Abstract

The application of a plethora of wireless technologies to support real-time food quality monitoring during transportation has significantly improved the performance of fresh food delivery systems. However, deployment of these technologies increases the capital and operational costs of food delivery and, hence, not all food delivery operations need to employ them. This paper looks at the trade-off of the costs involved in utilizing these technologies with the nature of food delivered, the length of transportation, and the perceived costs of food wasted using a linear programming model. The problem is formulated over a bi-echelon network with the possibility of transporting the fresh produce through dry vans, vans with temperature control but without monitoring capability, and vans with temperature control and monitoring capability. Results indicate that under situations of infinite vehicle resource availability, the optimal choice of the van type is independent of the demand levels; however, the optimal choice changes for different travel distances and the value of penalty costs (of allowing food to go waste). For example, technologies that maintain and monitor the temperature of storage conditions will be useful for food items that quickly become waste, especially when transported over longer distances and when the penalty costs are higher.

1. Introduction

Delivering fresh food products to the end user of the right quality while adhering to perishability constraints is of foremost importance in fresh food supply chain networks. Unlike other products, the quality of perishable fresh food degrades endlessly during the downstream activities in the supply chain, leading to food-borne diseases or food wastage. According to the Centers for Disease Control and Prevention (CDC), as many as 48 million people become sick due to food-borne illnesses every year in The United states (US) alone. However, tracing back the origin of these diseases due to food contamination is challenging [1]. According to the Food and Agriculture Organization, around one-third of fresh food is wasted throughout the supply chain post-production every year [2]. This is due to poor transportation and storage facilities, as well as inadequate temperature and humidity control systems [3,4]. Several international standards, such as Hazard Analysis of Critical Control Points (HACCP), Good Agricultural Practice (GAP), and Good Manufacturing Practices (GMP) are implemented for quality assurance and a reduction in food wastage [3,5,6]. The threshold levels of temperature to safeguard food from quality damage vary depending on the type of food. For example, for frozen foods, the temperature range is between −18 and −24 °C (see [7]), while for frozen milk the range is 0–4 °C in fridges, and at or below −20 °C for long-term storage in freezers [8].

Owing to the growing need for reducing food wastage and increasing quality preservation, several food quality monitoring and control technologies that enable tracking and traceability during transportation and post-harvest storage have recently evolved [9]. These technologies range from simple Internet of Things (IoT) enabled sensors, radio frequency identification (RFID) systems, to sophisticated imaging technologies, such as spectroscopy, muti-sensor topologies, thermal imaging systems, and physics-based digital twins [4,7,9,10,11,12]. Traditional food supply chain retailers and logistics providers still depend on the use of dry vans without any temperature-controlled systems installed, usually due to the high cost of installation and maintenance of the RFID and wireless sensor network (WSN). Therefore, most of the small- and medium-sized enterprises [13,14] are unable to afford to adopt such systems despite the high level of technological maturity. Previous studies [15] have revealed that, compared to a non-temperature-controlled system, the shelf life of food can be increased by a factor of two or even three times in a temperature-controlled system. Thus, fresh food supply chain planning is seldom conducted looking at the trade-offs between the possibilities of cost reduction by preventing quality affected food losses and the increase in total supply cost due to wastage from oversupply or overstocking. However, technologies for delivering fresh food faster with optimum quality and quantity reap financial benefits and can be perceived as a strategic asset to the organization [16]. Temperature-controlled systems with monitoring capabilities are designed for automating decision-making processes during transportation. In addition to their ability to remotely monitor food safety and commodity settings, some of these systems can also control in-transit ripening and pest-management treatments [17]. To our knowledge, there is no previous research that builds integrated logistic decision models to support the right choice of transport with technology-enabled tracking and traceability for temperature-controlled systems. Our paper contributes to filling this important research gap. Accordingly, the present work focusses on addressing the following key research questions.

- (i)

- What are the trade-offs to companies when choosing between investing in trucks with monitoring infrastructure and bearing the cost of food quality loss?

- (ii)

- How do these trade-offs change with respect to the distance over which the food is transported and demand variations?

2. Literature Review

Temperature control refers to the capability of the refrigeration unit fitted to trucks in maintaining the pre-specified temperature, while monitoring refers to the continuous recording of this temperature using Internet of Things sensors whose outputs are made available via the Internet for further analytics, monitoring, and decision support. In this section, the first subsection discusses various technologies currently available for controlling and monitoring temperature in fresh food supply chains. The discussion in subsequent subsections is distributed into three classes of transport pertaining to temperature control and monitoring: non-temperature-controlled transport systems, temperature-controlled transport systems without monitoring capability, and temperature-controlled transport systems with monitoring capability.

2.1. Technologies Used for Quality Monitoring of Fresh Food Transportation

Several researchers have focused on developing and implementing technologies for monitoring quality. Imaging and thermography technologies have been deployed for temperature distribution studies on a pallet of fruits to evaluate and monitor food spoilage during storage using classification techniques [18,19,20]. Ref. [21] proposed a decision support method for quality monitoring by data acquisition from multi-sensor technologies. In any food supply chain, temperature control is essential for quality assurance and safety until consumption [22]. However, fluctuations in temperature are inevitable during the transportation and distribution of perishable foods due to their vulnerability and small inherent heat capacity [20]. Thus, most of the research on fresh food logistics primarily aims at temperature control [21]. However, a wide arena of research work exists on temperature monitoring and control using newer technologies, such as RFID, WSN, IoT, wireless networks, digital twins, and gas sensing, for improving tracking and traceability of the quality of fresh food. Ref. [22] developed a tribo-electric nanogenerator-based wireless gas sensor system for real-time spoilage marker gas monitoring.

2.2. Non-Temperature-Controlled Transport Systems

Non-temperature-controlled transport systems are low-cost dry vans which may not prevent food wastage during transit. They are relatively inexpensive transport options, but they can be used only over shorter distances because food might become bad over time. Most of the studies concerning fresh food transportation deal with this type of transport and have made efforts to perform cost optimization and inculcate sustainability while addressing perishability and quality concerns using mathematical modelling. In [23], researchers deployed a three-objective linear programming model-based food distribution planner (FDP) to minimize cost, carbon emissions, and delivery time. FDP facilitates strategic planning of food distribution by considering perishability and multi-modal transport. In [20], the researchers optimized the cost of a fast-moving consumer goods (FMCGs) distribution network using scenario analysis. Ref. [16] presented a fast-moving consumer goods network design model with a consideration of greenhouse gases and other logistic leverages. Ref. [24] proposed a bi-objective food supply chain model for minimizing total cost and carbon dioxide (CO2) emissions for a milk distribution channel in Ireland. Ref. [25] developed a hybrid approach of mixed integer linear programming and constraint programming to examine integrated production planning and scheduling for the case of the dairy supply chain. Ref. [26] addressed the problem of van route scheduling for fresh food transportation cost optimization using an NSGA-II meta-heuristic approach. Ref. [27] presented a model for a food supply chain to study the effect of temperature and storage on product quality, costs, and sustainability of the chain.

