Efficiency Improvement of Eco-Friendly Solar Heat Supply System as a Building Coating

Abstract

1. Introduction

2. Solar Heat Supply Systems and Building Aspects

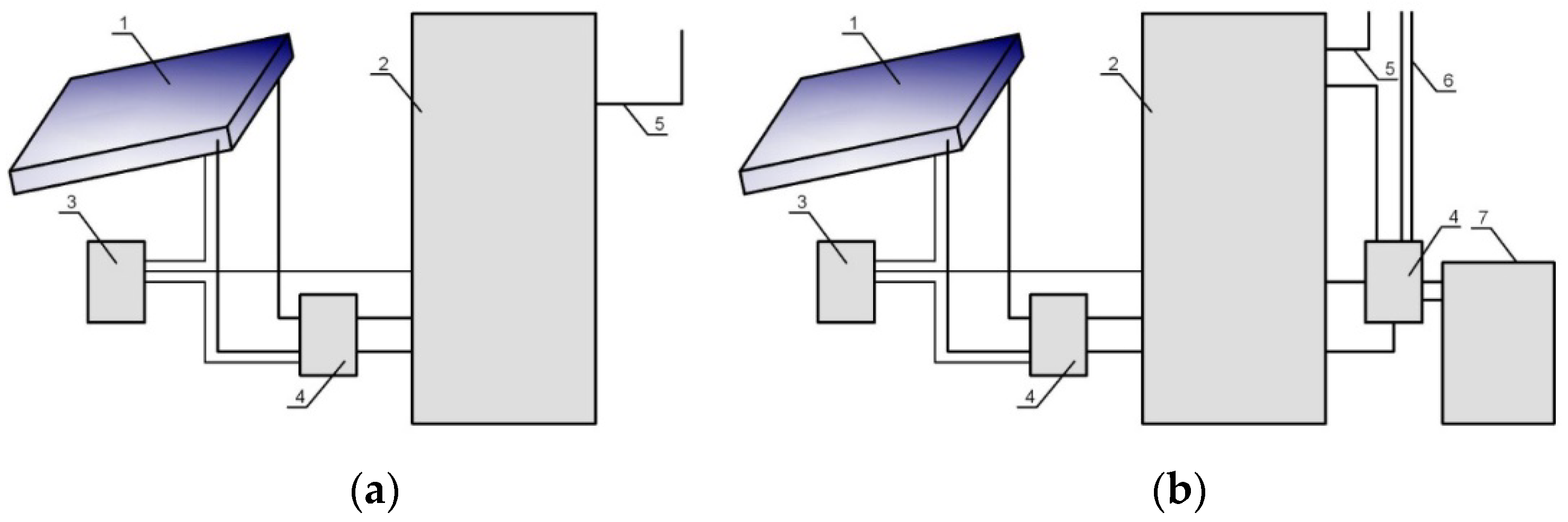

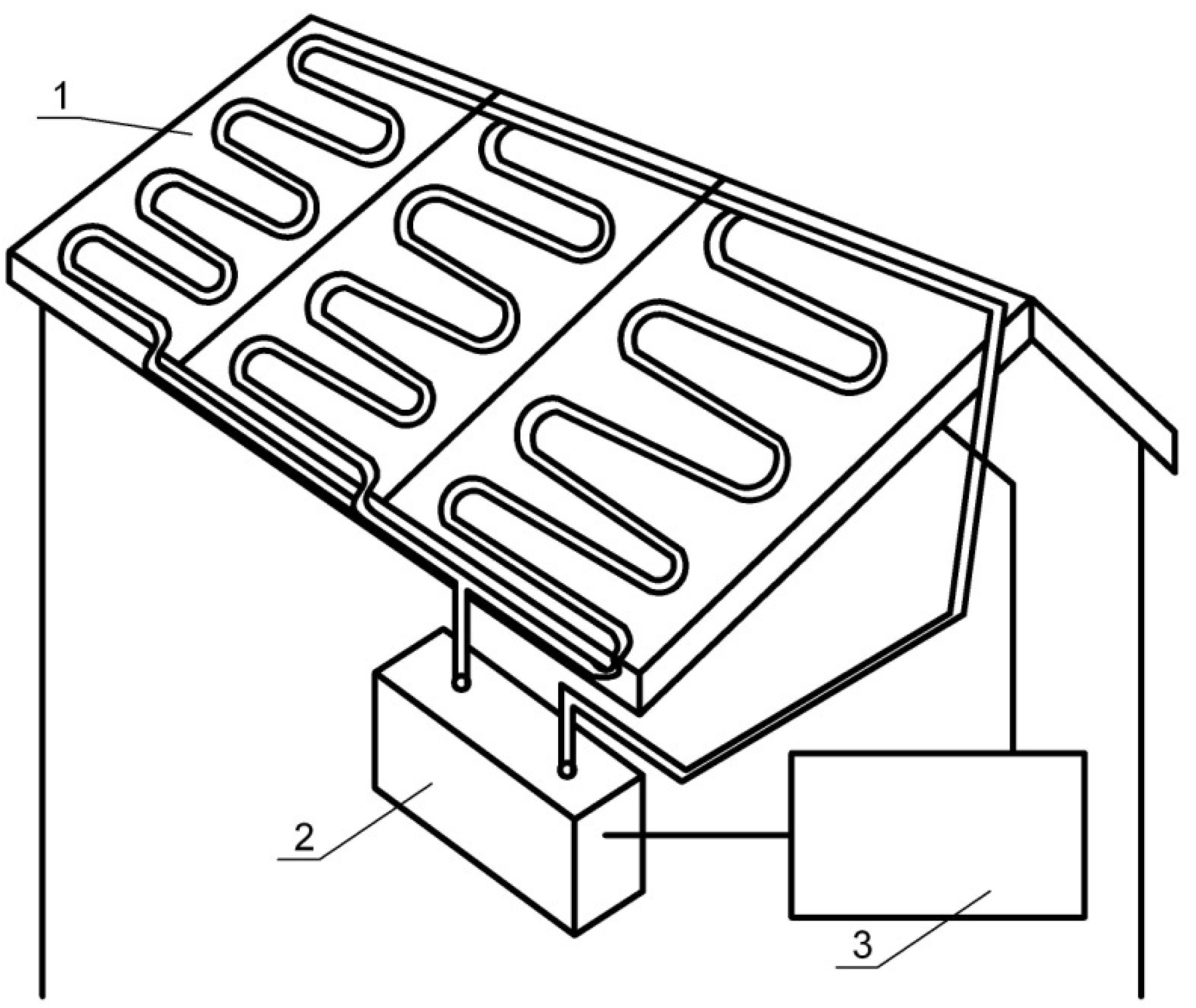

2.1. Systems with Active Use of Solar Energy

2.2. Systems of Solar Heat Supply with Passive Consuming of Sun Energy

2.3. Combined Solar Heat Supply Systems

2.4. Building Insulation Aspect

3. The Purpose of This Article

- -

- Analyze previous theoretical and experimental data, as well as calculation methods for solar heat supply systems with solar panels;

- -

- Perform theoretical and experimental studies of solar panels with various designs to determine and build the most effective one;

