The Role of Environmental Management Systems and Energy Management Systems in the Adoption of Energy Recuperation Technologies in Central European Manufacturing Companies

Abstract

:1. Introduction

2. Theoretical Background

2.1. Factors That Aim to Interpret the Adoption of EETs

2.2. Internal Firm-Specific Factors and Adoption of EETs

2.3. EMS and Adoption of EETs

2.4. EnMS and Adoption of EETs

2.5. Energy Recovery Technologies (ERTs)

3. Materials and Methods

3.1. Data

- Technologies to recuperate kinetic and process energy (e.g., waste heat recovery, energy storage) (further “ERTs”).

- Certified environmental management system (e.g., EN ISO 14001) (further “EnMS”).

- Certified energy management system (e.g., EN ISO 50001) (further “EMS”).

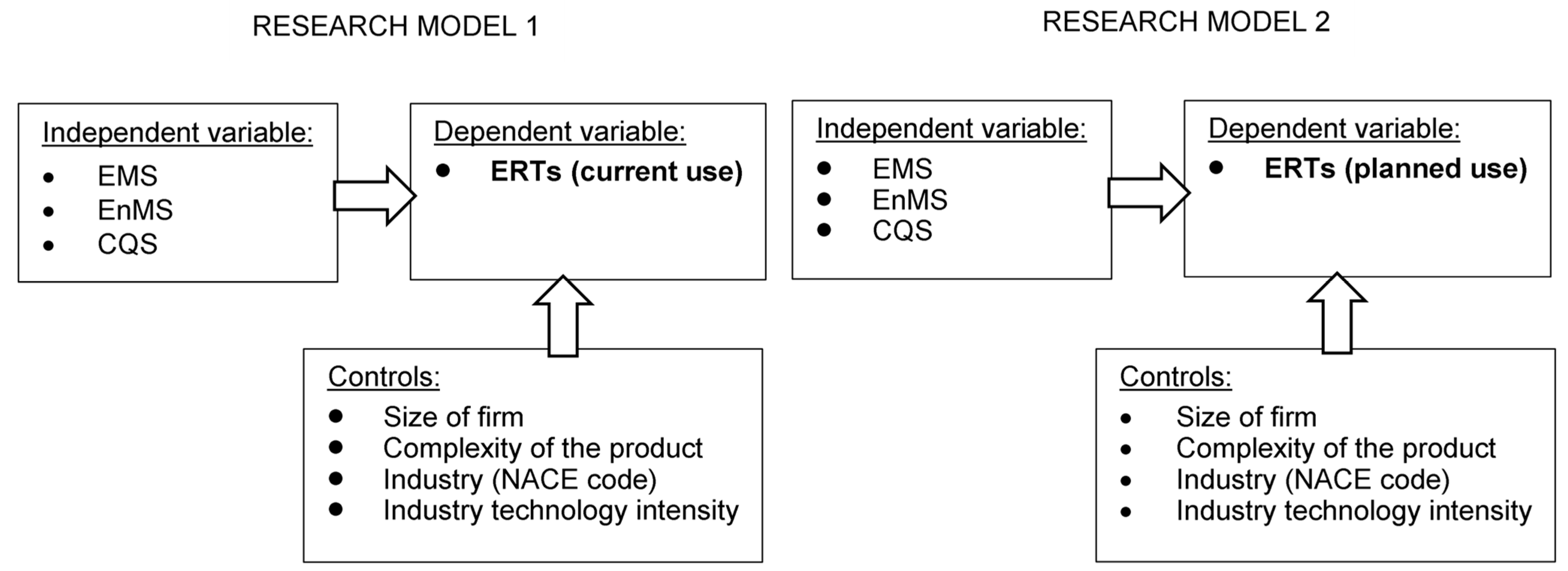

3.2. Regression Analysis

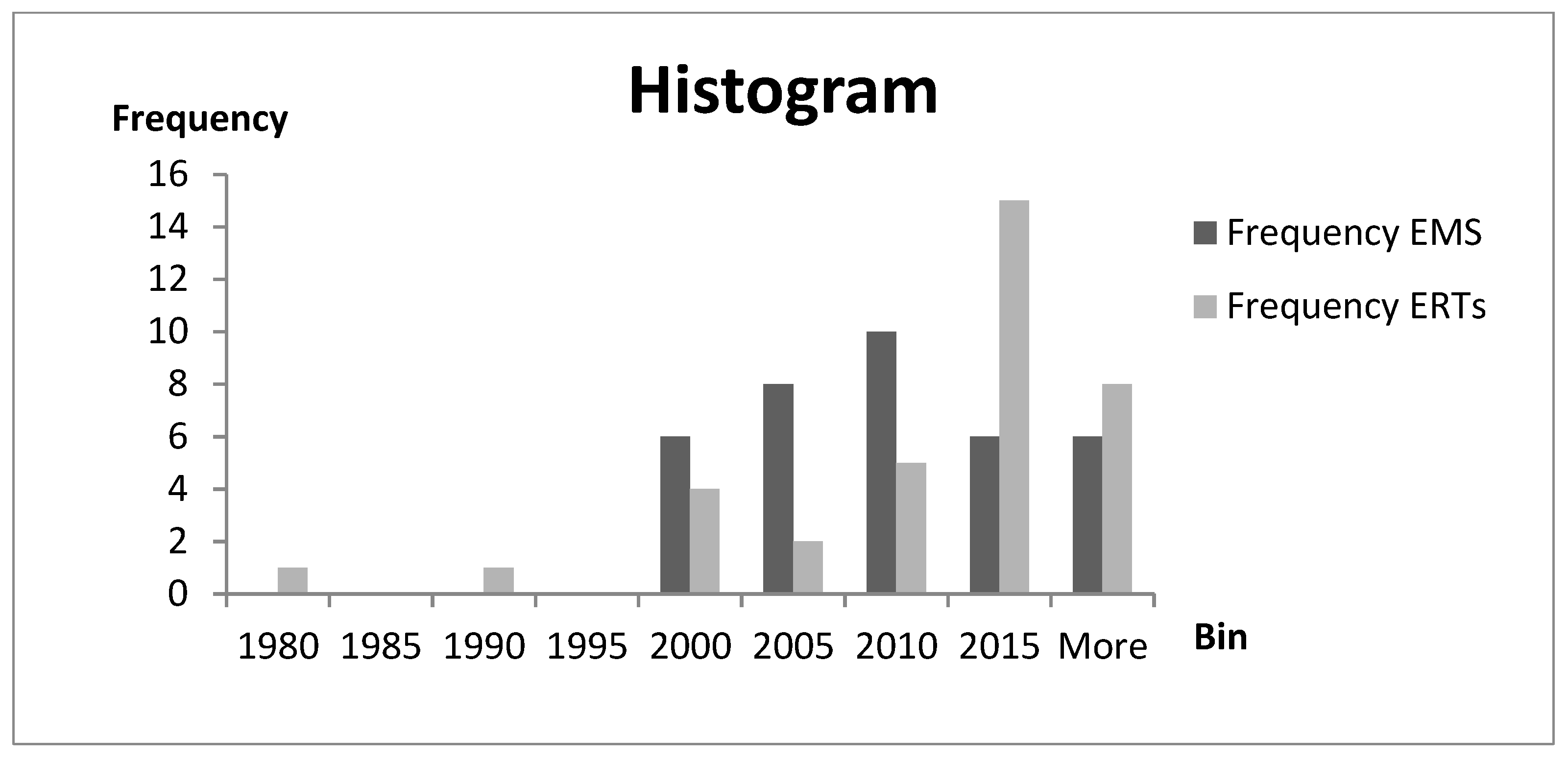

