Generic Multi-Layered Digital-Twin-Framework-Enabled Asset Lifecycle Management for the Sustainable Mining Industry

Abstract

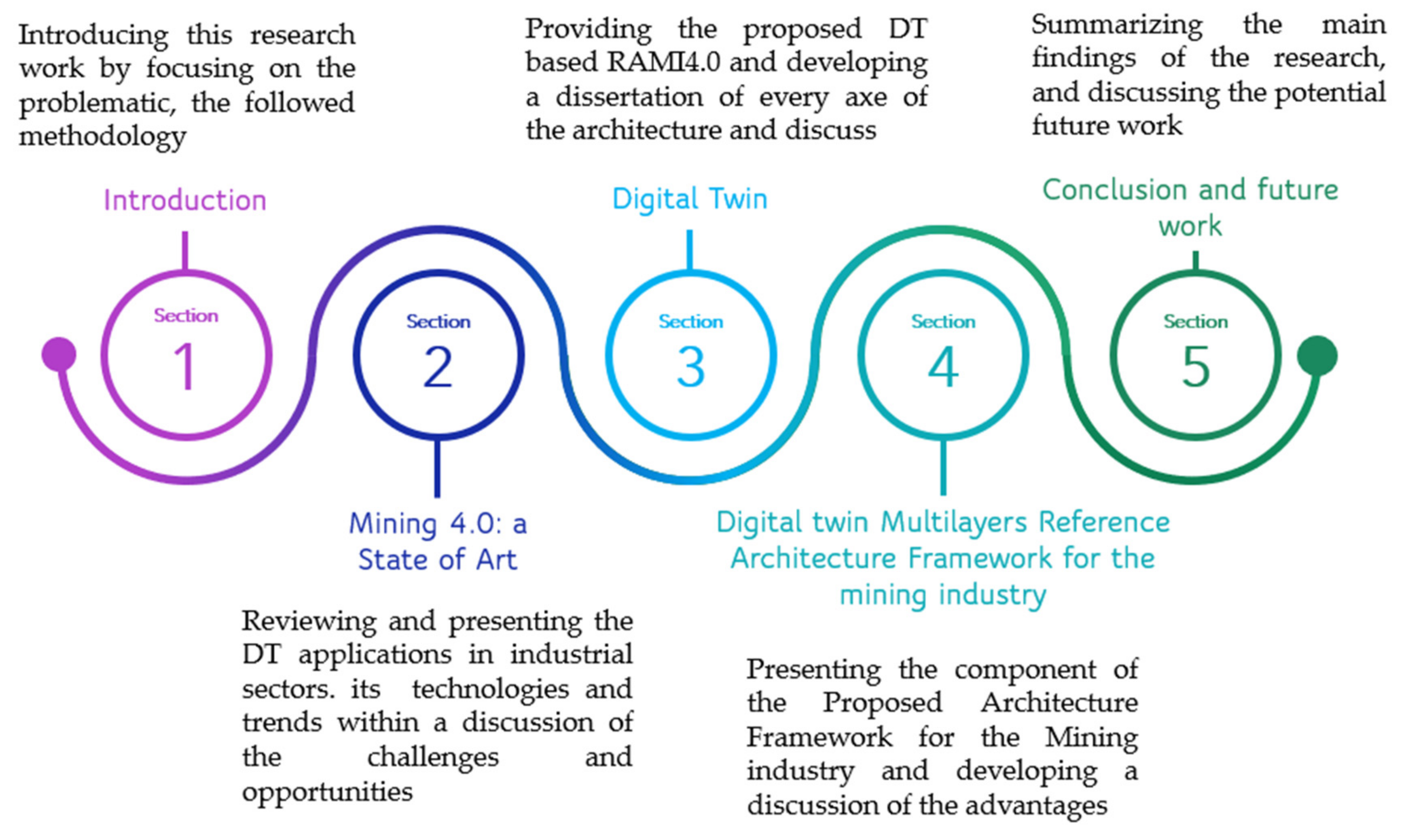

:1. Introduction

2. Research Methodology

3. Mining 4.0: The State of the Art

3.1. Industry 4.0 toward 5.0

3.2. Mining Industry: The Experimental Open Pit Mine

4. Digital Twin

4.1. Related Research

4.2. Digital Twin Reference Model and Architecture

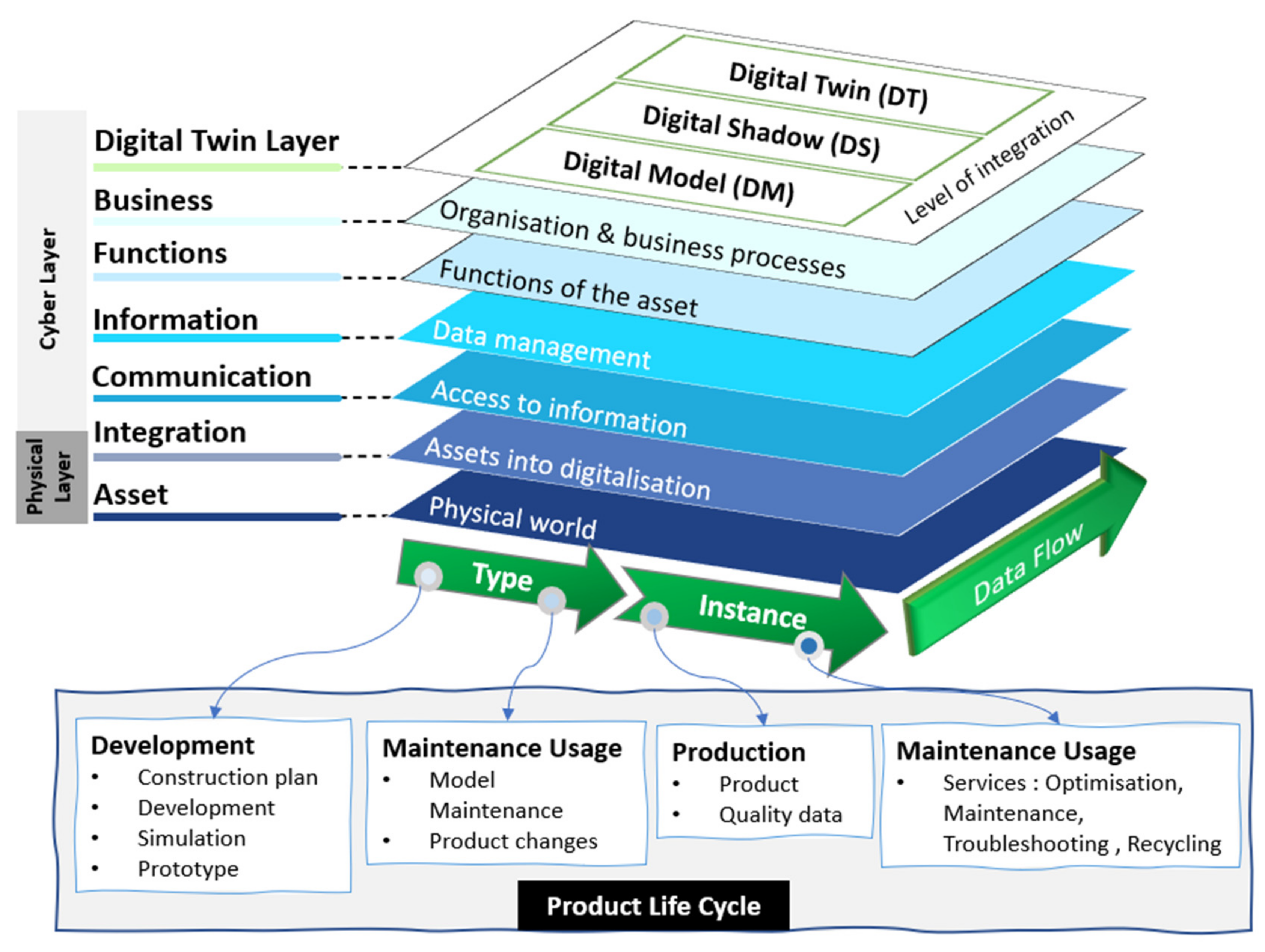

4.2.1. Digital Twin Reference Architecture Model in Industry 4.0

Horizontal Axis: Agile Product Lifecycle

Vertical Axis: RAMI4.0 Layers

- The asset layer: This corresponds to the physical entity where the DT’s physical representation is located.

- The integration layer: Run-time data and engineering data can be separated in this layer. Run-time data are produced by sensors or events and show the physical entity’s current state. Typically, they are time series data. The underlying infrastructure must adapt to application-specific requirements, such as big data processing or real-time reaction, because these data are particularly dynamic. Often static, engineering data do not frequently alter over time. Examples include details about a physical component inside a plant or the topology of the plant.

- The communication layer: Mostly, industrial communication or Industrial Internet of Things (IIoT) protocols can be used. The specific protocol is determined by the demands of the application, such as real-time capabilities or support for publications and subscriptions. As a result, a combination of several protocols can be envisaged, essentially to ease the data flow into the upper levels.

- The information layer: Here, the acquired data are semantically processed and related to additional context information; the core element of the information layer is the shared knowledge base, which contains context-sensitive data about resources and services. This information’s semantics are increased by linking data to it. By using various information modeling tools, various levels of semantic expressivity can be attained. Data should ideally be kept in suitable databases in their original formats.

- The functional layer: From an architectural perspective, the function layer describes functions and services, along with their interactions. In applications, systems, and components, the functions are represented without the use of actors or actual physical implementations, whereas it provides a framework for the horizontal mixing of diverse functions and allows for the formal description of functions and services. It includes a run-time environment for applications and technical functions, as well as a modeling environment for services supporting business processes.

- The business layer: This relates to process logic, abstract business models (rules), and assuring the quality of operations along the value chain. This layer facilitates business model mapping, value stream function integrity assurance, and process output assurance. It permits the modeling of the requirements that the process must adhere to and contains the legal and regulatory framework conditions. This layer also establishes a connection between various business processes and organizations.

