Abstract

The global market for Additive Manufacturing (AM) is expected to grow, which may increase the prominence of sustainability aspects in the manufacturing process. A growing number of AM academics and practitioners have started to pay attention to the environmental and societal impacts of AM instead of only focusing on its economic aspect. Yet, AM is still not widely adopted, and the research on AM sustainability is still at the nascent stage. This paper aims to better understand AM’s sustainable adoption and seeks to address three questions: what the sustainability implications of AM are; what challenges may prevent the broad adoption of AM; and what opportunities can enable AM sustainability. The research adopts a multiple case study method to investigate six AM companies that play different roles in the AM ecosystem, including AM design, AM machine, AM material, AM service, AM education, and AM consulting. The results from these studies reveal that AM has the potential to reduce environmental and social impacts; however, it might also cause negative consequences and lead to some rebound effects. We identified 43 categories (synthesized from 199 examples) of key challenges for AM adoption and proposed 55 key solutions in moving AM towards sustainability. It is evident that AM acts as a promising digital technology for manufacturing and has the potential to pave the way for a new era of sustainable manufacturing.

1. Introduction

Additive Manufacturing, also known as 3D Printing, has seen significant advances in technology; however, companies may not fully understand how to maximize its value and whether it is environmentally or socially beneficial. The sustainability performance of AM has been positively portrayed in the grey literature, which highlights its ability to reduce the use of raw materials and reduce transportation distances. However, limited research has been done to determine if AM always has a positive impact on environmental sustainability [1]. It remains unclear if AM is more energy-efficient or environmentally friendly than subtractive manufacturing processes [2]. The impact on resource use and materials toxicity is also unclear, despite the process being materially efficient. There is a potential for health hazards to be generated during the handling of printed and unprinted materials. Further research into the sustainability implications of AM is necessary before the market matures globally. Early studies have shown that AM may not be as sustainable as previously thought, as it consumes more energy than casting and injection molding [3]. The research into AM’s social and environmental implications is still in its early stages and the results remain inconclusive, making it challenging to determine its impact compared to other digital technologies [1,2].

This paper employs a multiple case study approach to examine various AM companies within the AM ecosystem and investigate the resulting sustainability implications and key challenges for sustainable AM adoption. The study extends the existing literature by using a theoretical replication logic to select contrasting cases that serve as examples of AM technology application [1,4]. A coding process was applied to extract the sustainability implications, challenges, and adoption opportunities from the case studies. This process led to the identification of critical challenges in different AM sectors, some of which have not been previously addressed in the literature. These challenges hinder the widespread adoption of AM and must be addressed for more sustainable outcomes. The results of the study reveal that, while AM has the potential to reduce environmental and social impacts, it can also lead to negative consequences and rebound effects. This paper contributes to the literature on sustainability in AM technologies by focusing on the critical challenges and opportunities for widespread adoption and provides both theoretical and managerial implications for AM development.

The paper begins by providing an overview of AM technologies, their characteristics, and the principles of AM processes, as presented in Table 1. This is followed by an analysis of previous studies that highlights the strengths and limitations of AM, presented in Table 2. The paper then delves into the sustainability of AM, focusing primarily on the environmental and social aspects. To gain a deeper understanding of AM’s sustainability, different AM cases are investigated and presented in Table 3 and the sustainability implications of AM are illustrated in Table 4. Based on these insights, the key challenges facing different AM sectors are identified in Table 5, and theoretical implications are provided. The paper presents potential solutions that can lead to more sustainable outcomes, summarized in Table 6. These findings serve as a starting point for further exploration of the challenges, sustainability solutions, and new applications of AM. The results provide insights into the barriers that must be overcome in order to enable the wider adoption of AM technologies in Table 7. The paper concludes with theoretical implications for AM development, providing a foundation for future research in this field. The results can help guide companies and policy makers in their decision-making process, leading to a more sustainable future for AM technologies. It is clear that AM is a powerful digital technology for manufacturing and has the potential to lead the way towards a more sustainable manufacturing era.