- -

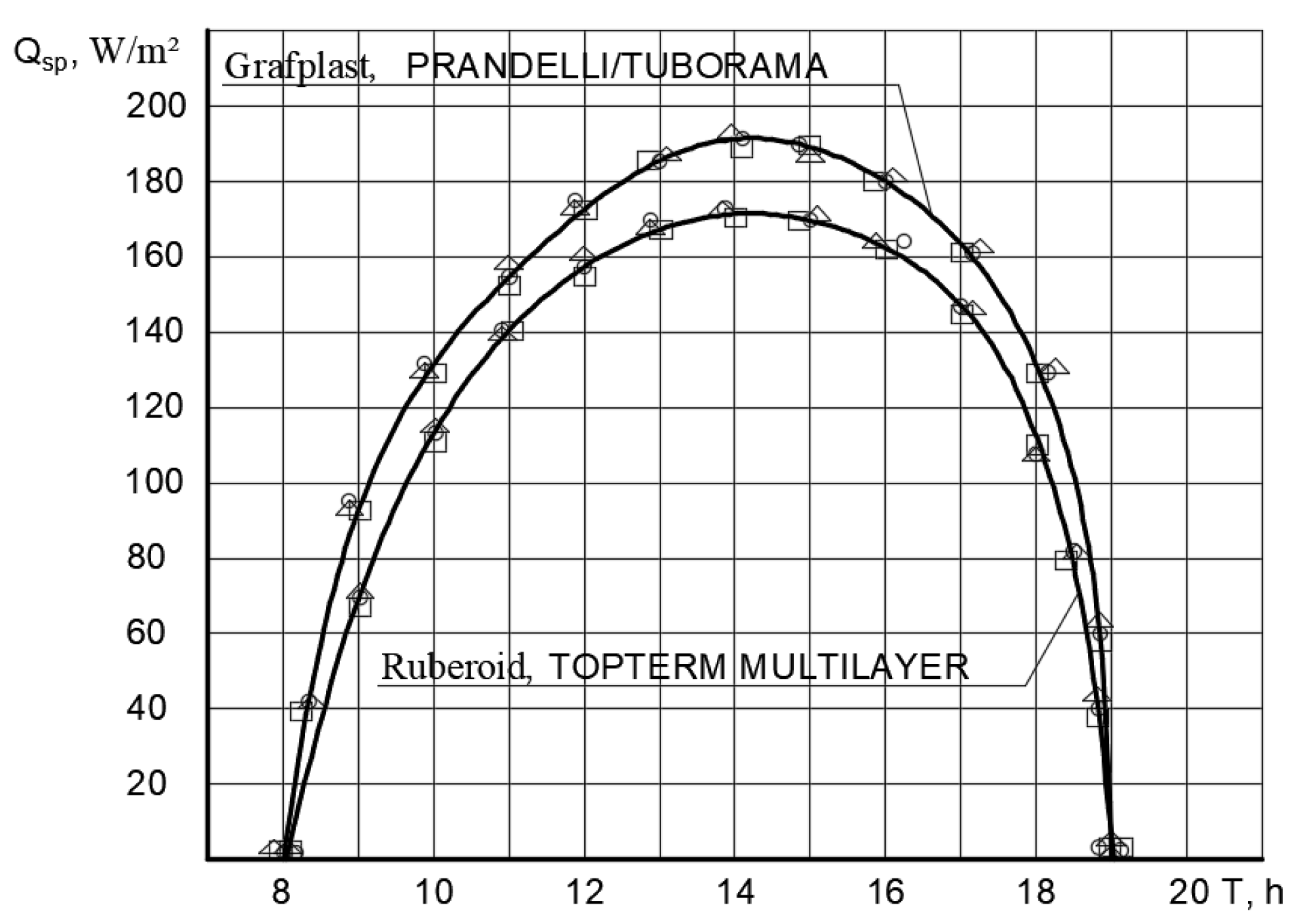

- Analyze the influence of typical and modern roofing materials and various types of pipes in solar collectors on their heat storage capacity;

- -

- Perform a field study of the proposed collectors;

- -

- Develop an engineering methodology for calculating the potential of the combined solar heat supply system.

4. Materials and Methods

4.1. Model of Solar Panel’s Thermal Accumulation

- -

- the temperature of each element in the investigated time interval was considered constant;

- -

- the flow of solar energy is evenly distributed over the surface of the heat absorber;

- -

- wavelength does not affect the radiative properties of surfaces;

- -

- heat is released into the environment from the outer cover by radiation and convection from the heat sink.

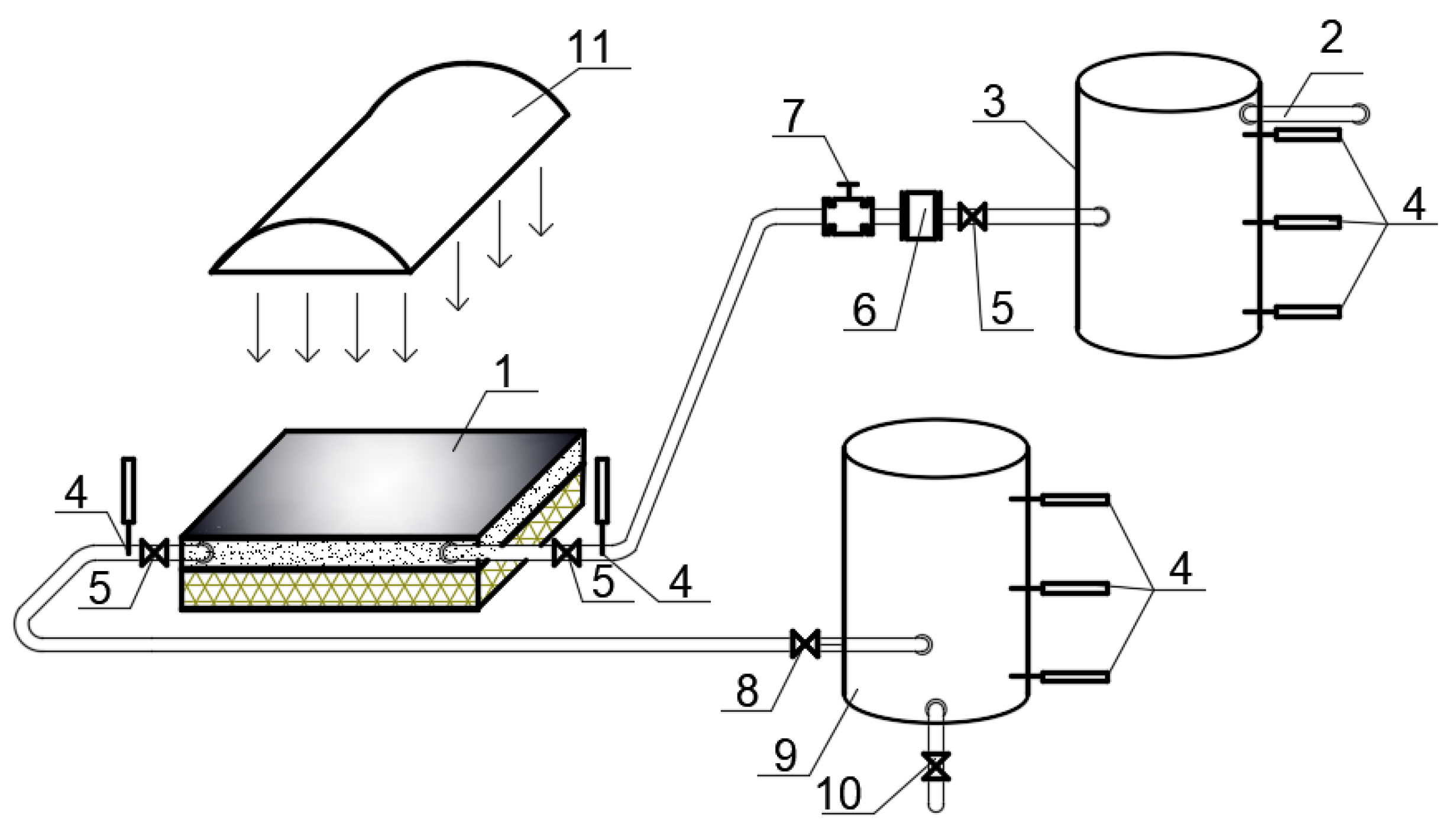

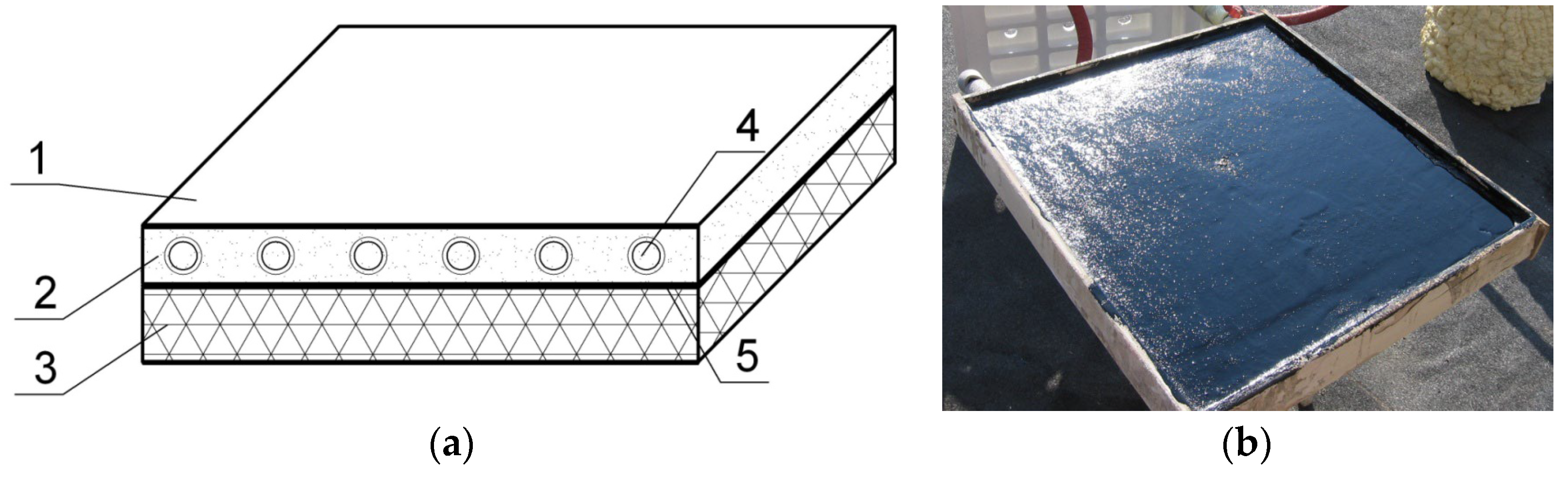

4.2. Laboratory Set Up

- -

- 400 kg sand,

- -

- 200 kg of cement M 400,

- -

- 30 L of water,

- -

- 4 kg Sanpol plasticizer.

- -

- Heat flow from the Sun emission was uniform;

- -

- Reflected solar radiation from environment was neglected;

- -

- Adequacy of the theory of the experiment was accepted as α = 0.95.

