A Meta-Heuristic Sustainable Intelligent Internet of Things Framework for Bearing Fault Diagnosis of Electric Motor under Variable Load Conditions

Abstract

:1. Introduction

1.1. Theoretical Contributions

- Intelligent Diagnosis Framework (IDF): The introduction of the IDF represents a novel and innovative approach to tackling bearing defect diagnosis. It is founded on a fusion of machine learning techniques within an efficient framework, and this theoretical innovation serves as a pivotal cornerstone for advancing diagnostic precision and fault categorization.

- Integration of Meta-Heuristic Optimization: The incorporation of the Grasshopper Optimization Algorithm (GOA) into the IDF framework establishes a robust theoretical foundation for optimizing hyperparameters. This integration significantly bolsters the accuracy and reliability of the diagnostic process.

1.2. Practical Contributions

- Enhanced Accuracy: Through the introduction of the IDF and the GOA optimizer, our work provides a practical solution to the challenging task of accurate bearing defect diagnosis. This contributes meaningfully to the improvement of reliability and safety in real-world applications involving electrical machinery.

- Efficiency and Computational Economy: The proposed GOA-IDF offers not only heightened accuracy but also demonstrates noteworthy computational efficiency. This practical advantage renders it particularly suitable for real-time applications where timely and dependable diagnoses hold paramount importance.

- Real-World Applicability: The comparative analysis against other machine learning algorithms underscores the practical superiority of the developed Internet of Things (IoT) GOA-IDF. This carries significant implications for industries relying on electrical machinery, such as manufacturing, energy, and the Internet of Things.

- Robustness in Handling Noisy Data: Our research delves into the robustness of GOA-IDF when dealing with high-frequency data, which may inherently contain noise. This practical contribution underscores the algorithm’s applicability in scenarios characterized by varying data quality.

2. Related Work

Problems Definitions and Formulation

- The demand for large sample datasets increases the chance of data overfitting.

- Trial and error methods are typically used to develop the structure of the methods, which complicates and prolongs the structure estimation procedure.

- The deep learning method uses additional steps to process data for executing predicted performance that results in requiring large computational costs like high training and testing time and needs a large memory size.

- Both the capability to generalize and the robustness of the system must be enhanced, as machine data are typically obtained at high sample rates.

3. Methodology

3.1. Proposed Intelligent Diagnosis Framework

| Algorithm 1. Pseudo-code for the proposed intelligent framework. |

|

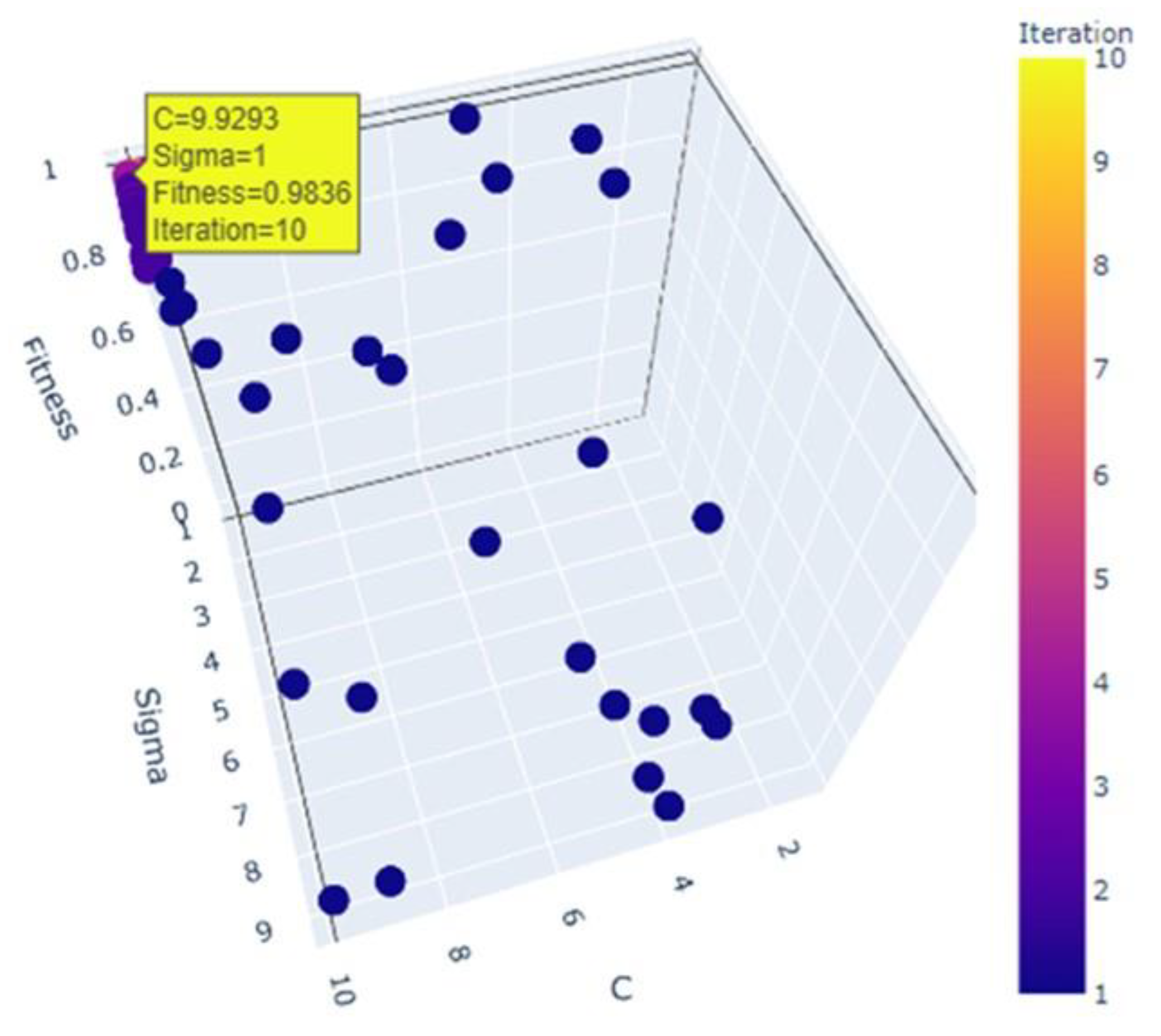

3.2. Design of Meta-Heuristic Optimization Algorithm

| Algorithm 2. Pseudo-codes of the Grasshopper Optimization Algorithm. |

| Start the swarm Xp(p = 1, 2,3, ....., n) Set up , , , and max no. of iterations Calculate each search agent’s fitness. L = the best search agent While (t < Limit of iterations) Adjust c with the aid of Equation (17) For each search agent Standardize the spacing between agents [1,10] Adjust the equation to reflect the changed location of the search agent (17) If the search agent leaves the specified boundary, bring it back. end for Update L and position if a better solution is available. End While Return L (the target fitness and target position) |