Table 1.

Characteristics and principles of AM processes for each category, adapted from [5,6,7,8,9,10,11,12,13].

Table 2.

Strengths and limitations of AM (adapted from [14,15,16,17,18,19,20]).

Table 3.

An overview of six AM cases.

Table 4.

Sustainability implications of AM from the value perspective in each case.

Table 5.

Identification and analysis of 199 key challenges in different AM cases.

Table 6.

Development of 55 sustainability solutions for different AM sectors.

Table 7.

The 43 categories of key challenges for wide AM adoption.

2. Literature Background

2.1. The AM Processes

This section reviews the literature on AM technologies, focusing on their processes, strengths, and weaknesses. AM has experienced significant growth over the past three decades and differs from conventional manufacturing processes such as casting, milling, forming, and machining. The American Society for Testing and Materials (ASTM) has classified AM processes into seven categories: vat photopolymerization, directed energy deposition, powder bed fusion, material extrusion, material jetting, binder jetting, and sheet lamination [5,6,7,8,9]. These categories have been widely recognized and adopted. The paper investigates the characteristics of each AM process category and provides a comprehensive review of the principles of AM processes in terms of printing materials, power sources, implementation challenges, applications, strengths, and opportunities in Table 1. AM can produce 3D physical objects using raw materials such as powders, liquids, or filaments, with minimal waste and good geometric accuracy [5,6,7]. It has the potential to transform the manufacturing industry and bring new design and market opportunities [2]. However, the economic value of AM remains based on conceptual studies, and ongoing research mainly focuses on the technological aspects of AM processes, with limited focus on AM management, operations, and strategy [21]. While AM has demonstrated benefits such as customized and functional products in various industries, its resource efficiency and environmental friendliness are still in question for some applications [22]. The implementation of AM technologies is still in its early stages, with several challenges in direct production contexts, and it may not make conventional manufacturing processes obsolete [22].

This paper aims to gain a better understanding of the challenges and opportunities for the adoption of Additive Manufacturing (AM) compared to traditional manufacturing methods. Table 2 presents both the strengths and limitations of the development and implementation of AM. The strengths and limitations addressed in the literature provide valuable insights into AM technologies. Researchers and practitioners have been working tirelessly for decades to improve AM processes to overcome these barriers. It is crucial to develop a method and framework to guide the adoption of AM technologies in a well-informed and sustainable manner [23]. The widespread adoption of AM would disrupt the way that manufacturing companies operate and capture value. Therefore, there is a need for empirical studies to examine the challenges faced by AM companies and the opportunities for widespread implementation of AM in practice.

2.2. AM Sustainability

Researchers argue that AM can bring several benefits from a sustainability perspective and can become a key manufacturing technology in the sustainable society of the future [1,2,9,14,24]. To support this claim, it is necessary to investigate and estimate the environmental and social impacts of AM processes. Research in this area is still in its early stages and has focused on the resource efficiency of different AM processes [15,25]. Some studies have monitored AM production processes and quantified their environmental impacts [15,26,27], while others have compared the consumption of materials and energy use between AM and conventional manufacturing methods such as injection molding and casting [2,14]. For example, Frazier [28] reviewed metal AM processes to demonstrate how they reduce energy, materials, and other resource consumption. Despite the technological advancements in AM, including the improvement of mechanical properties and materials, the research on its sustainability is still limited and lacks consistency and continuity [29]. The absence of a strategic plan for sustainability in AM calls for further investigation and understanding of its impact on the environment and society [16].

AM may not be as sustainable as some suggest, as in some cases it may generate more energy consumption compared to casting and injection molding [3]. There is no clear conclusion that AM is more energy-efficient or environmentally friendly compared to subtractive manufacturing processes overall [22]. The literature suggests that coming to the conclusion that AM processes have lower environmental impacts than traditional manufacturing is biased, as data on total waste are missing, and uncertainties exist [22,30]. The sustainability of AM, especially in terms of its environmental sustainability, can vary depending on the specific circumstances and on a case-by-case basis [31]. More comprehensive sustainability evaluations are required to assess the performance, accuracy, and feasibility of the environmental impacts of AM.