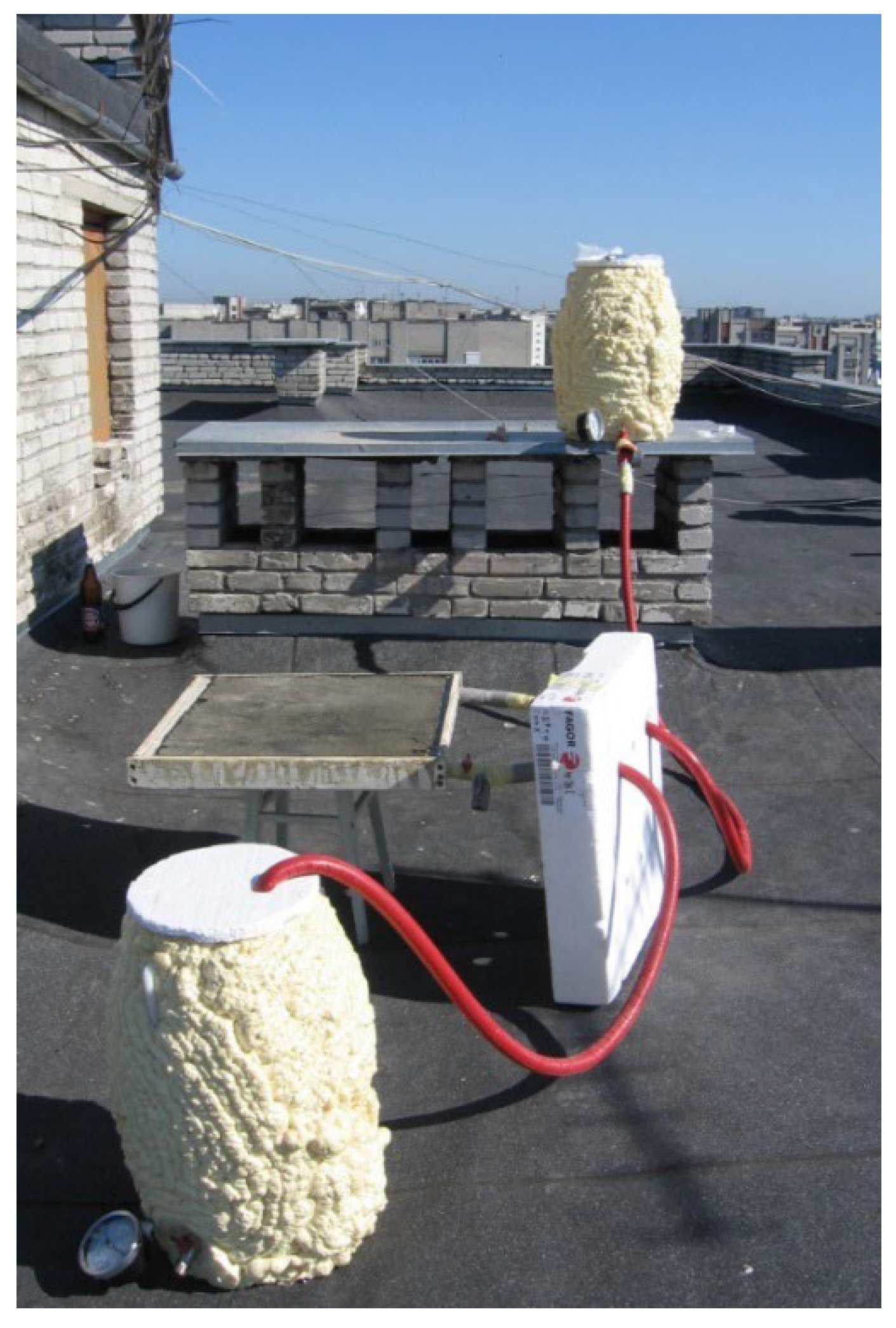

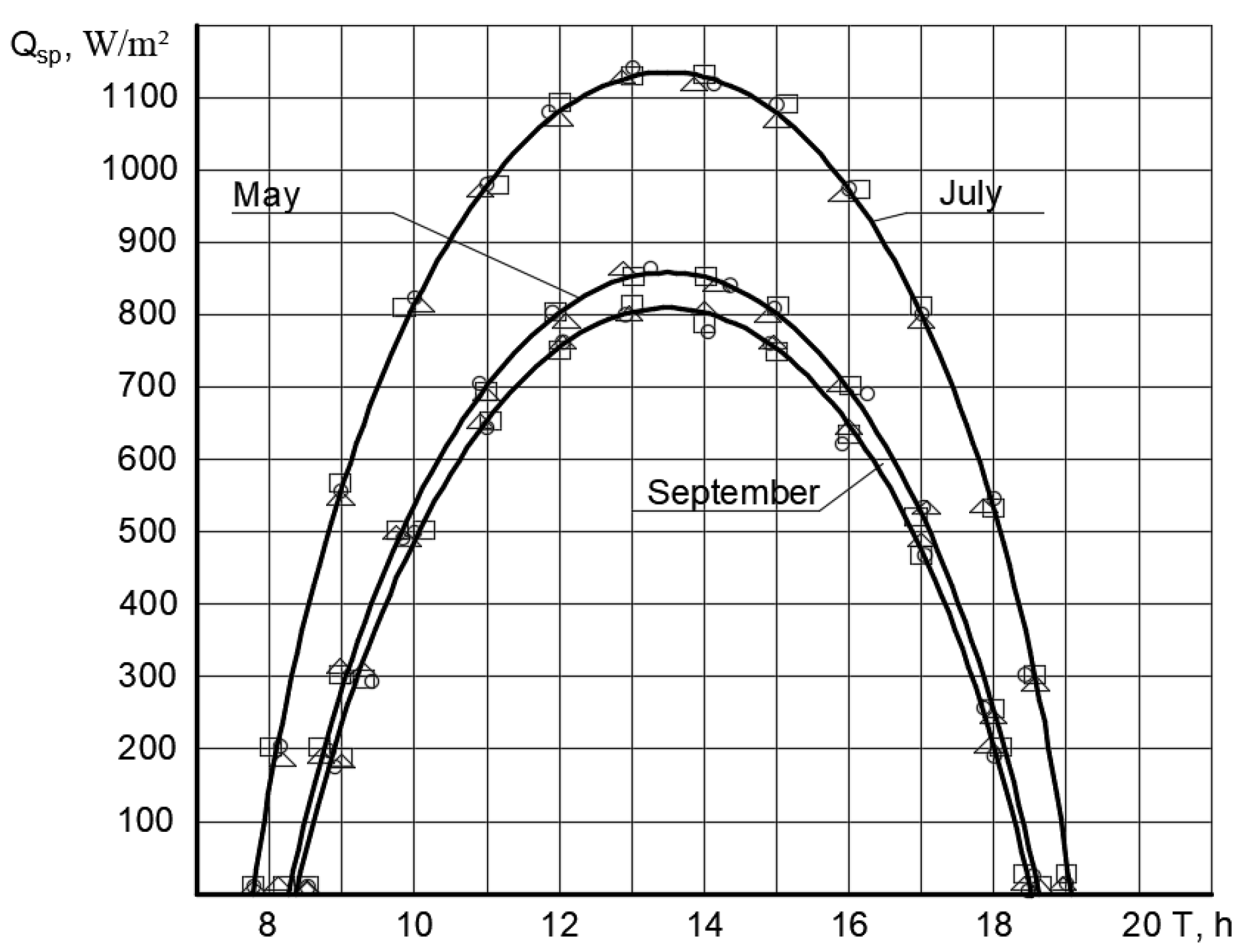

4.3. Experiment

4.4. Field Studies

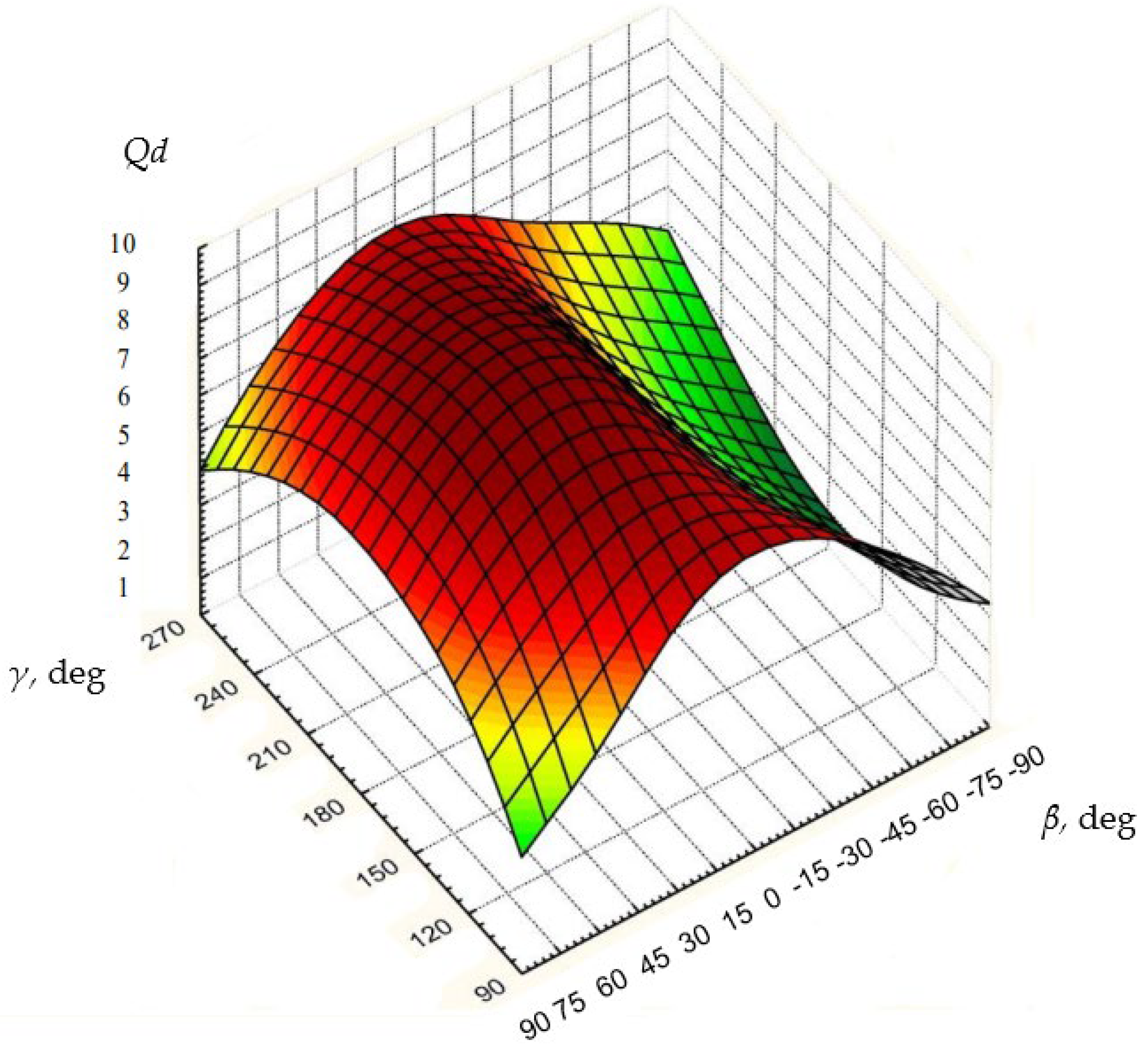

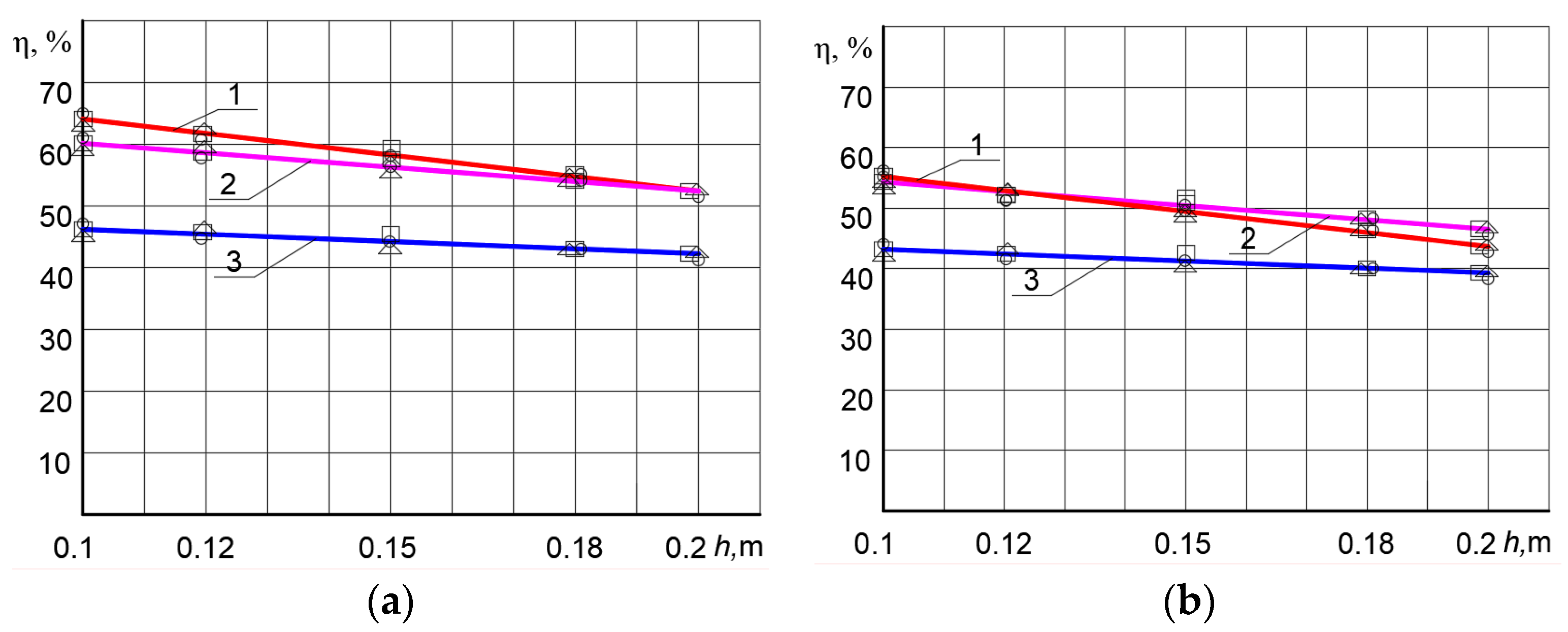

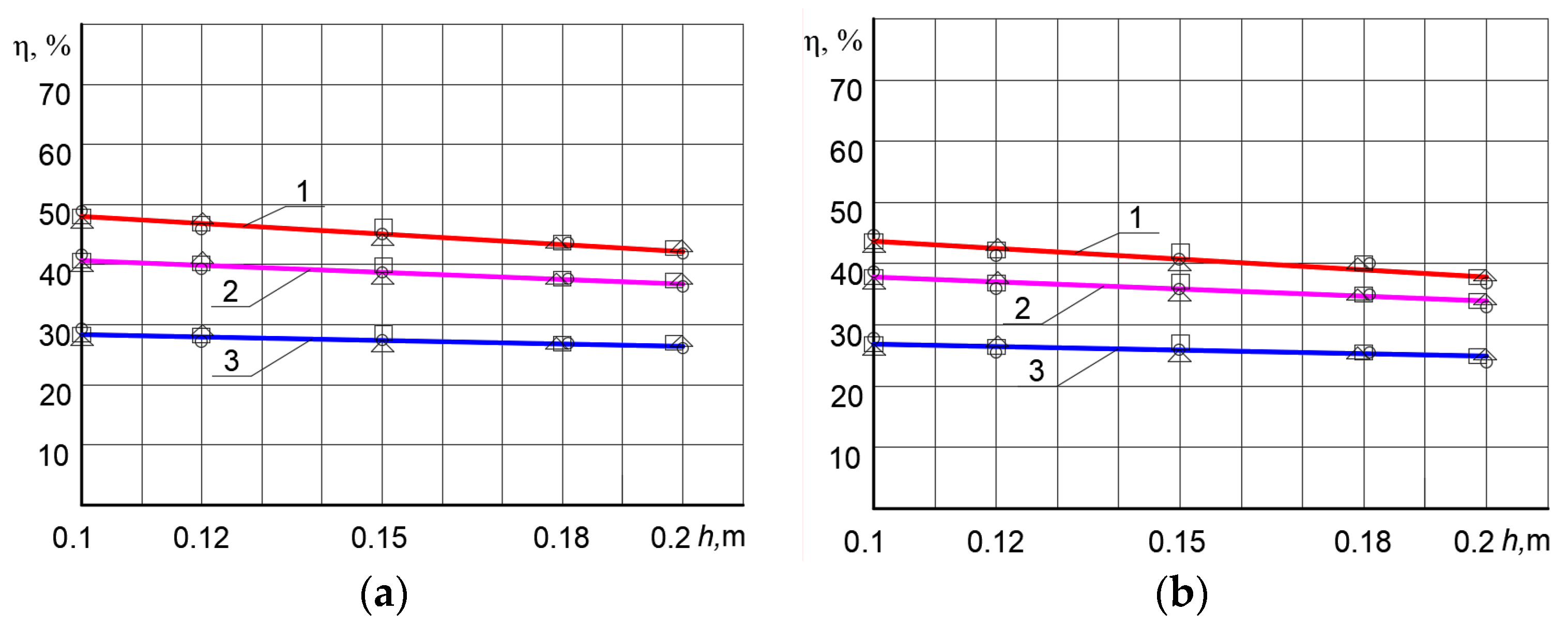

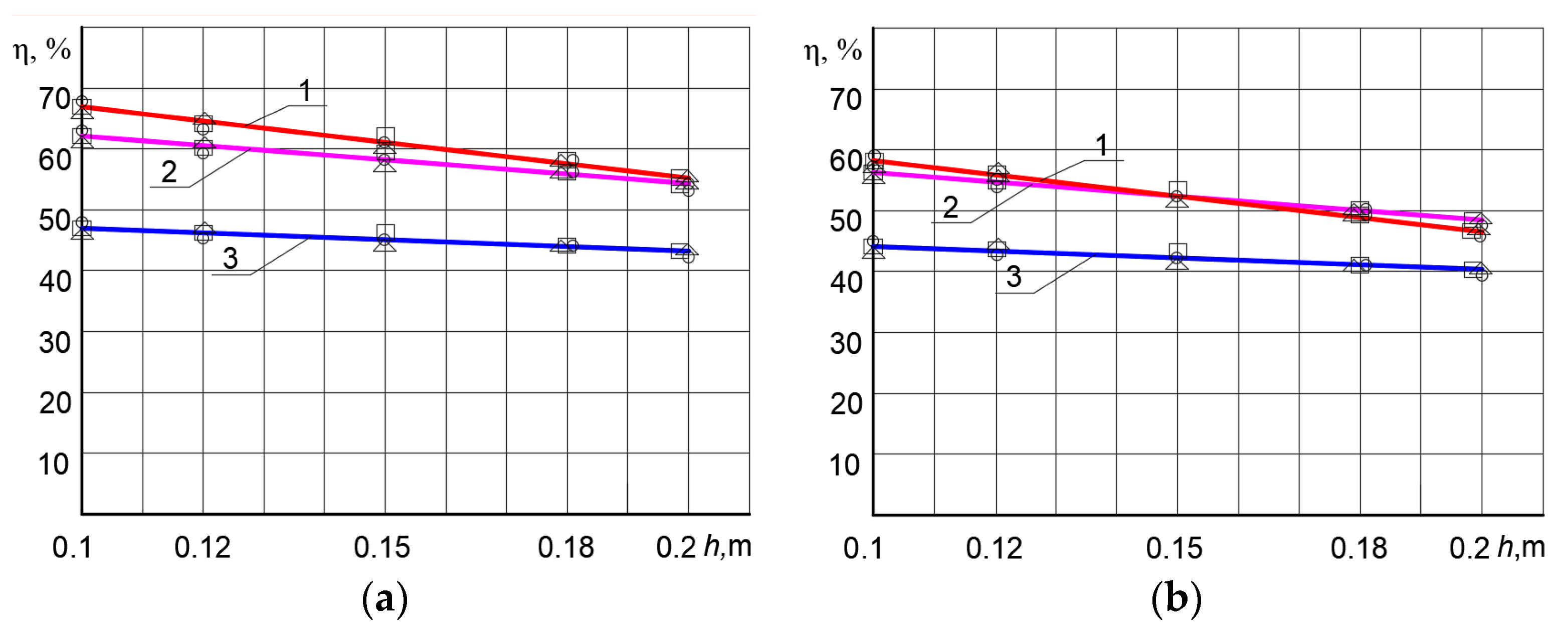

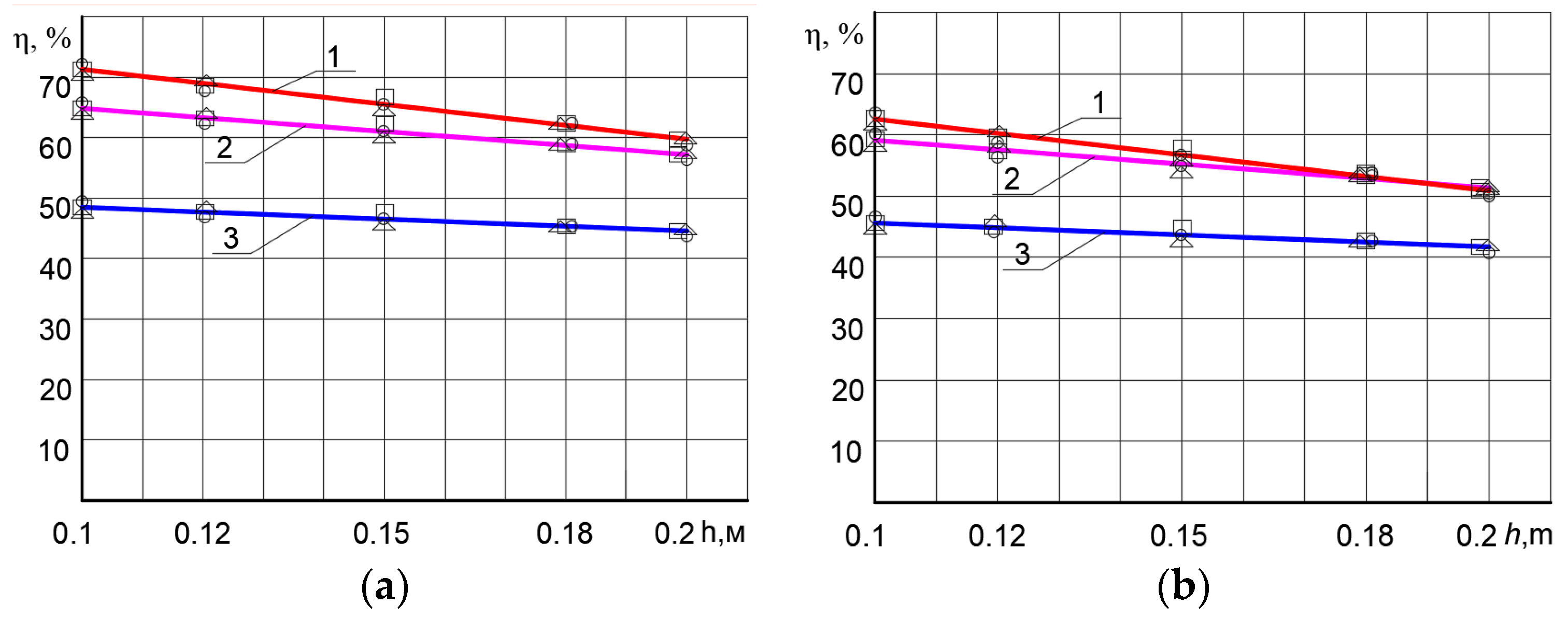

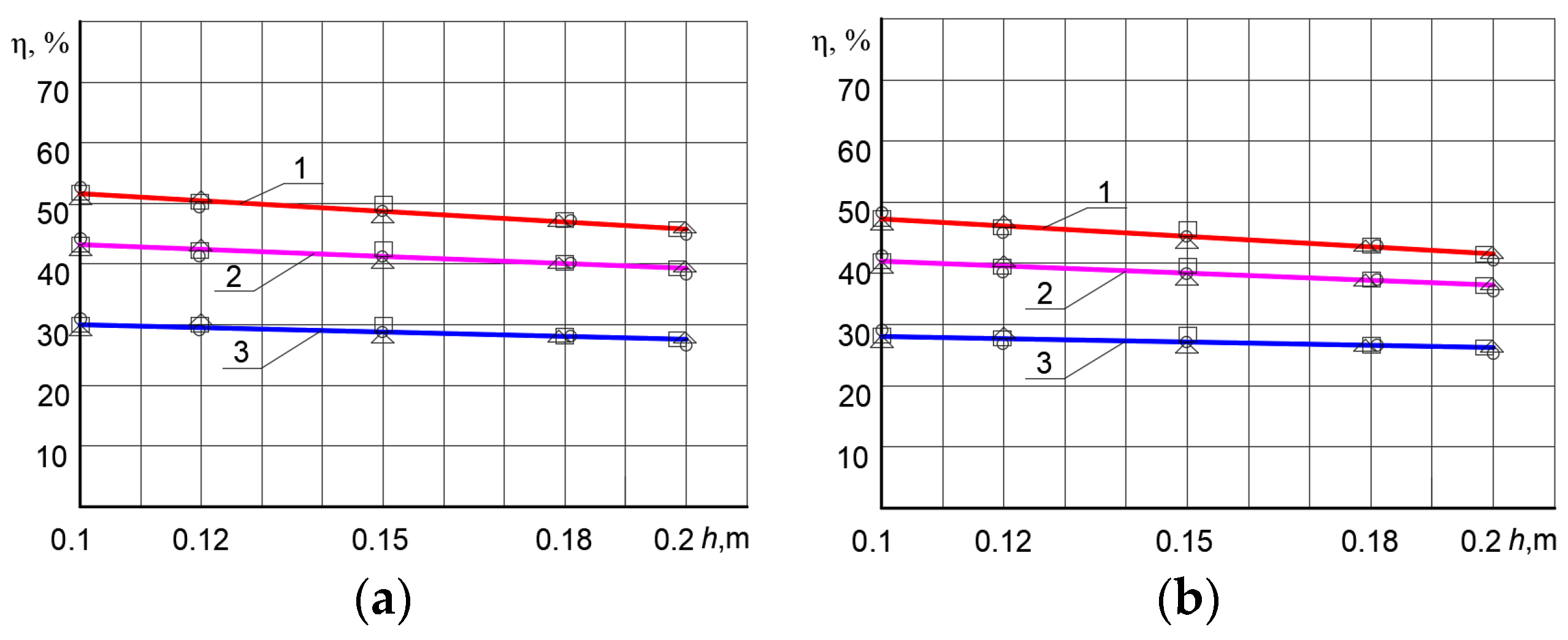

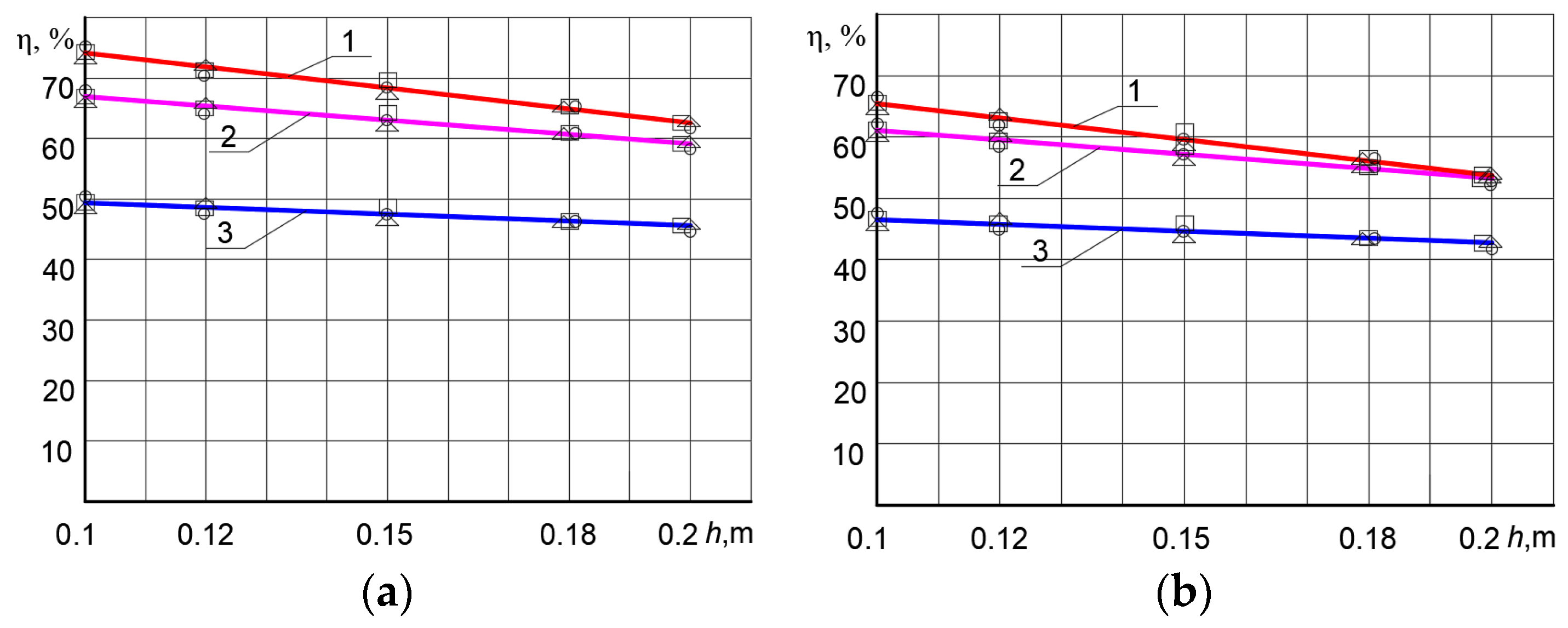

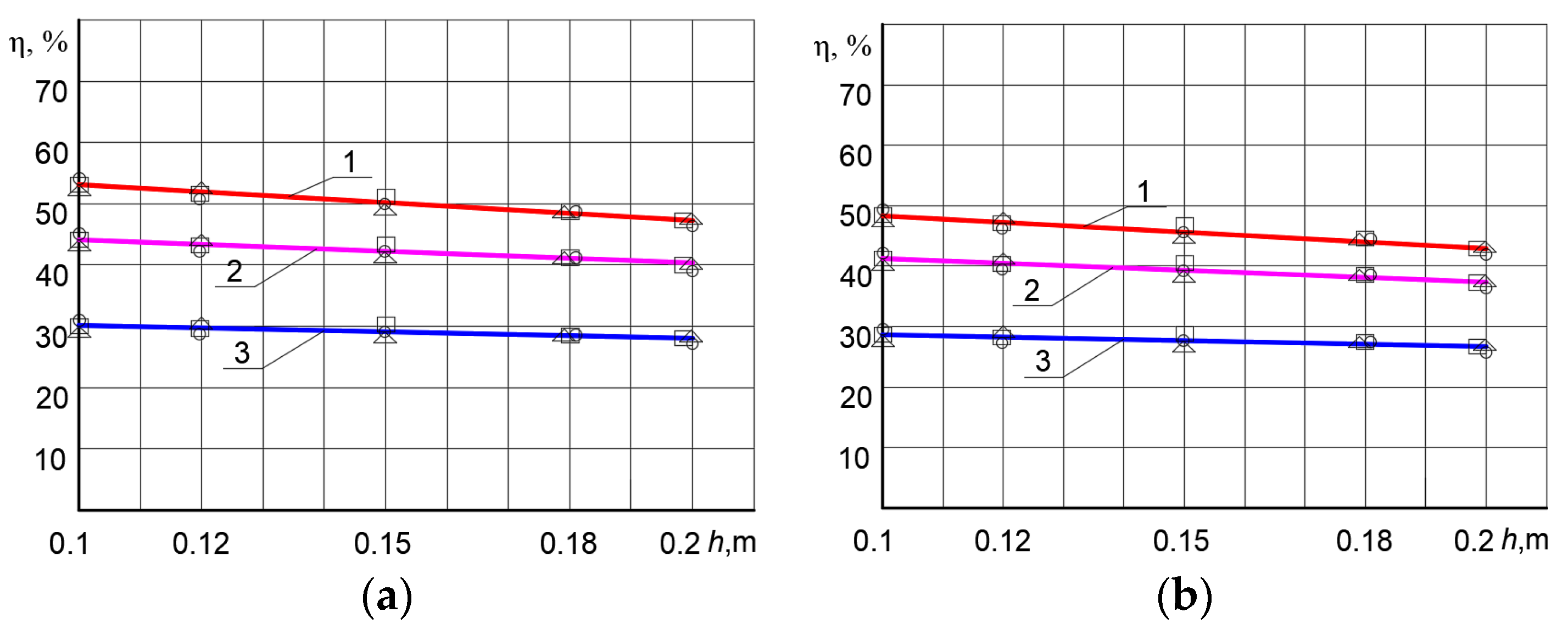

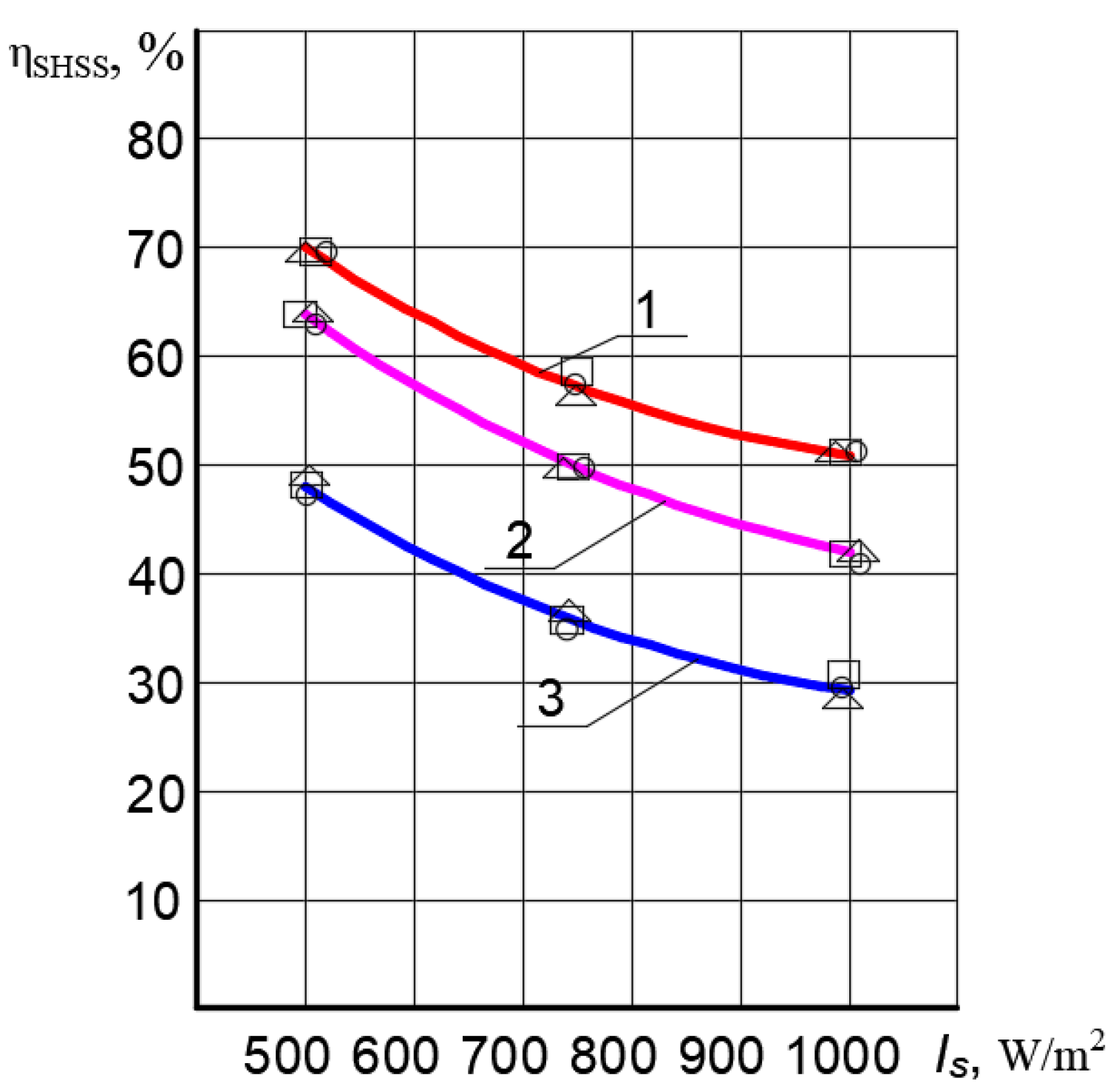

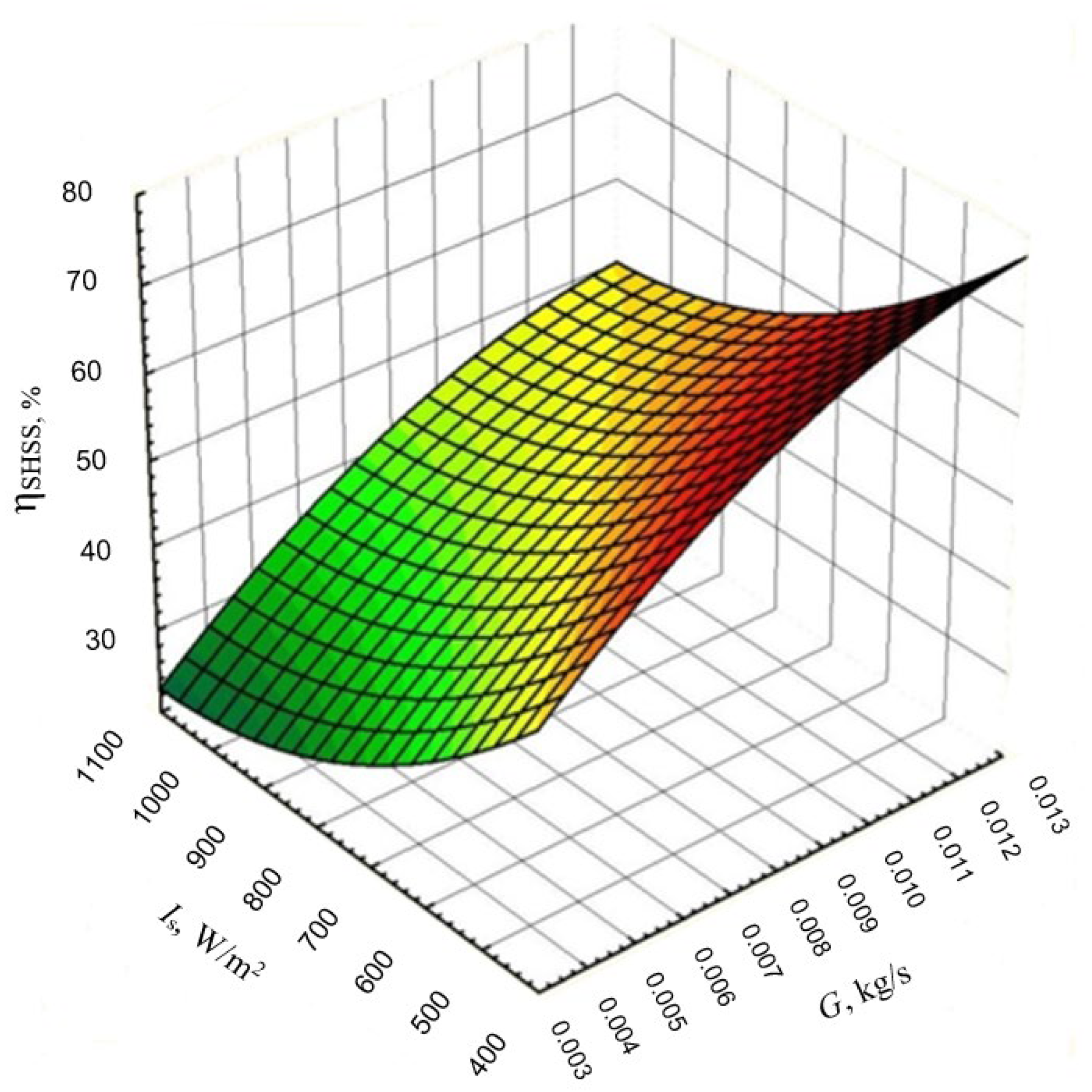

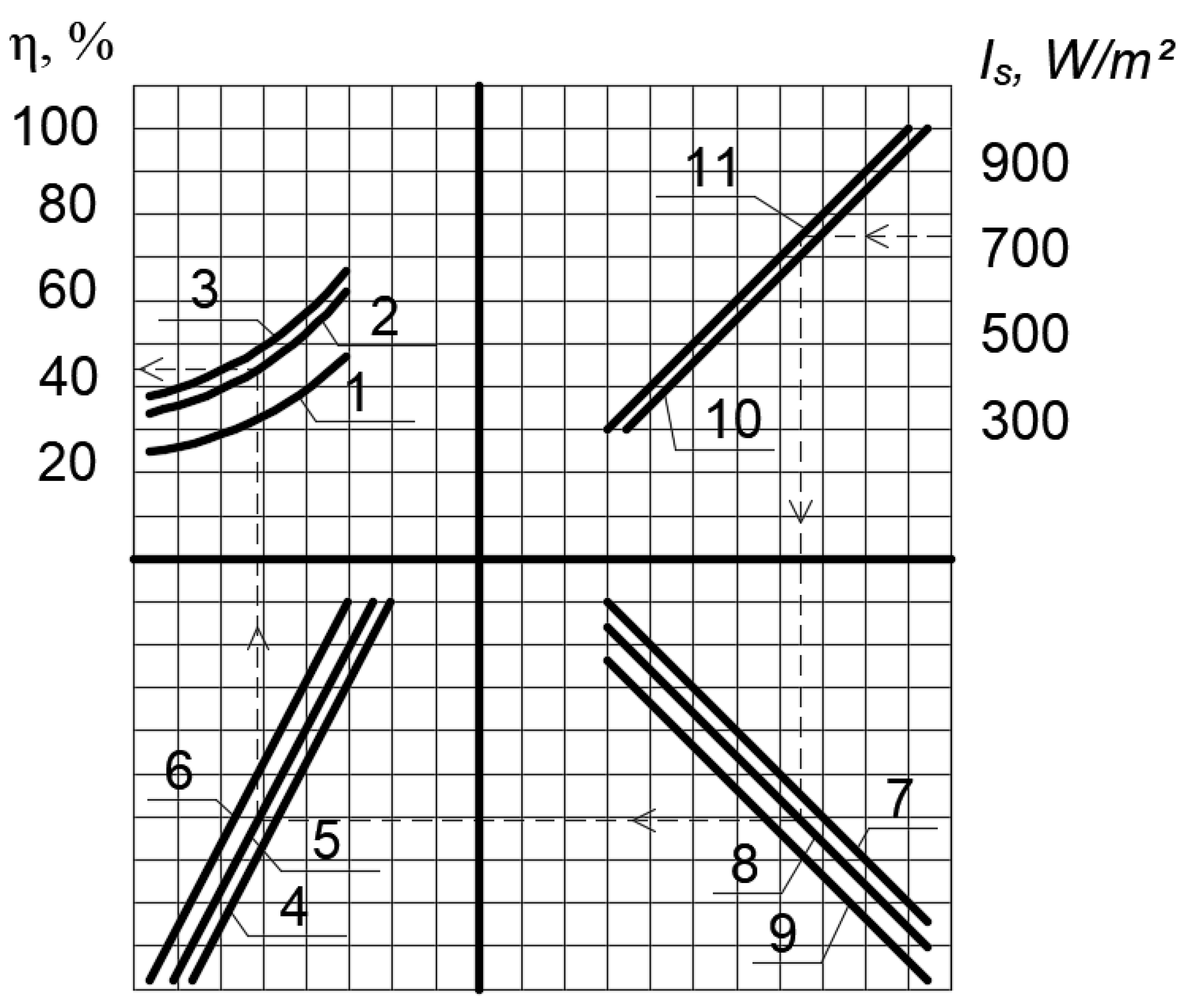

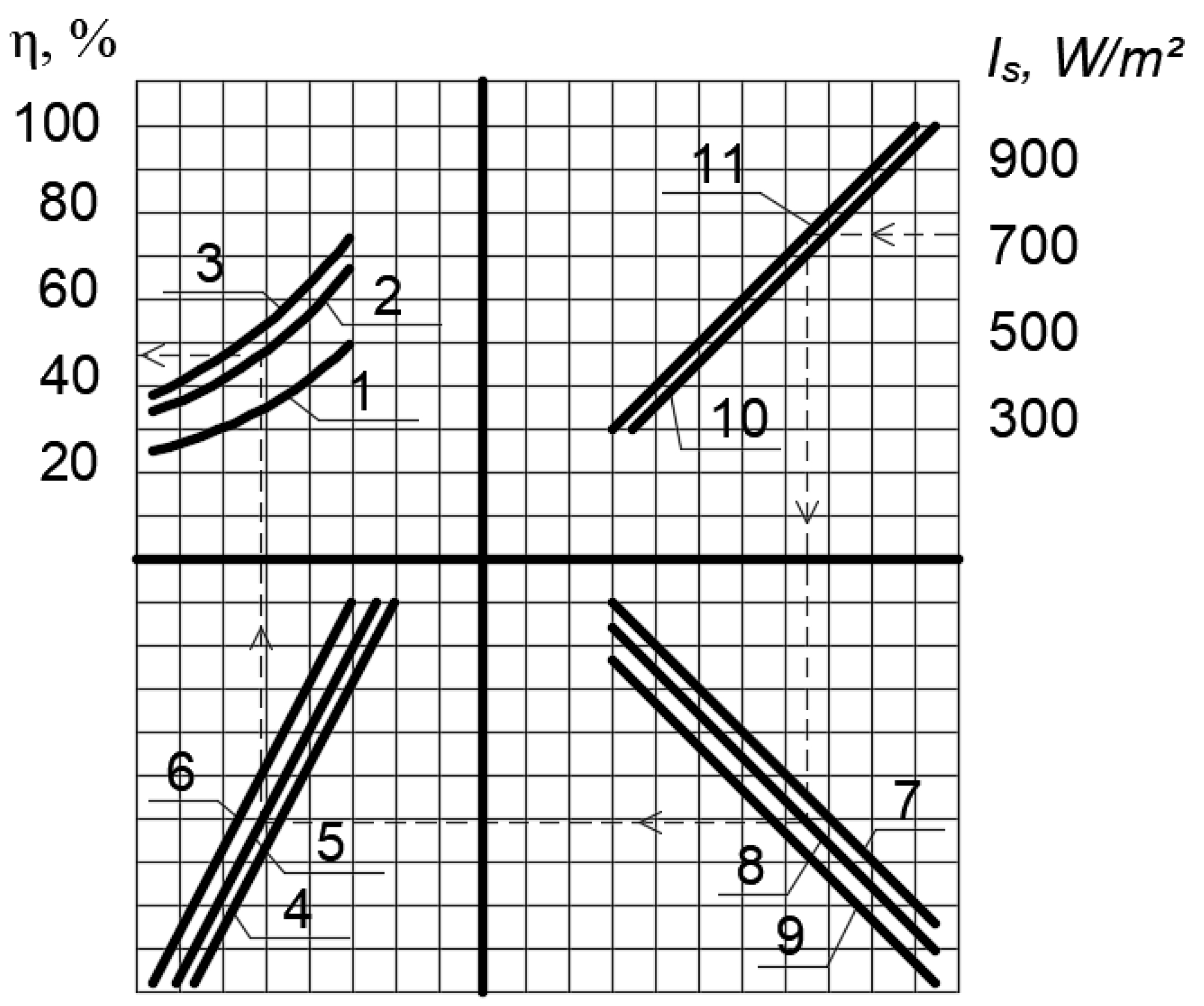

5. Results and Discussion

6. Economic Analysis

CS = (0.12·97,680 + 100)/140.9 = 83.9 UAH/GJ.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kordana-Obuch, S.; Starzec, M. Horizontal Shower Heat Exchanger as an Effective Domestic Hot Water Heating Alternative. Energies 2022, 15, 4829. [Google Scholar] [CrossRef]

- Ratajczak, K.; Amanowicz, Ł.; Szczechowiak, E. Assessment of the air streams mixing in wall-type heat recovery units for ventilation of existing and refurbishing buildings toward low energy buildings. Energy Build. 2020, 227, 110427. [Google Scholar] [CrossRef]

