The Possibility of Achieving Zero CO2 Emission in the Indonesian Cement Industry by 2050: A Stakeholder System Dynamic Perspective

Abstract

1. Introduction

2. Materials and Methods

2.1. AHP’s Priority Calculation

- Respondents from the cement industry association considered clinker substitution the priority, with a value of 0.545.

- Those from the research institute ranked CCS technology first, with a value of 0.429.

- Stakeholders from the government ministry set energy efficiency as the priority, with a score of 0.475.

- Environmental NGO’s respondents set alternative fuel as a top priority, with a value of 0.453.

2.2. Consistency Ratio

3. System Dynamic Model for CO2 Emission in Cement Production

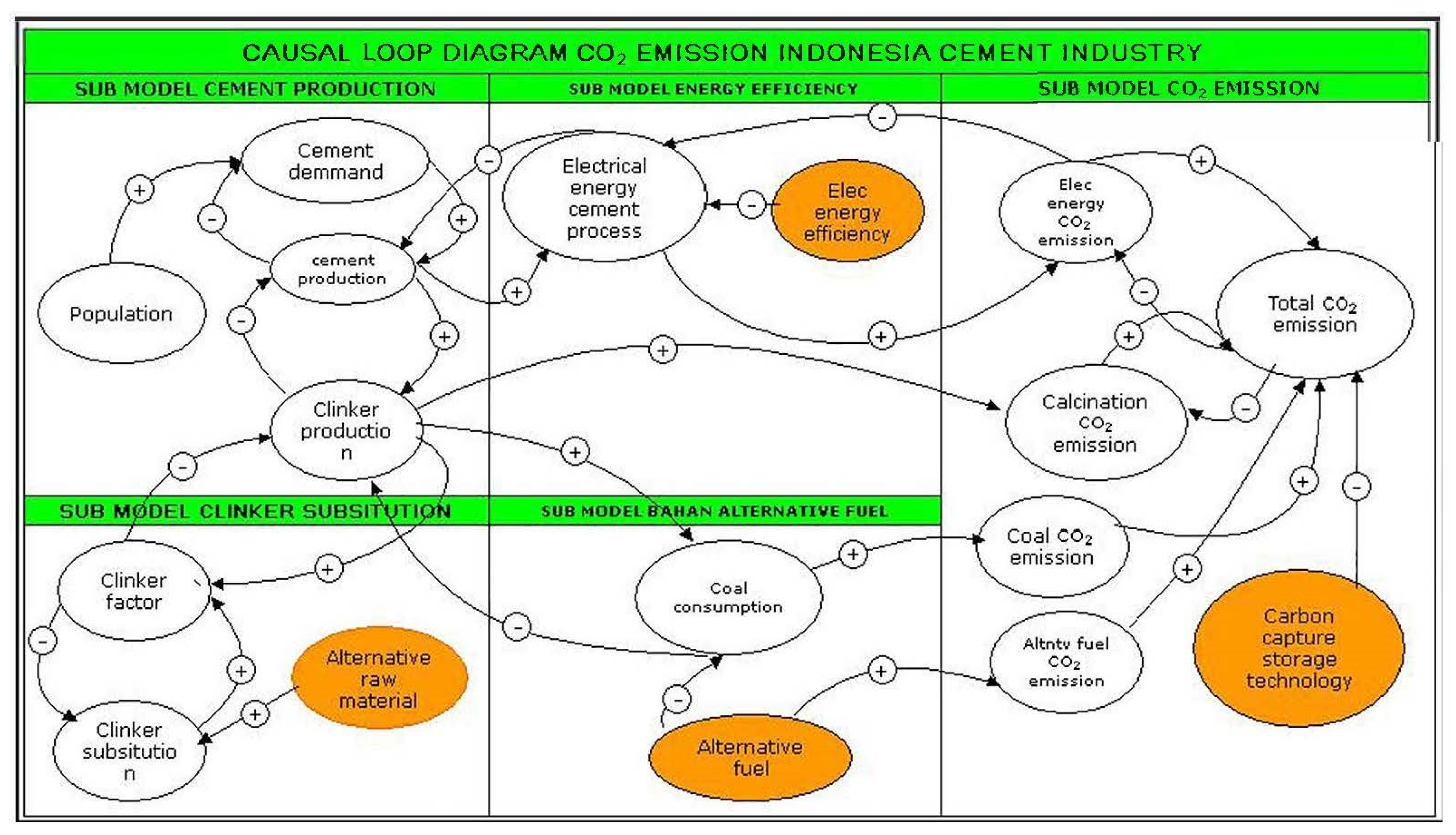

3.1. Causal Loop Diagram

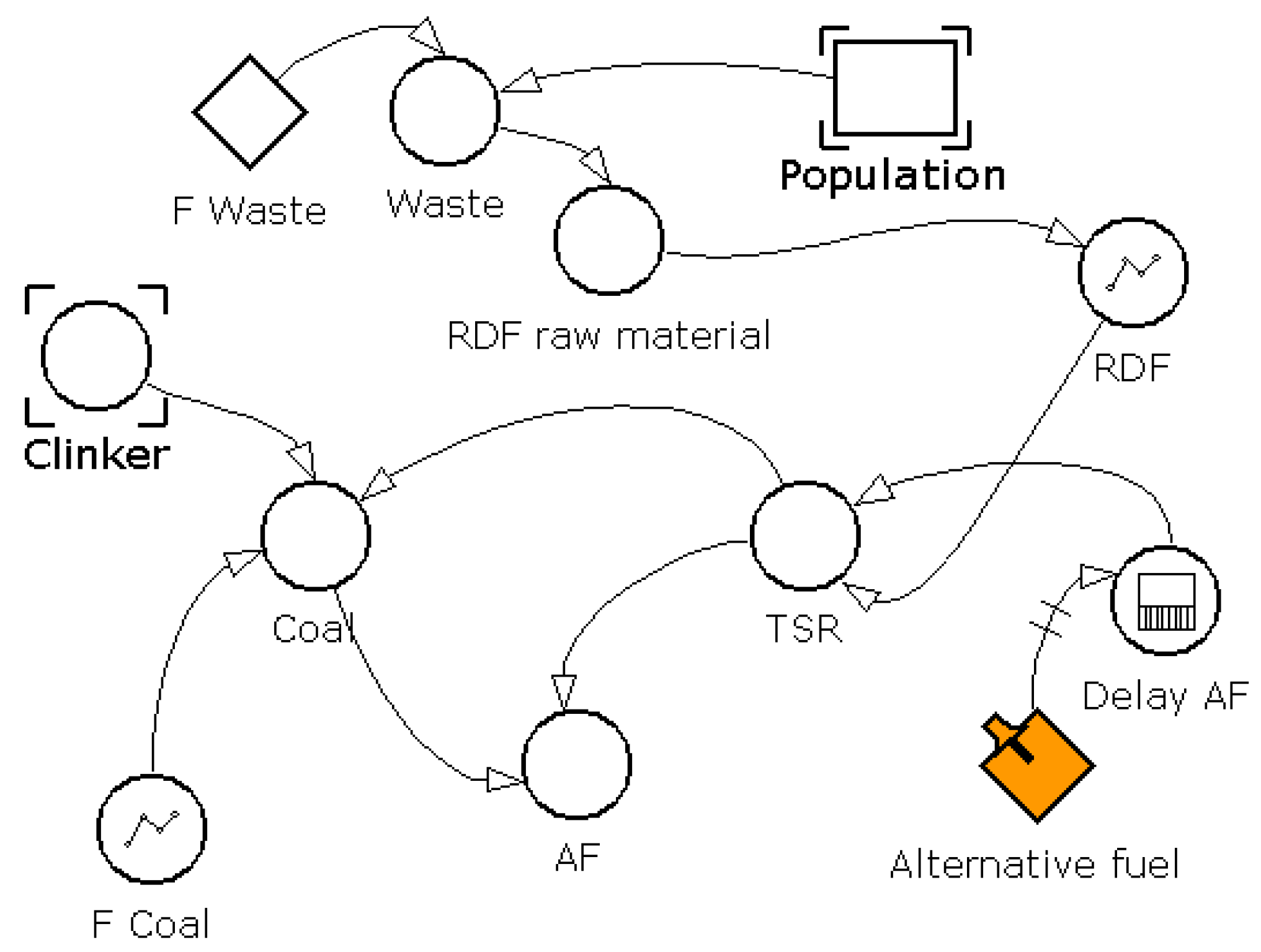

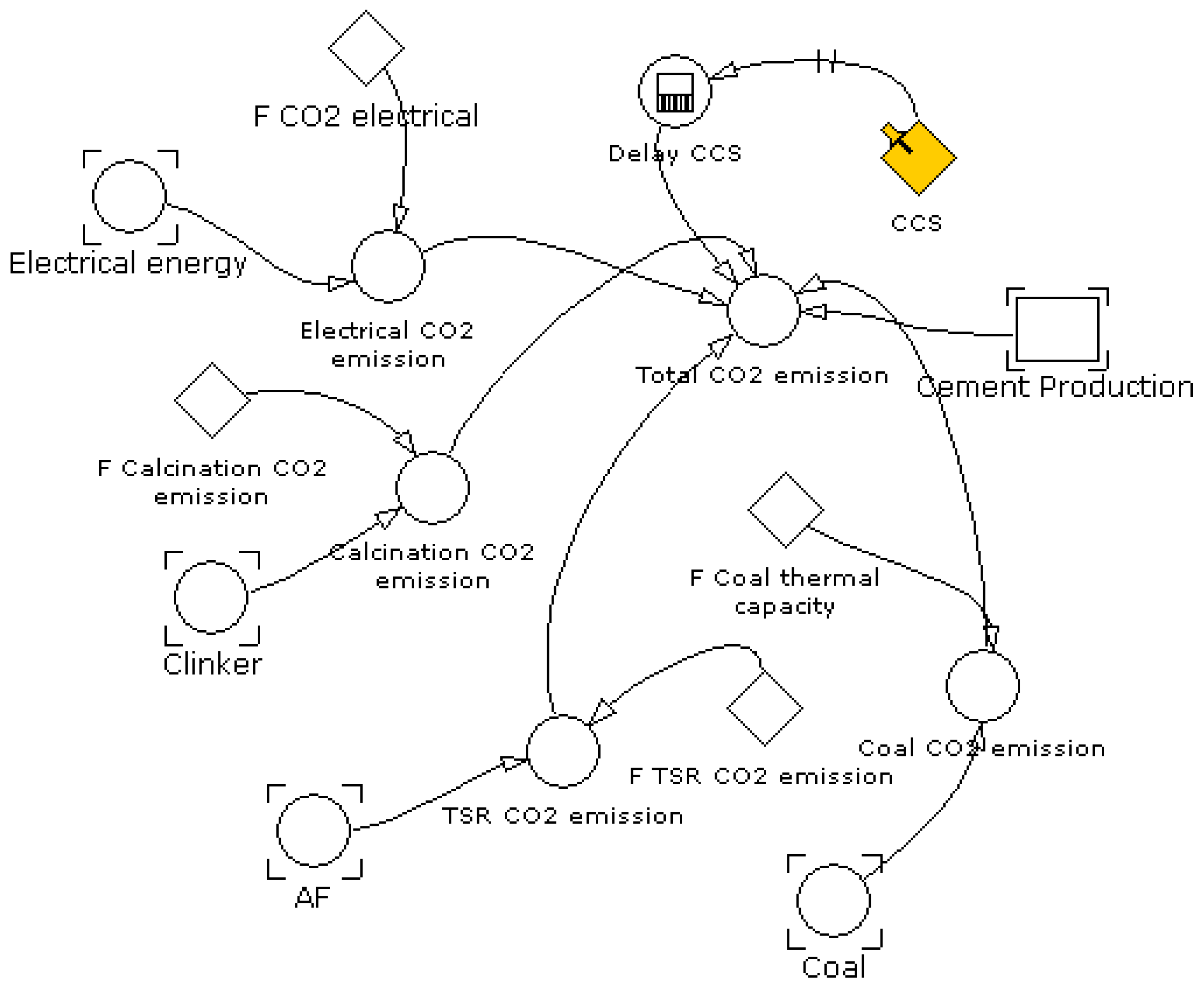

