 container ships (feeders and mother vessels), 14,000 trucks, and 550 railway compositions enter the system every month via the regular rail connections. The growth in throughput is putting increasing strain on the existing infrastructure and requires additional optimisation in handling operations. At the current operating level, the terminal’s capacity is reaching its limits, which is reflected in traffic congestion in the surrounding port areas and waiting times for container ships anchored outside the port. One challenge for the terminal is managing container flows in the direction of import, in particular determining the correct storage block for each container. This leads to additional movements of containers and handling equipment at the terminal, which has a direct impact on CO2 emissions, the terminal’s productivity and the associated operating costs. The terminal endeavours to obtain high quality data from stakeholders in order to better plan processes. This requires updates to the PCSs and the implementation of modern technological IT solutions.

The development process of digitalisation in the CT has been ongoing for 20 years and is directly proportional to the growth in throughput. The development process involves all stakeholders within the port community, as some user requirements are interconnected. When designing the system architecture, the possible future integration into global logistics chains was taken into account in order to improve the competitiveness of the terminal on the global logistics market. The aim of the further business digitalisation development is to establish a PCSs system that acts as a unified platform and ensures greater efficiency in the execution of processes, better traceability and control of container movements, optimisation of terminal capacity, improved communication between stakeholders in the port and a reduction of the carbon footprint.

4.2. Operational Processes and Interaction with PCSs

4.2.1. Announcement of the Arrival of a Container Ship

The flow of containers through the port is outbound (containers arrive at the terminal by land and are loaded onto the ship) and inbound (containers arrive by ship and are loaded onto trucks or railway waggons). The ship notification process covers container movements in the inbound direction and involves stakeholders from three defined groups. Firstly, these are the container lines and/or their ship agents, then CTs and finally the public authorities. All these stakeholders are involved in the process based on the ship’s arrival notification and require a wide range of mandatory information. This includes ship data, crew data, cargo characteristics and cargo owners’ information about the ship, E.T.A and E.T.D, coordination of work plans on the ship, etc. Data about the ship is exchanged via the PCSs between the shipping agent and the port or CT, and additionally with pilots and tugs. The exchange of freight data (ship cargo manifest), which the shipping agent provides to the authorities, is supported electronically and also processed via the PCSs system. Data exchange outside the PCSs system includes communication with the national single window (NEO), where advance notifications of arriving ships are sent to public institutions. Shipping agents also use NEO to send the necessary documents to the authorities. Outside the PCSs, communication also takes place between the CT and the container lines in order to obtain the list of containers (bapli) on the arriving ship. This data is exchanged via structured messages. The analysis of the existing information support for the container ship announcement process has shown that all processes and parties involved are well supported.

4.2.2. Discharging/Loading a Container Ship

The most complex and operationally demanding process is the unloading and loading of a ship, which occasionally takes place simultaneously on the same container ship. All four groups of stakeholders are involved in this process and exchange a lot of information. Shipping agents give instructions for the unloading of containers and indicate the type of land transport and the final destination of the container. This enables a more efficient grouping of containers in the storage area. Freight forwarders provide information about containers in the export direction. Based on this information, the CT draws up a work plan (unloading and/or loading the ship), while public authorities play a role in the release of containers/cargo. INVOCCs are involved in the operational process and take over the dispatch and/or delivery of containers in the “ship–terminal” relationship and vice versa. The aim of each container line is to carry out unloading and loading operations as quickly as possible and to minimise the time the ship spends at berth.

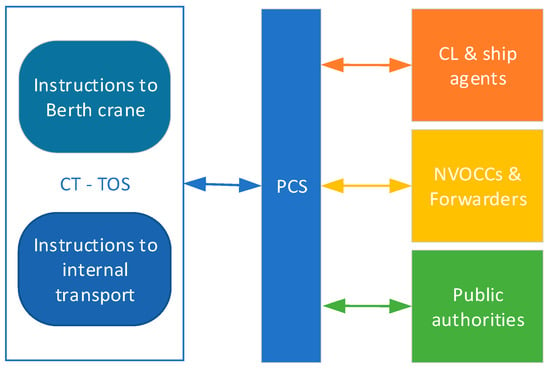

According to the data received, CTs and the stakeholders in the port community cover these processes sufficiently through the PCSs to ensure smooth operations. The TOS dictates the execution of all operations in the loading and unloading process in a way that sends work instructions to shore cranes and internal transport vehicles that transport containers in the “yard–ship–yard” relationship (Figure 2). Each completed manipulation is recorded in real time via the PCSs system in the form of a message, which is then transmitted to the NVOCC or the port forwarder.