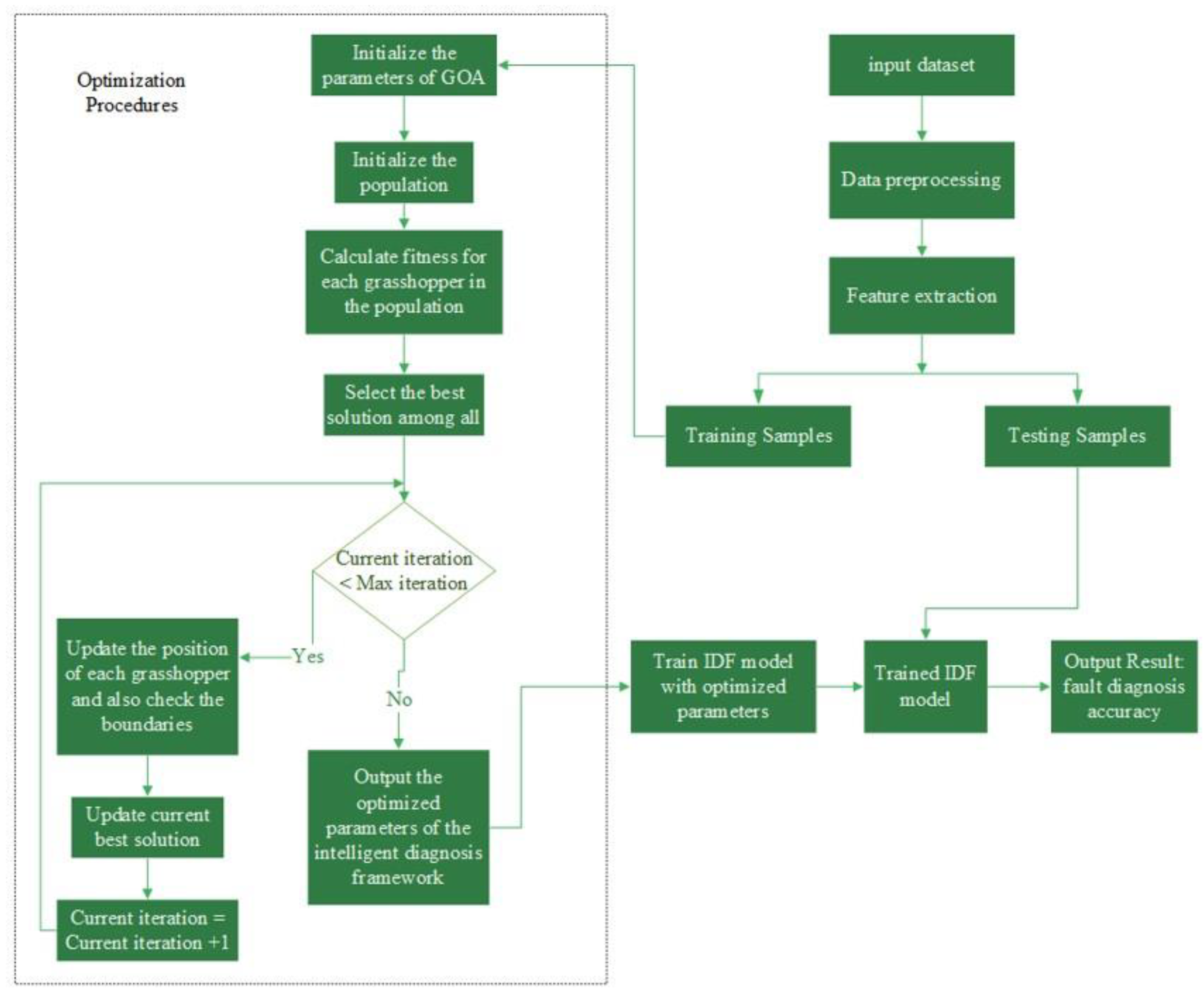

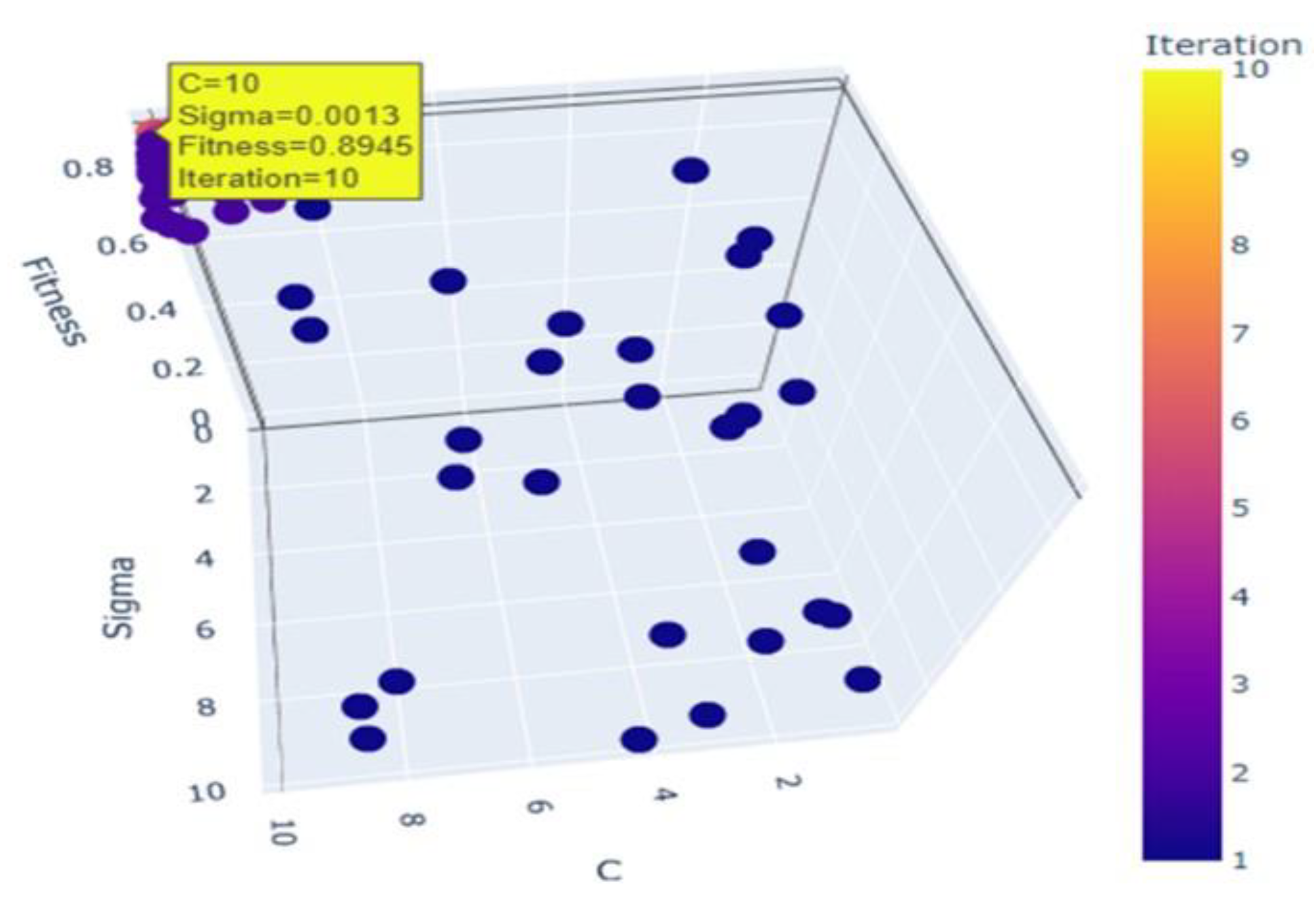

3.3. Meta-Heuristic Optimization Configured Intelligent Diagnosis Framework

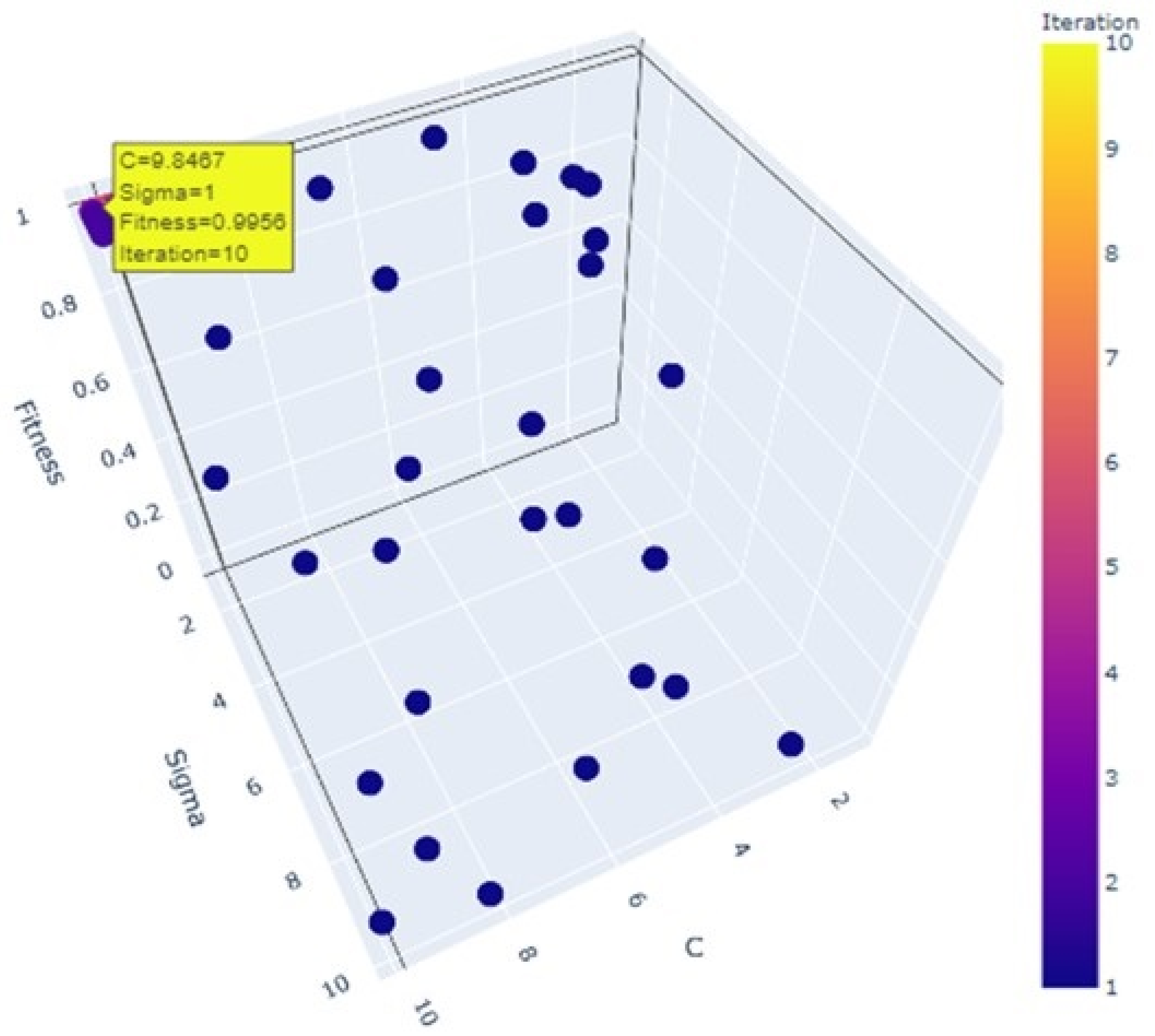

- Initialization: Set the parameters for the Grasshopper Optimization Algorithm (GOA). Here, we configure the maximum number of iterations to 10 and define a population size of n= 30 grasshoppers.

