A Superstructure Mixed-Integer Nonlinear Programming Optimization for the Optimal Processing Pathway Selection of Sludge-to-Energy Technologies

Abstract

1. Introduction

1.1. Motivation

1.2. Background Information

1.2.1. Sludge Characterization

1.2.2. Anaerobic Digestion

1.2.3. Incineration

1.2.4. Gasification

1.2.5. Pyrolysis

1.2.6. Supercritical Water Treatment Methods

Supercritical Water Oxidation (SCWO)

Supercritical Water Gasification (SCWG)

- No need for prior drying of the feedstock to the SCWG reactor. Conversely, the moisture content of the feed is necessary for the reaction;

- Higher yield of H2 compared to CO in the syngas product whereas in dry gasification processes CO is the main constituent of syngas and an extra water–gas shift process is required to achieve such high H2:CO ratios;

- Lower amounts of coke and tar formation;

- Salts remain in the aqueous solution which avoids corrosion problems during the treatment of the produced gas.

1.2.7. Dewatering and Drying

1.3. Sludge-to-Energy Fundamental Concepts

1.3.1. Sludge-to-Energy Decision-Making Frameworks

1.3.2. Sludge Management Optimization Models

1.3.3. Waste-to-Energy Optimization Models

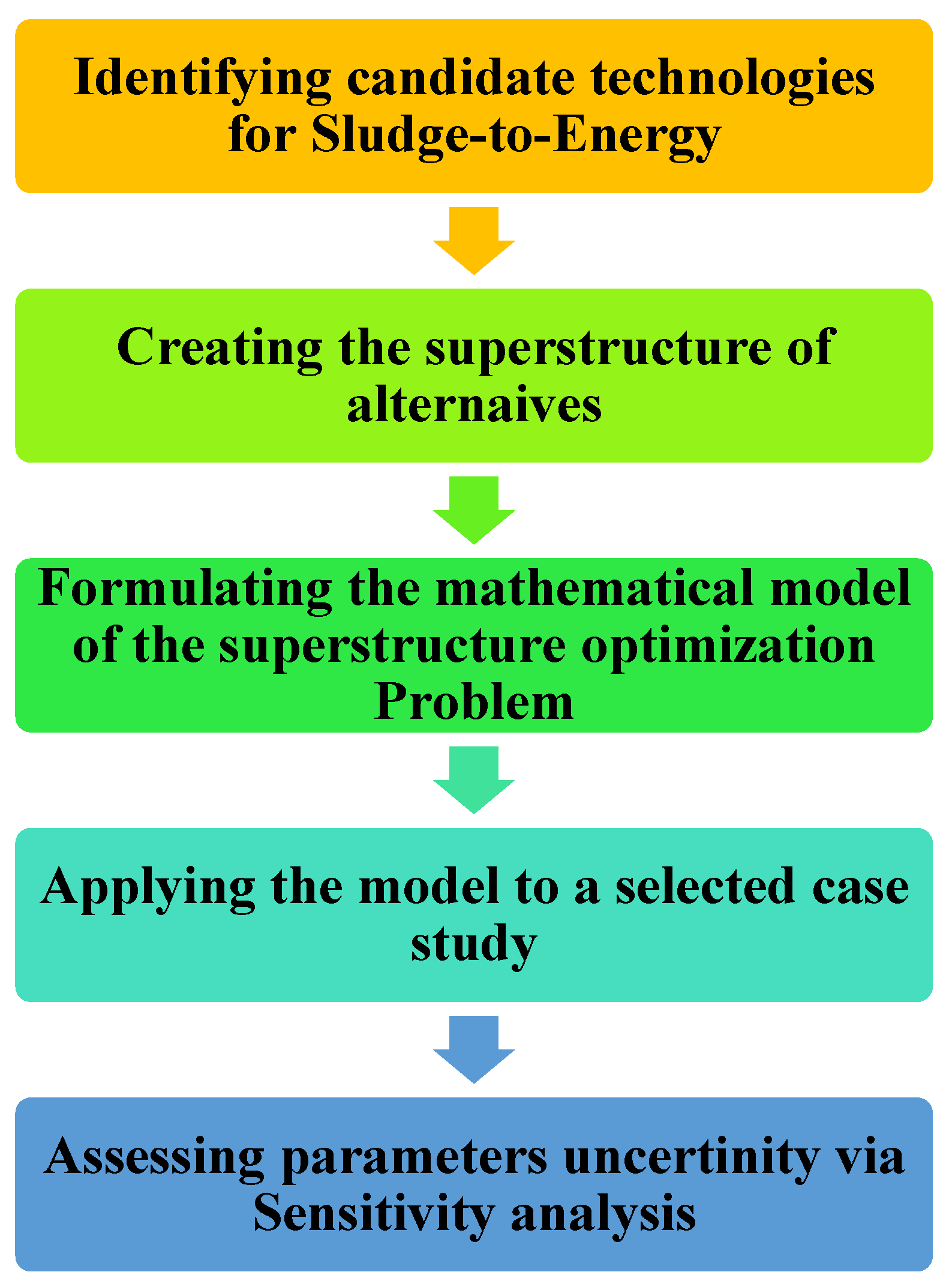

2. Methodology

2.1. Overview

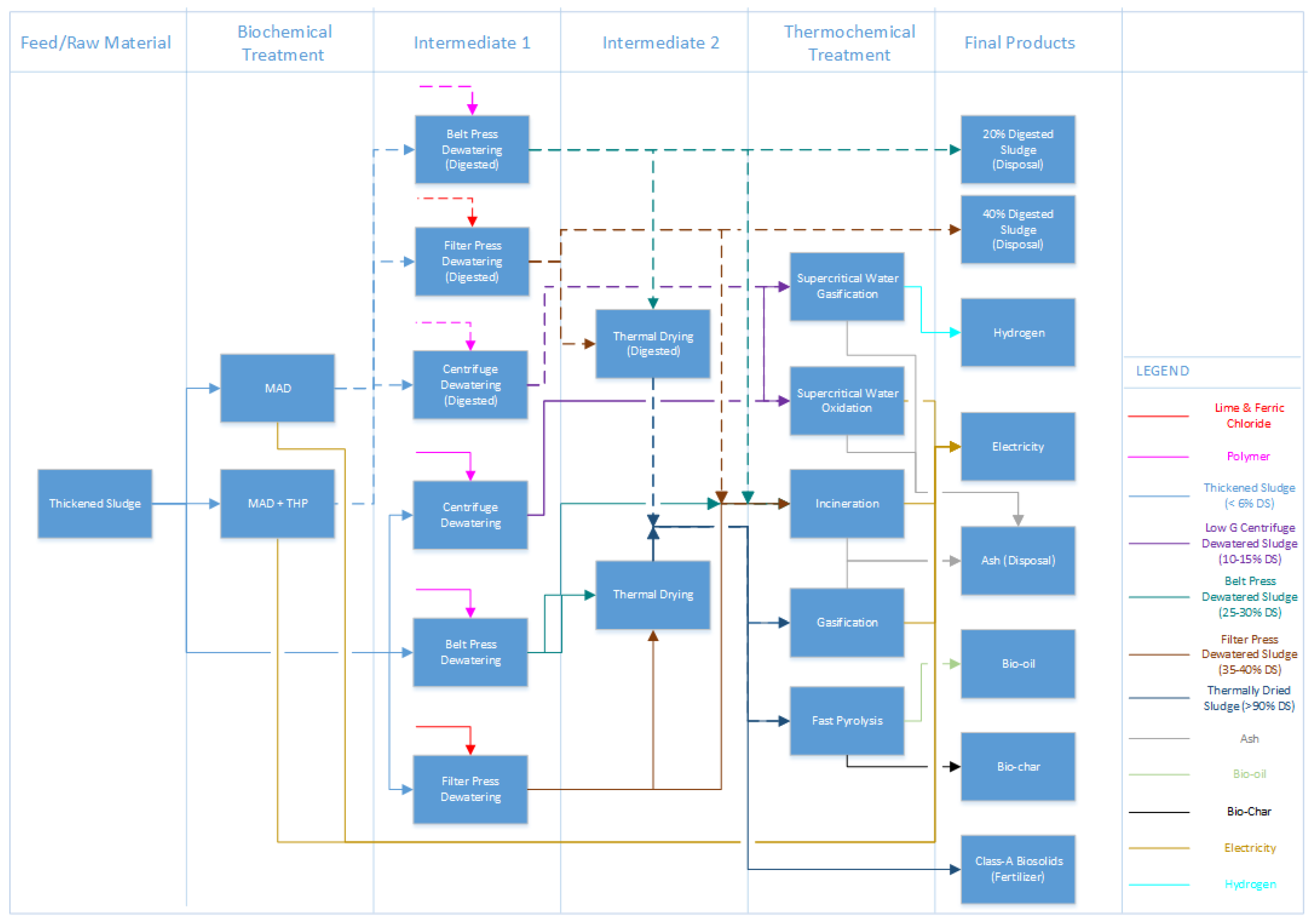

2.2. Superstructure Development

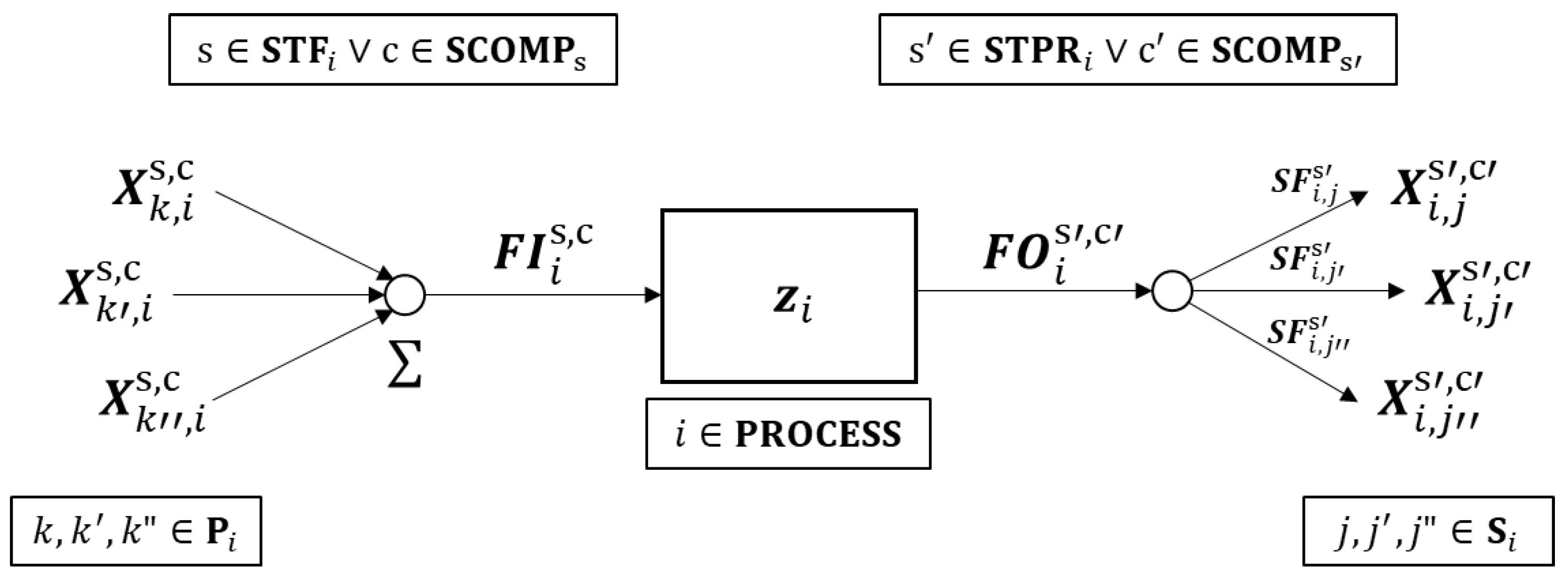

2.3. Mathematical Model Formulation

2.3.1. General

2.3.2. Thickened Sludge Block

2.3.3. Anaerobic Digestion Blocks

2.3.4. Dewatering Blocks

2.3.5. Thermal Drying Block

2.3.6. Incineration Block

2.3.7. Gasification Block

2.3.8. Pyrolysis Block

2.3.9. SCWO and SCWG blocks

2.3.10. Objective Function

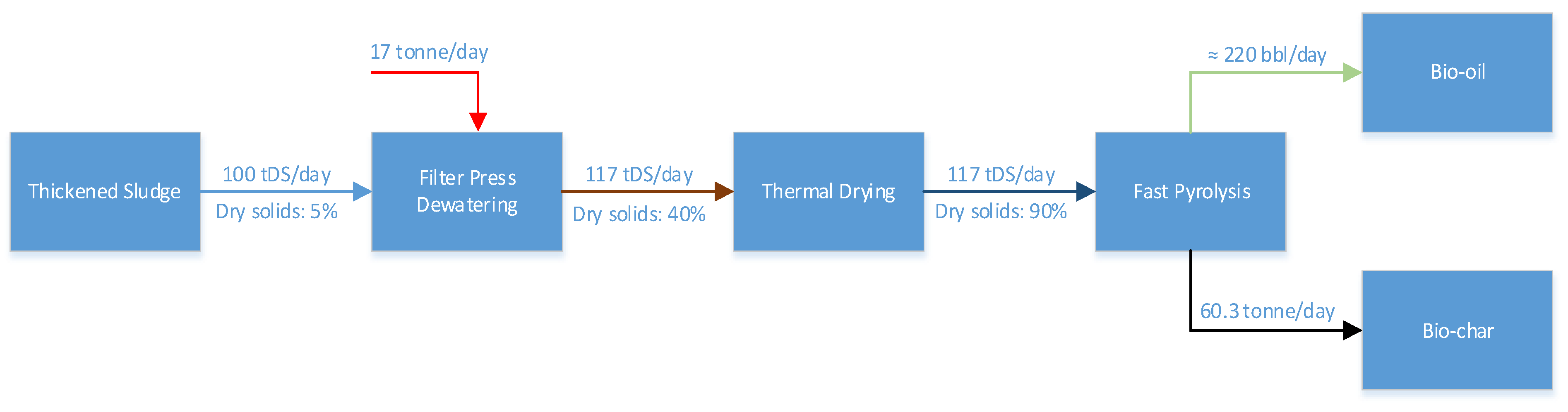

3. Case Study

3.1. Case Study Parameters

3.2. Sensitivity Analysis

3.3. Results and Discussion

3.3.1. Base Case Results

3.3.2. Sensitivity Analysis Results

Feed Characteristics

- -

- Feed Flowrate

- -

- Feed Composition

Economic Parameters

- -

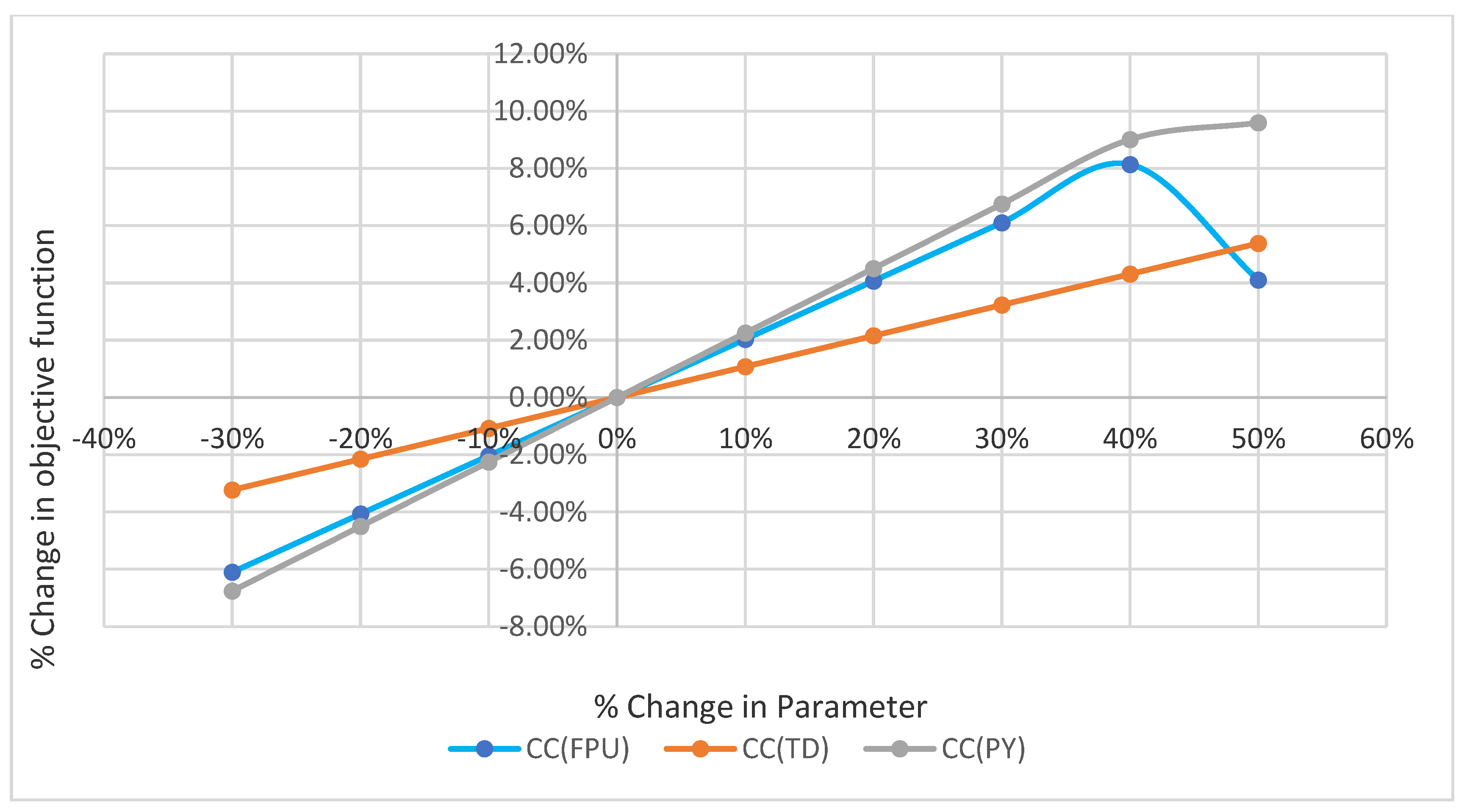

- Capital and Operating Costs

- -

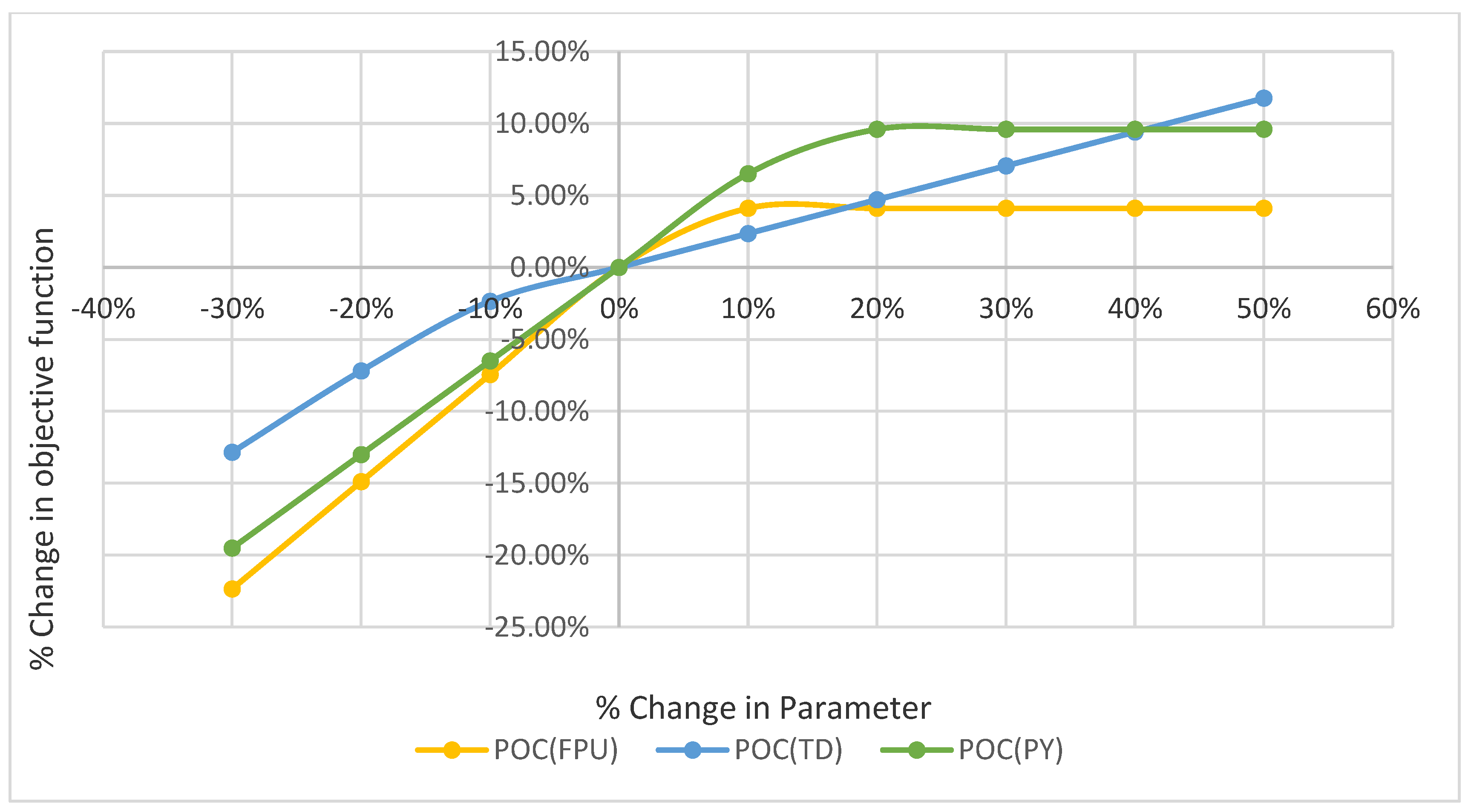

