An In-Depth Analysis of Physical, Chemical, and Microplastic Parameters of Landfill Fine Fraction for Biocover Construction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Object

2.2. Physical and Chemical Characterization

2.3. Concentration of Microplastics

2.4. Data Analysis

3. Results and Discussion

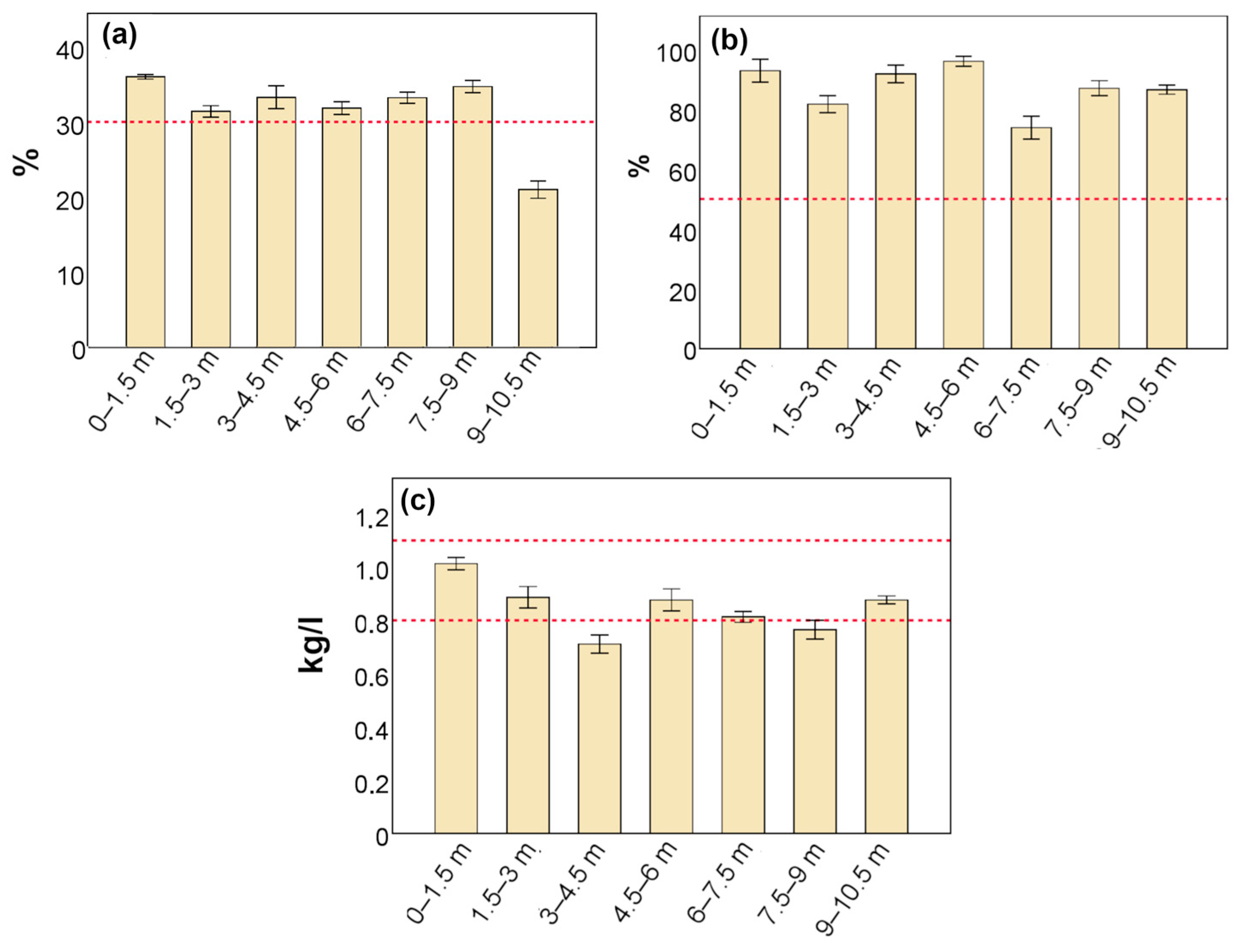

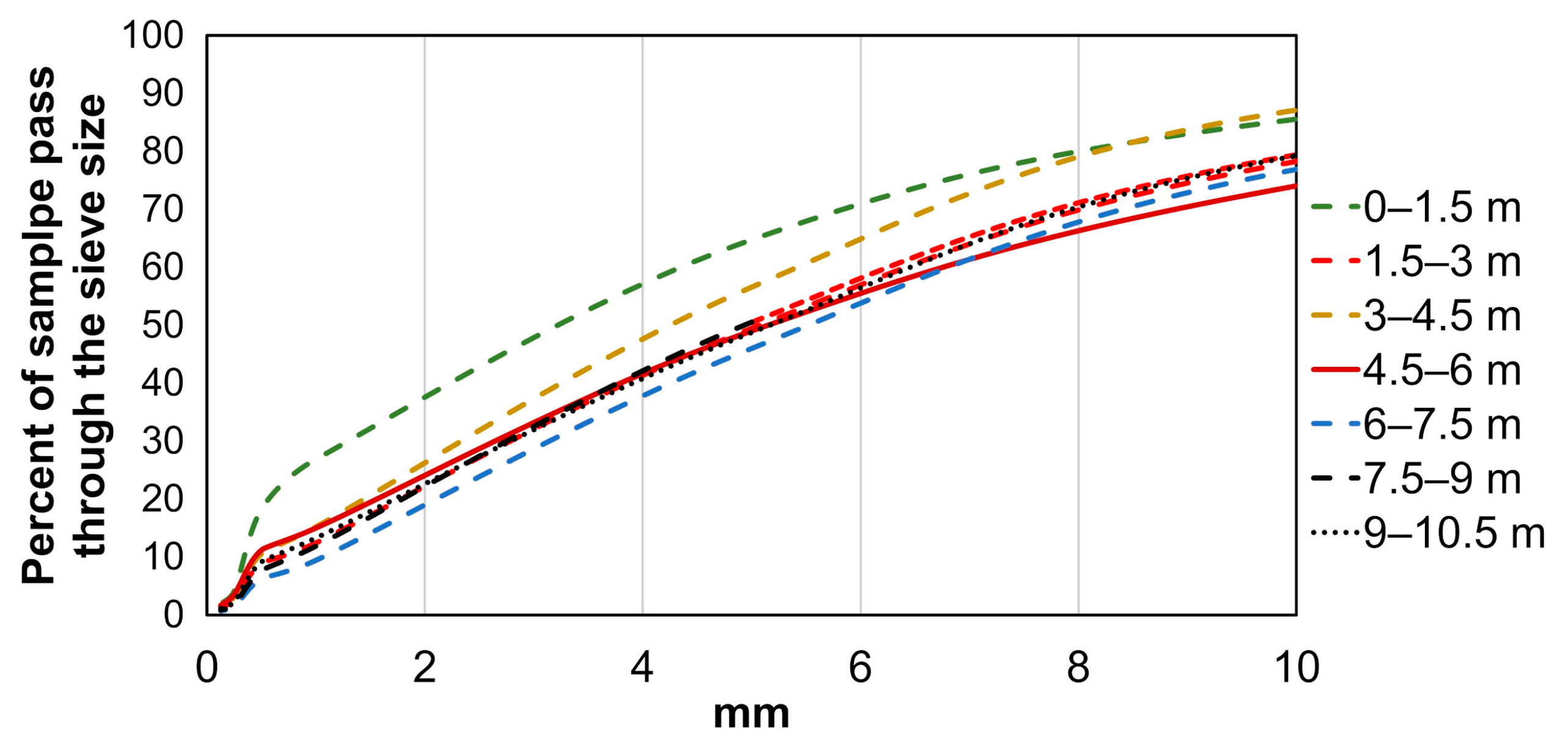

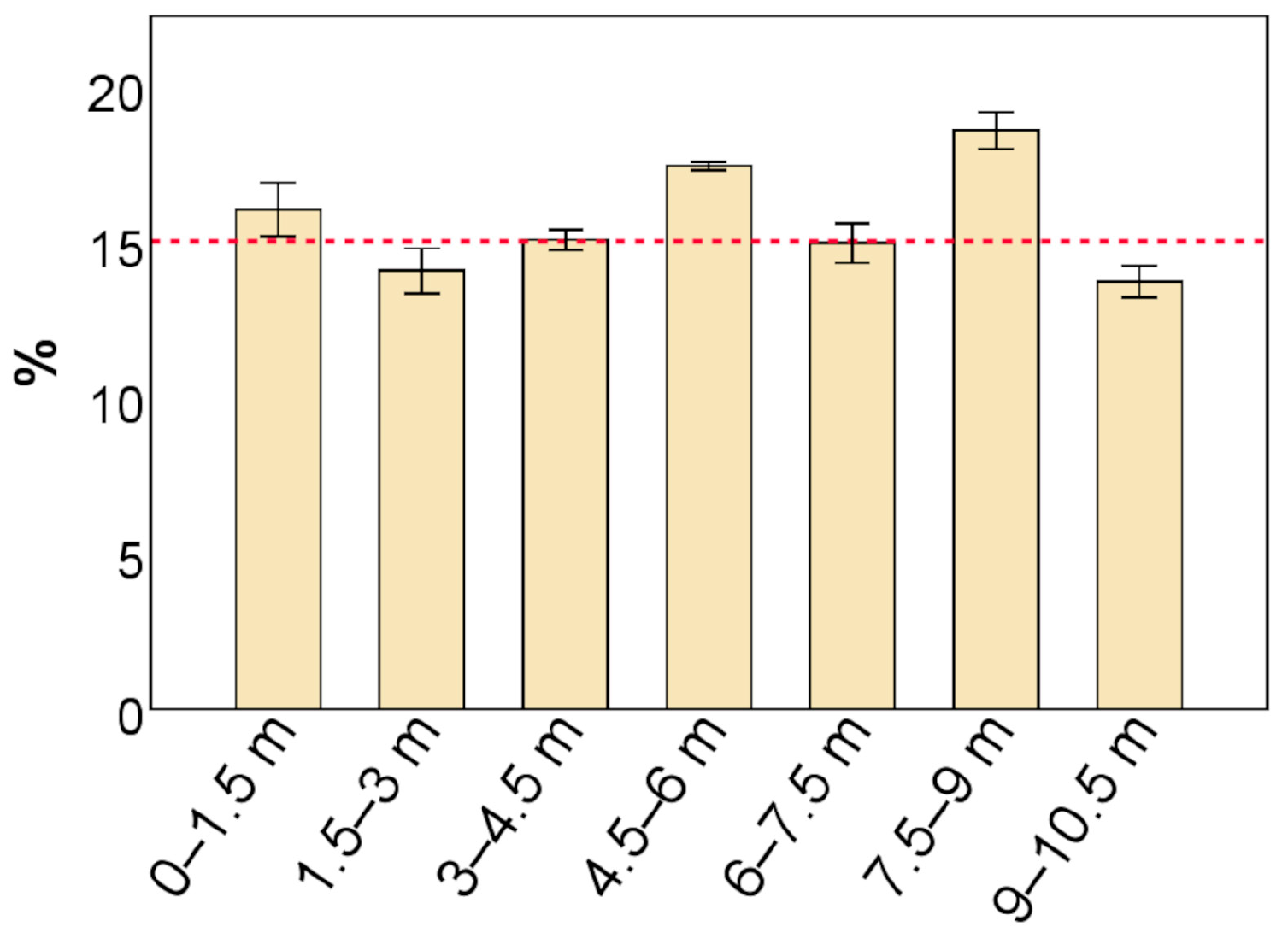

3.1. Physical Parameters

