Fostering Sustainable LNG Bunkering Operations: Development of Regulatory Framework

Abstract

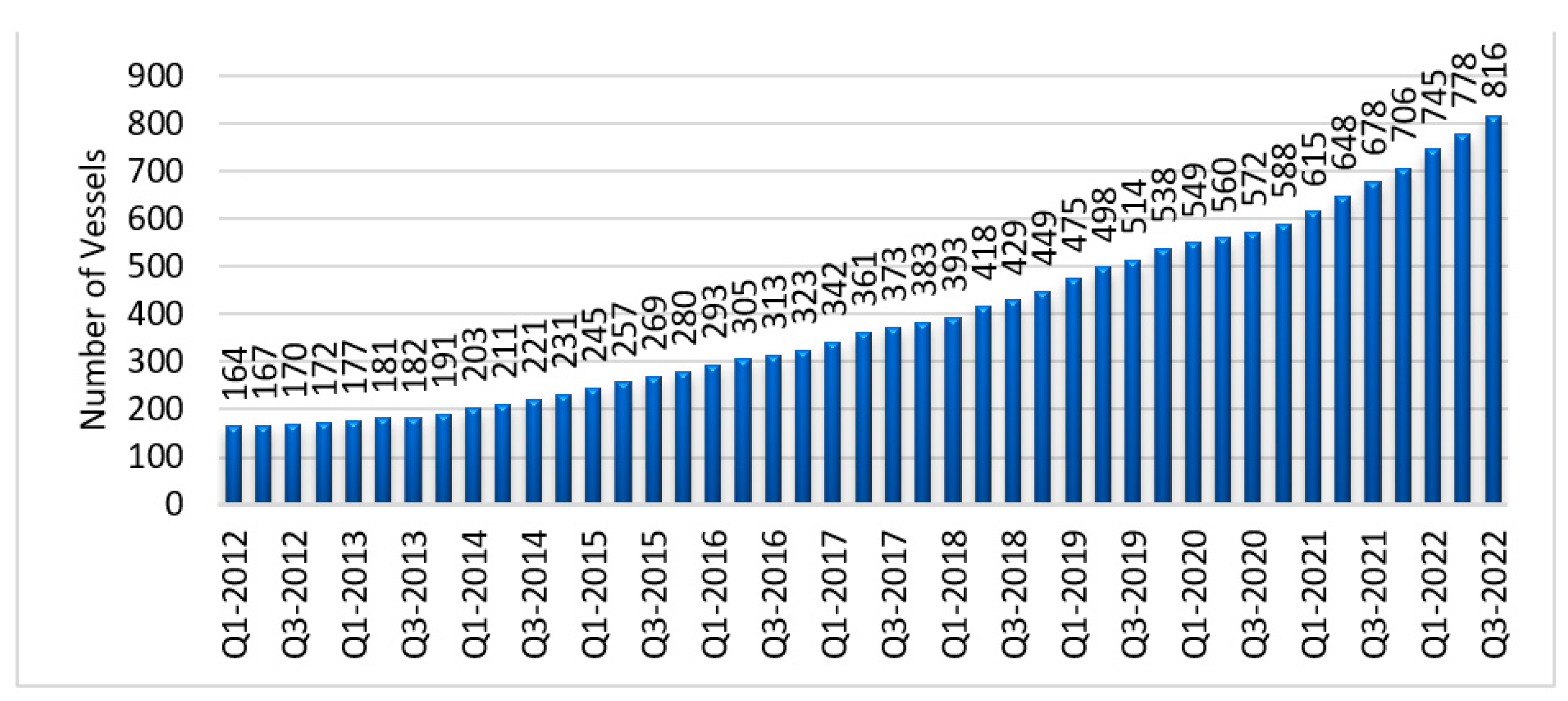

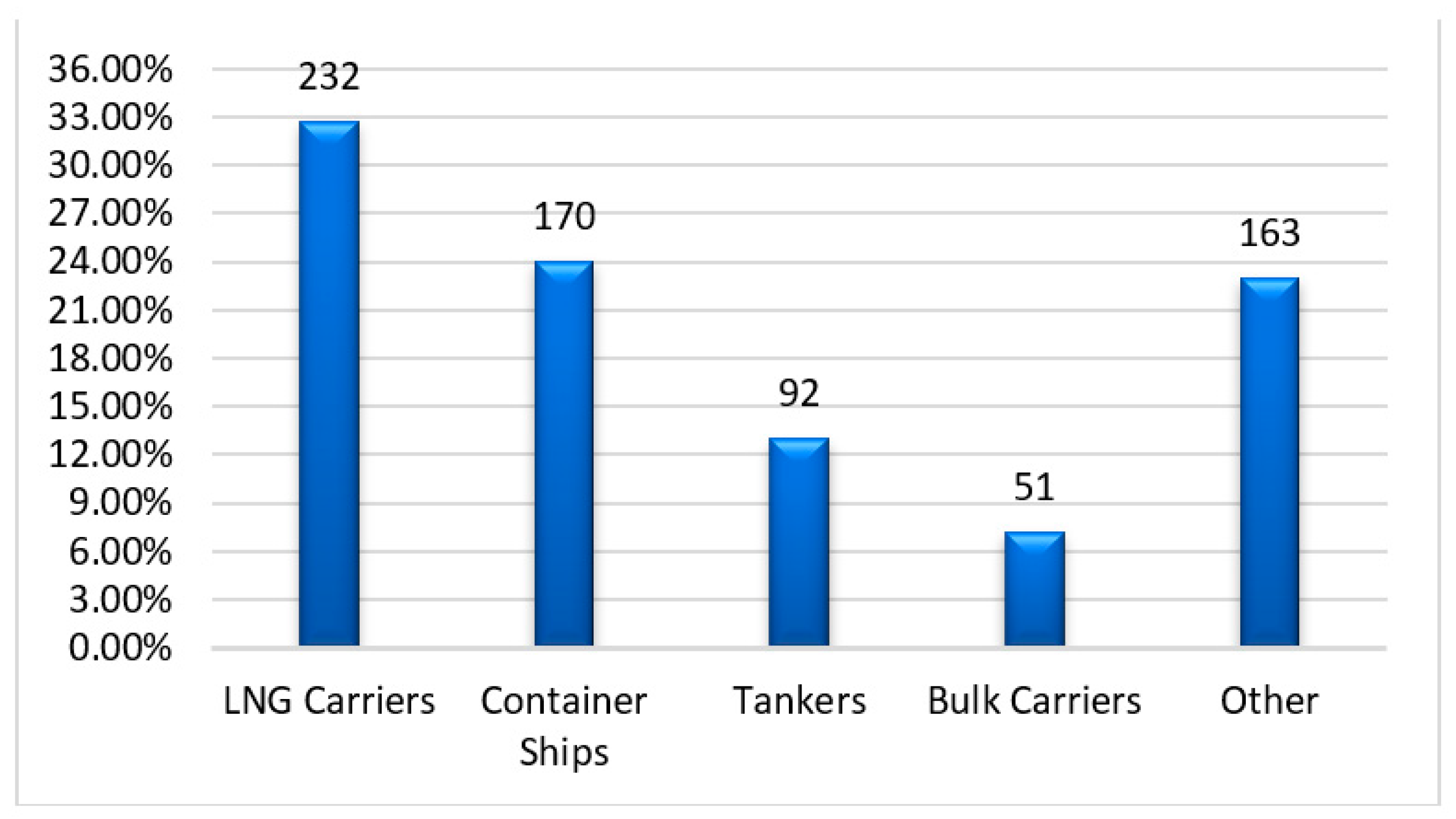

:1. Introduction

2. High-Level Instruments

2.1. Marpol

- Annex I—Prevention of pollution by oil;

- Annex II—Prevention of pollution by noxious liquid substances in bulk;

- Annex III—Prevention of pollution by harmful substances carried by sea in packaged form;

- Annex IV—Prevention of pollution by sewage from ships;

- Annex V—Prevention of pollution by garbage from ships;

- Annex VI—Prevention of air pollution from ships.

2.2. IGF Code

- Part A—General;

- Part A-1—Specific requirements for ships using natural gas as a fuel;

- Part B-1—Manufacture, workmanship, and testing;

- Part C-1—Drills and emergency exercises;

- Part D—Training.

3. Technical Standards

- Hardware: Liquid and vapor transfer systems;

- Operational procedures;

- Requirement for the LNG provider to provide and LNG bunker delivery note;

- Training and qualifications of personnel involved;

- Requirements for LNG facilities to meet applicable ISO standards and local codes.

4. Industry Guidance

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- S&P Global. Available online: https://www.spglobal.com/en/ (accessed on 4 November 2022).

- Fourth IMO GHG Study 2020 Full Report. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Fourth-IMO-Greenhouse-Gas-Study-2020.aspx (accessed on 5 December 2022).