- Product Selling and Disposal Prices

- -

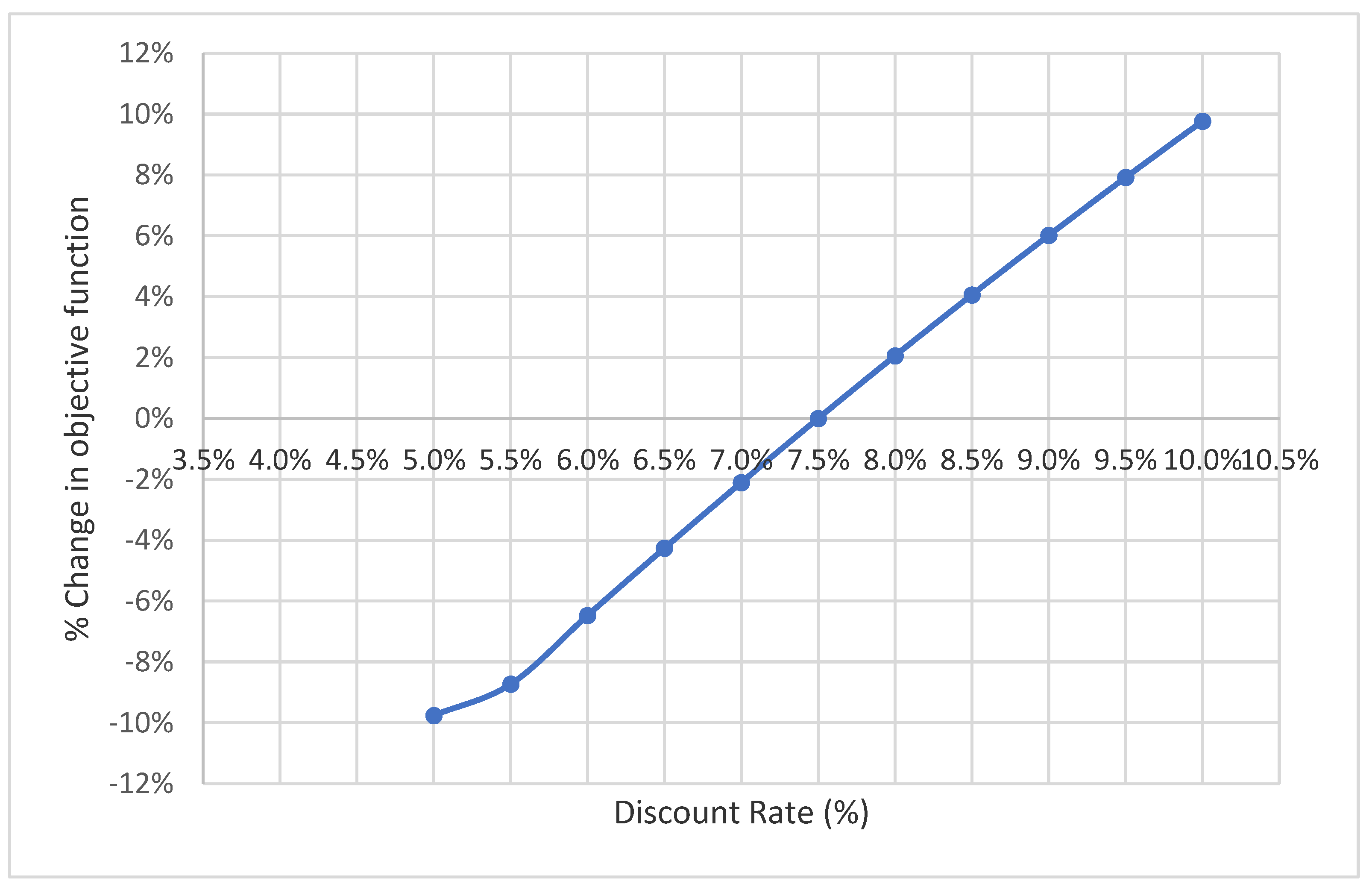

- Discount Rate

Performance-Related Parameters

3.3.3. Complementary Analysis

4. Conclusions

- -

- The technology selection route was sensitive to the capital cost parameter of MADT, and operating costs of FPD and BPU. Changes in the remainder of the technologies’ capital and operating cost parameters did not impact the model outputs;

- -

- Variations in the final products’ prices also had a significant effect on the selected optimal pathway and the net costs of the selected plant. Electricity price was the most sensitive parameter followed by hydrogen and biochar prices, while bio-oil and Class A biosolids (fertilizer) prices were found to have the least relative effect on the objective function values;

- -

- The objective function values were also sensitive to the value of discount rates; however, the technology selection did not change with reasonable interest variations;

- -

- Changing the yield parameters of technologies other than fast pyrolysis had no influence on the solution. This indicates the robustness of the pyrolysis pathway against a wide range of process efficiencies of the competing technologies;

- -

- The objective function was highly sensitive to all the parameters related to the technologies in the base case optimal pathway, which proved the applicability of the proposed model and provided sensible results;

- -

- The feed characteristics affected the optimal cost value, which was explained by the economies of scale. The inverse relationship between net cost and process capacity effects started to diminish at capacities above 200 tDS/day. There were slight impacts from changing the composition of the sewage sludge where cost reductions were observed at a higher %VS due to an increased yield of energy products correlated with an increase in the organic contents of the sludge.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- U.S. Environmental Protection Agency. Wastewater Management Fact Sheet—Energy Conservation; U.S. Environmental Protection Agency: Washington, DC, USA, 2006.

