Experimental Study on the Mechanical Behavior of Sandy Soil Reinforced by Disposable Face Mask Chips under Different Stress Paths

Abstract

1. Introduction

2. Materials and Methods

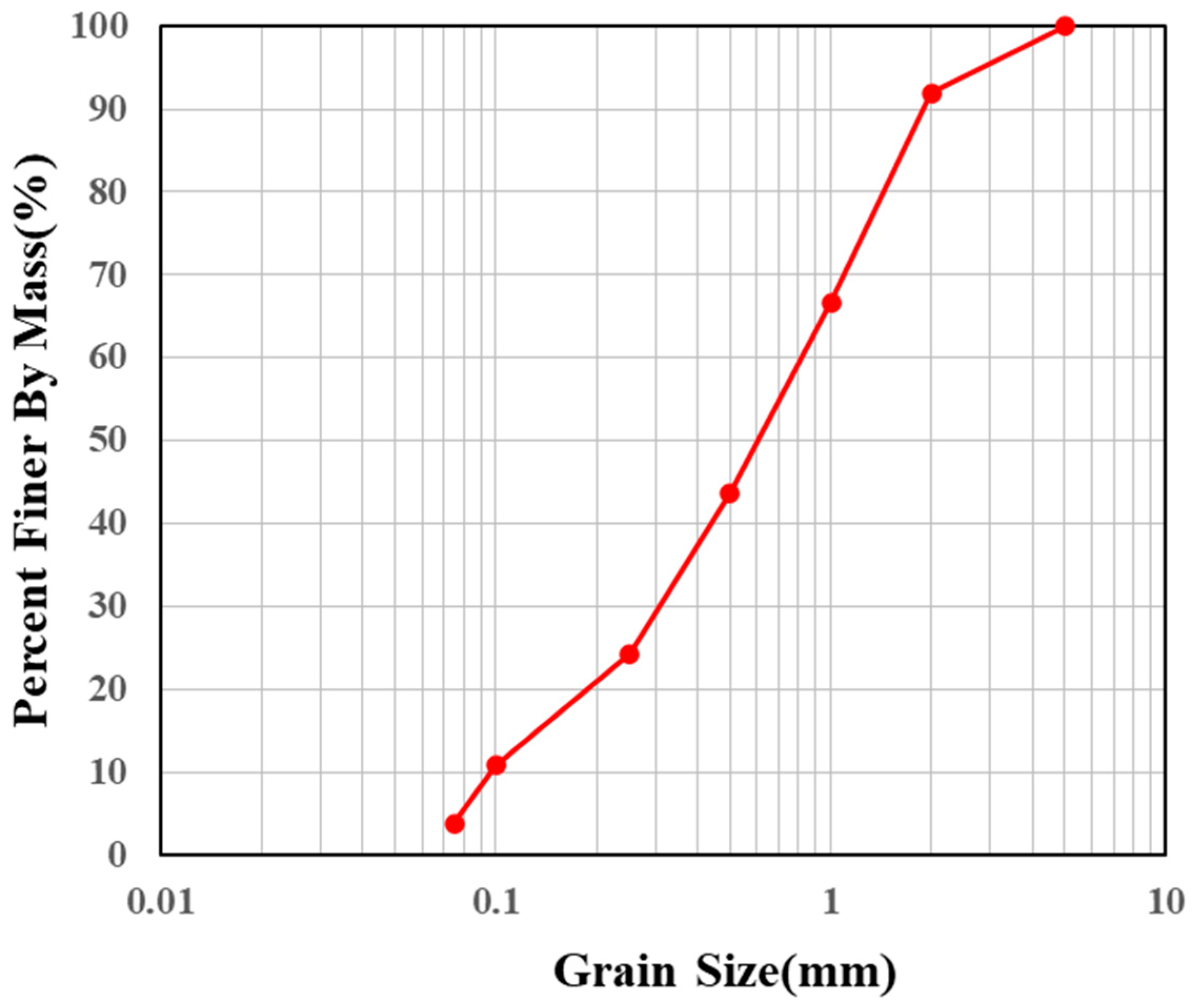