Figure 2.

Data exchange architecture in the operational process of discharging/loading a container ship in CT. Source: Authors.

4.2.3. Arrival and Departure of a Container to CT by Truck Gate

Efficient operational planning for the arrival and departure of containers by land plays a crucial role in the pre-notification process. This process regulates the occupancy of the port area as well as the internal and external routes. Prior to the announcement, the forwarder uses the IT system to compile a range of data about the container and cargo, which is then sent to the PCSs in the form of a “hashtag” message. The PCSs system identifies the type of message, checks which operational process it is intended for and sends the message to the TOS. The TOS forwards the pre-notification via the PCSs system to the customs office information system, which identifies the goods based on the attached information about the customs procedure.

Before entering the port/CT, the trucking company selects a free entry slot in the VBS on the basis of the advertised slots. These slots are planned daily by CT within the VBS system. When a full container is delivered, the information is also forwarded to the customs authorities, who check the required transport and commercial documents before the container enters the port.

Different procedures are used for the arrival of full containers by rail. Before a full train composition enters the port/CT area, the railway operator and CT exchange information about the list of containers and cargo via the PCS. The information received on the list of railway waggons is then forwarded to the TOS via the PCS. The CT then creates a work plan that is optimised with an algorithm that takes into account all the information from the pre-announcement and the list exchanged with the railway operator. The customs office in the customs information system confirms the authorisation for the container to enter the port. As unloading and loading takes place simultaneously on the railway waggons, the internal transport vehicles transport the containers on the relation “handling tracks–terminal–handling tracks” route. The TOS sends handling instructions to internal transport vehicles and RMG cranes, including information about the container number and location at the terminal as well as the waggon number onto which the container is loaded or unloaded.

4.2.4. Container Storage Area

The central part of the CT is the container storage area, where the containers are temporarily stored before they leave the terminal and where additional tasks are carried out. The additional tasks include the provision of containers for cargo inspections in accordance with the instructions of public authorities, the loading and/or unloading of containers with additional cargo, etc.

The TOS plays a crucial role in managing the processes in the storage area of the terminal. Specifically, the TOS uses algorithms to assign a specific storage location to each container, which is determined on the basis of information received from the PCSs. Key information includes data on the owner of the container, the destination and the intended means of transport by which the container is to be dispatched from the terminal. The TOS records every movement of the container within the terminal, with the basic container movements being sent via the PCS in the form of a “hashtag” message to the stakeholders involved. This includes the arrival of the container, the movement of the container from the CT to a delivery point that has been ordered as additional work, and the movement when the container is dispatched from the terminal.

4.3. PCS Architecture

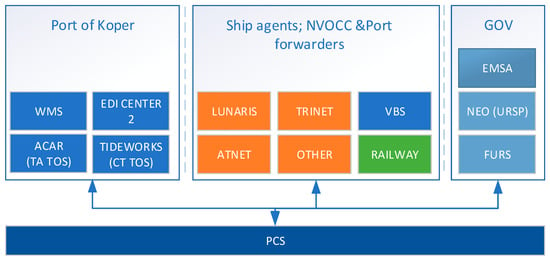

The research of existing PCS architecture illustrates its complexity, which is due to the historical development of different IT solutions within the Koper port system (Figure 3). Each group of stakeholders, depending on the nature of their involvement in the execution of the operational process of cargo movement through the port, has specific data requirements that are crucial for the coordinated and efficient execution of their tasks and decisions in the logistics chain. Port terminals need accurate information on ship arrivals, the sequence of containers and their destinations in order to plan unloading and loading operations, while NVOCCs and port forwarders need data on container availability, customs procedures and delivery times in order to organise transport on time. Public institutions need information on the content of containers, customs documents and all regulatory requirements to fulfil their regulatory tasks and conduct oversight. By each group of stakeholders requesting and sharing specific data, a higher level of coordination in the execution of processes is achieved, increasing the efficiency and safety of cargo movements in the port.

Figure 3.

PCS architecture in the port community of the Port of Koper. Source: Authors.

The results of the analysis indicate that different information solutions are used for communication via the PCS, enabling separate data exchange for each group of processes. Various business-to-business (B2B) portals such as Lunaris, Trinet and Atnet are used to announce the arrival of cargo and transport vehicles, while the VBS is responsible for announcing and coordinating the arrival of road vehicles. The announcement of railway waggons is handled separately, supported by the exchange of messages between the PCS and the railway companies’ system. The announcement of the arrival of ships, which requires advance notification of data to public institutions, is supported by the NEO system. The container lines and/or their agents use NEO to transmit the required documents to the public authorities. The management of the status of goods in import, export and transit is handled via communication between the PCS and the eTaxes solution (FURS system), which establishes a link with the national tax office. The customs service is also part of this system. The CT manages the processes via the communication between the PCS and TOS. Information related to the cargo reporting process initiated by the port forwarders is sent via the PCS to the TOS, where it is then utilised and shaped by the operators for further processes related to the operational execution of cargo handling processes.