The literature on the social impacts of AM is under-explored [14,22,32]. The social aspects typically relate to work safety, health conditions, employment schemes, quality of life, and human well-being, among others. Some printed materials have the potential to negatively affect health conditions. Harsh skin reactions, eye irritation, and allergies may occur if powder or liquid materials come into contact with skin. Prolonged exposure to certain materials and chemicals may impact health and result in chronic allergies [22]. The adverse effects of some AM materials are not yet well understood [22]. It is important to gain a better understanding of the potential health and occupational hazards and toxicities associated with AM. Few conclusions have been made about its sustainability implications in both the environmental and social dimensions. To conclude, AM is likely to have a greater sustainability impact if (1) closer integration and deeper cross-disciplinary collaboration is established, and (2) timely and comprehensive research is conducted to identify opportunities for energy-efficient and environmentally friendly improvements. AM is expected to play a key role in the sustainable manufacturing of the future.

2.3. Research Questions

The research shows that the current theoretical and empirical studies on AM sustainability are still in their early stages. The focus of AM research has been mainly on material development, process innovation, and energy consumption [2,3,15], and the sustainability implications of AM have received limited attention [1,33,34]. While some studies have explored the broad sustainability implications of AM [1,18,26], a better understanding of the sustainability implications and wider adoption of AM are needed.

In light of this, the objective of this research is to address the gap in the current literature by exploring the challenges and opportunities for the wide adoption of AM. The following research questions are proposed:

RQ1: What are the sustainability implications of AM from a value perspective?

RQ2: What are the key challenges that prevent the widespread adoption of AM?

RQ3: What opportunities and solutions can promote more sustainable outcomes in AM?

3. Research Methods

This research addresses a real-world problem identified in the AM industry and offers new knowledge to enable AM sustainability. The purpose of the research is to explore the challenges and opportunities regarding AM in moving towards sustainability. This research primarily relies on practitioners’ opinions, experiences, and perspectives of the current AM companies to build new knowledge from empirical evidence. Using a qualitative approach is considered adequate for addressing the research questions through inductively building theory and moving from particular to general themes [35]. The richness of the data will be a key factor for this qualitative study. It is believed that the case study method is an effective empirical approach for gaining exploratory, real-life insights and building theory [4]. Therefore, a qualitative approach has been proposed as the primary method to enhance the understanding of the research questions and findings. Despite the increasing amount of literature on AM technologies, few studies offer insights into the challenges and solutions regarding the sustainable adoption of AM based on empirical evidence. The main focus of this research is to understand a practical problem and develop an in-depth description of multiple cases in the AM industry. The case study was chosen as a fundamental data collection method because it is deemed suitable for this research.

The aim of this paper is to understand a practical problem by talking directly with people, visiting workplaces, and conducting fieldwork [4]. Multiple case studies will be conducted to generate robust theory and validate the findings through replication in various situations [4,36]. Thus, six cases were identified following a theoretical replication logic for contrasting results from three countries: China, the USA, and Japan. The case selection criteria targeted exemplars of AM sectors that have a significant market impact and share substantial business experiences. Six cases were chosen due to the degree of theoretical saturation reached when incremental improvement is minimal and gathering new data no longer sparks new insights [36,37]. The data were directly drawn from semi-structured interviews with managers, fieldwork in workplaces, and factories. The interviews typically lasted 1–3 h and were conducted in English. All interview processes were audio-taped with prior consent for later transcription and analysis. Table 3 presents the details of the case studies, including 6 companies, 34 interviews, and 25 participants for data collection. The cross-case analysis interpreted different data forms and looked for patterns across multiple cases. The data analysis process was conducted through three stages of coding: open coding (i.e., reading the data, noting codes for related statements and assigning them to categories), axial coding (i.e., re-reading the data, confirming the concepts and categories accurately), and thematic coding (i.e., identifying patterns in coding and clustering codes into common themes); this was done until saturation was reached to explore how the categories are related [35].