- EPRI; WRF. Electricity Use and Management in the Municipal Water Supply and Wastewater Industries; EPRI: Palo Alto, CA, USA, 2013. [Google Scholar]

- Spinosa, L.; Ayol, A.; Baudez, J.-C.; Canziani, R.; Jenicek, P.; Leonard, A.; Rulkens, W.; Xu, G.; Van Dijk, L. Sustainable and Innovative Solutions for Sewage Sludge Management. Water 2011, 3, 702–717. [Google Scholar] [CrossRef]

- Basic Information about Biosolids | US EPA. Available online: https://www.epa.gov/biosolids/basic-information-about-biosolids (accessed on 26 February 2022).

- Rulkens, W.H.; Bien, J.D. Recovery of energy from sludge—Comparison of the various options. Water Sci. Technol. 2004, 50, 213–221. [Google Scholar] [CrossRef]

- Pérez-Elvira, S.I.; Nieto Diez, P.; Fdz-Polanco, F. Sludge minimisation technologies. Rev. Environ. Sci. Biotechnol. 2006, 5, 375–398. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.; Champagne, P.; Mabee, W. Overview of current biological and thermo-chemical treatment technologies for sustainable sludge management. Waste Manag. Res. 2014, 32, 586–600. [Google Scholar] [CrossRef]

- Raheem, A.; Sikarwar, V.S.; He, J.; Dastyar, W.; Dionysiou, D.D.; Wang, W.; Zhao, M. Opportunities and challenges in sustainable treatment and resource reuse of sewage sludge: A review. Chem. Eng. J. 2018, 337, 616–641. [Google Scholar] [CrossRef]

- Adar, E.; Karatop, B.; Ince, M.; Bilgili, M.S. Comparison of methods for sustainable energy management with sewage sludge in Turkey based on SWOT-FAHP analysis. Renew. Sustain. Energy Rev. 2016, 62, 429–440. [Google Scholar] [CrossRef]

- Santibañez-Aguilar, J.E.; González-Campos, J.B.; Ponce-Ortega, J.M.; Serna-González, M.; El-Halwagi, M.M. Optimal Planning of a Biomass Conversion System Considering Economic and Environmental Aspects. Ind. Eng. Chem. Res. 2011, 50, 8558–8570. [Google Scholar] [CrossRef]

- Kim, J.; Sen, S.M.; Maravelias, C.T. An optimization-based assessment framework for biomass-to-fuel conversion strategies. Energy Environ. Sci. 2013, 6, 1093–1104. [Google Scholar] [CrossRef]

- Rizwan, M.; Lee, J.H.; Gani, R. Optimal processing pathway for the production of biodiesel from microalgal biomass: A superstructure based approach. Comput. Chem. Eng. 2013, 58, 305–314. [Google Scholar] [CrossRef]

- Rizwan, M.; Lee, J.H.; Gani, R. Optimal design of microalgae-based biorefinery: Economics, opportunities and challenges. Appl. Energy 2015, 150, 69–79. [Google Scholar] [CrossRef]

- Satchatippavarn, S.; Martinez-Hernandez, E.; Leung Pah Hang, M.Y.; Leach, M.; Yang, A. Urban biorefinery for waste processing. Chem. Eng. Res. Des. 2016, 107, 81–90. [Google Scholar] [CrossRef]

- Rizwan, M.; Saif, Y.; Almansoori, A.; Elkamel, A. Optimal processing route for the utilization and conversion of municipal solid waste into energy and valuable products. J. Clean. Prod. 2018, 174, 857–867. [Google Scholar] [CrossRef]

- Ma, J.; You, F. Superstructure optimization of thermal conversion based poultry litter valorization process. J. Clean. Prod. 2019, 228, 1111–1121. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Lo, S.L. Sludge: A waste or renewable source for energy and resources recovery? Renew. Sustain. Energy Rev. 2013, 25, 708–728. [Google Scholar] [CrossRef]

- Stone, L.; Kuchenrither, R.; Quintanilla, A.; Torres, E.; Groome, M.; Pfeifer, T.; Dominak, R.; Taylor, D. Renewable Energy Resources: Banking on Biosolids; NACWA: Washington, DC, USA, 2010. [Google Scholar]

- Fonts, I.; Azuara, M.; Gea, G.; Murillo, M.B. Study of the pyrolysis liquids obtained from different sewage sludge. J. Anal. Appl. Pyrolysis 2009, 85, 184–191. [Google Scholar] [CrossRef]

- Cao, Y.; Pawłowski, A. Sewage sludge-to-energy approaches based on anaerobic digestion and pyrolysis: Brief overview and energy efficiency assessment. Renew. Sustain. Energy Rev. 2012, 16, 1657–1665. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical processing of sewage sludge to energy and fuel: Fundamentals, challenges and considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Towards sewage sludge based biofuels via thermochemical conversion—A review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A review of sludge-to-energy recovery methods. Energies 2019, 12, 60. [Google Scholar] [CrossRef]

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Samolada, M.C.; Zabaniotou, A.A. Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge-to-energy management in Greece. Waste Manag. 2014, 34, 411–420. [Google Scholar] [CrossRef]

- Khiari, B.; Marias, F.; Zagrouba, F.; Vaxelaire, J. Analytical study of the pyrolysis process in a wastewater treatment pilot station. Desalination 2004, 167, 39–47. [Google Scholar] [CrossRef]

- Alvarez, J.; Lopez, G.; Amutio, M.; Artetxe, M.; Barbarias, I.; Arregi, A.; Bilbao, J.; Olazar, M. Characterization of the bio-oil obtained by fast pyrolysis of sewage sludge in a conical spouted bed reactor. Fuel Process. Technol. 2016, 149, 169–175. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.; Champagne, P. Energy recovery from secondary pulp/paper-mill sludge and sewage sludge with supercritical water treatment. Bioresour. Technol. 2010, 101, 2713–2721. [Google Scholar] [CrossRef]

- Paul, E.; Liu, Y. Biological Sludge Minimization and Biomaterials/Bioenergy Recovery Technologies; John Wiley and Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Svanström, M.; Modell, M.; Tester, J. Direct energy recovery from primary and secondary sludges by supercritical water oxidation. Water Sci. Technol. 2004, 49, 201–208. [Google Scholar] [CrossRef]

- Gasafi, E.; Reinecke, M.Y.; Kruse, A.; Schebek, L. Economic analysis of sewage sludge gasification in supercritical water for hydrogen production. Biomass Bioenergy 2008, 32, 1085–1096. [Google Scholar] [CrossRef]

- Binder, M.; Kraussler, M.; Kuba, M.; Luisser, M.; Rauch, R. Hydrogen from Biomass Gasification. IEA Bioenergy; IEA: Paris, France, 2018. [Google Scholar]

- Vitorio, C.; Andreoli, M.; von Sperling, F.; Fernandes, F. Sludge Treatment and Disposal; IWA Publishing: London, UK, 2007; Volume 6. [Google Scholar]

- U.S. Environmental Protection Agency. Handbook: Estimating Sludge Management Costs; Water Engineering Research Laboratory: Cincinnati, OH, USA, 1985.