2.1. Tested Materials

2.2. Sample Preparation

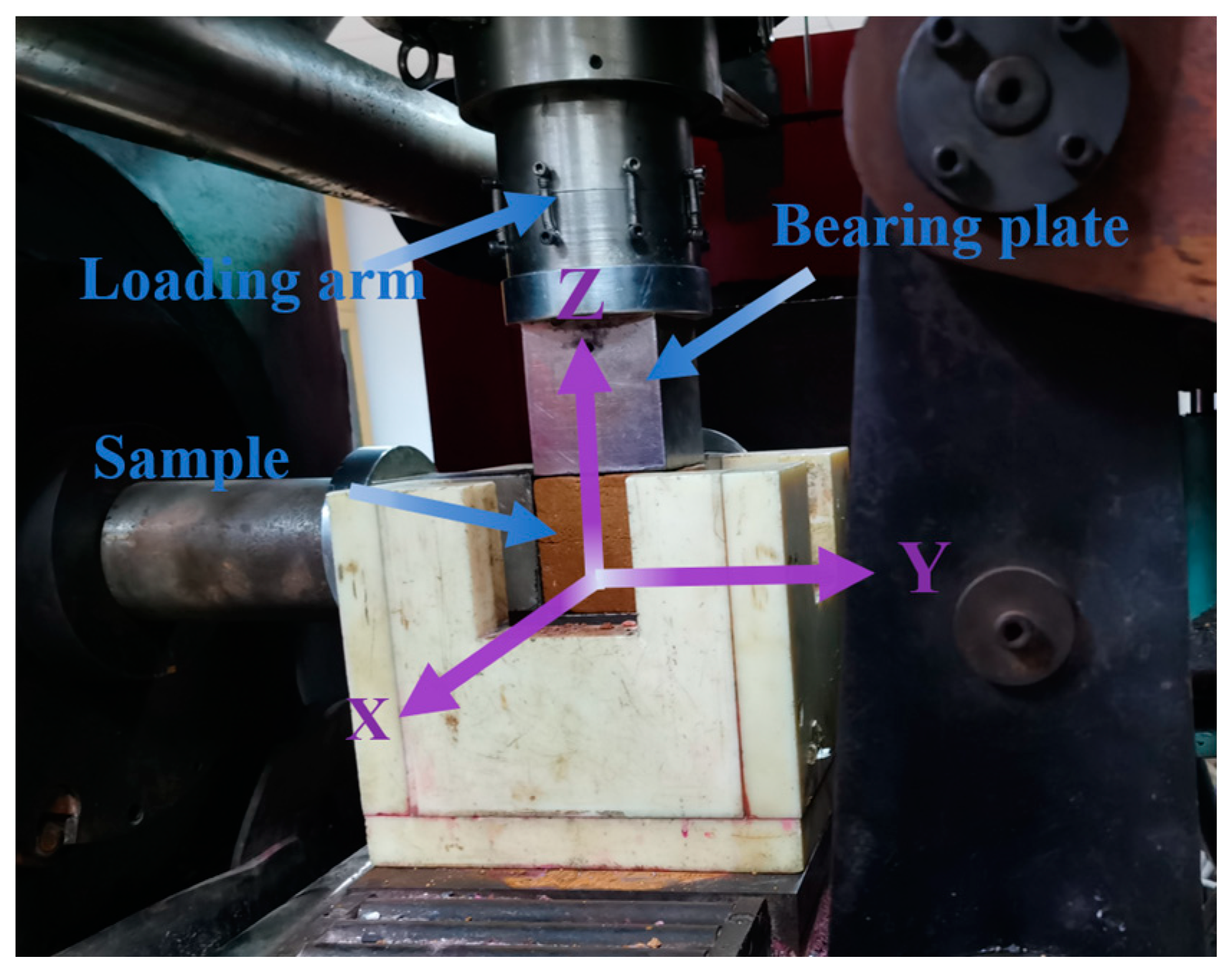

2.3. Testing System

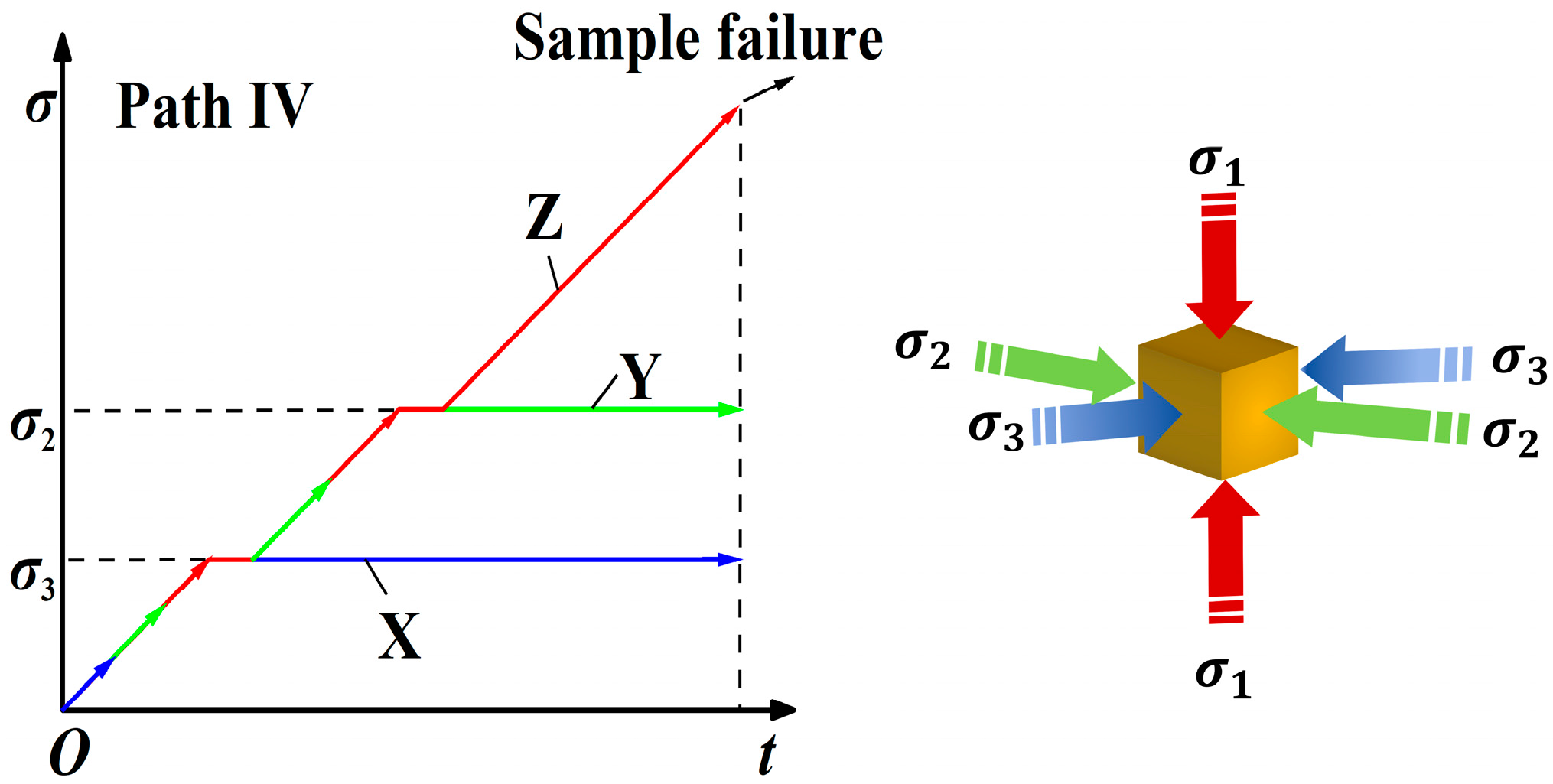

2.4. Testing Procedure

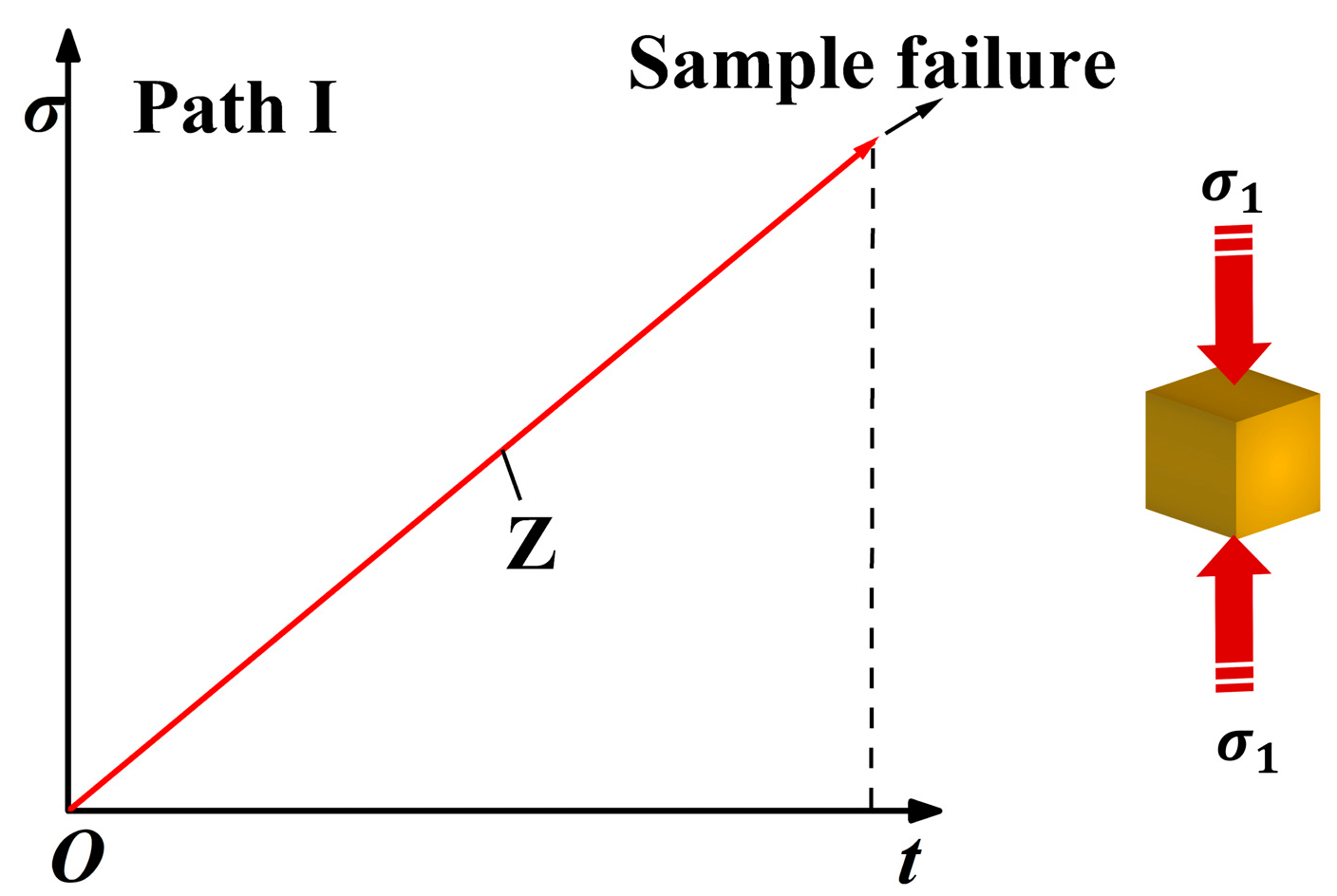

- (1)

