Thermoelectric Generator Using Low-Cost Thermoelectric Modules for Low-Temperature Waste Heat Recovery

Abstract

1. Introduction

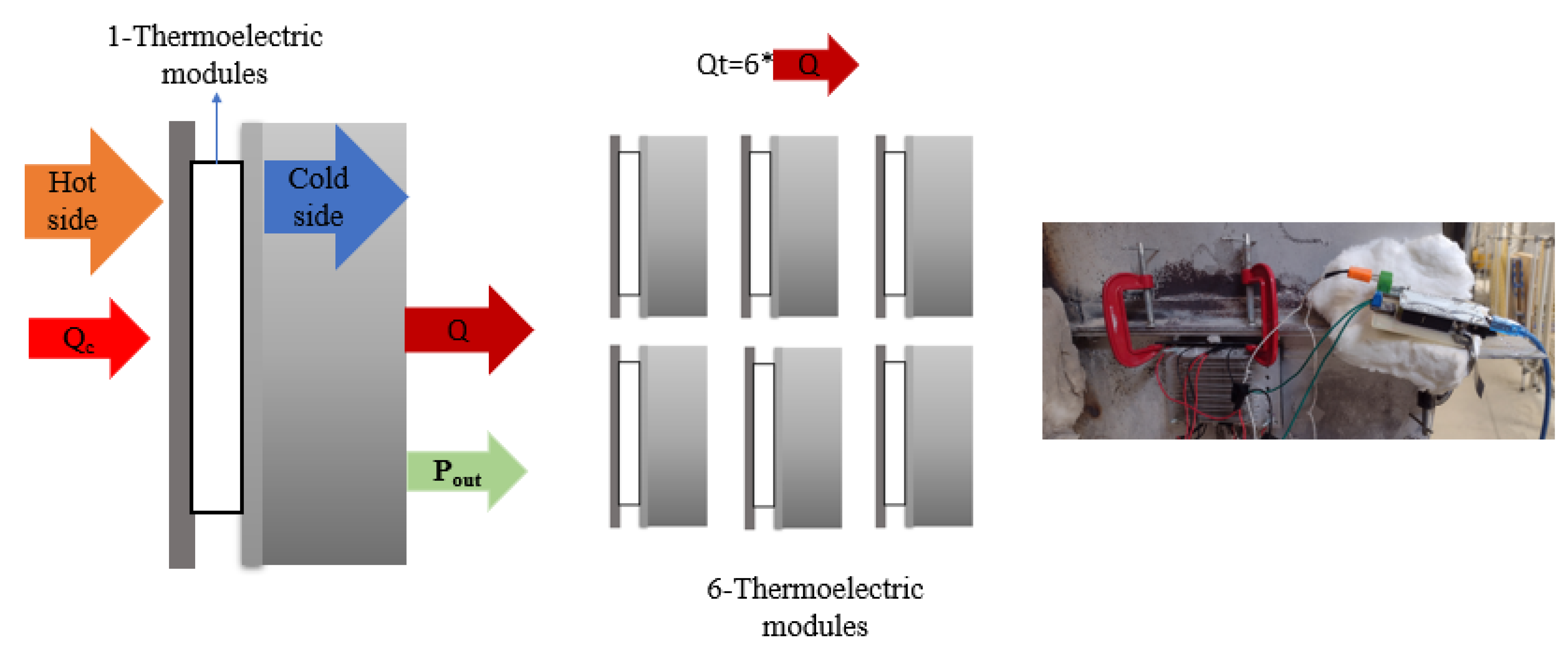

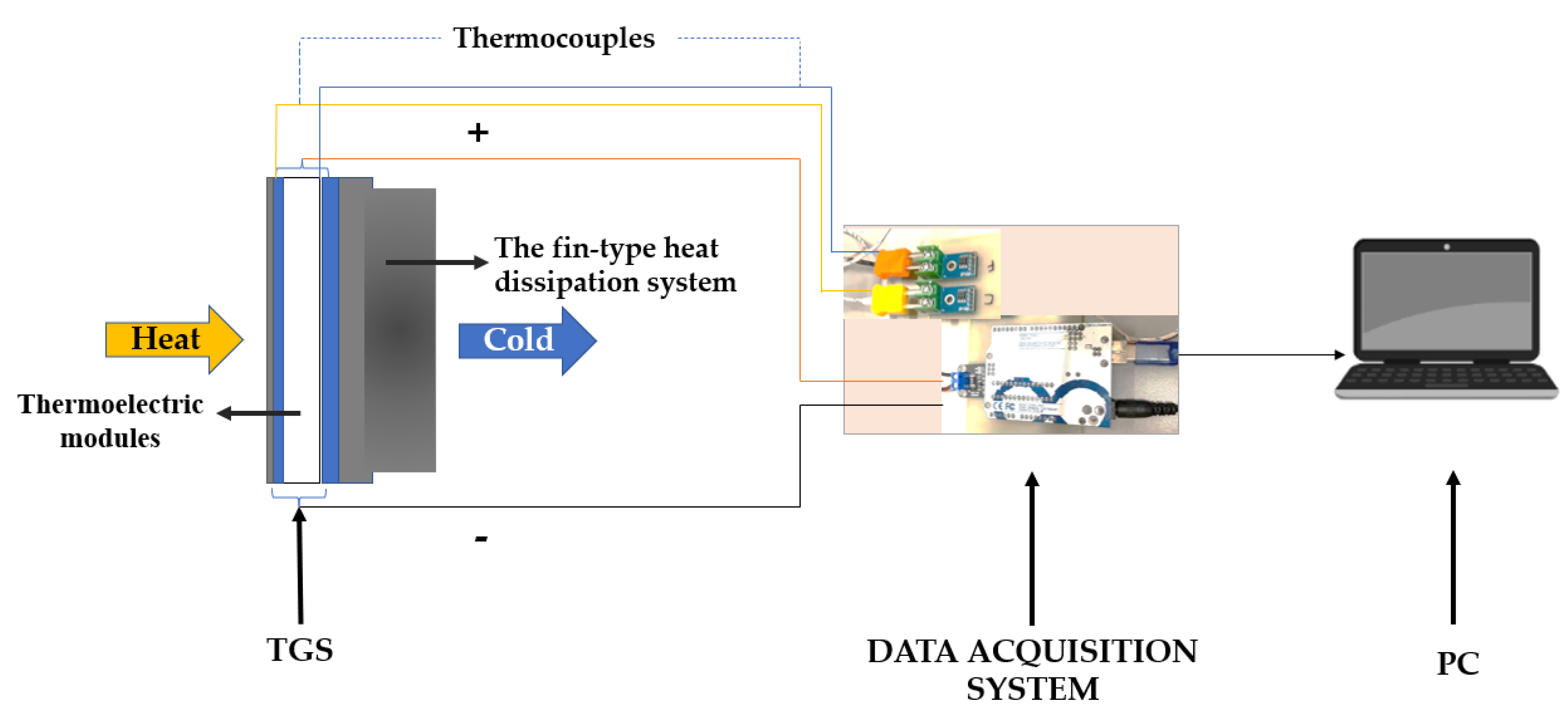

2. Materials and Methods

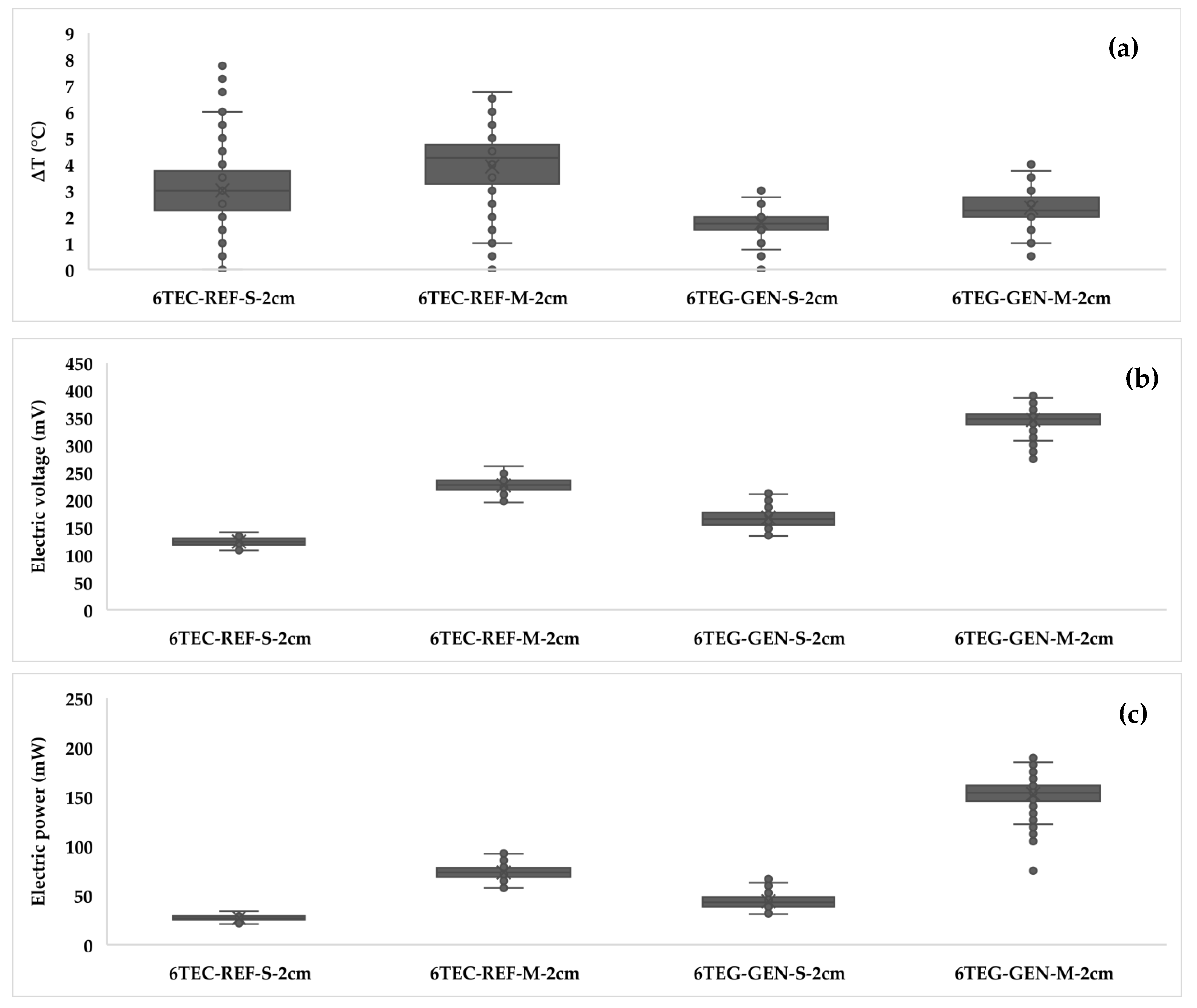

3. Results and Discussion

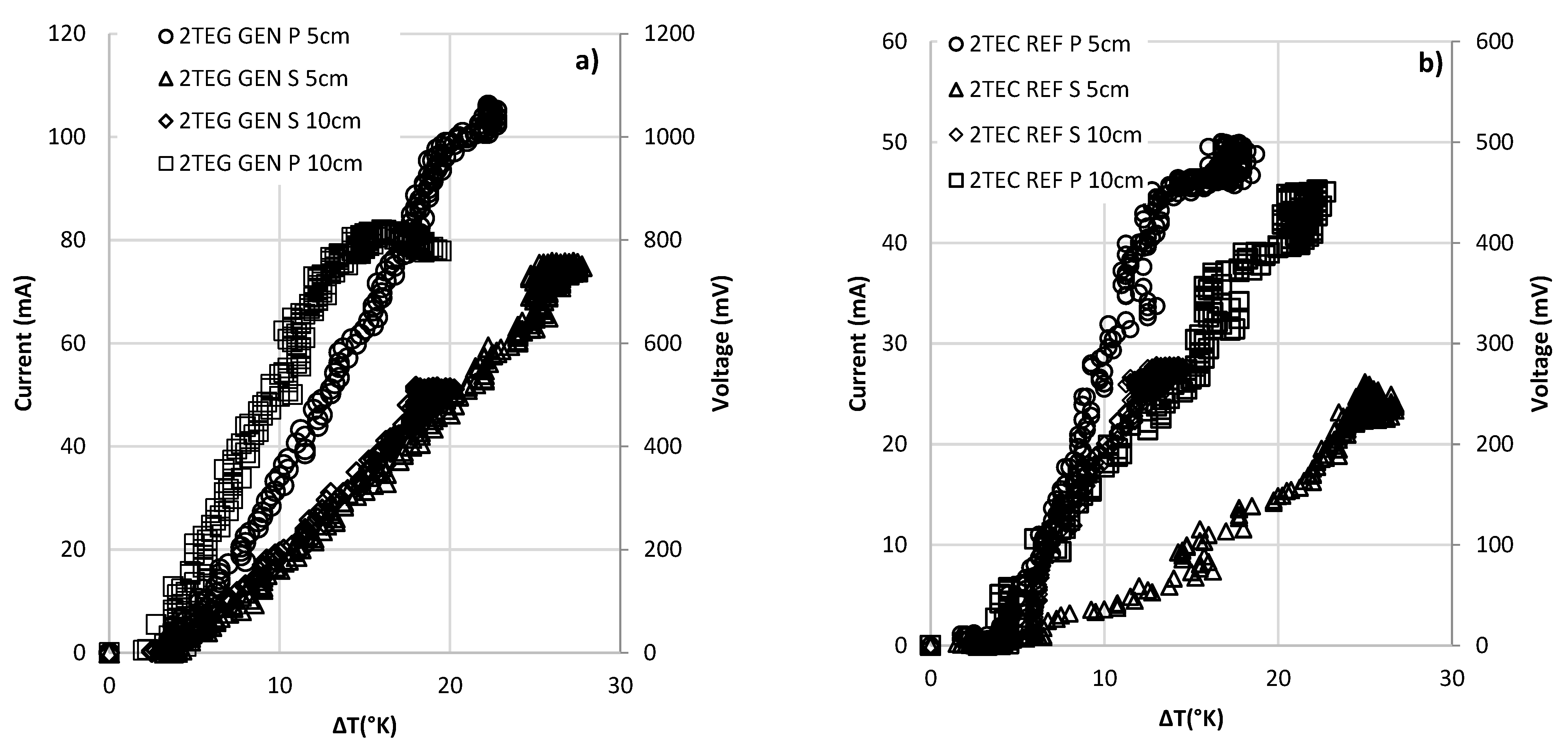

3.1. Characterization of Commercial Thermoelectric Cells and Construction of the TGS

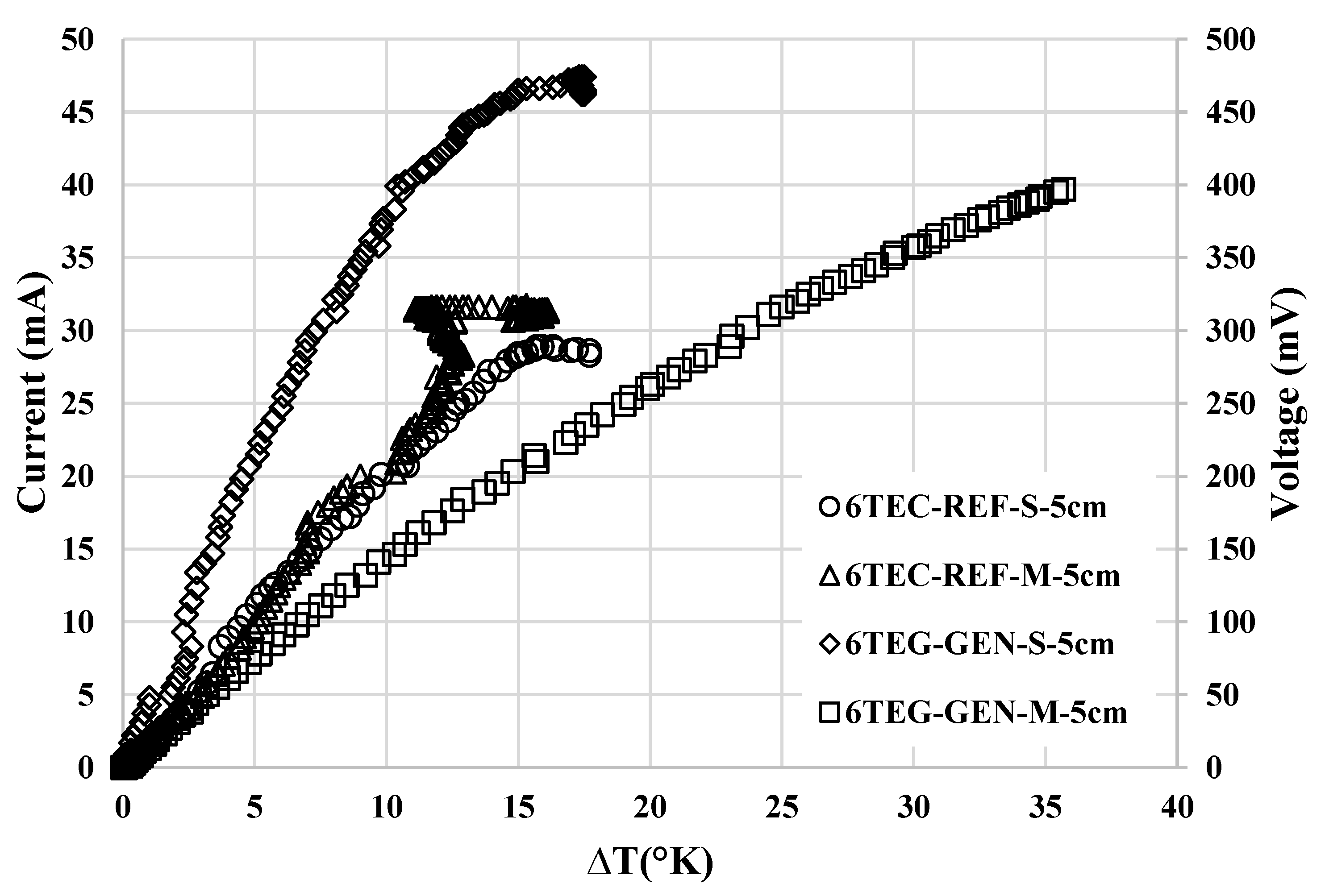

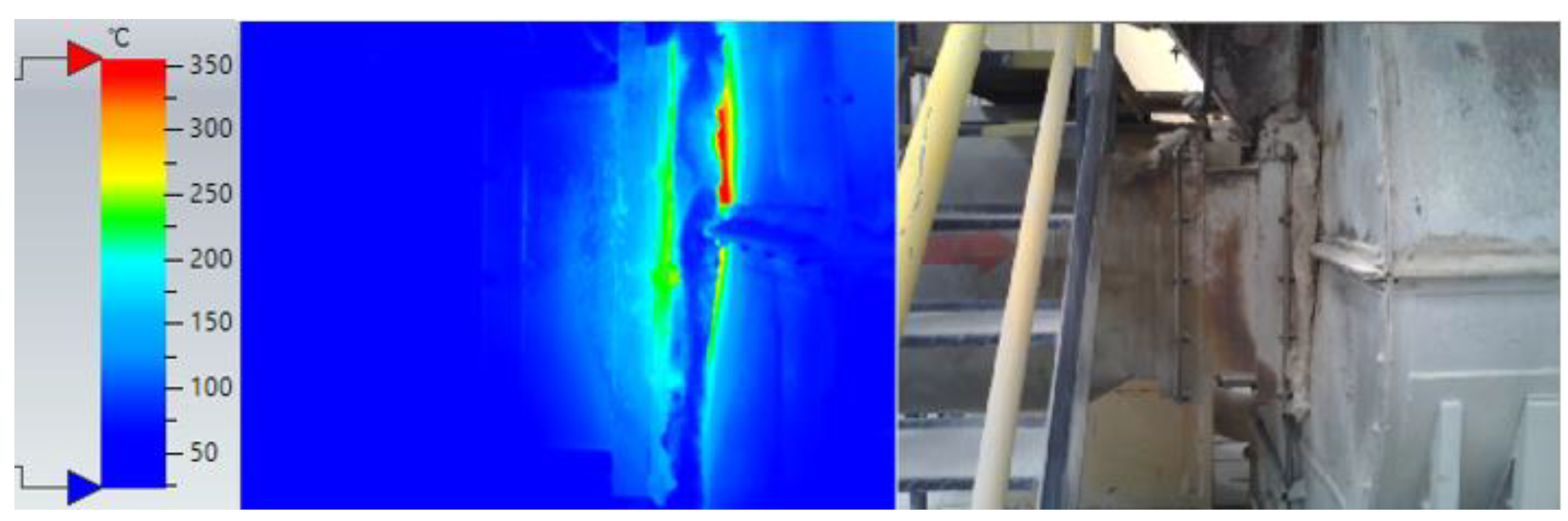

3.2. Industrial-Level Tests in a Drying Oven of the Sumicol S.A.S Company

4. Remarks and Conclusions

- An adequate coupling between the parts of the generation system promotes the best performance of the thermoelectric modules.

