Safety Evaluation of Plain Concrete Lining Considering Deterioration and Aerodynamic Effects

Abstract

1. Introduction

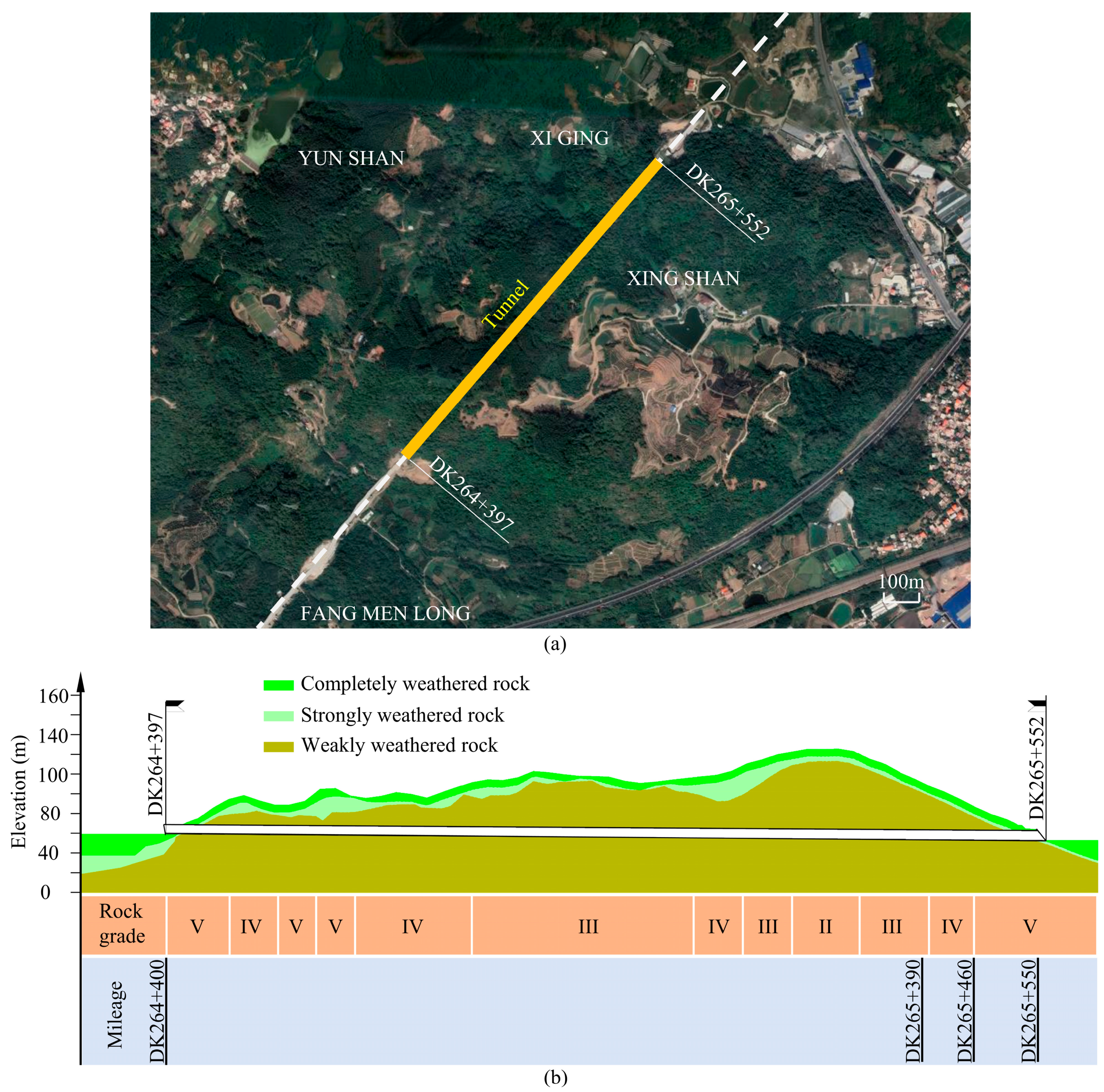

2. Tunnel Overview

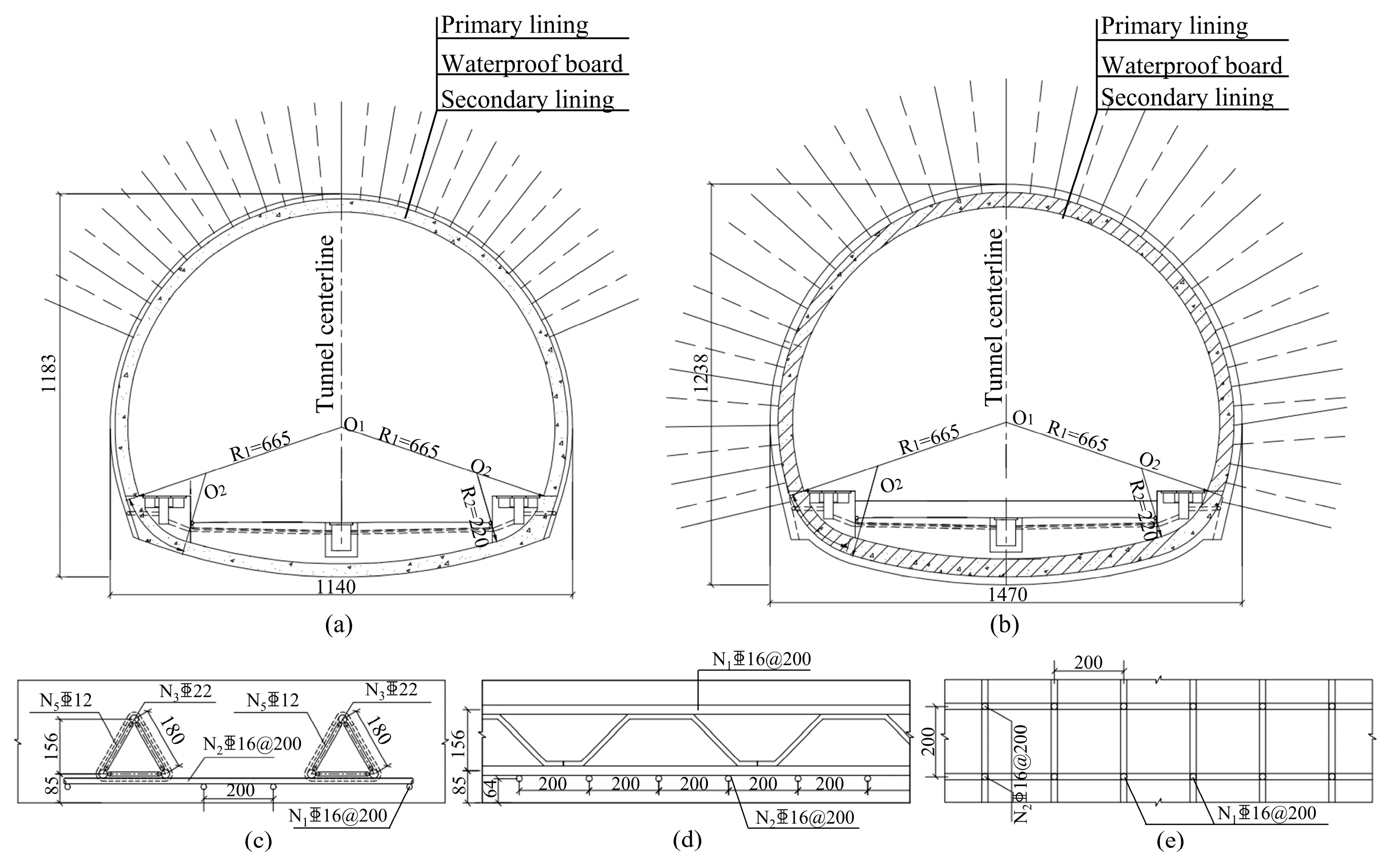

2.1. Geology Conditions and Lining Structure

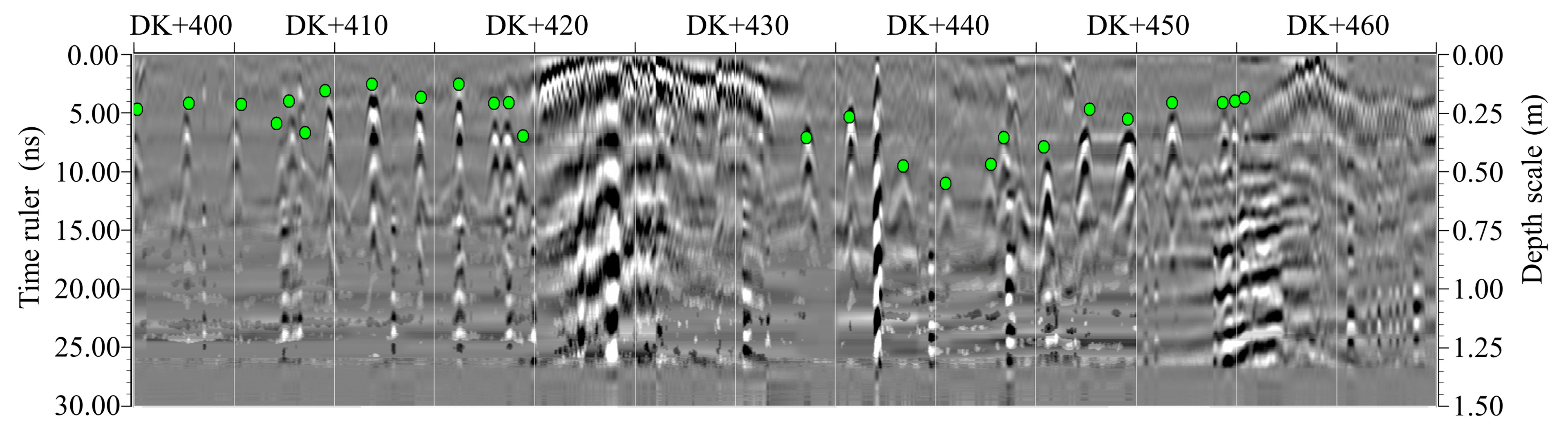

2.2. Overview of Defective Section