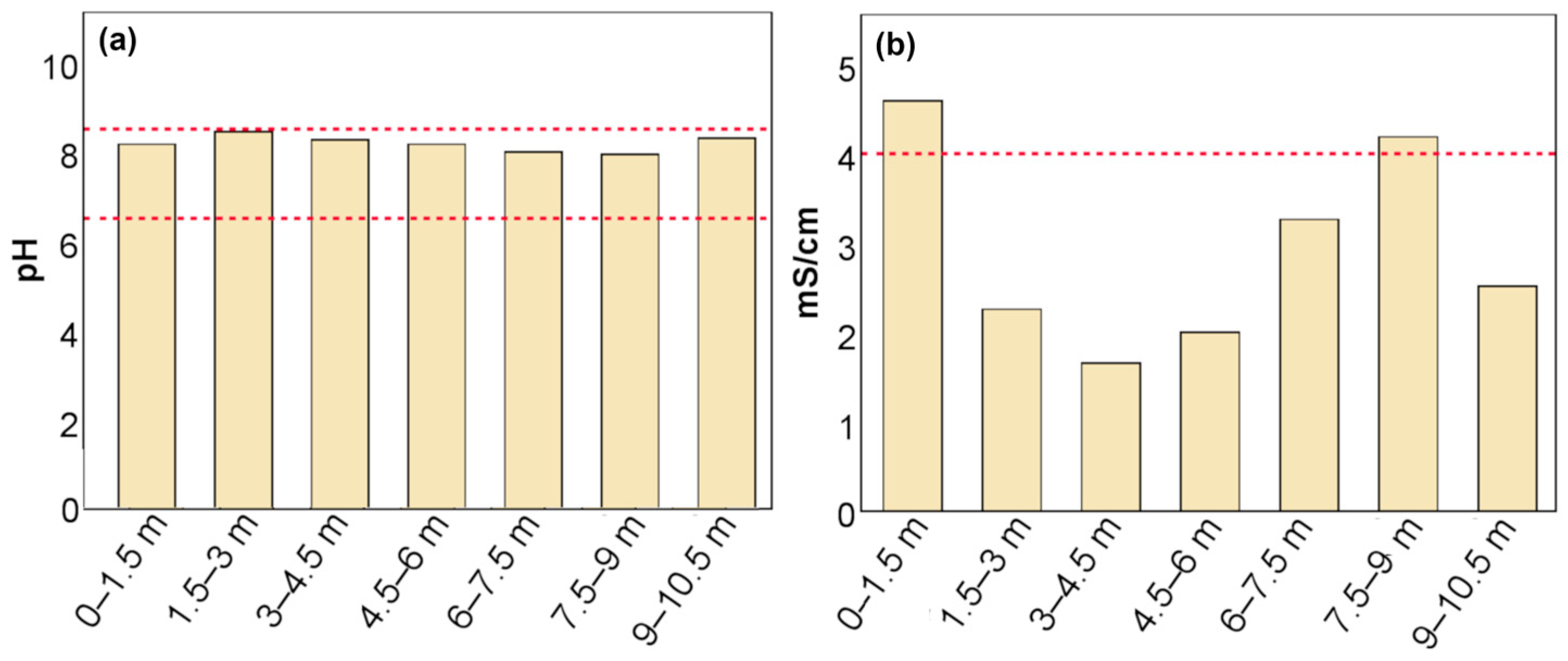

3.2. Chemical Parameters

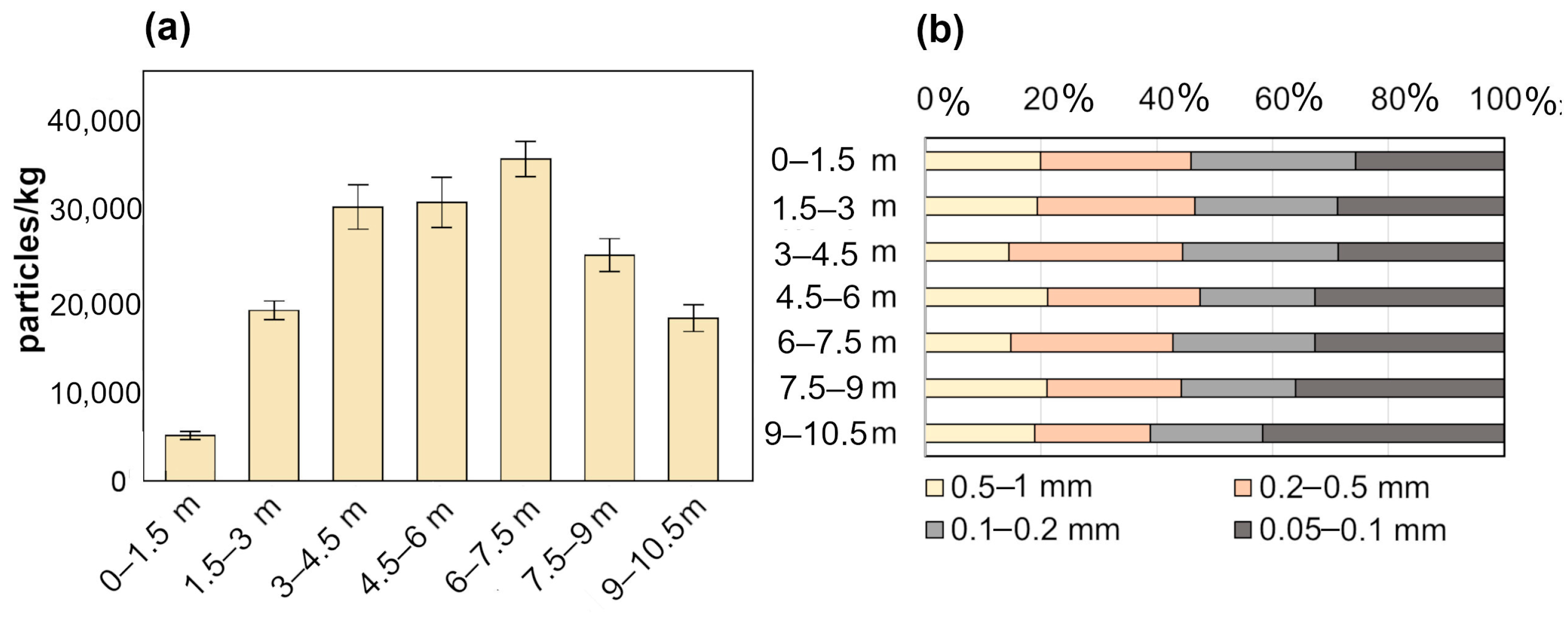

3.3. Concentration of Microplastics and Size Distribution

3.4. Comprehensive Assessment of Fine Fraction Suitability for Biocover

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- EUROLCO Data Launched on the Landfill Situation in the EU-28. Available online: https://eurelco.org/2018/09/30/data-launched-on-the-landfill-situation-in-the-eu-28/ (accessed on 30 September 2023).