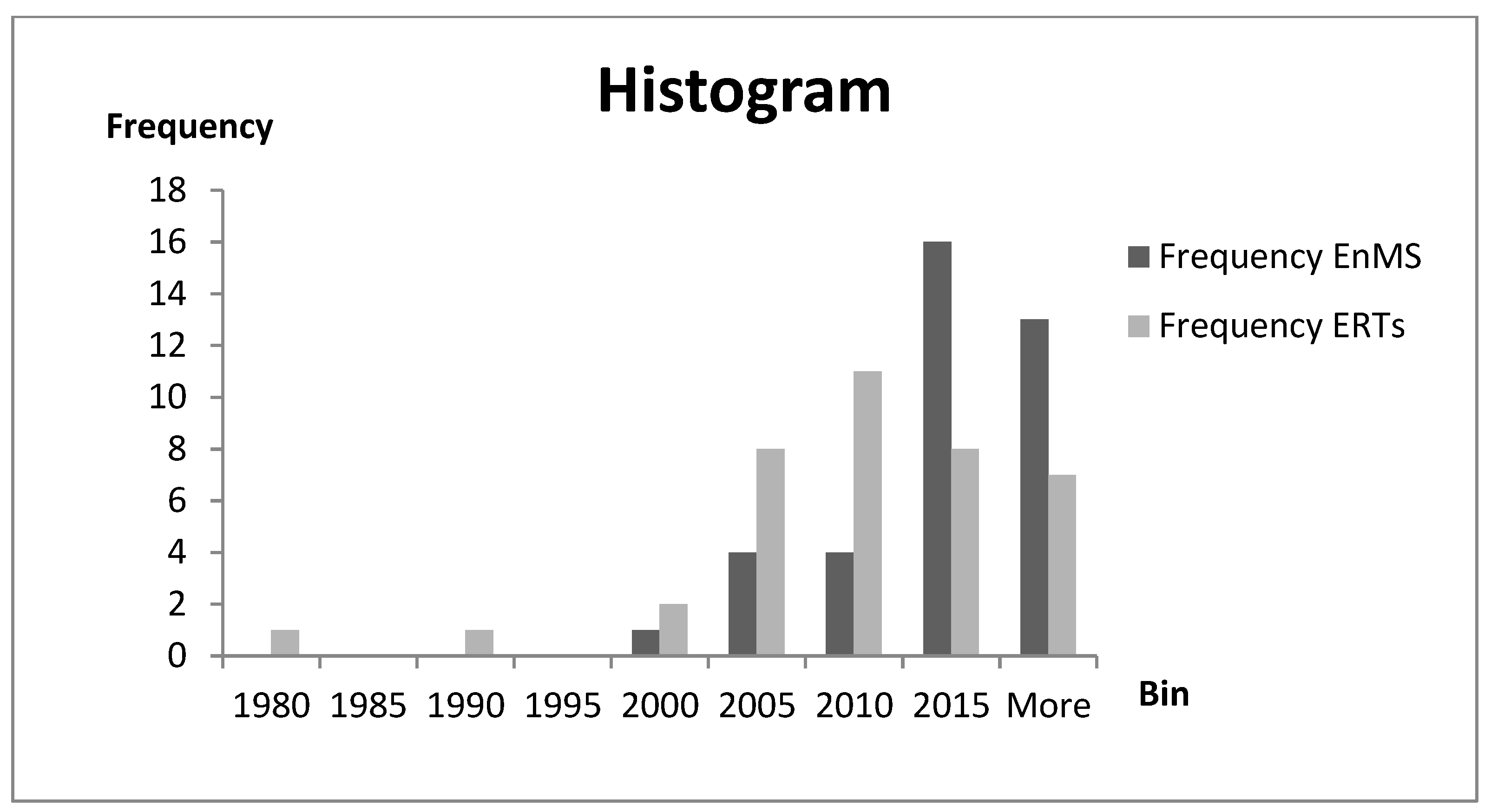

3.3. Years of Implementation Comparison

3.4. Testing Differences among Company Groups

- Group A: Companies without EMS or EnMS;

- Group B: Companies with EMS but no EnMS;

- Group C: Companies without EMS but with EnMS;

- Group D: Companies with both EMS and EnMS.

- Group X: Companies without ERTs;

- Group Y: Companies with ERTs.

4. Results

4.1. Regression Analysis

4.2. Years of Implementation Comparison

4.3. Testing Differences among Company Groups

5. Discussion and Conclusions

5.1. Implications for Theory

5.1.1. EMS

5.1.2. EnMS

5.1.3. EMS versus EnMS

5.1.4. Contextual Factors

5.2. Implications for Practice

5.3. Limitations of the Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Year of Implementation of EMS (Year) | Year of Implementation of ERTs (Year) | Delay between EMS and ERT Implementation (Years) |