- Neumann, F.; Patschke, M.; Schoennenbeck, M. Heliothermal Flat Collector Module Having a Sandwich Structure. U.S. Patent 7,610,911, 3 November 2009. [Google Scholar]

- Kaplun, V.; Osypenko, V. About Using Electricity Pricing for Smart Grid Dynamic Management with Renewable Sources. In Proceedings of the 2019 IEEE 6th International Conference on Energy Smart Systems, ESS 2019, Kyiv, Ukraine, 17–19 April 2019; pp. 256–260. [Google Scholar]

- Zhelykh, V.; Shapoval, P.; Shapoval, S.; Kasynets, M. Influence of Orientation of Buildings Facades on the Level of Solar Energy Supply to Them. Lect. Notes Civ. Eng. 2021, 100, 499–504. [Google Scholar]

- Dudkiewicz, E.; Fidorów-Kaprawy, N. The energy analysis of a hybrid hot tap water preparation system based on renewable and waste sources. Energy 2017, 127, 198–208. [Google Scholar] [CrossRef]

- Shapoval, S.; Zhelykh, V.; Spodyniuk, N.; Dzeryn, O.; Gulai, B. The effectiveness to use the distribution manifold in the construction of the solar wall for the conditions of circulation. Pollack Period. 2019, 14, 143–154. [Google Scholar] [CrossRef]

- Zhelykh, V.; Venhryn, I.; Kozak, K.; Shapoval, S. Solar collectors integrated into transparent facades. Prod. Eng. Arch. 2020, 26, 84–87. [Google Scholar] [CrossRef]