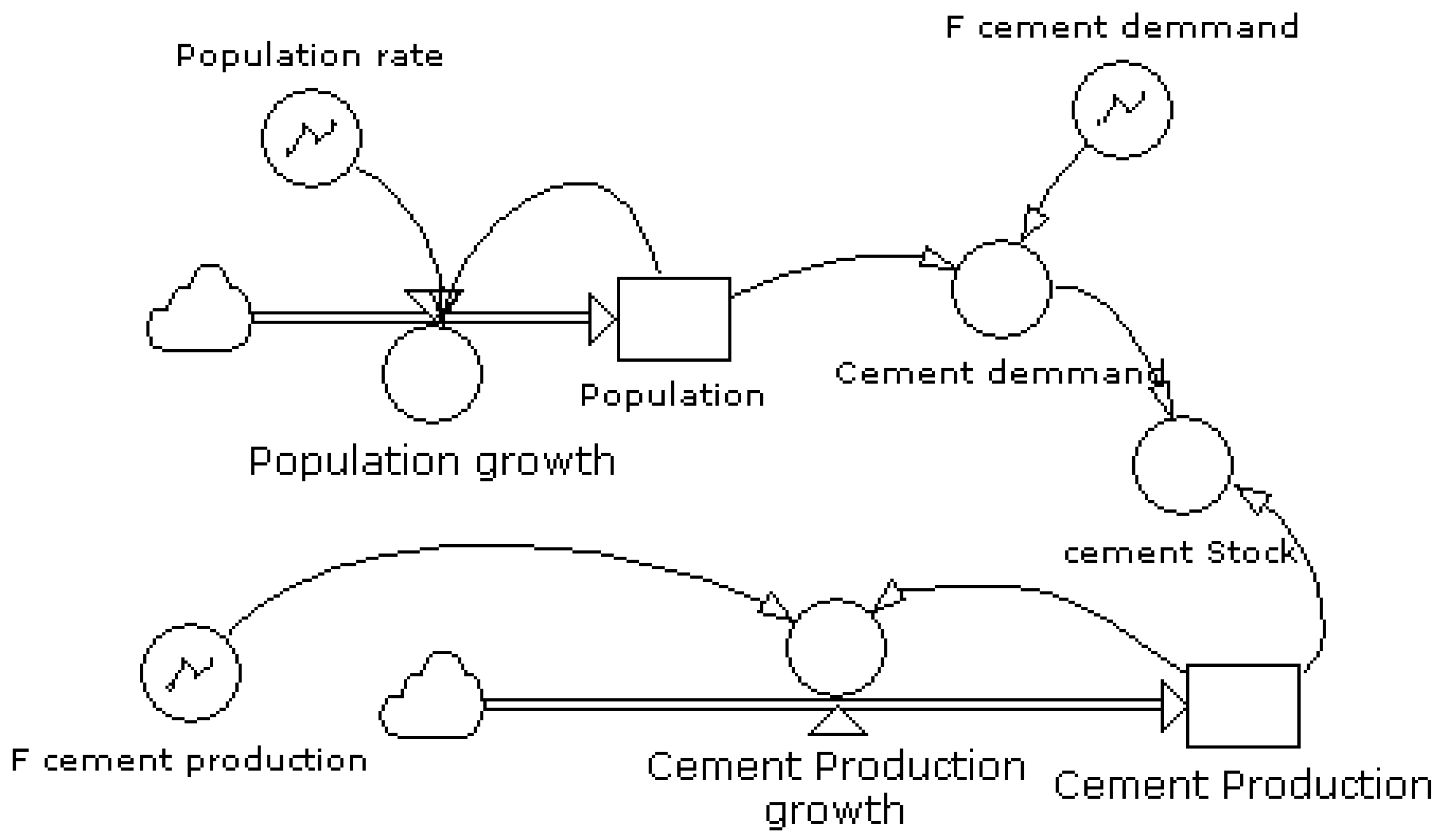

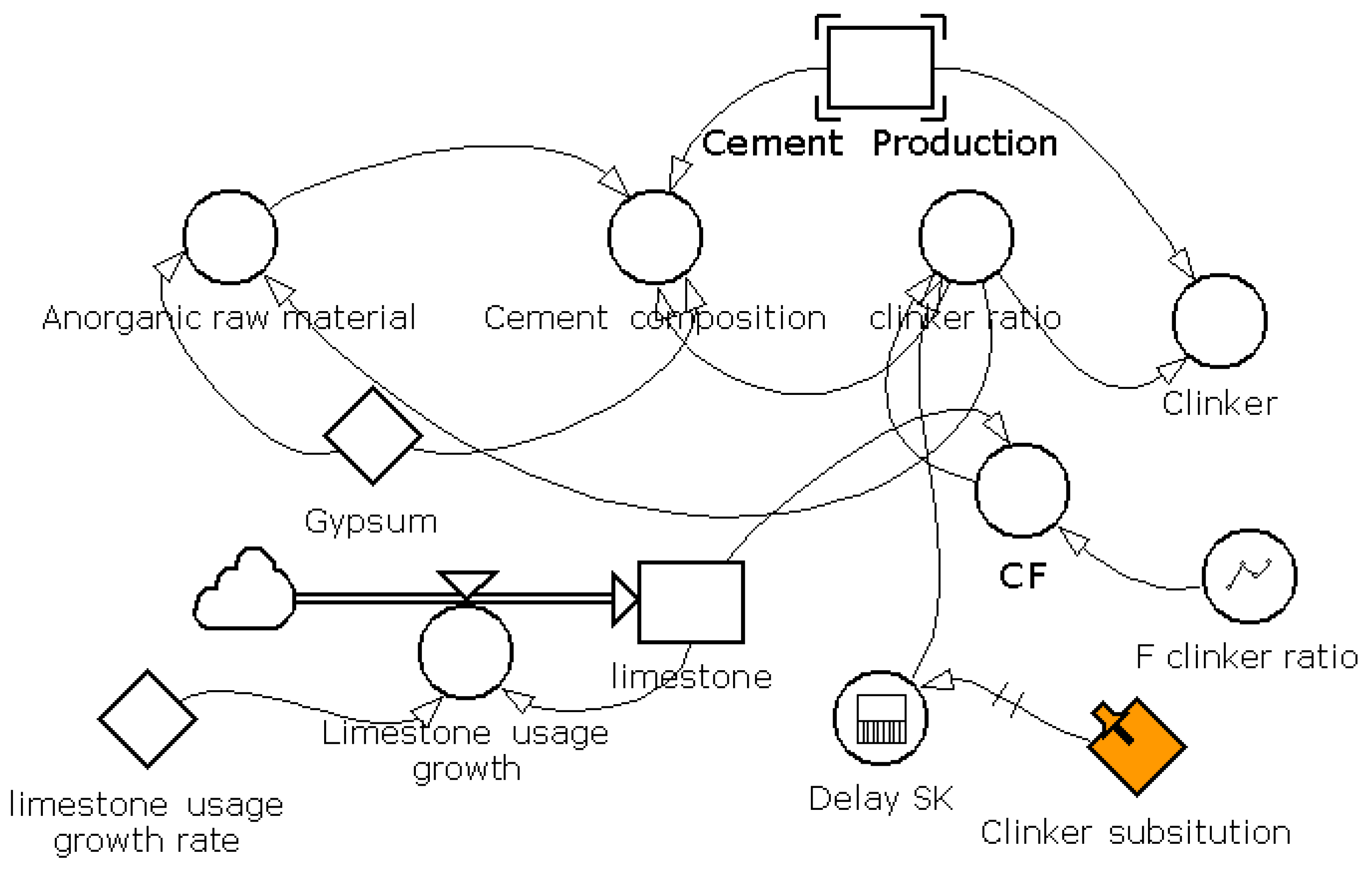

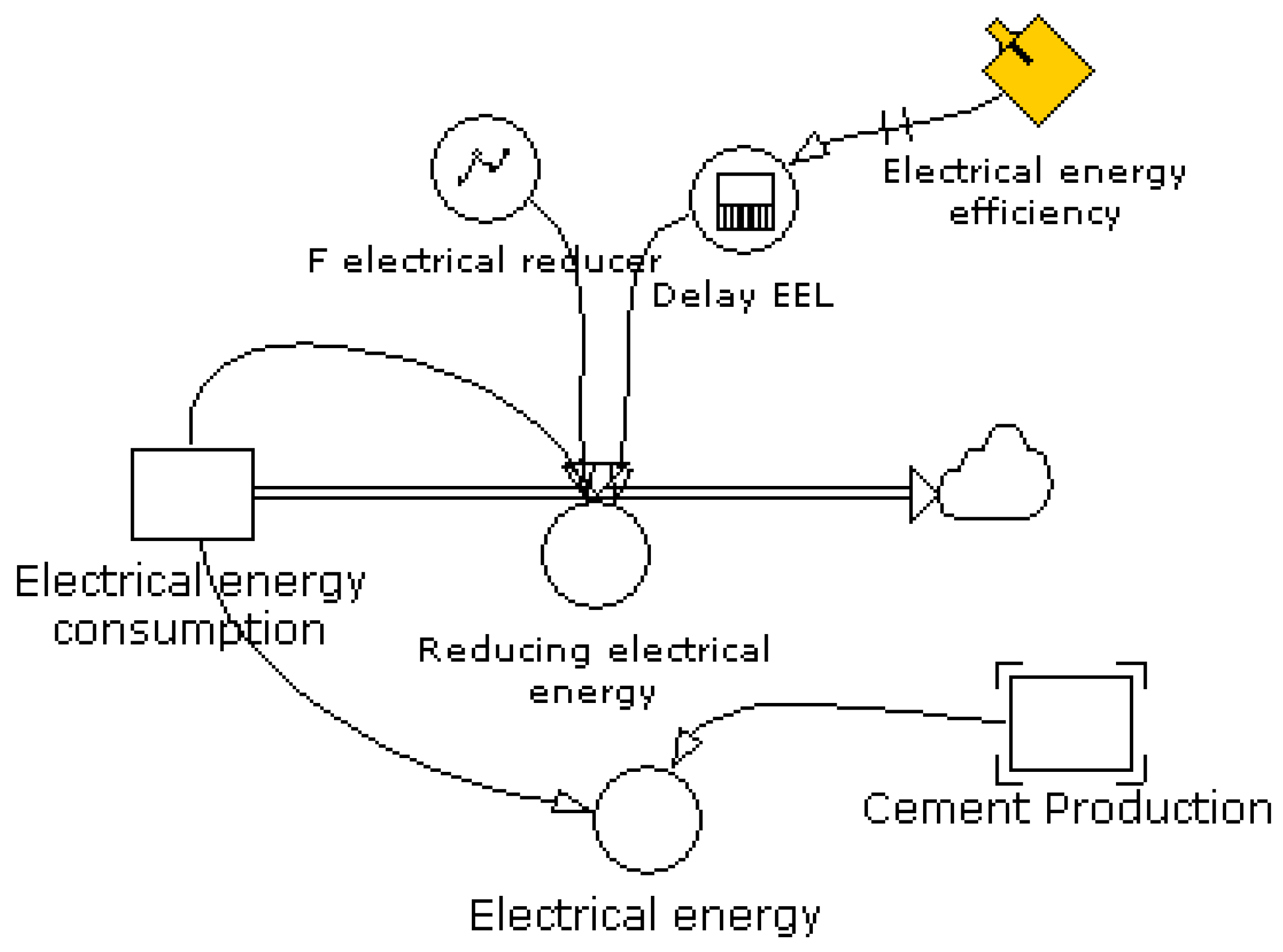

3.2. Stock–Flow Diagram

- Population growth = Population rate × Population

- Population rate = GRAPH (TIME; 2015; 1; {1.138; 1.106; 1.074; 1.041; 1.008//Min: −1; Max: 11//}<<%/year>>)

- auxiliary of F cement demand is cement demand (tons) per person from 2015–2020 [27].

- F cement demand = GRAPH (TIME; 2015; 1; {0.24189; 0.23766; 0.25820; 0.26909; 0.26682; 0.23593//Min: −1; Max: 11//}<<Ton/person>>)

- Cement production growth = F cement production × cement production

- F cement production = GRAPH (TIME; 2015; 1; {1535; 11,516; 5191; 1667; −9888; 2468 //Min: −1; Max:11//}<<%/year>>)

- Clinker = ‘Cement Production’ × ‘clinker ratio’, while clinker ratio and CF depend on the cement composition.