The study of the interaction between the PCS and TOS in CT has shown that the necessary data is exchanged for the execution of important operational processes, such as the announcement of the arrival of ships, the announcement of the arrival of containers by road and rail, the release of containers for free circulation and the ordering of additional work for containerised cargo (Table 1). However, there are several different B2B solutions and a large set of structured messages, which illustrates the complexity of the architecture.

Table 1.

List of stakeholders, use of IT solutions and operational process support of the PCS system in the port community of the Port of Koper.

The standards and message formats for exchange between the various stakeholders within the PCSs system vary depending on the time period in which the solution was introduced. Proprietary message standards developed for communication with the PCSs are often used in the port community. The messages exchanged between the systems have a predefined structure and are not bound to a specific standard. Their format is often in the form of “hashtags” and “Extended Markup Language (XML)”. The EC2 solution for data exchange between container carriers, the PCS and TOS, is an exception. Messages in EDIFACT format are used for EC2. With EC2, full integration between CT and the container lines has been achieved, which has a positive effect on the timely delivery of container data for arrivals and departures. Information arrives in the TOS which allows the CT to create more accurate lists of manipulations and organise operational processes more efficiently.

5. Discussion

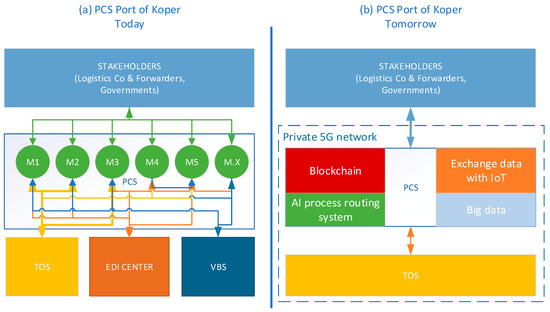

This research has shown that CT in the port of Koper is still at an early stage in the development of its communication system. Most of the functionalities supported by the current PCSs in CT were developed already two decades ago in major ports such as Rotterdam, Hamburg, Antwerp, Singapore, Hong Kong and New York [34]. The functionality of the PCSs system is based on the exchange of data between the stakeholders involved in the form of simple messages for the purpose of planning operations. The PCSs is designed so that each operational process corresponds to a specific message type (M1, M2, … M.X) and a specific response. The exchange of messages involving several stakeholders at the same time is not supported to the extent that it has an optimal impact on process execution (Figure 4a). The messaging system works on the principle that each message receives a response to check that it has been written correctly. In terms of content, it refers to the correct freight identifier. The verification of the messages is ensured by a pre-written algorithm that checks certain segments and contents of the messages. While the system enables real-time data exchange and therefore information transfer between different information systems in the port community, planning for further competitive development is a challenge when simply upgrading the existing system.

Figure 4.

Comparison of existing PCS operations and guidelines for modernisation. Source: Authors.

Given the continuous growth in cargo throughput and the CT’s limited spatial expansion possibilities, as well as the vision to reach an annual container throughput of 1.75 million by 2030, CT must continue to invest in the digitalisation of operational processes. The port and terminal must follow the smart port guidelines by improving the existing PCS and introducing new digital technologies. These technologies will enable a high level of security in data exchange, greater integration and connectivity between all stakeholders involved in data exchange. Research into port system development has identified trends that will ensure the development of models that leverage key elements such as digitalisation, sustainability, resilience and big data [35]. Modern information technologies need to be implemented as they enable automatic data collection on cargo location and characteristics, cargo manipulation planning, efficient data exchange between stakeholders, reduced environmental impact and increased energy efficiency [36,37].