2.3. Temperature-Controlled Transport Systems without Monitoring Capability

According to a transport economics report by USTDA (2000), temperature-controlled systems or reefer vehicles can be more than twice as expensive as the traditional dry vans if purchased, although the cost might have reduced in the last two decades [28]. The temperature-controlled transport systems are advantageous in the sense that they can keep food produce fresh, thereby causing them to be transported over longer distances. However, these vans do not have the functionality of generating sufficient data for predictive modelling and informed decision making. If these transport systems do not have monitoring capability (in other words the temperature readings are not made available over the Internet for continuous monitoring), then there is some chance that the temperature control system fails and is detected only at the end of the journey. By this time, it would be too late to take any corrective action, and the entire food consignment would be wasted.

Quality and perishability concerns in fresh food transportation can still be addressed by installing temperature-controlled systems without the capability for monitoring. Various researchers have developed and utilized such technologies for dynamic shelf life determination and temperature control. Due to lack of remote and automatic control mechanisms, these systems fail to assist in the decision-making process in the event of disruptions and uncertainties [9] in real time; however, are useful for generating offline data and providing a route for retrospection. Post-harvest food loss management was given a fresh perspective by [29] in terms of studying technology adoption barriers and by conducting a feasibility study for the successful implementation of various temperature control technologies. Ref. [30] proposed a multi-temperature joint distribution (MTJD) for better handling temperature-sensitive food. The use of cold cabins and eutectic plates was adopted for operational cost reduction and to ensure food quality and safety during transportation. Ref. [20] developed an integrated critical temperature indicator (CTI)-RFID for maintaining the fresh cut fruit supply chain within the temperature range of 18–19 °C. Ref. [31] have developed a load-dependent vehicle routing model for optimal route decisions after accounting for emissions from the refrigeration system. Similarly, [32] have discussed the scope of IoT based systems to support food supply chains and suggested that simulation gaming could provide promise for studying the system in detail. Furthermore, [33] have developed a mixed-integer network flow model that considers the rates of product quality decay of heterogeneous food products.

2.4. Temperature-Controlled Transport Systems with Monitoring Capability

An efficient cold chain logistics requires an automated temperature monitoring and controlling facility during transportation. Such a system can not only maintain appropriate temperatures to keep food produce fresh for longer but can also transport the produce over longer distance and, at the same time, provide confidence that the produce will arrive at the destination still fresh. The main advantage of temperature control and monitoring is that in case that the temperature control mechanism fails while the truck is in transit, the failure is rapidly identified, and corrective actions can be taken to preserve the quality of food, thereby minimizing the chance of it becoming waste. However, the downside is this would incur additional costs for installing and maintaining technologies to monitor and send alerts to decision-makers rapidly. These costs are slowly coming down as more and more companies are starting to use such advanced systems.

During the last decade, the use of IoT-based sensors for food quality monitoring and tracking temperature has become more and more operational in cold chain fresh food logistics. Furthermore, it is of great use to automate the decision-making process during transit. Numerous works have focused on developing and adopting these technologies. Ref. [34] utilized Electronic Product Code Information Services (EPCIS)-based online monitoring and a time–temperature maintenance system in a cold meat chain. This helped to decrease the losses caused due to temperature fluctuations. Similarly, [35] developed a real-time monitoring system based on RFID to improve the efficiency of a perishable goods delivery system. Additionally, it provides warnings when temperature, humidity, or any other environmental condition goes beyond safety limits. Ref. [35] proposed an “Intelligent Container”, which tracks and traces the temperature history and monitors the perishable food quality. Ref. [4] approached the problem of delivering perishable goods using wireless sensor node-based temperature control systems and proposed a smart cold chain management system. This framework enabled offline as well as online tracking and traceability through data centralization. Ref. [36] proposed an intelligent container-based framework for the shelf life prediction and remote monitoring of fresh food during transportation. Ref. [37] used RFID-based technology to gauge the quality and control the temperature in real-time throughout the supply chain. Ref. [38] introduced a real-time monitoring system based on the ZigBee standard, which sensed various environmental parameters, such as temperature, CO2, humidity, vibrations, etc. Ref. [12] proposed a real-time smartphone-based monitoring system to ensure the quality and safety of food products. The system considers parameters, such as temperature, humidity, and location during transportation. Ref. [39] proposed an intelligent distribution strategy for perishable food considering the destination hub’s shelf life, transit time, and consumption rate. According to this strategy, pallets with low shelf life are transported to the destination with high proximity and a higher consumption rate and vice-versa. Ref. [40] proposed a methodology based on sensory and chemical attributes to predict and monitor the shelf life of perishables. Ref. [41] demonstrated an automatic freshness/quality monitoring and controlling tool based on predictive data transmission technology. The work also showed that the use of such technologies helps to reduce transportation costs. Ref. [42] proposed data-driven traceability tool highlighting the impact of logistics operations on fresh food.

From the above literature, it is observed that several attempts have been made to improve the quality of fresh food using temperature-controlled systems as well as temperature-controlled systems with monitoring capability. Although cost concerns are evident from the reported literature, the existing work does not focus on developing a cost-effective model or address the dilemma of choosing the appropriate type of van for the transportation of fresh food. This paper aims to fill this important research gap by building a model which would help retailers to choose between the vans while maintaining the economic feasibility and focusing on reductions in fresh food wastage. Thus, the underpinning contributions of this work are two-fold. First, it evaluates how the trade-off based on cost of transportation and quality of fresh food to be delivered to customers affect the retailer’s choice of transport. Secondly, it considers how these trade-offs change with range of distances and demand to achieve optimal conditions.

3. Problem Description and Mathematical Modelling

Despite the rising development of automated technologies for food quality monitoring, most of the retailers and logistic providers resist investing in temperature-controlled vans with full monitoring capability. This is due to the perceived high costs of installation and maintenance associated with temperature-controlled vans in comparison to dry vans. While using dry vans may initially look cost effective from a retailer’s point of view, the high rate of quality degradation and fresh food wastage might result in a negative economic and environmental impact. That being the case, retailers are often subjected to a dilemma in choosing the appropriate type of van for the transportation of fresh food which is not only cost-effective but also helps to reduce fresh food wastage. In addition, the growing concern about the sustainability impacts of food waste [43] and increased awareness of the need to reduce food waste (for example, Europe’s resolve to reduce food waste by half in 2030, see [44]) mean that the social and environmental costs of food waste might become more visible to companies as penalty costs in the long run. Hence, the perception of optimal transportation option may need to change depending on the importance associated with food waste (captured via a penalty cost) and the distance travelled. In this paper, an integrated food quality driven logistics decision support model (M) is proposed as a linear programming problem for finding out the optimal transport plan under the possibility of transporting fresh food in different type of vans associated with different levels of quality monitoring technologies. For simplicity, the proposed model M uses the following assumptions.

