The Paradigm of Circular Economy and an Effective Electronic Waste Management

Abstract

1. Introduction

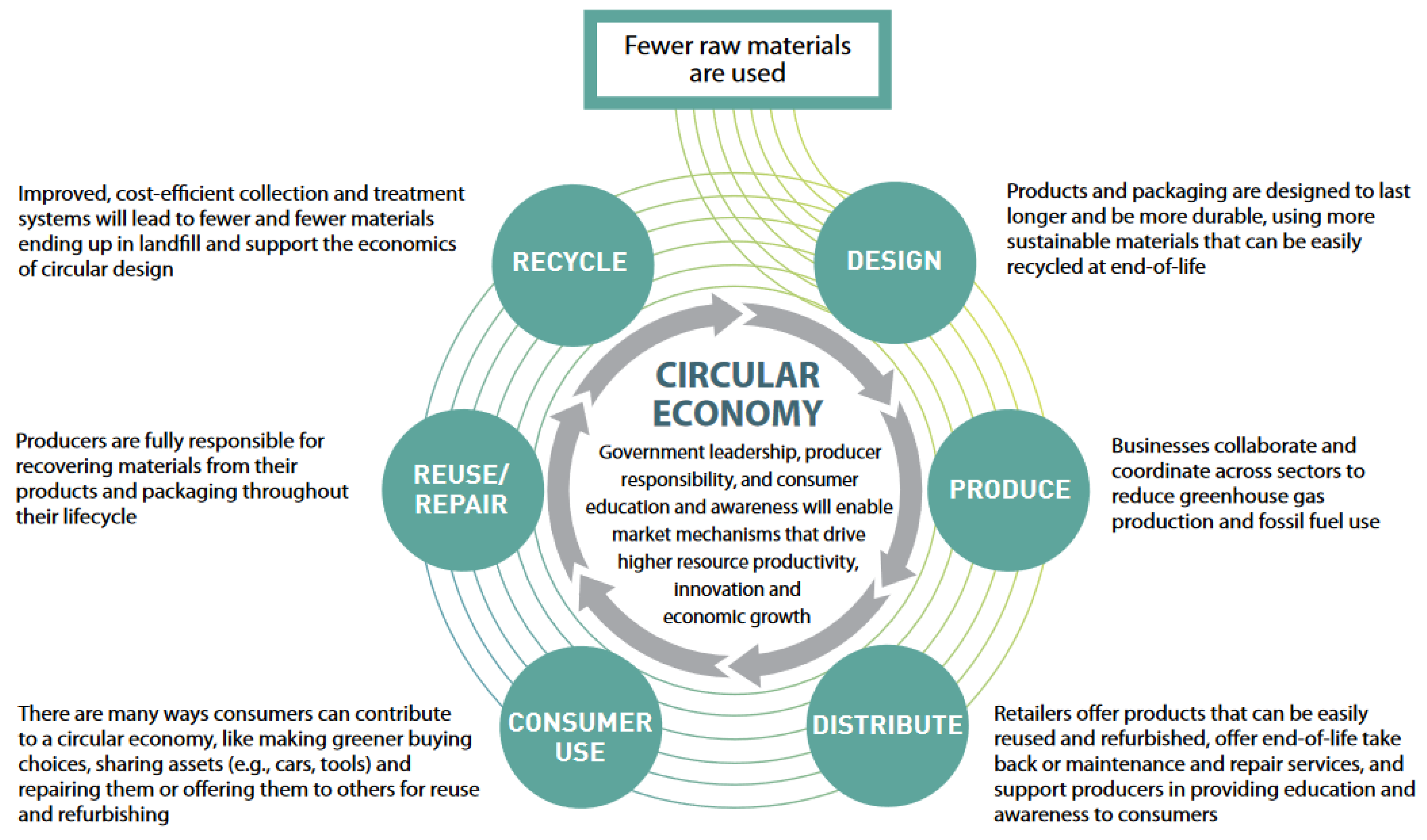

- Few raw materials used: Most of the raw resources used are extracted, and products are manufactured, used, and disposed of. As a result, there is a shortage in raw materials, large quantities of waste, and a plethora of environmental issues. Throughout a circular economy, products and materials stay within the circulation. As a result, fewer virgin materials are utilized compared to the traditional linear economy. Furthermore, products are greater in value, and less waste is produced. The goal is not just to create long-lasting end-of-life recovery but also to lower the use of virgin materials and energy through a restorative system.