2.2.1. Defect Description

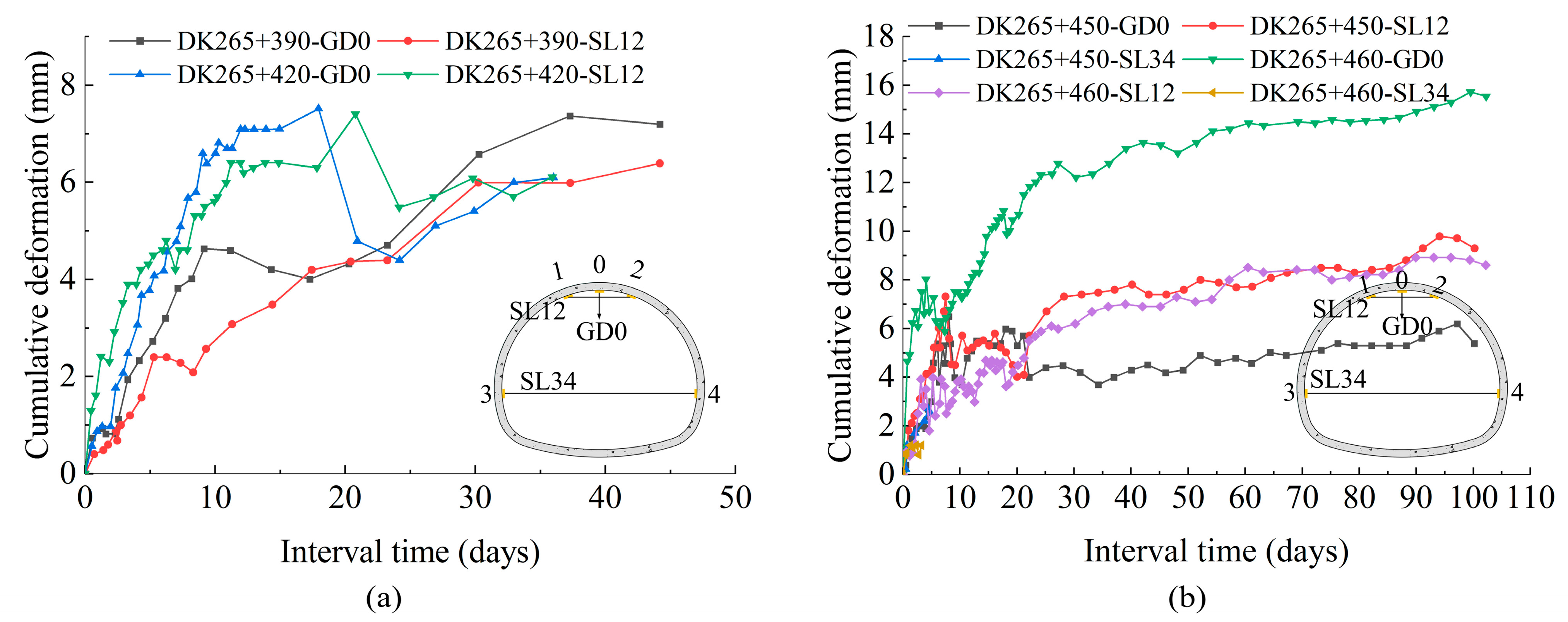

2.2.2. Deformation Characteristics of Defective Section during Construction

2.2.3. Strength Test of Secondary Lining at Defective Section

3. Safety Evaluation Method

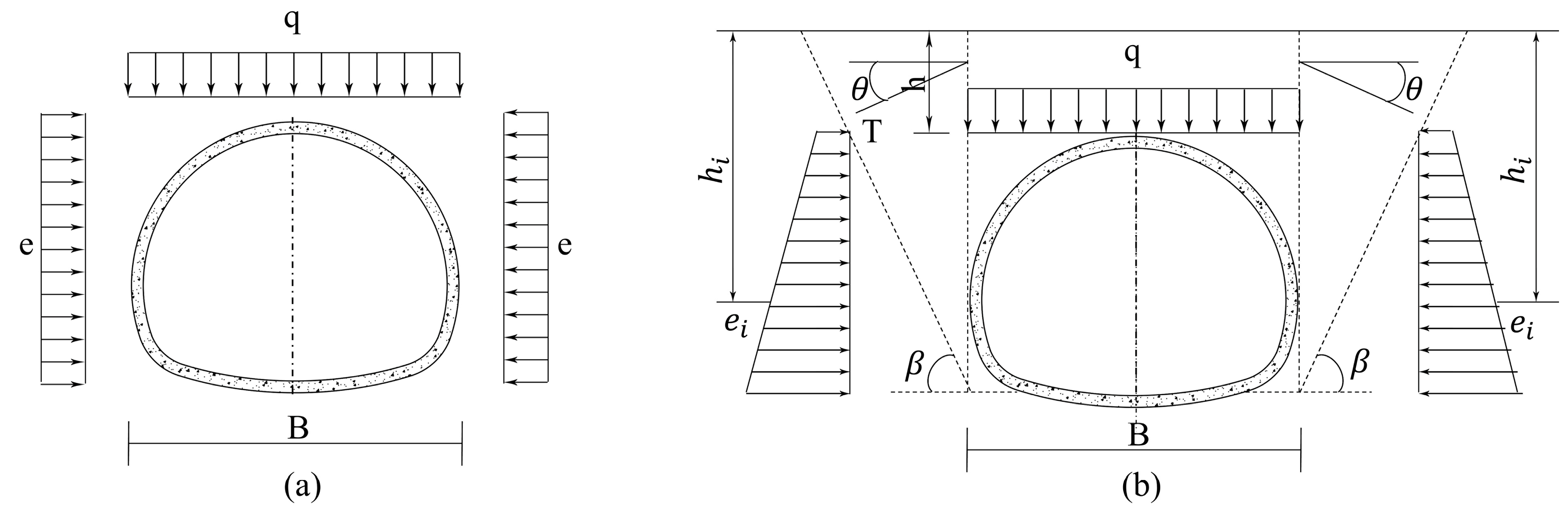

3.1. Load-Structure Method

3.1.1. Deep and Shallow Burial Classification

