Life Cycle Assessment for Geopolymer Concrete Bricks Using Brown Coal Fly Ash

Abstract

1. Introduction

2. Research Methodology

2.1. Research Framework

2.2. Goal and Scope Definition

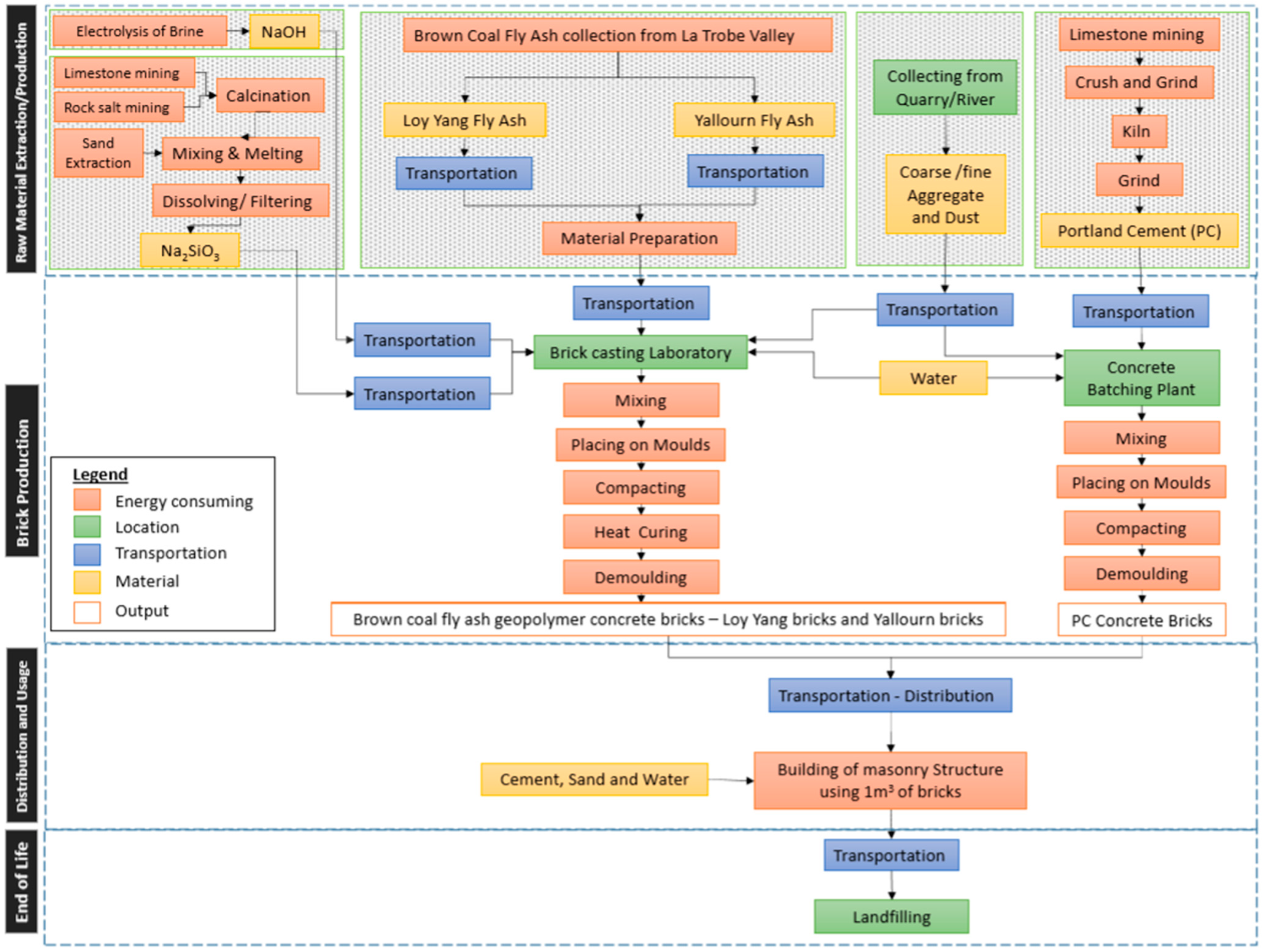

- Raw material extraction/production, which presents the production and preparation of different materials used in the later production stage; those materials included Na2SiO3, the two brown coal fly ashes, the extraction of aggregates, and the production of the PC. The Na2SiO3, NaOH, brown coal fly ashes, and aggregates were used in the fly ash bricks’ production. The aggregates and PC were used to produce the PC concrete.

- The brick production stage represented the transportation of raw materials for the production of the bricks and the production process.

- Distribution and usage represented the transportation of the bricks and the brick wall construction process.

- End-of-life represented the transportation of demolished brick walls and the landfill.