Data Flow Axis

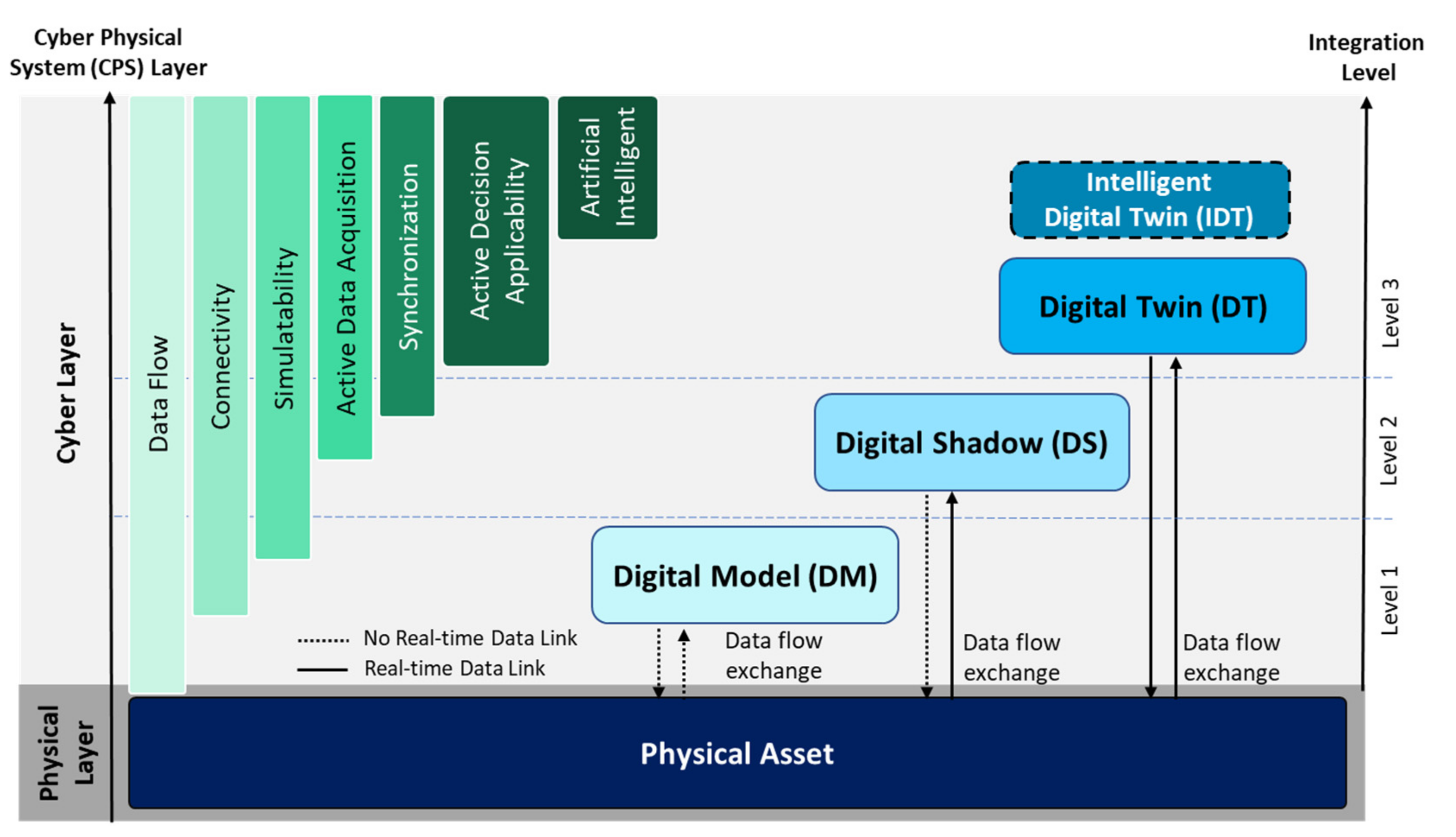

4.2.2. Digital Twin Integration Level

- Connectivity is the ability to connect systems, services, or application programs. Ideally, these connections are established without requiring many changes to the applications or the systems on which they run.

- Simulatability: The ability of the system to replicate the model and the behavior of the physical asset with the capacity to deal with all of its properties and parameters.

- Active data acquisition is the key point to feed the models with data and establish the real-time link between the two sides of the cyber-physical system (CPS).

- Synchronization brands the sequencing of the data flow between both components of the cyber-physical system, and without any problems creates a full, synchronous, and real-time exchange for the DT in its third level of integration.

- Active decision applicability: In our case, the significant benefit of the utilization of the DT replica is the bidirectional data flow exchange centrally located in the physical part and DT of the system. This makes it possible to exploit and apply the decision token on the physical plant.

4.2.3. Digital-Twin-Enabled Value Lifecycle Management

4.2.4. Digital-Twin-Based Collaborative Environment

- Engineering: Improve the efficiency of your engineering procedures, so that new products may be produced with insights based on the behavior of existing items in the real world, connecting the virtual models with the actual physical objects. By conducting what-if scenarios, the DT helps you to uncover product faults in early product design and development phases, which lowers engineering costs and speeds up design cycles. For instance, client usage is represented in the DT and is integrated into the processes of product development and manufacturing. The DT will strengthen the bond between your organization’s technical and operational teams by establishing a feedback loop throughout the lifecycle of your product.

- Production: Gain knowledge about the manufacturing processes from the DT to prognostic or diagnostic condition monitoring. For example, the maintenance of plants might be optimized using this knowledge. The DT’s analytical capabilities will increase production effectiveness by predicting faults so that they may be corrected before having an impact on manufacturing goals. By modifying factors throughout the production process in the DT to enhance utilization, you may simulate different plant plans. DTs assist in detecting quality trend impacts and maintaining quality standards during real manufacturing.

- Operation and process: By optimizing the information flow throughout all of your operational and servicing activities, the DT enables you to comprehend how to run your shop floor more effectively and efficiently. Performance evaluations may be evaluated by the DT conductive to reducing production costs, which is one of its most important capabilities. Gain an insight into everything that happens to your items, and your supply chain network will be improved overall. Owners and operators, for instance, may track their fleet of cars, fleet assets, or logistical assets using DTs, as well as improve infrastructures.

- Marketing and go-to-market: Implementing DTs will improve the effectiveness of customer interaction workflows in marketing and sales. Before, when a product was handed over to a client, product development essentially came to a stop. These times are long gone. With product feedback going well beyond product delivery into service, complete data management is made possible. Improve your customer validation strategy and aim for top-notch digital marketing. You may be able to identify new business models for the product as a service depending on how the product is used or consumed.

5. Digital Twin Multi-Layer Reference Architecture Framework for the Mining Industry

5.1. Physical Layer

5.2. Cyber Layer

5.2.1. Data Pre-Processing Sublayer

5.2.2. Edge Computing Sublayer

- Quick data processing and analysis in real time: The edge computing approach does not upload data to a cloud computing platform, instead storing and processing it on edge devices. The rapid rise in data volume and the strain on network capacity are drawbacks of cloud computing. Edge computing offers an advantage over regular cloud computing in terms of response time and real time. Since the edge computing node is located closer to the data source, it may perform computing and data storage functions locally, reducing the need for intermediate data transmission. It emphasizes being close to users and offering them superior intelligent services, which enhances data transmission performance and ensures real-time processing while decreasing wait time. In the realm of automatic driving, intelligent manufacturing, video surveillance, and other forms of location awareness, quick feedback is crucial. Edge computing offers users a range of fast response services.

