Sustainable Design Orientation in Furniture-Manufacturing SMEs in Zimbabwe

Abstract

1. Introduction

- What are your current sustainable design practices and goals?

- What are your biggest challenges in implementing sustainable design practices?

- What are some of the most innovative sustainable practices you have implemented?

- How do you engage employees in sustainability initiatives?

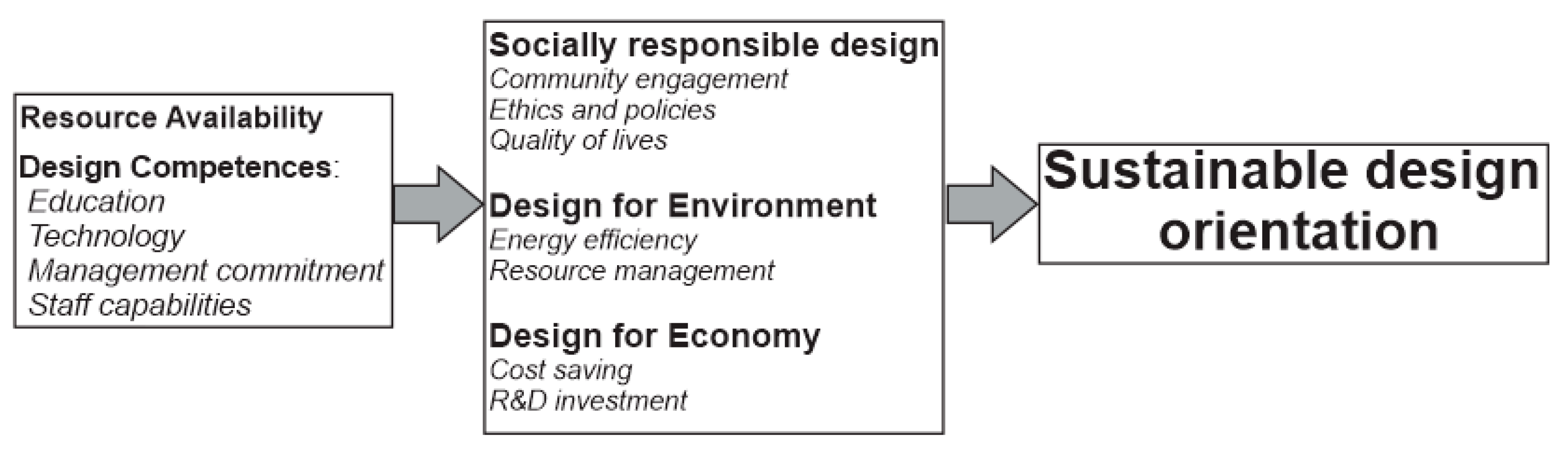

Conceptual Framework

2. Literature Review

2.1. SMEs and Sustainability

2.2. Sustainability-Oriented Innovation in SMEs

2.3. Sustainable Design in Manufacturing SMEs

3. Materials and Methods

- What does sustainable design mean to you? How do you incorporate sustainability into your business practices?

- What are some of the biggest challenges you face when it comes to sustainability and sustainable design?

- What are some of the most innovative sustainable design practices you have implemented?

- How do you measure the success of your sustainability initiatives?

3.1. Data Collection

3.2. Individual in-Depth Interviews

3.3. On-Site Observations

3.4. Summary Design Matrix Tool

4. Findings

“We cannot afford to employ an individual or team for R&D that will increase our expenditure immediately as the company’s survival today is much more important than tomorrow; we rather eat what we kill today since there is too much competition”.(Respondent Manager-M03)

4.1. Design Orientation

“In design, we can be inspired by the same things found in nature and thereby end up with similar products, and the customers fail to differentiate our products and end up assuming the design is the same”.(Respondent Designer-D05)

“My manager will sit down with me in a meeting to ask for ideas, and you give input or insights about sustainability from the three dimensions, but he always argues to say it is of no use in the immediate future and, therefore, cannot be implemented”(Respondent Designer-D02)