- Krook, J.; Svensson, N.; Eklund, M. Landfill Mining: A Critical Review of Two Decades of Research. Waste Manag. 2012, 32, 513–520. [Google Scholar] [CrossRef]

- Jain, M.; Kumar, A.; Kumar, A. Landfill Mining: A Review on Material Recovery and Its Utilization Challenges. Process Saf. Environ. Prot. 2023, 169, 948–958. [Google Scholar] [CrossRef]

- Joseph, K.; Nagendran, R.; Palanivelu, K.; Thanasekaran, K.; Visvanathan, C. Dumpsite Rehabilitation and Landfill Mining. ARRPER Report; Anna University: Chennai, India, 2004; pp. 1–53. [Google Scholar]

- Burlakovs, J.; Kriipsalu, M.; Klavins, M.; Bhatnagar, A.; Vincevica-Gaile, Z.; Stenis, J.; Jani, Y.; Mykhaylenko, V.; Denafas, G.; Turkadze, T.; et al. Paradigms on Landfill Mining: From Dump Site Scavenging to Ecosystem Services Revitalization. Resour. Conserv. Recycl. 2017, 123, 73–84. [Google Scholar] [CrossRef]

- Hernández Parrodi, J.C.; Höllen, D.; Pomberger, R. Characterization of Fine Fractions from Landfill Mining: A Review of Previous Investigations. Detritus 2018, 2, 46. [Google Scholar] [CrossRef]

- Hull, R.M.; Krogmann, U.; Strom, P.F. Composition and Characteristics of Excavated Materials from a New Jersey Landfill. J. Environ. Eng. 2005, 131, 478–490. [Google Scholar] [CrossRef]

- Quaghebeur, M.; Laenen, B.; Geysen, D.; Nielsen, P.; Pontikes, Y.; Van Gerven, T.; Spooren, J. Characterization of Landfilled Materials: Screening of the Enhanced Landfill Mining Potential. J. Clean. Prod. 2013, 55, 72–83. [Google Scholar] [CrossRef]

- Burlakovs, J.; Jani, Y.; Kriipsalu, M.; Vincevica-Gaile, Z.; Kaczala, F.; Celma, G.; Ozola, R.; Rozina, L.; Rudovica, V.; Hogland, M.; et al. On the Way to ‘Zero Waste’ Management: Recovery Potential of Elements, Including Rare Earth Elements, from Fine Fraction of Waste. J. Clean. Prod. 2018, 186, 81–90. [Google Scholar] [CrossRef]

- Chandana, N.; Goli, V.S.N.S.; Mohammad, A.; Singh, D.N. Characterization and Utilization of Landfill-Mined-Soil-Like-Fractions (LFMSF) for Sustainable Development: A Critical Appraisal. Waste Biomass Valorization 2021, 12, 641–662. [Google Scholar] [CrossRef]

- Jani, Y.; Kaczala, F.; Marchand, C.; Hogland, M.; Kriipsalu, M.; Hogland, W.; Kihl, A. Characterisation of Excavated Fine Fraction and Waste Composition from a Swedish Landfill. Waste Manag. Res. J. Sustain. Circ. Econ. 2016, 34, 1292–1299. [Google Scholar] [CrossRef]

- Parrodi, J.C.H.; Höllen, D.; Pomberger, R. Potential and Main Technological Challenges for Material and Energy Recovery from Fine Fractions of Landfill Mining: A Critical Review. Detritus 2018, 3, 19–29. [Google Scholar] [CrossRef]

- Mönkäre, T.J.; Palmroth, M.R.T.; Rintala, J.A. Characterization of Fine Fraction Mined from Two Finnish Landfills. Waste Manag. 2016, 47, 34–39. [Google Scholar] [CrossRef]

- Pehme, K.M.; Orupõld, K.; Kuusemets, V.; Tamm, O.; Jani, Y.; Tamm, T.; Kriipsalu, M. Field Study on the Efficiency of a Methane Degradation Layer Composed of Fine Fraction Soil from Landfill Mining. Sustainability 2020, 12, 6209. [Google Scholar] [CrossRef]

- Scheutz, C.; Duan, Z.; Møller, J.; Kjeldsen, P. Environmental Assessment of Landfill Gas Mitigation Using Biocover and Gas Collection with Energy Utilisation at Aging Landfills. Waste Manag. 2023, 165, 40–50. [Google Scholar] [CrossRef]

- Kriipsalu, M.; Somani, M.; Pehme, K.; Tamm, O.; Truu, J.; Truu, M.; Orupold, K. Performance of Biocover in Controlling Methane Emissions from Landfill: A Decade of Full-Scale Investigation. Process Saf. Environ. Prot. 2023, 172, 486–495. [Google Scholar] [CrossRef]