- Recycle: In this phase, products are collected, separated, and dismantled to remove any toxic substances and ensure that secondary raw resources are of high quality and can be reused. Ultimately, in a circular economy, the objective is to go beyond traditional recycling practices. For example, a product is only taken for recycling if it cannot be reused, repaired, recreated, or refurbished.

- Design: This component refers to how products (including electronics) are part of a cyclable and sustainable production. Specifically, products must be manufactured to be durable, incorporate modular design, and dismantled easily. Additionally, no pollutants are used to cause environmental damage, and, lastly, materials should be safe, separable, recyclable, and reused.

- Produce: The circular economy is a collaborative and team effort. Its goals can only be reached if stakeholders encompass the interaction with citizens and groups that may be affected by circular policies and regulations—creating strong partnerships that are beneficial for communities for constructing economies of scale for diversion projects. Such partnerships can lead to cost-sharing, improving infrastructure, implementing new waste reduction plans for industries, and lowering GHG emissions and fossil fuel usage.

- Distribute: As we lessen our dependence on virgin materials, significant value is added to the economy by generating or increasing the reuse and reproduction industries. Companies collect, separate, and process recovered waste materials, and such businesses also create and redistribute these products made from recovered materials. As a result, such items benefit from expanding markets and consumers in these regions.

- Consumer use: Customers are essential stakeholders in the circular economy; hence, they have a significant role in its success or failure. For example, consumers can make eco-friendly choices by buying environmentally sustainable products, sharing assets, and even choosing to self-repair their obsolete electronics.

- Repair/Reuse: Reuse refers to a product that is still functional and can be passed on to other users or the owner. Repair refers to extending the longevity of a product through advanced refurbishment and repair and efficient second-hand markets. Repair/reuse initiatives and businesses are crucial as they are beneficial for the environment in most cases due to the fact that energy, water usage, and chemicals are needed for recycling procedures, hence straining the system.

2. The Financial Sustainability of E-Waste Management

2.1. The Economic Worth of E-Waste

2.2. Transformation towards a Circular Economy

- Design: Electronic products must be manufactured robustly so that consumers can reuse them [15]. Specifically, products should be lighter and smaller with enhanced digitalization and cloud-computing services. It is important to remember that many multinational corporations have pledged to eliminate wasteful components being utilized in their electronic supply chains. In contrast, other companies are committing to building electronics free of poisonous materials [15]. These aspects must be collaborated throughout the sector [15]. By creating better electronic designs, it can be confirmed that these products will be dispersed for longer timeframes and have prolonged lifespans leading to their reuse and refurbishment. Moreover, designing durable EEE through holistic methods will ultimately create greater value in a circular economy.

- Reintegration of Manufacturing Scrap: Many of the resources in electronics, such as precious metals, are reintroduced as newer parts.

- Repair and Durability (life extension): Right-to-repair regulations allow customers to have access to fix and amend their own electrical and electronic products. Such legislation advocates for enhanced product design and quality, accessible spare components and tools, and documentation for repairing devices. Ultimately, the objective is to extend the lifecycle of devices and reduce e-waste created from obsolete or unused products.

- Higher Product collection and return with incentives for consumers (end of life):The efficient collection of e-waste is a prerequisite for a successful circular economy. Global collection rates are quite low, and only advancing production with improvements in the collection and recycling infrastructures will close the manufacturing and consumption loops. Hence, it is important to pay attention to and examine consumer behavior related to their collection and recycling habits. In addition, businesses need to provide consumers the necessary incentives and technology needed to ensure that electronics can be returned and fixed to last longer.