- Clinker Ratio = GRAPH (TIME; 2015; 1; {77.0642094990512; 78.7065471441271; 77.6899699349955; 74.5685259262785; 72.024; 70.6; 70.3; 69.68; 66.7; 65.8; 65.2; 64.6; 64.3; 63.7; 63; 62.5; 62.2; 61.6; 61.3; 61; 60.7; 60.7; 60.35; 59.8; 59.5; 59; 58.6; 58.3; 58; 57.4; 57.4; 57; 56.5; 56;55.3; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55; 55//Min:55; Max:100//}<<%>>)

- Inorganic raw material = 100 <<%>>-(Gypsum + Clinker Ratio)

- Reducing electrical energy = IF (Electrical energy consumption > ‘Delay EEL’; Electrical energy consumption‘ × ’F electrical reducer’)

- Delay EEL = DELAYINF (‘Electrical energy effiency’; 10; 1; 83 <<Kwh/Ton>>)

- Electrical energy efficiency = 83 Kwh/Ton (as Constanta)

- F electrical reducer = GRAPH (TIME; 2015; 1; {1.9762; 3.662; 0.9415; 1.2531; 3.8860; 0.5//Min: −1; Max: 11//}<<%>>)

- F Coal = GRAPH (TIME; 2015; 1; {0.363346040669620; 0.370608580457636; 0.381539050451196; 0.388524288490419; 0.403115388984129; 0.423331998151721; 0.424249486175100; 0.475369759565820//Min: −1; Max: 11//})

- TSR = IF (‘Delay BBA’ = 0<<%>>; RDF; ’Delay BBA’)

- RDF = GRAPH (‘RDF raw material; 0 <<Ton>>; 13290570.80<<Ton>>;{20; 27; 33; 37; 42; 88; 54; 59; 65; 70; 76; 82; 93; 106; 115; 123; 132; 139; 147; 154; 160; 166; 169; 173; 177; 181; 186; 190; 195; 199; 203; 207; 214; 220; 227; 233; 238; 242; 248; 250; 253; 259; 263; 266; 270; 274; 276; 283; 287; 293; 298; 300; 300; 300; 300; 300; 300; 300; 300; 300; 300//Min: 20; Max: 300//}<<%>>)

- Delay BBA = DELAYINF (Alternative fuel; 10; 1; 0<<%>>)

- Alternative fuel = 0

- F Waste = 0.26

- Waste = F Waste × Population

- RDF raw material = 0.2× Waste

- Calcination CO2 emission = Clinker × F Calcination CO2 emission

- F Calcination CO2 emission = 678.9640823 kgCO2/ton (as Constanta)

- Electrical CO2 emission = Electrical energy × F CO2 electrical

- F CO2 electrical = 1.05 kgCO2/Kwh (as Constanta)

- TSR CO2 emission = AF × F TSR CO2 emission

- F TSR CO2 emission = 13.12 kgCO2/ton (as Constanta)

- Coal CO2 emission = Coal × F Coal thermal capacity

- F Coal thermal capacity = 234.75 kgCO2/ton (as Constanta)

- Delay CCS = DELAYINF(CCS; 20; 1; 0<<%>>)

3.3. Scenario Generation

- Scenario 1 (BAU) was generated from the existing data of the Indonesian cement industry from 2015 to 2020 and was projected up to 2050 using a system dynamic.

- Scenario 2 from the cement industry association has the following parameters:Table 5. Scenario 2 from cement industry association.

Stakeholder Efforts Values Priorities Scenario 2 Cement industry association Energy Efficiency 0.166 III 92 Kwh/Ton cement Clinker Substitution 0.545 I 54.5% Alternative Fuel 0.174 II 17.4% CCS Technology 0.114 IV 11.4% - Scenario 3 from the research institute has the following parameters (Table 6):Table 6. Scenario 3 from research institute.

Stakeholder Efforts Values Priorities Scenario 3 Research Institute Energy Efficiency 0.098 IV 86.7 Kwh/ton cement Clinker Substitution 0.130 III 63% Alternative Fuel 0.344 II 34% CCS Technology 0.429 I 43% - Scenario 4 from the government and related ministry has the following parameters (Table 7):Table 7. Scenario 4 from the government and related ministry.

Stakeholder Efforts Values Priorities Scenario 4 Govt ministry Energy Efficiency 0.475 I 41.5 Kwh/ton cement Clinker Substitution 0.210 II 71% Alternative Fuel 0.161 III 16% CCS Technology 0.154 IV 15% - Scenario 5 from Environmental NGOs has the following parameters (Table 8):Table 8. Scenario 5 from environmental NGOs.

Stakeholder Effort Value Priority Scenario 5 Environmental NGOs Energy Efficiency 0.177 III 93 Kwh/Ton cement Clinker Substitution 0.124 IV 62.4% Alternative Fuel 0.453 I 45.3% CCS Technology 0.246 II 24.6% - Scenario 6 is the combination of all respondents’ parameters (Table 9).Table 9. Scenario 6 from the combination of all respondents’ parameters.

Stakeholder Efforts Values Priorities Scenario 6 Combine Energy Efficiency 0.206 III 95 Kwh/Ton cement Clinker Substitution 0.405 I 59.5% Alternative Fuel 0.225 II 22.5% CCS Technology 0.165 IV 16.5% - Scenario 7 is the parameters referenced from IEA and Paris agreement trackers (Table 10).Table 10. Scenario 7 from IEA and Paris agreement trackers reference.