- Huber-Humer, M.; Röder, S.; Lechner, P. Approaches to Assess Biocover Performance on Landfills. Waste Manag. 2009, 29, 2092–2104. [Google Scholar] [CrossRef] [PubMed]

- Niemczyk, M.; Berenjkar, P.; Wilkinson, N.; Lozecznik, S.; Sparling, R.; Yuan, Q. Enhancement of CH4 Oxidation Potential in Bio-Based Landfill Cover Materials. Process Saf. Environ. Prot. 2021, 146, 943–951. [Google Scholar] [CrossRef]

- Pedersen, G.B.; Scheutz, C.; Kjeldsen, P. Availability and Properties of Materials for the Fakse Landfill Biocover. Waste Manag. 2011, 31, 884–894. [Google Scholar] [CrossRef]

- Scheutz, C.; Pedersen, R.B.; Petersen, P.H.; Jørgensen, J.H.B.; Ucendo, I.M.B.; Mønster, J.G.; Samuelsson, J.; Kjeldsen, P. Mitigation of Methane Emission from an Old Unlined Landfill in Klintholm, Denmark Using a Passive Biocover System. Waste Manag. 2014, 34, 1179–1190. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Z.; Wu, D.; Zhan, L.; Shi, H.; Xie, B. Occurrence of Microplastics in Landfill Systems and Their Fate with Landfill Age. Water Res. 2019, 164, 114968. [Google Scholar] [CrossRef]

- Puthcharoen, A.; Leungprasert, S. Determination of Microplastics in Soil and Leachate from the Landfills. Thai Environ. Eng. J. 2019, 33, 39–46. [Google Scholar]

- Sholokhova, A.; Denafas, G.; Ceponkus, J.; Omelianenko, T. Microplastics in Landfill Bodies: Abundance, Spatial Distribution and Effect of Landfill Age. Sustainability 2023, 15, 5017. [Google Scholar] [CrossRef]

- Goli, V.S.N.S.; Singh, D.N. Extraction and Characterization of Microplastics in Landfill-Mined-Soil-like-Fractions: A Novel Methodology. Chem. Eng. J. 2023, 452, 139217. [Google Scholar] [CrossRef]

- Sima, J.; Wang, J.; Song, J.; Du, X.; Lou, F.; Pan, Y.; Huang, Q.; Lin, C.; Wang, Q.; Zhao, G. Dielectric Barrier Discharge Plasma for the Remediation of Microplastic-Contaminated Soil from Landfill. Chemosphere 2023, 317, 137815. [Google Scholar] [CrossRef] [PubMed]

- He, P.; Chen, L.; Shao, L.; Zhang, H.; Lü, F. Municipal Solid Waste (MSW) Landfill: A Source of Microplastics? -Evidence of Microplastics in Landfill Leachate. Water Res. 2019, 159, 38–45. [Google Scholar] [CrossRef] [PubMed]

- van Praagh, M.; Hartman, C.; Brandmyr, E. Microplastics in Landfill Leachates in the Nordic Countries; Nordic Council of Ministers: Copenhagen, Denmark, 2019. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Plastic Waste Degradation in Landfill Conditions: The Problem with Microplastics, and Their Direct and Indirect Environmental Effects. Int. J. Environ. Res. Public Health 2022, 19, 13223. [Google Scholar] [CrossRef] [PubMed]

- Bajwa, T.M.; Fall, M.; Alshawmar, F. Experimental Characterization of the Engineering Properties of Landfill Compost-Biocover. Appl. Sci. 2022, 12, 4276. [Google Scholar] [CrossRef]

- Pansu, M.; Gautheyrou, J. Handbook of Soil Analysis: Mineralogical, Organic and Inorganic Methods; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1–993. [Google Scholar] [CrossRef]

- ISO 16968:2015; Solid Biofuels—Determination of Minor Elements. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 12846:2012; Water Quality—Determination of Mercury. International Organization for Standardization: Geneva, Switzerland, 2012.