- International Maritime Organization. MARPOL: Articles, Protocols, Annexes and Unified Interpretations of the International Convention for the Prevention of Pollution from Ships, 1973, as Modified by the 1978 and 1997 Protocols: Incorporating All Amendments in Force on 1 January 2017/IMO, 6th ed.; International Maritime Organization: London, UK, 2017. [Google Scholar]

- International Maritime Organization. Amendments to the Annex of The Protocol of 1997 to Amend the International Convention for the Prevention of Pollution from Ships, 1973, as modified by the Protocol of 1978 Relating Thereto (Revised MARPOL Annex VI). 2010. Available online: https://www.epa.gov/sites/default/files/2016-09/documents/resolution-mepc-202-62-7-15-2011.pdf (accessed on 21 December 2022).

- Amendments to the Annex of the Protocol of 1997 to Amend the International Convention for the Prevention of Pollution from ships, 1973, as Modified by the Protocol of 1978 Relating Thereto (Inclusion of Regulations on Energy Efficiency for Ships in MARPOL Annex VI). 2011. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.203(62).pdf (accessed on 3 June 2022).

- Annex 8 Resolution MEPC.346(78) (Adopted on 10 June 2022) 2022 Guidelines for the Development of a Ship Energy Efficiency Management Plan (SEEMP). Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.346(78).pdf (accessed on 12 September 2022).

- CII Operations Clause for Time Charter Parties. 2022. Available online: https://www.bimco.org/contracts-and-clauses/bimco-clauses/current/cii-operations-clause-2022 (accessed on 12 January 2023).

- MEPC.352(78)-2022 Guidelines on Operational Carbon Intensity Indicators and the Calculation Methods (CII Guidelines, G1). Available online: https://www.ccs.org.cn/ccswzen//articleDetail?id=202212210561846752 (accessed on 9 July 2022).

- Annex 1 Resolution MEPC.328(76) Amendments to the Annex of the Protocol of 1997 to Amend the International Convention for the Prevention of Pollution From Ships, 1973, as Modified by the Protocol of 1978 Relating Thereto 2021 Revised MARPOL Annex VI. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.328(76).pdf (accessed on 29 January 2023).

- International Maritime Organization. Adoption of the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC CODE). Available online: https://www.imo.org/en/ourwork/safety/pages/igc-code.aspx (accessed on 17 February 2023).

- SOLAS Consolidated Edition. 2018. Available online: https://www.samgongustofa.is/media/english/SOLAS-Consolidated-Edition-2018.docx.pdf (accessed on 14 October 2022).

- Clarkson Research Services Limited 2022. Shipping Intelligence Network Timeseries. September 2022. Available online: https://sin.clarksons.net/ (accessed on 12 July 2022).

- International Maritime Organization Resolution MSC.285(86) (Adopted on 1 June 2009) Interim Guidelines on Safety for Natural Gas-fuelled Engine Installations in ships. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MSCResolutions/MSC.285(86).pdf (accessed on 12 January 2023).

- International Maritime Organization. MSC 392 95. 2016. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MSCResolutions/MSC.392(95).pdf (accessed on 14 July 2022).

- International Maritime Organization. IGF Code: International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels; IMO: London, UK, 2016. [Google Scholar]

- International Maritime Organization. MSC 396 95. 2016. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/HumanElement/Documents/MSC.396(95).pdf (accessed on 15 February 2023).

- International Maritime Organization. MSC 397 95. Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MSCResolutions/MSC.397(95)NotyetavailableonIMODOCS.pdf (accessed on 11 September 2022).

- Guidance on LNG Bunkering to Port Authorities and Administrations EMSA Guidance on LNG Bunkering to Port Authorities/Administrations 2 Cover Image Courtesy: AGA EMSA Guidance on LNG Bunkering to Port Authorities/Administrations. 2017. Available online: https://www.emsa.europa.eu/publications/inventories/item/3207-guidance-on-lng-bunkering-to-port-authorities-and-administrations.html (accessed on 18 June 2022).

- ISO—About, Us. Available online: https://www.iso.org/about-us.html (accessed on 31 October 2022).

- ISO_TC 8; Ships and Marine Technology. ISO: Geneva, Switzerland, 1947.

- ISO_TC 67; Oil and Gas Industries Including Lower Carbon Energy. ISO: Geneva, Switzerland, 1947.

- ISO/TS 18683; Standards Publication Guidelines for Systems and Installations for Supply of LNG as Fuel to Ships. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO—ISO/TS 18683:2021; Guidelines for Safety and Risk Assessment of LNG Fuel Bunkering Operations. Available online: https://www.iso.org/standard/76811.html (accessed on 31 October 2022).