3.1.2. Calculation of Surrounding Rock Pressure under Deep Burial Conditions

3.1.3. Calculation of Surrounding Rock Pressure under Shallow Burial Conditions

3.1.4. Safety Factor Calculation and Safety Criteria

3.2. Short-Term Safety Evaluation

3.3. Long-Term Safety Evaluation

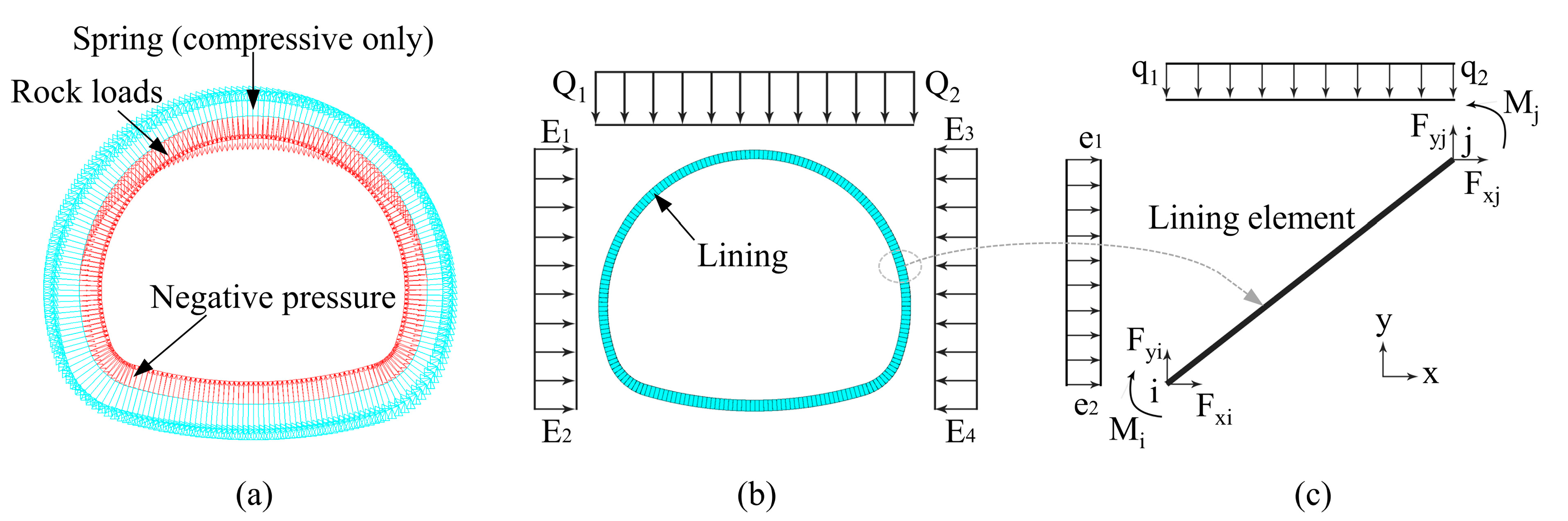