“Concept of minimalism can be mistaken for laziness on the part of the designer. At first, my superior used to send the ideas I had sketched to his traditional customers. It is these customers who gave positive feedback on the designs. Otherwise, it was difficult to convince him on my own”.(Respondent Designer-D07)

4.2. Environmental Orientation

“Resources limit us; therefore, spending our time and money in such activities as sustainability will distract us from our efforts to make more profits and ensure the company survives as we want to remain operational.”(Owner-Manager-H05)

5. Discussion

6. Theoretical and Practical Implications

7. Conclusions

8. Limitations and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Masocha, R. Social sustainability practices on small businesses in developing economies: A case of South Africa. Sustainability 2019, 11, 3257. [Google Scholar] [CrossRef]

- Woodard, R. Waste Management in Small and Medium Enterprises (SMEs)—A barrier to developing circular cities. Waste Manag. 2020, 118, 369–379. [Google Scholar] [CrossRef]

- Calogirou, C.; Sørensen, S.Y.; Larsen, P.B.; Alexopoulou, S. SMEs and the Environment in the European Union; European Commission: Brussels, Belgium, 2010.

- Bititci, U.; Maguire, C.; Gregory, I. Adaptive Capability. A Must for Manufacturing SMEs of the Future; FutureSME: Glasgow, UK, 2010. [Google Scholar]

- Côté, R.; Booth, A.; Louis, B. Eco-efficiency and SMEs in Nova Scotia, Canada. J. Clean. Prod. 2006, 14, 542–550. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E. Sustainability-oriented Innovation of SMEs: A Systematic Review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Hampton, S. It’s the soft stuff that’s hard: Investigating the role played by low carbon small-and medium-sized enterprise advisors in sustainability transitions. Local Econ. 2018, 33, 384–404. [Google Scholar] [CrossRef]

- Coldwell, D.; Venter, R.; Joosub, T.; Duh, H. The Tension between SMEs’ Growth and Sustainability in Emerging and Developed Countries’ Internationalization: Towards a Conceptual Model. Sustainability 2022, 14, 4418. [Google Scholar] [CrossRef]

- Wu, W.P.; Leung, A. Does a micro-macro link exist between managerial value of reciprocity, social capital and firm performance? The case of SMEs in China. Asia Pac. J. Manag. 2005, 22, 445–463. [Google Scholar] [CrossRef]

- Zvarivadza, T. Artisanal and Small-Scale Mining as a challenge and possible contributor to Sustainable Development. Resour. Policy 2018, 56, 49–58. [Google Scholar] [CrossRef]

- Scagnelli, S.D.; Corazza, L.; Cisi, M. How SMEs disclose their sustainability performance. Which variables influence the choice of reporting guidelines? In Accounting and Control for Sustainability; Emerald Group Publishing Limited: Bingley, UK, 2013; pp. 77–114. [Google Scholar] [CrossRef]

- Chowdhury, P.; Shumon, R. Minimising the Gap between Expectation and Ability: Strategies for SMEs to Implement Social Sustainability Practices. Sustainability 2020, 12, 6408. [Google Scholar] [CrossRef]

- Das, M.; Rangarajan, K.; Dutta, G. Corporate sustainability in small and medium-sized enterprises: A literature analysis and road ahead. J. Ind. Bus. Res. 2020, 12, 271–300. [Google Scholar] [CrossRef]

- Preuss, L.; Perschke, J. Slipstreaming the larger boats: Social responsibility in medium-sized businesses. J. Bus. Ethics 2010, 92, 531–551. [Google Scholar] [CrossRef]

- Dlamini, B.; Schutte, D.P. An overview of the historical development of Small and Medium Enterprises in Zimbabwe. Small Enterp. Res. 2020, 27, 306–322. [Google Scholar] [CrossRef]