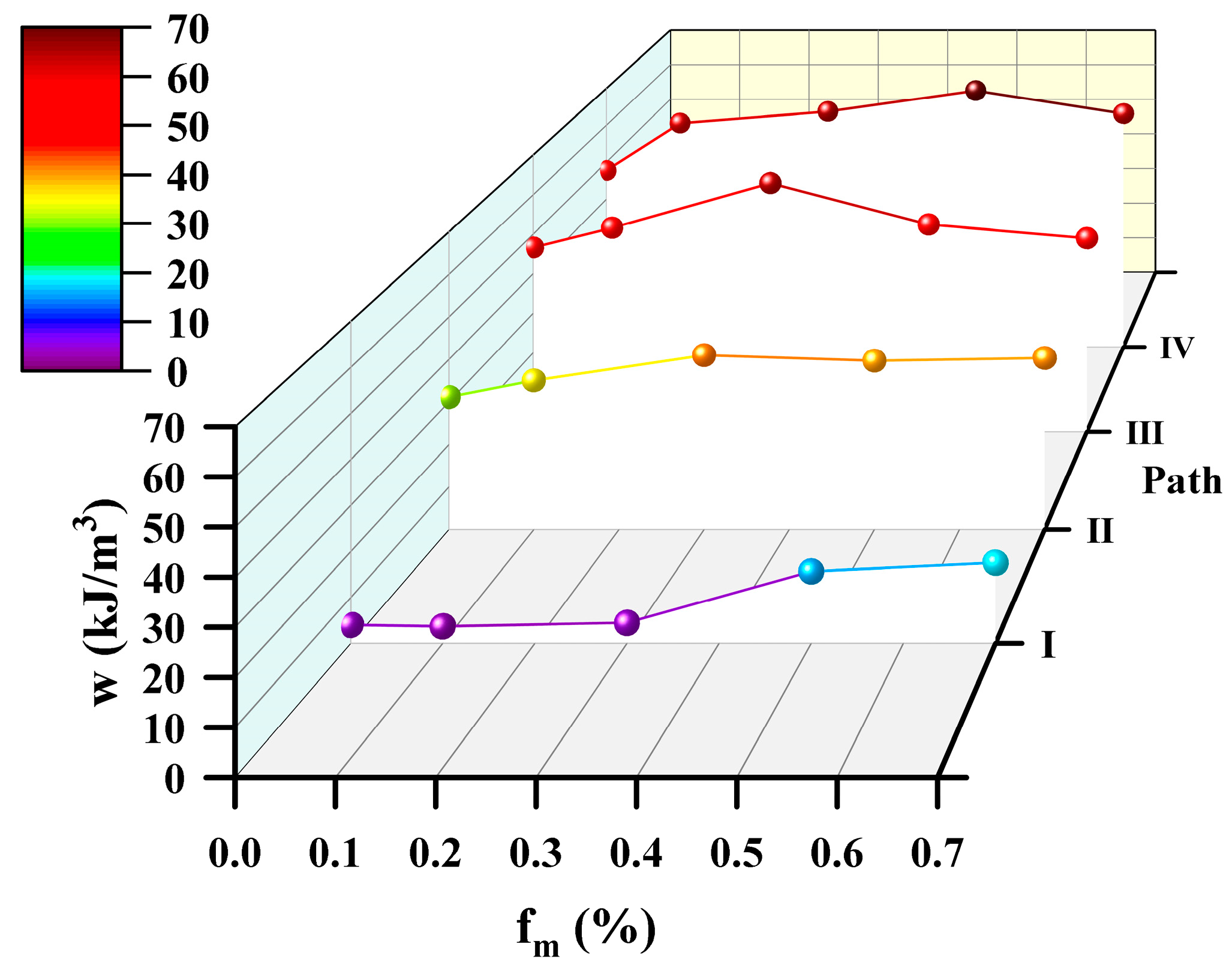

- Path I: uniaxial stress path

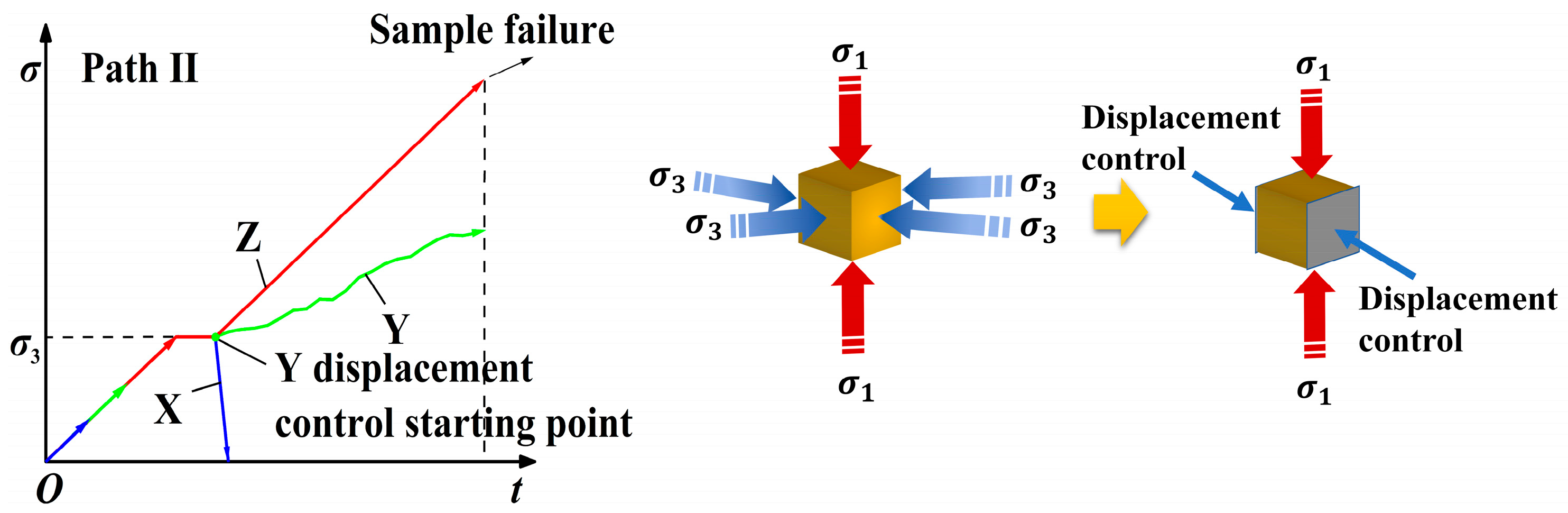

- (2)

- Path II: biaxial stress path

- (3)

- Path III: conventional triaxial stress path

- (4)