- Ulewicz, M.; Zhelykh, V.; Furdas, Y.; Kozak, K. Assessment of the Economic Feasibility of Using Alternative Energy Sources in Ukraine. Lect. Notes Civ. Eng. 2021, 100, 482–489. [Google Scholar]

- Kasynets, M.; Kozak, K.; Piznak, B.; Venhryn, I. Enhancing of Efficiency of Solar Panels Combined with Building Coating. In Proceedings of EcoComfort 2022; Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2023; Volume 290, pp. 136–149. [Google Scholar]

- Artemenko, M.; Kaplun, V.; Bobrovnyk, V.; Polishchuk, S. Active filters application for energy losses reduction in three-phase power supply systems. Tech. Electrodyn. 2018, 4, 53–56. [Google Scholar]

- Adamski, M. Mini longitudinal flow spiral recuperator. In Proceedings of the Healthy Buildings Europe, Lublin, Poland, 2–5 July 2017. [Google Scholar]

- Shapoval, S.; Shapoval, P.; Zhelykh, V.; Pona, O.; Spodyniuk, N.; Gulai, B.; Savchenko, O.; Myroniuk, K. Ecological and energy aspects of using the combined solar collectors for low-energy houses. Chem. Chem. Technol. 2017, 11, 503–508. [Google Scholar] [CrossRef]

- Shapoval, S.; Zhelykh, V.; Venhryn, I.; Kozak, K. Simulation of Thermal Processes in the Solar Collector Which Is Combined with External Fence of an Energy Efficient House. Lect. Notes Civ. Eng. 2020, 47, 510–517. [Google Scholar]