4. Numerical Simulation

4.1. Calculation Condition

4.2. Calculation Parameters

4.3. Model Establishment

5. Numerical Results and Discussion

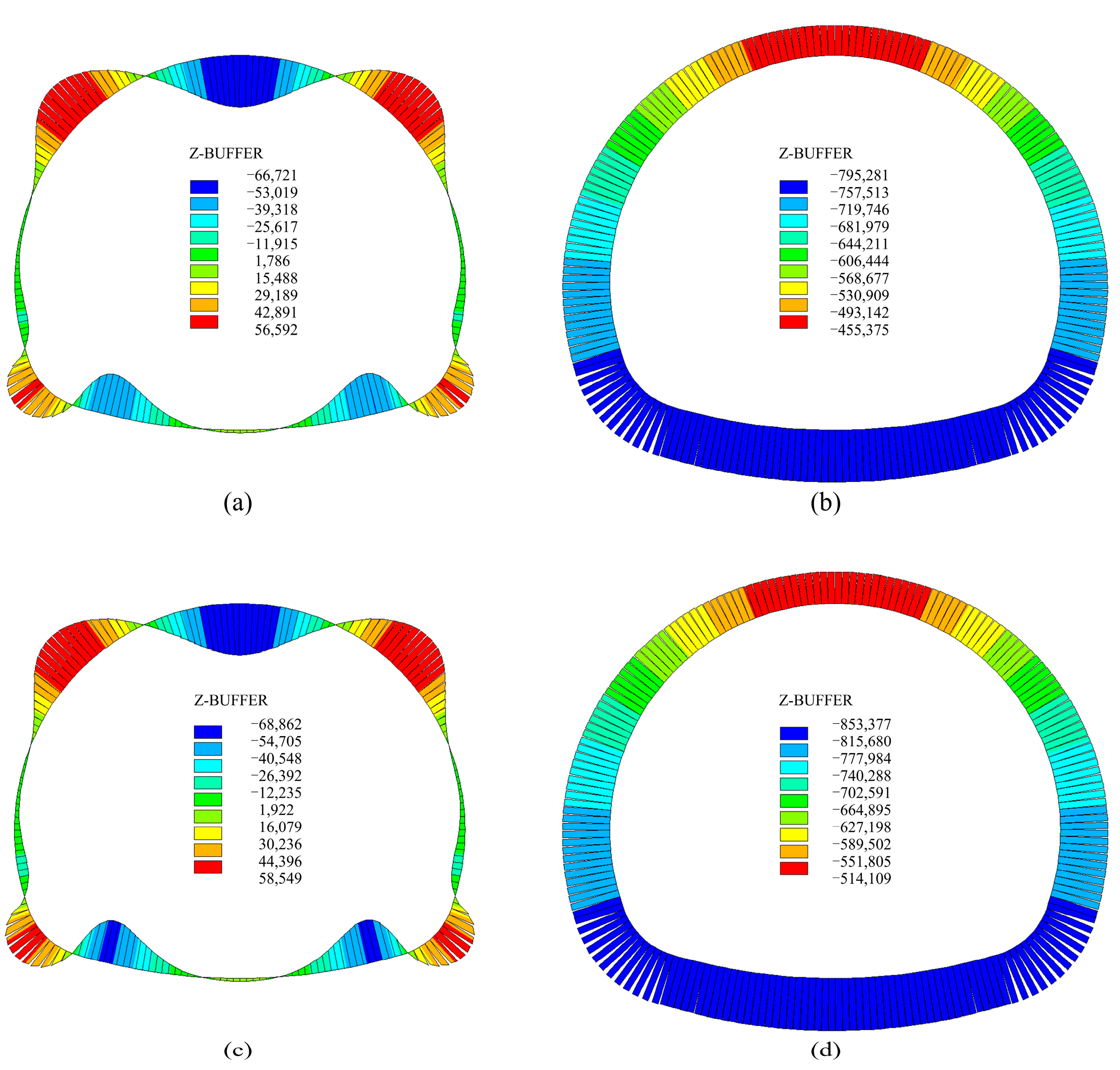

5.1. Short-Term Safety Evaluation of Defective Section

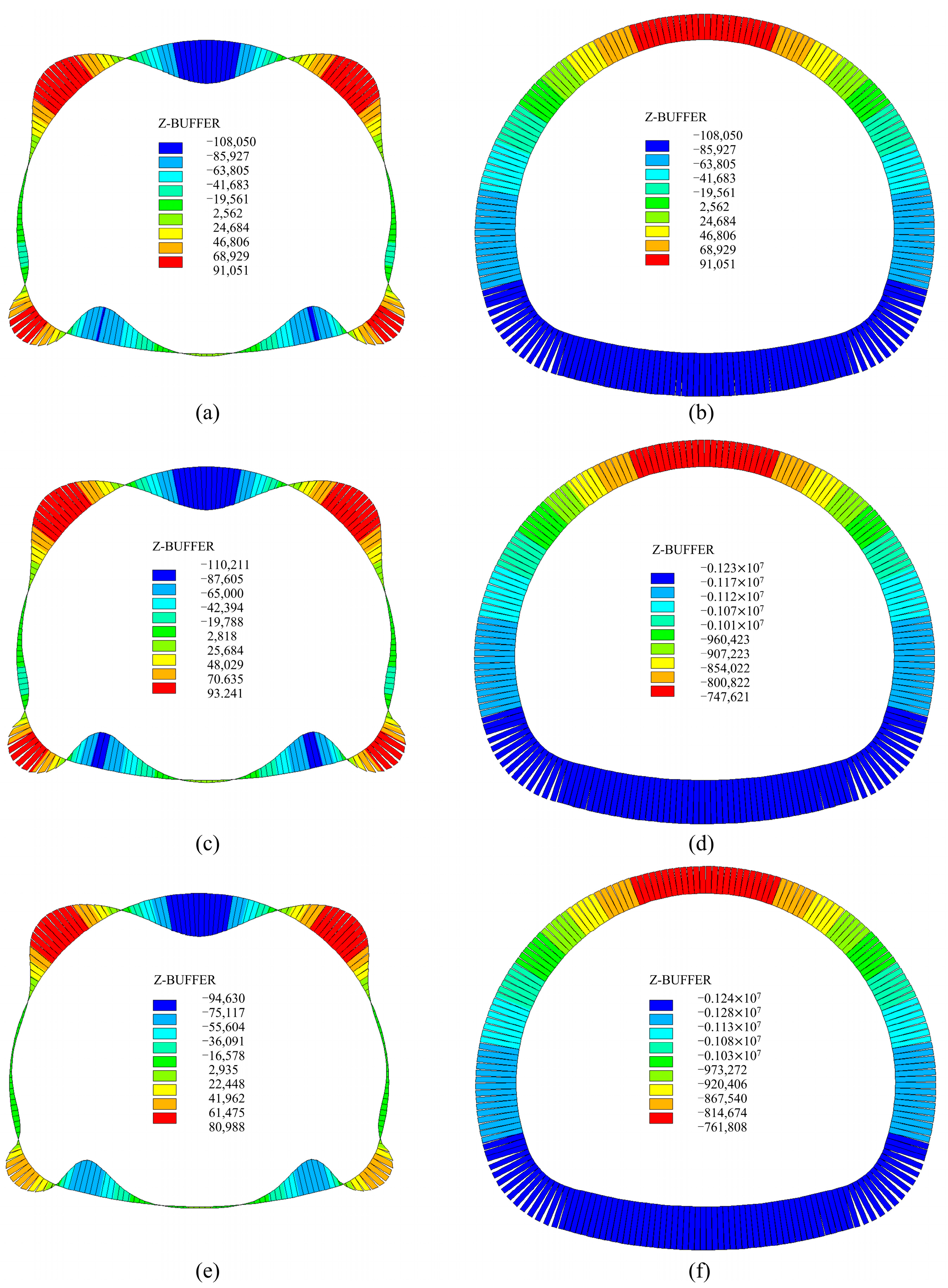

5.2. Long-Term Safety Evaluation of Defective Section