- Path IV: true triaxial stress path

3. Results and Discussion

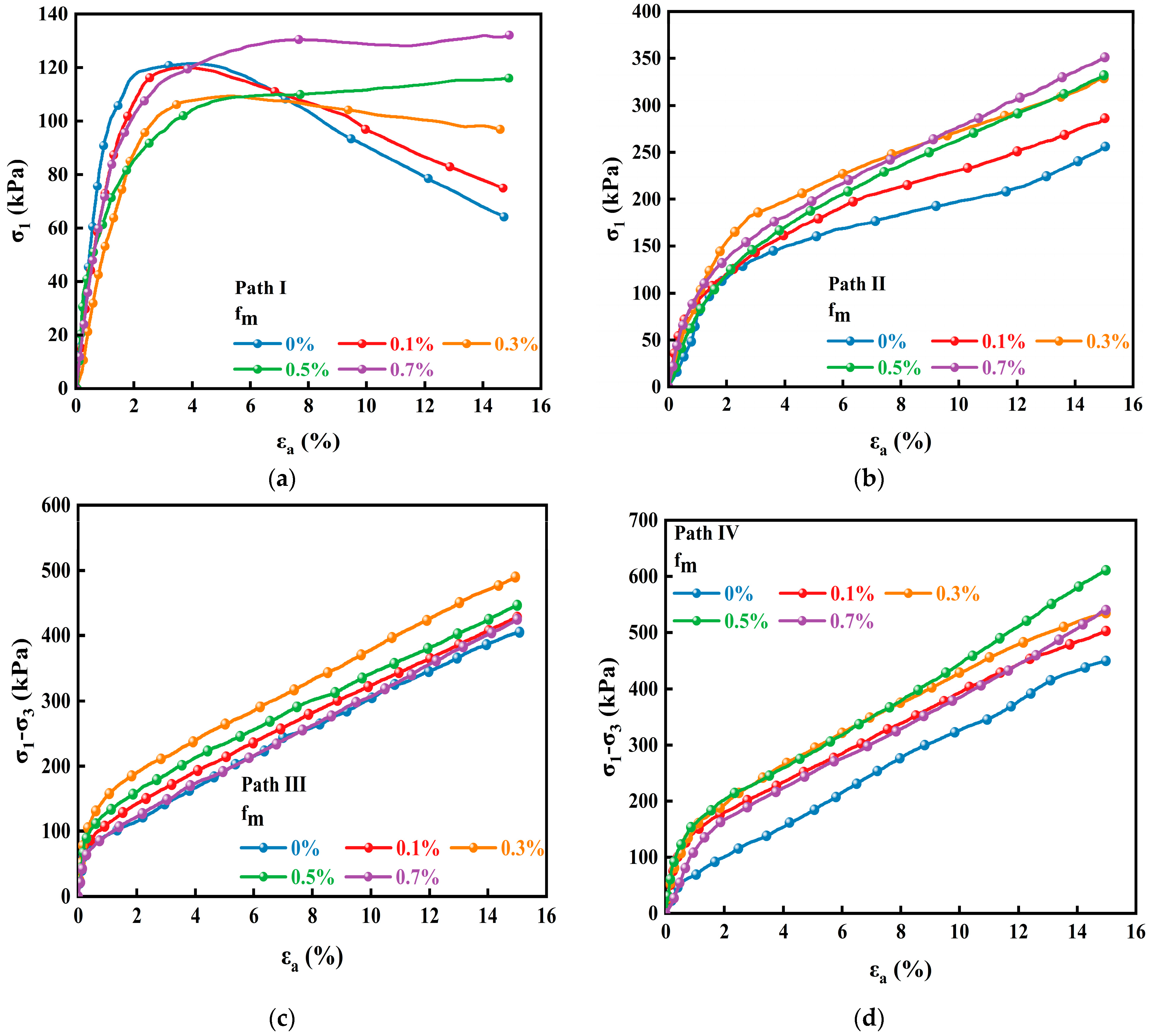

3.1. Stress–Strain Behavior

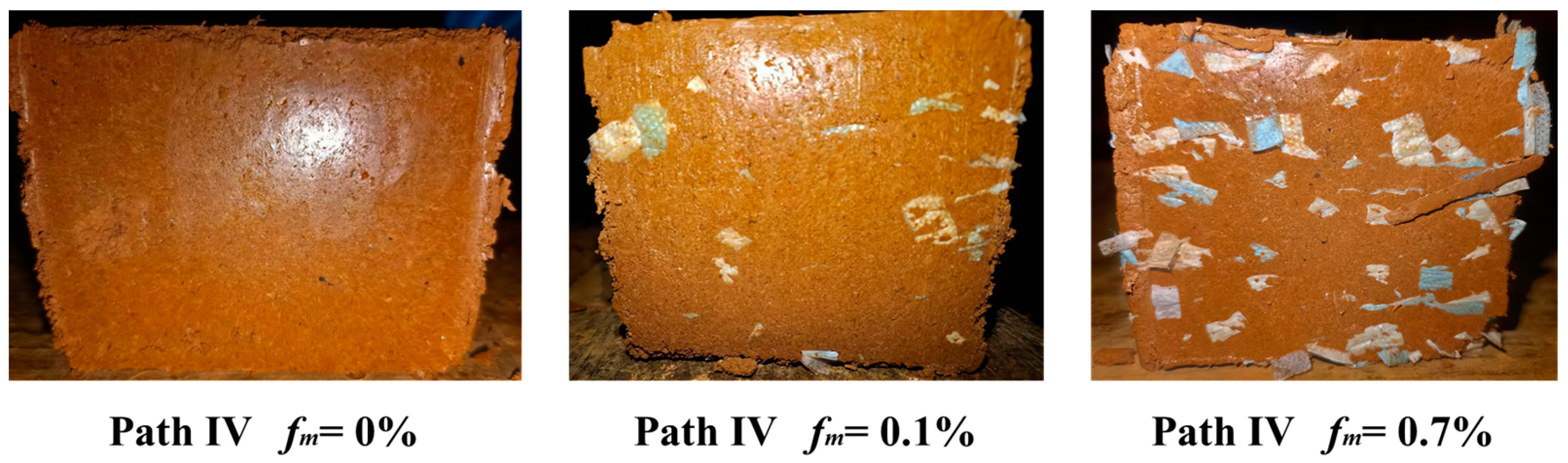

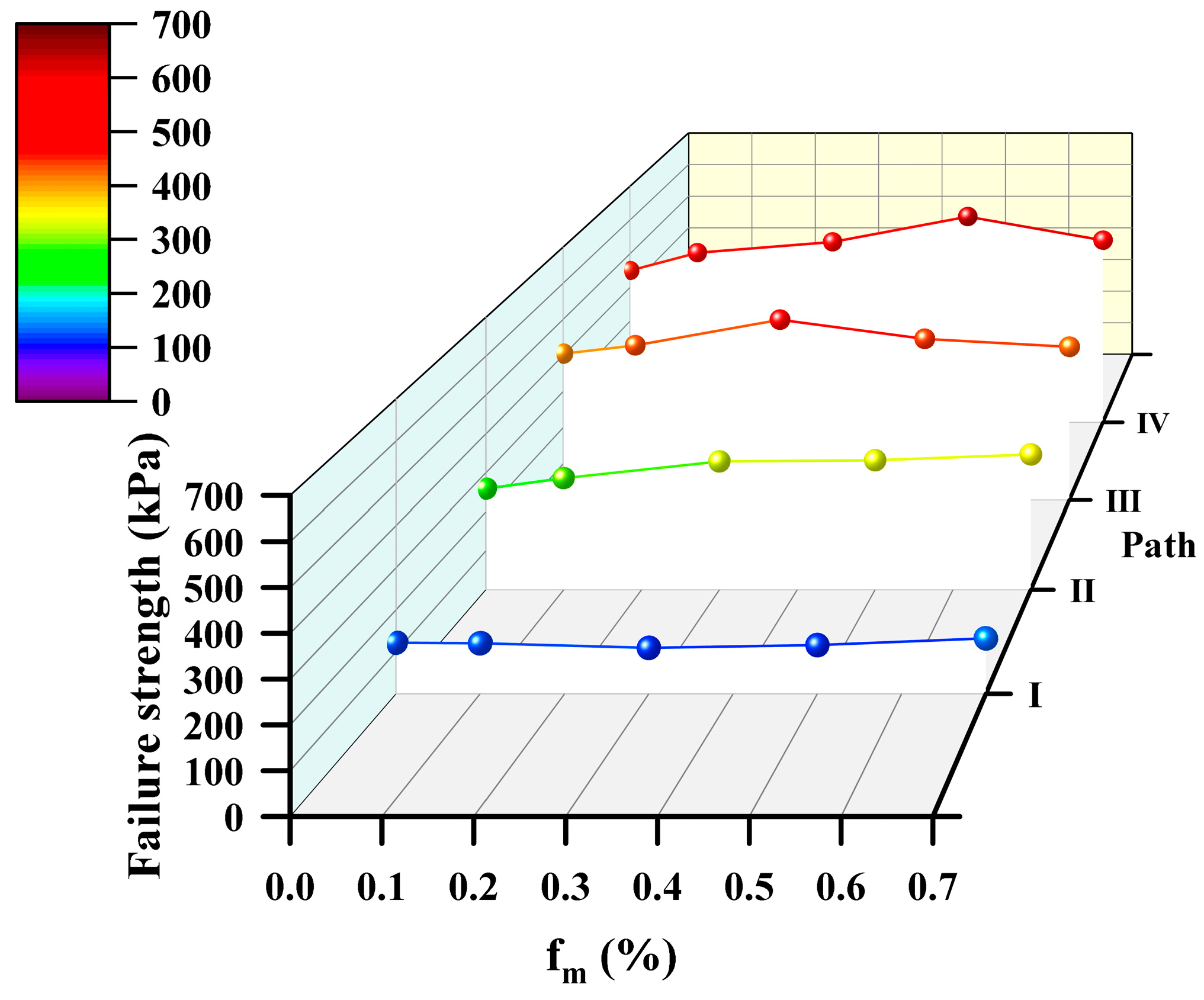

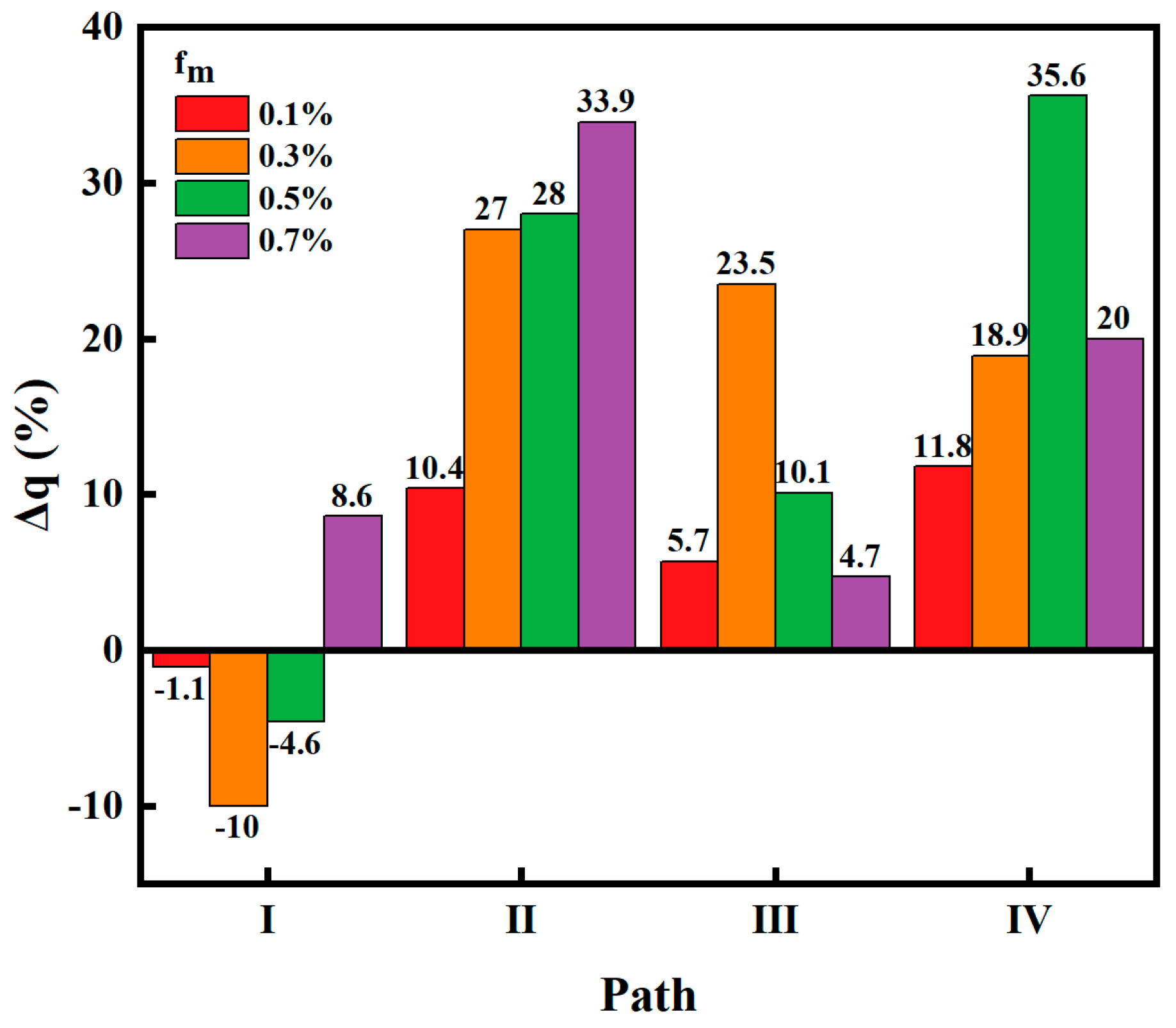

3.2. Failure Strength

3.3. Elastic Modulus

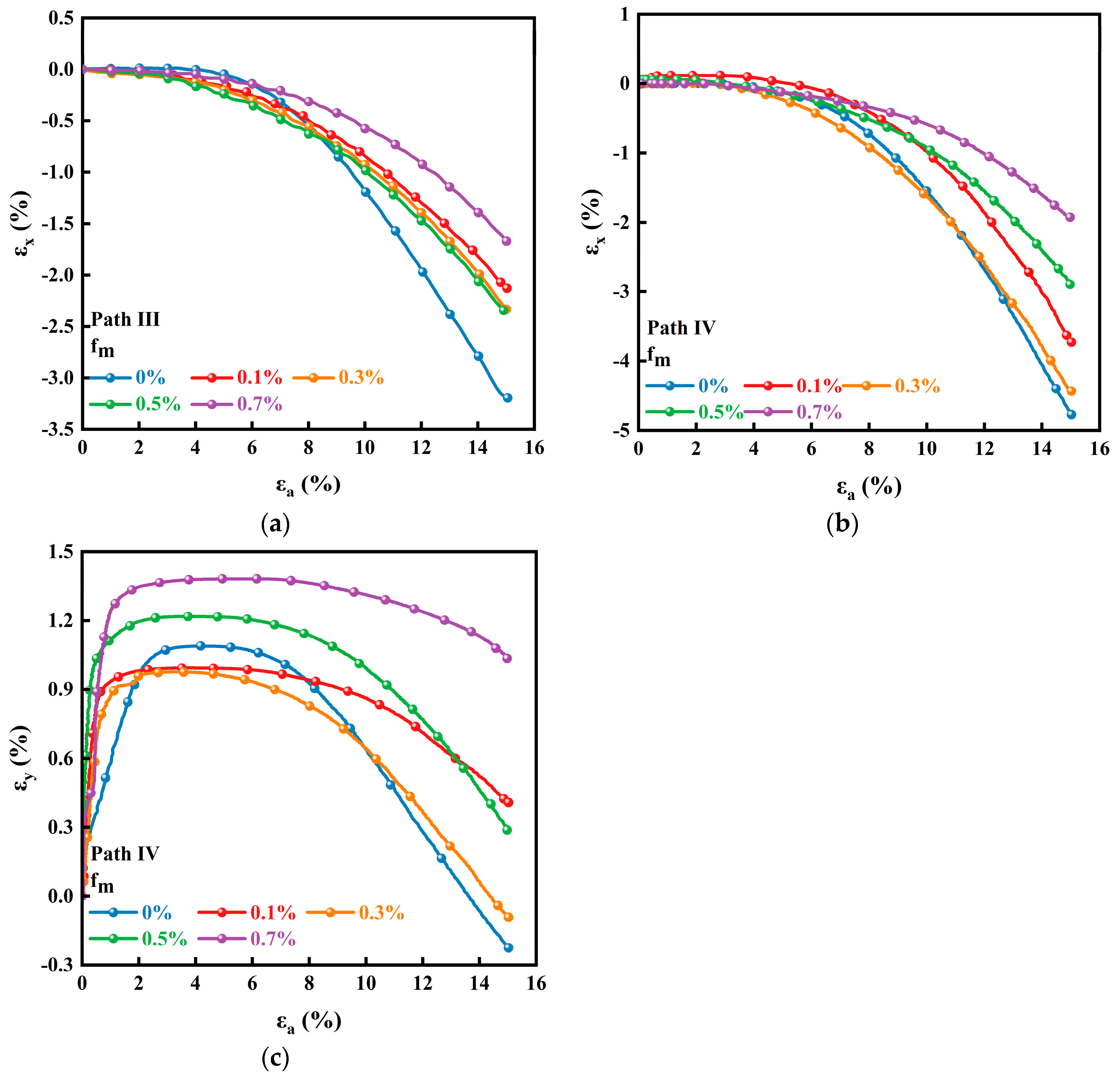

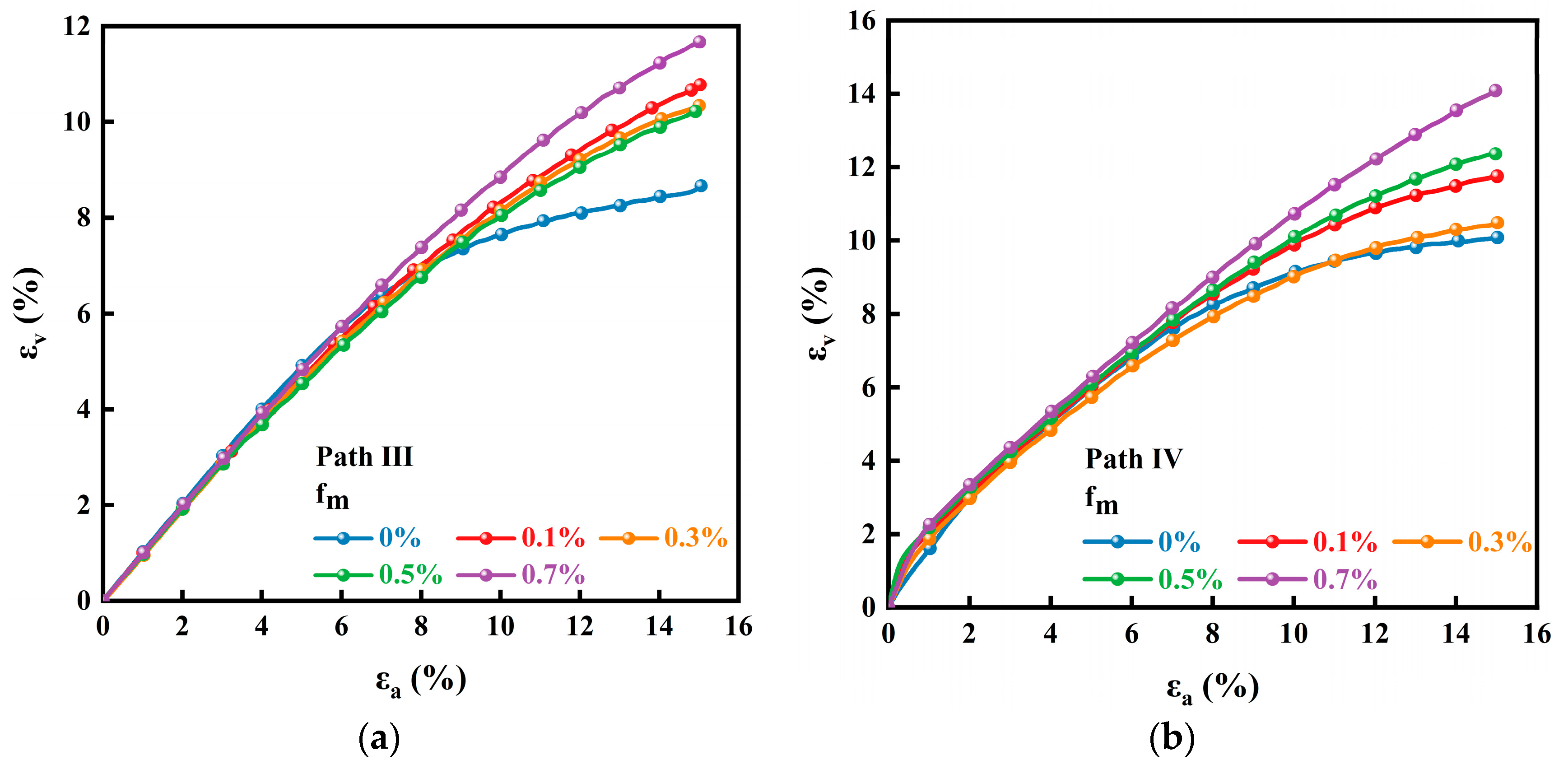

3.4. Lateral Strain and Volumetric Strain

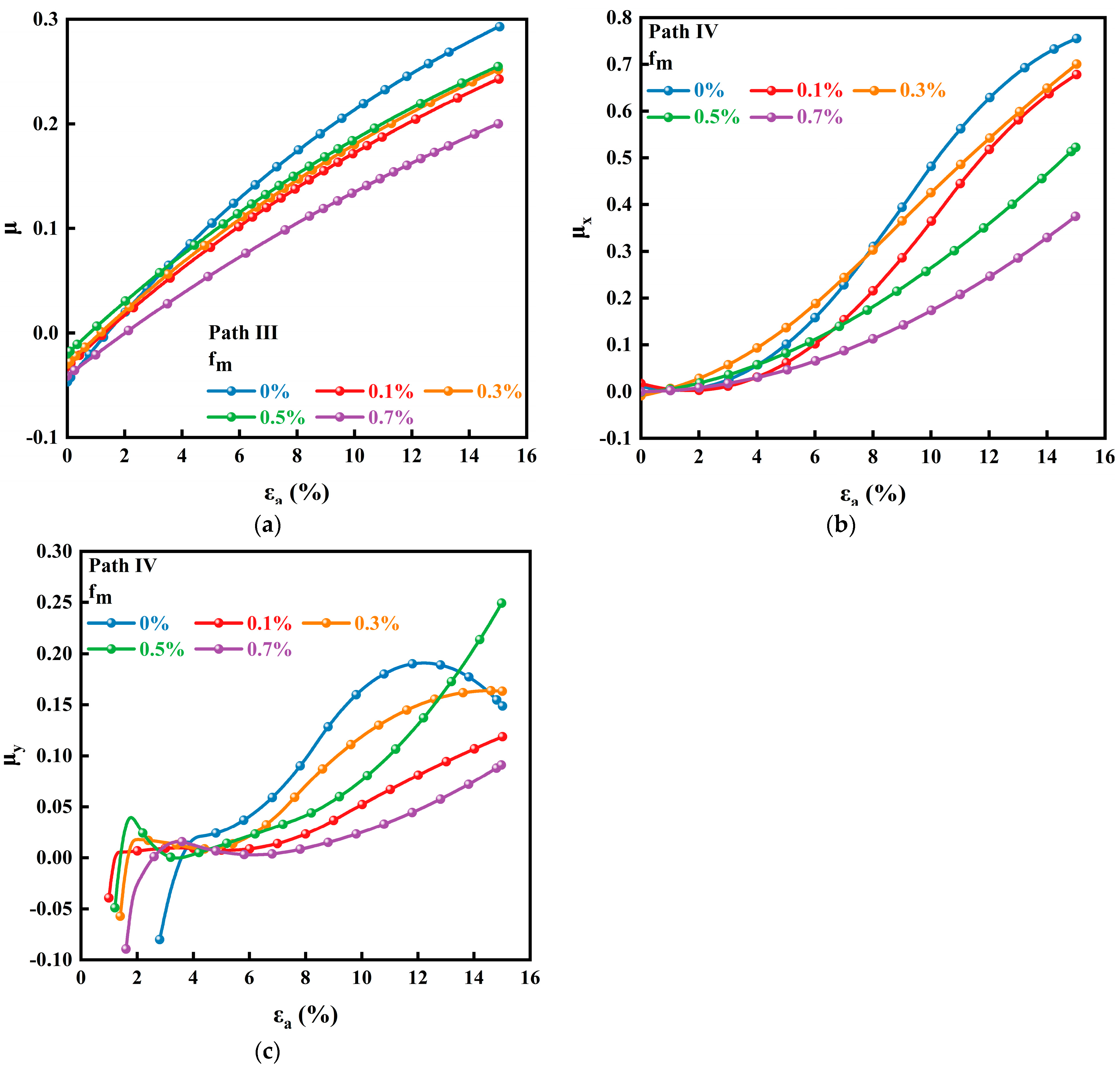

3.5. Poisson’s Ratio

3.6. Energy Absorption

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prata, J.C.; Silva, A.L.P.; Walker, T.R.; Duarte, A.C.; Rocha–Santos, T. COVID–19 Pandemic Repercussions on the Use and Management of Plastics. Environ. Sci. Technol. 2020, 54, 7760–7765. [Google Scholar] [CrossRef]

- Fadare, O.O.; Okoffo, E.D. COVID–19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 4. [Google Scholar] [CrossRef] [PubMed]

- Erjavec, A.; Plohl, O.; Zemljic, L.F.; Valh, J.V. Significant Fragmentation of Disposable Surgical Masks–Enormous Source for Problematic Micro/Nanoplastics Pollution in the Environment. Sustainability 2022, 14, 18. [Google Scholar] [CrossRef]

