Study of Key Parameters and Uncertainties Based on Integrated Energy Systems Coupled with Renewable Energy Sources

Abstract

:1. Introduction

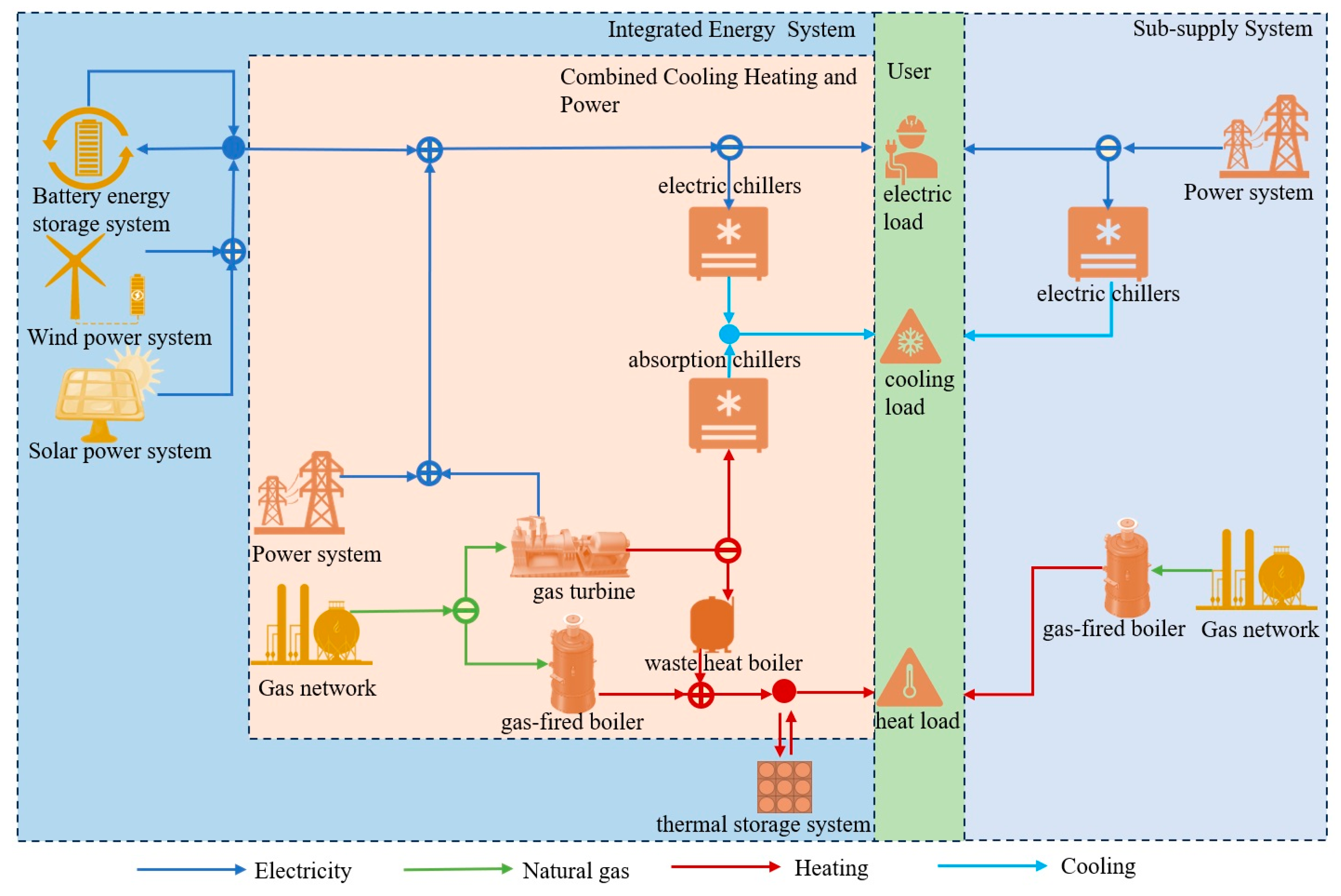

- By establishing a linear programming model with the minimum annual total operating cost of IES as the objective function, the equipment capacity configuration and operation scheduling strategy of the IES system coupled with PV and wind power are optimally designed.

- A comprehensive evaluation framework including economic, energy efficiency, and environmental aspects is constructed to comprehensively evaluate the performance of IES.

- Taking the IES of an industrial park in Xi’an, China, as the specific case, a sensitivity analysis is used to explore the impact of various key parameters on equipment capacity and operation strategies.