- The model considers one distinct type of fresh produce.

- All demands and availability of fresh produce at each producer and retailer are deterministic.

- Transportation of fresh produce is by road.

- The transportation takes place within a single time period.

The notations for the decision variable and parameters used in problem formulation are described in Table 1.

Table 1.

Notations for parameters and the decision variable.

Objective Function,

The model aims to minimize the total cost of transport including quality loss cost with key decisions to evaluate the optimal quantity of produce that will need to be transported from producers to retailers, the transportation route, and the type of van to be chosen for the route to transport the required quantity. Equation (1) represents the objective function constituting the summation of the total fixed cost of hiring each type of van used between producer–retailer links, variable transportation cost, and total cost for fresh food loss. The total cost of fresh food loss is estimated by multiplying the penalty incurred for losing a unit quantity of food with the total amount of food lost. The amount of food lost for a given combination of origin node, destination node, and van type are calculated by the term , and is added to the total food loss quantity if and only if there is a food loss for the distance () travelled. This is ensured by the activation of }, which takes a value of 1 whenever the distance between two nodes () is greater than the threshold distance (). The given objective function is constrained to meet the demand at each retailer node, as shown in Equation (2), subject to the availability of food quantity at each producer, as represented in Equation (3). Equation (4) represents the non-negativity constraints for each decision variable.

The constraints are as follows.

Demand constraint:

Capacity constraint:

Non-negativity constraints:

Equation (2) ensures the demand at each retailer node is met after considering the occurrence of fresh food loss, if any, for a given type of transport van. Each type of van is associated with a loss factor of . We assume that is the lowest for temperature-controlled vans with full monitoring capability and highest for dry vans. The binary parameter } is defined by comparing the actual distance between the producer–retailer pair and threshold distance each type of van can travel without any quality loss, bearing in mind the possible extension of shelf life () with an improvement factor of . The value of is zero for dry vans and highest for the temperature-controlled vans with full monitoring capability. In this paper, the shelf life is taken as the difference between primary shelf life and display shelf life in order to ensure that the food remains at the right quality while it reaches the retailer. Primary shelf life is the time period from the point of harvest to the point the fresh produce becomes unacceptable, whereas display shelf life is the time for which fresh produce can be stored under specific conditions of store display [45].

4. Data and Experiments

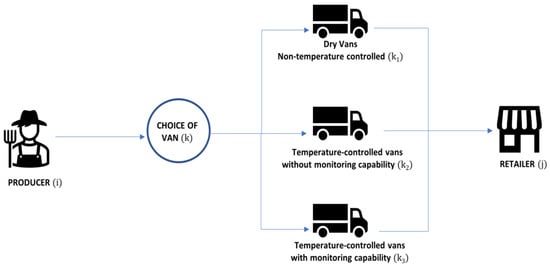

The fresh food transportation problem is articulated in the context of a north-western European-based fresh food supply chain where different types of fresh food are transported from the producers to the retailers. While transporting the food, temperature-controlled systems with monitoring capability increases the potential of decreasing the perishability rate of fresh food, thereby reducing food wastage. Therefore, the food company has three options to transport their fresh food, namely dry vans with no temperature monitoring and control, temperature-controlled vans with no quality monitoring capability, and temperature-controlled vans with quality monitoring capability, as shown in Figure 1. Multiple combinations of various parameters are used to solve the model for different instances. These parameter values are shown in Table 2.

Figure 1.

Fresh food supply network with different transport types.

Table 2.

Parameters for the case of mixed configuration of distances () [17,22,30].

The model was solved with CPLEX solver in a Pyomo Python 3.1 environment using an Intel(R) Core (TM) i5-10400 CPU, 2.90GHz processor, and 16 GB RAM. Results obtained for the low and high demand instances with low unit penalty cost of quality loss are described in Table 3 and Table 4, respectively. Table 5 describes the results for a case of high demand instance with high penalty cost for quality loss.

Table 3.

Results obtained for low demand and low unit penalty cost instance with mixed travel distances.

Table 4.

Results obtained for high demand instance with mixed travel distances.

Table 5.

Results obtained for high demand instance and high unit penalty cost ( EUR/kg) with mixed travel distances.

It is observed that for producers with high proximity to the retailers (), the dry van is chosen, and , indicating no quality loss. However, as the distance increases beyond or for those corresponding transport segments which have transport distances greater than the dry van threshold transport distance to incur food loss (), the set of type of variables take a unity value.

Hence, for retailers at low proximity from producers ( a trade-off between temperature-controlled vans and temperature-controlled vans with full monitoring capability is observed. The results suggest that the decision on the choice of a particular type of van is independent of the demand level.

The data and results presented in Table 3, Table 4 and Table 5 show very interesting trade-offs in the decision on optimal transportation choice for the fresh food supply chain. The results are discussed via three theorems, as seen below.

Theorem 1.

For a given problem of type M, with short distances over which there is no perceptible change in food quality, dry vans without temperature monitoring and control systems are the optimal choice.

Proof.

Please see Appendix A.1. □

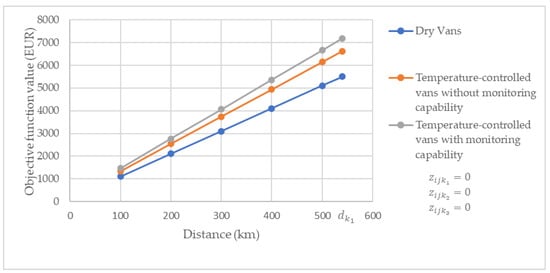

For distances < . This indicates that which suggests that irrespective of the vans chosen, the fresh food quality loss or fresh food wastage does not occur in this case. Hence, the cost for quality loss and fresh food wastage becomes zero . Now, the decision on choice of van is solely dependent on the fixed and variable transportation cost. It is also known that fixed hiring costs for different types of vans are related, as . Furthermore, variable costs of transport per unit distance per unit quantity for different van types are interrelated as . Therefore, transport using dry vans becomes the best choice because the total cost of transportation is lowest for this case. This is illustrated for a simple case of one producer and one retailer, as seen in Figure 2, which clearly shows the difference in cost of transportation through each type of van with the total objective function value being the least for dry vans. Additionally, for the case of 8 producers and 10 retailers with a demand of 10,000 kg at each sink node, dry vans are chosen to achieve the optimum, as shown in Table 6.