2.3. Models and Testing Scenarios

3. Life Cycle Inventory Analysis

3.1. Life Cycle Phases

3.2. Raw Material Acquisition

3.3. Transportation Details

3.4. Energy Consumption

4. Results

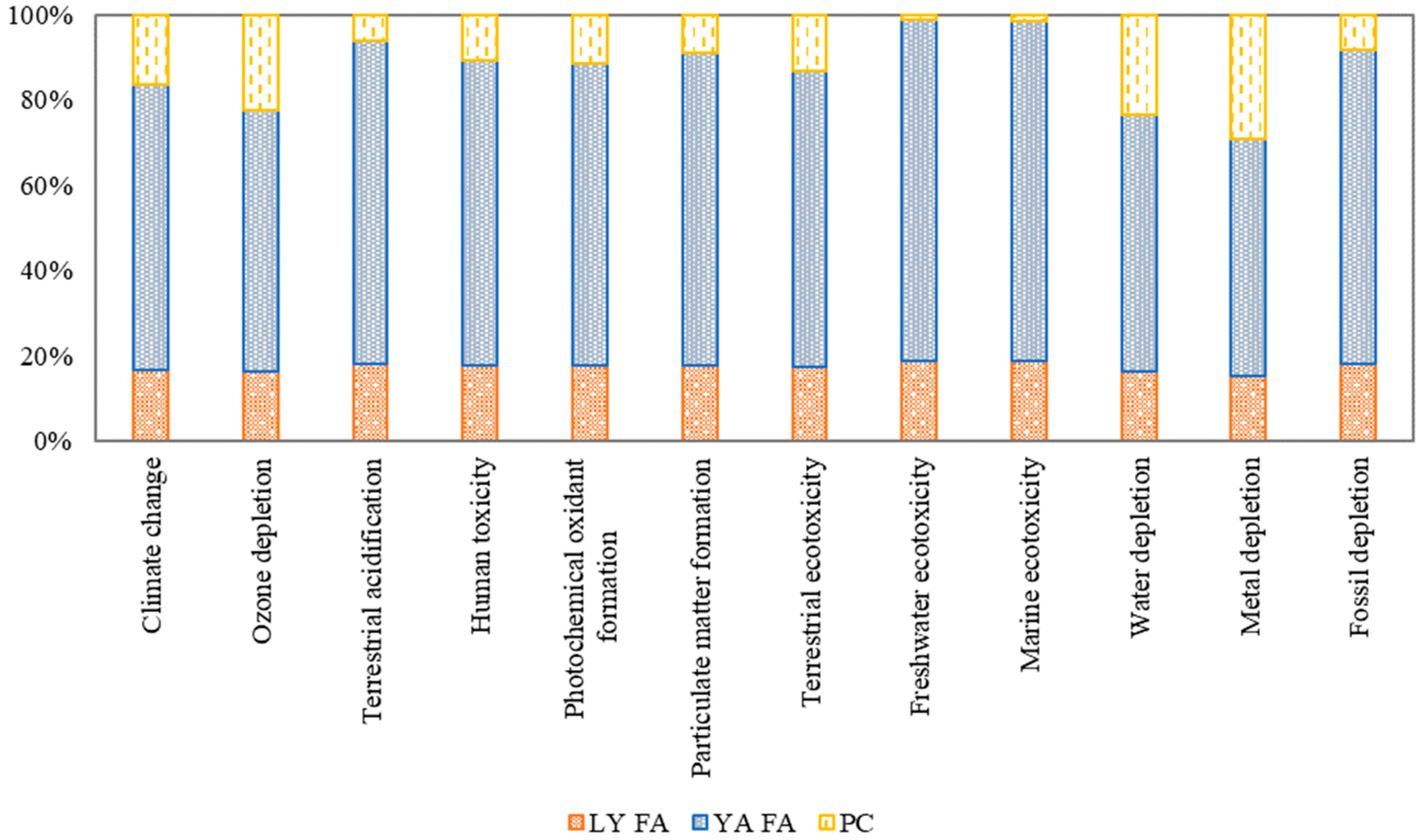

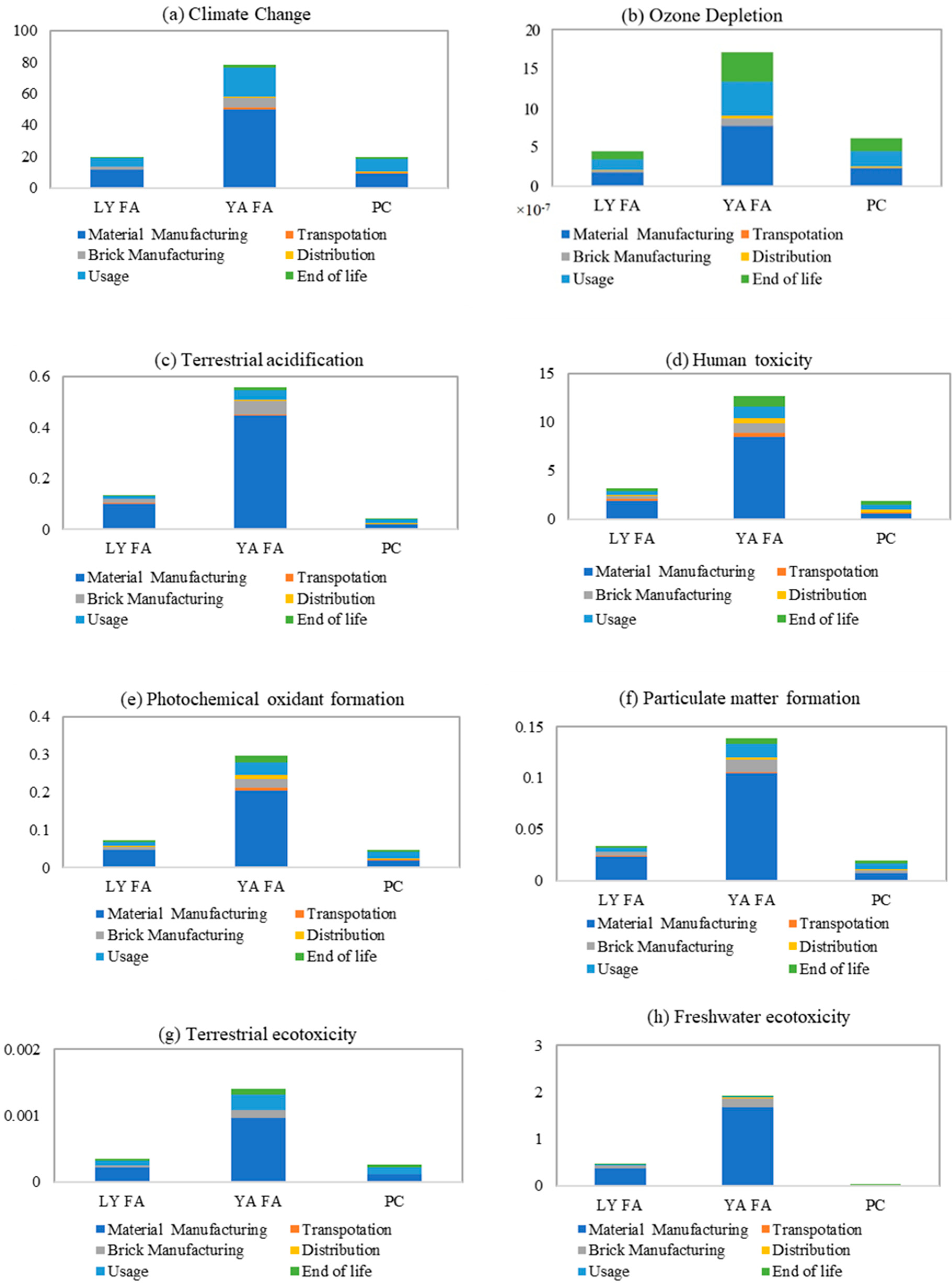

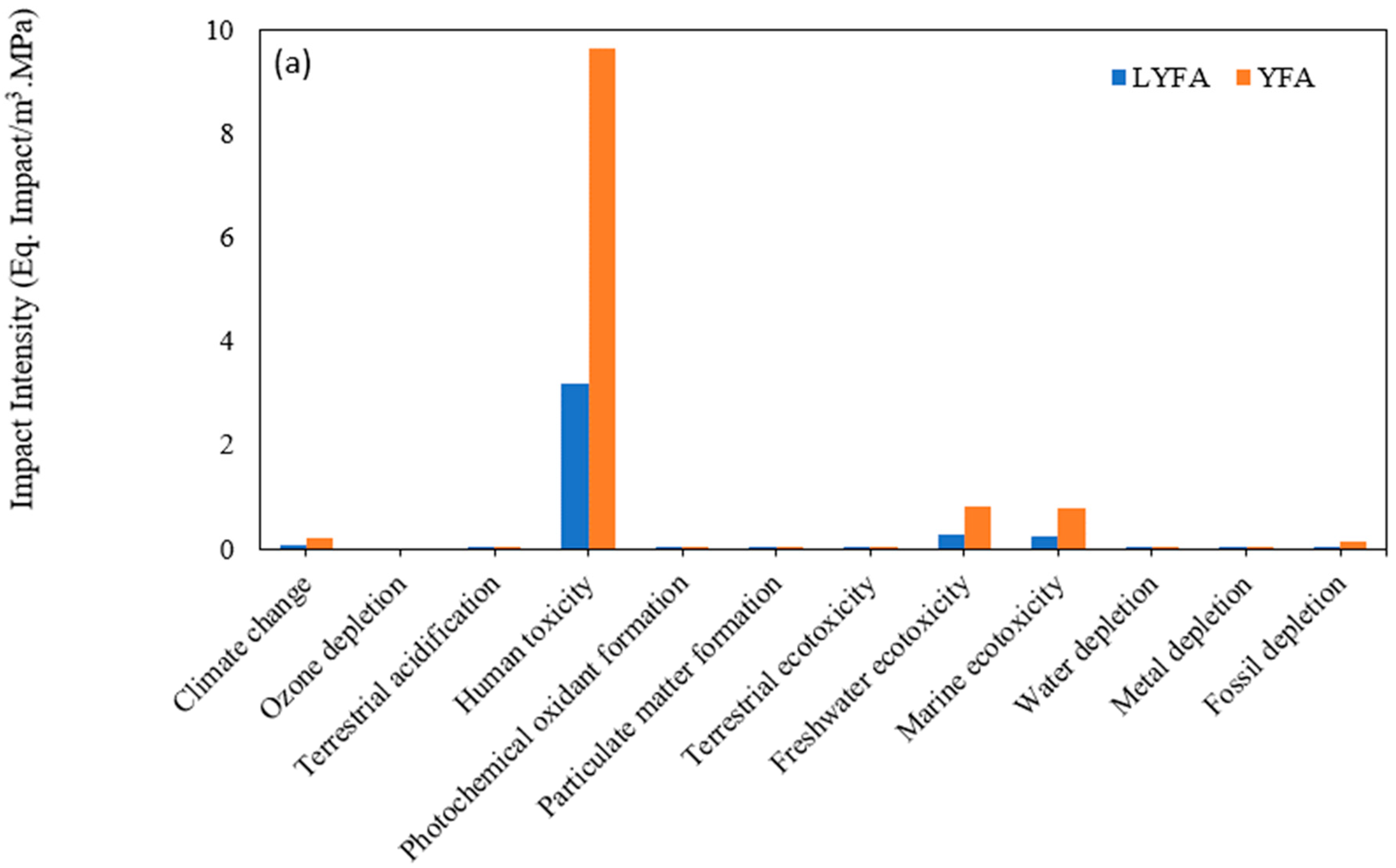

4.1. Comparative Analysis

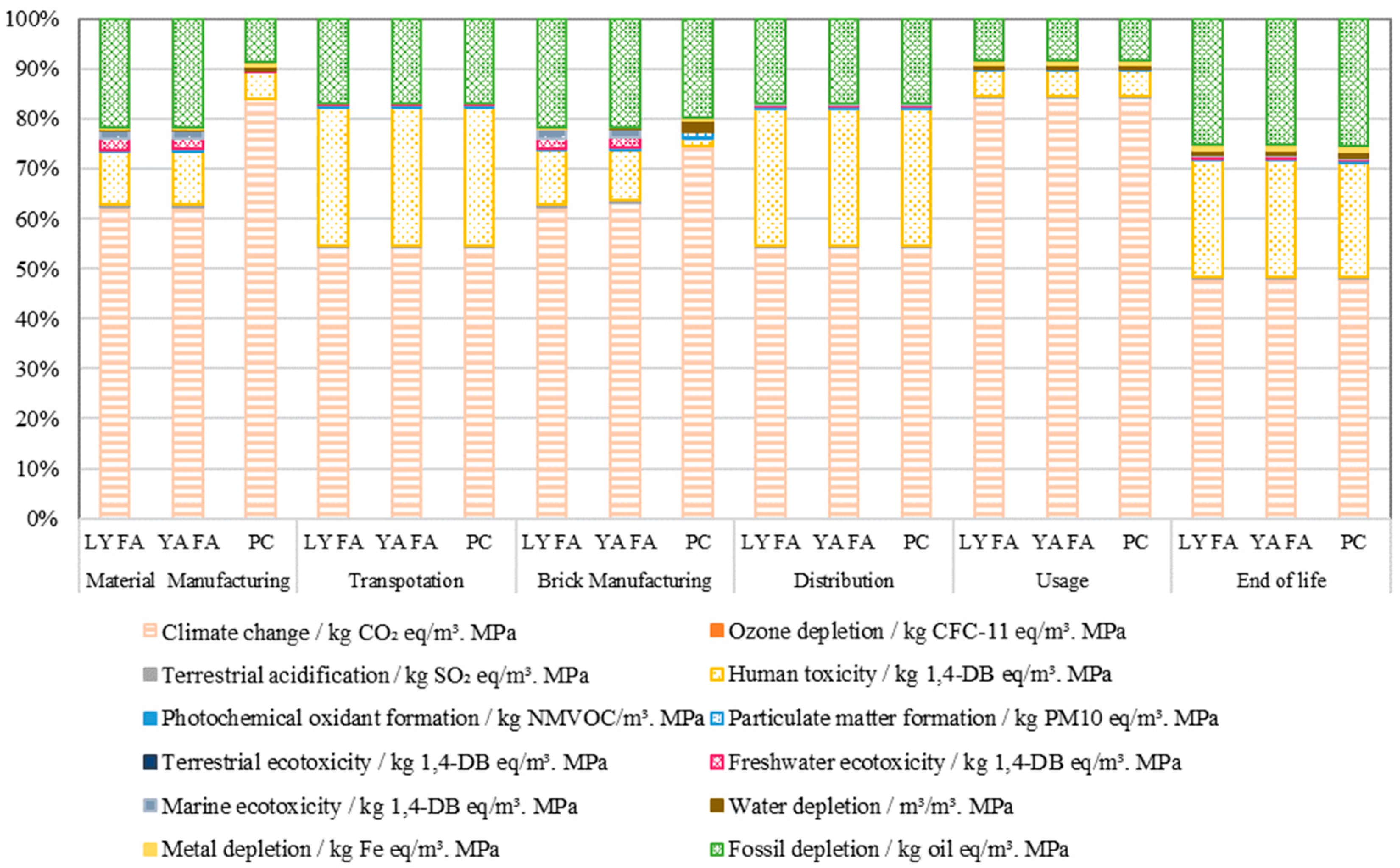

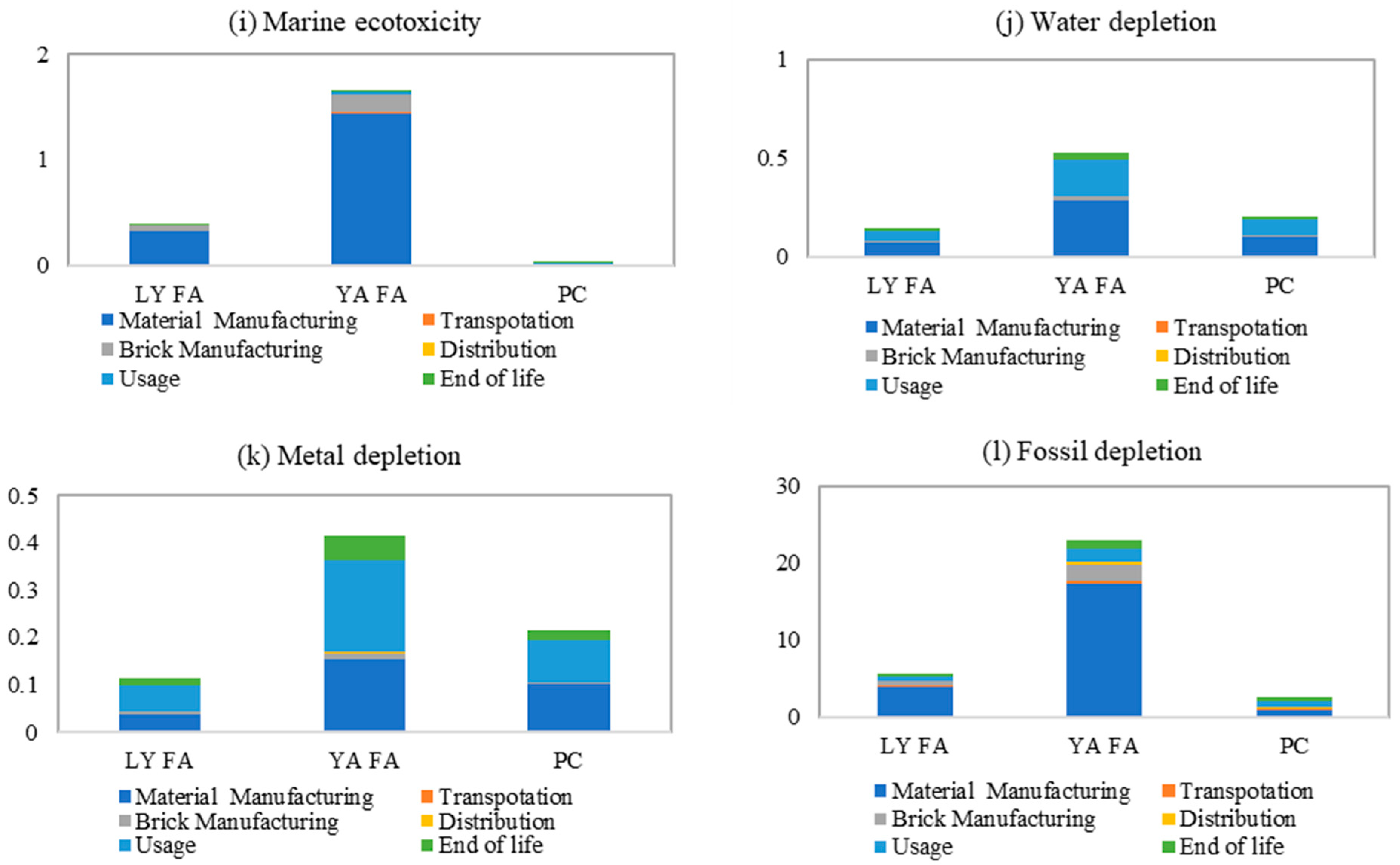

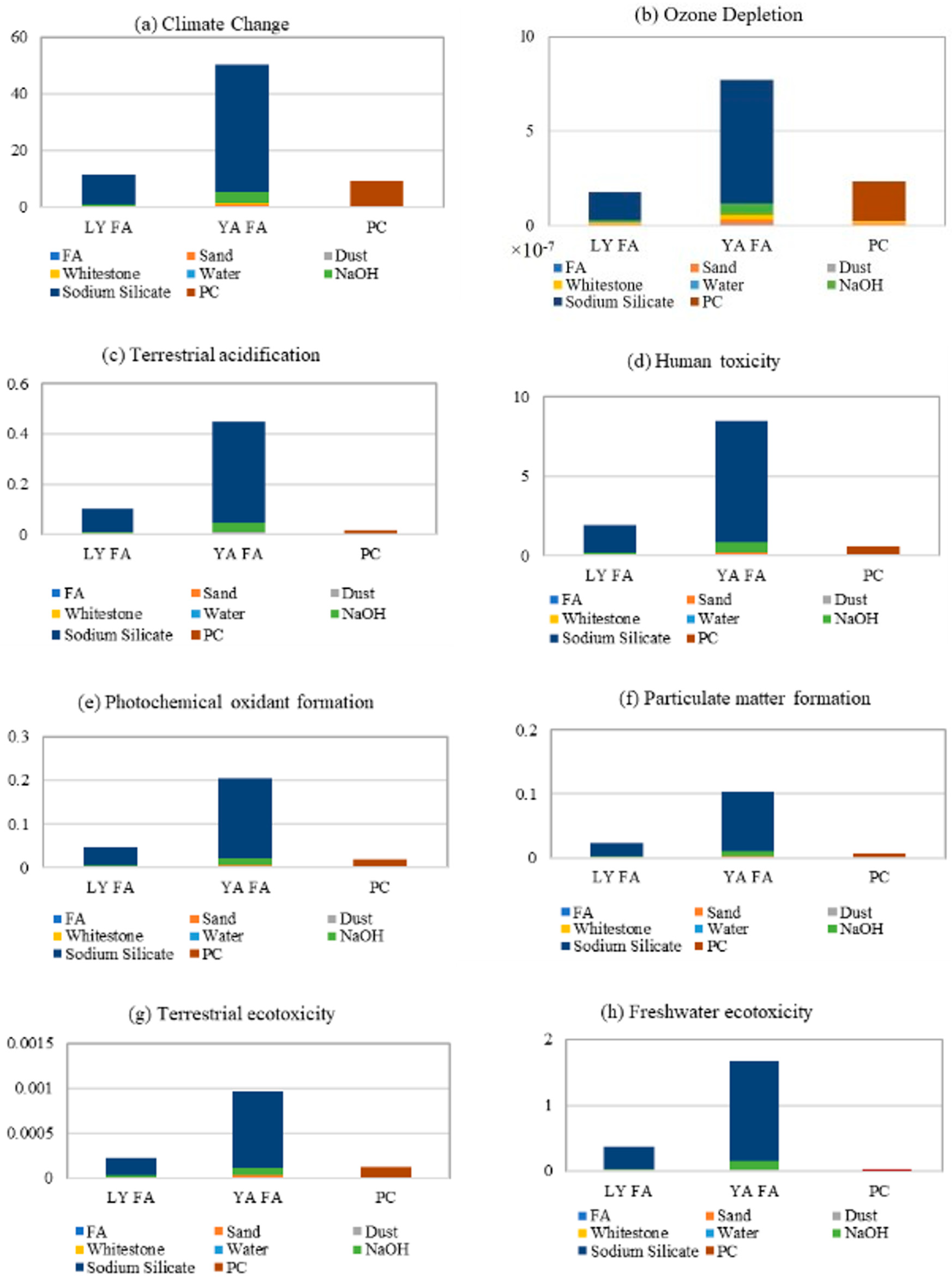

4.2. Contribution Analysis

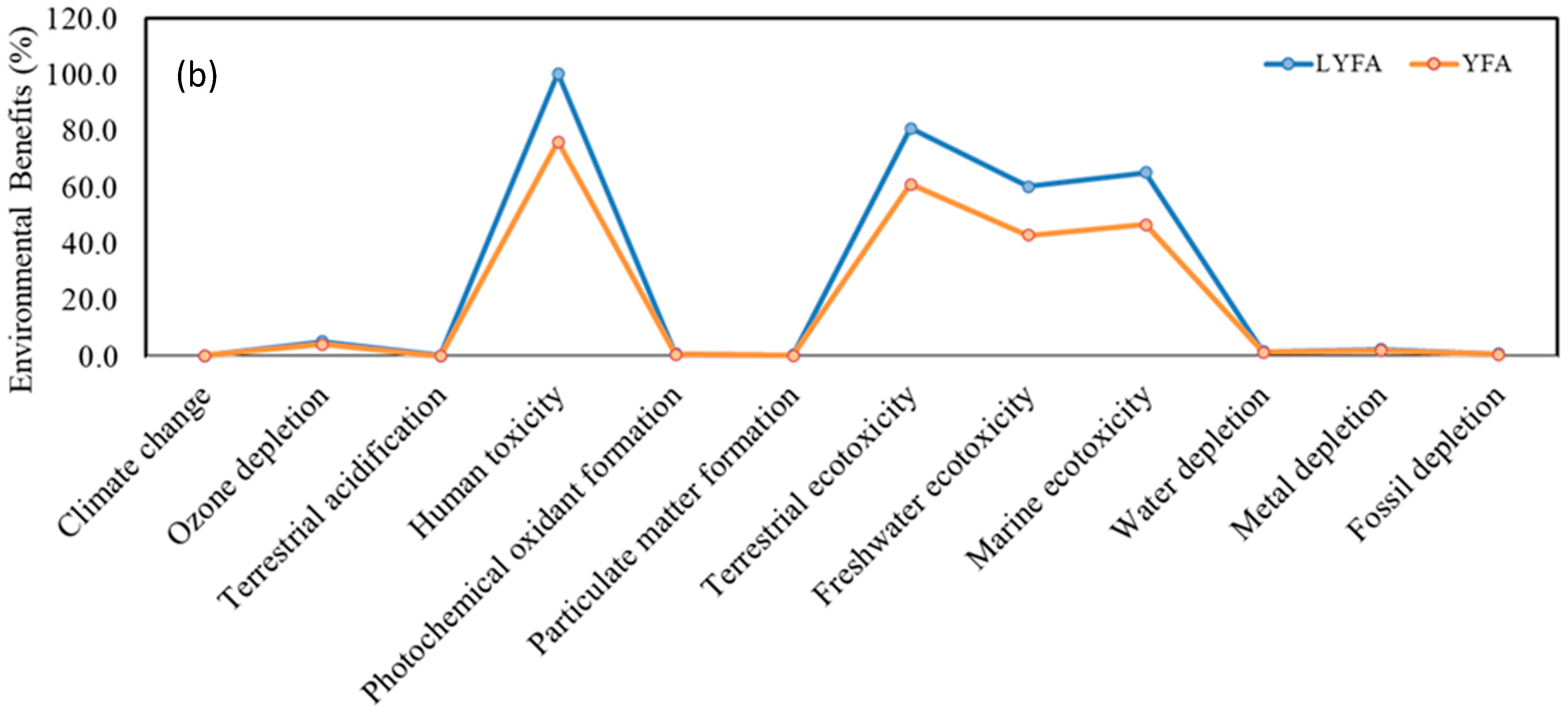

4.3. Benefit Analysis

4.4. Cost Analysis

5. Discussion

6. Conclusions and Future Research

- The Loy Yang FA (LYFA) bricks demonstrated slightly higher climate change impact intensities compared to the Portland cement (PC) bricks.

- The Yallourn FA (YFA) bricks showed higher environmental impact intensities for all midpoint categories when compared to both the LYFA and PC bricks due to the lower compressive strength.