- Fitness Assessment: Evaluate the fitness of each grasshopper within the population and identify the best solution among them.

- Iteration Check: Check if the current iteration is within the defined maximum iteration limit. If it is, proceed to the next step (Step 4); if not, display the best solution found and conclude the process.

- Position Update: Update the positions of the grasshoppers while considering the distances between them. This step also involves checking if any grasshoppers have strayed beyond the defined boundaries.

- Best Solution Update: Update the current best solution and replace it with any new, superior solution that emerges during the iteration.

- Iteration Control: Increment the iteration counter and verify if the current iteration is still below the maximum iteration limit. If this condition holds true, return to Step 4 for the next iteration. If it is false, display the best solution obtained.

- Output: Finally, present the optimized parameters for the proposed Intelligent Diagnosis Framework.

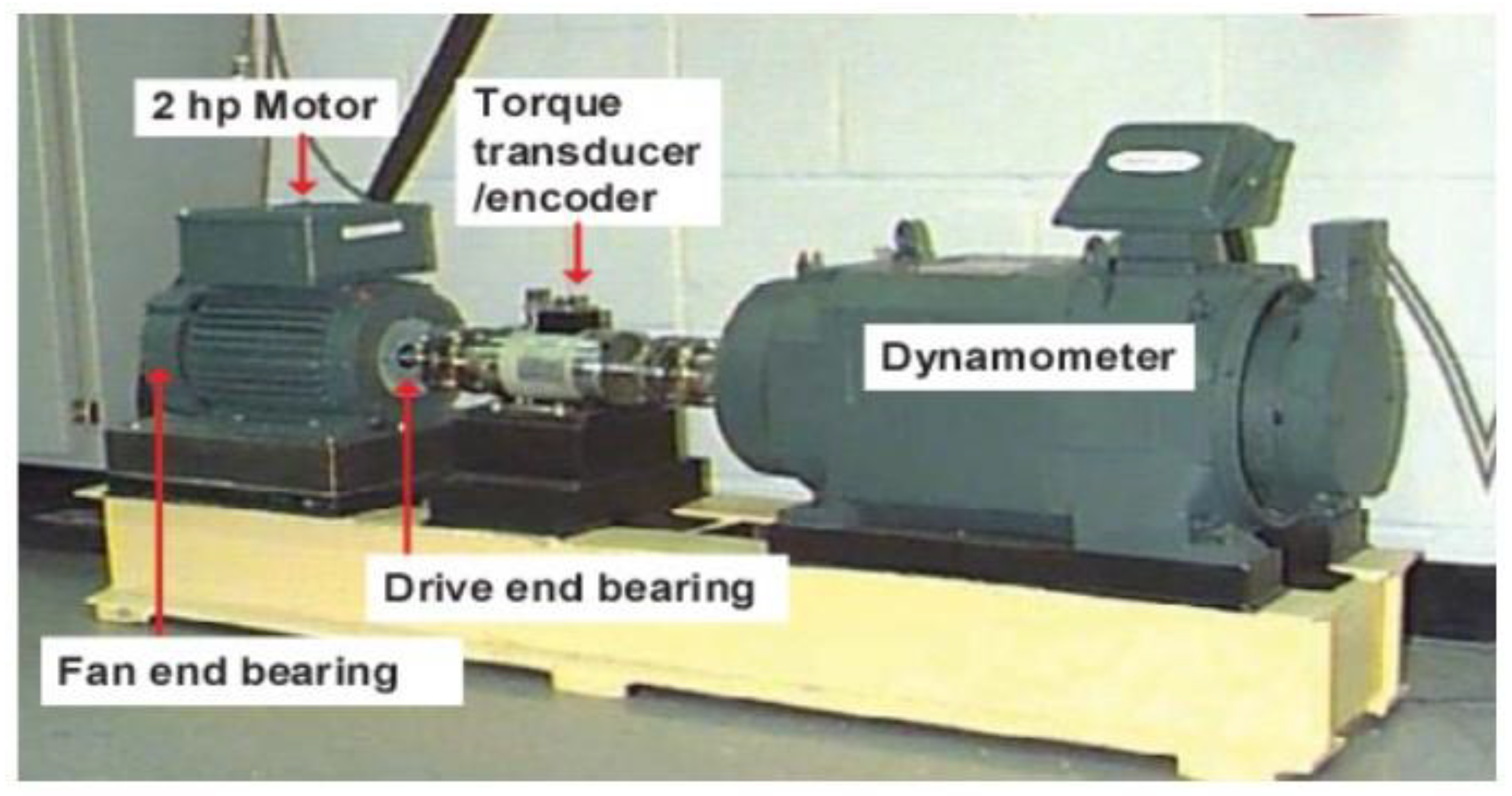

4. Dataset

- Ball Bearings;

- Roller Bearings.

- Fault Types: There are several fault conditions simulated in the dataset:

- Normal (healthy) condition;

- Inner race fault (IR);

- Outer race fault (OR);

- Ball fault (BF);

- Cage fault (CF).