|---|---|---|

| 2007 | 2015 | 8 |

| 2004 | 2016 | 12 |

| 2000 | 2015 | 15 |

| 2000 | 1997 | |

| 2019 | 2018 | |

| 2018 | 2015 | |

| 2017 | 2015 | |

| 2007 | 2012 | 5 |

| 2000 | 2015 | 15 |

| 2013 | 2017 | 4 |

| 2015 | 2000 | |

| 2011 | 1990 | |

| 2009 | 2009 | |

| 2000 | 2015 | 15 |

| 2004 | 2013 | 9 |

| 2018 | 2010 | |

| 1998 | 2015 | 17 |

| 2001 | 2012 | 11 |

| 2010 | 2010 | |

| 2015 | 2015 | |

| 2010 | 2007 | |

| 2016 | 2003 | |

| 2007 | 2015 | 8 |

| 2004 | 1998 | |

| 2010 | 2011 | 1 |

| 2000 | 2017 | 17 |

| 2009 | 2016 | 7 |

| 2005 | 2005 | |

| 2005 | 2000 | |

| 2005 | 2017 | 12 |

| 2016 | 2016 | |

| 2012 | 2012 | |

| 2008 | 2017 | 9 |

| 2012 | 1980 | |

| 2002 | 2015 | 13 |

| 2008 | 2007 | 8 |

| Year of Implementation of EnMS (Year) | Year of Implementation of ERTs (Year) | Delay between EnMS and ERT Implementation (Years) |