- Yusoff, F.M.; Abdullah, A.F.; Aris, A.Z.; Umi, W.A.D. Impacts of COVID–19 on the Aquatic Environment and Implications on Aquatic Food Production. Sustainability 2021, 13, 27. [Google Scholar] [CrossRef]

- Singh, E.; Kumar, A.; Mishra, R.; Kumar, S. Solid waste management during COVID–19 pandemic: Recovery techniques and responses. Chemosphere 2022, 288, 15. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.; Wu, X.L.; Wang, R.L.; Li, C.; Zhang, Q.; Wei, D.Q. Medical waste management practice during the 2019–2020 novel coronavirus pandemic: Experience in a general hospital. Am. J. Infect. Control. 2020, 48, 918–921. [Google Scholar] [CrossRef]

- Chen, H.M.; Dong, X.; Zhao, Y.; Wang, D.J. Recycling and Chemical Upcycling of Waste Disposable Medical Masks. Acta Polym. Sin. 2020, 51, 1295–1306. [Google Scholar]

- Gutierrez, A.S.; Eras, J.J.C.; Hens, L.; Vandecasteele, C. The energy potential of agriculture, agroindustrial, livestock, and slaughterhouse biomass wastes through direct combustion and anaerobic digestion. The case of Colombia. J. Clean Prod. 2020, 269, 17. [Google Scholar]

- Selvaranjan, K.; Navaratnam, S.; Rajeev, P.; Ravintherakumaran, N. Environmental challenges induced by extensive use of face masks during COVID–19: A review and potential solutions. Environ. Chall. 2021, 3, 100039. [Google Scholar] [CrossRef]