- Security: For unified processing, a centralized processing technique, traditional cloud computing demands that all data be uploaded to the cloud. Risks such as data loss and leakage will be present during this procedure; thus, security and privacy cannot be guaranteed. Account passwords, past search history, and even trade secrets can all be made public. The security of data can be guaranteed since edge computing exclusively handles the tasks that are within its purview, relies on local processing rather than uploading to the cloud, and avoids the dangers associated with network transmission. When data are attacked, just the local data are impacted—not all data.

- Low cost, low bandwidth cost, and low energy cost: Since edge computing does not require the processing of data to be uploaded to a cloud computing facility, there is a reduction in the demand on the network’s bandwidth as well as a significant reduction in the energy consumption of intelligent devices at the network’s edge. Edge computing is “small-scale”, and, in practice, businesses can lower the price of processing data on local hardware. Edge computing hence reduces the volume of data carried across the network, lowers the cost of transmission and the demand on the network’s capacity, lowers the energy consumption of local equipment, and increases computing efficiency.

5.2.3. Cloud Computing Sublayer

Co-Simulation Service

- Co-simulation based on functional mock-up interface (FMI): The functional mock-up interface (FMI) offers the ability to interchange models between simulation programs in addition to providing a standard for co-simulation. It is not allowed to incorporate simulation tools into the co-simulation that do not support FMI due to the need that the employed simulation tools support FMI. Likewise, the tools only communicate at specific times while operating independently of one another in between. The data exchange and slave simulations are synchronized by a master algorithm, with FMI allowing for configurable time steps between two synchronization phases. A functional mock-up unit (FMU) that implements the simulation tool’s interface must be used to represent each simulation tool in a co-simulation. FMI is not suited for a dynamic co-simulation with “Plug-and-Simulate” features, since its master algorithm requires input from each slave simulation before beginning the simulation [55].

- Co-simulation based on high-level architecture (HLA): The United States Department of Defense created the high-level architecture (HLA) as a distributed and parallel simulation architecture federation for the many simulators, and the run time infrastructure (RTI), a hub for federate coordination, which makes up the co-simulation with HLA known as a federation. An object model template defines the information that may be shared between the federates, and an interface specification defines the interfaces between the federates and the RTI. There are also some HLA rules that a simulator must adhere to, conductive to being considered to conform to HLA. The RTI may be thought of as the simulation master in charge of synchronizing the federates. Although HLA permits the dynamic entry of federates during run-time, a new Federation Agreement, that is domain- and use-case-specific, must be prepared for each federate. There are several RTI implementations available, both paid and unpaid [56].

- Co-simulation based on open services gateway initiative (OSGI): The open services gateway initiative (OSGi) is a framework that was created for the building of applications made up of dynamically combinable and reusable components. It is based on Java. The implementation of the components in OSGi is isolated from other components, conductive to decreasing complexity, and the components communicate with one another via services. The framework may load, delete, swap, or update the bundles that serve as representations of the components at run-time. These bundles may be located on a single computer or spread across a number of machines. A dynamic co-simulation is made possible by the dynamic exchange of bundles. A bundle that is linked to the simulation by a simulator coupler serves as a representation of each simulation. The simulation coupler makes use of OPC and permits data exchange and synchronization between the simulations. Another option is to directly incorporate a model into an OSGi bundle. For switching simulators during run-time, a separate bundle is needed, in which the states of the withdrawn simulators are maintained to allow for their re-entry.

- Co-simulation based on OPC unified architecture: The OPC Foundation created OPC UA, a machine-to-machine communication standard that is service-oriented and enables the exchange of process data and their machine-readable description. The reference implements a co-simulation with OPC UA, in which each simulator is connected to a generic adapter via an interface that houses both an OPC-UA server and an OPC-UA client. This adapter uses OPC UA to connect to a central server that also has an OPC-UA server and a client. Each simulator must be registered on the central server, with the first simulator to do so being the simulation master and the following simulators being the simulation slaves. The co-simulation is coordinated and synchronized by the master. If the co-simulation master exits, another simulator assumes control of the co-simulation.

- Agent-based co-simulation: This concept of multi-agent systems was chosen to couple the simulation tools, as long as software agents can join and leave multi-agent systems at any time during run-time, are domain-independent, have no restrictions during any stage of the lifecycle, and have the ability to add intelligence on top of the models [56]. Each IoT component is modeled in its own simulation, maybe using multiple simulation tools, and each simulation is linked to and embodied by an agent, as shown in Figure 7. It is feasible to interchange the models at run-time by simulating each IoT component separately and linking them to agents, due to the ability of the agents to enter and exit the multi-agent system at any moment, just like IoT components can enter and exit the IoT system. Through agent-to-agent communication, the agents advance the interaction between the models. For illustration, if a heating unit model asks for the temperature value of a temperature sensor model, the agent associated with the heating unit model sends this request to every other agent, who then sends it to their corresponding models. The models then determine for themselves whether the message received is valuable before responding appropriately. A notion for an interface has to be established in order to facilitate communication between the agents and their respective simulation tools.

Operation Data Service

Synchronization Service

5.3. Discussion

5.3.1. Features to Consider for Designing Digital Twin Frameworks

- The type of data sources and integration methods: Different DT frameworks may utilize different types of data sources and integration methods, such as sensors, simulations, and historical data, and may have varying levels of interoperability between these sources [60].