- Tinarwo, R. An investigation into the challenges faced by small to Medium Enterprises in Zimbabwe: A case of Gazaland market. IOSR J. Bus. Manag. 2016, 18, 148–153. [Google Scholar] [CrossRef]

- Sibanda, B. Sustainability of Small Businesses in Zimbabwe during the First 5 Years. Doctoral Dissertation, Walden University, Minneapolis, MN, USA, 2016. [Google Scholar]

- Dzingirai, M.; Tshuma, N.; Sikomwe, S. Post-Pandemic Sustainability Strategies for Zimbabwean SMEs. In Handbook of Research on Strategies and Interventions to Mitigate COVID-19 Impact on SMEs; IGI Global: Hershey, PA, USA, 2021; pp. 457–476. [Google Scholar]

- Majukwa, D.; Fan, S.K.; Dwyer, R.J. Impact of sustainability strategies on small-and medium-sized enterprises in Zimbabwe. World J. Entrep. Manag. Sustain. Dev. 2020, 16, 149–163. [Google Scholar] [CrossRef]

- Mungozhi, F.; Hlabiso, G. Determinants of small to medium enterprises’ success or failure: An ex-post appraisal of start-up business by young entrepreneurs in Zimbabwe. Int. J. Humanit. Soc. Stud. 2017, 5, 35–46. [Google Scholar]

- Brammer, S.; Hoejmose, S.; Marchant, K. Environmental management in SMEs in the UK: Practices, pressures and perceived benefits. Bus. Strategy Environ. 2012, 21, 423–434. [Google Scholar] [CrossRef]

- Cassels, S.; Lewis, K. SMEs and environmental responsibility: Do actions reflect attitudes? Corp. Soc. Responsib. Environ. Manag. 2011, 18, 186–199. [Google Scholar] [CrossRef]

- Yu, J.; Bell, J.N.B. Building a sustainable business in China’s small and medium-sized enterprises (SMEs). J. Environ. Assess. Policy Manag. 2007, 9, 19–43. [Google Scholar] [CrossRef]

- Johnson, M.P. Sustainability management and small and medium-sized enterprises: Managers’ awareness and implementation of innovative tools. Corp. Soc. Responsib. Environ. Manag. 2015, 22, 271–285. [Google Scholar] [CrossRef]

- Behjati, S. Critical remarks about environmentalism implication by Iranian SMEs. Eur. J. Sustain. Dev. 2017, 6, 209. [Google Scholar] [CrossRef]

- Bos-Brouwers, H.E.J. Corporate sustainability and innovation in SMEs: Evidence of themes and activities in practice. Bus. Strategy Environ. 2010, 19, 417–435. [Google Scholar] [CrossRef]

- Stawińska, A. (Ed.) Key Figures on European Business with a Special Feature on SMEs: 2011 Edition; Publications Office: Washington, DC, USA, 2011. [Google Scholar]

- Adamu, A.A.; Wan, C.Y.; Gorondutse, A.H. Determinants of sustainable performance of SMEs: A proposed framework. Int. J. Res. Sci. Innov. 2019, 6, 182–188. [Google Scholar]

- Heras, I.; Arana, G. Alternative models for environmental management in SMEs: The case of Ekoscan vs. ISO 14001. J. Clean. Prod. 2010, 18, 726–735. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Chowdhury, S.A.; Abdelaziz, F.B. The impact of lean management practices and sustainably oriented innovation on sustainability performance of small and medium-sized enterprises: Empirical evidence from the UK. Br. J. Manag. 2020, 31, 141–161. [Google Scholar] [CrossRef]

- Katz-Gerro, T.; López Sintas, J. Mapping circular economy activities in the European Union: Patterns of implementation and their correlates in small and medium-sized enterprises. Bus. Strat. Environ. 2019, 28, 485–496. [Google Scholar] [CrossRef]