It is advisable to include blockchain technology, AI, IoT technology for infrastructure communication and big data technology in the development of the PCS in the Port of Koper. It is recommended to complement the system with a private 5G network that ensures secure and fast data exchange with high bandwidth (Figure 4b). Switching to blockchain technology would mean abandoning the PCS’s existing messaging system, which is based on hashtags, XML and the EDIFACT standard. This change would also mean that the EC2 solution for the CT would have to be changed. Blockchain would facilitate the expansion of the types of data and content exchanged between stakeholders and enable a more comprehensive exchange of data. This would mean a more extensive exchange of data such as Bills of lading, certificates, crew data, the ship’s cargo manifest, etc. In addition, such a method of data exchange would provide a solid foundation for future integration with other logistics companies and ports in the region that co-operate with the CT. Ahmad et al. [38] emphasise the most important advantages of implementing blockchain technology. In addition to the positive impact on the security of data exchange, real-time data exchange, the elimination of the possibility of misuse and falsification of documents, the technology has an impact on reducing GHG emissions, which is reflected in the reduction of container turnaround times by eliminating the manual creation and exchange of documents. The key to the effective implementation of this technology lies in the collaboration of all stakeholders involved and the establishment of standards for its use. However, as Tsamboulas and Ballis [39] emphasise, one of the biggest challenges lies in the technical imbalance and investment readiness of the different stakeholders in the port community.

The development of IoT in the CT will enable the connection and monitoring of various physical devices and sensors, allowing for better traffic and resource management. In practise, sensors can monitor the status of cargo handling equipment, equipment congestion, ship traffic, etc. [40]. Integrating IoT into the infrastructure outside the port can provide real-time data on the arrival of trucks before they enter the truck terminal or make the data visible in the VBS. Cargo tracking using IoT technology and real-time data exchange are highlighted by Caldeirinha et al. [41], as they underline, among other things, that this is the fourth phase of port development. IoT technology represents a direct source of information for PCSs, whereby data about the position of trucks could be sent to the PCS or TOS while they are en route to the CT. This technological solution could even replace the existing VBS application, resulting in less congestion and CO2 emissions in the immediate vicinity of the port. Trucks could be directed to parking lots along the access roads to the port to use them. Irannezhad [42] emphasises that there are opportunities for easy integration of PCSs with smart infrastructure or the IoT. Moreover, PCSs can also be complemented by application programming interfaces (API) and software development kits (SKD).

Solutions based on AI and big data are widely used in major global ports to solve various problems, such as traffic management, cargo arrival prediction, operations management, etc. [43]. Abu Ghazaleh [44] states that AI enables the verification of reliability, dependency and scalability of information between stakeholders when sharing data and this is very important for optimisation processes. Consequently, the current rule-based approach to message routing used in Luka Koper PCSs could be replaced by machine learning based on real-time construction of a decision model for data routing [45]. The use of AI and big data in CTs would make it possible to make optimal decisions about future inland routes and transport modalities. The message control system using machine learning and AI allows to verify the authenticity of the input data sent by the stakeholders when they announce the arrival/departure of cargo via PCSs. The way it works today, the information sent by the stakeholders is delayed and to some extent inaccurate, which is a problem in determining the correct storage location in the yard area, which is subsequently reflected in the execution plan for the dispatch of the containers. The information that has proven to be key to reducing unnecessary movements is the final destination, the date of dispatch of the container and the way in which the container leaves the CT. By checking the information received, the AI is able to determine in advance the correct storage strategy for the container in the CT. This approach could significantly reduce the volume of unnecessary transhipments in CTs. Various studies highlight that this transhipment can account for up to 60% on smaller CT terminals, depending on the utilisation of the terminal [46,47]. Zaire Iyoob and van Nierek [48] have developed a model based on the use of a range of modern technologies and an AI-based algorithm to reduce congestion near ports and thus directly reduce GHG emissions. With regard to the green transition and sustainable operation, the savings in carbon footprint must be taken into account, as the handling of a container in a non-automated terminal generates between 16 and 19 kg/CO2. For smaller and non-automated CTs, almost half of these emissions are caused by RTG container cranes [49], which coincides with the handling at the terminal’s storage yard. Assuming that there are around 200,000 such manipulations per year, this corresponds to around 1400 t of CO2. According to the operational report of the Port of Koper [50], despite the increase in cargo throughput in 2023 compared to 2022, the share of energy consumption has decreased, which is also due to the introduction of new handling technologies and IT solutions that ensure better planning and execution of operational processes in the Port of Koper.

Wen et al. [51] state that with the increasing number of IoT devices, long term evolution (LTE) networks are no longer sufficient and a stable, secure and highly available network such as a 5G network must be provided. This necessity is also emphasised by Cavalli et al. [52] in the case of the port of Livorno. Therefore, the study highlights that the upgrade of the PCS in the port of Koper must include the installation of a 5G network at the same time. With the establishment of a private 5G network, the port has its own network infrastructure that is fully available for the port’s internal needs to exchange information between IoT devices and PCSs.