- Košičanová, D.; Fedorčák, P. Reducing energy consumption with using ventilation and solar cooling, school building’s case study. Pollack Period. 2011, 6, 131–138. [Google Scholar] [CrossRef]

- Ulewicz, M.; Zhelykh, V.; Kozak, K.; Furdas, Y. Application of Thermosiphon Solar Collectors for Ventilation of Premises. Lect. Notes Civ. Eng. 2020, 47, 180–187. [Google Scholar]

- Venhryn, I.; Shapoval, S.; Voznyak, O.; Datsko, O.; Gulai, B. Modelling of optical characteristics of the Thermal Photovoltaic Hybrid Solar Collector. In Proceedings of the International Scientific and Technical Conference on Computer Sciences and Information Technologies, Lviv, Ukraine, 22–25 September 2021; Volume 1, pp. 255–258. [Google Scholar]

- Zhelykh, V.; Kozak, C.; Savchenko, O. Using of thermosiphon solar collector in an air heating system of passive house. Pollack Period. 2016, 11, 125–133. [Google Scholar] [CrossRef]

- Zhelykh, V.; Ulewicz, M.; Spodyniuk, N.; Shapoval, S.; Shepitchak, V. Analysis of the Processes of Heat Exchange on Infrared Heater Surface. Diagnostyka 2016, 17, 81–85. [Google Scholar]

- Kaplun, V.; Shcherbak, V. Multifactor analysis of university buildings’ energy efficiency. Actual Probl. Econ. 2016, 186, 349–359. [Google Scholar]