- Advanced recycling and recapture (sourcing): Many obstacles prohibit the economic viability of e-waste recycling, and investment incentives are limited. Governments must provide economic incentives to improve and scale-up recycling processes and increase investments in state-of-the-art technology. Such facilities must be planned carefully, considering capacity, location, and specialty. It must be noted that increasing the quantities of recycled materials in electronics production is vital for reducing the demand for new resources. This will allow producers to increase the sourcing of recycled materials.

3. Take-Back and Return Systems

3.1. Resilience and Repair

3.2. Urban Mining

3.3. Reverse Logistics

4. The Social Sustainability of E-Waste Management

5. A Case Study

5.1. The Political Background and Problems with Instruments for Circularity

- Modifications in the Swiss Environmental Protection Act: The Swiss Federal Council now has the authority to stop the promotion of virgin items if their extraction techniques have the potential to negatively affect the environment or compromise the sustainable usage of natural resources [28].

- Regulatory changes on public procurement: In January 2021, the contracts awarded by the Confederation and its enterprises are not only supposed to be based on lowered costs but must also include the notions of sustainability [28].

5.2. The Economic Background and Circularity Problems with Resources

5.3. Repairing Not Recycling as a Solution to Combat E-Waste from Smartphones

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential. United Nations Institute for Training and Research (UNITAR). Available online: https://ewastemonitor.info/wp-content/uploads/2020/11/GEM_2020_def_july1_low.pdf (accessed on 11 June 2021).

- Zaman, A.U.; Lehmann, S. Urban growth and waste management optimization towards ‘zero waste city’. City Cult. Soc. 2011, 2, 177–187. [Google Scholar] [CrossRef]

- Zaman, A.U. Measuring waste management performance using the ‘Zero Waste Index’: The case of Adelaide, Australia. J. Clean. Prod. 2014, 66, 407–419. [Google Scholar] [CrossRef]

- Zhang, S.; Forssberg, E. Mechanical separation-oriented characterization of electronic scrap. Resour. Conserv. Recycl. 1997, 21, 247–269. [Google Scholar] [CrossRef]

- Kiddee, P.; Naidu, R.; Wong, M.H. Electronic waste management approaches: An overview. Waste Manag. (Elmsford) 2013, 33, 1237–1250. [Google Scholar] [CrossRef] [PubMed]

- Wilson, D.C.; Araba, A.O.; Chinwah, K.; Cheeseman, C.R. Building recycling rates through the informal sector. Waste Manag. (Elmsford) 2009, 29, 629–635. [Google Scholar] [CrossRef]

- Scheinberg, A.; Spies, S.; Simpson, M.H.; Mol, A.P.J. Assessing urban recycling in low- and middle-income countries: Building on modernised mixtures. Habitat Int. 2011, 35, 188–198. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. The zero-waste index: A performance measurement tool for waste management systems in a ‘zero waste city’. J. Clean. Prod. 2013, 50, 123–132. [Google Scholar] [CrossRef]

- Potocnik, J.; Antonia, G. The World’s Economy is Only 9% Circular. We Must Be Bolder about Saving Resources. World Economic Forum. Available online: https://www.weforum.org/agenda/2019/11/economy-circular-recycling/ (accessed on 11 November 2019).

- HDR Consulting, Dillon Consulting Limited, Love Environmental Inc. and Robins Environmental. Solid Waste Master Plan: Review of Policy and Trends; Technical Memorandum #4: City of Ottawa, ON, Canada, 2020.

- Ontario’s Strategy for a Waste-Free Ontario: Building the Circular Economy. Available online: https://www.ontario.ca/page/strategy-waste-free-ontario-building-circular-economy (accessed on 12 February 2019).