Figure 2.

Change in total cost of transportation with cost of fresh food loss with increasing distance for the case of one producer and one retailer pair with demand Dj = 10,000 kg and distance .

Table 6.

Results obtained for the case of short distances .

Theorem 2.

For a given problem of type M, with medium range distances over which freshness of the food can be maintained with appropriate temperature control, temperature-controlled vans without monitoring capability are the optimal choice.

Proof.

Please see Appendix A.2. □

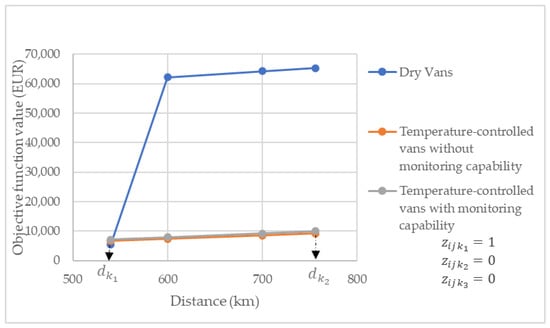

When distances are between , for dry vans, while for temperature-controlled vans with or without monitoring capability, , which means if dry vans are chosen, it would lead to quality loss and fresh food wastage with the loss factor of . Hence, with each quantity transported through dry vans, in addition to the increase in variable transportation cost, the cost of fresh food loss also increases. Furthermore, to satisfy the demand, extra quantities with a factor of must be transported to compensate for the lost quantities. As is highest for dry vans, the cost of fresh food loss increases steeply, as observed in Figure 3, and it becomes economically impractical to choose dry vans for travel distances beyond . The choice between temperature-controlled vans with monitoring capability and without monitoring capability is dependent only on the minimum total of fixed and variable transportation cost, as neither would lead to quality loss when . With the cost of transportation being lower for temperature-controlled vans without monitoring capability, they become the optimum choice. This can also be observed from Figure 3 for the illustrated case of one producer and one retailer. Furthermore, the results obtained for another case of 8 producers and 10 retailers are described in Table 7, where again the optimal choice of type of vans is showcased.

Figure 3.

Change in total cost of transportation with cost of fresh food loss with increasing distance for the case of one producer and one retailer pair with demand Dj = 10,000 kg and distance .

Table 7.

Results obtained for the case of distances .

Theorem 3.

For a given problem of type M, and, and unit penalty cost for quality loss, the optimal choice of transport changes from temperature-controlled vans without monitoring capability to temperature-controlled vans with monitoring capability when the unit penalty cost exceeds.

Proof.

Please see Appendix A.3. □

In this case, the travel distances are such that , and non-dry vans also incur fresh food quality loss and fresh food wastage. As , the parameter for all and for each Hence, in this case, irrespective of the type of van chosen, fresh food quality degrades, leading to fresh food wastage. From Theorem 2, it is proved that in such cases dry vans incur huge amount of fresh food loss and, hence, are not viable. The trade-off between the and types of vans is made based on unit penalty cost for quality loss. is defined in Table 1 as the cost of fresh food loss associated with quality loss per unit food quantity for k type of van (EUR/kg). However, this value can be interpreted practically for a company as the loss of revenue for the food wasted. However, food waste is associated with significant environmental and social costs, especially when it ends up in landfill where it emits greenhouse gases. In addition, food wastage also means wasted resources (such as water, electricity, labor, and fertilizers) that went into the production of the food, which were also involved in the emission of greenhouse gases. If food waste is avoided and the saved food is used to feed those in need, it could also result in reduced poverty and, consequently, crime rates. This can be interpreted as one of the social costs of food waste. In order to internalize the social and environmental costs, governments across the world are making policy changes in the form of regulatory charges. Hence, the costs of food waste could be much higher than the value of the private cost perceived by a single food firm.

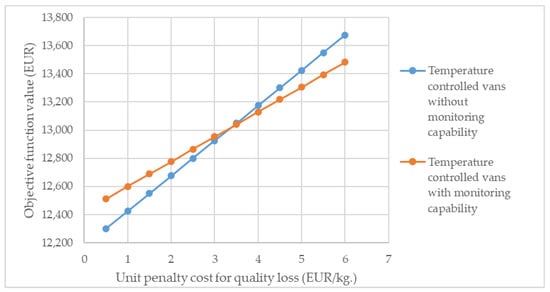

Considering the importance of fresh food loss from economic, environmental, and social perspectives, it is important to know the trade-off point of the unit penalty cost at which the retailers prioritize preventing fresh food loss with an appropriate choice of vans. We arrive at this threshold penalty cost looking at the decrease in the total cost of transportation (including fixed hiring cost, variable transportation cost, and quality loss cost) for temperature-controlled vans with monitoring capability in comparison to temperature-controlled vans without monitoring capability at the threshold point. The detailed explanation for this reduction in total cost of transportation for the third category of vans is explained in Appendix A.3. This can be observed for the case of one producer and one retailer, as shown in Figure 4. Furthermore, Table 8 and Table 9 showcase this shift in the choice of vans from temperature-controlled vans without monitoring capability to temperature-controlled vans with monitoring capability with the increase in unit penalty cost, respectively, for a case of 8 producer and 10 retailers.

Figure 4.

Change in total cost of transportation with cost of fresh food loss with increasing unit penalty cost for the case of one producer and one retailer pair with demand Dj = 10,000 kg and distance .

Table 8.

Results obtained for the case of long distances , high demand, and unlimited availability with low unit penalty cost.

Table 9.

Results obtained for the case of long travel distances , high demand, unlimited availability, and with low unit penalty cost.

Sensitivity Analysis for Different Types of Perishables

For the purpose of understanding the behavior of the proposed model for the transport of different fresh food types, a classification of fresh foods based on their perishable nature, temperature and humidity requirements, and ethylene sensitivity is carried out, as shown in Table 10. According to the study conducted by [46], some fresh foods, such as apples and cabbages, may have the same ideal temperature and relative humidity requirements but are placed in two different categories due to difference in their ethylene sensitivity levels. For example, fruits, such as apples, cherries, and berries produce high levels of ethylene which leads to discoloration, softening, and bitterness of ethylene sensitive crops, thereby reducing their shelf life. Furthermore, products, such as onions and garlics may disseminate off-flavors to odor sensitive fruits and vegetables, such as apples and potatoes. The majority of fruits have high relative humidity requirements due to the high water content in them, while onions and garlic would decay in the presence of high humidity.