Based on the research conducted and the literature reviewed, it can be anticipated that the development of PCSs will have a positive impact on reducing operational tasks for all stakeholders. There will be less manual data entry and duplicate data entry, less congestion will relieve the burden on hauliers, and more efficient container handling processes will reduce the burden on CT staff or lead to higher productivity. The effectiveness of the change to the PCSs architecture will be measured in the second part of the project study, when the reduction in data entry, the reduction in internal container handling operations and the reduction of truck congestion outside the port will be verified. On this basis, it will also be possible to define sustainability indicators such as the reduction of CO2 emissions from internal processes in CT, the reduction of CO2 emissions from congestion around the port, noise levels, etc.

For the successful application of the proposed PCS model, it is important to define the framework for cooperation between the stakeholders and to appoint a coordinator. Within the port community, the Association of port logistics providers has been identified as such, in which all major port forwarders and the NVOCC are represented. This group of stakeholders provides most of the input to the PCS for operational processes. An important stakeholder is the Ship and Freight Agents Association, representing container lines and ship agents, and of course Luka Koper Ltd. If the IT cooperation with the existing IT company continues, it is one of the most important stakeholders, but it adapts the development to the functional needs of the stakeholders. When managing the change requests made, it is important that the proposals are handled in a project-orientated way and implemented into the system in a meaningful way. To do this, it is necessary to set up a project team made up of stakeholders from different areas to promote the transition to the new PCS with all its benefits. The project team could be led by the Faculty of Maritime and Transport as the overall project coordinator, bringing together the stakeholders and professionally analysing the user requirements, reviewing their positive impact and proposing them for application in the operational process itself. The implementation aspect remains at the level of the port, working closely with the developer of the PCS.

As neighbouring ports and CTs are also struggling with the issue of further development of PCSs and TOSs, it would be prudent to explore opportunities for coordinated development between different port communities within the NAPA association (Koper, Trieste, Rijeka, Venice, Chioggia, Monfalcone and Ravenna) and also more broadly with Ploče, Ancona, Bar and Durres. These systems have similar starting points for the development of CT and fall into the category of smaller container terminals. All systems will need to evolve into smart terminals, and it would make sense to use this for maximum protocol standardisation. Studying the approaches of other ports in the Adriatic and Mediterranean is crucial for the design of standards and guidelines for data exchange. The introduction of standards that are uniform across all ports will enable better co-operation, better logistics and better traceability of container ships. The ability to network with neighbouring ports increases the amount of information available and can have a positive impact on the efficiency of operational processes [53]. After all, all the ports mentioned are served by the same container lines, so standardised protocols and information would facilitate streamlined procedures. The situation is similar for NVOCCs and freight forwarders, which are involved in maritime logistics in most ports. Within companies, regional standardised procedures could centralise development, which would lead to better workforce management.

Research limitations include financial and time risks that were not considered in the study. Their extent depends on the degree of realisation and the willingness of those involved in such a development. The analysis of processes, functions and communication of the PCS shows the specificities of the port of Koper. Although the proposed adaptations are tailored to this case study, to a certain extent they can also be considered as solutions for other similar port communities and port systems.

6. Conclusions

The study enriches the scientific and professional knowledge on the development of PCSs by providing a concrete analysis of the current state of operations and the involvement of stakeholders in standardised operational processes. Modern technologies such as AI, IoT, blockchain and 5G networks bring a new level of communication between stakeholders in port communities. The study of the PCS in Koper emphasises the complexity of the existing architecture, which has evolved in parallel with the increase in cargo volumes and in the context of outdated technology. The research results confirm H1 and indicate that the current PCS in the Port of Koper does not allow for a smooth transition to modern technologies. The introduction of a PCS in the Port of Koper based on modern technologies would represent a significant breakthrough for the port community, as both the architecture and the communication methods would undergo a complete transformation. H2 also confirms that the use of modern technologies can significantly improve communication protocols between PCS stakeholders and have a positive impact on the sustainable operation of the port community. The elimination of the current messaging system and the transition to a new approach will undoubtedly have a positive impact on the operational processes of CT. At the same time, the study opens up opportunities for further research into the impact of the new data exchange approach in terms of reducing human workload and influencing social and environmental aspects.

The study provides a scientific basis for further research into the gradual development of PCSs to achieve positive economic, social and environmental impacts. The next phase will investigate the positive impact of implementing new technologies in PCS operations, which will translate into reduced workload and more efficient planning solutions for NVOCCs and port forwarders.