- World Bank. Where Is the Wealth of Nations? Measuring Capital for the 21st Century; WB: Washington, DC, USA, 2006. [Google Scholar]

- Moldan, B.; Janoušková, S.; Hák, T. How to understand and measure environmental sustainability: Indicators and targets. Ecol. Indic. 2012, 17, 4–13. [Google Scholar] [CrossRef]

- OECD. Measuring Sustainable Development: Report of the Joint Working Party on Statistics for Sustainable Development. In Proceedings of the Annual Meeting of Sustainable Development Experts (AMSDE), Paris, France, 2–3 July 2008. [Google Scholar]

- World Economic Forum. A New Circular Vision for Electronics: Time for a Global Reboot. 2019. Available online: http://www3.weforum.org/docs/WEF_A_New_Circular_Vision_for_Electronics.pdf (accessed on 19 January 2020).

- Moore, Mike. Smartphone Sales See Significant Drop in 2017. Tech Radar. Available online: www.techradar.com/news/smartphone-sales-see-significant-drop-in-2017 (accessed on 28 February 2017).

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-Waste Monitor 2017: Quantities, Flows, and Resources; UNU: Bonn, Germany; ITU: Geneva, Switzerland; ISWA: Vienna, Austria, 2017. [Google Scholar]

- Woolacott, E. E-waste mining could be big business—And good for the planet. BBC News Online. Available online: www.bbc.co.uk/news/business-44642176 (accessed on 6 July 2018).

- Winkler, H. Closed-loop production systems—A sustainable supply chain approach. CIRP J. Manuf. Sci. Technol. 2011, 4, 243–246. [Google Scholar] [CrossRef]

- Roskill. Cobalt Outlook to 2030, 16th ed.; Wood Mackenzie: Edinburgh, UK, 2020. [Google Scholar]

- Dempsey, N.; Bramley, G.; Power, S.; Brown, C. The social dimension of sustainable development: Defining urban social sustainability. Sustain. Dev. (Bradf. West Yorks. Engl.) 2011, 19, 289–300. [Google Scholar] [CrossRef]

- Office of the Deputy Prime Minister (ODPM). UK Presidency: EU Ministerial Informal on Sustainable Communities Policy Papers. ODPM: London. 2006. Available online: http://www.communities.gov.uk/documents/regeneration/pdf/143108.pdf (accessed on 13 January 2023).

- Hopwood, B.; Mellor, M.; O’Brien, G. Sustainable development: Mapping different approaches. Sustain. Dev. (Bradf. West Yorks. Engl.) 2005, 13, 38–52. [Google Scholar] [CrossRef]

- ILO. Decent Work in the Management of Electrical and Electronic Waste (E-Waste). Geneva, Switzerland. 2019. Available online: https://www.ilo.org/wcmsp5/groups/public/---ed_dialogue/---sector/documents/publication/wcms_673662.pdf (accessed on 12 July 2020).

- ILO. Tackling Informality in E-Waste Management: The Potential of Cooperative Enterprises. 2014. Available online: https://www.ilo.org/wcmsp5/groups/public/---ed_dialogue/---sector/documents/publication/wcms_315228.pdf (accessed on 15 September 2019).

- Karcher, S.; Karcher, Y.; Valdivia, S.; Schluep, M. From Worst to Good Practices in Secondary Metals Recovery, Sustainable Recycling Industries: St. Gallen, Switzerland, 2018. Available online: https://www.sustainable-recycling.org/wp-content/uploads/2018/07/worst-practices-web-25.7.18.pdf (accessed on 25 July 2019).

- Hinchliffe, D.; Gunsilius, E.; Wagner, M.; Hemkhaus, M.; Batteiger, A.; Rabbow, E.; Radulovic, V.; Cheng, C.; Fautereau, B.; Ott, D.; et al. Case Studies and Approaches to Building Partnerships between the Informal and the Formal Sector for Sustainable E-Waste Management; Solving the E-Waste Problem (StEP) Initiative: Vienna, Austria, 2020. [Google Scholar]

- Cleantech Alps and Sofies. The Circular Economy: An Economic and Environmental Opportunity for Switzerland? 2021. Available online: https://www.cleantech-alps.com/multimedia/docs/2021/05/etude-eco_circulaire-2021-EN_FULL_WEB.pdf (accessed on 18 February 2022).