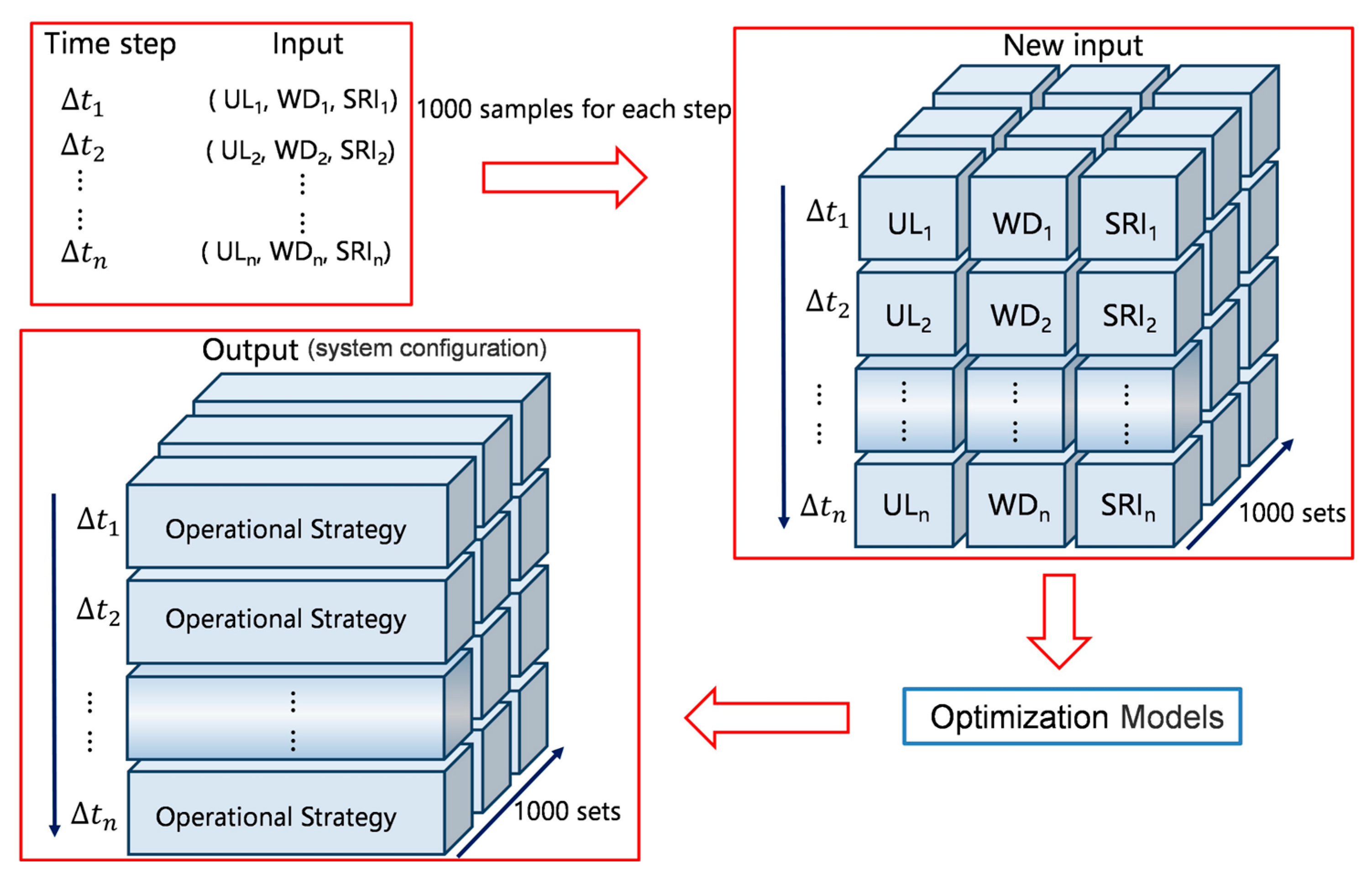

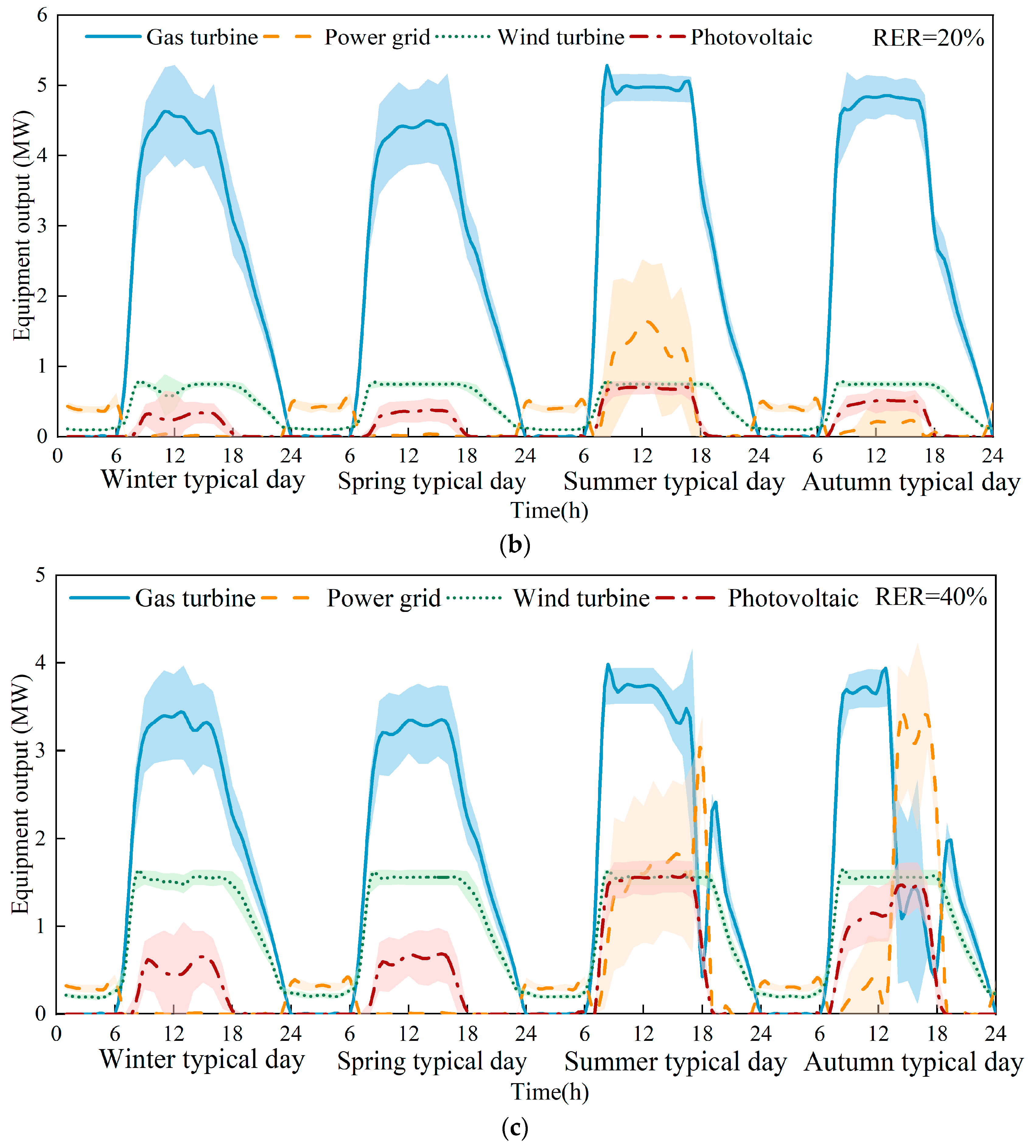

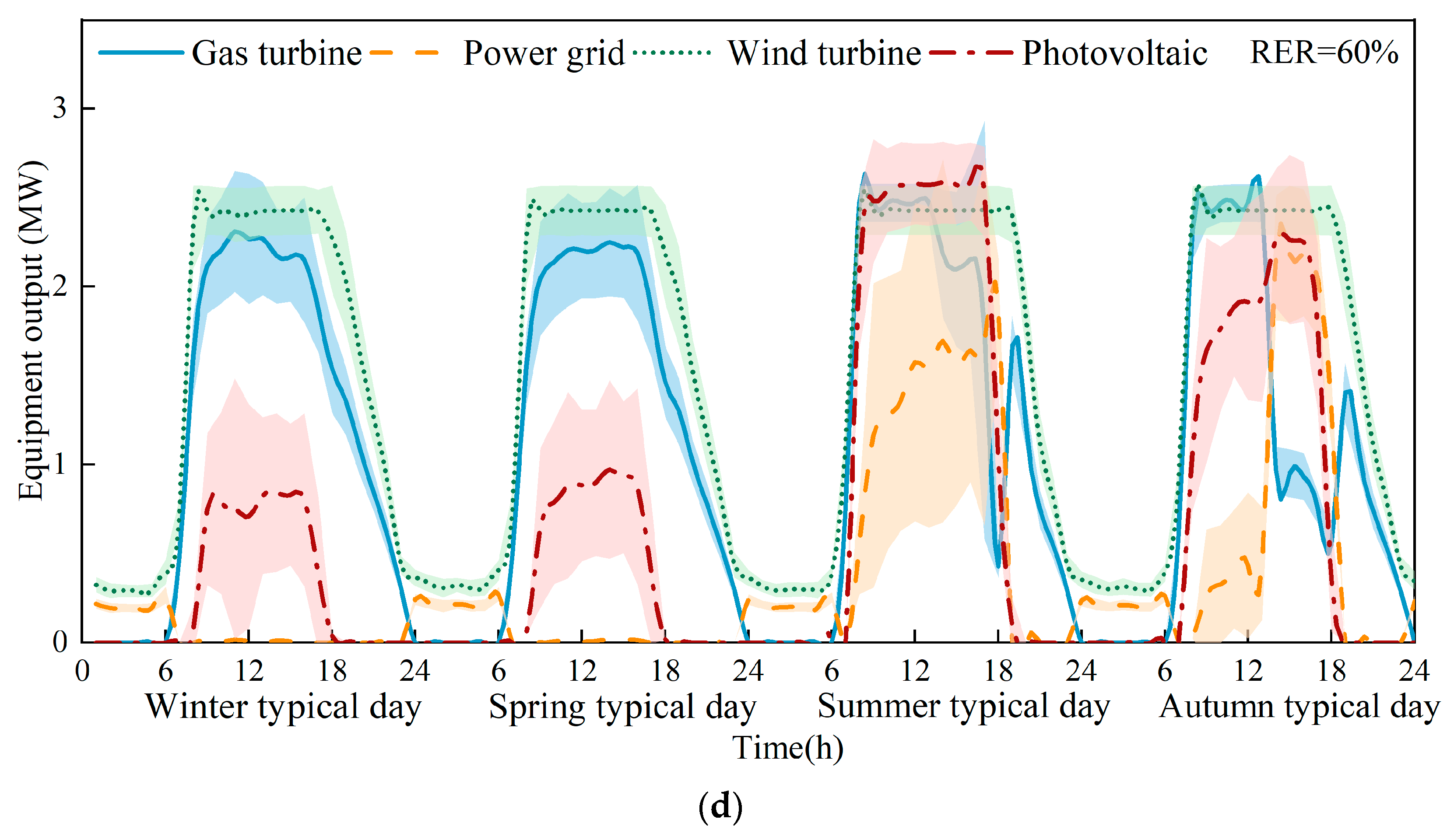

- Considering the regional characteristics of the impacts of PV and wind power on IES, the Monte Carlo method is utilized to investigate the impacts of source-load uncertainty on the equipment configuration and output profile of IES in Xi’an area, China.

2. Methodology

2.1. Optimization

2.1.1. Objective Function

2.1.2. Equipment Constraints

2.2. Comprehensive Assessment Framework

2.2.1. Economic Indicators

2.2.2. Energy Indicators

2.2.3. Environmental Indicators

3. Case Study

Parameters Setting and Optimization

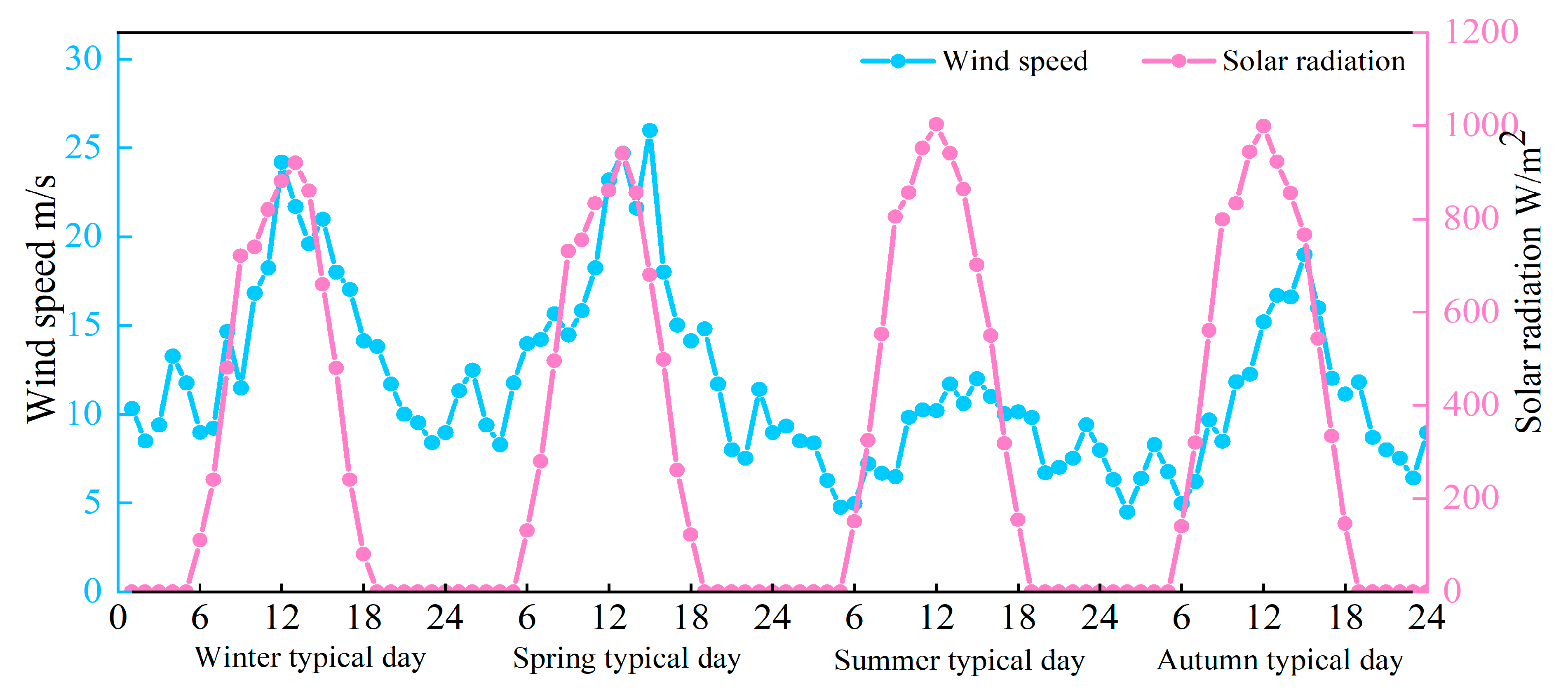

- Using the user load requirements for four representative days to represent the annual user load demand helps reduce the optimization dimension of the established model, i.e., the number of decision variables;

- The efficiency of the equipment remains constant, and the output of each device remains constant within an optimization time frame to ensure the solution speed and accuracy of the optimization model.