- Ali, M.; Opulencia, M.J.C.; Chandra, T.; Chandra, S.; Muda, I.; Dias, R.; Chetthamrongchai, P.; Jalil, A.T. An Environmentally Friendly Solution for Waste Facial Masks Recycled in Construction Materials. Sustainability 2022, 14, 14. [Google Scholar] [CrossRef]

- Deng, Y.S.; Wu, P.; Zhao, M.H.; Duan, B.Z. Strength of expansive soil reinforced by polypropylene fiber under optimal water content. Rock Soil Mech. 2017, 38, 349–353. [Google Scholar]

- Liu, J.L.; Jia, Y.M.; Wang, J. Experimental Study on Mechanical and Durability Properties of Glass and Polypropylene Fiber Reinforced Concrete. Fibers Polym. 2019, 20, 1900–1908. [Google Scholar] [CrossRef]

- Li, L.H.; Zang, T.B.; Xiao, H.L.; Feng, W.Q.; Liu, Y.L. Experimental study of polypropylene fibre–reinforced clay soil mixed with municipal solid waste incineration bottom ash. Eur. J. Environ. Civ. Eng. 2020. [Google Scholar] [CrossRef]

- Mo, Y.X.; Pang, J.Y.; Huang, J.K. Dynamic Mechanical Properties and Fractal Characteristics of Polypropylene Fiber–Reinforced Cement Soil under Impact Loading. Adv. Mater. Sci. Eng. 2019, 2019, 14. [Google Scholar] [CrossRef]