- Metcalf & Eddy Inc. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Ding, W.; Li, L.; Liu, J. Investigation of the effects of temperature and sludge characteristics on odors and VOC emissions during the drying process of sewage sludge. Water Sci. Technol. 2015, 72, 543–552. [Google Scholar] [CrossRef]

- Ren, J.; Liang, H.; Dong, L.; Gao, Z.; He, C.; Pan, M.; Sun, L. Sustainable development of sewage sludge-to-energy in China: Barriers identification and technologies prioritization. Renew. Sustain. Energy Rev. 2017, 67, 384–396. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, J.; Man, Y.; Lin, R.; Lee, C.K.M.; Ji, P. Prioritization of sludge-to-energy technologies under multi-data condition based on multi-criteria decision-making analysis. J. Clean. Prod. 2020, 273, 123082. [Google Scholar] [CrossRef]

- Tang, C.; Xu, D.; Chen, N. Sustainability prioritization of sewage sludge to energy scenarios with hybrid-data consideration: A fuzzy decision-making framework based on full consistency method and fusion ranking model. Environ. Sci. Pollut. Res. 2020, 285, 5548–5565. [Google Scholar] [CrossRef]

- Vadenbo, C.; Guillén-Gosálbez, G.; Saner, D.; Hellweg, S. Multi-objective optimization of waste and resource management in industrial networks—Part II: Model application to the treatment of sewage sludge. Resour. Conserv. Recycl. 2014, 89, 41–51. [Google Scholar] [CrossRef]

- U-Tapao, C.; Gabriel, S.A.; Peot, C.; Ramirez, M. Stochastic, Multiobjective, Mixed-Integer Optimization Model for Wastewater-Derived Energy. J. Energy Eng. 2015, 141, B5014001. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Ostermeyer, P.; Van Orshoven, J. Implementation of OPTIMASS to optimise municipal wastewater sludge processing chains: Proof of concept. Resour. Conserv. Recycl. 2016, 114, 168–178. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Van Orshoven, J. A generic mathematical model to optimise strategic and tactical decisions in biomass-based supply chains (OPTIMASS). Eur. J. Oper. Res. 2015, 245, 247–264. [Google Scholar] [CrossRef]

- Amoedo, R.C.; Damartzis, T.; Granacher, J.; Marechal, F.M.A. System Design and Performance Evaluation of Wastewater Treatment Plants Coupled With Hydrothermal Liquefaction and Gasification. Front. Energy Res. 2020, 8, 233. [Google Scholar] [CrossRef]

- Ng, W.P.Q.; Lam, H.L.; Varbanov, P.S.; Klemeš, J.J. Waste-to-Energy (WTE) network synthesis for Municipal Solid Waste (MSW). Energy Convers. Manag. 2014, 85, 866–874. [Google Scholar] [CrossRef]

- Mohammadi, M.; Harjunkoski, I. Performance analysis of waste-to-energy technologies for sustainable energy generation in integrated supply chains. Comput. Chem. Eng. 2020, 140, 106905. [Google Scholar] [CrossRef]

- Yousefloo, A.; Babazadeh, R. Designing an integrated municipal solid waste management network: A case study. J. Clean. Prod. 2020, 244, 118824. [Google Scholar] [CrossRef]

- Zhao, N.; Lehmann, J.; You, F. Poultry Waste Valorization via Pyrolysis Technologies: Economic and Environmental Life Cycle Optimization for Sustainable Bioenergy Systems. ACS Sustain. Chem. Eng. 2020, 8, 4633–4646. [Google Scholar] [CrossRef]

- Morsy, O. Optimal Processing Pathway for Sludge-to-Energy Technologies: A Superstructure Optimization-Based MINLP Model. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2022. Available online: http://hdl.handle.net/10012/18184 (accessed on 1 November 2022).

- Bertran, M.O.; Frauzem, R.; Sanchez-Arcilla, A.S.; Zhang, L.; Woodley, J.M.; Gani, R. A generic methodology for processing route synthesis and design based on superstructure optimization. Comput. Chem. Eng. 2017, 106, 892–910. [Google Scholar] [CrossRef]

- Lumley, N.P.G. Techno-Economic Analysis of Wastewater Sludge Gasification: A Decentralized Urban Perspective. Master’s Thesis, Colorado School of Mines, Golden, CO, USA, 2013. Available online: https://repository.mines.edu/bitstream/handle/11124/12062/Lumley_mines_0052N_10344.pdf?sequence=1&isAllowed=y (accessed on 1 February 2022).

- The Chemical Engineering Plant Cost Index—Chemical Engineering. Available online: https://www.chemengonline.com/pci-home (accessed on 19 January 2022).

- Mills, N. Unlocking the Full Energy Potential of Sewage Sludge. Ph.D. Thesis, University of Surrey, Guildford, UK, 2015. [Google Scholar]

- Haque, N.; Somerville, M. Techno-economic and environmental evaluation of biomass dryer. Procedia Eng. 2013, 56, 650–655. [Google Scholar] [CrossRef]

- 2011 Sewage Sludge Incineration (SSI) New Source Performance Standards (NSPS) and Emission Guidelines (EG) Source Data Files | US EPA. Available online: https://www.epa.gov/stationary-sources-air-pollution/2011-sewage-sludge-incineration-ssi-new-source-performance (accessed on 19 January 2022).

- Bridgwater, A.V.; Toft, A.J.; Brammer, J.G. A techno-economic comparison of power production by biomass fast pyrolysis with gasification and combustion. Renew. Sustain. Energy Rev. 2002, 6, 181–246. [Google Scholar] [CrossRef]

- Lumley, N.P.G.; Ramey, D.F.; Prieto, A.L.; Braun, R.J.; Cath, T.Y.; Porter, J.M. Techno-economic analysis of wastewater sludge gasification: A decentralized urban perspective. Bioresour. Technol. 2014, 161, 385–394. [Google Scholar] [CrossRef]

- Hydrothermal Oxidation Technology | AquaCritox| Scfi. Available online: https://www.scfi.eu/water/the-technology/what-is-aquacritox/ (accessed on 3 October 2021).

- Electric Power Monthly—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a (accessed on 20 January 2022).

- Darvodelsky, P. Biosolids Snapshot. 2012. Available online: https://www.awe.gov.au/sites/default/files/documents/biosolids-snapshot.pdf (accessed on 20 January 2022).

- Xin, C.; Zhao, J.; Ruan, R.; Addy, M.M.; Liu, S.; Mu, D. Economical feasibility of bio-oil production from sewage sludge through Pyrolysis. Therm. Sci. 2018, 22, 459–467. [Google Scholar] [CrossRef]

- Patel, S.; Kundu, S.; Paz-Ferreiro, J.; Surapaneni, A.; Fouche, L.; Halder, P.; Setiawan, A.; Shah, K. Transformation of biosolids to biochar: A case study. Environ. Prog. Sustain. Energy 2019, 38, 13113. [Google Scholar] [CrossRef]

- Hydrogen Production Costs by Production Source, 2018—Charts—Data & Statistics—IEA. Available online: https://www.iea.org/data-and-statistics/charts/hydrogen-production-costs-by-production-source-2018 (accessed on 20 January 2022).