4. Experimental Results and Discussion

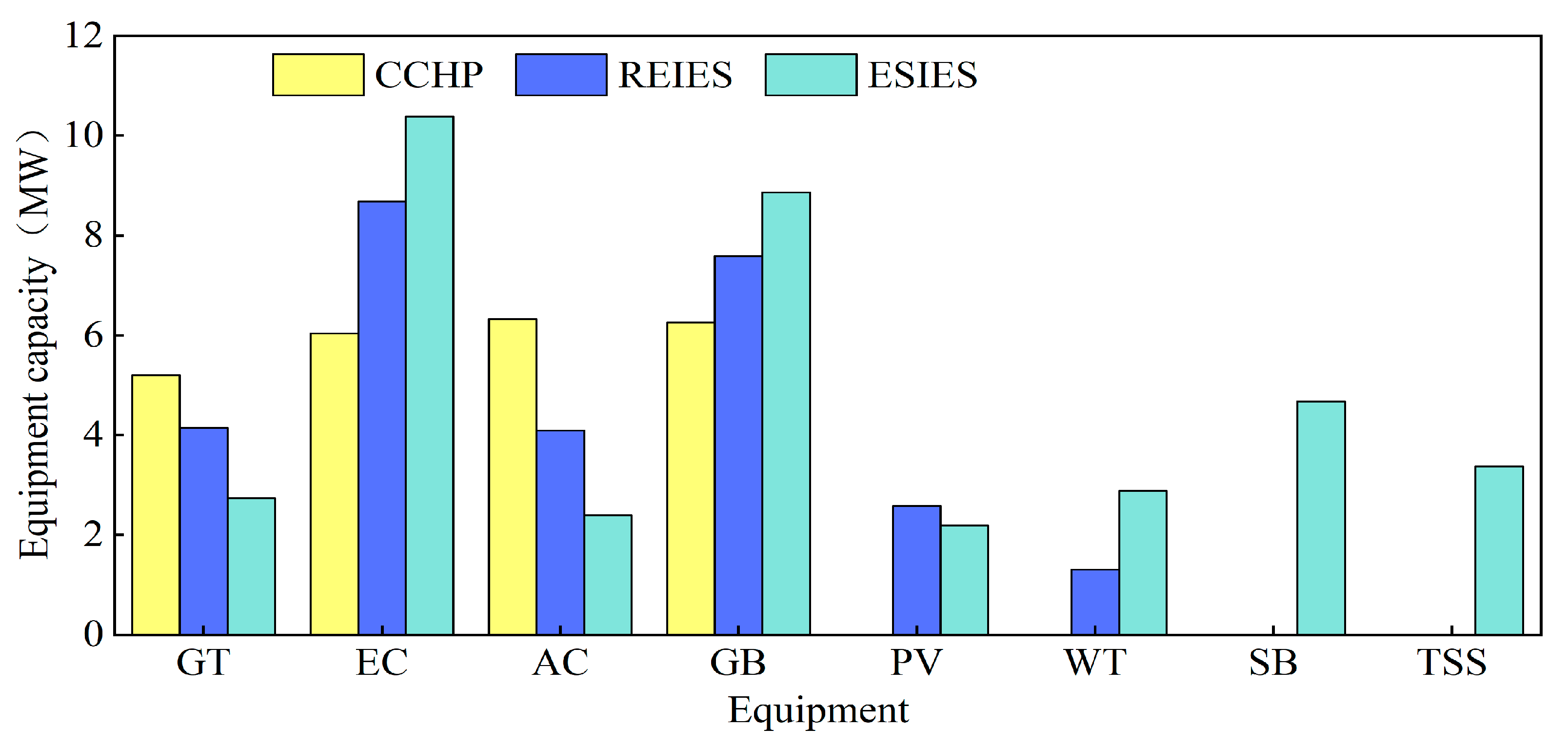

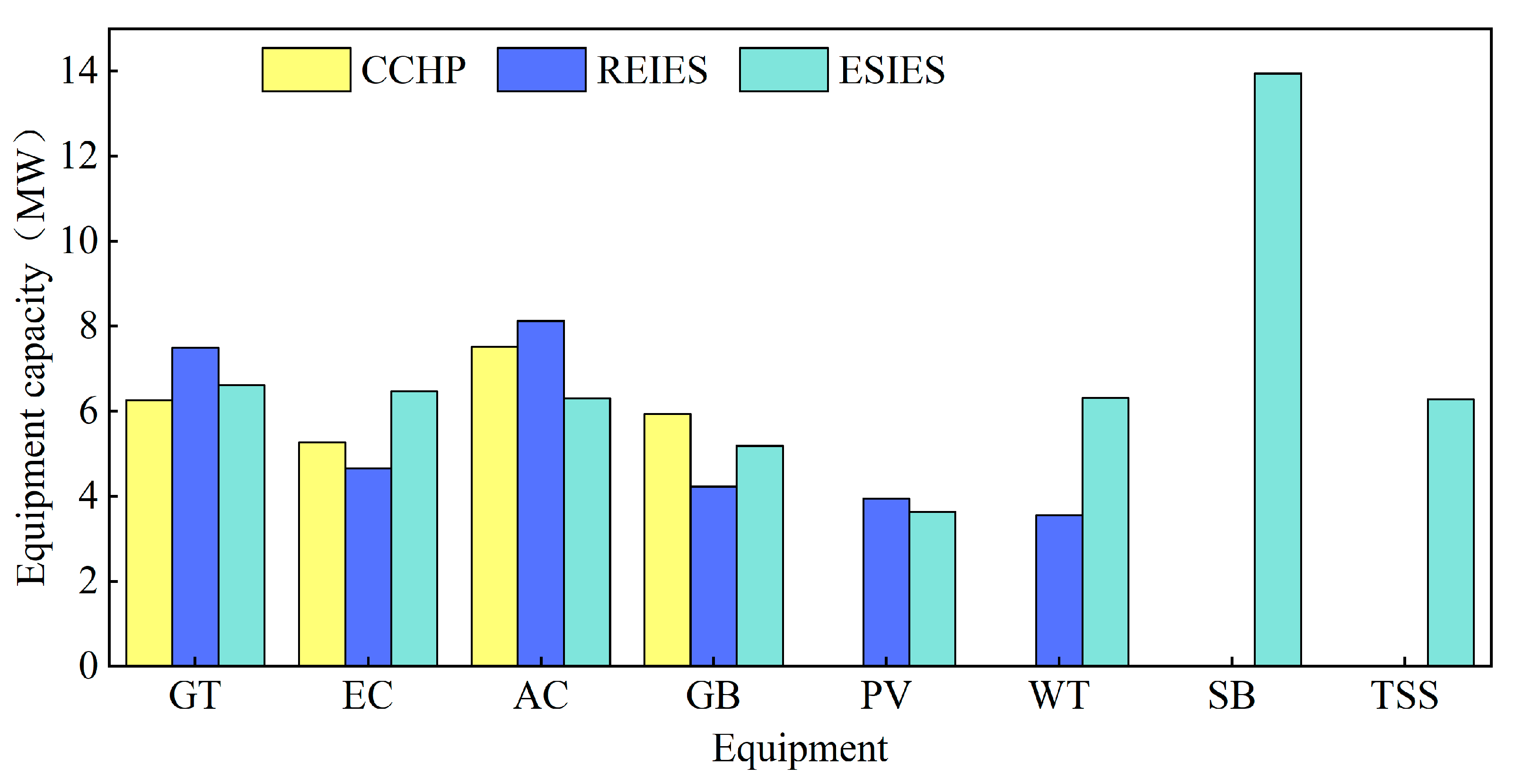

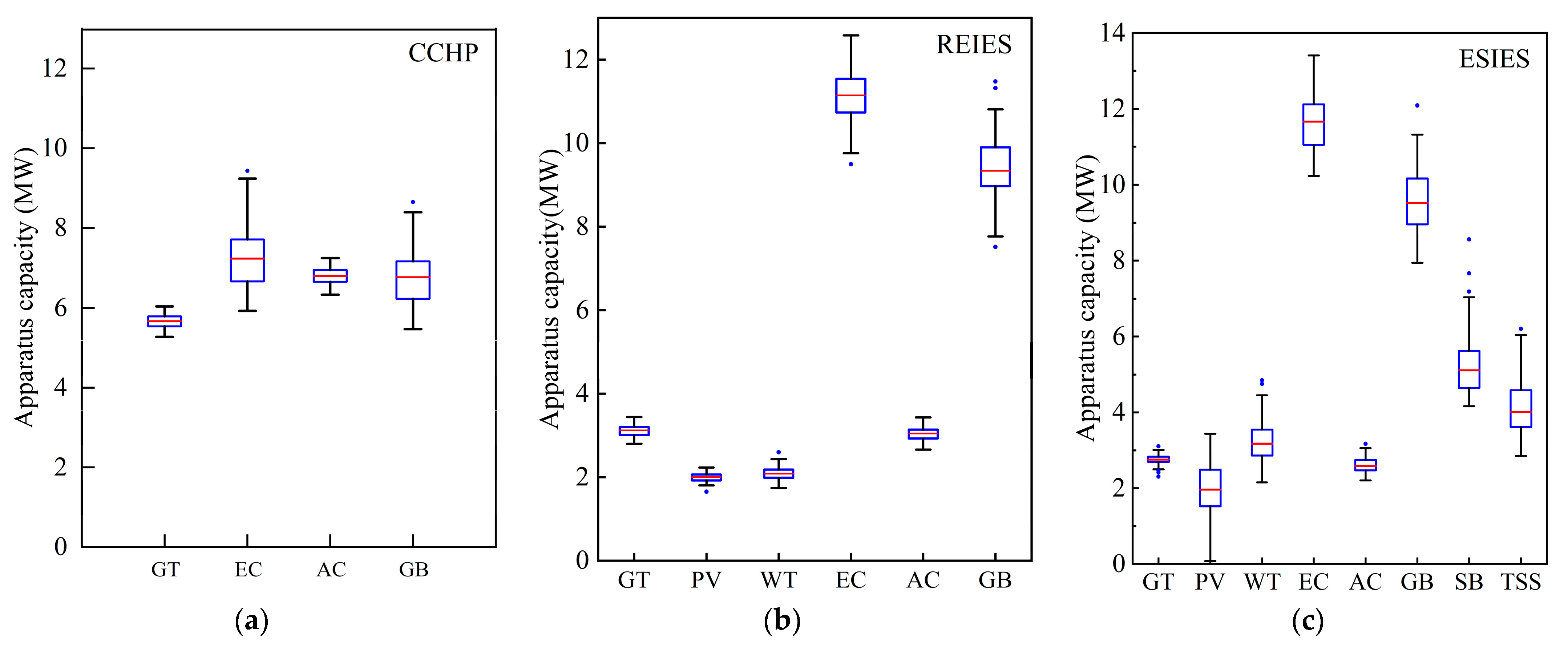

4.1. Optimal Device Capacity of the System

4.2. Research on Key Parameters

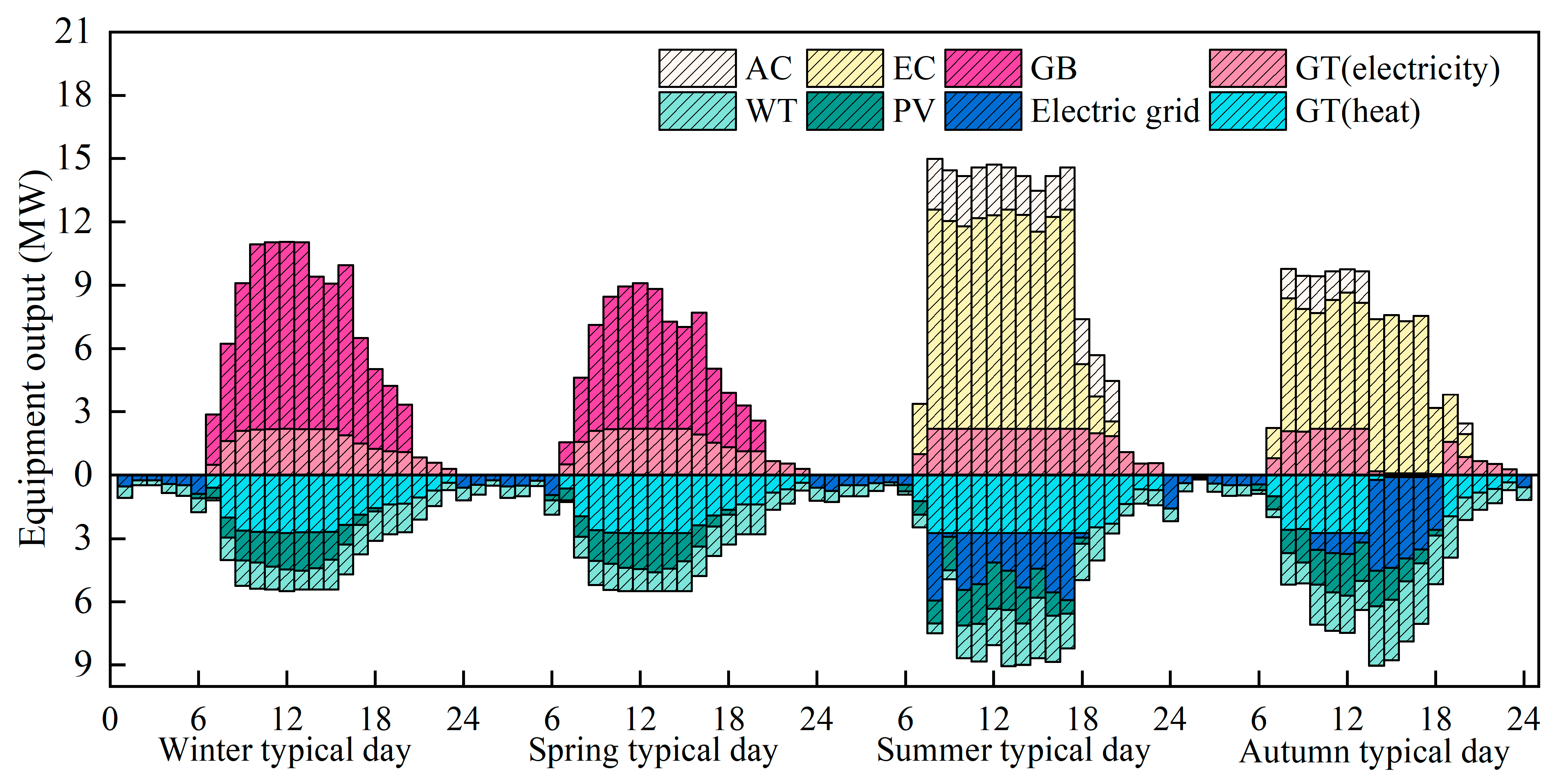

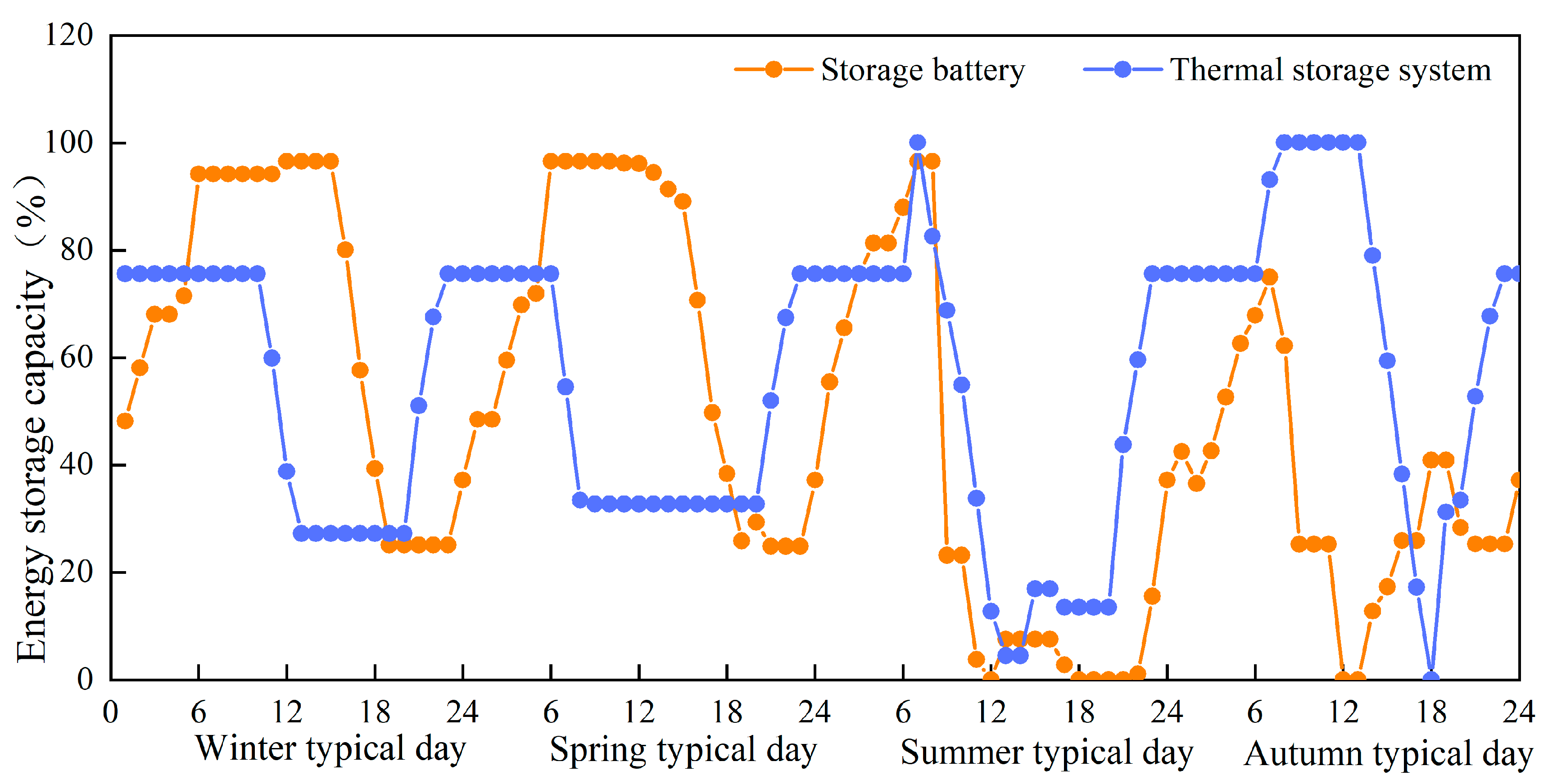