- Idrees, M.; Akbar, A.; Mohamed, A.M.; Fathi, D.; Saeed, F. Recycling of Waste Facial Masks as a Construction Material, a Step towards Sustainability. Materials 2022, 15, 13. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.Q.; Wang, X.; Yin, Z.Y.; Yang, N.Y. Static and dynamic behaviors of granular soil reinforced by disposable face–mask chips. J. Clean Prod. 2022, 331, 9. [Google Scholar] [CrossRef]

- Xu, W.Q.; Yin, Z.Y.; Wang, H.L.; Wang, X. Experimental study on the monotonic mechanical behavior of completely decomposed granite soil reinforced by disposable face–mask chips. J. Clean Prod. 2022, 352, 11. [Google Scholar] [CrossRef]

- Meng, M.Q.; Wang, L.; Jiang, X.; Wang, C.G.; Liu, H.L.; Xiao, Y. Single–particle crushing test and numerical simulation of coarse grained soil based on size effect. Rock Soil Mech. 2020, 41, 2953–2962. [Google Scholar]

- ASTM International. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Ghadr, S.; Chen, C.S.; Liu, C.H.; Hung, C. Mechanical behavior of sands reinforced with shredded face masks. Bull. Eng. Geol. Environ. 2022, 81, 21. [Google Scholar] [CrossRef]

- SFDA. Surgical Mask; Standards Press of China: Beijing, China, 2011. [Google Scholar]