- Schaum, C.; Lensch, D.; Cornel, P. Evaluation of the energetic potential of sewage sludge by characterization of its organic composition. Water Sci. Technol. 2016, 73, 3072–3079. [Google Scholar] [CrossRef]

- AACE International. Cost Estimate Classification System—As Applied in Engineering, Procurement, and Construction for the Process Industries; AACE International Recommended Practice No. 18R-97 (Rev. 1 March 2016); AACE International: Morgantown, WV, USA, 2016. [Google Scholar]

- Tawarmalani, M.; Sahinidis, N.V. A polyhedral branch-and-cut approach to global optimization. Math. Program. 2005, 103, 225–249. [Google Scholar] [CrossRef]

- Peccia, J.; Westerhoff, P. We Should Expect More out of Our Sewage Sludge. Environ. Sci. Technol. 2015, 49, 8271–8276. [Google Scholar] [CrossRef]

| Superstructure Element | Identifier | Description |

|---|---|---|

| General | i,j,k | Aliases of subscripts identifiers for feed, process, and product blocks. |

| s | Generic identifier of a process stream | |

| c | Generic identifier of a component in a stream | |

| Feed Source | TH | Thickened Sludge |

| Technologies/Processes | MAD | Mesophilic Anaerobic Digestion |

| MADT | MAD + Thermal Hydrolysis Pretreatment | |

| CD | Centrifuge dewatering for digested sludge | |

| CU | Centrifuge dewatering for undigested sludge | |

| BPD | Belt press dewatering for digested sludge | |

| BPU | Belt press dewatering for undigested sludge | |

| FPD | Filter press dewatering for digested sludge | |

| FPU | Filter press dewatering for undigested sludge | |

| TD | Thermal Drying | |

| INC | Incineration | |

| GN | Gasification | |

| PY | Fast Pyrolysis | |

| SCO | Supercritical Water Oxidation | |

| SCG | Supercritical Water Gasification | |

| Final Products | DS20 | 20% dewatered digested sludge |

| DS40 | 40% dewatered digested sludge | |

| ASH | Ash | |

| E | Electricity | |

| FERT | Class A Biosolids (Fertilizer) | |

| BO | Bio-oil from pyrolysis | |

| BC | Biochar from pyrolysis | |

| H2 | Hydrogen | |

| Process Streams | THS | Thickened Sludge |

| ADS | Anaerobically Digested Sludge | |

| E | Electricity | |

| P | Polymer for chemical conditioning | |

| L | Lime for chemical conditioning | |

| FC | Ferric chloride for chemical conditioning | |

| DWS | Dewatered Sludge | |

| TDS | Thermally dried sludge | |

| ASH | Ash | |

| BO | Bio-oil | |

| BC | Biochar | |

| H2 | Hydrogen | |

| Components in process streams | VS | Total volatile solids |

| ASH | Ash | |

| DS | Total dry solids (VS + Ash) | |

| W | Water or moisture in the sludge/biosolids | |

| E | Electricity | |

| BO | Bio-oil | |

| BC | Biochar | |

| H2 | Hydrogen |

| Set | Description |

|---|---|

| Combined set of feed, process, and final product blocks | |

| Subset of feed blocks, | |

| Subset of processing technologies, | |

| Subset of final products, | |

| Set of process streams | |

| Subset of chemicals streams used for conditioning | |

| Set of components of process streams | |

| Set of descendant block(s) from block . Where | |

| Set of precedent block(s) of block . Where | |

| Set of inlet stream(s) applicable with process . Where | |

| Set of outlet stream(s) applicable with process . Where | |

| Set of component(s) applicable to stream . Where | |

| Set of component(s) used for specifying the revenue/disposal cost of a final product . Where |

| Parameter | Description |

|---|---|

| Maximum processing capacity of a certain process in tDS/day. | |

| Base (reference) capital cost of process in USD (USD 2019) | |

| Base (reference) processing capacity of process used in capital cost calculation. | |

| Economies of scale exponent of process . | |

| Operating cost parameter for a certain process . | |

| Days of operation per year |

| Variable | Type | Description |

|---|---|---|

| Process, continuous, dependent | Total inlet flowrate of a component within a process stream into process . | |

| Process, continuous, dependent | Total outlet flowrate of a component within a process stream out of process . | |

| Process, continuous, dependent | Flowrate of a component within a process stream going from any block to another block . | |

| Process, continuous, independent | Split factor of a process stream going from any block to another block . | |

| Process, binary, independent | Binary variable that dictates whether a certain process exists or not. | |

| Economic, continuous, dependent | Capital cost of a certain process in USD (USD 2019) | |

| Economic, continuous, dependent | Operating cost of a certain process in USD/yr (USD 2019). |

| Symbol | Type | Description | Units/Set Elements |

|---|---|---|---|

| Parameter | Flowrate of thickened sludge to be processed in tons of dry solids per day | tDS/day | |

| Parameter | Feed volatile solids mass percentage of total dry solids flowrate | % | |

| Parameter | Ash mass percentage of dry solids | % | |

| Parameter | Dry solids mass percentage of total sludge flowrate | % |

| Symbol | Type | Description | Units/Set Elements |

|---|---|---|---|

| Set | Subset of anaerobic digestion blocks | {MAD, MADT} | |

| Parameter | Volatile solids destruction percentage | % | |

| Parameter | Yield of net electricity per ton of dry volatile solids destructed | kWh/tVSD |

| Symbol | Type | Description | Units/Set Elements |

|---|---|---|---|

| Set | Subset of dewatering processes . | {CU, CD, BPU, BPD, FPU, FPD} | |

| Set | Set of matching a certain chemical conditioning stream to a corresponding dewatering process . | {P} for {L, FC} for | |

| Parameter | Dosage rate of conditioning chemical stream . | ton/tDS | |

| Parameter | Percentage of total dry solids in dewatering process . | % | |

| Variable | Flowrate of conditioning chemical to a certain dewatering technology | ton/day |

| Symbol | Type | Description | Units |

|---|---|---|---|

| Parameter | Percentage of total dry solids from thermal drying | % | |

| Variable | Total flowrate of water evaporated in the thermal dryer | tonH2O/day |

| Symbol | Type | Description | Units |

|---|---|---|---|

| Parameter | Lower heating value parameter (coefficient) for sludge | MJ/tVDS | |

| Parameter | Latent heat of vaporization of water | MJ/ton | |

| Parameter | Heat Loss Factor in the incinerator | Dimensionless | |

| Parameter | Efficiency of the Rankine cycle | % | |

| Parameter | Conversion factor of MJ to kWh | Dimensionless | |

| Variable | Heat flow of volatile solids entering the incineration block | kWh(th)/day | |

| Variable | Heat required to evaporate moisture in sludge entering the incineration block | kWh(th)/day | |

| Variable | Net heat recovered from incineration | kWh(th)/day |

| Symbol | Type | Description | Units |

|---|---|---|---|

| Parameter | Yield of net electricity per ton dry volatile solids fed to the SCWO block | kWh/tVS | |

| Parameter | Yield of hydrogen per ton dry volatile solids fed to the SCWG block | kgH2/tVS |