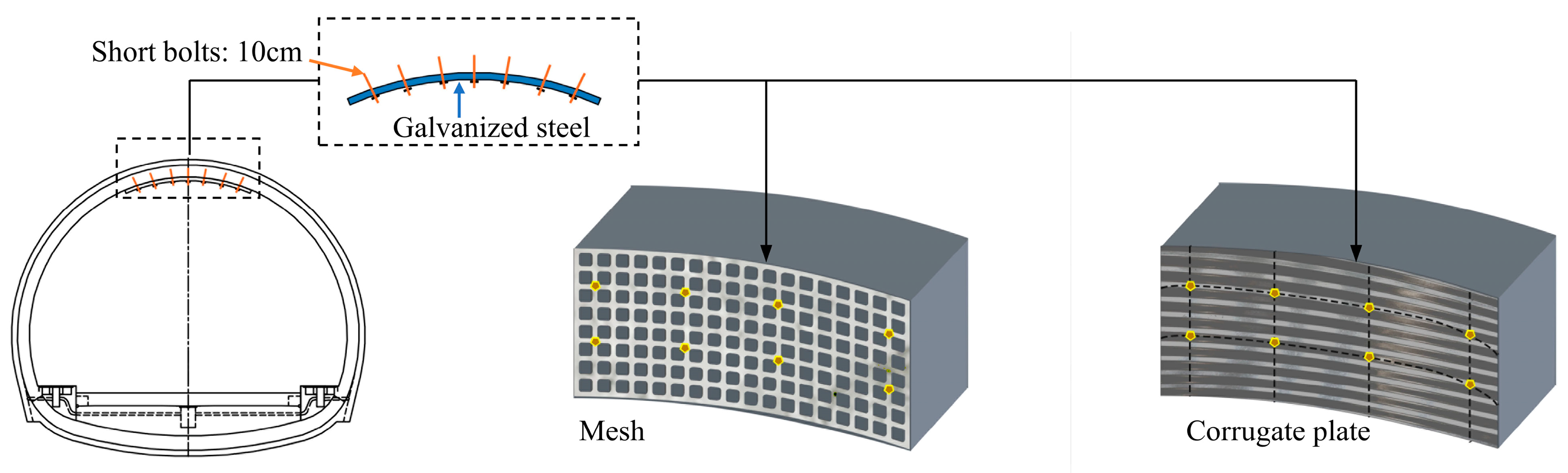

6. Treatment Measures

7. Conclusions

- (1)

- The safety of the lining structure can meet the requirements of the code when the defective section of the secondary lining is not affected by other adverse factors. The influence of aerodynamic effects can be ignored in the short-term safety analysis.