Table 10.

Results obtained for sensitivity analysis for a high instance case for different perishable types with high demand, unlimited availability, and high unit penalty cost.

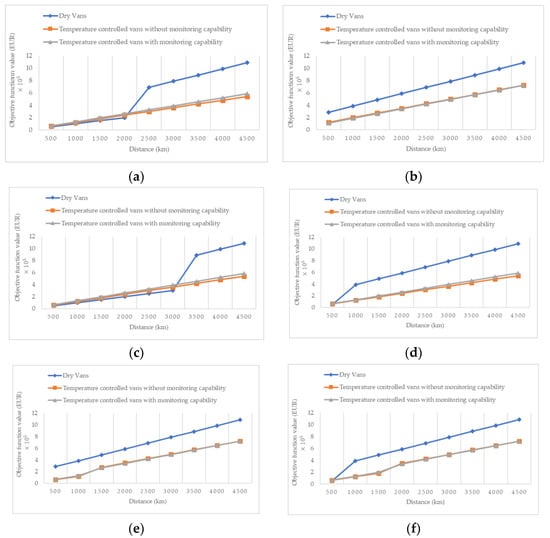

Considering the varied nature of each food type, sensitivity analysis is performed over each perishable food type. One distinct fresh food from each type was selected and was solved for two instances—for the 1 producer and 1 retailer case, as illustrated in Figure 5a–e, and for the 37 producers and 37 retailers’ case, as described in Table 10. From the results obtained it can be inferred that for the perishable types 1 and 3 which have a long shelf life of up to 3–4 weeks with adequate temperature control, a combination of dry vans and temperature-controlled vans is optimal considering the distances spanning from 46–4508 km between the major European cities. The trade-off between temperature-controlled vans and temperature-controlled vans with monitoring capability for fresh food with high perishability (type 2, type 5, and type 6) is made at the penalty cost of quality loss, as elucidated in Theorem 3. For type 3 perishables, the importance of using temperature-controlled vans with monitoring capability to prevent fresh food loss is realized at a penalty cost as low as EUR 1.716, while for type 5 and type 6 it is realized at a penalty cost greater than EUR 4.89 and EUR 6.9, respectively. Type 3 perishables, such as cranberries, may be transported using temperature-controlled vans, as fresh food loss can be prevented to a greater extent by maintaining adequate temperature. This can also be observed in Figure 5d, where the total cost of transportation using temperature-controlled vans is considerably lower in comparison to temperature-controlled vans with monitoring capability and dry vans throughout the sample distance range. Wise use of temperature-controlled vans for transporting selective fresh vegetables and fruits can help reduce food waste, which indirectly helps green logistics and distribution.

Figure 5.

Change in total cost of transportation with cost of fresh food loss for the case of one producer and one retailer pair with demand Dj = 10,000 kg and increasing distance for (a) perishable type 1 (apples); (b) perishable type 2 (strawberries); (c) perishable type 3 (onions); (d) perishable type 4 (cranberries); (e) perishable type 5 (eggplants); (f) perishable type 6 (bananas).

5. Discussion

Based on the validation of the proposed model on several instances in the previous section and the theorems elicited therein, effective strategies for choosing the appropriate van types for fresh food transportation have been derived. To summarize, for shorter distances, fresh food transport through dry vans is the optimal choice. This is because of the deteriorating effect of temperature and humidity on the fresh food quality, leading to fresh food wastage which does not kick in within the delivery time window. Hence, it is viable for retailers with high proximity to producers to opt for dry vans. It is important to note that, to prevent further decay of fresh food items, especially with high perishability rates, an adequate temperature-controlled environment must be made available at the store. As the travel distance increases, more time is needed to transport fresh food; therefore, the choice of vans shifts from dry vans towards non-dry vans.

Given that the quantity loss factor for temperature-controlled vans with monitoring capability is the lowest, the fresh food wastage is lowest for them at any given instance. Therefore, the temperature-controlled vans with monitoring capability become the optimal choice of transport when the penalty cost of quality loss is taken into consideration from economic, environmental, and social perspectives, in spite of their higher cost of hiring. This observation will be helpful for larger supplier–retailer travel distances for planning efficient last mile deliveries. This will help the retailers to enhance their services by providing optimal quality fresh food to customers, leading to an increase in their goodwill. Furthermore, Theorem 3 proves that temperature-controlled vans with monitoring capability gain more advantage for longer travel distances over dry vans, in addition to having the benefit of lesser costs of fresh food loss. For a given range of distance temperature-controlled vans without monitoring capability are viable. Although this is a better option than choosing dry vans and temperature-controlled vans with monitoring capability for this case, it could be a sub-optimal choice for the retailers who may want to expand their businesses to a larger geographical territory in the long term, because it restricts the retailers from providing optimal quality fresh food to their customers located at greater distances, leading to a competitive disadvantage in the market.

On the other hand, the retailer may use the observations from this research to look at a hybrid choice of vans, with both dry vans and temperature-controlled vans. For example, when operating at distances , vans can be chosen such that part of the distance is served by dry vans and part of it is served by the second category of vans. This would help them in increasing their service region while simultaneously providing fresh food of optimal quality. It is also evident from the results obtained that the demand levels have no effect over the choice of vans. Fresh food wastage occurs regardless beyond a given threshold distance, and the condition is worse if it is not delivered with the appropriate choice of transport. These inferences are summarized in Table 11.

Table 11.

A synthesis of trade-off of monitoring capability with distance and demand.

This research is a part of a larger study of installing monitoring systems in the food supply chains of several companies across Europe, and some of the ideas in this model have been implemented during these activities. They helped us to gain a deeper understanding of the needs of logistical services depending on the nature of the project and expected quality. One of the retail stores, ‘Cool-X’, operating in the Netherlands, is making home deliveries after picking the products from retail stores. This company uses small cool packs to deliver cold and frozen items. These cool packs are filled with ice-cubes to maintain specific temperature ranges, such as from −5 °C to 2 °C. There are two different options possible: one is having the cool packs installed along with sensors and data connectivity, and the other option is having cool packs with only ice-cubes. The first option is used for long-distance travel or high-value products to avoid any quality loss, while option 2 is used for short-distance travel, thereby reaping the benefits of high-end technology monitoring for long range transport.