| Symbol | Type | Description | Units/Set Elements |

|---|---|---|---|

| Set | Subset of revenue-generating products | {E, Fert, BO, BC, H2} | |

| Set | Subset of cost-incurring products to be disposed | {DS20, DS40, ASH} | |

| Variable | Objective function variable to be minimized representing the net production cost of the chosen pathway | USD/yr (USD 2019). | |

| Variable | Total annualized capital costs of the chosen processes in the optimal pathway. | USD/yr (USD 2019). | |

| Variable | Total annualized operating costs of the chosen processes in the optimal pathway. | USD/yr (USD 2019). | |

| Variable | Total annual disposal costs from the disposal of final byproducts. | USD/yr (USD 2019). | |

| Variable | Total revenues from selling of final products. | USD/yr (USD 2019). | |

| Variable | Total flowrate of a final product | unit product/day | |

| Parameter | Annualized capital charge ratio | dimensionless | |

| Parameter | Interest/discount rate | % | |

| Parameter | Number of years of the project life | yr | |

| Parameter | Price of selling of a final product . | USD/unit product | |

| Parameter | Disposal cost of a final product . | USD/unit product |

| Parameter | Value | Units |

|---|---|---|

| 100 | tDS/day | |

| 70 | % | |

| 30 | % | |

| 5 | % |

| Technology | (MMUSD) | (tDS/day) | (USD/tDS) | Ref. |

|---|---|---|---|---|

| MAD | 31.86 | 100 | 52 | [54] |

| MADT | 33.26 | 100 | 62 | [54] |

| CD | 2.16 | 50 | 58 | [35] |

| CU | 2.16 | 50 | 58 | [35] |

| BPD | 6.6 | 50 | 69 | [35] |

| BPU | 6.6 | 50 | 69 | [35] |

| FPD | 8.2 | 50 | 134 | [35] |

| FPU | 8.2 | 50 | 134 | [35] |

| TD | 12.59 | 480 * | 26 ** | [55] |

| INC | 34.62 | 130 | 95 | [56,57] |

| GN | 2.09 | 5 | 154 | [58] |

| PY | 8.26 | 50 | 100 | [57] |

| SCO | 9 | 14 | 113 *** | Correspondence with SCFI [59] |

| SCG | 18.44 | 24 | 175 | [32] |

| Final Product | (USD/ton) | (USD/ton) | Ref. |

|---|---|---|---|

| DS20 | 250 | N/A | [56] |

| DS40 | 125 | N/A | [56] |

| ASH | 77 | N/A | [56] |

| E | N/A | 0.08 | [60] |

| FERT | N/A | 30 | [61] |

| BO | N/A | 285 * | [62] |

| BC | N/A | 200 | [63] |

| H2 | N/A | 2 ** | [64] |

| Parameter | Value | Units | Ref. |

|---|---|---|---|

| 50 | % | [54] | |

| 2390 | kWh/tVSD | [54] | |

| 60 | % | [54] | |

| 2390 | kWh/tVSD | [54] | |

| 0.004 | ton/tDS | [34] | |

| 0.1 | ton/tDS | [34] | |

| 0.07 | ton/tDS | [34] | |

| 10 | % | [35] | |

| 20 | % | [35] | |

| 40 | % | [35] | |

| 90 | % | Typical | |

| 21,000 | MJ/tVDS | [65] | |

| 2260 | MJ/tonne | Steam Table | |

| 0.05 | Dimensionless | assumed | |

| 25 | % | [57] | |

| 0.27778 | Dimensionless | ||

| 1368 | kWh/tVS | [58] | |

| 1 | Dimensionless | ||

| 1 | Dimensionless | ||

| 825 | kWh/tVS | Correspondence with SCFI [59] | |

| 112 | kgH2/tVS | [32] |

| Model Statistics | Solver Statistics | ||

|---|---|---|---|

| Single Equations | 635 | Solver | BARON |

| Single Variables | 418 | Optimality Tolerance | 10−6 |

| Non-linear matrix entries | 371 | Branch-and-reduce iterations | 41 |

| Discrete Variables | 14 | Max. no. of nodes in memory | 21 |

| Non-zero elements | 1700 | CPU Time (s) | 70.72 |

| (Cases) | 22% (and Lower) | 27% | 32% | 37% |

|---|---|---|---|---|

| Optimal Pathway | FPU + TD + PY | BPU + TD | BPU + TD | BPU + TD |

| (MMUSD/yr) | 3.21 | 1.84 | 1.72 | 1.62 |

| (MMUSD/yr) | 9.77 | 4.54 | 4.03 | 3.67 |

| (MMUSD/yr) | 6.99 | 1.00 | 1.00 | 1.00 |

| (MMUSD/yr) | 5.99 | 5.37 | 4.75 | 4.28 |

| (Cases) | 35% (and Lower) | 39% | 43% | 48% |

|---|---|---|---|---|

| Optimal Pathway | BPU + TD + PY | FPU + TD + PY | FPU + TD + PY | FPU + TD + PY |

| (MMUSD/yr) | 3.30 | 3.23 | 3.16 | 3.10 |

| (MMUSD/yr) | 9.01 | 9.83 | 9.59 | 9.39 |

| (MMUSD/yr) | 6.08 | 6.99 | 6.99 | 6.99 |

| (MMUSD/yr) | 6.24 | 6.07 | 5.76 | 5.50 |

| Processing Pathway | |||||

|---|---|---|---|---|---|

| MAD + FPD | +0.80 MMUSD/yr [+25%] | −5.13 MMUSD/yr [−52%] | +3.17 MMUSD/yr [N/A] | −4.76 MMUSD/yr [−68%] | +3.65 MMUSD/yr [+61%] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morsy, O.; Hourfar, F.; Zhu, Q.; Almansoori, A.; Elkamel, A. A Superstructure Mixed-Integer Nonlinear Programming Optimization for the Optimal Processing Pathway Selection of Sludge-to-Energy Technologies. Sustainability 2023, 15, 4023. https://doi.org/10.3390/su15054023

Morsy O, Hourfar F, Zhu Q, Almansoori A, Elkamel A. A Superstructure Mixed-Integer Nonlinear Programming Optimization for the Optimal Processing Pathway Selection of Sludge-to-Energy Technologies. Sustainability. 2023; 15(5):4023. https://doi.org/10.3390/su15054023

Chicago/Turabian StyleMorsy, Omar, Farzad Hourfar, Qinqin Zhu, Ali Almansoori, and Ali Elkamel. 2023. "A Superstructure Mixed-Integer Nonlinear Programming Optimization for the Optimal Processing Pathway Selection of Sludge-to-Energy Technologies" Sustainability 15, no. 5: 4023. https://doi.org/10.3390/su15054023

APA StyleMorsy, O., Hourfar, F., Zhu, Q., Almansoori, A., & Elkamel, A. (2023). A Superstructure Mixed-Integer Nonlinear Programming Optimization for the Optimal Processing Pathway Selection of Sludge-to-Energy Technologies. Sustainability, 15(5), 4023. https://doi.org/10.3390/su15054023