Author Contributions

Conceptualization, P.Č. and B.B.; methodology, P.Č. and B.B.; formal analysis, P.Č.; investigation, P.Č.; resources, P.Č.; data curation, P.Č. and B.B.; writing—original draft preparation, P.Č.; writing—review and editing, P.Č. and B.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Peter Čerin is employed at the company Izoterm Plama d.o.o. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Song, D. A Literature Review, Container Shipping Supply Chain: Planning Problems and Research Opportunities. Logistics 2021, 5, 41. [Google Scholar] [CrossRef]

- Brinkmann, B. Operations Systems of Container Terminals: A Compendious Overview. In Handbook of Terminal Planning; Springer: Cham, Switzerland, 2011. [Google Scholar]

- Steenken, D.; Voss, S.; Stahlbock, R. Container terminal operation and operations research—A classification and literature review. OR Spectr. 2004, 26, 3–49. [Google Scholar]

- Placek, M. Container Shipping—Statistics & Facts. Statista. 2023. Available online: https://www.statista.com/topics/1367/container-shipping (accessed on 7 October 2023).

- Giuffrida, N.; Stojaković, M.; Twrdy, E.; Ignaccolo, M. The Importance of Environmental Factors in the Planning of Container Terminals: The Case Study of the Port of Augusta. Appl. Sci. 2021, 11, 2153. [Google Scholar] [CrossRef]

- European Commission. Reducing Emissions from the Shipping Sector. Available online: https://climate.ec.europa.eu/eu-action/transport/reducing-emissions-shipping-sector_it#eu-action (accessed on 7 October 2023).

- Caldeirinha, V.; Felicio, J.A.; Sena Salvador, A.; Nabais, J.; Pinho, T. The impact of port community systems (PCS) characteristics on performance. Res. Transp. Econ. 2020, 80, 100818. [Google Scholar] [CrossRef]

- Jović, M.; Aksentijević, S.; Plentaj, B.; Tijan, E. Port Community System Business Models. In Proceedings of the 34th Bled eConference Digital Support from Crisis to Progressive Change, Bled, Slovenia, 27–30 June 2021. [Google Scholar]

- Heilig, L.; Stahlbock, R.; Voß, S. From Digitalization to Data-Driven Decision Making in Container Terminals. In Handbook of Terminal Planning: Operations Research/Computer Science; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Aloini, D.; Benevento, E.; Stefanini, A.; Zerbino, P. Process fragmentation and port performance: Merging SNA and text mining. Int. J. Inf. Manag. 2019, 51, 101925. [Google Scholar] [CrossRef]

- Sfiroera, E.; Alafodimos, C.; Papoutsidakis, M.; Papachristos, D. New Trends in Port Community Systems and Fundamental Descriptions. Int. J. Comput. Appl. 2019, 178, 20–25. [Google Scholar] [CrossRef]

- Port of Koper. About Port of Koper. Available online: https://www.luka-kp.si/en/ (accessed on 15 October 2023).

- Beškovnik, B.; Zanne, M.; Golnar, M. Dynamic Changes in Port Logistics Caused by the COVID-19 Pandemic. J. Mar. Sci. Eng. 2022, 10, 1473. [Google Scholar] [CrossRef]

- Venus, Y.H.L. Green management practices and firm performance: A case of container terminal operations. Resour. Conserv. Recycl. 2011, 55, 559–566. [Google Scholar] [CrossRef]

- Haraldson, S. Digitalization of Sea Transports—Enabling Sustainable Multi-Modal Transports. In Proceedings of the 21st Americas Conference on Information Systems, Fajardo, Puerto Rico, 13–15 August 2015. [Google Scholar]

- Szu-Yu Kuo, S.Z.; Lin, P.C. Determinants of green performance in container terminal operations: A lean management. J. Clean. Prod. 2020, 275, 123105. [Google Scholar] [CrossRef]

- Tsolakis, N.; Zissis, D.; Papaefthimiou, S.; Korfiatis, N. Towards AI driven environmental sustainability: An application of automated logistics in container port terminals. Int. J. Prod. Res. 2022, 60, 4508–4528. [Google Scholar] [CrossRef]

- Tijan, E.; Jović, M.; Panjako, A.; Žgaljić, D. The Role of Port Authority in Port Governance and Port Community System Implementation. Sustainability 2021, 13, 2795. [Google Scholar] [CrossRef]

- Keceli, Y.; Choi, H.R.; Cha, Y.; Aydogdu, V. A Study on Adoption of Port Community Systems According to Organization Size. In Proceedings of the 3rd International Conference on Convergence and Hybrid Information Technology, Busan, Republic of Korea, 11–13 November 2008. [Google Scholar] [CrossRef]