|---|---|---|

| 2011 | 2008 | |

| 2008 | 2008 | |

| 2001 | 2010 | 9 |

| 2017 | 2016 | |

| 2003 | 2003 | |

| 2016 | 2016 | |

| 2018 | 2016 | |

| 2019 | 2018 | |

| 2017 | 2015 | |

| 2017 | 2012 | |

| 2017 | 2009 | |

| 2017 | 2013 | |

| 2015 | 2015 | |

| 2015 | 2010 | |

| 2016 | 2003 | |

| 2018 | 2015 | |

| 2000 | 2017 | 17 |

| 2013 | 2018 | 5 |

| 2012 | 2005 | |

| 2010 | 2002 | |

| 2010 | 2010 | |

| 2016 | 2010 | |

| 2014 | 2013 | |

| 2016 | 1998 | |

| 2005 | 2005 | |

| 2014 | 2015 | 1 |

| 2011 | 2008 | |

| 2012 | 2001 | |

| 2014 | 1990 | |

| 2015 | 2016 | 1 |

| 2001 | 2004 | 3 |

| 2016 | 2013 | |

| 2015 | 1980 | |

| 2014 | 2007 | |

| 2015 | 2000 | |

| 2013 | 2003 | |

| 2015 | 2010 | |

| 2010 | 2010 |

References

- Bourghelle, D.; Jawadi, F.; Rozin, P. Oil Price Volatility in the Context of COVID-19. Int. Econ. 2021, 167, 39–49. [Google Scholar] [CrossRef]

- Zhang, C.; Mou, X.; Ye, S. How Do Dynamic Jumps in Global Crude Oil Prices Impact China’s Industrial Sector? Energy 2022, 249, 123605. [Google Scholar] [CrossRef]

- Clairand, J.-M.; Briceño-León, M.; Escrivá-Escrivá, G.; Pantaleo, A.M. Review of Energy Efficiency Technologies in the Food Industry: Trends, Barriers, and Opportunities. IEEE Access 2020, 8, 48015–48029. [Google Scholar] [CrossRef]

- Marques, M. Potential for ORC Application in the Portuguese Manufacturing Industry. Master’s Thesis, Faculdade de Ciências e Tecnologia, Lisboa, Portugal, 2014. [Google Scholar]

- Zhang, Q.; Zhao, X.; Lu, H.; Ni, T.; Li, Y. Waste Energy Recovery and Energy Efficiency Improvement in China’s Iron and Steel Industry. Appl. Energy 2017, 191, 502–520. [Google Scholar] [CrossRef]

- Palomba, I.; Wehrle, E.; Carabin, G.; Vidoni, R. Minimization of the Energy Consumption in Industrial Robots through Regenerative Drives and Optimally Designed Compliant Elements. Appl. Sci. 2020, 10, 7475. [Google Scholar] [CrossRef]

- Grebers, R.; Gadaleta, M.; Paugurs, A.; Senfelds, A.; Avotins, A.; Pellicciari, M. Analysis of the Energy Consumption of a Novel DC Power Supplied Industrial Robot. Procedia Manuf. 2017, 11, 311–318. [Google Scholar] [CrossRef]

- Eurostat Energy Balance Visualisation Tool. Available online: https://ec.europa.eu/eurostat/cache/infographs/energy_balances/enbal.html (accessed on 15 June 2022).

- Costa-Campi, M.T.; García-Quevedo, J.; Segarra, A. Energy Efficiency Determinants: An Empirical Analysis of Spanish Innovative Firms. Energy Policy 2015, 83, 229–239. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Kulatunga, A.K.; Ravichandran, M.; Kandasamy, J. Application of Multi Grade Fuzzy Approach to Compute the Circularity Index of Manufacturing Organizations. Procedia CIRP 2021, 98, 476–481. [Google Scholar] [CrossRef]

- Fu, Y.; Kok, R.A.W.; Dankbaar, B.; Ligthart, P.E.M.; van Riel, A.C.R. Factors Affecting Sustainable Process Technology Adoption: A Systematic Literature Review. J. Clean. Prod. 2018, 205, 226–251. [Google Scholar] [CrossRef]

- Reddy, K.N.; Kumar, A. Capacity Investment and Inventory Planning for a Hybrid Manufacturing—Remanufacturing System in the Circular Economy. Int. J. Prod. Res. 2021, 59, 2450–2478. [Google Scholar] [CrossRef]

- Šebo, J.; Šebová, M.; Palčič, I. Implementation of Circular Economy Technologies: An Empirical Study of Slovak and Slovenian Manufacturing Companies. Sustainability 2021, 13, 12518. [Google Scholar] [CrossRef]