- Fossil fuel depletion and climate change were identified as the highest impacted categories during the brick production stage.

- The combination of sodium silicate and sodium hydroxide was responsible for approximately 90% of the total impact for all categories except metal and water depletion for both brown coal geopolymer bricks.

- Terrestrial acidification, human toxicity, photochemical oxidant formation, particulate matter formation, terrestrial ecotoxicity, freshwater ecotoxicity, marine ecotoxicity, and fossil fuel depletion showed higher impacts for the LYFA bricks compared to the PC bricks.

- Significant environmental benefits in terms of human, freshwater, and marine water ecotoxicity can be obtained by utilizing brown coal ash for the brick manufacturing process.

- The most-significant benefits for the LYFA geopolymer bricks over the PC bricks were recorded for the ozone depletion, water depletion, and metal depletion (natural resources other than fossil fuels) categories due to the replacement of PC as a raw material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Olhoff, A.; Christensen, J.M. Emissions Gap Report 2018. 2018. Available online: https://www.unep.org/resources/emissions-gap-report-2018 (accessed on 1 November 2020).

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A.J. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Sentman, S.D.; Del Percio, S.T.; Koerner, P. A Climate for Change: Green Building Policies, Programs, and Incentives. J. Green Build. 2008, 3, 46–63. [Google Scholar] [CrossRef]

- Reber, A.P.J.K.L. Taking the LEED: Determining the Appropriate Amount of Government Regulation in Green Building Projects. Ky. Law J. 2009, 98, 573. [Google Scholar]

- Furr, J.E. Green Building and Sustainable Development: The Practical Legal Guide; American Bar Association: Chicago, IL, USA, 2009. [Google Scholar]

- Weyant, C.; Athalye, V.; Ragavan, S.; Rajarathnam, U.; Lalchandani, D.; Maithel, S.; Baum, E.; Bond, T.C. Emissions from South Asian Brick Production. Environ. Sci. Technol. 2014, 48, 6477–6483. [Google Scholar] [CrossRef]

- Bricks, T. Ever Wondered How Bricks Are Made? Think Brick Australia: St Leonards, Australia, 2020. [Google Scholar]

- Hall, M.R.; Lindsay, R.; Krayenhoff, M. Modern Earth Buildings: Materials, Engineering, Constructions and Applications; Elsevier Science & Technology: Cambridge, UK, 2012; Volume 33. [Google Scholar]

- Gartner, E. Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- ISO14040; Environmental Management-Life Cycle Assessment-Principles Framework. ISO: Geneva, Switzerland, 2006.