- Simoni, M.; Schiavone, F.; Risitano, M.; Leone, D.; Chen, J. Group-specific business process improvements via a port community system: The case of Rotterdam. Prod. Plan. Control. 2020, 33, 371–385. [Google Scholar] [CrossRef]

- Torlak, I.; Tijan, E.; Aksentijević, S.; Oblak, R. Analysis of Port Community System Introduction in Croatian Seaports—Case Study Split. Trans. Marit. Sci. 2020, 9, 331–341. [Google Scholar] [CrossRef]

- Carlan, V.; Sys, C.; Vanelslander, T. How port community systems can contribute to port competitiveness: Developing a cost–benefit framework. Res. Transp. Bus. Manag. 2016, 19, 51–64. [Google Scholar] [CrossRef]

- Anwar, M.; Henesey, L.; Casalicchio, E. Digitalization in Container Terminal Logistics: A Literature Review. In Proceedings of the IAME 2019 Conference, Athene, Greece, 25–28 June 2019. [Google Scholar]

- Zerbino, P.; Aloini, D.; Dulmin, R.; Mininno, V. Towards Analytics-Enabled Efficiency Improvements in Maritime Transportation: A Case Study in a Mediterranean Port. Sustainability 2019, 11, 4473. [Google Scholar] [CrossRef]

- Tijan, E.; Jović, M.; Aksentijević, S.; Pucihar, A. Digital transformation in the maritime transport sector. Technol. Forecast. Soc. Chang. 2021, 170, 120879. [Google Scholar] [CrossRef]

- Kaup, M.; Deja, A.; Ślączka, W.; Gróbarczyk, M. The Port Community System as an example of integration of port users. Procedia Comput. Sci. 2021, 192, 4396–4405. [Google Scholar] [CrossRef]

- de la Peña Zarzuelo, I.; Freire Soeane, M.J.; López Bermúdez, B. Industry 4.0 in the port and maritime industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100173. [Google Scholar] [CrossRef]

- Beškovnik, B.; Bajec, P. Strategies and approach for smart city–port ecosystems development supported by the internet of things. Transport 2021, 36, 433–443. [Google Scholar] [CrossRef]

- Cil, A.Y.; Abdurahman, D.; Cil, I. Internet of Things enabled real time cold chain monitoring in a container port. J. Ship. Trade 2022, 7, 9. [Google Scholar] [CrossRef]

- Heikkilä, M.; Saarni, J.; Saurama, A. Innovation in Smart Ports: Future Directions of Digitalization in Container Ports. J. Mar. Sci. Eng. 2022, 10, 1925. [Google Scholar] [CrossRef]

- Madkhali, A.; Sithole, S.T.M. Exploring the Role of Information Technology in Supporting Sustainability Efforts in Saudi Arabia. Sustainability 2023, 15, 12375. [Google Scholar] [CrossRef]

- Alahmadi, D.H.; Baothman, F.A.; Alrajhi, M.M.; Alshahrani, F.S.; Albalawi, H.Z. Comparative analysis of blockchain technology to support digital transformation in ports and shipping. J. Intell. Syst. 2022, 31, 55–69. [Google Scholar] [CrossRef]

- UNECE. Introducing UN/EDIFACT. Available online: https://unece.org/trade/uncefact/introducing-unedifact/ (accessed on 20 October 2023).

- Srour, F.; Oosterhout, M.; Baalen, P.J.; Zuidwijk, R. Port Community System Implementation: Lessons Learned from International Scan. In Proceedings of the Transportation Research Board 87th Annual Meeting, Washington, DC, USA, 13–17 January 2008. [Google Scholar]

- Del Giudice, M.; Di Vaio, A.; Hassan, R.; Palladino, R. Digitalization and new technologies for sustainable business models at the ship–port interface: A bibliometric analysis. Marit. Policy Manag. 2021, 49, 410–446. [Google Scholar] [CrossRef]

- Ilin, I.; Jahn, C.; Weigell, J.; Kalyazina, S. Digital Technology Implementation for Smart City and Smart Port Cooperation. In Proceedings of the International Conference on Digital Transformation in Logistics and Infrastructure (ICDTLI 2019), St. Petersburg, Russia, 4–5 April 2019. [Google Scholar]

- Gasparotti, C.; Benec Mincu, G.M.; Nitu, C.; Raileanu, A.; Turcanu, A.M. Ports Digitization—A Challenge for Sustainable Development. Rom. J. Econ. Forecast. 2023, 26, 143–160. [Google Scholar]