A case company Green-X, located in Luxemburg, is playing various roles in the food supply chain as suppliers, distributors, and retailers. When this company is working closely with the farmers, they prefer to use trucks or vans with no climate control options for food produce which can stay in normal temperature for a week, such as in the case of potatoes and carrots. However, the company is using temperature-controlled transport and warehouses for fresh vegetables and fruits with less than 5 days of shelf life. These trucks are fitted with sensors and connected to the cloud to monitor the temperature on the move. Mobile alert facilities are provided to some trucks which travel beyond a range of 50 miles. This is mainly to help the decision makers and to make sure that any remedial action should be possible immediately in case of abnormal temperature fluctuations.

More case studies documenting our experiences have been published [7,47,48]. Ref. [47] describe in detail the efforts made in implementing the control and monitoring system in vans of a last-mile delivery provider in The United Kingdom (UK). Ref. [7] describe the details of a similar system in a frozen food company, while [8] describe the experiences of transporting valuable human milk for a UK human milk bank. The motivations and barriers for companies for engaging in the control and monitoring system are discussed in [48], along with a discussion on business models. A detailed exploration of the costs, including environmental costs, has been carried out by [49] for selected case studies.

6. Conclusions

This paper addressed an important gap in the fresh food transportation literature by developing a novel prescriptive mathematical model to evaluate the cost-effective choice of transport in the presence of multiple van types to transport fresh food. For the purpose of this study, three types of vans, namely vans without temperature monitoring and control ability (dry vans), vans with temperature control without a monitoring facility, and vans with temperature control and monitoring capability, were considered. The proposed linear programming formulation integrates conventional transport network decisions, such as food quantity shipment and producer–retailer allocations, with van type choices to maintain food quality enroute. The model was solved using CPLEX and a Pyomo environment on two mixed instances initially, which contained all configurations of travel distances. By the method of inference, three theorems were proposed and proved to finally deduce the cost-effective choice of vans for cases of short-, medium-, and long-distance configurations. The findings from the three theorems were validated on several data sets comprising various combinations of travel distances, demand levels, and penalty costs, which also revealed that the optimal choice of vans is independent of demand levels under infinite vehicle resource availability. Importantly, the study derives a general expression of the trade-off point defined by the value of unit penalty cost, which makes the optimal choice of transport shift from vans without temperature monitoring capability to vans with temperature monitoring capability. Furthermore, sensitivity analysis was conducted to observe cost trade-offs and threshold penalties pertaining to the choice of vans for different types of perishables. These novel findings will be useful to food logistics operators to understand the economic implications of using dry or reefer vans for fresh food transportation.

The present work provides a strong foundation to investigate several other issues under additional complexities in the future for fresh food transport that, in other words, form the limitations of this study. For example, the model proposed in this work can be improved to evaluate optimal van choices under vehicle resource restrictions. Although the vehicle fleet composition can be derived easily for the current problem as they are treated as dependent decision variables, this can be further deeply examined by internalizing fleet composition as independent decision variables. More complicated vehicle routing models with different van types can be developed to explore complex trade-offs. It can also be further extended from a single type of food transport to multiple food types with different shelf lives. Newer vehicle routing models can be developed to identify the choice of these three types of vans after considering emissions from refrigeration. We could include the impact of variations in quality decay due to interaction between two or more fruits when carrying multiple perishable products. Furthermore, it was assumed here that all the vans are operating under a hire/lease model, whereas, in practice, large retailers may be interested to see cost–benefit trade-offs of investing on in-house transport resources. Finally, cost may not be the only factor influencing the choice of vans. In most cases, the appropriate choice of sensors is decided based on the specific application scenario and, therefore, could have other priorities affecting the choice of vans, such as the minimum accuracy and standards of sensors needed (for example if sensors with high levels of accuracy for relative humidity measurements are a necessary requirement), which can form interesting research avenues for future consideration and investigation.

Author Contributions

Conceptualization, R.R.; data curation, I.R.; formal analysis, I.R.; funding acquisition, L.M.M., R.R. and U.R.; methodology, L.M.M. and I.R.; project administration, R.R.; resources, L.M.M. and I.R.; software, I.R.; supervision, L.M.M. and R.R.; validation, L.M.M. and R.R.; writing—original draft, L.M.M. and I.R.; writing—review and editing, L.M.M., U.R., R.R. and I.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research reported in this paper is based on the work done in the REAMIT project (www.reamit.eu, accessed on 1 November 2022) funded by the Interreg North-West Europe (ref NWE831) and seed grant project on Reducing Food Waste and Inculcating Sustainability in Post COVID Fresh Food Supply Chains (ref SG-108) funded by the Indian Institute of Technology, Hyderabad.

Institutional Review Board Statement

The study was conducted after gaining ethical approval (ref BMRI/Ethics/Staff/2018-19/005) from the University of Bedfordshire, UK.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

REAMIT project and case study videos are available at www.reamit.eu (accessed on 1 November 2022).

Acknowledgments

The authors are thankful to Tahmina Ajmal in Engineering, University of Bedfordshire, UK for the valuable suggestions to improve the quality of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Parameter notations for different types of vans.

Table A1.

Parameter notations for different types of vans.

| Description | Notations | ||

|---|---|---|---|

| Dry Vans (k1) | |||

| Fixed hiring cost per unit quantity | |||

| Variable transportation cost per unit quantity per unit distance | |||

| Cost for fresh food loss per unit quantity | |||

| Distance limit (beyond this distance quality starts deteriorating) | |||

| Basic quantity loss factor | |||

Appendix A.1. Proof of Theorem 1

All notations used for proving the theorems have been described in Table A1. For distances ,. As implies, Hence, the cost for quality loss does not incur irrespective of the choice of vehicle. Considering the total cost of transportation through each type of vans without the cost for fresh food loss, we know that a quantity of (demand) must be transported. Total cost of transportation through dry vans, . Total cost of transportation through temperature-controlled vans without monitoring capability,. Total cost of transportation through temperature-controlled vans with monitoring capability, . Now, Hence, , making dry vans the optimal choice for .

Appendix A.2. Proof of Theorem 2

When distance ,, therefore, . If dry vans are chosen, it would incur a cost of for fresh food loss where the quantity of fresh food to be transported , while since . Hence, for both temperature-controlled vans with and without monitoring capability there is no cost for quality loss. Considering the total cost for each type of van for this case:

Total cost of transportation through the dry van, .

Total cost of transportation through temperature-controlled vans without monitoring capability, .

Total cost of transportation through temperature-controlled vans with monitoring capability, .

From theorem 1 we know that . Hence, . To check if , it needs to be proved that .

We know that , since the cost for quality loss is much higher. Therefore, . Hence, it is found that , making it the optimal choice of van in this case.

Appendix A.3. Proof of Theorem 3

For distances ,. As implies, . Therefore, in this case, irrespective of the choice of vehicle, all types of vans would incur costs due to fresh food loss. Considering the total cost of transportation for each type of van in this case:

Total cost of transportation through the dry van, .