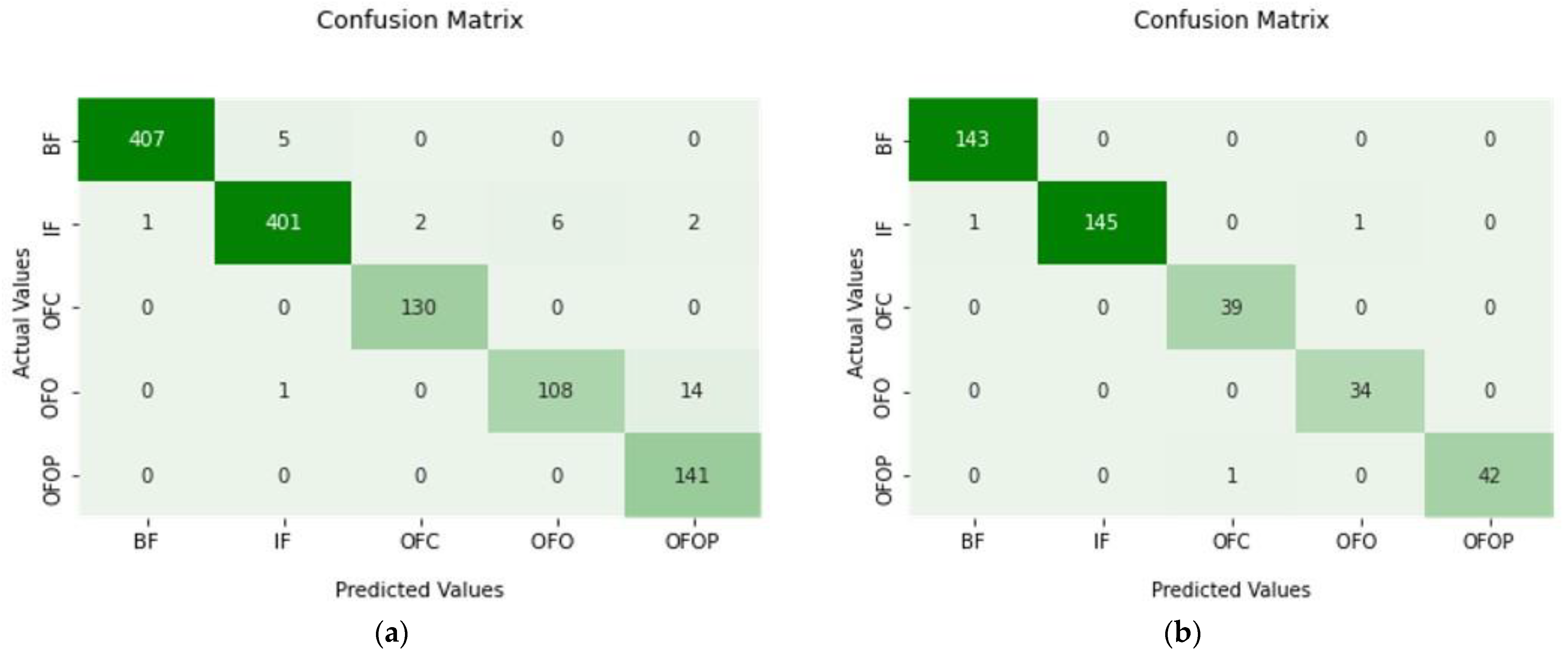

5. Experimental Results

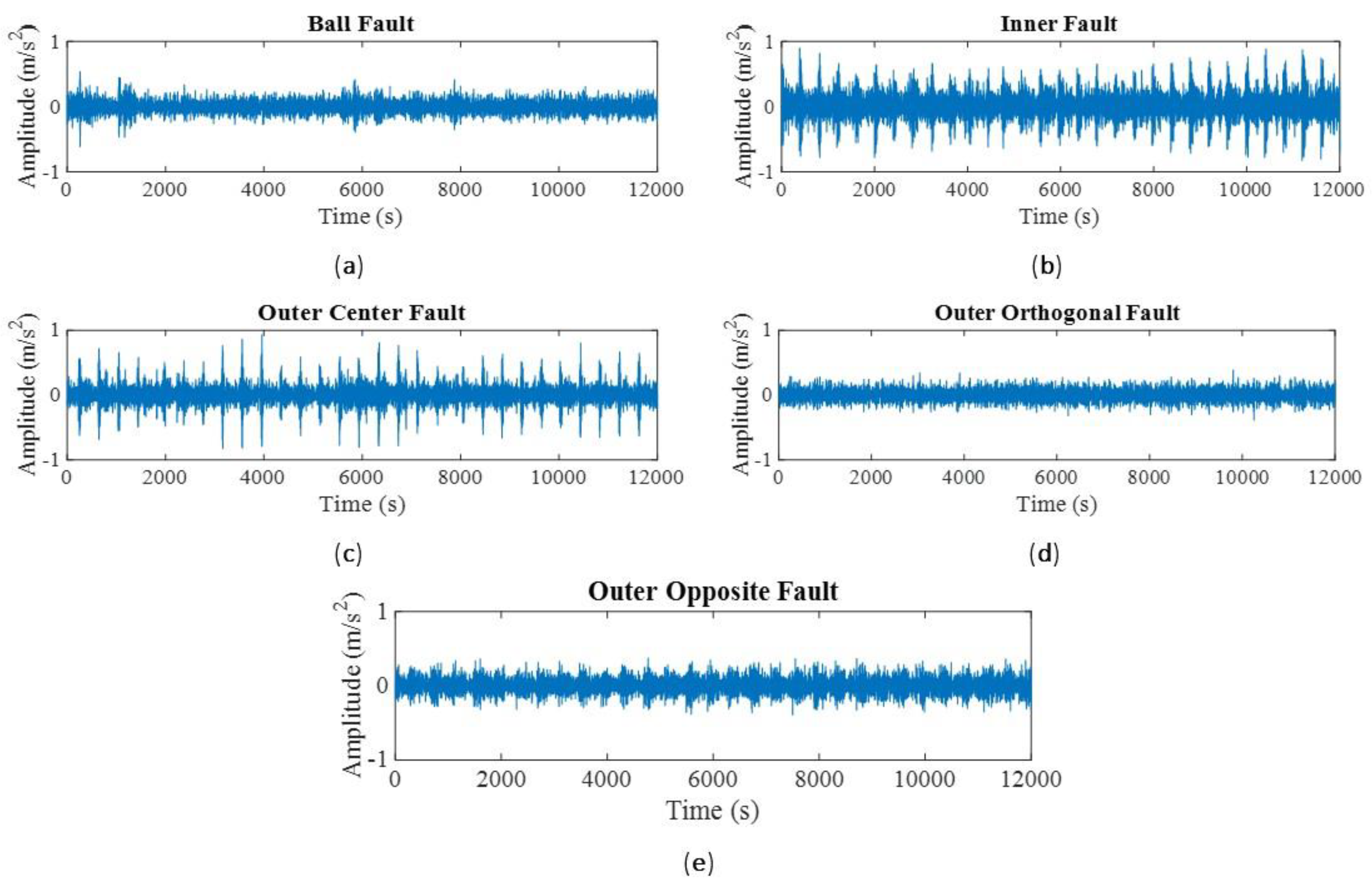

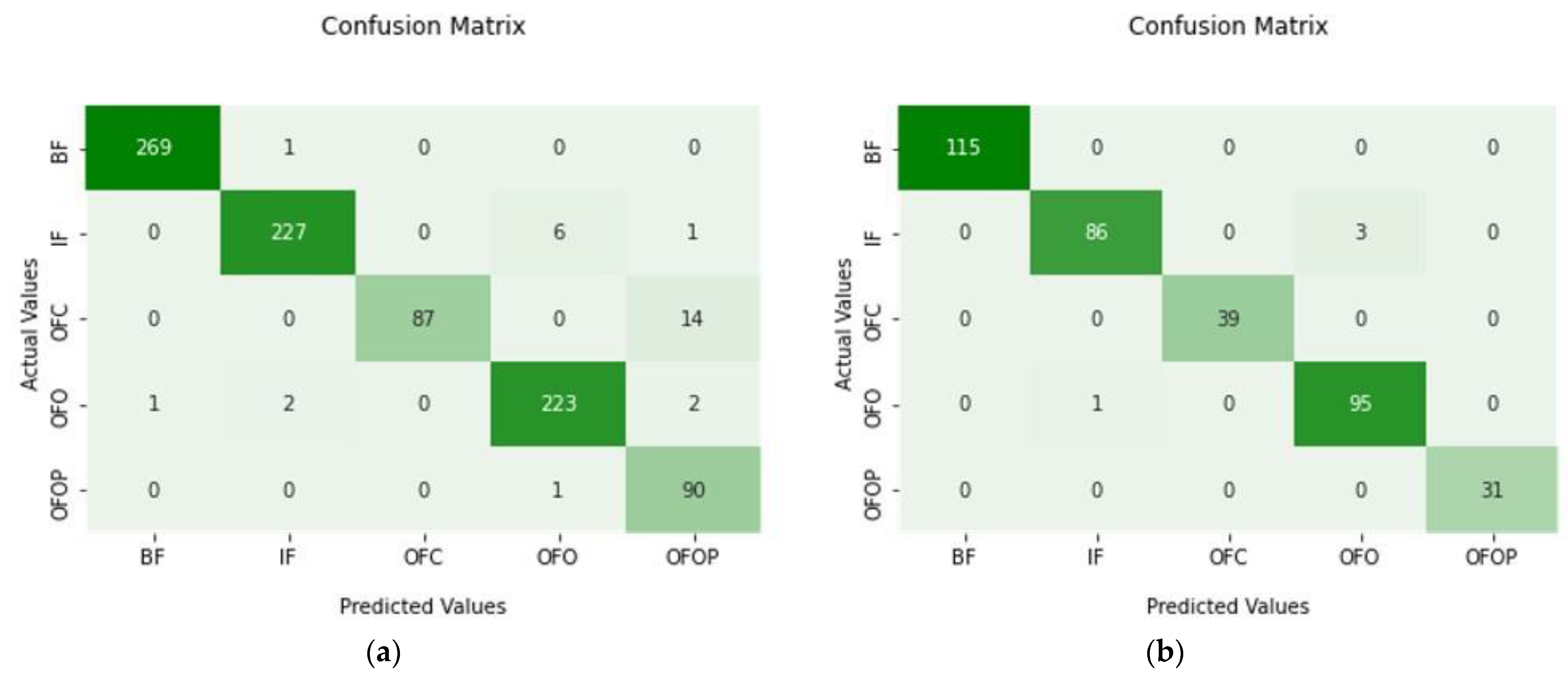

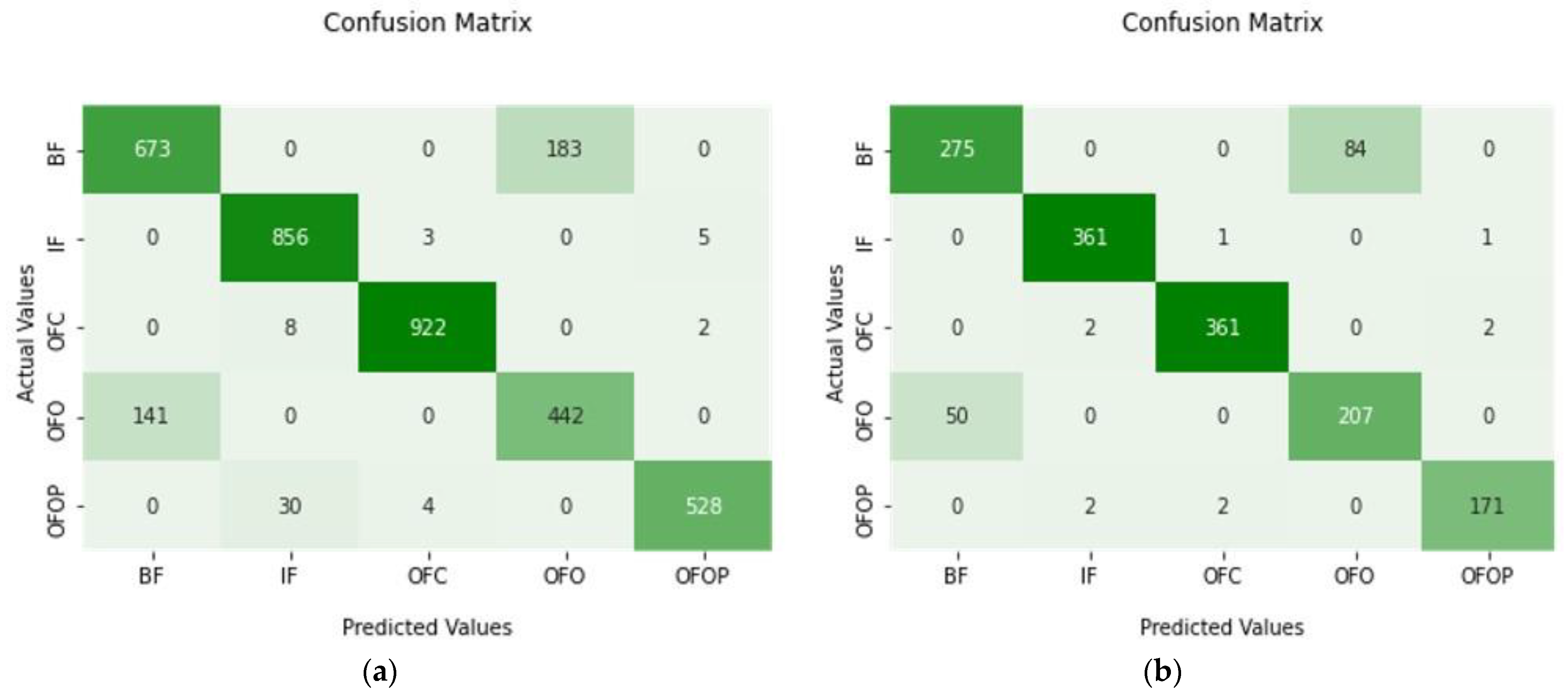

5.1. Case 1

5.2. Case 2

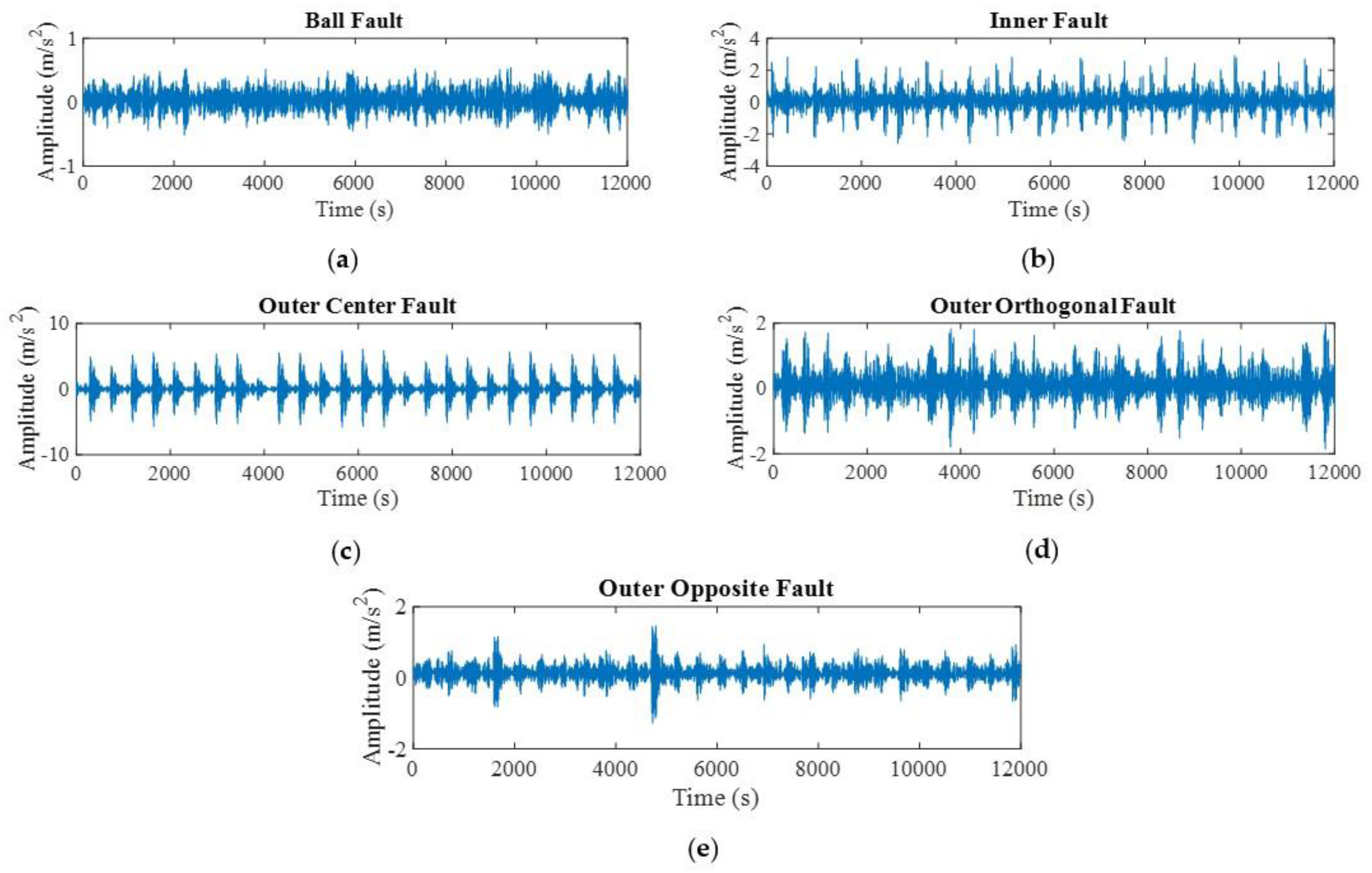

5.3. Robustness Measurement (Case 3)

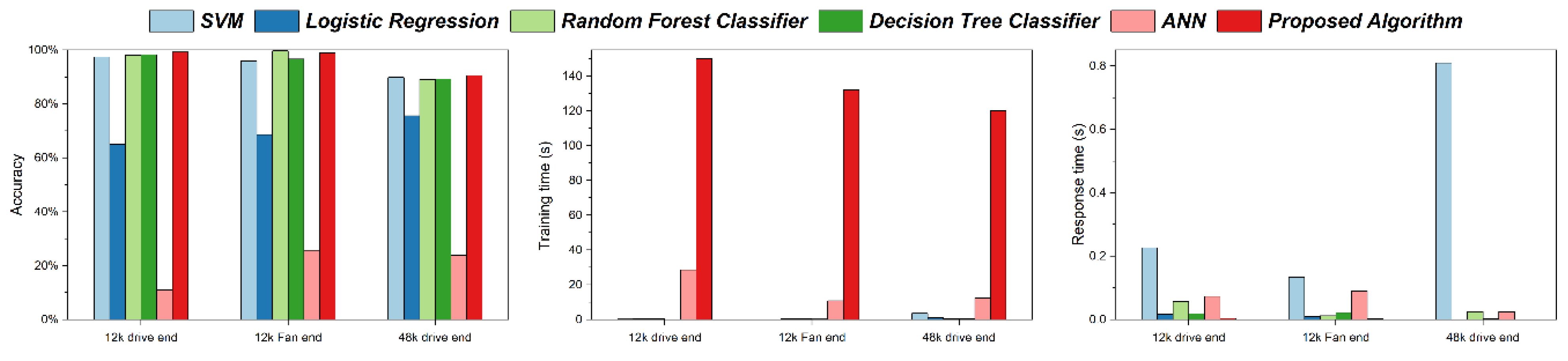

5.4. Comparative Analysis

- Importance of Bearing Fault Diagnosis: Bearing faults in rotating machinery can have significant consequences, leading to uncontrolled speed and potential damage to the entire system. The early monitoring and diagnosis of bearing conditions are crucial to prevent these issues.