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Ferone, C.; Liguori, B.; Capasso, I.; Colangelo, F.; Cioffi, R.; Cappelletto, E.; Di Maggio, R. Thermally treated clay sediments as geopolymer source material. Appl. Clay Sci. 2015, 107, 195–204. [Google Scholar] [CrossRef]

- De Felice, F.; Petrillo, A.; Cooper, O. An integrated conceptual model to promote green policies. Int. J. Innov. Sustain. Dev. 2013, 7, 333. [Google Scholar] [CrossRef]

- Britt, A.F.; Summerfield, D.; Senior, A.B.; Roberts, D.; Kay, P.; Hitchman, A.; Champion, D.C.; Huston, D.; Sexton, M.; Schofield, A.; et al. Australia’s Identified Mineral Resources 2016; Geoscience Australia: Canberra, Australia, 2016. [Google Scholar]

- Macphee, D.; Black, C.; Taylor, A. Cements incorporating brown coal fly ash from the latrobe valley region of Victoria, Australia. Cem. Concr. Res. 1993, 23, 507–517. [Google Scholar] [CrossRef]

- Habert, G.; d’Espinose de Lacaillerie, J.B.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Weil, M.; Dombrowski, K.; Buchwald, A. Life-cycle analysis of geopolymers. Geopolymers 2009, 194–210. [Google Scholar] [CrossRef]

- Yan, H.; Shen, Q.; Fan, L.C.; Wang, Y.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. Manag.-Life Cycle Assess.-Princ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- Youssef, N.; Rabenantoandro, A.Z.; Dakhli, Z.; Chehade, F.H.; Lafhaj, Z. Environmental evaluation of geopolymer bricks. MATEC Web Conf. 2019, 281, 03005. [Google Scholar] [CrossRef]

- Petrillo, A.; Cioffi, R.; Ferone, C.; Colangelo, F.; Borrelli, C. Eco-sustainable Geopolymer Concrete Blocks Production Process. Agric. Agric. Sci. Procedia 2016, 8, 408–418. [Google Scholar] [CrossRef]

- Abdulkareem, M.; Havukainen, J.; Nuortila-Jokinen, J.; Horttanainen, M. Environmental and economic perspective of waste-derived activators on alkali-activated mortars. J. Clean. Prod. 2020, 280, 124651. [Google Scholar] [CrossRef]

- Xing, S.; Xu, Z.; Jun, G. Inventory analysis of LCA on steel- and concrete-construction office buildings. Energy Build. 2008, 40, 1188–1193. [Google Scholar] [CrossRef]

- Lozano-Miralles, J.A.; Hermoso-Orzáez, M.J.; Gago-Calderón, A.; Brito, P. LCA Case Study to LED Outdoor Luminaries as a Circular Economy Solution to Local Scale. Sustainability 2019, 12, 190. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, G.; Bhuiyan, M.A.; Agostino, J. Comparative life cycle assessment of kerbside collection methods for waste glass cullet for asphalt production. J. Clean. Prod. 2022, 374, 134055. [Google Scholar] [CrossRef]

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A. Life cycle assessment applied to bituminous mixtures containing recycled materials: Crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 2017, 117, 204–212. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J. Estimation of building-related construction and demolition waste in Shanghai. Waste Manag. 2014, 34, 2327–2334. [Google Scholar] [CrossRef] [PubMed]

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; De Haes, H.A.U. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000, 5, 319–326. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Khodr, M. The Use of Brown Coal Fly Ash as a Replacement of Cement in Concrete Masonry Bricks. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2020. [Google Scholar]

- Khodr, M.; Law, D.; Gunasekara, C.; Setunge, S.; Brkljaca, R. Compressive strength and microstructure evolution of low calcium brown coal fly ash-based geopolymer. J. Sustain. Cem. Mater. 2020, 9, 17–34. [Google Scholar] [CrossRef]

- AEU. Australian Energy Update 2020. Available online: https://www.energy.gov.au/publications/australian-energy-update-2020 (accessed on 1 November 2020).

- Fawer, M.; Concannon, M.; Rieber, W. Life cycle inventories for the production of sodium silicates. Int. J. Life Cycle Assess. 1999, 4, 207–212. [Google Scholar] [CrossRef]

- Gomes, K.C.; Carvalho, M.; Diniz, D.D.P.; Abrantes, R.D.C.C.; Branco, M.A.; de Carvalho, P.R.O., Jr. Carbon emissions associated with two types of foundations: CP-II Portland cement-based composite vs. geopolymer concrete. Matéria 2019, 24. [Google Scholar] [CrossRef]

- Thannimalay, L.; Yusoff, S.; Zawawi, N. Life cycle assessment of sodium hydroxide. Aust. J. Basic Appl. Sci. 2013, 7, 421–431. [Google Scholar]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’adamo, I.; Gastaldi, M. Sustainable management of waste-to-energy facilities. Renew. Sustain. Energy Rev. 2014, 33, 719–728. [Google Scholar] [CrossRef]

- GreenFacts. The Mining of Sand, a Non-Renewable Resource; Authority of the GreenFacts Scientific Board: Brussels, Belgium, 2021. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.A.J.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008: A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint the Endpoint Level. 2009, pp. 1–126. Available online: https://www.researchgate.net/publication/302559709_ReCiPE_2008_A_life_cycle_impact_assessment_method_which_comprises_harmonised_category_indicators_at_the_midpoint_and_the_endpoint_level (accessed on 1 November 2020).

- Gottlieb, B.; Gilbert, S.G.; Evans, L.G. Coal Ash: The Toxic Threat to Our Health and Environment; Physicians for Social Responsibility: Bethesda, MD, USA, 2010. [Google Scholar]

- Adak, S.; Adhikari, K.; Brahmachari, K. Effect of Fly Ash on Crop Coverage around coal-fired Thermal Power Plant in Rural India. Int. J. Environ. Agric. Biotechnol. 2016, 1, 238565. [Google Scholar] [CrossRef]

- Rowe, C.L.; Hopkins, W.A.; Congdon, J.D. Ecotoxicological implications of aquatic disposal of coal combustion residues in the United States: A review. Environ. Monit. Assess. 2002, 80, 207–276. [Google Scholar] [CrossRef]

- Asif, Z.; Chen, Z.; Wang, H.; Zhu, Y. Update on air pollution control strategies for coal-fired power plants. Clean Technol. Environ. Policy 2022, 24, 2329–2347. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, X.; Tse, C.K. Effects of High Level of Penetration of Renewable Energy Sources on Cascading Failure of Modern Power Systems. IEEE J. Emerg. Sel. Top. Circuits Syst. 2022, 12, 98–106. [Google Scholar] [CrossRef]

- Yi, W.; Hill, D.J.; Song, Y. Impact of High Penetration of Renewable Resources on Power System Transient Stability. In Proceedings of the 2019 IEEE Power & Energy Society General Meeting (PESGM), Atlanta, GA, USA, 4–8 August 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Wang, Y.; Byers, E.; Parkinson, S.; Wanders, N.; Wada, Y.; Mao, J.; Bielicki, J.M. Vulnerability of existing and planned coal-fired power plants in Developing Asia to changes in climate and water resources. Energy Environ. Sci. 2019, 12, 3164–3181. [Google Scholar] [CrossRef]

- Association, W.C. Coal & Electricity. 2020. Available online: https://www.worldcoal.org/coal-facts/coal-electricity/ (accessed on 10 April 2023).