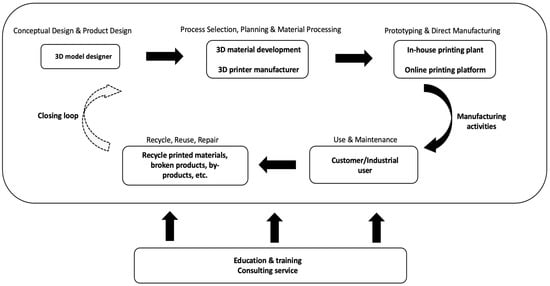

We selected six case companies from different AM sectors based on the product life cycle, starting from the stage of conceptual and product design, moving through process selection, planning, and material processing, to production activities such as prototyping and direct manufacturing, and, finally, to the use, maintenance, and recycling, reusing, and repairing of printed products and waste materials to close the loop, as shown in Figure 1. The AM ecosystem perspective informed our decision to choose the six most representative cases that encompass various technology functions and business orientations, including a 3D model design company, a material development company, a machine manufacturer, a printing service platform, an AM education provider, and an AM consulting firm. As depicted in Figure 1, designers create 3D models, material suppliers develop materials, machine manufacturers produce 3D printers, and products can be printed through online platforms or in-house facilities. The printed products are then used by customers and industrial users; however, the arrows with dashes indicate that recycling, reuse, and repair are not always well executed, and not all used parts return to the system to close the loop. We used multiple sources of evidence to reduce bias and increase validity, including industry reports, website articles, newspapers, observations, and interview transcripts. The data analysis was conducted using a thematic coding process until saturation was reached to extract the sustainability implications and challenges from the case descriptions. The sustainability implications from the value perspective of the six cases were identified and extended throughout the multi-case study analysis to move AM towards sustainability, as shown in Table 4. The cross-case analysis also investigated the social, environmental, and economic value systems of each case to ensure research validity and reliability [4]

Figure 1.

Case study selection based on the AM ecosystem.

4. Results

4.1. Key Challenges of Different AM Sectors

We identified and summarized 199 key challenges across the AM design processes, machine development, material development, printing service platform, education, and consulting service that AM firms encountered. The root causes were extracted and analyzed from interviews, observations, documentary analysis, and the existing literature in the AM field. The findings confirmed some previously established results (indicated by a “★” symbol), while other results were original. The extracted codes related to root causes were categorized into different types, as shown in Table 5. For example, in Case Study E, the root causes of the challenges in AM education services were analyzed and categorized into 29 examples, which were further classified into 6 categories: educational materials, qualified educator, education equipment, sustainability education, design for education, and education service. In Company F, the root causes of customer problems were used as practical evidence to confirm the challenges in AM consulting services. The data were analyzed, and similar root causes were classified into 13 examples under 4 categories: qualified consultant, consulting service, external environment, and sustainability consulting( as shown in Table 5).

Overall, the data from AM cases were analyzed and produced into different key challenges. For instance, the negative root causes in the AM design process impede the broad adoption of AM for practitioners and traditional manufacturers. In particular, the lack of qualified designers in the market has negatively impacted the development of AM design and value creation. This indicates that the key challenges in AM design were hidden within the existing business models and uncovered through root cause analysis. Further, the key challenges of AM machine development were identified and grouped into five categories: printer knowledge, printing speed, printing market, printing development, printing quality, and printing cost and sustainability. The negative root causes of AM materials were categorized into 46 examples and were summarized into 7 categories: material properties, material recycling and reuse, material quality, material standard, material costs, material selection, and material development. Identifying the root causes can help to uncover sustainable opportunities for the companies, and particularly for the environment and society.