- The TEC1-12706 and SP 1848-27145 generation cooling cells are modules for low-temperature applications. In the tests carried out, the hot face of the module can reach a maximum temperature of 120 °C when the assembly is 5 cm from the source, which may explain the fluctuations in the measurements and the mechanical failures in the cells.

- The speed of variation of the temperature gradient is a determining factor in the power value generated by the module system, and due to the fact that the two sides of the cell can reach the same temperature very quickly, the efficiency of the thermoelectric modules is decreased.

- A heat dissipation mechanism is required that allows a temperature gradient between the cell faces, and that can be maintained for longer times, which improves the optimal performance of the generation system, guaranteeing higher voltages and a better system performance.

- The maximum heat recovery efficiency was 1.18% for the 6TEG-GEN-M-2cm test, in which the SP 1848-27145 cells of thermoelectric generation in mixed connection were used. It is recommended for future work that a hybrid heat dissipation system be implemented that uses the recirculation of air or wastewater from industrial processes. This is necessary to increase the temperature delta and to obtain better performances of the modules.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Colorado, H.A.; Mendoza, D.E.; Lin, H.-T.; Gutierrez-Velasquez, E. Additive Manufacturing against the Covid-19 Pandemic: A Technological Model for the Adaptability and Networking. J. Mater. Res. Technol. 2022, 16, 1150–1164. [Google Scholar] [CrossRef] [PubMed]

- International Energy Agency Electricity Generation by Source, World 1990–2019. Available online: https://www.iea.org/fuels-and-technologies/electricity#key-findings (accessed on 1 June 2022).

- Looney, B. Statistical Review of World Energy Globally Consistent Data on World Energy Markets and Authoritative Publications in the Field of Energy. Rev. World Energy Data. 2021, 70, 8–20. [Google Scholar]

- Zhang, L.; Li, H.; Lee, W.J.; Liao, H. COVID-19 and Energy: Influence Mechanisms and Research Methodologies. Sustain. Prod. Consum. 2021, 27, 2134–2152. [Google Scholar] [CrossRef] [PubMed]

- Rita, E.; Chizoo, E.; Cyril, U.S. Sustaining COVID-19 Pandemic Lockdown Era Air Pollution Impact through Utilization of More Renewable Energy Resources. Heliyon 2021, 7, e07455. [Google Scholar] [CrossRef] [PubMed]

- Gu, P.; Zheng, M.; Zhao, Q.; Xiao, X.; Xue, H.; Pang, H. Rechargeable Zinc–Air Batteries: A Promising Way to Green Energy. J. Mater. Chem. A Mater. 2017, 5, 7651–7666. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, D.; Kim, C.; Lee, C.; Kang, H.; Woo, H.Y.; Kim, B.J. Eco-Friendly Polymer Solar Cells: Advances in Green-Solvent Processing and Material Design. ACS Nano 2020, 14, 14493–14527. [Google Scholar] [CrossRef] [PubMed]