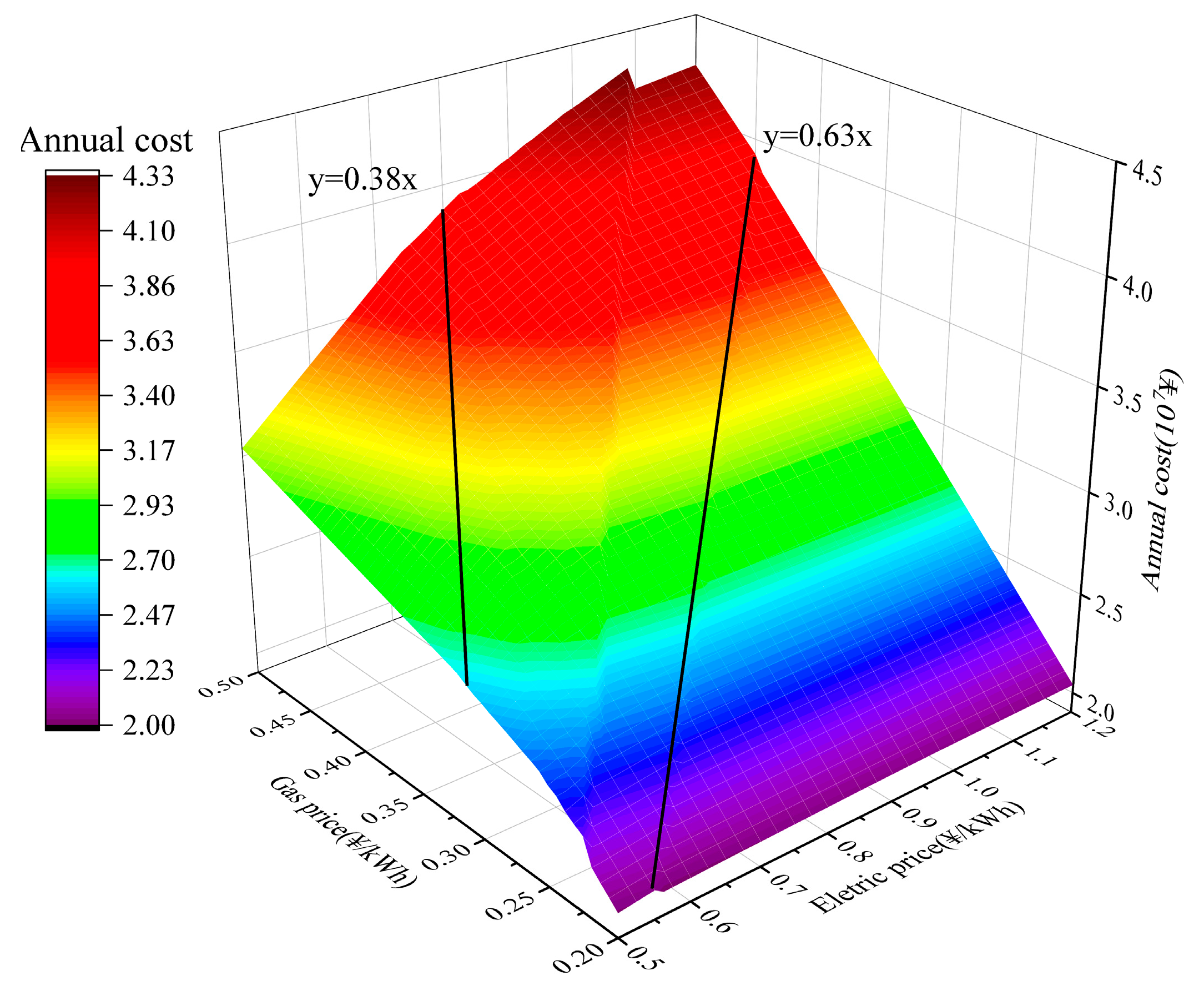

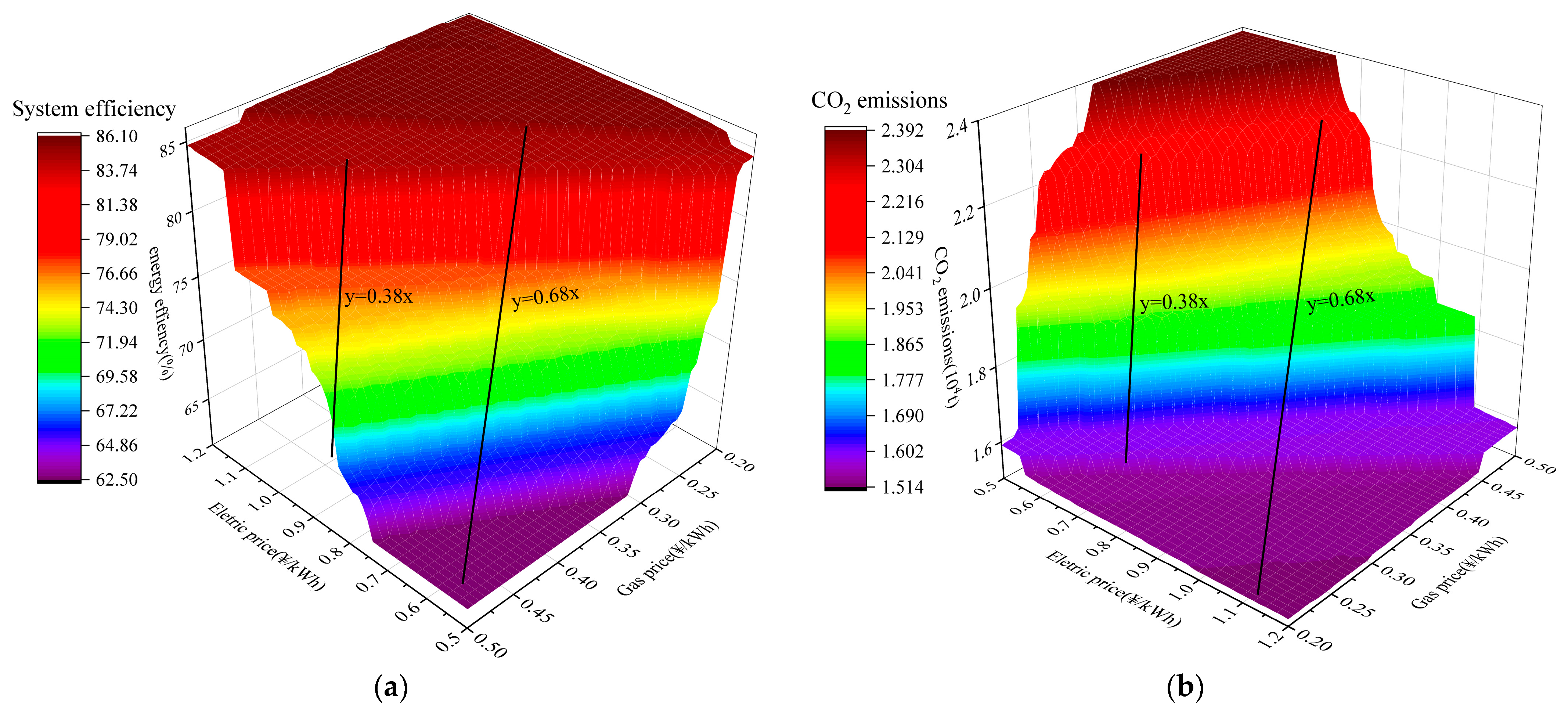

4.2.1. Impact of Energy Prices on System Operation

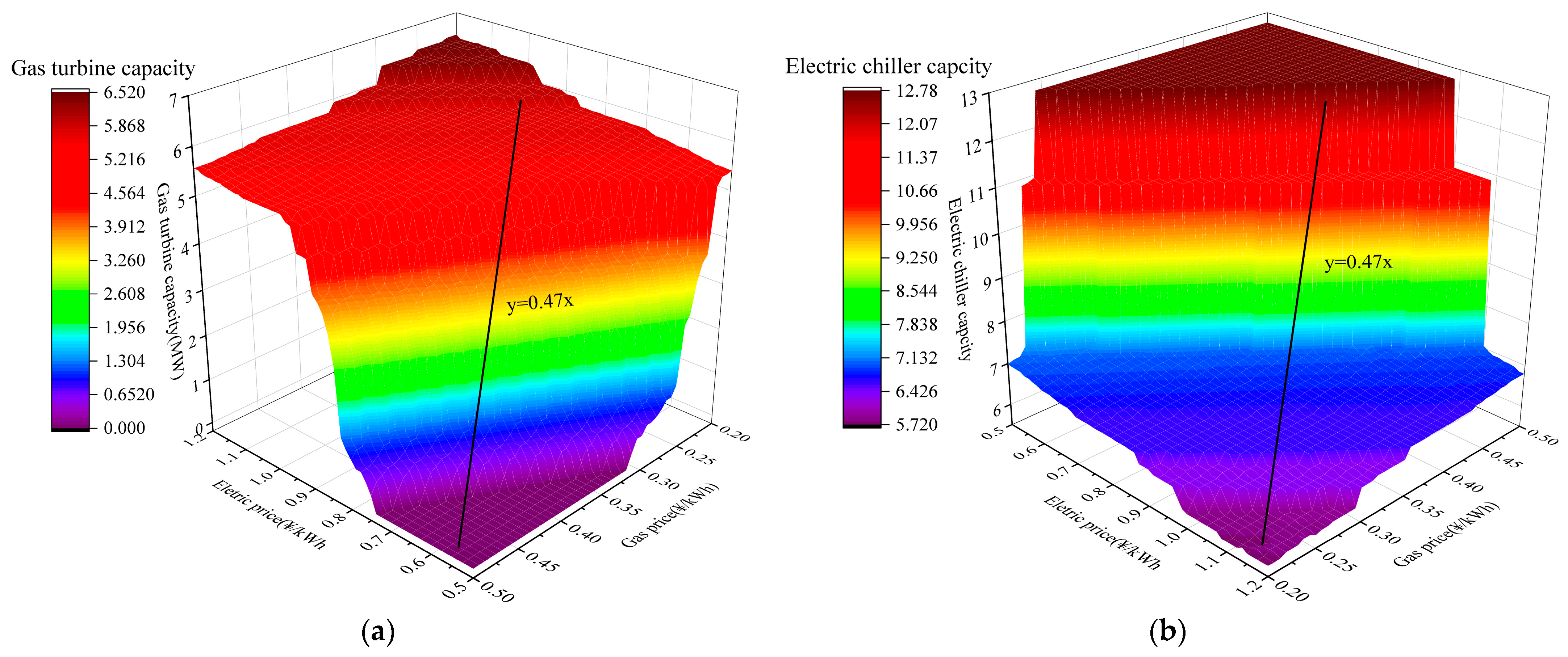

4.2.2. Impact of Energy Prices on Capacity of Equipment

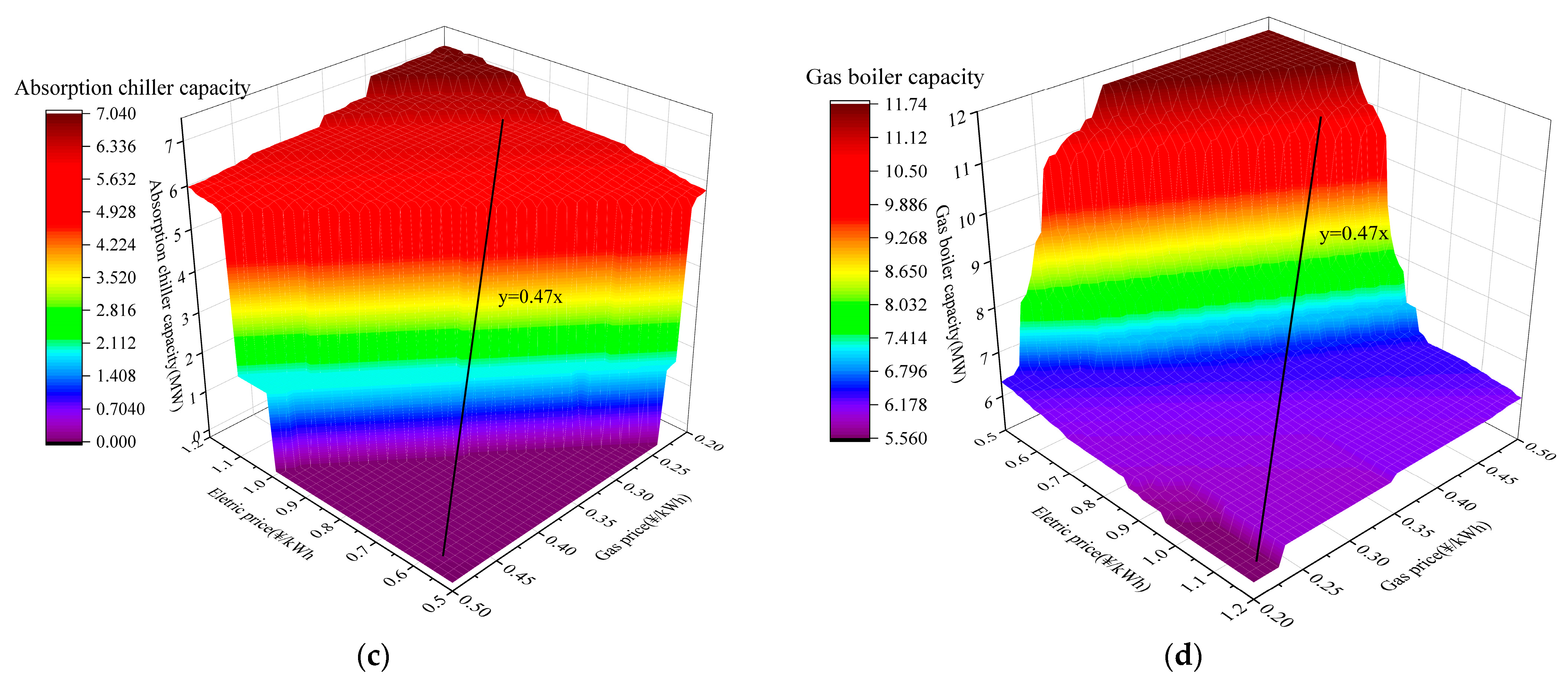

4.2.3. Impact of Feed-in Tariffs on System Operation