- (2)

- When there is deterioration of the surrounding rock and concrete, the safety factor at the vault position of the defective section does not meet the requirements. When considering the combined action of the surrounding rock and concrete deterioration, negative pressure and the concrete fatigue effect, the safety factor of the lining will be further reduced. When evaluating the long-term safety of a plain concrete-lined defect section in a high-speed railway tunnel, the influence of these long-term factors should be considered.

- (3)

- Under the negative pressure caused by the aerodynamic effects, the tensile trend of the lining structure decreases and the compressive stress increases. The influence of the aerodynamic effects on the long-term safety of the tunnel is mainly due to the fatigue damage it causes to the lining of the concrete.

- (4)

- This paper presents a safety evaluation method for anti-crack reinforcement mesh defects in the plain concrete lining of high-speed railway tunnels based on a load-structure method and suggests treatment measures. The research results can provide a reference for future short-term and long-term safety evaluations and treatment of tunnels with quality defects in their plain concrete lining.

- (5)

- This paper only used a numerical simulation to conduct a safety evaluation on the lining of the defective section. In the future, the numerical results should be compared and verified through model tests and on-site monitoring. In addition, further research should be conducted on safety evaluation methods using the ground-structure method to better consider the interaction between the surrounding rock and support.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Gong, R.; Zhang, H.; He, W. The Sustainability Performance of Reinforced Concrete Structures in Tunnel Lining Induced by Long-Term Coastal Environment. Sustainability 2020, 12, 3946. [Google Scholar] [CrossRef]

- Wang, F.; Shao, J.; Li, W.; Wang, L.; Wang, Y.; Liu, H. Numerical Simulation Study on Lining Damage of Shield Tunnel under Train Load. Sustainability 2022, 14, 14018. [Google Scholar] [CrossRef]

- Li, H.; Fu, J.; Chen, B.; Zhang, X.; Zhang, Z.; Lang, L. Mechanical Properties of GFRP Bolts and Its Application in Tunnel Face Reinforcement. Materials 2023, 16, 2193. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Zhang, D.; Zhang, S. Characteristics and Treatment Measures of Lining Damage: A Case Study on a Mountain Tunnel. Eng. Fail. Anal. 2021, 128, 105595. [Google Scholar] [CrossRef]

- Lu, F.; Wang, H.; Wang, L.; Zhao, K.; Zhang, J. Degradation Law and Service Life Prediction Model of Tunnel Lining Concrete Suffered Combined Effects of Sulfate Attack and Drying–Wetting Cycles. Materials 2022, 15, 4435. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Li, H.; Zhu, K.; Chen, Y.; Lei, Z. Study on Expansion Characteristics and Expansion Potential of Gypsum Rock. Geofluids 2022, 2022, 6921150. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, K.; Zhu, X.; Tian, Z.; Zhang, Q. Study on the Freeze-Thaw Process of the Lining Structures of a Tunnel on Qinghai-Tibet Plateau with the Consideration of Lining Frost Damage. Adv. Mater. Sci. Eng. 2021, 2021, 4921365. [Google Scholar] [CrossRef]

- Zhou, B.-Q.; Yang, Z.; Hu, R.; Zhao, X.-J.; Chen, Y.-F. Assessing the Impact of Tunnelling on Karst Groundwater Balance by Using Lumped Parameter Models. J. Hydrol. 2021, 599, 126375. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, X.; Taniguchi, T. Quantitative Condition Inspection and Assessment of Tunnel Lining. Autom. Constr. 2019, 102, 258–269. [Google Scholar] [CrossRef]

- Usman, M.; Galler, R. Long-Term Deterioration of Lining in Tunnels. Int. J. Rock Mech. Min. Sci. 2013, 64, 84–89. [Google Scholar] [CrossRef]

- Deng, H.; Fu, H.; Chen, W.; Zhao, Y.; Yi, H. Study on Deterioration, Cracking Mechanism and Treatment Measures of Plain Concrete Lining with Cold Joints in High-Speed Railroad Tunnel. Case Stud. Constr. Mater. 2023, 18, e01895. [Google Scholar] [CrossRef]

- Ye, F.; Qin, N.; Liang, X.; Ouyang, A.; Qin, Z.; Su, E. Analyses of the Defects in Highway Tunnels in China. Tunn. Undergr. Space Technol. 2021, 107, 103658. [Google Scholar] [CrossRef]

- Asakura, T.; Kojima, Y. Tunnel Maintenance in Japan. Tunn. Undergr. Space Technol. 2003, 18, 161–169. [Google Scholar] [CrossRef]

- Zhai, W. Vehicle–Track Coupled Dynamics; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Liu, Z. Study on Aerodynamic Instability and Galloping Response of Rail Overhead Contact Line Based on Wind Tunnel Tests. IEEE Trans. Veh. Technol. 2023. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Z.; Liu, Z.; Wang, R. A Spatial Coupling Model to Study Dynamic Performance of Pantograph-Catenary with Vehicle-Track Excitation. Mech. Syst. Signal Process. 2021, 151, 107336. [Google Scholar] [CrossRef]

- Sandrone, F.; Labiouse, V. Analysis of the Evolution of Road Tunnels Equilibrium Conditions with a Convergence–Confinement Approach. Rock Mech. Rock Eng. 2010, 43, 201–218. [Google Scholar] [CrossRef]