- Colorado, S.A.; Colorado, H.A. Manufacturing of Zinc Oxide Structures by Thermal Oxidation Processes as Scalable Methods towards Inexpensive Electric Generators. Ceram. Int. 2017, 43, 15846–15855. [Google Scholar] [CrossRef]

- Li, Y.; Lu, J. Lightweight Structure Design for Wind Energy by Integrating Nanostructured Materials. Mater. Des. 2014, 57, 689–696. [Google Scholar] [CrossRef]

- MIT Energy Initiative. The Future of Nuclear Energy in a Carbon-Constrained World An Interdisciplinary MIT Study; MIT Energy Initiative: Boston, MA, USA, 2018. [Google Scholar]

- Zheng, X.F.; Liu, C.X.; Yan, Y.Y.; Wang, Q. A Review of Thermoelectrics Research-Recent Developments and Potentials for Sustainable and Renewable Energy Applications. Renew. Sustain. Energy Rev. 2014, 32, 486–503. [Google Scholar] [CrossRef]

- Castañeda, M.; Gutiérrez-Velásquez, E.I.; Aguilar, C.E.; Monteiro, S.N.; Amell, A.A.; Colorado, H.A. Sustainability and Circular Economy Perspectives of Materials for Thermoelectric Modules. Sustainability 2022, 14, 5987. [Google Scholar] [CrossRef]

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; la Commare, U.; Micale, G. Industrial Waste Heat: Estimation of the Technically Available Resource in the EU per Industrial Sector, Temperature Level and Country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Fang, H.; Xia, J.; Zhu, K.; Su, Y.; Jiang, Y. Industrial Waste Heat Utilization for Low Temperature District Heating. Energy Policy 2013, 62, 236–246. [Google Scholar] [CrossRef]

- Jouhara, H.; Olabi, A.G. Editorial: Industrial Waste Heat Recovery. Energy 2018, 160, 1–2. [Google Scholar] [CrossRef]

- Luo, D.; Wang, R.; Yan, Y.; Yu, W.; Zhou, W. Transient Numerical Modelling of a Thermoelectric Generator System Used for Automotive Exhaust Waste Heat Recovery. Appl. Energy 2021, 297, 117151. [Google Scholar] [CrossRef]

- Fernández-Yáñez, P.; Romero, V.; Armas, O.; Cerretti, G. Thermal Management of Thermoelectric Generators for Waste Energy Recovery. Appl. Therm. Eng. 2021, 196, 117291. [Google Scholar] [CrossRef]

- Kempf, N.; Saeidi-Javash, M.; Xu, H.; Cheng, S.; Dubey, M.; Wu, Y.; Daw, J.; Li, J.; Zhang, Y. Thermoelectric Power Generation in the Core of a Nuclear Reactor. Energy Convers Manag. 2022, 268, 115949. [Google Scholar] [CrossRef]

- Martín-Gómez, C.; Zuazua-Ros, A.; del Valle de Lersundi, K.; Sánchez Saiz-Ezquerra, B.; Ibáñez-Puy, M. Integration Development of a Ventilated Active Thermoelectric Envelope (VATE): Constructive Optimization and Thermal Performance. Energy Build. 2021, 231, 110593. [Google Scholar] [CrossRef]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Doraghi, Q.; Ahmad, L.; Norman, L.; Axcell, B.; Wrobel, L.; Dai, S. Thermoelectric Generator (TEG) Technologies and Applications. Int. J. 2021, 9, 100063. [Google Scholar] [CrossRef]

- Nesarajah, M.; Frey, G. Thermoelectric Power Generation: Peltier Element versus Thermoelectric Generator. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 4252–4257. [Google Scholar]

- Freire, L.O.; Navarrete, L.M.; Corrales, B.P.; Castillo, J.N. Efficiency in Thermoelectric Generators Based on Peltier Cells. Energy Rep. 2021, 7, 355–361. [Google Scholar] [CrossRef]

- Luo, D.; Wang, R.; Yu, W.; Zhou, W. A Novel Optimization Method for Thermoelectric Module Used in Waste Heat Recovery. Energy Convers Manag. 2020, 209, 112645. [Google Scholar] [CrossRef]

- Twaha, S.; Zhu, J.; Yan, Y.; Li, B. A Comprehensive Review of Thermoelectric Technology: Materials, Applications, Modelling and Performance Improvement. Renew. Sustain. Energy Rev. 2016, 65, 698–726. [Google Scholar] [CrossRef]

- Araiz, M.; Casi, Á.; Catalán, L.; Martínez, Á.; Astrain, D. Prospects of Waste-Heat Recovery from a Real Industry Using Thermoelectric Generators: Economic and Power Output Analysis. Energy Convers Manag. 2020, 205, 112376. [Google Scholar] [CrossRef]

- Dongxu, J.; Zhongbao, W.; Pou, J.; Mazzoni, S.; Rajoo, S.; Romagnoli, A. Geometry Optimization of Thermoelectric Modules: Simulation and Experimental Study. Energy Convers Manag. 2019, 195, 236–243. [Google Scholar] [CrossRef]