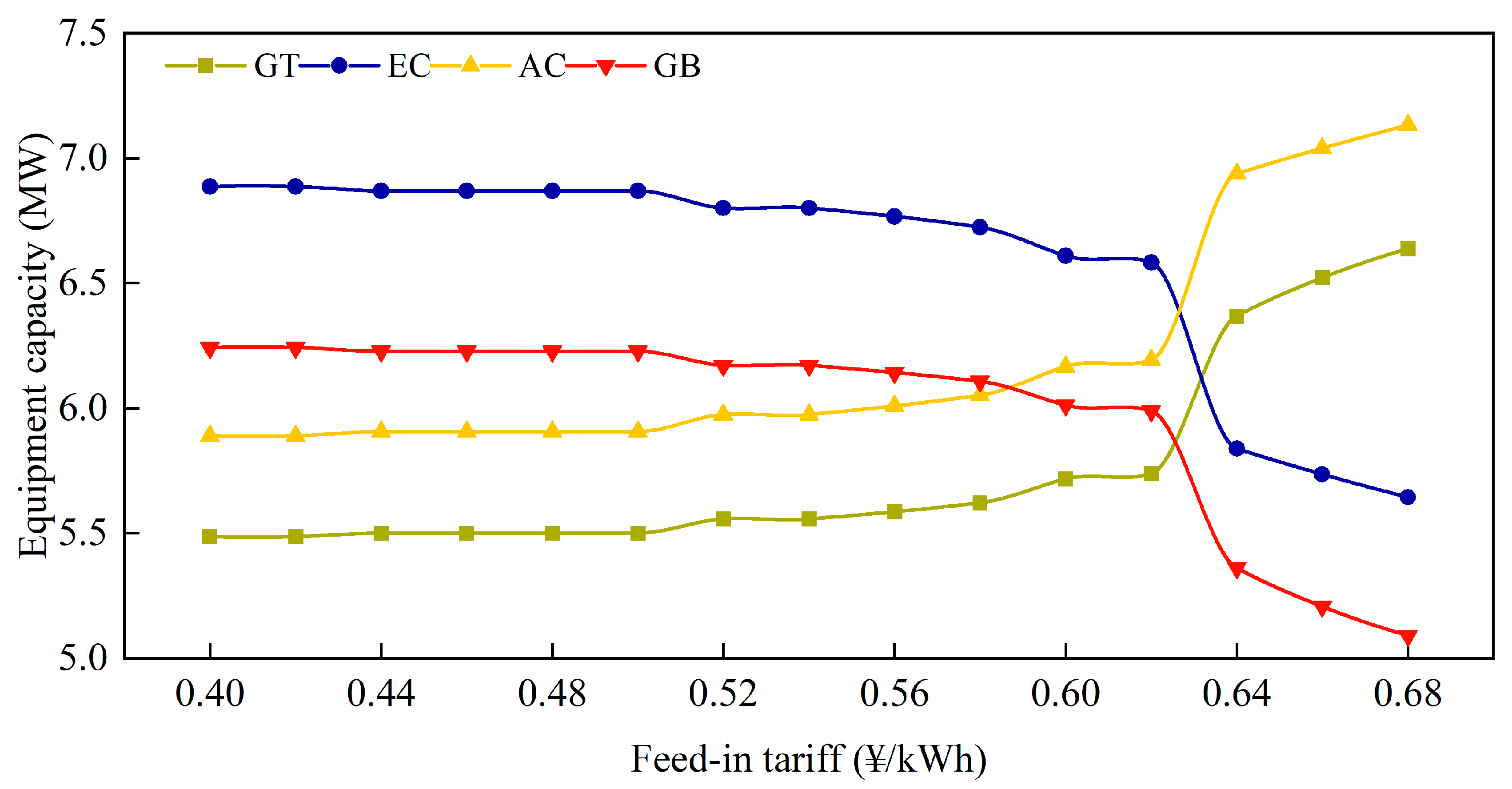

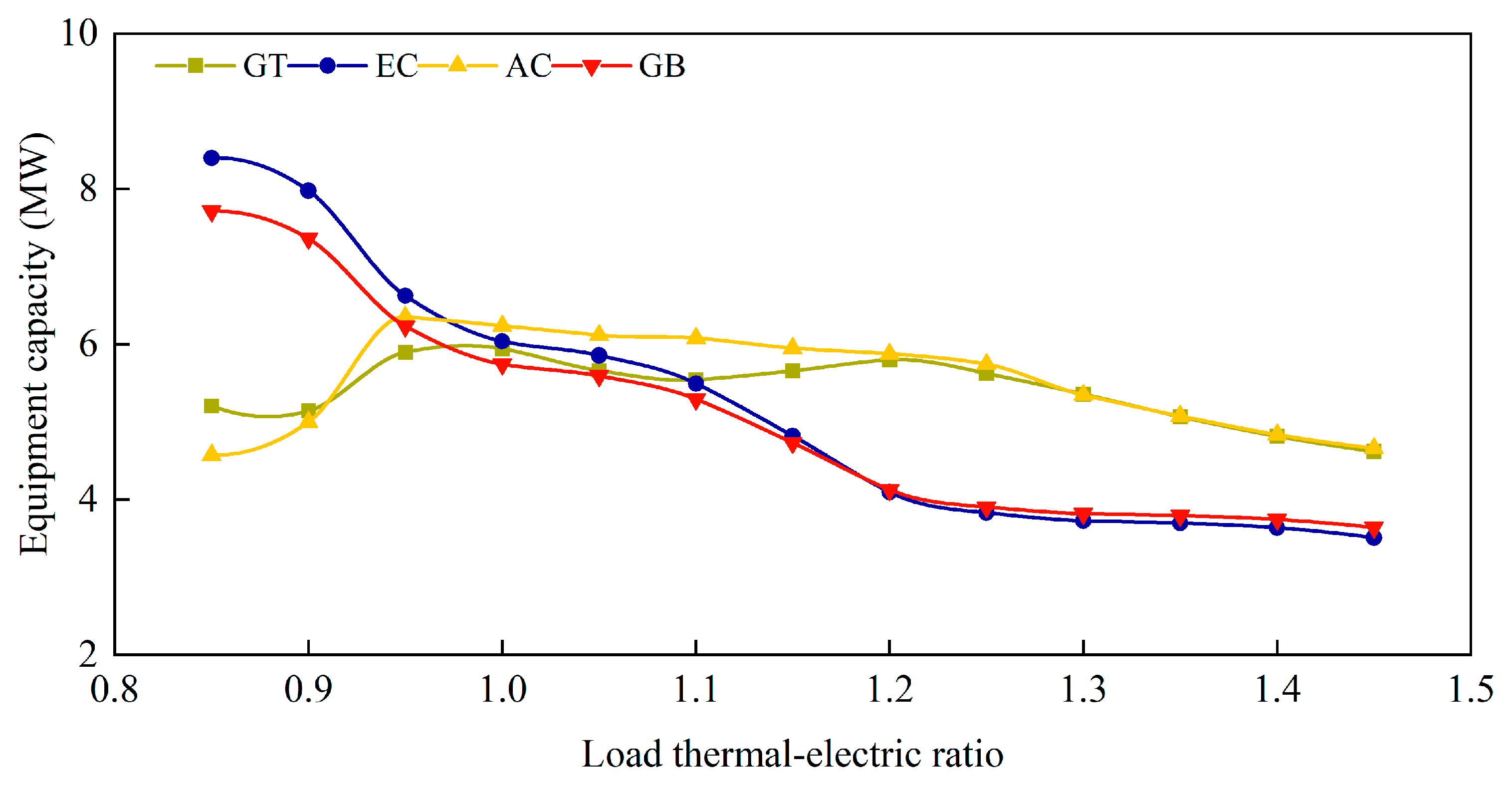

4.2.4. Impact of Thermoelectric Ratios on System Operation

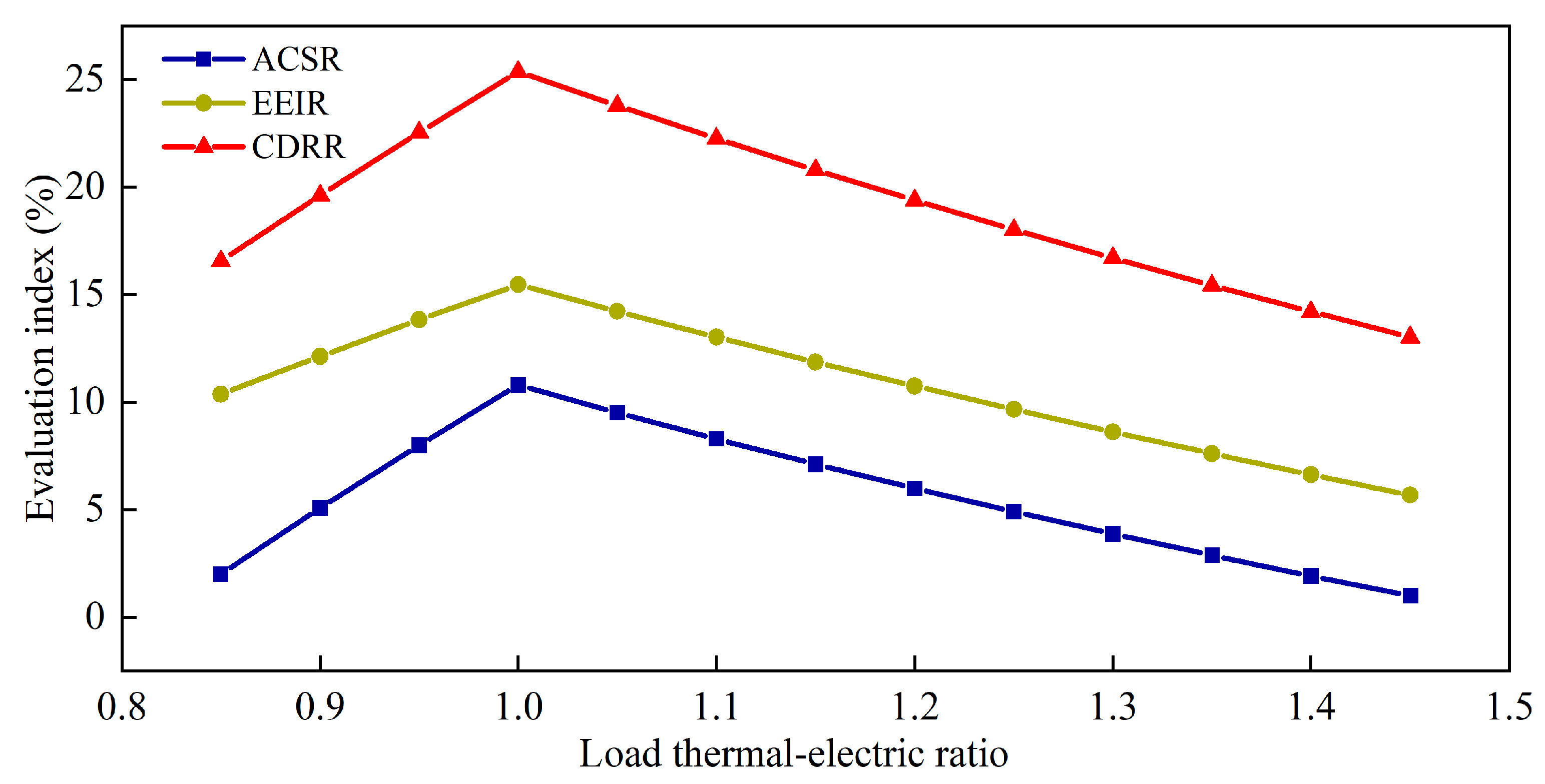

4.2.5. Impact of Renewable Energy Uncertainty on System Operation

User Load Probability Model

Monte Carlo Simulation

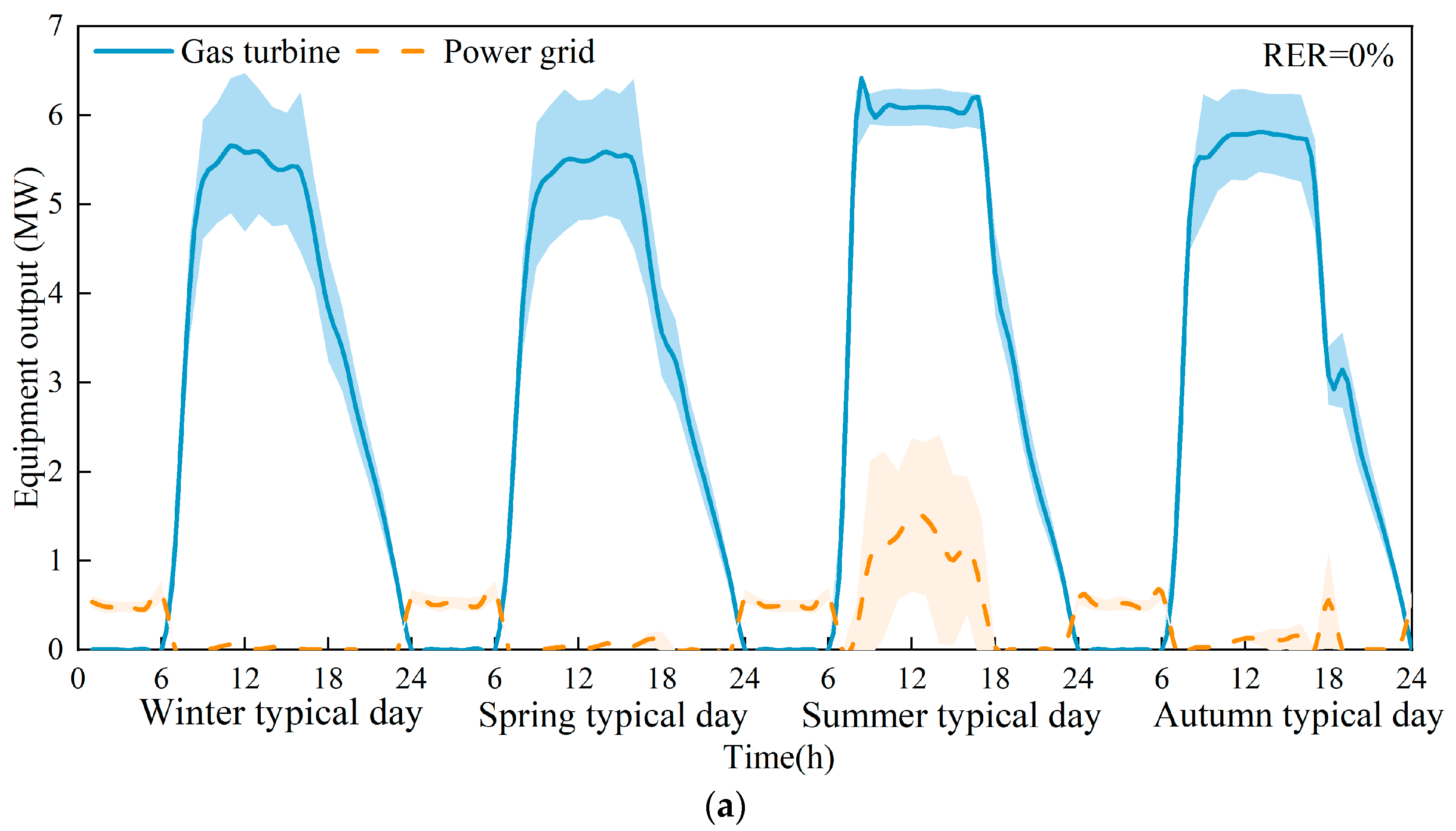

Penetration Rate of Renewable Energy

5. Conclusions

- Based on the simulation results, it is found that the promotion or constraint relationship between renewable energy supply and energy cascade utilization depends on the relative sizes of the user’s load thermal–electric ratio and the prime mover’s thermal–electric ratio. Specifically, when the user’s load thermal–electric ratio is greater than the prime mover’s thermal–electric ratio, renewable energy and energy storage devices reduce the capacity of the cogeneration unit, leading to a constrained relationship between renewable energy supply and energy cascade utilization. Conversely, it exhibits a promotion relationship.