Total cost of transportation through temperature-controlled vans without monitoring capability, .

Total cost of transportation through temperature-controlled vans with monitoring capability, .

Comparing with , from theorem 1 we know that . However, and . Thus, it can be inferred that .

Now, subtracting from , we obtain the following:

To arrive at the threshold value of unit penalty cost for quality loss, let the above equation be below 0, as at this point temperature-controlled vans with monitoring capability would be the optimal choice of transport.

Rewriting the above equation:

On simplifying, we arrive at the threshold unit penalty cost, . Hence, the unit penalty cost being more than this threshold penalty cost per unit would lead to the optimal choice of transport as temperature-controlled vans with monitoring capability.

References

- Amitangshu, P.; Kant, K. Provenance and traceability in IoT-integrated food logistics: How blockchain can help? IEEE Comput. 2019, 52, 94–98. [Google Scholar]

- Dib, O.H.; Assaf, A.; Pean, A.; Durand, M.-J.; Jouanneau, S.; Ramanathan, R.; Thouand, G. Raman Spectroscopy Application in Food Waste Analysis: A Step towards a Portable Food Quality-Warning System. Sustainability 2023, 15, 188. [Google Scholar] [CrossRef]

- Amoa-Awua, W.K.; Ngunjiri, P.; Anlobe, J.; Kpodo, K.; Halm, M.; Hayford, A.E.; Jakobsen, M. The effect of applying GMP and HACCP to traditional food processing at a semi-commercial kenkey production plant in Ghana. Food Control 2007, 18, 1449–1457. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Temperature management for the quality assurance of a perishable food supply chain. Food Control 2014, 40, 198–207. [Google Scholar] [CrossRef]

- Baldera Zubeldia, B.; Nieto Jiménez, M.; Valenzuela Claros, M.T.; Mariscal Andrés, J.L.; Martin-Olmedo, P. Effectiveness of the cold chain control procedure in the retail sector in Southern Spain. Food Control 2016, 59, 614–618. [Google Scholar] [CrossRef]

- González-Rodríguez, R.; Noguerol-Pato, R.; González-Barreiro, C.; Cancho-Grande, B.; Simal-Gándara, J. Application of new fungicides under good agricultural practices and their effects on the volatile profile of white wines. Food Res. Int. 2011, 44, 397–403. [Google Scholar] [CrossRef]

- Ramanathan, U.; Ramanathan, R.; Adefisan, A.; Da Costa, T.; Cama-Moncunill, X.; Samriya, G. Adapting Digital Technologies to Reduce Food Waste and Improve Operational Efficiency of a Frozen Food Company—The Case of Yumchop Foods in the UK. Sustainability 2022, 14, 16614. [Google Scholar] [CrossRef]

- Ramanathan, U.; Pelc, K.; da Costa, T.P.; Ramanathan, R.; Shenker, N. A case study of human milk banking with focus on the role of IoT sensor technology. Sustainability 2023, 15, 243. [Google Scholar] [CrossRef]

- Onwude, D.I.; Chen, G.; Eke-Emezie, N.; Kabutey, A.; Khaled, A.Y.; Sturm, B. Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Processes 2020, 8, 1431. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Robla Villalba, J.I. New trends in cold chain monitoring applications—A review. Food Control. 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Da Costa, T.P.; Gillespie, J.; Cama-Moncunill, X.; Ward, S.; Condell, J.; Ramanathan, R.; Murphy, F. A Systematic Review of Real-Time Monitoring Technologies and Its Potential Application to Reduce Food Loss and Waste: Key Elements of Food Supply Chains and IoT Technologies. Sustainability 2023, 15, 614. [Google Scholar] [CrossRef]

- Alfian, G.; Syafrudin, M.; Rhee, J. Real-Time Monitoring System Using Smartphone-Based Sensors and NoSQL Database for Perishable Supply Chain. Sustainability 2017, 9, 2073. [Google Scholar] [CrossRef]

- Frost and Sullivan Japan, K.K. Business Opportunity Analysis on Temperature-Controlled Rail Logistics Industry in India for Japanese Companies. 2018. Available online: https://dl.ndl.go.jp/pid/11222665/1/1 (accessed on 27 October 2022).

- Sun, S.; Wang, X. Promoting traceability for food supply chain with certification. J. Clean. Prod. 2019, 217, 658–665. [Google Scholar] [CrossRef]

- Van Holsteijn, F.; Kemna, R. Minimizing food waste by improving storage conditions in household refrigeration. Resour. Conserv. Recycl. 2018, 128, 25–31. [Google Scholar] [CrossRef]

- Igl, J.; Kellner, F. Exploring greenhouse gas reduction opportunities for retailers in Fast Moving Con-sumer Goods distribution networks. Transp. Res. Part D Transp. Environ. 2017, 50, 55–69. [Google Scholar] [CrossRef]

- McGregor, B. Protecting Perishable Foods During Transport by Truck and Rail; U.S. Department of Agriculture, Agricultural Marketing Service: Washington, DC, USA, 2019.

- Shin, Y.; Liu, R.H.; Nock, J.F.; Holliday, D.; Watkins, C.B. Temperature and relative humidity effects on quality, total ascorbic acid, phenolics and flavonoid concentrations, and antioxidant activity of strawberry. Postharvest Biol. Technol. 2007, 45, 349–357. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Choy, K.L.; Wu, C.H.; Ho, G.T.S.; Lam, H.Y.; Tang, V. An intelligent model for assuring food quality in managing a multi-temperature food distribution centre. Food Control 2018, 90, 81–97. [Google Scholar] [CrossRef]

- Lorite, G.S.; Selkälä, T.; Sipola, T.; Palenzuela, J.; Jubete, E.; Viñuales, A.; Cabañero, G.; Grande, H.J.; Tuominen, J.; Uusitalo, S.; et al. Novel, smart and RFID assisted critical temperature indicator for supply chain monitoring. J. Food Eng. 2017, 193, 20–28. [Google Scholar] [CrossRef]

- James, S.; James, C.; Evans, J. Modelling of food transportation systems—A review. Int. J. Refrig. 2006, 29, 947–957. [Google Scholar] [CrossRef]

- Cai, C.; Mo, J.; Lu, Y.; Zhang, N.; Wu, Z.; Wang, S.; Nie, S. Integration of a porous wood-based triboelectric nanogenerator and gas sensor for real-time wireless food-quality assessment. Nano Energy 2021, 83, 105833. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Bhattacharya, R. Solving a tri-objective supply chain problem with modified NSGA-II algorithm. J. Manuf. Syst. 2014, 33, 41–50. [Google Scholar] [CrossRef]

- Sel, C.; Bilgen, B.; Bloemhof-Ruwaard, J.; van der Vorst, J. Multi-bucket optimization for integrated planning and scheduling in the perishable dairy supply chain. Comput. Chem. Eng. 2015, 77, 59–73. [Google Scholar] [CrossRef]

- Musavi, M.; Bozorgi-Amiri, A. A multi-objective sustainable hub location-scheduling problem for perishable food supply chain. Comput. Ind. Eng. 2017, 113, 766–778. [Google Scholar] [CrossRef]

- Zanoni, S.; Zavanella, L. Chilled or frozen? Decision strategies for sustainable food supply chains. Int. J. Prod. Econ. 2012, 140, 731–736. [Google Scholar] [CrossRef]

- Feasibility Study for the Port of Durres Multi-Modal Container Facility. In Transport Economics; U.S Trade and Development Agency: Arlington, VA, USA, 2000; Volume II.