- Rocha, H.; Albuquerque, D.; Protásio, C. Measurement of Parameters and Degradation of Thermoelectric Modules. IEEE Instrum. Meas. Mag. 2017, 20, 13–19. [Google Scholar]

- Poon, S.J. Half Heusler Compounds: Promising Materials for Mid-to-High Temperature Thermoelectric Conversion. J. Phys. D Appl. Phys. 2019, 52, 493001. [Google Scholar] [CrossRef]

- Salvador, J.R.; Cho, J.Y.; Ye, Z.; Moczygemba, J.E.; Thompson, A.J.; Sharp, J.W.; König, J.D.; Maloney, R.; Thompson, T.; Sakamoto, J.; et al. Thermal to Electrical Energy Conversion of Skutterudite-Based Thermoelectric Modules. J. Electron. Mater. 2013, 42, 1389–1399. [Google Scholar] [CrossRef]

- Hong, M.; Chen, Z.-G.; Zou, J. Fundamental and Progress of Bi 2 Te 3 -Based Thermoelectric Materials. Chin. Phys. B 2018, 27, 048403. [Google Scholar] [CrossRef]

- Nguyen, N.Q.; Pochiraju, K.V. Behavior of Thermoelectric Generators Exposed to Transient Heat Sources. Appl. Therm. Eng. 2013, 51, 1–9. [Google Scholar] [CrossRef]

- Charilaou, K.; Kyratsi, T.; Louca, L.S. Design of an Air-Cooled Thermoelectric Generator System through Modelling and Simulations, for Use in Cement Industries. Mater. Today Proc. 2021, 44, 3516–3524. [Google Scholar] [CrossRef]

- Unite States Deparment of Energy. Energy Efficiency and Renewable Energy.Improvent Process Heating Sytem Performace: A Sourcebook for Industry, 2nd ed.; Unite States Department of Energy: Washington, DC, USA, 2007.

- Loaiza, A.; Colorado, H.A. Marshall Stability and Flow Tests for Asphalt Concrete Containing Electric Arc Furnace Dust Waste with High ZnO Contents from the Steel Making Process. Constr. Build. Mater. 2018, 166, 769–778. [Google Scholar] [CrossRef]

- Colorado, H.A.; Muñoz, A.; Monteiro, S.N. Circular Economy of Construction and Demolition Waste: A Case Study of Colombia. Sustainability 2022, 14, 7225. [Google Scholar] [CrossRef]

- Colorado, H.A.; Echeverri-Lopera, G.I. The Solid Waste in Colombia Analyzed via Gross Domestic Product: Towards a Sustainable Economy. Rev. Fac. Ing. 2020, 96, 51–63. [Google Scholar] [CrossRef]

- Jiménez, J.E.; Fontes Vieira, C.M.; Colorado, H.A. Composite Soil Made of Rubber Fibers from Waste Tires, Blended Sugar Cane Molasses, and Kaolin Clay. Sustainability 2022, 14, 2239. [Google Scholar] [CrossRef]

- Agudelo, G.; Palacio, C.A.; Neves Monteiro, S.; Colorado, H.A. Foundry Sand Waste and Residual Aggregate Evaluated as Pozzolans for Concrete. Sustainability 2022, 14, 9055. [Google Scholar] [CrossRef]

- Punin, W.; Maneewan, S.; Punlek, C. Heat Transfer Characteristics of a Thermoelectric Power Generator System for Low-Grade Waste Heat Recovery from the Sugar Industry. Heat Mass Transf. 2019, 55, 979–991. [Google Scholar] [CrossRef]

| SP1848-27145SA (TEG-GEN) | TEC1-12706 (TEC-REF) | ||

|---|---|---|---|

| Cost (USD) | 3.50 | Cost (USD) | 3.05 |

| Dimensions (mm) | 40 × 40 × 3.4 | Dimensions (mm) | 40 × 40 × 3.8 |

| Maximum temperature difference (°C) | 100 | Max. temp. difference between faces (°C) | 66–75 |

| Nominal current (mA) | 669 | Maximum current (A) | 6.4 |

| Maximum open circuit voltage (V) | 4.8 | Maximum voltage (V) | 16.4 |

| Nominal power (W) | ------ | Nominal power (W) | 72 |

| Hot side temperature (°C) | 150 | Hot side temperature (°C) | 50–57 |

| Thermal conductivity (W/cm.°C) | 1.6 | Thermal conductivity (W/cm.°C) | 1.2 |

| TGS Designation | Level Test | Module Type | Number of Modules | Connection Type | Distance from Source |