- Dijken, K.V.; Prince, Y.; Wolters, T.J.; Frey, M.; Mussati, G.; Kalff, P.; Hansen, O.; Kerndrup, S.; Søndergård, B.; Rodrigues, E.L.; et al. Adoption of Environmental Innovations: The Dynamics of Innovation as Interplay between Business Competence, Environmental Orientation and Network Involvement; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1999; ISBN 978-0-7923-5561-8. [Google Scholar]

- Mattes, J.; Huber, A.; Koehrsen, J. Energy Transitions in Small-Scale Regions—What We Can Learn from a Regional Innovation Systems Perspective. Energy Policy 2015, 78, 255–264. [Google Scholar] [CrossRef]

- Haider, S.; Danish, M.S.; Sharma, R. Assessing Energy Efficiency of Indian Paper Industry and Influencing Factors: A Slack-Based Firm-Level Analysis. Energy Econ. 2019, 81, 454–464. [Google Scholar] [CrossRef]

- Cantore, N. Factors Affecting the Adoption of Energy Efficiency in the Manufacturing Sector of Developing Countries. Energy Effic. 2017, 10, 743–752. [Google Scholar] [CrossRef]

- Schützenhofer, C. Overcoming the Efficiency Gap: Energy Management as a Means for Overcoming Barriers to Energy Efficiency, Empirical Support in the Case of Austrian Large Firms. Energy Effic. 2021, 14, 45. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A.; Spallina, G.; Marchesani, F. Drivers for Energy Efficiency and Their Effect on Barriers: Empirical Evidence from Italian Manufacturing Enterprises. Energy Effic. 2017, 10, 855–869. [Google Scholar] [CrossRef]

- Thollander, P.; Danestig, M.; Rohdin, P. Energy Policies for Increased Industrial Energy Efficiency: Evaluation of a Local Energy Programme for Manufacturing SMEs. Energy Policy 2007, 35, 5774–5783. [Google Scholar] [CrossRef]

- Kounetas, K.; Tsekouras, K. The Energy Efficiency Paradox Revisited through a Partial Observability Approach. Energy Econ. 2008, 30, 2517–2536. [Google Scholar] [CrossRef]

- Solnørdal, M.T.; Foss, L. Closing the Energy Efficiency Gap—A Systematic Review of Empirical Articles on Drivers to Energy Efficiency in Manufacturing Firms. Energies 2018, 11, 518. [Google Scholar] [CrossRef]

- Okereke, C. An Exploration of Motivations, Drivers and Barriers to Carbon Management:: The UK FTSE 100. Eur. Manag. J. 2007, 25, 475–486. [Google Scholar] [CrossRef]

- Garrone, P.; Grilli, L.; Mrkajic, B. The Energy-Efficient Transformation of EU Business Enterprises: Adapting Policies to Contextual Factors. Energy Policy 2017, 109, 49–58. [Google Scholar] [CrossRef]

- Lee, K.-H. Drivers and Barriers to Energy Efficiency Management for Sustainable Development. Sustain. Dev. 2015, 23, 16–25. [Google Scholar] [CrossRef]

- Thollander, P.; Backlund, S.; Trianni, A.; Cagno, E. Beyond Barriers—A Case Study on Driving Forces for Improved Energy Efficiency in the Foundry Industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 2013, 111, 636–643. [Google Scholar] [CrossRef]

- Timilsina, G.R.; Hochman, G.; Fedets, I. Understanding Energy Efficiency Barriers in Ukraine: Insights from a Survey of Commercial and Industrial Firms. Energy 2016, 106, 203–211. [Google Scholar] [CrossRef]

- Parker, S.; Liddle, B. Energy Efficiency in the Manufacturing Sector of the OECD: Analysis of Price Elasticities. Energy Econ. 2016, 58, 38–45. [Google Scholar] [CrossRef]

- Askarany, D.; Yazdifar, H.; Dow, K. B2B Networking, Renewable Energy, and Sustainability. J. Risk Financ. Manag. 2021, 14, 290. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M. Energy Management in Manufacturing: Toward Eco-Factories of the Future—A Focus Group Study. Appl. Energy 2016, 164, 628–638. [Google Scholar] [CrossRef]

- Zhu, J.; Niu, L.; Ruth, M.; Shi, L. Technological Change and Energy Efficiency in Large Chinese Firms. Ecol. Econ. 2018, 150, 241–250. [Google Scholar] [CrossRef]

- Accordini, D.; Cagno, E.; Trianni, A. Identification and Characterization of Decision-Making Factors over Industrial Energy Efficiency Measures in Electric Motor Systems. Renew. Sustain. Energy Rev. 2021, 149, 111354. [Google Scholar] [CrossRef]