4.2. Sustainability Solutions for Different AM Sectors

The case studies indicate that identifying challenges in AM helps to reveal sustainability solutions. We then developed effective sustainability solutions for each AM sector, enabling the generation of sustainable outcomes. The examples of solutions were categorized into six types: design for sustainability, material for sustainability, machine for sustainability, printing for sustainability, service for sustainability, and education for sustainability. For example, in the AM design case, we identified 35 key challenges (see Table 5). Based on these challenges, we uncovered 11 critical tactics for design for sustainability, as shown in Table 6. Some tactics were deleted or merged into others based on their significance and frequency. We then developed and synthesized the key tactics consecutively for AM material, machine, printing service, education, and consulting service for sustainability. It is important to note that some of the sustainable solutions overlap and some might not be feasible for certain companies. As a result, 55 types of sustainability solutions were uncovered, forming a comprehensive set of actions that will enable AM companies to generate more sustainable outcomes. Some of these key solutions are novel and have not been covered in the previous literature.

The 55 types of tactics were presented to AM companies and reactions were sought. We applied the AM sustainability solutions to the interviews and workshops to validate the key tactics. Notably, the CTO of the AM material company said: “We try to develop the polymers that can be recycled and reused as sustainability solutions; however, these recycled polymers are typically not mechanically strong. They are quite weak mechanically […].” The Director of the AM material company also commented: “We will not put the recycled materials into our new materials production process, which would negatively affect the properties of the overall material.” The solutions indicate a need for developing recycling and reuse technologies for wasted and printed materials. However, it is still quite challenging to recycle and reuse most AM materials, particularly for multi-material products and mixed materials with different colors. The interviewees indicated that the recycling technologies were immature and that recycled materials properties were not good enough. The AM materials manufacturers lacked knowledge and awareness of material sustainability concepts.

The research findings showed that very few AM companies are taking action in material recycling and reuse. Only a minimal number of printed materials were dealt with in the recycling process and sent back to the inputs of the new materials. The CTO of the AM materials company also emphasized: “Material recycling is pretty difficult. The recycled filament is not good quality with small porosity and dust inside, which negatively affect the nozzle.” One sustainability solution for materials is to develop environmentally-friendly printing materials. However, the printing service company only considered PLA for recycling, as it is is biodegradable, and did not consider ABS, TPU, and PC, which are not recyclable. It should be noted that recycled materials have fragile mechanical properties and low strength that are not ideal for re-printing and negatively impact the overall material properties. The Sales Manager of a printing service company emphasized: “Senior managers in our company are not paying the materials recycling much attention. We still set making profits as the priority.” The CTO of the printing service company also mentioned: “The generated wastes of traditional manufacturing are million times more than that of 3D printing. We do not need to care about the wastes in 3D printing because it is too little and has minimal impact on the environment.”

The data validation showed that the sustainability solutions for AM are valuable and helpful. However, sustainability considerations have not been embedded into the current production systems and business models. As the interviewees indicated, AM material companies still set making profits as the priority without paying much attention to environmental and social value. Furthermore, 3D printer manufacturers sell the machines with limited additional services. One of the ‘machine for sustainability’ solutions is to provide machine sharing, subscription, and leasing services. Delivering functionality rather than selling product ownership to fulfil customers’ needs would bring resource efficiency and environmental benefits. However, 3D printer manufacturers are not likely to change current business models and deliver functionalities rather than ownership through machine subscriptions, although the companies are aware of the environmental and social benefits. Still, the companies would only consider it if it were combined with economic value. This confirms the findings from the case studies that AM companies intend to consider environmental and social value when they can make financial profits. It is expected that more AM companies would sell the availability of the printers without customer ownership because industrial printers are quite expensive and not widely adopted by industrial customers. In sum, we developed the critical sustainability solutions list, which could be helpful for AM companies to improve competitiveness and sustainability. In comparison, the implementation effectiveness of the sustainability solutions is not discussed in the scope of this research but could be further investigated in the future. The 55 significant tactics could help AM companies to develop sustainable business models and technologies. However, due to the limitations of the data, the summary list might not be complete. Table 6 can be extended to embrace more AM sectors and develop more tactics in future work. The summary of the sustainability solutions contributes to the concept of sustainability in the context of AM technologies.