- Bi, D.M.; Kong, G.Q.; Chen, G.; Liu, W.H.; Qin, H.Y.; Xu, X.L. Strength Characteristics and Failure Mode of Solidified Soil Reinforced by Waste Masks. J. Disaster Prev. Mitig. Eng. 2022, 42, 993–998. [Google Scholar]

- ASTM International. Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM International. Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM International. Standard Test Methods for Determination of Maximum Dry Unit Weight of Granular Soils Using a Vibrating Hammer; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM International. Standard Test Method for Particle–Size Analysis of Soils; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Garg, A.; Bordoloi, S.; Mondal, S.; Ni, J.J.; Sreedeep, S. Investigation of mechanical factor of soil reinforced with four types of fibers: An integrated experimental and extreme learning machine approach. J. Nat. Fibers 2020, 17, 650–664. [Google Scholar] [CrossRef]

- An, N.; Yan, C.G.; Wang, Y.C.; Lan, H.X.; Bao, H.; Xu, J.B.; Shi, Y.L.; Sun, W.F. Experimental study on anti–erosion performance of polypropylene fiber–reinforced loess. Rock Soil Mech. 2021, 42, 501–510. [Google Scholar]

- Chen, M.; Shen, S.L.; Arulrajah, A.; Wu, H.N.; Hou, D.W.; Xu, Y.S. Laboratory evaluation on the effectiveness of polypropylene fibers on the strength of fiber–reinforced and cement–stabilized Shanghai soft clay. Geotext. Geomembr. 2015, 43, 515–523. [Google Scholar] [CrossRef]

- Lei, J.; Cheng, J.J.; Ding, B.S.; Ma, B.T.; Gao, L.; Li, Y.P.; Cheng, Y.L. Triaxial test study on aeolian sand cement–based materials with different fiber content. J. Railw. Sci. Eng. 2022. [CrossRef]

- ASTM International. Standard Test Method for Unconsolidated–Undrained Triaxial Compression Test on Cohesive Soils; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Szypcio, Z. Stress–Dilatancy for Soils. Part III: Experimental Validation for the Biaxial Condition. Stud. Geotech. Mech. 2017, 39, 73–80. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Liu, J.; Meng, T.Y.; Shao, S.J.; She, F.T. An Experimental Study on the Deformation and Strength Characteristics of Q3 Loess under a Plain Strain Anisotropic Consolidation Condition. Adv. Civ. Eng. 2021, 2021, 13. [Google Scholar] [CrossRef]

- Liu, J.L.; Hou, T.S.; Luo, Y.S. Unconfined compressive strength of synthetic cotton fibers reinforced soil. J. Hydroelectr. Eng. 2018, 37, 12–21. [Google Scholar]

- Gao, L.; Hu, G.H.; Xu, N.; Fu, J.Y.; Xiang, C.; Yang, C. Experimental Study on Unconfined Compressive Strength of Basalt Fiber Reinforced Clay Soil. Adv. Mater. Sci. Eng. 2015, 2015, 8. [Google Scholar] [CrossRef]

- Jiang, H.T.; Cai, Y.; Liu, J. Engineering Properties of Soils Reinforced by Short Discrete Polypropylene Fiber. J. Mater. Civ. Eng. 2010, 22, 1315–1322. [Google Scholar] [CrossRef]

- Chen, C.L.; Fang, J.; Luo, A.Z.; Shao, S.J. In Study of Artificial Structural Loess under the True Triaxial Tests. In Proceedings of the International Conference on Structures and Building Materials (ICSBM 2013), Guizhou, China, 9–10 March 2013; Trans Tech Publications Ltd.: Guizhou, China, 2013; pp. 343–348. [Google Scholar]

- Benziane, M.M.; Della, N.; Denine, S.; Sert, S.; Nouri, S. Effect of randomly distributed polypropylene fiber reinforcement on the shear behavior of sandy soil. Stud. Geotech. Mech. 2019, 41, 151–159. [Google Scholar] [CrossRef]

- Yin, Z.Y.; Hicher, P.Y.; Jin, Y.F. Practice of Constitutive Modelling for Saturated Soils; Springer: Singapore, 2020. [Google Scholar]

- Jiang, P.; Lv, S.W.; Wang, Y.; Li, N.; Wang, W. Investigation on Direct Shear and Energy Dissipation Characteristics of Iron Tailings Powder Reinforced by Polypropylene Fiber. Appl. Sci. 2019, 9, 16. [Google Scholar] [CrossRef]

| Soil Properties | Standard Test Specifications | Value |

|---|---|---|

| Mean Specific Gravity, Gs (.) | ASTM D854–14 [23] | 2.673 |

| Plastic Limit, PL (%) | ASTM D4318–17 [24] | 21.8 |

| Liquid Limit, LL (%) | ASTM D4318–17 [24] | 44.3 |

| Maximum Dry Density, ρdmax (g/cm3) | ASTM D7382–20 [25] | 1.93 |

| Medium Grain Size, D50 (mm) | ASTM D422–63 [26] | 0.64 |

| Maximum Diameter, Dmax (mm) | ASTM D422–63 [26] | 5.00 |

| Coefficient of Uniformity, Cu (.) | ASTM D422–63 [26] | 8.81 |

| Coefficient of Curvature, Cc (.) | ASTM D422–63 [26] | 1.26 |

| Name | fm (%) | w (%) | ρd (g·cm3) | Stress Path |

|---|---|---|---|---|

| C0PⅠ | 0 | 15 | 1.74 | Ⅰ |

| C01PⅠ | 0.1 | |||

| C03PⅠ | 0.3 | |||

| C05PⅠ | 0.5 | |||

| C07PⅠ | 0.7 | |||

| C0PⅡ | 0 | 15 | 1.74 | Ⅱ |

| C01PⅡ | 0.1 | |||

| C03PⅡ | 0.3 | |||

| C05PⅡ | 0.5 | |||

| C07PⅡ | 0.7 | |||

| C0PⅢ | 0 | 15 | 1.74 | Ⅲ |

| C01PⅢ | 0.1 | |||

| C03PⅢ | 0.3 | |||

| C05PⅢ | 0.5 | |||

| C07PⅢ | 0.7 | |||

| C0PⅣ | 0 | 15 | 1.74 | Ⅳ |

| C01PⅣ | 0.1 | |||

| C03PⅣ | 0.3 | |||

| C05PⅣ | 0.5 | |||

| C07PⅣ | 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Chen, M.; Hu, B.; Du, G.; Li, K. Experimental Study on the Mechanical Behavior of Sandy Soil Reinforced by Disposable Face Mask Chips under Different Stress Paths. Sustainability 2023, 15, 4059. https://doi.org/10.3390/su15054059

Hu X, Chen M, Hu B, Du G, Li K. Experimental Study on the Mechanical Behavior of Sandy Soil Reinforced by Disposable Face Mask Chips under Different Stress Paths. Sustainability. 2023; 15(5):4059. https://doi.org/10.3390/su15054059

Chicago/Turabian StyleHu, Xiangqi, Mingliang Chen, Bo Hu, Guangzhen Du, and Kaihui Li. 2023. "Experimental Study on the Mechanical Behavior of Sandy Soil Reinforced by Disposable Face Mask Chips under Different Stress Paths" Sustainability 15, no. 5: 4059. https://doi.org/10.3390/su15054059

APA StyleHu, X., Chen, M., Hu, B., Du, G., & Li, K. (2023). Experimental Study on the Mechanical Behavior of Sandy Soil Reinforced by Disposable Face Mask Chips under Different Stress Paths. Sustainability, 15(5), 4059. https://doi.org/10.3390/su15054059