Stakeholder Efforts Values Priorities Scenario 7 IEA reference Energy Efficiency 0.177 III 79 Kwh/Ton cement Clinker Substitution 0.124 IV 50% Alternative Fuel 0.453 I 65% CCS Technology 0.246 II 60%

3.4. Model Validation

- Si = Si N, where S = simulation result

- Ai = Ai N, where A = actual data

- N = time interval

| Year | Emission (kg CO2/ton Cement) | AME (%) | |

|---|---|---|---|

| Ministry of Industry Data | Simulation Data | ||

| 2015 | 674.89 | 672.15 | 0.41 |

| 2016 | 687.87 | 683.31 | 0.66 |

| 2017 | 691.02 | 673.58 | 2.52 |

| 2018 | 668.16 | 659.29 | 1.33 |

| 2019 | 646.09 | 631.91 | 2.20 |

| 2020 | 641.46 | 620.08 | 3.33 |

| Mean | 666.92 | 653.63 | 2.01 |

4. Result and Discussion

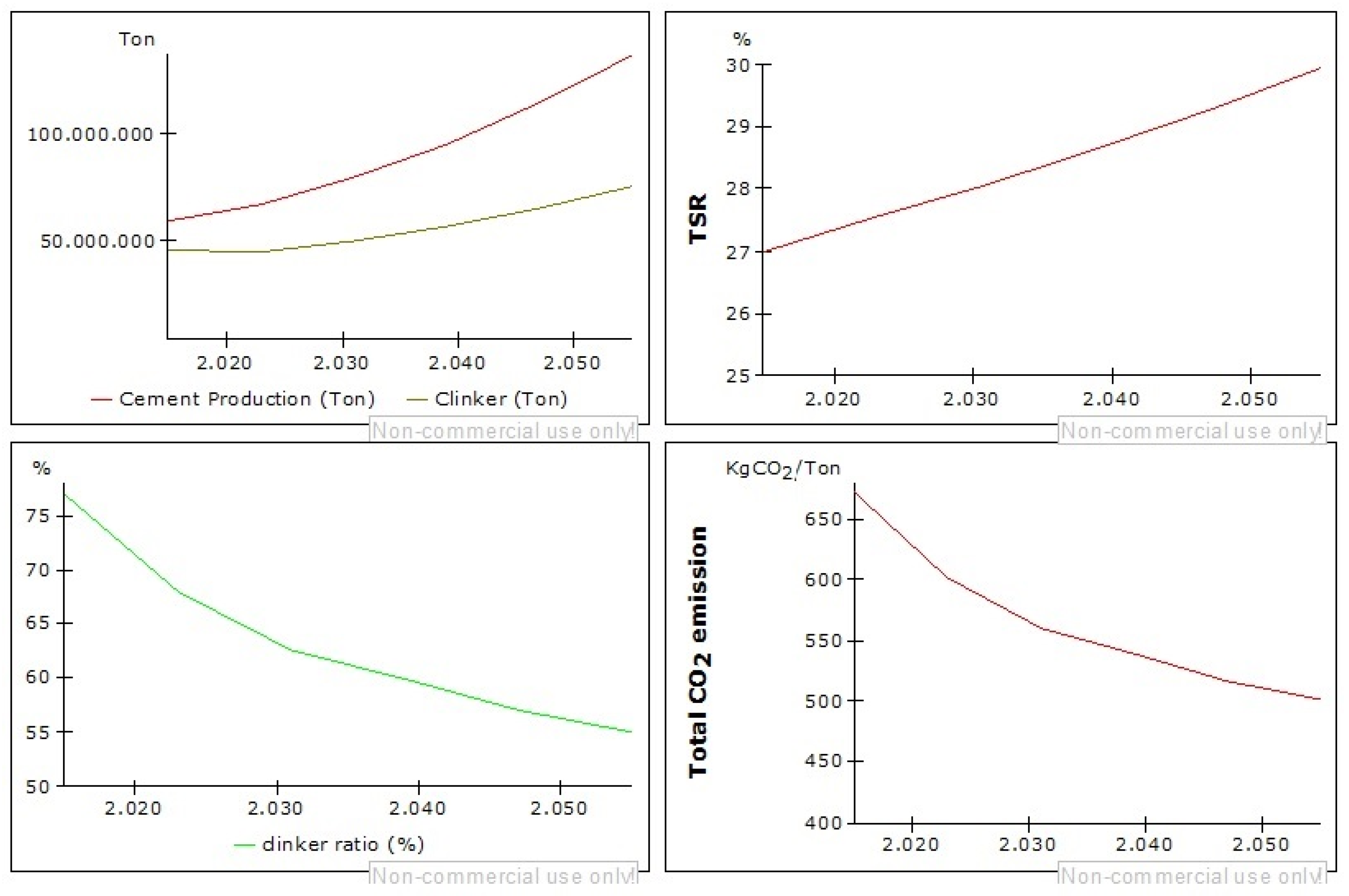

4.1. Baseline or Business as Usual (BAU) Scenario

4.2. Modified Scenarios

5. Conclusions and Policy Implementation

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Statista. Available online: https://www.statista.com/statistics/746354/domestic-cement-consumption-indonesia/ (accessed on 12 September 2022).

- Güereca, L.P.; Torres, N.; Juárez-López, C.R. The co-processing of municipal waste in a cement kiln in Mexico. A life-cycle assessment approach. J. Clean. Prod. 2015, 107, 741–748. [Google Scholar] [CrossRef]

- Harjanto, T.R.; Fahrurrozi, M.; Bendiyasa, I.M. Life Cycle Assessment Cement Plant PT Holcim Indonesia Tbk. Pabrik Cilacap: Coal fuel Compare with Biomass. J. Rekayasa Proses 2014, 6, 51–58. [Google Scholar]

- Wen, L.; Bai, L.; Zhang, E. System dynamic modeling and scenario simulation on Beijing industrial carbon emissions. Environ. Eng. Res. 2016, 21, 355–364. [Google Scholar] [CrossRef]

- McKinsey. Laying the Foundation for a Zero-Carbon Cement Industry. 2017, pp. 1–9. Available online: https://www.mckinsey.com/industries/chemicals/our-insights/laying-the-foundation-for-zero-carbon-cement (accessed on 12 September 2022).

- International Energy Agency. Technology Roadmap Low-Carbon Transition in the Cement Industry. Available online: https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 27 September 2022).

- Kemenperin. Indonesia Industrial Minister No. 12. JDIH. 2012. Available online: http://jdih.kemenperin.go.id/site/peraturan/7/2012/50/ (accessed on 27 September 2022).

- Kementerian Lingkungan Hidup dan Kehutanan (KLHK). Indonesia Long-Term Strategy for Low Carbon and Climate Resilience 2050 (Indonesia LTS-LCCR 2050). 2021. Available online: https://unfccc.int/sites/default/files/resource/Indonesia_LTS-LCCR_2021.pdf/ (accessed on 12 September 2022).