- Johansen, J.P.; Isaeva, I. Developing and (Not) Implementing Radical Energy Efficiency Innovations: A Case Study of R&D Projects in the Norwegian Manufacturing Industry. J. Clean. Prod. 2021, 322, 129077. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Exploring Drivers for Energy Efficiency within Small- and Medium-Sized Enterprises: First Evidences from Italian Manufacturing Enterprises. Appl. Energy 2013, 104, 276–285. [Google Scholar] [CrossRef]

- Hrovatin, N.; Dolšak, N.; Zorić, J. Factors Impacting Investments in Energy Efficiency and Clean Technologies: Empirical Evidence from Slovenian Manufacturing Firms. J. Clean. Prod. 2016, 127, 475–486. [Google Scholar] [CrossRef]

- Backlund, S.; Thollander, P.; Palm, J.; Ottosson, M. Extending the Energy Efficiency Gap. Energy Policy 2012, 51, 392–396. [Google Scholar] [CrossRef]

- de Groot, H.L.F.; Verhoef, E.T.; Nijkamp, P. Energy Saving by Firms: Decision-Making, Barriers and Policies. Energy Econ. 2001, 23, 717–740. [Google Scholar] [CrossRef]

- De Marchi, V. Environmental Innovation and R&D Cooperation: Empirical Evidence from Spanish Manufacturing Firms. Res. Policy 2012, 41, 614–623. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, Drivers and Decision-Making Process for Industrial Energy Efficiency: A Broad Study among Manufacturing Small and Medium-Sized Enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Urpelainen, J. Export Orientation and Domestic Electricity Generation: Effects on Energy Efficiency Innovation in Select Sectors. Energy Policy 2011, 39, 5638–5646. [Google Scholar] [CrossRef]

- Fernando, Y.; Hor, W.L. Impacts of Energy Management Practices on Energy Efficiency and Carbon Emissions Reduction: A Survey of Malaysian Manufacturing Firms. Resour. Conserv. Recycl. 2017, 126, 62–73. [Google Scholar] [CrossRef]

- Palm, J.; Thollander, P. Chapter 2.3—Reframing Energy Efficiency in Industry: A Discussion of Definitions, Rationales, and Management Practices. In Energy and Behaviour; Lopes, M., Antunes, C.H., Janda, K.B., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 153–175. ISBN 978-0-12-818567-4. [Google Scholar]

- Jeong, S.; Lee, J. Environment and Energy? The Impact of Environmental Management Systems on Energy Efficiency. Manuf. Serv. Oper. Manag. 2022, 24, 1311–1328. [Google Scholar] [CrossRef]

- Zobel, T.; Malmgren, C. Evaluating the Management System Approach for Industrial Energy Efficiency Improvements. Energies 2016, 9, 774. [Google Scholar] [CrossRef]

- Hrovatin, N.; Cagno, E.; Dolšak, J.; Zorić, J. How Important Are Perceived Barriers and Drivers versus Other Contextual Factors for the Adoption of Energy Efficiency Measures: An Empirical Investigation in Manufacturing SMEs. J. Clean. Prod. 2021, 323, 129123. [Google Scholar] [CrossRef]

- Schulze, M.; Heidenreich, S.; Spieth, P. The Impact of Energy Management Control Systems on Energy Efficiency in the German Manufacturing Industry. J. Ind. Ecol. 2018, 22, 813–826. [Google Scholar] [CrossRef]

- Gerstlberger, W.; Knudsen, M.P.; Dachs, B.; Schröter, M. Closing the Energy-Efficiency Technology Gap in European Firms? Innovation and Adoption of Energy Efficiency Technologies. J. Eng. Technol. Manag. 2016, 40, 87–100. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating Energy Efficiency Performance in Production Management—Gap Analysis between Industrial Needs and Scientific Literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2021.

- Introna, V.; Cesarotti, V.; Benedetti, M.; Biagiotti, S.; Rotunno, R. Energy Management Maturity Model: An Organizational Tool to Foster the Continuous Reduction of Energy Consumption in Companies. J. Clean. Prod. 2014, 83, 108–117. [Google Scholar] [CrossRef]

- Franz, E.; Erler, F.; Langer, T.; Schlegel, A.; Stoldt, J.; Richter, M.; Putz, M. Requirements and Tasks for Active Energy Management Systems in Automotive Industry. Procedia Manuf. 2017, 8, 175–182. [Google Scholar] [CrossRef]

- Johansson, M.T.; Thollander, P. A Review of Barriers to and Driving Forces for Improved Energy Efficiency in Swedish Industry—Recommendations for Successful in-House Energy Management. Renew. Sustain. Energy Rev. 2018, 82, 618–628. [Google Scholar] [CrossRef]

- ISO 50001:2018; Energy Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018.