- Data-Driven Techniques: The use of data-driven techniques for bearing fault diagnosis has gained popularity. These techniques are independent of system dynamics and can effectively classify and estimate faults based on recorded data.

- Support Vector Machine (SVM): SVM is highlighted as a top-of-the-line algorithm in machine learning for bearing fault diagnosis. However, incorrect parameter settings or kernel functions can lead to errors in fault detection.

- Optimization of SVM Parameters: Some studies have focused on optimizing SVM parameters for more accurate fault diagnosis. While heuristic methods can improve classification accuracy, they may be time-consuming and struggle to find the global optimal solution.

- Meta-Heuristic Optimization: To address the limitations of heuristic methods, the paper proposes a meta-heuristic configured intelligent framework for improving the accuracy of bearing fault diagnosis. It combines the Grasshopper Optimization Algorithm (GOA) and SVM.

- GOA: GOA is introduced as a bio-inspired optimization technique that balances global exploration and local exploitation in a high-dimensional search space. It is used for hyperparameter optimization in the proposed framework.

- Robustness to Real-World Conditions: Investigate the model’s performance in real-world industrial environments, where factors like varying loads, temperature fluctuations, and environmental noise can affect the accuracy of diagnosis. Developing techniques to make the model more robust to such conditions is essential [51,52,53,54,55].

- Online Monitoring and Predictive Maintenance: Develop methodologies for real-time monitoring and predictive maintenance. This would involve implementing the diagnosis framework on IoT devices or edge computing platforms for continuous monitoring and early fault prediction [3,56,57,58,59,60,61,62,63,64].

- Integration with Maintenance Scheduling: Integrate the diagnosis framework with maintenance scheduling systems. This would enable the automatic scheduling of maintenance tasks based on the severity and urgency of detected faults.

- Fault Severity Estimation: Develop methods to estimate the severity of bearing faults accurately. Knowing the extent of a fault’s progression can help prioritize maintenance efforts and resources.

- Advanced Optimization Algorithms: Continue exploring and experimenting with different optimization algorithms beyond the Grasshopper Optimization Algorithm to further enhance the performance and efficiency of the diagnosis framework.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Parmar, U.; Pandya, D. Experimental investigation of cylindrical bearing fault diagnosis with SVM. Mater. Today Proc. 2021, 44, 1286–1290. [Google Scholar] [CrossRef]

- Senanayaka, J.S.L.; Kandukuri, S.T.; Van Khang, H.; Robbersmyr, K.G. Early detection and classification of bearing faults using support vector machine algorithm. In Proceedings of the 2017 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Nottingham, UK, 20–21 April 2017. [Google Scholar]

- Wang, H.; Wu, X.; Zheng, X.; Yuan, X. Model Predictive Current Control of Nine-Phase Open-End Winding PMSMs With an Online Virtual Vector Synthesis Strategy. IEEE Trans. Ind. Electron. 2022, 70, 2199–2208. [Google Scholar] [CrossRef]

- Ding, Z.; Wu, X.; Chen, C.; Yuan, X. Magnetic Field Analysis of Surface-Mounted Permanent Magnet Motors Based on an Improved Conformal Mapping Method. IEEE Trans. Ind. Appl. 2023, 59, 1689–1698. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C. Virtual-Vector-Based Robust Predictive Current Control for Dual Three-Phase PMSM. IEEE Trans. Ind. Electron. 2021, 68, 2048–2058. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C. Direct Harmonic Current Control Scheme for Dual Three-Phase PMSM Drive System. IEEE Trans. Power Electron. 2021, 36, 11647–11657. [Google Scholar] [CrossRef]

- Liao, K.; Lu, D.; Wang, M.; Yang, J. A Low-Pass Virtual Filter for Output Power Smoothing of Wind Energy Conversion Systems. IEEE Trans. Ind. Electron. 2022, 69, 12874–12885. [Google Scholar] [CrossRef]

- Li, J.; Deng, Y.; Sun, W.; Li, W.; Li, R.; Li, Q.; Liu, Z. Resource Orchestration of Cloud-Edge–based Smart Grid Fault Detection. ACM Trans. Sens. Netw. 2022, 18, 46. [Google Scholar] [CrossRef]

- Aminizadeh, S.; Heidari, A.; Toumaj, S.; Darbandi, M.; Navimipour, N.J.; Rezaei, M.; Talebi, S.; Azad, P.; Unal, M. The applications of machine learning techniques in medical data processing based on distributed computing and the Internet of Things. Comput. Methods Programs Biomed. 2023, 241, 107745. [Google Scholar] [CrossRef]

- Wang, L. (Ed.) Support Vector Machines: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005; Volume 177. [Google Scholar]

- Saremi, S.; Mirjalili, S.; Lewis, A. Grasshopper Optimisation Algorithm: Theory and application. Adv. Eng. Softw. 2017, 105, 30–47. [Google Scholar] [CrossRef]

- Abualigah, L.; Diabat, A. A comprehensive survey of the Grasshopper optimization algorithm: Results, variants, and applications. Neural Comput. Appl. 2020, 32, 15533–15556. [Google Scholar] [CrossRef]

- He, F.; Ye, Q. A Bearing Fault Diagnosis Method Based on Wavelet Packet Transform and Convolutional Neural Network Optimized by Simulated Annealing Algorithm. Sensors 2022, 22, 1410. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, T.; Jiang, B.; Yang, X. Intelligent bearing fault diagnosis using PCA–DBN framework. Neural Comput. Appl. 2019, 32, 10773–10781. [Google Scholar] [CrossRef]

- Toma, R.N.; Kim, J.-M. Bearing Fault Classification of Induction Motors Using Discrete Wavelet Transform and Ensemble Machine Learning Algorithms. Appl. Sci. 2020, 10, 5251. [Google Scholar] [CrossRef]

- Amiri, Z.; Heidari, A.; Navimipour, N.J.; Unal, M.; Mousavi, A. Adventures in data analysis: A systematic review of Deep Learning techniques for pattern recognition in cyber-physical-social systems. Multimed. Tools Appl. 2023, 1–65. [Google Scholar] [CrossRef]

- Guo, J.; Wan, J.-L.; Yang, Y.; Dai, L.; Tang, A.; Huang, B.; Zhang, F.; Li, H. A deep feature learning method for remaining useful life prediction of drilling pumps. Energy 2023, 282, 128442. [Google Scholar] [CrossRef]

- Ma, J.; Li, Z.; Li, C.; Zhan, L.; Zhang, G.-Z. Rolling Bearing Fault Diagnosis Based on Refined Composite Multi-Scale Approximate Entropy and Optimized Probabilistic Neural Network. Entropy 2021, 23, 259. [Google Scholar] [CrossRef]

- Yapici, H.; Cetinkaya, N. A new meta-heuristic optimizer: Pathfinder algorithm. Appl. Soft Comput. 2019, 78, 545–568. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Karaboga, D.; Basturk, B. Artificial bee colony (ABC) optimization algorithm for solving constrained optimi-zation problems. In International Fuzzy Systems Association World Congress; Springer: Berlin/Heidelberg, Germany, 2007; pp. 789–798. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Zorarpacı, E.; Özel, S.A. A hybrid approach of differential evolution and artificial bee colony for feature selection. Expert Syst. Appl. 2016, 62, 91–103. [Google Scholar] [CrossRef]

- Herrera, P.J.; Pajares, G.; Guijarro, M.; Ruz, J.J.; Jesús, M. Combining Support Vector Machines and simulated annealing for stereovision matching with fish eye lenses in forest environments. Expert Syst. Appl. 2011, 38, 8622–8631. [Google Scholar] [CrossRef]

- Bazan, G.H.; Goedtel, A.; Castoldi, M.F.; Godoy, W.F.; Duque-Perez, O.; Morinigo-Sotelo, D. Mutual Information and Meta-Heuristic Classifiers Applied to Bearing Fault Diagnosis in Three-Phase Induction Motors. Appl. Sci. 2020, 11, 314. [Google Scholar] [CrossRef]

- Bhatti, U.A.; Huang, M.; Neira-Molina, H.; Marjan, S.; Baryalai, M.; Tang, H.; Wu, G.; Bazai, S.U. MFFCG—Multi feature fusion for hyperspectral image classification using graph attention network. Expert Syst. Appl. 2023, 229, 120496. [Google Scholar] [CrossRef]