- Abdulkareem, M.; Havukainen, J.; Horttanainen, M. Environmental Assessment of Alkali-Activated Mortars Using Different Activators. In SARDINIA; CISA: Padova, Italy, 2019. [Google Scholar]

- Marwa, D.; Heinonen, J.; El-Mahdy, D.; Hassan, D.M. A comparative study of life cycle carbon emissions and embodied energy between sun-dried bricks and fired clay bricks. J. Clean. Prod. 2020, 275, 122998. [Google Scholar]

- Huarachi, D.A.R.; Gonçalves, G.; de Francisco, A.C.; Canteri, M.H.G.; Piekarski, C.M. Life cycle assessment of traditional and alternative bricks: A review. Environ. Impact Assess. Rev. 2020, 80, 106335. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Song, X.; Marosszekya, M.; Brungsb, M.; Munna, R. Durability of fly ash based geopolymer concrete against sulphuric acid attack. In Proceedings of the International Conference on Durability of Building Materials and Components, Lyon, France, 17–20 April 2005. [Google Scholar]

- Thokchom, S.; Ghosh, P.; Ghosh, S. Effect of water absorption, porosity and sorptivity on durability of geopolymer mortars. Mater. Sci. 2009, 4, 28–32. [Google Scholar]

| Bricks | Mix Design (kg/m3) | Water to Solid | 28-Day Compressive Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PC | Brown Coal Ash | Sand | Dust | White Stone (7 mm) | Water | Activator Solution | ||||

| Na2SiO3 | NaOH | |||||||||

| PC | 160 | - | 728 | 182 | 291 | 76.8 | - | - | 0.48 | 15.0 |

| LYFA | - | 160 | 728 | 182 | 291 | 10 | 208 | 12 | 0.52 | 21.7 |

| YFA | - | 152 | 689 | 172 | 276 | 0 | 271 | 17 | 0.58 | 6.8 |

| Material | PC | Brown Coal Ash | Fine Aggregate | Coarse Aggregate | NaOH | Sodium Silicate | Geopolymer Brick | PC Brick |

|---|---|---|---|---|---|---|---|---|

| Raw material extraction and production | - | |||||||

| Collection and drying | - | - | - | - | - | - | - | |

| Transportation | ||||||||

| Mixing | - | - | - | - | - | - | ||

| Heat curing | - | - | - | - | - | - | - | |

| Distribution | - | - | - | - | - | - | ||

| Usage | - | - | - | - | - | - | ||

| End of life | - | - | - | - | - | - |

| Transportation Stage | Distance (km) |

|---|---|

| LYFA to manufacturing plant | 168 |

| YFA to manufacturing plant | 145 |

| PC to manufacturing plant | 50 |

| Sodium silicate to manufacturing plant | 38.5 |

| NaOH to manufacturing plant | 26.1 |

| Chelvon sand to manufacturing plant | 16.7 |

| Chelvon dust to manufacturing plant | 16.7 |

| White stone to manufacturing plant | 29.8 |

| Distribution | 50 |

| Disposal (landfilling) distance | 56 |

| Impact Category | Unit | Impact Intensity | ||

|---|---|---|---|---|

| LYFA | YFA | PC | ||

| Climate change | kg CO2 eq/m3. MPa | 1.97 × 101 | 7.86 × 101 | 1.94 × 101 |

| Ozone depletion | kg CFC-11 eq/m3. MPa | 4.53 × 10−7 | 1.71 × 10−6 | 6.19 × 10−7 |

| Terrestrial acidification | kg SO2 eq/m3. MPa | 1.34 × 10−1 | 5.58 × 10−1 | 4.47 × 10−2 |

| Human toxicity | kg 1,4-DB eq/m3. MPa | 3.17 × 100 | 1.26 × 101 | 1.91 × 100 |

| Photochemical oxidant formation | kg NMVOC/m3. MPa | 7.36 × 10−2 | 2.97 × 10−1 | 4.83 × 10−2 |

| Particulate matter formation | kg PM10 eq/m3. MPa | 3.40 × 10−2 | 1.39 × 10−1 | 1.68 × 10−2 |

| Terrestrial ecotoxicity | kg 1,4-DB eq/m3. MPa | 3.50 × 10−4 | 1.41 × 10−3 | 2.65 × 10−4 |

| Freshwater ecotoxicity | kg 1,4-DB eq/m3. MPa | 4.52 × 10−1 | 1.92 × 100 | 2.91 × 10−2 |

| Marine ecotoxicity | kg 1,4-DB eq/m3. MPa | 3.91 × 10−1 | 1.66 × 100 | 2.86 × 10−2 |

| Water depletion | m3/m3. MPa | 1.46 × 10−1 | 5.31 × 10−1 | 2.08 × 10−1 |

| Metal depletion | kg Fe eq/m3. MPa | 1.16 × 10−1 | 4.16 × 10−1 | 2.17 × 10−1 |

| Fossil fuel depletion | kg oil eq/m3. MPa | 5.61 × 100 | 2.31 × 101 | 2.53 × 100 |

| Impact Category | Unit | Mixing | Heat Curing | ||||

|---|---|---|---|---|---|---|---|

| LYFA | YFA | PC | LYFA | YFA | PC | ||

| Climate change | kg CO2 eq/m3. MPa | 3.83 × 10−2 | 4.18 × 10−1 | 1.90 × 10−1 | 1.70 × 100 | 5.76 × 100 | 0.00 × 100 |

| Ozone depletion | kg CFC-11 eq/m3. MPa | 5.63 × 10−10 | 1.01 × 10−8 | 4.58 × 10−9 | 2.50 × 10−8 | 8.46 × 10−8 | 0.00 × 100 |

| Terrestrial acidification | kg SO2 eq/m3. MPa | 3.44 × 10−4 | 7.74 × 10−4 | 3.51 × 10−4 | 1.53 × 10−2 | 5.17 × 10−2 | 0.00 × 100 |

| Human toxicity | kg 1,4-DB eq/m3. MPa | 6.51 × 10−3 | 8.17 × 10−3 | 3.71 × 10−3 | 2.89 × 10−1 | 9.78 × 10−1 | 0.00 × 100 |

| Photochemical oxidant formation | kg NMVOC/m3. MPa | 1.56 × 10−4 | 1.61 × 10−3 | 7.29 × 10−4 | 6.93 × 10−3 | 2.34 × 10−2 | 0.00 × 100 |

| Particulate matter formation | kg PM10 eq/m3. MPa | 7.99 × 10−5 | 4.19 × 10−4 | 2.85 × 10−3 | 3.55 × 10−3 | 1.20 × 10−2 | 0.00 × 100 |

| Terrestrial ecotoxicity | kg 1,4-DB eq/m3. MPa | 7.37 × 10−7 | 4.99 × 10−6 | 2.26 × 10−6 | 3.27 × 10−5 | 1.11 × 10−4 | 0.00 × 100 |

| Freshwater ecotoxicity | kg 1,4-DB eq/m3. MPa | 1.30 × 10−3 | 2.12 × 10−4 | 9.59 × 10−5 | 5.78 × 10−2 | 1.95 × 10−1 | 0.00 × 100 |

| Marine ecotoxicity | kg 1,4-DB eq/m3. MPa | 1.12 × 10−3 | 2.35 × 10−4 | 1.06 × 10−4 | 4.99 × 10−2 | 1.69 × 10−1 | 0.00 × 100 |

| Water depletion | m3/m3. MPa | 8.77 × 10−5 | 1.26 × 10−2 | 5.70 × 10−3 | 3.90 × 10−3 | 1.32 × 10−2 | 0.00 × 100 |