- Kementerian Lingkungan Hidup dan Kehutanan (KLHK). Indonesia Green House Gases Inventory Report and Monitoring, Reporting, Verification Year 2018. 2019. Available online: https://ditjenppi.menlhk.go.id/reddplus/images/adminppi/dokumen/igrk/lapigrkmrv2018.pdf (accessed on 27 September 2022).

- Ppkl, D.; KLHK, I. Perdirjen PPKL P15 Amendment to Perdirjen PPKL P17 Regarding Benchmarking for the Cement Industry Sector. 2021. Available online: https://ppkl.menlhk.go.id/website/index.php?q=637&s=88a9d5a83b2b7e4bc74200cc205858df88a90f44/ (accessed on 27 September 2022).

- Climate Action Tracker. Elaborating the Decarbonization Roadmap Climate Action Tracker. Available online: https://climateactiontracker.org/data-portal (accessed on 27 September 2022).

- Climate Action Taker. Paris Agreement Compatible Sectoral Benchmarks Elaborating the Decarbonisation Roadmap. 2020. Available online: https://climateactiontracker.org/data-portal (accessed on 27 September 2022).

- Xu, J.H.; Fleiter, T.; Fan, Y.; Eichhammer, W. CO2 emissions reduction potential in China’s cement industry compared to IEA’s Cement Technology Roadmap up to 2050. Appl. Energy 2014, 130, 592–602. [Google Scholar] [CrossRef]

- Zuraiqi, K.; Zavabeti, A.; Clarke-Hannaford, J.; Murdoch, B.J.; Shah, K.; Spencer, M.J.S.; McConville, C.F.; Daeneke, T.; Chiang, K. Direct conversion of CO2 to solid carbon by Ga-based liquid metals. Energy Environ. Sci. 2022, 15, 595–600. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Z.; Liu, R.; Tang, M.; Wu, F. Can China achieve its CO2 emission mitigation target in 2030: A system dynamics perspective. Pol. J. Environ. Stud. 2018, 27, 2861–2872. [Google Scholar] [CrossRef] [PubMed]

- Obrist, M.D.; Kannan, R.; Schmidt, T.J.; Kober, T. Decarbonization pathways of the Swiss cement industry towards net zero emissions. J. Clean. Prod. 2021, 288, 125413. [Google Scholar] [CrossRef]

- Bataille, C.; Åhman, M.; Neuhoff, K.; Nilsson, L.J.; Fischedick, M.; Lechtenböhmer, S.; Solano-Rodriquez, B.; Denis-Ryan, A.; Stiebert, S.; Waisman, H.; et al. A review of technology and policy deep decarbonization pathway options for making energy-intensive industry production consistent with the Paris Agreement. J. Clean. Prod. 2018, 187, 960–973. [Google Scholar] [CrossRef]

- The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete. GCCA: London, UK, 2021. Available online: https://gccassociation.org/concretefuture/wp-content/uploads/2021/10/GCCA-Concrete-Future-Roadmap-Document-AW.pdf (accessed on 28 August 2022).

- Suryanto, A.A. Application of mean absolute error (mea) method in linear regression algorithm for rice production prediction. SAINTEKBU 2019, 11, 78–83. [Google Scholar] [CrossRef]

- Saaty, T.L. The modern science of multicriteria decision making and its practical applications: The AHP/ANP approach. Oper. Res. 2013, 61, 1101–1118. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making with the Analytic Hierarchy Process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Prakoso, A.B.; Negoro, N. Analisa Strategi Pemasaran Produk Kosmetik Wardah dengan Pendekatan SWOT-AHP (Analytic Hierarchy Process). J. Sains Seni ITS 2017, 6, 62–67. [Google Scholar]

- Anand, S.; Vrat, P.; Dahiya, R.P. Application of a system dynamics approach for assessment and mitigation of CO2 emissions from the cement industry. J. Environ. Manag. 2006, 79, 383–398. [Google Scholar] [CrossRef] [PubMed]

- Jokar, Z.; Mokhtar, A. Policy making in the cement industry for CO2 mitigation on the pathway of sustainable development—A system dynamics approach. J. Clean. Prod. 2018, 201, 142–155. [Google Scholar] [CrossRef]

- Ansari, N.; Seifi, A. A system dynamics model for analyzing energy consumption and CO2 emission in Iranian cement industry under various production and export scenarios. Energy Policy 2013, 58, 75–89. [Google Scholar] [CrossRef]

- BPS. Indonesia Statistic Bureau (Badan Pusat Statistik Indonesia). 2021. Available online: https://www.bps.go.id/indicator/12/1976/3/laju-pertumbuhan-penduduk.html (accessed on 27 September 2022).

- [ASI] Cement Association Indonesia Cement Statistic, Yearly Book. 2020. Available online: https://asi.or.id/upaya-industri-semen-dalam-pengendalian-emisi-gas-rumah-kaca/ (accessed on 12 September 2022).

- Agliata, R.; Marino, A.; Mollo, L.; Pariso, P. Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster—A Case Study. Sustainability 2020, 12, 4620. [Google Scholar] [CrossRef]

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Challenges against CO2 abatement strategies in cement industry: A review. J. Environ. Sci. 2021, 104, 84–101. [Google Scholar] [CrossRef] [PubMed]

- Farfan, J.; Fasihi, M.; Breyer, C. Trends in the global cement industry and opportunities for long-term sustainable CCU potential for Power-to-X. J. Clean. Prod. 2019, 217, 821–835. [Google Scholar] [CrossRef]