- The visualization and analysis tools: The quality and flexibility of the visualization and analysis tools provided by a DT framework can significantly influence its usability and effectiveness [61].

- The scalability and performance of the system: As the size and complexity of a mine increases, the scalability and performance of the DT framework may become increasingly important considerations [62].

- The cost and resources required for implementation and maintenance: The cost and resources required for implementing and maintaining a DT framework can vary greatly depending on the system’s complexity and scope [63].

- Customizability and adaptability: Some DT frameworks may offer a higher degree of customizability and adaptability to meet the specific needs and requirements of a mine, while others may be more rigid in their capabilities [64].

- Ease of use and user experience: The usability of a DT framework can greatly impact its adoption and effectiveness. Some frameworks may be more intuitive and user-friendly, while others may require specialized training or expertise to be used [65].

- Integration with other systems and platforms: A DT framework that can easily integrate with other systems and platforms used by a mine, such as enterprise resource planning (ERP) systems and asset management systems, may be more effective [66].

- Security: DT frameworks may handle sensitive data and intellectual property, so it is important to consider the security and privacy measures in place to protect this information.

- Support and maintainability: The level of support and maintenance provided by the developer or vendor of a DT framework can be important factors in its long-term viability and reliability [66].

5.3.2. Proposed Digital Twin Framework Advantages

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Macchi, M.; Roda, I.; Negri, E.; Fumagalli, L. Exploring the Role of Digital Twin for Asset Lifecycle Management. IFAC Pap. 2018, 51, 790–795. [Google Scholar] [CrossRef]

- Davila Delgado, J.M.; Oyedele, L. Digital Twins for the Built Environment: Learning from Conceptual and Process Models in Manufacturing. Adv. Eng. Inform. 2021, 49, 101332. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Zhong, R.Y.; Lu, Y. Digital Twin as a Service (DTaaS) in Industry 4.0: An Architecture Reference Model. Adv. Eng. Inform. 2021, 47, 101225. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human-Robot Co-Working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Laayati, O.; El Hadraoui, H.; Bouzi, M.; El-Alaoui, A.; Kousta, A.; Chebak, A. Smart Energy Management System: Blockchain-Based Smart Meters in Microgrids. In Proceedings of the 2022 4th Global Power, Energy and Communication Conference (GPECOM), Nevsehir, Turkey, 14–17 June 2022; pp. 580–585. [Google Scholar]

- NIBUSINESSINFO.CO.UK. Industry 4.0 Challenges and Risks. Available online: https://www.nibusinessinfo.co.uk/content/industry-40-challenges-and-risks (accessed on 8 November 2022).

- Artificial Intelligence and Industry 4.0—1st Edition. Available online: https://www.elsevier.com/books/artificial-intelligence-and-industry-40/hassanien/978-0-323-88468-6 (accessed on 8 November 2022).

- Hosamo, H.H.; Imran, A.; Cardenas-Cartagena, J.; Svennevig, P.R.; Svidt, K.; Nielsen, H.K. A Review of the Digital Twin Technology in the AEC-FM Industry. Adv. Civ. Eng. 2022, 2022, e2185170. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. Is Digital Twin Technology Supporting Safety Management? A Bibliometric and Systematic Review. Appl. Sci. 2021, 11, 2767. [Google Scholar] [CrossRef]

- Carvalho, R.; da Silva, A.R. Sustainability Requirements of Digital Twin-Based Systems: A Meta Systematic Literature Review. Appl. Sci. 2021, 11, 5519. [Google Scholar] [CrossRef]

- Global Logic a Hitachi Group Company. Digital Twins Technology, Its Benefits & Challenges to Information Security. 2020. Available online: https://www.globallogic.com/insights/blogs/if-you-build-products-you-should-be-using-digital-twins/ (accessed on 22 October 2022).

- Kohne, T.; Burkhardt, M.; Theisinger, L.; Weigold, M. Technical and Digital Twin Concept of an Industrial Heat Transfer Station for Low Exergy Waste Heat. Procedia CIRP 2021, 104, 223–228. [Google Scholar] [CrossRef]

- Gao, Y.; Chang, D.; Chen, C.-H.; Xu, Z. Design of Digital Twin Applications in Automated Storage Yard Scheduling. Adv. Eng. Inform. 2022, 51, 101477. [Google Scholar] [CrossRef]

- Jiang, Z.; Guo, Y.; Wang, Z. Digital Twin to Improve the Virtual-Real Integration of Industrial IoT. J. Ind. Inf. Integr. 2021, 22, 100196. [Google Scholar] [CrossRef]

- Brosinsky, M.C.; Song, M.X.; Westermann, D. Digital Twin—Concept of a Continuously Adaptive Power System Mirror. In Proceedings of the International ETG-Congress 2019, Esslingen, Germany, 8–9 May 2019. [Google Scholar]

- O’Dwyer, E. Integration of an Energy Management Tool and Digital Twin for Coordination and Control of Multi-Vector Smart Energy Systems. Sustain. Cities Soc. 2020, 62, 102412. [Google Scholar] [CrossRef]

- Qiuchen Lu, V.; Parlikad, A.K.; Woodall, P.; Ranasinghe, G.D.; Heaton, J. Developing a Dynamic Digital Twin at a Building Level: Using Cambridge Campus as Case Study. In Proceedings of the International Conference on Smart Infrastructure and Construction 2019 (ICSIC), Cambridge, UK, 8–10 July2019; pp. 67–75. [Google Scholar]

- Agostinelli, S.; Cumo, F.; Guidi, G.; Tomazzoli, C. Cyber-Physical Systems Improving Building Energy Management: Digital Twin and Artificial Intelligence. Energies 2021, 14, 2338. [Google Scholar] [CrossRef]