- Cooremans, C.; Schönenberger, A. Energy Management: A Key Driver of Energy-Efficiency Investment? J. Clean. Prod. 2019, 230, 264–275. [Google Scholar] [CrossRef]

- McKane, A. Thinking Globally: How ISO 50001—Energy Management Can Make Industrial Energy Efficiency Standard Practice. 2009. Available online: https://www.osti.gov/servlets/purl/983191-68x6aK/ (accessed on 7 July 2023).

- International Energy Agency. Tracking Industrial Energy Efficiency and CO2 Emissions: A Technology Perspective; IEA: Paris, France, 2007; ISBN 978-92-64-03016-9. [Google Scholar]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial Waste Heat Recovery Technologies: An Economic Analysis of Heat Transformation Technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Wu, Z.; Pan, D.; Gao, N.; Zhu, T.; Xie, F. Experimental Testing and Numerical Simulation of Scroll Expander in a Small Scale Organic Rankine Cycle System. Appl. Therm. Eng. 2015, 87, 529–537. [Google Scholar] [CrossRef]

- Algieri, A.; Šebo, J. Energetic Investigation of Organic Rankine Cycles (ORCs) for the Exploitation of Low-Temperature Geothermal Sources—A Possible Application in Slovakia. Procedia Comput. Sci. 2017, 109, 833–840. [Google Scholar] [CrossRef]

- Albayrak, F.İ.; Ergün, A.; Yıldız, G. Performance, Exergy, and Environmental Analysis of Blast Furnace Top Pressure Turbine in an Iron-Steel Factory. Period. Eng. Nat. Sci. 2023, 11, 189–202. [Google Scholar] [CrossRef]

- Smith, K.M.; Wilson, S.; Lant, P.; Hassall, M.E. How Do We Learn about Drivers for Industrial Energy Efficiency—Current State of Knowledge. Energies 2022, 15, 2642. [Google Scholar] [CrossRef]

- Zahradnik, G.; Dachs, B.; Rhomberg, W. Karl-Heinz Leitner trends und entwicklungen in der österreichischen produktion Highlights Aus Dem European Manufacturing Survey 2018. 2019. Available online: https://www.researchgate.net/publication/336825165_TRENDS_UND_ENTWICKLUNGEN_IN_DER_OSTERREICHISCHEN_PRODUKTION_Highlights_aus_dem_European_Manufacturing_Survey_2018 (accessed on 7 September 2022). [CrossRef]

- Vilkas, M.; Rauleckas, R.; Šeinauskienė, B.; Rutelionė, A. Lean, Agile and Service-Oriented Performers: Templates of Organising in a Global Production Field. Total Qual. Manag. Bus. Excell. 2021, 32, 1122–1146. [Google Scholar] [CrossRef]

- Sebo, J.; Kádárová, J.; Malega, P. Barriers and Motives Experienced by Manufacturing Companies in Implementing Circular Economy Initiatives: The Case of Manufacturing Industry in Slovakia. In Proceedings of the 2019 International Council on Technologies of Environmental Protection (ICTEP), Starý Smokovec, Slovakia, 23–25 October 2019; pp. 226–229. [Google Scholar]

- Palčič, I.; Prester, J. Impact of Advanced Manufacturing Technologies on Green Innovation. Sustainability 2020, 12, 3499. [Google Scholar] [CrossRef]

- ISO 9001:2015; Quality Management Systems—Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- De Oliveira, O.J.; Serra, J.R.; Salgado, M.H. Does ISO 14001 Work in Brazil? J. Clean. Prod. 2010, 18, 1797–1806. [Google Scholar] [CrossRef]

- Johnstone, N.; Scapecchi, P.; Ytterhus, B.; Wolff, R. The Firm, Environmental Management and Environmental Measures: Lessons from a Survey of European Manufacturing Firms. J. Environ. Plan. Manag. 2010, 47, 685–707. [Google Scholar] [CrossRef]