- Xu, P.; Wu, Y.; Huang, L.; Zhang, K. Study on the Progressive Deterioration of Tunnel Lining Structures in Cold Regions Experiencing Freeze–Thaw Cycles. Appl. Sci. 2021, 11, 5903. [Google Scholar] [CrossRef]

- Kong, C.; Wang, H.; Zhao, K.; Gao, X. Numerical Simulation of Long-Term Deterioration of Rock Mass Supported by Shotcrete Lining. Front. Earth Sci. 2022, 10, 891084. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, C.; Zhang, Y.; Yang, J.; Feng, T. Damaging Behavior Investigation of an Operational Tunnel Structure Induced by Cavities around Surrounding Rocks. Eng. Fail. Anal. 2019, 99, 203–209. [Google Scholar] [CrossRef]

- Ye, F.; Han, X.; Qin, N.; Ouyang, A.; Liang, X.; Xu, C. Damage Management and Safety Evaluation for Operating Highway Tunnels: A Case Study of Liupanshan Tunnel. Struct. Infrastruct. Eng. 2020, 16, 1512–1523. [Google Scholar] [CrossRef]

- Lu, P.; Qiao, D.; Wu, C.; Wang, S.; He, X.; Zhang, W.; Zhou, H. Effect of Defects and Remediation Measures on the Internal Forces Caused by a Local Thickness Reduction in the Tunnel Lining. Undergr. Space 2022, 7, 94–105. [Google Scholar] [CrossRef]

- Fu, J.; Xie, J.; Wang, S.; Yang, J.; Yang, F.; Pu, H. Cracking Performance of an Operational Tunnel Lining Due to Local Construction Defects. Int. J. Geomech. 2019, 19, 04019019. [Google Scholar] [CrossRef]

- Han, W.; Jiang, Y.; Li, N.; Koga, D.; Sakaguchi, O.; Chen, H. Safety Evaluation and Failure Behavior of Degraded Tunnel Structure with Compound Diseases of Voids and Lining Defects. Arab. J. Geosci. 2021, 14, 1531. [Google Scholar] [CrossRef]

- Yuan, Y.; Jiang, X.; Ai, Q. Probabilistic Assessment for Concrete Spalling in Tunnel Structures. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2017, 3, 04017011. [Google Scholar] [CrossRef]

- Lai, J.; Qiu, J.; Fan, H.; Chen, J.; Hu, Z.; Zhang, Q.; Wang, J. Structural Safety Assessment of Existing Multiarch Tunnel: A Case Study. Adv. Mater. Sci. Eng. 2017, 2017, 1697041. [Google Scholar] [CrossRef]

- Gao, C.; Zhou, Z.; Yang, W.; Lin, C.; Li, L.; Wang, J. Model Test and Numerical Simulation Research of Water Leakage in Operating Tunnels Passing through Intersecting Faults. Tunn. Undergr. Space Technol. 2019, 94, 103134. [Google Scholar] [CrossRef]

- Shi, C.-H.; Wang, A.; Sun, X.-H.; Yang, W.-C. Aerodynamic Behavior and Impact on Driving Safety of Spalling Blocks Comprising High-Speed-Railway Tunnel Lining. Appl. Sci. 2022, 12, 2593. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, W. Dynamic Response and Fatigue-Life Analysis of High-Speed Railway Tunnel Base with Defects. Math. Probl. Eng. 2022, 2022, 6622998. [Google Scholar] [CrossRef]

- Du, J.; Fang, Q.; Wang, G.; Zhang, D.; Chen, T. Fatigue Damage and Residual Life of Secondary Lining of High-Speed Railway Tunnel under Aerodynamic Pressure Wave. Tunn. Undergr. Space Technol. 2021, 111, 103851. [Google Scholar] [CrossRef]

- Li, W.; Liu, T.; Martinez-Vazquez, P.; Chen, Z.; Guo, Z.; Li, M.; Xia, Y.; Liu, H. Aerodynamic Effects of a High-Speed Train Travelling through Adjoining & Separated Tunnels. Tunn. Undergr. Space Technol. 2021, 113, 103973. [Google Scholar] [CrossRef]

- TB10003-2016; Code for Design of Railway Tunnel. China Railway Publishing House: Beijing, China, 2016.

- Zhang, H.J.; Wang, Z.Z.; Lu, F.; Xu, G.Y.; Qiu, W.G. Analysis of the Displacement Increment Induced by Removing Temporary Linings and Corresponding Countermeasures. Tunn. Undergr. Space Technol. 2018, 73, 236–243. [Google Scholar] [CrossRef]

- Papanikolaou, V.K.; Kappos, A.J. Practical Nonlinear Analysis of Unreinforced Concrete Tunnel Linings. Tunn. Undergr. Space Technol. 2014, 40, 127–140. [Google Scholar] [CrossRef]

- Vu, M.N.; Broere, W. Structural Design Model for Tunnels in Soft Soils: From Construction Stages to the Long-Term. Tunn. Undergr. Space Technol. 2018, 78, 16–26. [Google Scholar] [CrossRef]

- Ngan, V.M.; Broere, W.; Bosch, J.W. Structural Analysis for Shallow Tunnels in Soft Soils. Int. J. Geomech. 2017, 17, 04017038. [Google Scholar] [CrossRef]

- JTG 3370.1-2018; Design Specification of Highway Tunnel. China Communications Press: Beijing, China, 2018.

- Wang, M.; Wang, Z.; Tong, J.; Zhang, X.; Dong, Y.; Liu, D. Support Pressure Assessment for Deep Buried Railway Tunnels Using BQ-Index. J. Cent. South Univ. 2021, 28, 247–263. [Google Scholar] [CrossRef]

- Second Design Institute of Ministry of Railways. Railway Engineering Design Technical Manual—Tunnel; China Railway Publishing House: Beijing, China, 1999. [Google Scholar]

- GB 50010-2010; Code for Design of Concrete Structures. China Building Industry Press: Beijing, China, 2015.