- ISO 20519:2017; Ships and Marine Technology—Specification for Bunkering of Liquefied Natural Gas Fuelled Vessels. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 20519:2021; Ships and Marine Technology—Specification for Bunkering of Liquefied Natural Gas Fuelled Vessels. ISO: Geneva, Switzerland. Available online: https://www.iso.org/standard/80842.html (accessed on 31 October 2022).

- ISO 21593:2019; Ships and Marine Technology—Technical Requirements for Dry-Disconnect/Connect Couplings for Bunkering Liquefied Natural Gas. International Organization for Standardization: Geneva, Switzerland, 2019.

- DNV GL. Recommended Practice DNV GL as Development and Operation of Liquefied Natural Gas Bunkering Facilities. 2015. Available online: https://www.dnv.com/ (accessed on 11 January 2023).

- Safety Guide Bunkering V2 DRAFT. Available online: https://www.marineinsight.com/guidelines/the-ultimate-guide-to-fuel-oil-bunkering-process-on-ships/ (accessed on 7 December 2022).

- Marine. Guidelines on LNG Bunkering Guidance Note NI 618 DT R00 E. 2014. Available online: http://www.veristar.com (accessed on 13 December 2022).

- IAPH: LNG Bunker Checklist Ship to Ship. Available online: https://sustainableworldports.org/wp-content/uploads/iaph_lng_bunker_checklist_ship_to_ship_final_v3.7a_incl_guidelines.pdf (accessed on 20 January 2023).

- ACS: LNG Bunkering Guidelines; No. 142. Available online: https://iacs.org.uk/download/1962 (accessed on 2 February 2023).

- MPenfold. ABS|LNG Bunkering Technical and Operational Advisory|01 LNG Bunkering Technical and Operational Advisory. Available online: https://ww2.eagle.org/content/dam/eagle/advisories-and-debriefs/ABS_LNG_Bunkering_Advisory.pdf (accessed on 28 October 2022).

- CCNR. Standard for a Liquefied Natural Gas (LNG) Bunker Checklist Bunker station to Ship Edition 1.0 Adopted by the Police Regulations Committee on 27 October 2021. Available online: https://www.ccr-zkr.org/ (accessed on 13 February 2023).

| General Sulfur Requirements | Sulfur Requirements within SECAs * |

|---|---|

| 4.50% m/m prior to 1 January 2012 | 1.50% m/m prior to 1 July 2010 |

| 3.50% m/m on and after 1 January 2012 | 1.00% m/m on and after 1 July 2010 |

| 0.50% m/m on and after 1 January 2020 | 0.10% m/m on and after 1 January 2015 |

| Title | Publisher |

|---|---|

| Development and Operation of Liquefied Natural Gas Bunkering Facilities | Det Norske Veritas and Germanischer Lloyd (DNV-GL) |

| Gas as a Marine Fuel: Safety Guidelines | The Society for Gas as a Marine Fuel (SGMF) |

| Guidance on LNG Bunkering to Port Authorities and Administrations | European Maritime Safety Agency (EMSA) |

| Guidelines on LNG Bunkering | Bureau Veritas (BV) |

| LNG Bunker Checklist Ship to Ship | International Association of Ports and Harbors (IAPH) |

| LNG Bunkering Guidelines | International Association of Classification Societies (IACS) |

| LNG Bunkering Technical and Operational Advisory | American Bureau of Shipping (ABS) |

| Standard for a Liquefied Natural Gas (LNG) Bunker Checklist Bunker Station to Ship | Central Commission for the Navigation of the Rhine (CCNR) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vuskovic, B.; Rudan, I.; Sumner, M. Fostering Sustainable LNG Bunkering Operations: Development of Regulatory Framework. Sustainability 2023, 15, 7358. https://doi.org/10.3390/su15097358

Vuskovic B, Rudan I, Sumner M. Fostering Sustainable LNG Bunkering Operations: Development of Regulatory Framework. Sustainability. 2023; 15(9):7358. https://doi.org/10.3390/su15097358

Chicago/Turabian StyleVuskovic, Bernard, Igor Rudan, and Matthew Sumner. 2023. "Fostering Sustainable LNG Bunkering Operations: Development of Regulatory Framework" Sustainability 15, no. 9: 7358. https://doi.org/10.3390/su15097358

APA StyleVuskovic, B., Rudan, I., & Sumner, M. (2023). Fostering Sustainable LNG Bunkering Operations: Development of Regulatory Framework. Sustainability, 15(9), 7358. https://doi.org/10.3390/su15097358