|---|---|---|---|---|---|

| 2TEG-GEN-S-10cm | Laboratory | TEG-GEN | 2 | Serial | 10 cm |

| 2TEG-GEN-P-5cm | Laboratory | TEG-GEN | 2 | Parallel | 5 cm |

| 2TEC-REF-S-10cm | Laboratory | TEC-REF | 2 | Serial | 10 cm |

| 2TEC-REF-S-5cm | Laboratory | TEC-REF | 2 | Parallel | 5 cm |

| 6TEG-GEN-S-2cm | Laboratory | TEG-GEN | 6 | Serial | 2 cm |

| 6TEG-GEN-M-2cm | Laboratory | TEG-GEN | 6 | Mixed | 2 cm |

| 6TEG-REF-S-2cm | Laboratory | TEC-REF | 6 | Serial | 2 cm |

| 6TEG-REF-M-2cm | Laboratory | TEC-REF | 6 | Mixed | 2 cm |

| 6TEG-GEN-S-5cm | Industry | TEG-GEN | 6 | Serial | 5 cm |

| 6TEG-GEN-M-5cm | Industry | TEG-GEN | 6 | Mixed | 5 cm |

| 6TEG-REF-S-5cm | Industry | TEC-REF | 6 | Serial | 5 cm |

| 6TEG-REF-M-5cm | Industry | TEC-REF | 6 | Mixed | 5 cm |

| TGS | T. Cold (Tc) (°C) | T. Hot (Th) (°C) | Difference Temp (°K) | Electrical Voltage (mV) | Electrical Current (mA) | Electrical Power (W) | %ER |

|---|---|---|---|---|---|---|---|

| 2TEG GEN P 5cm | 70.75 | 93.00 | 22.25 | 1068.00 | 106.10 | 113.31 | 3.38 |

| 2TEG GEN S 5cm | 69.25 | 96.00 | 26.75 | 762.60 | 75.50 | 26.78 | 1.43 |

| 2TEG GEN P10cm | 64.50 | 80.50 | 16.00 | 820.00 | 80.80 | 66.26 | 2.75 |

| 2TEG GEN S 10cm | 65.25 | 84.25 | 19.00 | 521.00 | 51.40 | 57.58 | 0.94 |

| 2TEC REF P 5cm | 78.75 | 96.25 | 17.50 | 506.40 | 49.80 | 25.22 | 1.43 |

| 2TEC REF S 5cm | 80.5 | 105.75 | 25.25 | 256.00 | 25.50 | 20.13 | 0.26 |

| 2TEC REF P 10cm | 68.25 | 90.50 | 22.25 | 452.40 | 44.50 | 7.56 | 0.90 |

| 2TEC REF S 10cm | 75.75 | 90.00 | 14.25 | 279.00 | 27.10 | 6.53 | 0.53 |

| Test | ΔT (°K) | Pout (mW) | QT (W) | % ER |

|---|---|---|---|---|

| 6TEC-REF-M-5cm | 16.3 | 6.74 | 4941.47 | 0.17 |

| 6TEC-REF-S-5cm | 15.3 | 1.99 | 4638.32 | 0.22 |

| 6TEG-GEN-M-5cm | 17.3 | 14.71 | 7815.53 | 0.29 |

| 6TEG-GEN-S-5cm | 35.7 | 4.83 | 16,128.00 | 0.10 |

| TEST | ΔT (°K) | POUT (W) | QT (W) | % ER |

|---|---|---|---|---|

| 6TEC-REF-M-2cm | 6 | 6.74 | 2273.68 | 0.30 |

| 6TEC-REF-S-2cm | 0.75 | 1.99 | 284.21 | 0.70 |

| 6TEG-GEN-M-2cm | 2.75 | 14.71 | 1242.35 | 1.18 |

| 6TEG-GEN-S-2cm | 1.5 | 4.83 | 677.65 | 0.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castañeda, M.; Amell, A.A.; Correa, M.A.; Aguilar, C.E.; Colorado, H.A. Thermoelectric Generator Using Low-Cost Thermoelectric Modules for Low-Temperature Waste Heat Recovery. Sustainability 2023, 15, 3681. https://doi.org/10.3390/su15043681

Castañeda M, Amell AA, Correa MA, Aguilar CE, Colorado HA. Thermoelectric Generator Using Low-Cost Thermoelectric Modules for Low-Temperature Waste Heat Recovery. Sustainability. 2023; 15(4):3681. https://doi.org/10.3390/su15043681

Chicago/Turabian StyleCastañeda, Manuela, Andrés A. Amell, Mauricio A. Correa, Claudio E. Aguilar, and Henry A. Colorado. 2023. "Thermoelectric Generator Using Low-Cost Thermoelectric Modules for Low-Temperature Waste Heat Recovery" Sustainability 15, no. 4: 3681. https://doi.org/10.3390/su15043681

APA StyleCastañeda, M., Amell, A. A., Correa, M. A., Aguilar, C. E., & Colorado, H. A. (2023). Thermoelectric Generator Using Low-Cost Thermoelectric Modules for Low-Temperature Waste Heat Recovery. Sustainability, 15(4), 3681. https://doi.org/10.3390/su15043681