| Metal depletion | kg Fe eq/m3. MPa | 7.36 × 10−5 | 3.36 × 10−3 | 1.52 × 10−3 | 3.27 × 10−3 | 1.11 × 10−2 | 0.00 × 100 |

| Fossil fuel depletion | kg oil eq/m3. MPa | 1.34 × 10−2 | 1.10 × 10−1 | 4.99 × 10−2 | 5.94 × 10−1 | 2.01 × 100 | 0.00 × 100 |

| Phases | Brick | Cost (AUD) per 1 m3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PC | Brown Coal Ash | Sand | Dust | White Stone (7 mm) | Activator Solution | Total Cost per 1 m3 | Cost per Brick | |||

| Na2SiO3 | NaOH | |||||||||

| Material Manufacturing | PC | 64.00 | 0.00 | 400.40 | 100.10 | 144.77 | 0.00 | 0.00 | 709.28 | 1.33 |

| LYFA | 0.00 | 0.00 | 400.40 | 100.10 | 144.77 | 1033.11 | 157.24 | 1835.63 | 3.45 | |

| YFA | 0.00 | 0.00 | 378.95 | 94.60 | 137.31 | 1346.03 | 222.76 | 2179.65 | 4.10 | |

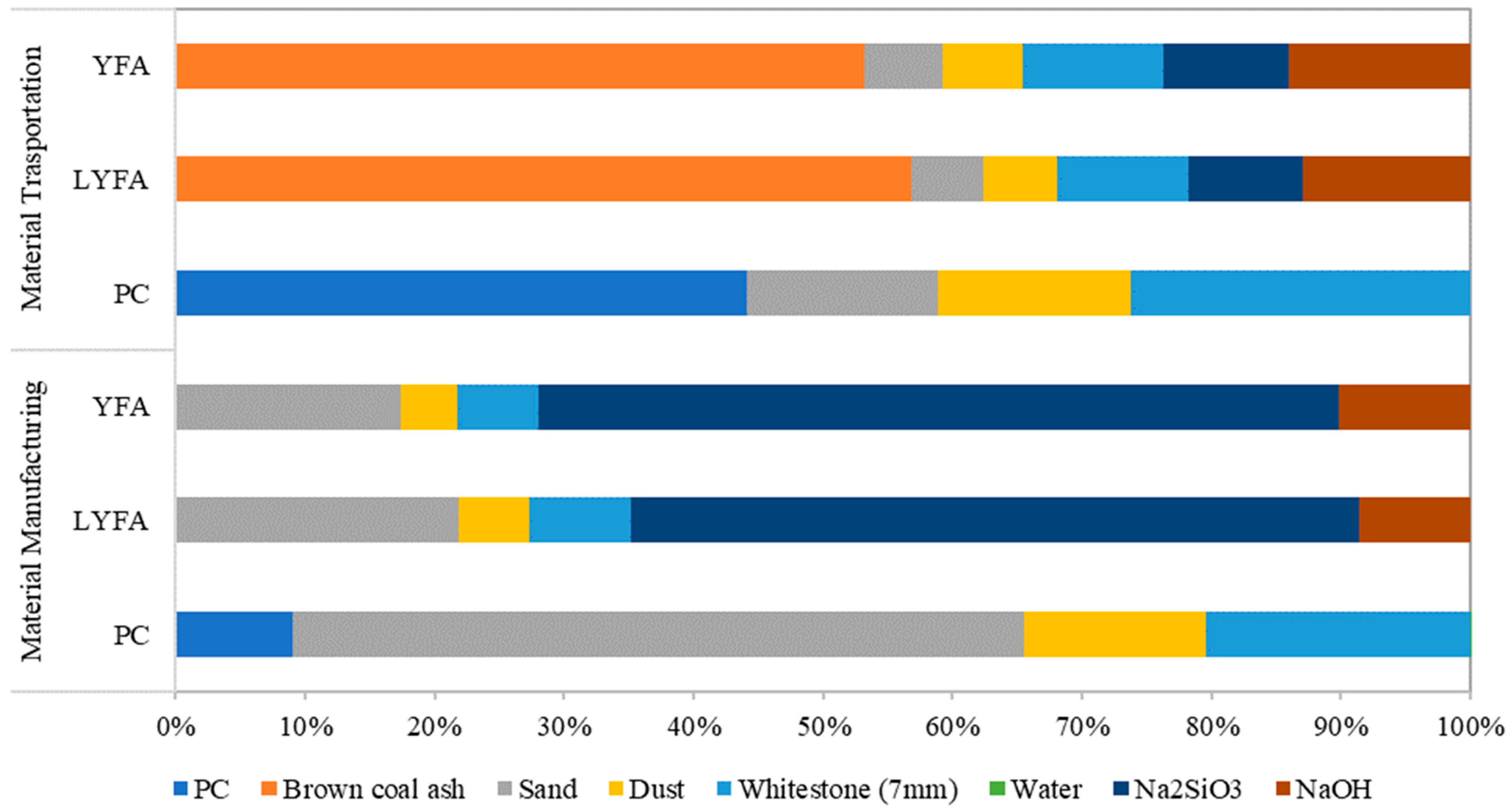

| Material Transportation | PC | 17.30 | 0.00 | 5.78 | 5.81 | 10.31 | 0.00 | 0.00 | 39.21 | 0.07 |

| LYFA | 0.00 | 58.14 | 5.78 | 5.81 | 10.31 | 9.03 | 13.32 | 102.40 | 0.19 | |

| YFA | 0.00 | 50.18 | 5.78 | 5.81 | 10.31 | 9.03 | 13.32 | 94.44 | 0.18 | |

| Brick Manufacturing | PC | - | 10.80 | 0.02 | ||||||

| LYFA | 69.40 | 0.13 | ||||||||

| YFA | 69.40 | 0.13 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Fernando, S.; Law, D.W.; Gunasekara, C.; Setunge, S.; Sandanayake, M.; Zhang, G. Life Cycle Assessment for Geopolymer Concrete Bricks Using Brown Coal Fly Ash. Sustainability 2023, 15, 7718. https://doi.org/10.3390/su15097718

Zhang J, Fernando S, Law DW, Gunasekara C, Setunge S, Sandanayake M, Zhang G. Life Cycle Assessment for Geopolymer Concrete Bricks Using Brown Coal Fly Ash. Sustainability. 2023; 15(9):7718. https://doi.org/10.3390/su15097718

Chicago/Turabian StyleZhang, Jingxuan, Sarah Fernando, David W. Law, Chamila Gunasekara, Sujeeva Setunge, Malindu Sandanayake, and Guomin Zhang. 2023. "Life Cycle Assessment for Geopolymer Concrete Bricks Using Brown Coal Fly Ash" Sustainability 15, no. 9: 7718. https://doi.org/10.3390/su15097718

APA StyleZhang, J., Fernando, S., Law, D. W., Gunasekara, C., Setunge, S., Sandanayake, M., & Zhang, G. (2023). Life Cycle Assessment for Geopolymer Concrete Bricks Using Brown Coal Fly Ash. Sustainability, 15(9), 7718. https://doi.org/10.3390/su15097718

_Zhang.png)