- Bayo-Moriones, A.; Bello-Pintado, A.; Merino-Díaz de Cerio, J. 5S Use in Manufacturing Plants: Contextual Factors and Impact on Operating Performance. Int. J. Qual. Reliab. Manag. 2010, 27, 217–230. [Google Scholar] [CrossRef]

| Country Name | Frequency | Percent | |

|---|---|---|---|

| Lithuania | 199 | 24.9 | |

| Slovenia | 127 | 15.9 | |

| Croatia | 105 | 13.2 | |

| Slovakia | 114 | 14.3 | |

| Austria | 253 | 31.7 | |

| Total | 798 | 100 | |

| Small <50 employees | Medium 50–249 employees | Large >250 employees | |

| EMS | 26 | 47 | 39 |

| EnMS | 27 | 55 | 50 |

| ERTs | 69 | 90 | 64 |

| Standardized Coefficients | Collinearity Statistics | |||

|---|---|---|---|---|

| Step | Beta | Sig. | VIF | |

| 1 | (Constant) | 0.844 | ||

| Complexity of the product | −0.034 | 0.545 | 1.026 | |

| Industry (NACE) | 0.022 | 0.745 | 1.505 | |

| Industry technology intensity | 0.041 | 0.546 | 1.487 | |

| Size of the firms | 0.214 | 0.000 | 1.041 | |

| Country | −0.057 | 0.325 | 1.069 | |

| 2 | (Constant) | 0.834 | ||

| Complexity of the product | −0.047 | 0.402 | 1.035 | |

| Industry (NACE) | 0.027 | 0.693 | 1.512 | |

| Industry technology intensity | 0.038 | 0.572 | 1.489 | |

| Size of the firms | 0.157 | 0.010 | 1.186 | |

| Country | −0.043 | 0.460 | 1.079 | |

| EMS (e.g., ISO 14001) * | 0.130 | 0.033 | 1.198 | |

| EnMS (e.g., ISO 50001) * | 0.099 | 0.093 | 1.119 | |

| CQS (e.g., ISO 9001) * | −0.007 | 0.906 | 1.030 |

| Four Groups of Management Systems * | ||||||

|---|---|---|---|---|---|---|

| Current Use of ERTs | No EMS or EnMS | EMS | EnMS | EMS + EnMS | Total | |

| No | Count (% within group) | 151 (82.5%) | 67 (68.4%) | 6 (75.0%) | 15 (51.7%) | 239 (75.2%) |

| Yes | Count (% within group) | 32 (17.5%) | 31 (31.6%) | 2 (25.0%) | 14 (48.3%) | 79 (24.8%) |

| Total | Count (% within group) | 183 (100%) | 98 (100.0%) | 8 (100.0%) | 29(100.0%) | 318 (100.0%) |

| Planned use of ERTs | ||||||

| No | Count (% within group) | 163 (88.1%) | 88 (89.8%) | 8 (100%) | 25 (86.2%) | 284 (88.8%) |

| Yes | Count (% within group) | 22 (11.9%) | 10 (10.2%) | 0 (0.0%) | 4 (13.8%) | 36 (11.3%) |

| Total | Count (% within group) | 185 (100%) | 98 (100%) | 8 (100%) | 29 (100%) | 320 (100%) |

| Currently Using ERTs * | ||||

|---|---|---|---|---|

| Planned Use of EMS | No | Yes | Total | |

| No | Count (% within group) | 203 (81.5%) | 74 (91.4%) | 27 (783.9%) |

| Yes | Count (% within group) | 46 (18.5%) | 7 (8.6%) | 53 (16.1%) |

| Total | Count (% within group) | 249 (100.0%) | 81(100.0%) | 330 (100.0%) |

| Planned use of EnMS | ||||

| No | Count (% within group) | 402 (84.8%) | 153 (86.9%) | 555 (85.4%) |

| Yes | Count (% within group) | 72 (15.2%) | 23 (13.1%) | 95 (14.6%) |

| Total | Count (% within group) | 474 (100.0%) | 176 (100.0%) | 650 (100.0%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šebo, J.; Prester, J.; Šebová, M. The Role of Environmental Management Systems and Energy Management Systems in the Adoption of Energy Recuperation Technologies in Central European Manufacturing Companies. Sustainability 2023, 15, 16913. https://doi.org/10.3390/su152416913

Šebo J, Prester J, Šebová M. The Role of Environmental Management Systems and Energy Management Systems in the Adoption of Energy Recuperation Technologies in Central European Manufacturing Companies. Sustainability. 2023; 15(24):16913. https://doi.org/10.3390/su152416913

Chicago/Turabian StyleŠebo, Juraj, Jasna Prester, and Miriam Šebová. 2023. "The Role of Environmental Management Systems and Energy Management Systems in the Adoption of Energy Recuperation Technologies in Central European Manufacturing Companies" Sustainability 15, no. 24: 16913. https://doi.org/10.3390/su152416913

APA StyleŠebo, J., Prester, J., & Šebová, M. (2023). The Role of Environmental Management Systems and Energy Management Systems in the Adoption of Energy Recuperation Technologies in Central European Manufacturing Companies. Sustainability, 15(24), 16913. https://doi.org/10.3390/su152416913