- Sholokhova, A.; Ceponkus, J.; Sablinskas, V.; Denafas, G. Abundance and Characteristics of Microplastics in Treated Organic Wastes of Kaunas and Alytus Regional Waste Management Centres, Lithuania. Environ. Sci. Pollut. Res. Int. 2022, 29, 20665–20674. [Google Scholar] [CrossRef]

- Cossu, R.; Stegmann, R. Solid Waste Landfilling: Concepts, Processes, Technologies; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 0128183365. [Google Scholar]

- Gebert, J.; Huber-Humer, M.; Cabral, A.R. Design of Microbial Methane Oxidation Systems for Landfills. Front. Environ. Sci. 2022, 10, 907562. [Google Scholar] [CrossRef]

- Hrad, M. Quantification of Landfill Gas Emissions in Biocovers—An Experimental Simulation in Lysimeters; Universitätsbibliothek Bodenkultur: Wien, Austria, 2010. [Google Scholar]

- Pariatamby, A.; Cheah, W.Y.; Shrizal, R.; Thamlarson, N.; Lim, B.T.; Barasarathi, J. Enhancement of Landfill Methane Oxidation Using Different Types of Organic Wastes. Environ. Earth Sci. 2015, 73, 2489–2496. [Google Scholar] [CrossRef]

- Singh, A.; Chandel, M.K. Physicochemical and FTIR Spectroscopic Analysis of Fine Fraction from a Municipal Solid Waste Dumpsite for Potential Reclamation of Materials. Waste Manag. Res. J. Sustain. Circ. Econ. 2020, 39, 374–385. [Google Scholar] [CrossRef]

- D1-230 Dėl Cheminėmis Medžiagomis Užterštų Teritorijų Tvarkymo Aplinkos/Apsaugos Reikalavimų Patvirtinimo. Available online: https://e-seimas.lrs.lt/portal/legalAct/lt/TAD/TAIS.319604/aWhXQOotGB (accessed on 11 October 2023).

- Kaczala, F.; Orupõld, K.; Augustsson, A.; Burlakovs, J.; Hogland, M.; Bhatnagar, A.; Hogland, W. Fractionation of Pb and Cu in the Fine Fraction (<10 Mm) of Waste Excavated from a Municipal Landfill. Waste Manag. Res. 2017, 35, 1175–1182. [Google Scholar] [CrossRef]

- Büks, F.; Kaupenjohann, M. Global Concentrations of Microplastics in Soils—A Review. SOIL 2020, 6, 649–662. [Google Scholar] [CrossRef]

- Medynska, A.; Medynska-Juraszek, M.; Szczepá, A. Microplastic Pollution in EU Farmland Soils: Preliminary Findings from Agricultural Soils (Southwestern Poland). Agriculture 2023, 13, 1733. [Google Scholar] [CrossRef]

- Porterfield, K.K.; Hobson, S.A.; Neher, D.A.; Niles, M.T.; Roy, E.D. Microplastics in Composts, Digestates, and Food Wastes: A Review. J. Environ. Qual. 2023, 52, 225–240. [Google Scholar] [CrossRef]

- Sholokhova, A.; Denafas, G.; Mykhaylenko, V. Microplastics Generation and Concentration during Mechanical-Biological Treatment of Mixed Municipal Solid Waste. Environ. Res. 2022, 214, 113815. [Google Scholar] [CrossRef]

- Khalid, N.; Aqeel, M.; Noman, A.; Khan, S.M.; Akhter, N. Interactions and Effects of Microplastics with Heavy Metals in Aquatic and Terrestrial Environments. Environ. Pollut. 2021, 290, 118104. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, H.; Chen, J.; Guo, B.; Zhao, X.; Lin, H.; Li, W.; Zhao, X.; Lv, S.; Huang, C. Adsorption Mechanism of Trace Heavy Metals on Microplastics and Simulating Their Effect on Microalgae in River. Environ. Res. 2022, 214, 113777. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and Its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Jain, M.S.; Daga, M.; Kalamdhad, A.S. Variation in the Key Indicators during Composting of Municipal Solid Organic Wastes. Sustain. Environ. Res. 2019, 29, 9. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Ibrahim, A.M.; Al-Sulaiman, A.M.; Okasha, R.A. Landfill Leachate: Sources, Nature, Organic Composition, and Treatment: An Environmental Overview. Ain Shams Eng. J. 2023, 15, 102293. [Google Scholar] [CrossRef]

- Lindamulla, L.; Nanayakkara, N.; Othman, M.; Jinadasa, S.; Herath, G.; Jegatheesan, V. Municipal Solid Waste Landfill Leachate Characteristics and Their Treatment Options in Tropical Countries. Curr. Pollut. Rep. 2022, 8, 273–287. [Google Scholar] [CrossRef]

| Depths | Soil for Industry Zone | Soil for Forest Areas | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0–1.5 m | 1.5–3 m | 3–4.5 m | 4.5–6 m | 6–7.5 m | 7.5–9 m | 9–10.5 m | |||

| As | <1.35 | 80 | 30 | ||||||

| Cd | <0.51 | 120 | 60 | ||||||

| Cr | 67.27 | 37.25 | 48.98 | 51.25 | 44.12 | 68.39 | 63.59 | 600 | 300 |

| Cu | 209.22 | 89.86 | 74.16 | 123.99 | 91.84 | 136.30 | 210.19 | 200 | 100 |

| Ni | 4.57 | <0.42 | 300 | 150 | |||||

| Pb | 31.63 | 5.24 | <1.20 | 91.99 | <1.20 | 105.33 | 88.37 | 500 | 150 |

| Zn | 281.02 | 465.09 | 217.64 | 367.20 | 262.19 | 589.16 | 244.35 | 1200 | 600 |