5. Discussion of Key Challenges for AM Adoption

We conducted a comprehensive analysis of the negative root causes that exist in various AM companies to answer the research question of “what are the key challenges preventing the wide adoption of AM?” By identifying these key challenges, we aimed to gain a better understanding of AM technologies and investigate how they can be more widely adopted. The limitations of AM technologies have been discussed in the previous literature; however, this study goes beyond by examining challenges in a range of AM applications, including design, printing service, education, consulting, etc. [2,3,15,17,20,22,38]. This study is novel because it combines both the literature and empirical data to identify challenges, encompassing broader concerns regarding business, management, and operational perspectives. As a result of our analysis, we uncovered 199 key challenges for different AM sectors, which were classified into 43 categories to better understand their sustainability implications, as shown in Table 7. These challenges help to explain why AM is not yet widely adopted and what needs to be overcome for more sustainable outcomes. For example, both AM machine and service companies face challenges in printing sustainability, such as “waste streams in the printing process (materials, scraps, printing support, etc.)” and “lack of materials recycling and reuse.” Similarly, AM material and service companies also face common challenges in material quality, such as “limited recyclability of materials due to quality loss” and “difficulty in guaranteeing recycled material properties for a given process.” We compared the key challenges in each AM case with the existing literature to validate our results, as shown in Table 8. This study provides the first categorization of challenges for these AM sectors, which has theoretical implications for AM development.

Table 8.

Literature confirmed/extended/contradicted for key challenges in each AM case.

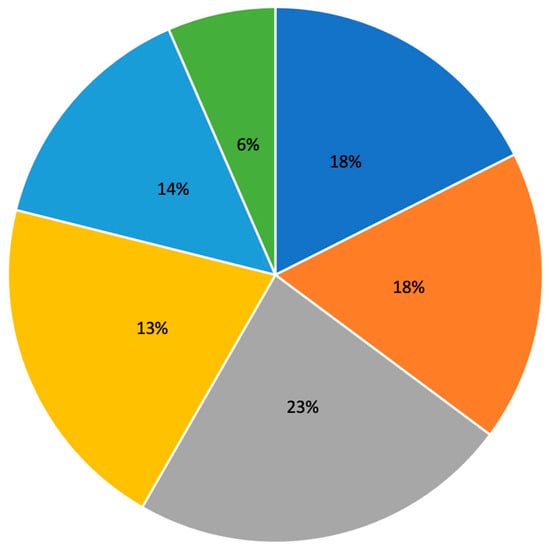

Figure 2 illustrates the percentages of key challenges across all six cases. It shows that more than half of the total 199 challenges (59%) are identified, respectively, in the AM design (18%), AM material (23%), and AM machine (18%) categories. This confirms the findings from the literature that the prominent AM limitations of the design methodology, materials development, and modelling, sensing, control, and process must be addressed [2]. This also indicates that AM technology innovation lays the foundation for broad adoption. We evaluated and compared the findings with the literature. It should be noted that some of the key challenges in this research correspond to the AM adoption challenges in SMEs [39]. The challenges identified in this paper extend the scopes and implications related to technology, strategy, supply chain, operation, organization, and other external clusters [39]. Regarding the technology-related challenges, we analyzed the technical difficulties from the perspectives of machine, materials, design, and processing issues. Martinsuo and Luomaranta [39] only investigated AM machines and materials challenges, and developed only 26 AM adoption challenges regarding the strategy, operation, and external marketing-related challenges. In comparison, this paper provides 199 examples/explanations for design, machine, materials, printing process, education, and consulting services that confirm and extend the existing literature regarding the abovementioned strategy, supply chain, operational, and organizational challenges.

Figure 2.

Percentage of key challenges in different AM cases.