- Klymchuk, O.; Denysova, A.; Shramenko, A.; Borysenko, K.; Ivanova, L. Theoretical and experimental investigation of the efficiency of the use of heat-accumulating material for heat supply systems. EUREKA Phys. Eng. 2019, 3, 32–40. [Google Scholar] [CrossRef]

- Bilous, I.; Deshko, V.; Sukhodub, I. Building inside air temperature parametric study. Mag. Civ. Eng. 2016, 68, 65–75. [Google Scholar] [CrossRef]

- Adamski, M. Ventilation system with spiral recuperator. Energy Build. 2010, 42, 674–677. [Google Scholar] [CrossRef]

- Buyak, N.; Deshko, V.; Sukhodub, I. Buildings energy use and human thermal comfort according to energy and exergy approach. Energy Build. 2017, 146, 172–181. [Google Scholar] [CrossRef]

- Deshko, V.; Buyak, N. A model of human thermal comfort for analyzing the energy performance of buildings. East.-Eur. J. Enterp. Technol. 2016, 4, 42–48. [Google Scholar]

- Voznyak, O.; Spodyniuk, N.; Savchenko, O.; Sukholova, I.; Kasynets, M. Enhancing energetic and economic efficiency of heating coal mines by infrared heaters. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2021, 2, 104–109. [Google Scholar] [CrossRef]