- Federal Office for the Environment (FOEN), 2021. Available online: https://www.bafu.admin.ch/bafu/en/home/topics/waste/guide-to-waste-az/electrical-and-electronic-equipment.html (accessed on 18 July 2019).

- Federal Statistical Office (FSO). Material flow accounts Statistics first contribution to measuring the circular economy. 2020. Available online: https://www.bfs.admin.ch/bfs/en/home/statistics/cataloguesdatabases.assetdetail.13487975.html (accessed on 18 July 2019).

- Jungbluth, N.; Nathani, C.; Stucki, M.; Leuenberger, M. Environmental Impacts of Swiss Consumption and Production. A Combination of Input-Output Analysis with Life Cycle Assessment; Federal Office for the Environment: Bern, Switzerland, 2011. [Google Scholar]

- Federal Office for the Environment (FOEN), 2013. Available online: https://www.bafu.admin.ch/bafu/en/home.html (accessed on 18 July 2019).

- Kazancoglu, Y.; Ozkan-Ozen, Y.D.; Mangla, S.K.; Ram, M. Risk assessment for sustainability in e-waste recycling in circular economy. Clean Technol. Environ. Policy 2022, 24, 1145–1157. [Google Scholar] [CrossRef]

- Islam, M.T.; Dias, P.; Huda, N. Young consumers’e-waste awareness, consumption, disposal, and recycling behavior: A case study of university students in Sydney, Australia. J. Clean. Prod. 2021, 282, 124490. [Google Scholar] [CrossRef]

- Roy, J.J.; Rarotra, S.; Krikstolaityte, V.; Zhuoran, K.W.; Cindy, Y.D.I.; Tan, X.Y.; Srinivasan, M. Green recycling methods to treat lithium-ion batteries E-waste: A circular approach to sustainability. Adv. Mater. 2022, 34, 2103346. [Google Scholar] [CrossRef] [PubMed]

- Lee, R.P.; Meyer, B.; Huang, Q.; Voss, R. Sustainable waste management for zero waste cities in China: Potential, challenges and opportunities. Clean Energy 2020, 4, 169–201. [Google Scholar] [CrossRef]

- Kerdlap, P.; Low, J.S.C.; Ramakrishna, S. Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour. Conserv. Recycl. 2019, 151, 104438. [Google Scholar] [CrossRef]

- Chatterji, Mo. 2021. “Repairing—Not Recycling—Is the First Step to Tackling E-Waste from Smartphones. Here’s Why”. World Economic Forum, July 19. Available online: https://www.weforum.org/agenda/2021/07/repair-not-recycle-tackle-ewaste-circular-economysmartphones/ (accessed on 12 March 2022).

- Liang, Z.; Luo, Z.; Yuan, J.; Li, M.; Xia, Y.; Che, T.; Liu, J. Evaluating the Environmental and Economic Performance of Municipal Solid Waste Disposal by All-Component Resource Recovery. Sustainability 2022, 14, 16898. [Google Scholar] [CrossRef]

- Sang, Y.; Yu, H.; Han, E. Understanding the Barriers to Consumer Purchasing of Zero-Waste Products. Sustainability 2022, 14, 16858. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.; Shirazi, F. The Paradigm of Circular Economy and an Effective Electronic Waste Management. Sustainability 2023, 15, 1998. https://doi.org/10.3390/su15031998

Ali S, Shirazi F. The Paradigm of Circular Economy and an Effective Electronic Waste Management. Sustainability. 2023; 15(3):1998. https://doi.org/10.3390/su15031998

Chicago/Turabian StyleAli, Saidia, and Farid Shirazi. 2023. "The Paradigm of Circular Economy and an Effective Electronic Waste Management" Sustainability 15, no. 3: 1998. https://doi.org/10.3390/su15031998

APA StyleAli, S., & Shirazi, F. (2023). The Paradigm of Circular Economy and an Effective Electronic Waste Management. Sustainability, 15(3), 1998. https://doi.org/10.3390/su15031998