6. Conclusions

AM technologies are still in their infancy and require further improvement. Therefore, it is no surprise that the research on AM sustainability is also at the nascent stage. This early study has shown that AM is not as sustainable as many have suggested, as it generates more energy consumption than casting and injection molding. Due to the immaturity of AM technologies in terms of mass production and customization, the realization of wide AM adoption highly depends on overcoming these key challenges in various aspects. The research questions were answered, and the theoretical and practical contributions were highlighted and reinforced. It is hoped that more AM companies will place importance on sustainability and incorporate sustainable solutions into their value creation and capture processes while advancing their technologies. The research findings provide opportunities for further work that would benefit both theory and practice, including investigating solutions to the key challenges and enabling mass customization regarding AM. The sustainability solutions could be applied in a broader context and the effectiveness of their implementation and execution could be studied in the future.

Author Contributions

Conceptualization, W.L., X.L. and S.E.; methodology, W.L., S.E. and M.Y.; validation, W.L., X.L. and S.E.; formal analysis, W.L., S.E. and M.Y.; data curation, W.L. and M.Y.; writing—original draft preparation, W.L., X.L. and S.E.; writing—review and editing, W.L., X.L., Y.L., J.W., S.E. and M.Y.; supervision, X.L., J.W. and S.E; project administration, W.L., X.L., Y.L., J.W. and S.E.; funding acquisition, X.L., S.E., J.W. and Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (71932009), National Natural Science Foundation of China (72272140), and EPSRC Centre for Innovative Manufacturing in Industrial Sustainability (EP/I033351/1).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, C.M.; Mazumder, J.; Donmez, A. Additive manufacturing: Current state, future potential, gaps and needs, and recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing environmental impacts of additive manufacturing vs traditional machining via life-cycle assessment. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef]

- Yin, R. Case Study Research: Design and Methods, 3rd ed.; Sage Publications: Thousand Oaks, CA, USA, 2003. [Google Scholar]

- ASTM F2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- Gopal, M.; Lemu, H.G.; Gutema, E.M. Sustainable Additive Manufacturing and Environmental Implications: Literature Review. Sustainability 2023, 15, 504. [Google Scholar] [CrossRef]

- Ribeiro, I.; Matos, F.; Jacinto, C.; Salman, H.; Cardeal, G.; Carvalho, H.; Godina, R.; Peças, P. Framework for Life Cycle Sustainability Assessment of Additive Manufacturing. Sustainability 2020, 12, 929. [Google Scholar] [CrossRef]

- Diegel, O.; Singamneni, S.; Reay, S.; Withell, A. Tools for sustainable product design: Additive manufacturing. J. Sustain. Dev. 2010, 3, 68. [Google Scholar] [CrossRef]

- Taddese, G.; Durieux, S.; Duc, E. Sustainability performance indicators for additive manufacturing: A literature review based on product life cycle studies. Int. J. Adv. Manuf. Technol. 2020, 107, 3109–3134. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive manufacturing technologies rapid prototyping to direct digital manufacturing. In Additive Manufacturing Technologies; Springer: New York, NY, USA, 2010. [Google Scholar]

- Agrawal, R.; Vinodh, S. Prioritisation of drivers of sustainable additive manufacturing using best worst method. Int. J. Sustain. Eng. 2021, 14, 1587–1603. [Google Scholar] [CrossRef]

- Chen, D.; Heyer, S.; Ibbotson, S.; Salonitis, K.; Steingrímsson, J.G.; Thiede, S. Direct digital manufacturing: Definition, evolution, and sustainability implications. J. Clean. Prod. 2015, 107, 615–625. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Bourell, D.L.; Sreenivasan, R.; Hague, R. Sustainability of additive manufacturing: Measuring the energy consumption of the laser sintering process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 2228–2239. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Kohtala, C. Addressing sustainability in research on distributed production: An integrated literature review. J. Clean. Prod. 2015, 106, 654–668. [Google Scholar] [CrossRef]

- Petrick, I.J.; Simpson, T.W. 3D printing disrupts manufacturing: How economies of one create new rules of competition. Res. Technol. Manag. 2013, 56, 12–16. [Google Scholar] [CrossRef]