- Zhao, K.; Jia, Z.; Jia, F.; Shao, H. Multi-scale integrated deep self-attention network for predicting remaining useful life of aero-engine. Eng. Appl. Artif. Intell. 2023, 120, 105860. [Google Scholar] [CrossRef]

- Xu, S.; Huang, W.; Huang, D.; Chen, H.; Chai, Y.; Ma, M.; Zheng, W.X. A Reduced-Order Observer-Based Method for Simultaneous Diagnosis of Open-Switch and Current Sensor Faults of a Grid-Tied NPC Inverter. IEEE Trans. Power Electron. 2023, 38, 9019–9032. [Google Scholar] [CrossRef]

- Bhatti, U.A.; Tang, H.; Wu, G.; Marjan, S.; Hussain, A. Deep Learning with Graph Convolutional Networks: An Overview and Latest Applications in Computational Intelligence. Int. J. Intell. Syst. 2023, 2023, 8342104. [Google Scholar] [CrossRef]

- A novel droop control method to achieve maximum power output of photovoltaic for parallel inverter system. CSEE J. Power Energy Syst. 2021, 8, 1636–1645. [CrossRef]

- Bhatti, U.A.; Marjan, S.; Wahid, A.; Syam, M.S.; Huang, M.; Tang, H.; Hasnain, A. The effects of socioeconomic factors on particulate matter concentration in China’s: New evidence from spatial econometric model. J. Clean. Prod. 2023, 417, 137969. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.; Wang, S.; Puig, V. Switching-based adaptive fault-tolerant control for uncertain nonlinear systems against actuator and sensor faults. J. Frankl. Inst. 2023, 360, 11462–11488. [Google Scholar] [CrossRef]

- Miaofen, L.; Youmin, L.; Tianyang, W.; Fulei, C.; Zhike, P. Adaptive synchronous demodulation transform with application to analyzing multicomponent signals for machinery fault diagnostics. Mech. Syst. Signal Process. 2023, 191, 110208. [Google Scholar] [CrossRef]

- Hu, W.; Wang, T.; Chu, F. Novel Ramanujan Digital Twin for Motor Periodic Fault Monitoring and Detection. IEEE Trans. Ind. Inform. 2023, 19, 11564–11572. [Google Scholar] [CrossRef]

- Cheng, B.; Zhu, D.; Zhao, S.; Chen, J. Situation-Aware IoT Service Coordination Using the Event-Driven SOA Paradigm. IEEE Trans. Netw. Serv. Manag. 2016, 13, 349–361. [Google Scholar] [CrossRef]

- Liu, S.; Jiang, H.; Wu, Z.; Li, X. Rolling bearing fault diagnosis using variational autoencoding generative adversarial networks with deep regret analysis. Measurement 2020, 168, 108371. [Google Scholar] [CrossRef]

- Ye, M.; Yan, X.; Jia, M. Rolling Bearing Fault Diagnosis Based on VMD-MPE and PSO-SVM. Entropy 2021, 23, 762. [Google Scholar] [CrossRef] [PubMed]

- Song, M.; Wang, J.; Zhao, H.; Li, Y. Bearing failure of reciprocating compressor sub-health recognition based on CAGOA-VMD and GRCMDE. Adv. Mech. Eng. 2022, 14, 16878132221082975. [Google Scholar] [CrossRef]

- Yang, K.; Zhao, L.; Wang, C. A new intelligent bearing fault diagnosis model based on triplet network and SVM. Sci. Rep. 2022, 12, 5234. [Google Scholar] [CrossRef] [PubMed]

- Khorram, A.; Khalooei, M.; Rezghi, M. End-to-end CNN + LSTM deep learning approach for bearing fault diagnosis. Appl. Intell. 2020, 51, 736–751. [Google Scholar] [CrossRef]

- Mao, M.; Zhou, C.; Yang, J.; Fang, B.; Liu, F.; Liu, X. Research on Fault Diagnosis Method of Rolling Bearing Based on Feature Optimization and Self-Adaptive SVM. Math. Probl. Eng. 2022, 2022, 6711019. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, S.; Li, W.; Sarkodie-Gyan, T.; Feng, S. A Hybrid Deep-Learning Model for Fault Diagnosis of Rolling Bearings. Measurement 2021, 169, 108502. [Google Scholar] [CrossRef]

- Li, X.; Jiang, H.; Wang, R.; Niu, M. Rolling bearing fault diagnosis using optimal ensemble deep transfer network. Knowl. Based Syst. 2021, 213, 106695. [Google Scholar] [CrossRef]

- Wang, J.; Guo, J.; Wang, L.; Yang, Y.; Wang, Z.; Wang, R. A hybrid intelligent rolling bearing fault diagnosis method combining WKN-BiLSTM and attention mechanism. Meas. Sci. Technol. 2023, 34, 85106. [Google Scholar] [CrossRef]

- Tian, H.; Liu, J.; Wang, Z.; Xie, F.; Cao, Z. Characteristic Analysis and Circuit Implementation of a Novel Fractional-Order Memristor-Based Clamping Voltage Drift. Fractal Fract. 2022, 7, 2. [Google Scholar] [CrossRef]

- Han, Y.; Chen, S.; Gong, C.; Zhao, X.; Zhang, F.; Li, Y. Accurate SM Disturbance Observer-Based Demagnetization Fault Diagnosis With Parameter Mismatch Impacts Eliminated for IPM Motors. IEEE Trans. Power Electron. 2023, 38, 5706–5710. [Google Scholar] [CrossRef]

- Mo, J.; Yang, H. Sampled Value Attack Detection for Busbar Differential Protection Based on a Negative Selection Immune System. J. Mod. Power Syst. Clean Energy 2023, 11, 421–433. [Google Scholar] [CrossRef]

- Xia, Y.; Ding, L.; Tang, Z. Interaction effects of multiple input parameters on the integrity of safety instrumented systems with the k-out-of-n redundancy arrangement under uncertainties. Qual. Reliab. Eng. Int. 2023, 39, 2515–2536. [Google Scholar] [CrossRef]

- Wu, Z.; Lin, B.; Fan, J.; Zhao, J.; Zhang, Q.; Li, L. Effect of Dielectric Relaxation of Epoxy Resin on Dielectric Loss of Medium-Frequency Transformer. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1651–1658. [Google Scholar] [CrossRef]

- Lu, C.; Zhou, H.; Li, L.; Yang, A.; Xu, C.; Ou, Z.; Wang, J.; Wang, X.; Tian, F. Split-core magnetoelectric current sensor and wireless current measurement application. Meas. J. Int. Meas. Confed. 2022, 188, 110527. [Google Scholar] [CrossRef]

- Huang, S.; Huang, M.; Lyu, Y. Seismic performance analysis of a wind turbine with a monopile foundation affected by sea ice based on a simple numerical method. Eng. Appl. Comput. Fluid Mech. 2021, 15, 1113–1133. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, B.; He, T.; Tu, L.; Lu, X.; Xu, H. Tribology and dynamic characteristics of textured journal-thrust coupled bearing considering thermal and pressure coupled effects. Tribol. Int. 2023, 180, 108292. [Google Scholar] [CrossRef]

- Ma, X.; Liao, Z.; Wang, Y.; Zhao, J. Fast Dynamic Phasor Estimation Algorithm Considering DC Offset for PMU Applications. IEEE Trans. Power Deliv. 2023, 38, 3582–3593. [Google Scholar] [CrossRef]

- Liang, X.; Huang, Z.; Yang, S.; Qiu, L. Device-Free Motion & Trajectory Detection via RFID. ACM Trans. Embed. Comput. Syst. 2018, 17, 78. [Google Scholar] [CrossRef]

- Deng, Y.; Lv, J.; Huang, D.; Du, S. Combining the theoretical bound and deep adversarial network for machinery open-set diagnosis transfer. Neurocomputing 2023, 548, 108292. [Google Scholar] [CrossRef]

- Wang, Y.; He, H.-S.; Xiao, X.-Y.; Li, S.-Y.; Chen, Y.-Z.; Ma, H.-X. Multi-Stage Voltage Sag State Estimation Using Event-Deduction Model Corresponding to EF, EG, and EP. IEEE Trans. Power Deliv. 2023, 38, 797–811. [Google Scholar] [CrossRef]

- Xie, X.; Sun, Y. A piecewise probabilistic harmonic power flow approach in unbalanced residential distribution systems. Int. J. Electr. Power Energy Syst. 2022, 141, 108114. [Google Scholar] [CrossRef]

- Zhang, X.; Pan, W.; Scattolini, R.; Yu, S.; Xu, X. Robust tube-based model predictive control with Koopman operators. Automatica 2022, 137, 110114. [Google Scholar] [CrossRef]