- Kajaste, R.; Hurme, M. Cement industry greenhouse gas emissions—Management options and abatement cost. J. Clean. Prod. 2016, 112, 4041–4052. [Google Scholar] [CrossRef]

| Stakeholder | Interest Focus |

|---|---|

| Ministry of Industry | Policy/Regulator |

| Ministry of Forestry and Environment | Policy/Regulator |

| Cement Industry | Implementation of reduction efforts |

| Cement Association | Coordination of cement industry members as an effort to reduce CO2 emissions |

| Research Institute | R&D new technology |

| Environmental NGOs | Control over policies and implementation of CO2 reduction efforts |

| Stakeholder | Goal | Efforts | Values | Priorities |

| Cement Industry Association (1 respondent) | To reduce CO2 emissions in the Indonesian cement industry | Energy Efficiency | 0.166 | III |

| Clinker Substitution | 0.545 | I | ||

| Alternative Fuel | 0.174 | II | ||

| CCS Technology | 0.114 | IV | ||

| Stakeholder | GOAL | Efforts | Values | Priorities |

| Research Institute (3 respondents) | To reduce CO2 emissions in the Indonesian cement industry | Energy Efficiency | 0.098 | IV |

| Clinker Substitution | 0.130 | III | ||

| Alternative Fuel | 0.344 | II | ||

| CCS Technology | 0.429 | I | ||

| Stakeholder | GOAL | Efforts | Values | Priorities |

| Govt ministry (2 respondents) | To reduce CO2 emissions in the Indonesian cement industry | Energy Efficiency | 0.475 | I |

| Clinker Substitution | 0.210 | II | ||

| Alternative Fuel | 0.161 | III | ||

| CCS Technology | 0.154 | IV | ||

| Stakeholder | GOAL | Efforts | Values | Priorities |

| Environmental NGO’s (2 respondents) | To reduce CO2 emissions in the Indonesian cement industry | Energy Efficiency | 0.177 | III |

| Clinker Substitution | 0.124 | IV | ||

| Alternative Fuel | 0.453 | I | ||

| CCS Technology | 0.246 | II | ||

| Stakeholders | GOAL | Efforts | Value | Priorities |

| Cement Industry (16 respondents) | To reduce CO2 emissions in the Indonesian cement industry | Energy Efficiency | 0.166 | III |

| Clinker Substitution | 0.545 | I | ||

| Alternative Fuel | 0.174 | II | ||

| CCS Technology | 0.114 | IV |

| Stakeholder | Goal | Efforts | Values | Priorities |

|---|---|---|---|---|

| Combined | To reduce CO2 emissions in the Indonesian cement industry | Energy Efficiency | 0.206 | III |

| Clinker Substitution | 0.405 | I | ||

| Alternative Fuel | 0.225 | II | ||

| CCS Technology | 0.165 | IV |

| Pairwise Comparison | CR | Remarks |

|---|---|---|

| Between Criteria (level 1) | 0.04 | Consistent |

| Between subcriteria energy | 0.09 | Consistent |

| Between subcriteria raw material | 0.07 | Consistent |

| Between subcriteria waste | 0.07 | Consistent |

| Between subcriteria technology | 0.07 | Consistent |

| Between subcriteria energy management | 0.07 | Consistent |

| Between subcriteria low energy equipment | 0.05 | Consistent |

| Between subcriteria recent cement technology | 0.07 | Consistent |

| Between subcriteria energy leaking prevention | 0.07 | Consistent |

| Between subcriteria utilization of low clinker cement product | 0.07 | Consistent |

| Between subcriteria regulation and standardization for low-carbon concrete | 0.07 | Consistent |

| Between subcriteria R&D for low clinker cement product | 0.07 | Consistent |

| Between subcriteria circular economy | 0.07 | Consistent |

| Between subcriteria waste co-processing | 0.07 | Consistent |

| Between subcriteria flexible waste regulation | 0.07 | Consistent |

| Between subcriteria community education for waste management | 0.07 | Consistent |

| Between subcriteria caloric value waste | 0.05 | Consistent |

| Between subcriteria low carbon cement product | 0.06 | Consistent |

| Between subcriteria CCS technology integration with the cement process | 0.06 | Consistent |

| Between subcriteria R&D for CCS technology | 0.06 | Consistent |

| Year | Net Specific kg CO2 Emission per ton Cementitious | Specific Power Consumption (kwh/ton Cement) | Specific Heat Consumption (MJ/ton Clinker) | Clinker Ratio (%) | Alternative Fuel Usage (%) |

|---|---|---|---|---|---|

| Total | |||||

| 2015 | 674.89 | 95.43 | 3506.58 | 77.06 | 3.43 |

| 2016 | 687.87 | 97.32 | 3460.95 | 78.71 | 3.53 |

| 2017 | 691.02 | 93.75 | 3465.22 | 77.69 | 2.50 |

| 2018 | 668.16 | 92.87 | 3447.32 | 74.57 | 3.16 |

| 2019 | 646.09 | 94.03 | 3436.23 | 72.02 | 3.47 |

| 2020 | 641.46 | 90.38 | 3428.54 | 70.23 | 3.70 |

| No | Respondents | Scenarios | CO2 Emissions in 2050 (kg CO2eq/ton Cement) | A Reduced Percentage from Baseline by 2050 |

|---|---|---|---|---|

| 1 | BAU | 1 | 506 | 21% |

| 2 | Cement Industry association | 2 | 470 | 24% |

| 3 | Research Institute | 3 | 350 | 43% |

| 4 | Govt ministry | 4 | 510 | 18% |

| 5 | Environmental NGOs | 5 | 420 | 32% |

| 6 | Combine | 6 | 450 | 27% |

| 7 | Reference | 7 | 255 | 75% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junianto, I.; Sunardi; Sumiarsa, D. The Possibility of Achieving Zero CO2 Emission in the Indonesian Cement Industry by 2050: A Stakeholder System Dynamic Perspective. Sustainability 2023, 15, 6085. https://doi.org/10.3390/su15076085

Junianto I, Sunardi, Sumiarsa D. The Possibility of Achieving Zero CO2 Emission in the Indonesian Cement Industry by 2050: A Stakeholder System Dynamic Perspective. Sustainability. 2023; 15(7):6085. https://doi.org/10.3390/su15076085

Chicago/Turabian StyleJunianto, Iman, Sunardi, and Dadan Sumiarsa. 2023. "The Possibility of Achieving Zero CO2 Emission in the Indonesian Cement Industry by 2050: A Stakeholder System Dynamic Perspective" Sustainability 15, no. 7: 6085. https://doi.org/10.3390/su15076085

APA StyleJunianto, I., Sunardi, & Sumiarsa, D. (2023). The Possibility of Achieving Zero CO2 Emission in the Indonesian Cement Industry by 2050: A Stakeholder System Dynamic Perspective. Sustainability, 15(7), 6085. https://doi.org/10.3390/su15076085