- Petrovic, V.; Gonzalez, J.V.H.; Ferrando, O.J.; Gordillo, J.D.; Puchades, J.R.B.; Grinan, L.P. Additive layered manufacturing: Sectors of industrial application shown through case studies. Int. J. Prod. Res. 2011, 49, 1061–1079. [Google Scholar] [CrossRef]

- Savolainen, J.; Collan, M. How Additive Manufacturing Technology Changes Business Models? Review of Literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Huang, S.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Despeisse, M.; Yang, M.; Evans, S.; Ford, S.; Minshall, T. Sustainable value roadmapping framework for additive manufacturing. Procedia CIRP 2017, 61, 594–599. [Google Scholar] [CrossRef]

- Hettiarachchi, B.D.; Brandenburg, M.; Seuring, S. Connecting additive manufacturing to circular economy implementation strategies: Links, contingencies and causal loops. Int. J. Prod. Econ. 2022, 246, 108414. [Google Scholar] [CrossRef]

- Sreenivasan, R.; Bourell, D. Sustainability study in selective laser sintering–An energy perspective. In Proceedings of the 20th Solid Freeform Fabrication Symposium, The University of Taxes at Austin, Austin, TX, USA, 3–5 August 2009. [Google Scholar]

- Gebler, M.; Schoot, U.; Anton, J.M.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Yoon, H.S.; Lee, J.Y.; Kim, H.S.; Kim, M.S.; Kim, E.S.; Shin, Y.J.; Chu, W.S.; Ahn, S.H. A comparison of energy consumption in bulk forming, subtractive, and additive processes: Review and case study. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 261–279. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Niaki, M.; Nonino, F. Additive manufacturing management: A review and future research agenda. Int. J. Prod. Res. 2016, 55, 1419–1439. [Google Scholar] [CrossRef]

- Dotchev, K.; Yussof, W. Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp. J. 2009, 15, 192–203. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, Q.; Zhang, Y.; Li, T.; Zhang, H. Sustainability of 3D Printing: A Critical Review and Recommendations. In Proceedings of the ASME, International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016. [Google Scholar]

- Matos, F.; Godina, R.; Jacinto, C.; Carvalho, H.; Ribiro, I.; Pecas, P. Additive Manufacturing: Exploring the Social Changes and Impacts. Sustainability 2019, 11, 3757. [Google Scholar] [CrossRef]

- Niaki, M.; Torabi, A.; Nonino, F. Why manufacturers adopt additive manufacturing technologies: The role of sustainability. J. Clean. Prod. 2019, 222, 381–392. [Google Scholar] [CrossRef]

- Zhao, M.; Yang, J.; Shu, C.; Liu, J. Sustainability orientation, the adoption of 3D printing technologies, and new product performance: A cross-institutional study of American and Indian firms. Technovation 2021, 101, 102197. [Google Scholar] [CrossRef]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 7–101. [Google Scholar] [CrossRef]

- Eisenhardt, K. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Charmaz, K. Constructing Grounded Theory; Sage: Thousand Oaks, CA, USA, 2006. [Google Scholar]

- Bourell, D.L.; Leu, M.C.; Rosen, D.W. Roadmap for Additive Manufacturing: Identifying the Future of Freeform Processing; The University of Texas at Austin, Laboratory for Freeform Fabrication: Austin, TX, USA, 2009. [Google Scholar]

- Martinsuo, M.; Luomaranta, T. Adopting additive manufacturing in SMEs: Exploring the challenges and solutions. J. Manuf. Technol. Manag. 2018, 29, 937–957. [Google Scholar] [CrossRef]

- Long, Y.; Pan, J.; Zhang, Q.; Hao, Y. 3D printing technology and its impact on Chinese manufacturing. Int. J. Prod. Res. 2017, 55, 1488–1497. [Google Scholar] [CrossRef]

- Patrick, H.; Robert, B.; Erich, S. Business model patterns for 3D printer manufacturers innovation management and entrepreneurship. J. Manuf. Technol. Manag. 2020, 31, 1281–1300. [Google Scholar]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Change 2016, 102, 193–201. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).