| Hg | <0.02 | 0.035 | 0.11 | 0.06 | 0.10 | <0.02 | <0.02 | 1.00 | 0.75 |

| Fe | 10,817.1 | 7517.5 | 10,665.6 | 8566.9 | 7470.1 | 11,042.7 | 10,338.2 | ||

| Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| pH | Conductivity, mS/cm | Organic Content, % | Moisture Content, % | Bulk Density, kg/l | WHC, % | Microplastics, Particle/kg | Heavy Metals, mg/kg | |

| target value | 6.5–8.5 | 4000 | 15 | 30–50 | 0.8–1.1 | 50–130 | as low as possible | separate per each metal |

| 0–1.5 m | 8.16 | 4592 | 16.02 | 36.01 | 1.01 | 92.9 | 4958 | Cu exceeds the limit |

| 1.5–3 m | 8.44 | 2260 | 14.06 | 31.41 | 0.89 | 81.6 | 18,500 | below the limit |

| 3–4.5 m | 8.26 | 1660 | 15.05 | 33.27 | 0.71 | 91.8 | 29,708 | |

| 4.5–6 m | 8.16 | 2000 | 17.42 | 31.82 | 0.88 | 96 | 30,208 | |

| 6–7.5 m | 7.99 | 3265 | 14.95 | 33.22 | 0.81 | 73.8 | 34,917 | |

| 7.5–9 m | 7.93 | 4188 | 18.55 | 34.70 | 0.76 | 87 | 24,500 | |

| 9–10.5 m | 8.29 | 2520 | 13.75 | 20.99 | 0.87 | 86.6 | 17,667 | Cu exceeds the limit |

| pH | Conductivity | Organic Content | Moisture Content | Bulk Density | WHC | Microplastics | |

|---|---|---|---|---|---|---|---|

| pH | 0.52, p > 0.05 | −0.74, p < 0.05 | −0.65, p > 0.05 | 0.32 | −0.13 | −0.39 | |

| Conductivity | 0.52, p > 0.05 | 0.21 | 0.5 | 0.32 | −0.14 | −0.45 | |

| Organic content | −0.74, p < 0.05 | 0.21 | 0.71, p < 0.05 | −0.14 | 0.64, p > 0.05 | 0.18 | |

| Moisture content | −0.65, p > 0.05 | 0.5 | 0.71, p < 0.05 | −0.11 | 0.39 | −0.04 | |

| Bulk density | 0.32 | 0.32 | −0.14 | −0.11 | 0.18 | −0.61, p > 0.05 | |

| WHC | −0.13 | −0.14 | 0.64, p > 0.05 | 0.39 | 0.18 | −0.18 | |

| Microplastics | −0.39 | −0.45 | 0.18 | −0.04 | −0.61, p > 0.05 | −0.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sholokhova, A.; Pitak, I.; Denafas, G.; Kalpokaitė-Dičkuvienė, R.; Praspaliauskas, M.; Burlakovs, J. An In-Depth Analysis of Physical, Chemical, and Microplastic Parameters of Landfill Fine Fraction for Biocover Construction. Sustainability 2023, 15, 16914. https://doi.org/10.3390/su152416914

Sholokhova A, Pitak I, Denafas G, Kalpokaitė-Dičkuvienė R, Praspaliauskas M, Burlakovs J. An In-Depth Analysis of Physical, Chemical, and Microplastic Parameters of Landfill Fine Fraction for Biocover Construction. Sustainability. 2023; 15(24):16914. https://doi.org/10.3390/su152416914

Chicago/Turabian StyleSholokhova, Anastasiia, Inna Pitak, Gintaras Denafas, Regina Kalpokaitė-Dičkuvienė, Marius Praspaliauskas, and Juris Burlakovs. 2023. "An In-Depth Analysis of Physical, Chemical, and Microplastic Parameters of Landfill Fine Fraction for Biocover Construction" Sustainability 15, no. 24: 16914. https://doi.org/10.3390/su152416914

APA StyleSholokhova, A., Pitak, I., Denafas, G., Kalpokaitė-Dičkuvienė, R., Praspaliauskas, M., & Burlakovs, J. (2023). An In-Depth Analysis of Physical, Chemical, and Microplastic Parameters of Landfill Fine Fraction for Biocover Construction. Sustainability, 15(24), 16914. https://doi.org/10.3390/su152416914