- Ahmad, R.W.; Hasan, H.; Jayaraman, R.; Salah, K.; Omar, M. Blockchain applications and architectures for port operations and logistics management. Res. Transp. Bus. 2021, 41, 100620. [Google Scholar] [CrossRef]

- Tsamboulas, D.; Ballis, A. Port Community systems: Requirements, functionalities and implementation complications. In Proceedings of the Selected Proceedings of the 13th World Conference of Transport Research, Rio de Janeiro, Brazil, 15–18 July 2013. [Google Scholar]

- Paardenkooper, K. The Role of Data-Driven Logistics in Arctic Shipping. In Arctic Maritime Logistics: The Potentials and Challenges of the Northern Sea Route; Springer International Publishing: Cham, Switzerland, 2022; pp. 173–191. [Google Scholar]

- Caldeirinha, V.; Nabais, J.L.; Pinto, C. Port Community Systems: Accelerating the Transition of Seaports toward the Physical Internet—The Portuguese Case. J. Mar. Sci. Eng. 2022, 10, 152. [Google Scholar] [CrossRef]

- Irannezhad, E. The Architectural Design Requirements of a Blockchain-Based Port Community System. Logistics 2020, 4, 30. [Google Scholar] [CrossRef]

- Jahn, C.; Nellen, N. Smart Port Concept: Strategic Development, Best Practices, Perspectives of Development. In Arctic Maritime Logistics; Springer Nature: Cham, Switzerland, 2022; pp. 81–93. [Google Scholar]

- Ghazaleh, M. Smartening up Ports Digitalization with Artificial Intelligence (AI): A Study of Artificial Intelligence Business Drivers of Smart Port Digitalization. Manag. Econ. Rev. 2023, 8, 78–97. [Google Scholar] [CrossRef]

- Latah, M.; Toker, L. Artificial intelligence enabled software defined networking: A comprehensive overview. IET Netw. 2019, 8, 79–99. [Google Scholar] [CrossRef]

- Rožić, T.; Ivanković, B.; Bajor, I.; Starčević, M. A Network-Based Model for Optimization of Container Location Assignment at Inland Terminals. Appl. Sci. 2022, 12, 5833. [Google Scholar] [CrossRef]

- Díaz-Ruiz-Navamuel, E.; Ortega Piris, A.; López-Diaz, A.I.; Gutiérrez, M.A.; Roiz, M.A.; Chaveli, J.M.O. Influence of Ships Docking System in the Reduction of CO2 Emissions in Container Ports. Sustainability 2021, 13, 5051. [Google Scholar] [CrossRef]

- Zaire Iyoob, M.; Van Niekerk, B. CAUDUS: An Optimisation Model to Reducing Port Traffic Congestion. In Proceedings of the 2021 International Conference on Artificial Intelligence, Big Data, Computing and Data Communication Systems (icABCD), Durban, South Africa, 5–6 August 2021. [Google Scholar]

- Budiyanto, M.A.; Huzaifi, M.H.; Sirait, S.J.; Prayoga, P.H.N. Evaluation of CO2 emissions and energy use with different container terminal layouts. Sci. Rep. 2021, 11, 5476. [Google Scholar] [CrossRef] [PubMed]

- Port of Koper. Non-Audited Report on the Operations of the Group and Luka Koper d.d. for the Period January—September 2023. Available online: https://www.luka-kp.si/en/investors/seonet-announcements/ (accessed on 3 December 2023).

- Wen, M.; Li, Q.; Kim, J.K.; Lopez-Perez, D.; Dobre, O.A.; Poor, H.V.; Popovski, P.; Tsiftsis, T.A. Private 5G Networks: Concepts, Architectures and Research Landscape. IEEE J. Sel. Top. Signal Process 2022, 16, 7–25. [Google Scholar] [CrossRef]

- Cavalli, L.; Lizzi, G.; Guerrieri, L.; Querci, A.; De Bari, F.; Barbieri, G.; Ferrini, S.; Di Meglio, R.; Cardone, R.; Tardo, A.; et al. Addressing Efficiency and Sustainability in the Port of the Future with 5G: The Experience of the Livorno Port. A Methodological Insight to Measure Innovation Technologies’ Benefits on Port Operations. Sustainability 2021, 13, 12146. [Google Scholar] [CrossRef]

- Michaelides, M.P.; Herodotou, H.; Lind, M.; Watson, R.T. Port-2-Port Communication Enhancing Short Sea Shipping Performance: The Case Study of Cyprus and the Eastern Mediterranean. Sustainability 2019, 11, 1912. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).