- Broccardo, L.; Zicari, A. Sustainability as a driver for value creation: A business model analysis of small and medium enterprises in the Italian wine sector. J. Clean. Prod. 2020, 259, 120852. [Google Scholar] [CrossRef]

- Spence, L.J. CSR and Small Business in a European Policy Context: The Five “C”s of CSR and Small Business Research Agenda. Bus. Soc. Rev. 2007, 112, 533–552. [Google Scholar] [CrossRef]

- Lee, J.; Pati, N. New Insights on the Operational Link between Corporate Sustainability and Firm Performance in Service Industries. Int. J. Bus. Insights 2012, 4, 80–93. [Google Scholar]

- Roxas, B.; Ashill, D.; Chadee, D. Effects of Entrepreneurial and Environmental Sustainability Orientations on Firm Performance: A Study of Small Businesses in the Philippines. J. Small Bus. Manag. 2017, 55, 163–178. [Google Scholar] [CrossRef]

- Masurel, E. Why SMEs Invest in Environmental Measures: Sustainability Evidence from Small and Medium-sized Printing Firms. Bus. Strat. Environ. 2007, 16, 190–201. [Google Scholar] [CrossRef]

- Boons, F.; Montalvo, C.; Quist, J.; Wagner, M. Sustainable innovation, business models and economic performance: An overview. J. Clean. Prod. 2013, 45, 1–8. [Google Scholar] [CrossRef]

- Khor, K.S.; Udin, Z.M. Reverse logistics in Malaysia: Investigating the effect of green product design and resource commitment. Resour. Conserv. Recycl. 2013, 81, 71–80. [Google Scholar] [CrossRef]

- Halila, F.; Rundquist, J. The development and market success of eco-innovations: A comparative study of eco-innovations and “other” innovations in Sweden. Eur. J. Innov. Manag. 2011, 14, 278–302. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, S. Drivers of proactive environmental strategy in family firms. Bus. Ethics Q. 2011, 21, 309–334. [Google Scholar] [CrossRef]

- Mady, K.; Abdul Halim, M.A.S.; Omar, K. Drivers of multiple eco-innovation and the impact on sustainable competitive advantage: Evidence from manufacturing SMEs in Egypt. Int. J. Innov. Sci. 2022, 14, 40–61. [Google Scholar] [CrossRef]

- Boeske, J.; Murray, P.A. The Intellectual Domains of Sustainability Leadership in SMEs. Sustainability 2022, 14, 1978. [Google Scholar] [CrossRef]

- Paramanathan, S.; Farrukh, C.; Phaal, R.; Probert, D. Implementing industrial sustainability: The research issues in technology management. RD Manag. 2004, 34, 527–537. [Google Scholar] [CrossRef]

- Altham, W. Benchmarking to trigger cleaner production in small businesses: Drycleaning case study. J. Clean. Prod. 2007, 15, 798–813. [Google Scholar] [CrossRef]

- Mangla, S.K.; Luthra, S.; Mishra, N.; Singh, A.; Rana, N.P.; Dora, M.; Dwivedi, Y. Barriers to effective circular supply chain management in a developing country context. Prod. Plann. Control 2018, 29, 551–569. [Google Scholar] [CrossRef]

- Rodríguez-Espíndola, O.; Cuevas-Romo, A.; Chowdhury, S.; Díaz-Acevedo, N.; Albores, P.; Despoudi, S.; Dey, P. The role of circular economy principles and sustainable-oriented innovation to enhance social, economic and environmental performance: Evidence from Mexican SMEs. Int. J. Prod. Econ. 2022, 248, 108495. [Google Scholar] [CrossRef]

- European Commission. Sustainable Product Policy. 2018. Available online: https://ec.europa.eu/jrc/en/research-topic/sustainable-product-policy (accessed on 18 December 2022).