- Myroniuk, K.; Voznyak, O.; Yurkevych, Y.; Gulay, B. Technical and economic efficiency after the boiler room renewal. In Advances in Resourse-Saving Technologies and Materials in Civil and Environmental Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 100, pp. 311–318. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voznyak, O.; Spodyniuk, N.; Antypov, I.; Dudkiewicz, E.; Kasynets, M.; Savchenko, O.; Tarasenko, S. Efficiency Improvement of Eco-Friendly Solar Heat Supply System as a Building Coating. Sustainability 2023, 15, 2831. https://doi.org/10.3390/su15032831

Voznyak O, Spodyniuk N, Antypov I, Dudkiewicz E, Kasynets M, Savchenko O, Tarasenko S. Efficiency Improvement of Eco-Friendly Solar Heat Supply System as a Building Coating. Sustainability. 2023; 15(3):2831. https://doi.org/10.3390/su15032831

Chicago/Turabian StyleVoznyak, Orest, Nadiia Spodyniuk, Ievgen Antypov, Edyta Dudkiewicz, Mariana Kasynets, Olena Savchenko, and Svitlana Tarasenko. 2023. "Efficiency Improvement of Eco-Friendly Solar Heat Supply System as a Building Coating" Sustainability 15, no. 3: 2831. https://doi.org/10.3390/su15032831

APA StyleVoznyak, O., Spodyniuk, N., Antypov, I., Dudkiewicz, E., Kasynets, M., Savchenko, O., & Tarasenko, S. (2023). Efficiency Improvement of Eco-Friendly Solar Heat Supply System as a Building Coating. Sustainability, 15(3), 2831. https://doi.org/10.3390/su15032831