- Agouzoul, A.; Tabaa, M.; Chegari, B.; Simeu, E.; Dandache, A.; Alami, K. Towards a Digital Twin Model for Building Energy Management: Case of Morocco. Procedia Comput. Sci. 2021, 184, 404–410. [Google Scholar] [CrossRef]

- Saad, A.; Faddel, S.; Mohammed, O. IoT-Based Digital Twin for Energy Cyber-Physical Systems: Design and Implementation. Energies 2020, 13, 4762. [Google Scholar] [CrossRef]

- Židek, K.; Piteľ, J.; Adámek, M.; Lazorík, P.; Hošovský, A. Digital Twin of Experimental Smart Manufacturing Assembly System for Industry 4.0 Concept. Sustainability 2020, 12, 3658. [Google Scholar] [CrossRef]

- Urazayev, D.; Bragin, D.; Zykov, D.; Hafizov, R.; Pospelova, I.; Shelupanov, A. Distributed Energy Management System with the Use of Digital Twin. In Proceedings of the 2019 International Multi-Conference on Engineering, Computer and Information Sciences (SIBIRCON), Novosibirsk, Russia, 21–22 October 2019; pp. 685–689. [Google Scholar]

- Ouahabi, N.; Chebak, A.; Zegrari, M.; Kamach, O.; Berquedich, M. A Distributed Digital Twin Architecture for Shop Floor Monitoring Based on Edge-Cloud Collaboration. In Proceedings of the 2021 Third International Conference on Transportation and Smart Technologies (TST), Tangier, Morocco, 27–28 May 2021; pp. 72–78. [Google Scholar]

- Laayati, O.; El Hadraoui, H.; El Magharaoui, A.; El-Bazi, N.; Bouzi, M.; Chebak, A.; Guerrero, J.M. An AI-Layered with Multi-Agent Systems Architecture for Prognostics Health Management of Smart Transformers: A Novel Approach for Smart Grid-Ready Energy Management Systems. Energies 2022, 15, 7217. [Google Scholar] [CrossRef]

- Rihi, A.; Baïna, S.; Mhada, F.; Elbachari, E.; Tagemouati, H.; Guerboub, M.; Benzakour, I. Predictive Maintenance in Mining Industry: Grinding Mill Case Study. Procedia Comput. Sci. 2022, 207, 2483–2492. [Google Scholar] [CrossRef]

- Greco, A.; Caterino, M.; Fera, M.; Gerbino, S. Digital Twin for Monitoring Ergonomics during Manufacturing Production. Appl. Sci. 2020, 10, 7758. [Google Scholar] [CrossRef]

- Autiosalo, J.; Ala-Laurinaho, R.; Mattila, J.; Valtonen, M.; Peltoranta, V.; Tammi, K. Towards Integrated Digital Twins for Industrial Products: Case Study on an Overhead Crane. Appl. Sci. 2021, 11, 683. [Google Scholar] [CrossRef]

- Pang, T.Y.; Pelaez Restrepo, J.D.; Cheng, C.-T.; Yasin, A.; Lim, H.; Miletic, M. Developing a Digital Twin and Digital Thread Framework for an ‘Industry 4.0’. Shipyard. Appl. Sci. 2021, 11, 1097. [Google Scholar] [CrossRef]

- Elbazi, N.; Mabrouki, M.; Chebak, A.; Hammouch, F. Digital Twin Architecture for Mining Industry: Case Study of a Stacker Machine in an Experimental Open-Pit Mine. In Proceedings of the 2022 4th Global Power, Energy and Communication Conference (GPECOM), Cappadocia, Turkey, 14–17 June 2022; pp. 232–237. [Google Scholar]

- Global Smart Mining Market to Grow 10% CAGR to 2031. Available online: https://miningdigital.com/smart-mining/global-smart-mining-market-to-grow-at-10-cagr (accessed on 8 November 2022).

- Consulting, A.R. and Mining Equipment Market Size Was Valued at USD 133 Billion in 2021 and Will Achieve USD 185 Billion by 2030 Growing at 4.1% CAGR Owing to the Rapidly Rising Construction Activities in Emerging Nations—Exclusive Report by Acumen Research and Consulting. Available online: https://www.globenewswire.com/news-release/2022/08/05/2492964/0/en/Mining-Equipment-Market-Size-Was-Valued-at-USD-133-Billion-in-2021-and-Will-Achieve-USD-185-Billion-by-2030-growing-at-4-1-CAGR-Owing-to-the-Rapidly-Rising-Construction-Activities-.html (accessed on 8 November 2022).

- El Maghraoui, A.; Ledmaoui, Y.; Laayati, O.; El Hadraoui, H.; Chebak, A. Smart Energy Management: A Comparative Study of Energy Consumption Forecasting Algorithms for an Experimental Open-Pit Mine. Energies 2022, 15, 4569. [Google Scholar] [CrossRef]

- Laayati, O.; Bouzi, M.; Chebak, A. Smart Energy Management System: Design of a Monitoring and Peak Load Forecasting System for an Experimental Open-Pit Mine. Appl. Syst. Innov. 2022, 5, 18. [Google Scholar] [CrossRef]

- Guerroum, M.; Zegrari, M.; Masmoudi, M.; Berquedich, M.; Elmahjoub, A. Machine Learning Technics for Remaining Useful Life Prediction Using Diagnosis Data: A Case Study of a Jaw Crusher. Int. J. Emerg. Technol. Adv. Eng. 2022, 12, 122–135. [Google Scholar] [CrossRef]

- Laayati, O.; Bouzi, M.; Chebak, A. Smart Energy Management System: SCIM Diagnosis and Failure Classification and Prediction Using Energy Consumption Data. In Proceedings of the Digital Technologies and Applications; Motahhir, S., Bossoufi, B., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1377–1386. [Google Scholar]