- Showkati, A.; Salari-rad, H.; Hazrati Aghchai, M. Predicting Long-Term Stability of Tunnels Considering Rock Mass Weathering and Deterioration of Primary Support. Tunn. Undergr. Space Technol. 2021, 107, 103670. [Google Scholar] [CrossRef]

- Li, Z.; Zeng, Y. Principles and Methods of Underground Structure Design; Southwest Jiaotong University Press: Chengdu, China, 2003. [Google Scholar]

- Lu, F.; Li, P.; Zheng, Y.; Chou, W. Experimental Investigation on the Mechanical Performance of Retrofitted Cracked Linings with Mesh-bolts and Plate-bolts. China J. Highw. Transp. 2022, 35, 128–139. [Google Scholar] [CrossRef]

| Surrounding Rock Grade | I–II | III | IV | V | VI |

|---|---|---|---|---|---|

| Horizontal Uniform Pressure | 0 | <0.15 q | (0.15~0.3) q | (0.3~0.5) q | (0.5~1.0) q |

| Condition Name | Description |

|---|---|

| 1 | Control group |

| 2 | Singular aerodynamic effect |

| 3 | Combination of surrounding rock and concrete deterioration |

| 4 | Combination of deterioration of surrounding rock and concrete, aerodynamic effects |

| 5 | Combination of surrounding rock and concrete deterioration, aerodynamic effects, concrete fatigue effect |

| Materials | Gravity (kN/m3) | Elastic Reaction Coefficient (MPa/m) | Elastic Modulus (GPa) | Poisson’s Ratio ν | Compressive Strength (MPa) |

|---|---|---|---|---|---|

| Surrounding rock | 21.5 | 500 | 3.65 | 0.325 | - |

| Surrounding rock (after deterioration) | 21.5 | 300 | 2.19 | 0.325 | - |

| Secondary lining | 23.0 | - | 32.5 | 0.2 | 47.3 |

| Secondary lining (after deterioration) | 23.0 | - | 27.1 | 0.2 | 38.3 |

| Secondary lining (deterioration + fatigue) | 23.0 | - | 12.04 | 0.2 | 23.0 |

| Condition Name | Vertical Load q (kPa) | Horizontal Load e (kPa) |

|---|---|---|

| 1, 2 | 75.852 | 18.963 |

| 3, 4, 5 | 120.435 | 30.109 |

| Condition Name | Location | Bending Moment (kN·m) | Axial Force (kN) | e0/h | Control Status | Safety Factor |

|---|---|---|---|---|---|---|

| 1 | Vault | −66.721 | −473.10 | 0.353 | Tensile control | 6.274 |

| Hance | 56.592 | −537.90 | 0.263 | Tensile control | 10.647 | |

| Arch foot | 43.874 | −769.93 | 0.142 | Compression control | 21.671 | |

| Inverted arch | −52.860 | −785.30 | 0.135 | Compression control | 27.018 | |

| 2 | Vault | −68.862 | −524.63 | 0.328 | Tensile control | 6.514 |

| Hance | 58.532 | −604.20 | 0.242 | Tensile control | 12.094 | |

| Arch foot | 47.654 | −835.41 | 0.143 | Compression control | 19.966 | |

| Inverted arch | −56.536 | −843.20 | 0.134 | Compression control | 25.190 |

| Condition Name | Location | Bending Moment (kN·m) | Axial Force (kN) | e0/h | Control Status | Safety Factor |

|---|---|---|---|---|---|---|

| 3 | Vault | −108.05 | −715.94 | 0.377 | Tensile control | 2.964 |

| Hance | 90.951 | −825.13 | 0.276 | Tensile control | 4.974 | |

| Arch foot | 77.791 | −1139.30 | 0.171 | Compression control | 11.046 | |

| Inverted arch | −86.313 | −1157.20 | 0.149 | Compression control | 14.373 | |

| 4 | Vault | −110.21 | −763.68 | 0.361 | Tensile control | 3.015 |

| Hance | 93.141 | −884.26 | 0.263 | Tensile control | 5.229 | |

| Arch foot | 82.358 | −1199.0 | 0.172 | Compression control | 10.466 | |

| Inverted arch | −90.373 | −1211.6 | 0.149 | Compression control | 13.727 | |

| 5 | Vault | −94.630 | −788.50 | 0.300 | Tensile control | 2.550 |

| Hance | 80.988 | −895.92 | 0.226 | Tensile control | 5.046 | |

| Arch foot | 51.641 | −1207.3 | 0.107 | Compression control | 7.193 | |

| Inverted arch | −71.255 | −1220.9 | 0.117 | Compression control | 8.745 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, F.; Wang, Y.; Fu, J.; Yang, Y.; Qiu, W.; Jing, Y.; Jiang, M.; Li, H. Safety Evaluation of Plain Concrete Lining Considering Deterioration and Aerodynamic Effects. Sustainability 2023, 15, 7170. https://doi.org/10.3390/su15097170

Lu F, Wang Y, Fu J, Yang Y, Qiu W, Jing Y, Jiang M, Li H. Safety Evaluation of Plain Concrete Lining Considering Deterioration and Aerodynamic Effects. Sustainability. 2023; 15(9):7170. https://doi.org/10.3390/su15097170

Chicago/Turabian StyleLu, Feng, Yi Wang, Junfu Fu, Yanxing Yang, Wenge Qiu, Yawen Jing, Manlin Jiang, and Huayun Li. 2023. "Safety Evaluation of Plain Concrete Lining Considering Deterioration and Aerodynamic Effects" Sustainability 15, no. 9: 7170. https://doi.org/10.3390/su15097170

APA StyleLu, F., Wang, Y., Fu, J., Yang, Y., Qiu, W., Jing, Y., Jiang, M., & Li, H. (2023). Safety Evaluation of Plain Concrete Lining Considering Deterioration and Aerodynamic Effects. Sustainability, 15(9), 7170. https://doi.org/10.3390/su15097170