- Mohan, A.; Krishnan, R.; Arshinder, K.; Vandore, J.; Ramanathan, U. Management of Postharvest Losses and Wastages in the Indian Tomato Supply Chain—A Temperature-Controlled Storage Perspective. Sustainability 2023, 15, 1331. [Google Scholar] [CrossRef]

- Kuo, J.-C.; Chen, M.-C. Developing an advanced Multi-Temperature Joint Distribution System for the food cold chain. Food Control 2010, 21, 559–566. [Google Scholar] [CrossRef]

- Stellingwerf, H.M.; Kanellopoulos, A.; van der Vorst, J.G.; Bloemhof, J.M. Reducing CO2 emissions in tempera-ture-controlled road transportation using the LDVRP model. Transp. Res. Part D Transp. Environ. 2018, 58, 80–93. [Google Scholar] [CrossRef]

- Accorsi, R.; Bortolini, M.; Baruffaldi, G.; Pilati, F.; Ferrari, E. Internet-of-things Paradigm in Food Supply Chains Control and Management. Procedia Manuf. 2017, 11, 889–895. [Google Scholar] [CrossRef]

- De Keizer, M.; Akkerman, R.; Grunow, M.; Bloemhof, J.M.; Haijema, R.; van der Vorst, J.G. Logistics network design for perishable products with heterogeneous quality decay. Eur. J. Oper. Res. 2017, 262, 535–549. [Google Scholar] [CrossRef]

- Thakur, M.; Forås, E. EPCIS based online temperature monitoring and traceability in a cold meat chain. Comput. Electron. Agric. 2015, 117, 22–30. [Google Scholar] [CrossRef]

- Lang, W.; Jedermann, R.; Mrugala, D.; Jabbari, A.; Krieg-Brückner, B.; Schill, K. The “Intelligent Container”—A Cognitive Sensor Network for Transport Management. IEEE Sens. J. 2011, 11, 688–698. [Google Scholar] [CrossRef]

- Jedermann, R.; Nicometo, M.; Uysal, I.; Lang, W. Reducing food losses by intelligent food logistics. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130302. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.R.; Aung, M.M.; Chang, Y.S.; Makatsoris, C. Freshness Gauge based cold storage management: A method for adjusting temperature and humidity levels for food quality. Food Control 2015, 47, 510–519. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; He, J.; Li, L.; Shen, M.; Tan, X.; Min, H.; Zheng, L. Wireless sensor network for real-time perishable food supply chain management. Comput. Electron. Agric. 2014, 110, 196–207. [Google Scholar] [CrossRef]

- Pal, A.; Kant, K. Smart Sensing, Communication, and Control in Perishable Food Supply Chain. ACM Trans. Sens. Networks 2020, 16, 1–41. [Google Scholar] [CrossRef]

- Torres-Sánchez, R.; Martínez-Zafra, M.T.; Castillejo, N.; Guillamón-Frutos, A.; Artés-Hernández, F. Real-Time Monitoring System for Shelf Life Estimation of Fruit and Vegetables. Sensors 2020, 20, 1860. [Google Scholar] [CrossRef]

- Li, G. Development of cold chain logistics transportation system based on 5G network and Internet of things system. Microprocess. Microsystems 2020, 80, 103565. [Google Scholar] [CrossRef]

- Gallo, A.; Accorsi, R.; Goh, A.; Hsiao, H.; Manzini, R. A traceability-support system to control safety and sustainability indicators in food distribution. Food Control 2021, 124, 107866. [Google Scholar] [CrossRef]

- Feng, Y.-Z.; Sun, D.-W. Determination of total viable count (TVC) in chicken breast fillets by near-infrared hyperspectral imaging and spectroscopic transforms. Talanta 2013, 105, 244–249. [Google Scholar] [CrossRef]

- Europa. EU Actions against Food Waste. 2022. Available online: https://food.ec.europa.eu/safety/food-waste/eu-actions-against-food-waste_en#:~:text=The%20EU%20and%20the%20EU,food%20production%20and%20supply%20chains (accessed on 27 October 2022).

- Piergiovanni, L.; Limbo, S. Food shelf-life models. In Sustainable Food Supply Chains; Elsevier: Amsterdam, The Netherlands, 2019; Volume 230, pp. 49–60. [Google Scholar] [CrossRef]

- Boyhan, G.E.; Hurst, W.C.; Kelley, W.T.; Krewer, G.W.; Taylor, K.C. Postharvest Handling and Transportation of Fruits and Vegetables; Cooperative Extension Fact Sheet 100; The University of Georgia: Athens, GA, USA, 2009. [Google Scholar]

- Gillespie, J.; da Costa, T.P.; Cama-Moncunill, X.; Cadden, T.; Condell, J.; Cowderoy, T.; Ramsey, E.; Murphy, F.; Kull, M.; Gallagher, R.; et al. Real-Time Anomaly Detection in Cold Chain Transportation Using IoT Technology. Sustainability 2023, 15, 2255. [Google Scholar] [CrossRef]

- Ramanathan, R.; Duan, Y.; Ajmal, T.; Pelc, K.; Gillespie, J.; Ahmadzadeh, S.; Condell, J.; Hermens, I.; Ramanathan, U. Motivations and Challenges for Food Companies in Using IoT Sensors for Reducing Food Waste: Some Insights and a Road Map for the Future. Sustainability 2023, 15, 1665. [Google Scholar] [CrossRef]

- Da Costa, T.P.; Gillespie, J.; Pelc, K.; Adefisan, A.; Adefisan, M.; Ramanathan, R.; Murphy, F. Life Cycle Assessment Tool for Food Supply Chain Environmental Evaluation. Sustainability 2022, 15, 718. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).