- El Hadraoui, H.; Laayati, O.; Guennouni, N.; Chebak, A.; Zegrari, M. A Data-Driven Model for Fault Diagnosis of Induction Motor for Electric Powertrain. In Proceedings of the 2022 IEEE 21st Mediterranean Electrotechnical Conference (MELECON), Palermo, Italy, 14–16 June 2022; pp. 336–341. [Google Scholar]

- Laayati, O.; Bouzi, M.; Chebak, A. Design of an Oil Immersed Power Transformer Monitoring and Self Diagnostic System Integrated in Smart Energy Management System. In Proceedings of the 2021 3rd Global Power, Energy and Communication Conference (GPECOM), Virtual, 5–8 October 2021; pp. 240–245. [Google Scholar]

- Laayati, O.; El Hadraoui, H.; Bouzi, M.; Chebak, A. Smart Energy Management System: Oil Immersed Power Transformer Failure Prediction and Classification Techniques Based on DGA Data. In Proceedings of the 2022 2nd International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Meknes, Morocco, 3–4 March 2022; pp. 1–6. [Google Scholar]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 85–113. ISBN 978-3-319-38756-7. [Google Scholar]

- Digital Twins—Michael Batty.2018. Available online: https://journals.sagepub.com/doi/full/10.1177/2399808318796416?casa_token=G_IVGe8ZBPEAAAAA:Mh90cEjcFA3gVv3X7srEWfBAYGrC5MXx-XRjm69m1BVOhH6wuC3mzdyxyVV7yh7LJCgTY2eQJswfScYD (accessed on 24 October 2022).

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Modeling, Simulation, Information Technology & Processing Roadmap. Natl. Aeronaut. Space Adm. 2012, 32, 1–38. [Google Scholar]

- Boschert, S.; Rosen, R. Digital Twin—The Simulation Aspect. In Mechatronic Futures: Challenges and Solutions for Mechatronic Systems and Their Designers; Hehenberger, P., Bradley, D., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 59–74. ISBN 978-3-319-32156-1. [Google Scholar]

- AMCR. Untangling the Requirements of a Digital Twin. The University of Sheffield AMRC Factory 2050, Europa Avenue, Sheffield, S9 1ZA. 2020. Available online: https://www.amrc.co.uk/files/document/404/1604658922_AMRC_Digital_Twin_AW.pdf (accessed on 23 November 2022).

- Aivaliotis, P.; Georgoulias, K.; Chryssolouris, G. The Use of Digital Twin for Predictive Maintenance in Manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 1067–1080. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7, 19990–19999. [Google Scholar] [CrossRef]

- Min, Q.; Lu, Y.; Liu, Z.; Su, C.; Wang, B. Machine Learning Based Digital Twin Framework for Production Optimization in Petrochemical Industry. Int. J. Inf. Manag. 2019, 49, 502–519. [Google Scholar] [CrossRef]

- Negri, E.; Berardi, S.; Fumagalli, L.; Macchi, M. MES-Integrated Digital Twin Frameworks. J. Manuf. Syst. 2020, 56, 58–71. [Google Scholar] [CrossRef]

- Zhang, M.; Tao, F.; Nee, A.Y.C. Digital Twin Enhanced Dynamic Job-Shop Scheduling. J. Manuf. Syst. 2021, 58, 146–156. [Google Scholar] [CrossRef]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A Digital Twin to Train Deep Reinforcement Learning Agent for Smart Manufacturing Plants: Environment, Interfaces and Intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Steindl, G.; Stagl, M.; Kasper, L.; Kastner, W.; Hofmann, R. Generic Digital Twin Architecture for Industrial Energy Systems. Appl. Sci. 2020, 10, 8903. [Google Scholar] [CrossRef]

- Niu, X.; Qin, S. Integrating Crowd-/Service-Sourcing into Digital Twin for Advanced Manufacturing Service Innovation. Adv. Eng. Inform. 2021, 50, 101422. [Google Scholar] [CrossRef]

- Ashtari, B.; Jung, T.; Lindemann, B.; Sahlab, N.; Jazdi, N.; Schloegl, W.; Weyrich, M. An Architecture of an Intelligent Digital Twin in a Cyber-Physical Production System. Automatisierungstechnik 2019, 67, 762–782. [Google Scholar] [CrossRef]

- A Review of Digital Twin in Product Design and Development. Available online: https://ouci.dntb.gov.ua/en/works/9GBYB0Pl/ (accessed on 8 November 2022).

- Abrazeh, S.; Mohseni, S.-R.; Zeitouni, M.J.; Parvaresh, A.; Fathollahi, A.; Gheisarnejad, M.; Khooban, M.-H. Virtual Hardware-in-the-Loop FMU Co-Simulation Based Digital Twins for Heating, Ventilation, and Air-Conditioning (HVAC) Systems. IEEE Trans. Emerg. Top. Comput. Intell. 2022, 1–11. [Google Scholar] [CrossRef]

- Jung, T.; Shah, P.; Weyrich, M. Dynamic Co-Simulation of Internet-of-Things-Components Using a Multi-Agent-System. Procedia CIRP 2018, 72, 874–879. [Google Scholar] [CrossRef]

- Talkhestani, B.A.; Jazdi, N.; Schlögl, W.; Weyrich, M. A Concept in Synchronization of Virtual Production System with Real Factory Based on Anchor-Point Method. Procedia CIRP 2018, 67, 13–17. [Google Scholar] [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Boyes, H.; Watson, T. Digital Twins: An Analysis Framework and Open Issues. Comput. Ind. 2022, 143, 103763. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.D.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Uhlenkamp, J.-F.; Hauge, J.B.; Broda, E.; Lütjen, M.; Freitag, M.; Thoben, K.-D. Digital Twins: A Maturity Model for Their Classification and Evaluation. IEEE Access 2022, 10, 69605–69635. [Google Scholar] [CrossRef]