- Ševčíková, R.; Knošková, L. Sustainable Design in the Furniture Industry. In Proceedings of the 21st International Joint Conference Central and Eastern Europe in the Changing Business Environment: Proceedings, Prague, Czech Republic, 20–21 May 2021. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Saad, E. Design for Sustainable Manufacturing: Approach, Implementation, and Assessment. Sustainability 2018, 10, 3604. [Google Scholar] [CrossRef]

- Rosen, M.A.; Kishawy, H.A. Sustainable Manufacturing and Design: Concepts, Practices and Needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, W. Design for the triple top line: New tools for sustainable commerce. Corp. Environ. Strat. 2002, 9, 1711–1716. [Google Scholar] [CrossRef]

- Aboelmaged, M.; Hashem, G. Absorptive capacity and green innovation adoption in SMEs: The mediating effects of sustainable organisational capabilities. J. Clean. Prod. 2019, 220, 853–863. [Google Scholar] [CrossRef]

- Karlsson, R.; Luttropp, C. Eco-design: What is happening An overview of the subject area of eco-design and the papers in this special issue. J. Clean. Prod. 2006, 14, 1291–1298. [Google Scholar] [CrossRef]

- Grote, C.A.; Jones, J.M.; Blount, G.N.; Goodyer, J.; Shayler, M. An approach to the EUP directive and the application of the economic eco-design for complex products. Int. J. Prod. Res. 2007, 45, 4099–4117. [Google Scholar] [CrossRef]

- Howarth, G.; Hadfield, M. A sustainable product design model. Mater. Des. 2006, 27, 1128–1133. [Google Scholar] [CrossRef]

- Ceschin, F.; Gaziulusoy, I. Evolution of design for sustainability: From product design to design for system innovations and transitions. Des. Stud. 2016, 47, 118–163. [Google Scholar] [CrossRef]

- Kivunja, C.; Kuyini, A.B. Understanding and applying research paradigms in educational contexts. Int. J. High. Educ. 2017, 6, 26–41. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; SAGE Publications: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Alvesson, M.; Skoldberg, K. Reflexive Methodology: New Vistas for Qualitative Research, 2nd ed.; SAGE Publications, Inc.: London, UK, 2012. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 5th ed.; Sage: Los Angeles, CA, USA, 2014. [Google Scholar]

- Guba, E.G.; Lincoln, Y.S. Paradigmatic Controversies, Contradictions, and Emerging Confluences. In The Sage Handbook of Qualitative Research, 3rd ed.; Denzin, N.K., Lincoln, Y.S., Eds.; Sage Publications: Los Angeles, CA, USA, 2005; pp. 191–215. [Google Scholar]

- Flick, U. From intuition to reflexive construction: Research design and triangulation in grounded theory research. In The SAGE Handbook of Current Developments in Grounded Theory; Bryant, A., Charmaz, K., Eds.; Sage Publications: Los Angeles, CA, USA, 2009; pp. 125–144. [Google Scholar]

- Quinlan, C.; Babin, B.; Carr, J.; Griffin, M.; Zikmund, W.G. Business Research Methods; Cengage: Andover, UK, 2015. [Google Scholar]

- Eldridge, S.M.; Lancaster, G.A.; Campbell, M.J.; Thabane, L.; Hopewell, S.; Coleman, C.L.; Bond, C.M. Defining feasibility and pilot studies in preparation for randomised controlled trials: Development of a conceptual framework. PLoS ONE 2016, 11, e0150205. [Google Scholar] [CrossRef]

- Hennink, M.; Hutter, I.; Bailey, A. Qualitative Research Methods; Sage: Los Angeles, CA, USA, 2020. [Google Scholar]

- Lee, S.Y.; Klassen, R.D. Drivers and enablers that foster environmental management capabilities in small and medium-sized suppliers in supply chains. Prod. Oper. Manag. 2008, 17, 573–586. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Domingues, J.P. Exploratory Research of ISO 14001:2015 Transition among Portuguese Organisations. Sustainability 2018, 10, 781. [Google Scholar] [CrossRef]