- Li, Q.-K.; Lin, H.; Tan, X.; Du, S. H∞ Consensus for Multiagent-Based Supply Chain Systems Under Switching Topology and Uncertain Demands. IEEE Trans. Syst. Man Cybern. Syst. 2018, 50, 4905–4918. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Zhang, W. A Composite Adaptive Fault-Tolerant Attitude Control for a Quadrotor UAV with Multiple Uncertainties. J. Syst. Sci. Complex. 2022, 35, 81–104. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, Z.; Shi, H.; Luo, Z.; Li, T. Identification of Subsurface Mesoscale Crack in Full Ceramic Ball Bearings Based on Strain Energy Theory. Appl. Sci. 2023, 13, 7783. [Google Scholar] [CrossRef]

- Shi, H.; Song, Z.; Bai, X.; Hu, Y.; Li, T.; Zhang, K. A novel digital twin model for dynamical updating and real-time mapping of local defect extension in rolling bearings. Mech. Syst. Signal Process. 2023, 193, 110255. [Google Scholar] [CrossRef]

- Bai, X.; Shi, H.; Zhang, K.; Zhang, X.; Wu, Y. Effect of the fit clearance between ceramic outer ring and steel pedestal on the sound radiation of full ceramic ball bearing system. J. Sound Vib. 2022, 529, 116967. [Google Scholar] [CrossRef]

- Lu, S.; Yin, Z.; Liao, S.; Yang, B.; Liu, S.; Liu, M.; Yin, L.; Zheng, W. An asymmetric encoder–decoder model for Zn-ion battery lifetime prediction. Energy Rep. 2022, 8, 33–50. [Google Scholar] [CrossRef]

- Liu, M.; Gu, Q.; Yang, B.; Yin, Z.; Liu, S.; Yin, L.; Zheng, W. Kinematics Model Optimization Algorithm for Six Degrees of Freedom Parallel Platform. Appl. Sci. 2023, 13, 3082. [Google Scholar] [CrossRef]

- Liu, X.; Li, Z.; Fu, X.; Yin, Z.; Liu, M.; Yin, L.; Zheng, W. Monitoring House Vacancy Dynamics in The Pearl River Delta Region: A Method Based on NPP-VIIRS Night-Time Light Remote Sensing Images. Land 2023, 12, 831. [Google Scholar] [CrossRef]

| References | Accuracy | Classifier | Data Amount | Fault Type | Required Time | Efficient | Robustness (High) |

|---|---|---|---|---|---|---|---|

| [37] | 97.27% | GAN | High | 10 | Moderate | Yes | Yes |

| [38] | 90.28% | MPE-PSOSVM | High | 6 | High | Yes | Yes |

| [38] | 96.56% | VMD-MPE-PSOSVM | Medium | 6 | High | Yes | Yes |

| [39] | 89.2% | VMD and GMDE | Medium | 4 | High | No | Yes (Noise only) |

| [40] | 97.09% | Triplet Network + SVM | High | 9 | Low | No | Yes |

| [1] | 93.8 | Quadratic SVM | High | 4 | High | Yes | No |

| [41] | 99.77% | CNN + LSTM Network | High | 5 | High | Yes | No |

| [42] | 98.5% | GWO-SVM | Medium | 8 | Low | No | No |

| [43] | 98.24% | Hybrid CNN | High | 3 | High | No | No |

| Proposed | High | GOA-SVM | High | 15 | Low | Yes | Yes |

| Bearing Status | Diameter (in) | Motor (hp) | Label |

|---|---|---|---|

| Ball fault | 0.007 | 0, 1, 2, 3 | BF |

| 0.014 | |||

| 0.021 | |||

| 0.028 | |||

| Inner race fault | 0.007 | 0, 1, 2, 3 | IF |

| 0.014 | |||

| 0.021 | |||

| 0.028 | |||

| Outer fault centered load zone | 0.007 | 0, 1, 2, 3 | OFC |

| 0.014 | |||

| 0.021 | |||

| Outer fault orthogonal load zone | 0.007 | 0, 1, 2, 3 | OFO |

| 0.014 | |||

| 0.021 | |||

| Outer fault opposite load zone | 0.007 | 0, 1, 2, 3 | OFOP |

| 0.014 | |||

| 0.021 |

| Feature | Equation | Feature | Equation |

|---|---|---|---|

| Mean: | RMS: | ||

| Standard Deviation: | Crest factor: | ||

| Skewness: | = | Form factor: | |

| Kurtosis: |

| Accuracy = |

| Precision = |

| Recall = |

| F1 score = |

| Data | Accuracy | Precision | Recall | F1 score |

|---|---|---|---|---|

| 12,000 drive end | 99.26% | 98.79% | 99.26% | 99.02% |

| 12,000 fan end | 98.92% | 99.15% | 99.1% | 99.13% |

| 48,000 drive end | 90.58% | 90.53% | 88.98% | 88.85% |

| Dataset | 12,000 Drive End | 12,000 Fan End | 48,000 Drive End | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Accuracy | Training Time (s) | Response Time (s) | Accuracy | Training Time (s) | Response Time (s) | Accuracy | Training Time (s) | Response Time (s) |

| SVM | 97.45% | 0.21 | 0.227 | 96% | 0.16 | 0.133 | 89.9% | 3.55 | 0.81 |

| Logistic Regression | 65.02% | 0.58 | 0.017 | 68.64% | 0.59 | 0.009 | 75.64% | 1.14 | 0.0003 |

| Random Forest Classifier | 98.05% | 0.61 | 0.057 | 99.72% | 0.43 | 0.012 | 89.15% | 0.48 | 0.025 |

| Decision Tree Classifier | 98.26% | 0.20 | 0.019 | 96.72% | 0.22 | 0.022 | 89.38% | 0.62 | 0.003 |

| ANN | 11.06% | 28.67 | 0.073 | 25.68% | 10.82 | 0.09 | 23.80% | 12.4 | 0.024 |

| Proposed Algorithm | 99.26% | 150.05 | 0.004 | 98.92% | 132.04 | 0.002 | 90.58% | 120 | 0.0002 |

| Study Ref | Year | Method | 12,000 Drive End | 12,000 Fan End | 48,000 Drive End | Database | Result |

|---|---|---|---|---|---|---|---|

| [13] | 2022 | Wavelet packet transform and convolutional neural network | X | X | X | Case Western Reserve University | 97% Accuracy |

| [15] | 2020 | Discrete wavelet transform (DWT) + Random forest (RF) and Extreme gradient boosting (XGBoost) | X | X | X | Real-time dataset of machine | 99% Accuracy |

| [33] | 2023 | Fault-tolerant control (FTC) | X | X | X | Real-time dataset of machine | Complexity reduction of 23.5% |

| [34] | 2023 | Adaptive synchronous demodulation transform (ASDT) | X | X | X | Real-time dataset of machine | Mean error = 0.0237 |

| Our work | Proposed | Grasshopper Optimization Algorithm with Improved Dimensional Filtering | ✔ | ✔ | ✔ | Public datasets | Accuracy = 90% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bristi, S.D.; Tatha, M.J.; Ali, M.F.; Bhatti, U.A.; Sarker, S.K.; Masud, M.; Ghadi, Y.Y.; Algarni, A.; Saha, D.K. A Meta-Heuristic Sustainable Intelligent Internet of Things Framework for Bearing Fault Diagnosis of Electric Motor under Variable Load Conditions. Sustainability 2023, 15, 16722. https://doi.org/10.3390/su152416722

Bristi SD, Tatha MJ, Ali MF, Bhatti UA, Sarker SK, Masud M, Ghadi YY, Algarni A, Saha DK. A Meta-Heuristic Sustainable Intelligent Internet of Things Framework for Bearing Fault Diagnosis of Electric Motor under Variable Load Conditions. Sustainability. 2023; 15(24):16722. https://doi.org/10.3390/su152416722

Chicago/Turabian StyleBristi, Swarnali Deb, Mehtar Jahin Tatha, Md. Firoj Ali, Uzair Aslam Bhatti, Subrata K. Sarker, Mehdi Masud, Yazeed Yasin Ghadi, Abdulmohsen Algarni, and Dip K. Saha. 2023. "A Meta-Heuristic Sustainable Intelligent Internet of Things Framework for Bearing Fault Diagnosis of Electric Motor under Variable Load Conditions" Sustainability 15, no. 24: 16722. https://doi.org/10.3390/su152416722

APA StyleBristi, S. D., Tatha, M. J., Ali, M. F., Bhatti, U. A., Sarker, S. K., Masud, M., Ghadi, Y. Y., Algarni, A., & Saha, D. K. (2023). A Meta-Heuristic Sustainable Intelligent Internet of Things Framework for Bearing Fault Diagnosis of Electric Motor under Variable Load Conditions. Sustainability, 15(24), 16722. https://doi.org/10.3390/su152416722