- Bowman, D.; Dwyer, L.; Levers, A.; Patterson, E.A.; Purdie, S.; Vikhorev, K. A Unified Approach to Digital Twin Architecture—Proof-of-Concept Activity in the Nuclear Sector. IEEE Access 2022, 10, 44691–44709. [Google Scholar] [CrossRef]

- Qamsane, Y.; Moyne, J.; Toothman, M.; Kovalenko, I.; Balta, E.C.; Faris, J.; Tilbury, D.M.; Barton, K. A Methodology to Develop and Implement Digital Twin Solutions for Manufacturing Systems. IEEE Access 2021, 9, 44247–44265. [Google Scholar] [CrossRef]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A New Concept of Digital Twin Supporting Optimization and Resilience of Factories of the Future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- Han, X.; Yu, H.; You, W.; Huang, C.; Tan, B.; Zhou, X.; Xiong, N.N. Intelligent Campus System Design Based on Digital Twin. Electronics 2022, 11, 3437. [Google Scholar] [CrossRef]

- Stojanovic, L.; Usländer, T.; Volz, F.; Weißenbacher, C.; Müller, J.; Jacoby, M.; Bischoff, T. Methodology and Tools for Digital Twin Management—The FA3ST Approach. IoT 2021, 2, 717–740. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital Twins-Based Smart Manufacturing System Design in Industry 4.0: A Review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Hribernik, K.; Cabri, G.; Mandreoli, F.; Mentzas, G. Autonomous, Context-Aware, Adaptive Digital Twins—State of the Art and Roadmap. Comput. Ind. 2021, 133, 103508. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D.; Tsaramirsis, G.; Papageorgas, P.; Tamimi, H. 3D Printing and Implementation of Digital Twins: Current Trends and Limitations. Appl. Syst. Innov. 2022, 5, 7. [Google Scholar] [CrossRef]

| Team | Year | Application | Features | Digital Twin |

|---|---|---|---|---|

| Tomas [13] | 2021 | Industrial heat transfer station | Functional mock-up interface Python OPC UA | Concept |

| Yinping [14] | 2022 | Storage yard scheduling | Genetic optimization Neural network prediction Co-simulation | Automation |

| Zongmin [15] | 2021 | Population health management | Virtual–real integration of industrial IoT | Concept |

| Christoph [16] | 2019 | Power system mirror | Neural network Energy management | Concept and design |

| Edward [17] | 2020 | EV charging Microgrid | Smart energy management systems | Concept |

| Vivi [18] | 2019 | Campus | Building | Case study |

| Sofia [19] | 2021 | Energy management | Building AI | Concept |

| Abdelali [20] | 2021 | Energy management | Building | Case study |

| Ahmed [21] | 2020 | Cyber-physical systems | Energy management Cyber-physical | Design and implementation |

| Kamil [22] | 2020 | Manufacturing | Assembly system Industry 4.0 | Concept |

| Damir [23] | 2019 | Energy management systems | Distributed EMS Prediction Simulation | Concept simulation |

| Nada [24] | 2021 | Shop floor monitoring | Monitoring Cloud collaboration Edge cloud | Concept and case study |

| Oussama [25] | 2022 | Power transformer | Multi-agent hybrid AI fault detection | System and case study |

| Ayoub [26] | 2022 | Grinding mill case study | Predictive, maintenance-based, data-driven | Case study |

| Allessandro [27] | 2020 | Manufacturing production | Monitoring ergonomics | Case study |

| Jusso [28] | 2021 | Overhead crane | Accelerating production pace | Case study |

| Toh Yen [29] | 2021 | Shipyard | Fully integrated digital thread and digital twin | Framework architecture |

| Nabil [30] | 2022 | Open pit mine stacker machine | Full digital twin of a stacker machine | Architecture |

| Machine | Number |

|---|---|

| Feeders | 2 |

| Jaw crushers | 1 |

| Stackers | 3 |

| Belt conveyors | 21 |

| Bucket wheel reclaimer | 2 |

| Screening machine | 9 |

| Pumps and compressors | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Bazi, N.; Mabrouki, M.; Laayati, O.; Ouhabi, N.; El Hadraoui, H.; Hammouch, F.-E.; Chebak, A. Generic Multi-Layered Digital-Twin-Framework-Enabled Asset Lifecycle Management for the Sustainable Mining Industry. Sustainability 2023, 15, 3470. https://doi.org/10.3390/su15043470

El Bazi N, Mabrouki M, Laayati O, Ouhabi N, El Hadraoui H, Hammouch F-E, Chebak A. Generic Multi-Layered Digital-Twin-Framework-Enabled Asset Lifecycle Management for the Sustainable Mining Industry. Sustainability. 2023; 15(4):3470. https://doi.org/10.3390/su15043470

Chicago/Turabian StyleEl Bazi, Nabil, Mustapha Mabrouki, Oussama Laayati, Nada Ouhabi, Hicham El Hadraoui, Fatima-Ezzahra Hammouch, and Ahmed Chebak. 2023. "Generic Multi-Layered Digital-Twin-Framework-Enabled Asset Lifecycle Management for the Sustainable Mining Industry" Sustainability 15, no. 4: 3470. https://doi.org/10.3390/su15043470

APA StyleEl Bazi, N., Mabrouki, M., Laayati, O., Ouhabi, N., El Hadraoui, H., Hammouch, F.-E., & Chebak, A. (2023). Generic Multi-Layered Digital-Twin-Framework-Enabled Asset Lifecycle Management for the Sustainable Mining Industry. Sustainability, 15(4), 3470. https://doi.org/10.3390/su15043470