- Vicente, J.; da Silva, F.M.; Frazao, R. Sustainable Design; A Furniture Focused Approach. In Proceedings of the 5th Internacional Conference of UNIDCOM/IADE “401ade40”, Lisboa, Portugal, 30 September–3 October 2009; IADE-Creative University: Lisbon, Portugal, 2009. [Google Scholar]

- Moalosi, R.; Sung, K. Promoting Upcycling through an International Research Network. In Proceedings of the International Online Conference on Reuse, Recycling, Upcycling, Sustainable Waste Management and Circular Economy (ICRSC–2022), Kerala, India, 9–11 September 2022. [Google Scholar]

- Oladoja, O.; Dare-Abel, O.; Jayeoba, S. Towards Sustainable Environment: The Untapped Opportunities in the Circular Economy through Upcycling. In Proceedings of the Future Forward: Disruptive Innovations What Next? Lagos, Nigeria, 26–27 October 2021; Available online: https://www.researchgate.net/publication/356760538_Upcycling_in_Lagos (accessed on 20 March 2023).

- Bofylatos, S. Upcycling systems design, developing a methodology through design. Sustainability 2022, 14, 600. [Google Scholar] [CrossRef]

| Phase 1-SMEs in Harare 5 SMEs (6 to 10 June 2022) | 5 SME Managers—In-depth Interviews 5 SME Designers—In-depth Interviews 5 On-site Observations |

| Phase 2-SMEs in Bulawayo 5 SMEs (20 to 24 June 2022) | 5 SME Managers—In-depth Interviews 5 SME Designers—In-depth Interviews 5 On-site Observations |

| Social | Economy | Environment | |

|---|---|---|---|

| Materials | |||

| Production process | |||

| Design process | |||

| Waste disposal | |||

| Management commitment | |||

| End of life |

| H1 | H2 | H3 | H4 | H5 | B1 | B2 | B3 | B4 | B5 | |

|---|---|---|---|---|---|---|---|---|---|---|

| No of employees | 12 | 16 | 23 | 14 | 29 | 10 | 8 | 17 | 11 | 20 |

| Gross sales annual (USD) ‘000 | USD 150 | USD 100 | USD 50 | USD 80 | USD 200 | USD 90 | USD 100 | USD 150 | USD 60 | USD 80 |

| Management Interviewed | Owner/ manager | Owner/ manager | Manager | Owner/ manager | Owner/ manager | Manager | Owner/ anager | Owner/ manager | Owner | Manager |

| Availability of Research and Development Section | Yes | Yes | No | Yes | Yes | No | Yes | Yes | No | No |

| Employed designer | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Principle | Sustainable Practice |

|---|---|

| Materials |

|

| Production process |

|

| Design process |

|

| Waste disposal |

|

| Management commitment |

|

| End of life |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chipambwa, W.; Moalosi, R.; Rapitsenyane, Y.; Molwane, O.B. Sustainable Design Orientation in Furniture-Manufacturing SMEs in Zimbabwe. Sustainability 2023, 15, 7515. https://doi.org/10.3390/su15097515

Chipambwa W, Moalosi R, Rapitsenyane Y, Molwane OB. Sustainable Design Orientation in Furniture-Manufacturing SMEs in Zimbabwe. Sustainability. 2023; 15(9):7515. https://doi.org/10.3390/su15097515

Chicago/Turabian StyleChipambwa, Walter, Richie Moalosi, Yaone Rapitsenyane, and Olefile Bethuel Molwane. 2023. "Sustainable Design Orientation in Furniture-Manufacturing SMEs in Zimbabwe" Sustainability 15, no. 9: 7515. https://doi.org/10.3390/su15097515

APA StyleChipambwa, W., Moalosi, R., Rapitsenyane, Y., & Molwane, O. B. (2023). Sustainable Design Orientation in Furniture-Manufacturing SMEs in Zimbabwe. Sustainability, 15(9), 7515. https://doi.org/10.3390/su15097515