- The two metrics, carbon dioxide emissions, and system efficiency, are sensitive to natural gas and electricity prices. Therefore, reasonably setting natural gas and electricity prices can help improve the benefits of the system. When the electricity price exceeds 2.63 times the gas price, the increase in electricity price has almost no significant impact on the system’s cost. Similarly, when the gas price surpasses 0.63 times the electricity price, the rise in gas price contributes only marginally to the system’s cost escalation. Therefore, in the design of energy systems, careful attention should be paid to the relative levels of electricity and natural gas prices to avoid negative impacts on the system due to energy price fluctuations and to enhance system performance.

- Equipment capacity is not sensitive to electricity, gas, and electricity buyback price fluctuations. Therefore, when designing system capacity, there is no need to pay too much attention to changes in energy prices. Regardless of price fluctuations in electricity and natural gas, the equipment capacity for gas boilers and electric chillers stays at a minimum of approximately 6MW. Consequently, when energy prices fluctuate, the impact on operational strategy design is more significant than capacity design.

- The uncertainty of renewable energy poses more significant challenges for the design of REIES systems. To cope with the negative impact of source-load uncertainty on the stable operation of the IES, the capacities of the electric chiller and absorption chiller should be increased by 4.0% and 5.8%, respectively. It is worth noting that the increase in the RER has not changed the system’s dependence on the grid.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bp B P. Statistical Review of World Energy 2022. 2023. Available online: https://www.energyinst.org/statistical-review (accessed on 5 August 2023).

- Action Plan for Carbon Dioxide Peaking before 2030. 2021. Available online: https://www.gov.cn/zhengce/zhengceku/2021-10/26/content_5644984.htm (accessed on 6 August 2023).

- Mehmood, A.; Ren, J.; Zhang, L. Achieving energy sustainability by using solar PV: System modelling and comprehensive techno-economic-environmental analysis. Energy Strategy Rev. 2023, 49, 101126. [Google Scholar] [CrossRef]

- Wu, J.; Wang, R.; Pu, G.; Qi, H. Integrated assessment of exergy, energy and carbon dioxide emissions in an iron and steel industrial network. Appl. Energy 2016, 183, 430–444. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Jia, H.J.; Wang, W.L.; Zhi, Y.Q.; Meng, Z.J.; Zhou, B.Y. Review of Key Problems Related to Integrated Energy Distribution Systems. CSEE J. Power Energy Syst. 2018, 4, 130–145. [Google Scholar] [CrossRef]

- Lin, Y.L.; Bie, Z.H. Study on the Resilience of the Integrated Energy System. Energy Procedia 2016, 103, 171–176. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.L.; Li, G.Q.; Wang, J.L.; Zhao, D.B.; Chen, C. Improving operational flexibility of integrated energy system with uncertain renewable generations considering thermal inertia of buildings. Energy Convers. Manag. 2020, 207, 15. [Google Scholar] [CrossRef]

- Herrando, M.; Wang, K.; Huang, G.; Otanicar, T.; Mousa, O.B.; Agathokleous, R.A.; Ding, Y.; Kalogirou, S.; Ekins-Daukes, N.; Taylor, R.A.; et al. A review of solar hybrid photovoltaic-thermal (PV-T) collectors and systems. Prog. Energy Combust. Sci. 2023, 97, 101072. [Google Scholar] [CrossRef]

- Yang, G.; Zhai, X.Q. Optimal design and performance analysis of solar hybrid CCHP system considering influence of building type and climate condition. Energy 2019, 174, 647–663. [Google Scholar] [CrossRef]

- Hanafizadeh, P.; Eshraghi, J.; Ahmadi, P.; Sattari, A. Evaluation and sizing of a CCHP system for a commercial and office buildings. J. Build. Eng. 2016, 5, 67–78. [Google Scholar] [CrossRef]

- Bazdar, E.; Sameti, M.; Nasiri, F.; Haghighat, F. Compressed air energy storage in integrated energy systems: A review. Renew. Sustain. Energy Rev. 2022, 167, 112701. [Google Scholar] [CrossRef]

- Sanaye, S.; Khakpaay, N. Simultaneous use of MRM (maximum rectangle method) and optimization methods in determining nominal capacity of gas engines in CCHP (combined cooling, heating and power) systems. Energy 2014, 72, 145–158. [Google Scholar] [CrossRef]

- Wang, J.; Xue, K.; Guo, Y.; Ma, J.; Zhou, X.; Liu, M.; Yan, J. Multi-objective capacity programming and operation optimization of an integrated energy system considering hydrogen energy storage for collective energy communities. Energy Convers. Manag. 2022, 268, 116057. [Google Scholar] [CrossRef]

- Cao, T.; Hwang, Y.H.; Radermacher, R. Development of an optimization based design framework for microgrid energy systems. Energy 2017, 140, 340–351. [Google Scholar] [CrossRef]

- Cao, T.; Lee, H.; Hwang, Y.; Radermacher, R.; Chun, H.H. Modeling of waste heat powered energy system for container ships. Energy 2016, 106, 408–421. [Google Scholar] [CrossRef]

- Cao, T.; Lee, H.; Hwang, Y.H.; Radermacher, R.; Chun, H.H. Performance investigation of engine waste heat powered absorption cycle cooling system for shipboard applications. Appl. Therm. Eng. 2015, 90, 820–830. [Google Scholar] [CrossRef]

- Deymi-Dashtebayaz, M.; Baranov, I.V.; Nikitin, A.; Davoodi, V.; Sulin, A.; Norani, M.; Nikitina, V. An investigation of a hybrid wind-solar integrated energy system with heat and power energy storage system in a near-zero energy building-A dynamic study. Energy Convers. Manag. 2022, 269, 16. [Google Scholar] [CrossRef]

- Luo, X.; Zhu, Y.; Liu, J.P.; Liu, Y.F. Design and analysis of a combined desalination and standalone CCHP (combined cooling heating and power) system integrating solar energy based on a bi-level optimization model. Sustain. Cities Soc. 2018, 43, 166–175. [Google Scholar] [CrossRef]

- Jian, W.; Yuan, R. Design and Optimization on Building Distributed Energy System; Tongji University: Shanghai, China, 2018. [Google Scholar]

- Feng, L.J.; Dai, X.Y.; Mo, J.R.; Shi, L. Performance assessment of CCHP systems with different cooling supply modes and operation strategies. Energy Convers. Manag. 2019, 192, 188–201. [Google Scholar] [CrossRef]

- Hawkes, A.D.; Leach, M.A. Modelling high level system design and unit commitment for a microgrid. Appl. Energy 2009, 86, 1253–1265. [Google Scholar] [CrossRef]

- Liu, Z.M.; Lim, M.Q.; Kraft, M.; Wang, X.N. Simultaneous design and operation optimization of renewable combined cooling heating and power systems. AIChE J. 2020, 66, 18. [Google Scholar] [CrossRef]

- Wu, X.; Liao, B.; Su, Y.; Li, S. Multi-objective and multi-algorithm operation optimization of integrated energy system considering ground source energy and solar energy. Int. J. Electr. Power Energy Syst. 2023, 144, 108529. [Google Scholar] [CrossRef]

- Habte, A.; Sengupta, M.; Lopez, A.; Xie, Y.; Maclaurin, G. Assessment of the National Solar Radiation Database (NSRDB 1998–2016). In Proceedings of the 7th IEEE World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 10–15 June 2018; pp. 2305–2308. [Google Scholar]

- Fan, H.; Wang, C.; Liu, L.; Li, X. Review of Uncertainty Modeling for Optimal Operation of Integrated Energy System. Front. Energy Res. 2022, 9, 641337. [Google Scholar] [CrossRef]

- Bacekovic, I.; Ostergaard, P.A. A smart energy system approach vs a non-integrated renewable energy system approach to designing a future energy system in Zagreb. Energy 2018, 155, 824–837. [Google Scholar] [CrossRef]

- Ghosh, S.; Dincer, I. Development and analysis of a new integrated solar-wind-geothermal energy system. Sol. Energy 2014, 107, 728–745. [Google Scholar] [CrossRef]

- Carpaneto, E.; Chicco, G.; Mancarella, P.; Russo, A. Cogeneration planning under uncertainty Part I: Multiple time frame approach. Appl. Energy 2011, 88, 1059–1067. [Google Scholar] [CrossRef]

- Deng, Y.; Zeng, R.; Liu, Y.C. A novel off-design model to optimize combined cooling, heating and power system with hybrid chillers for different operation strategies. Energy 2022, 239, 20. [Google Scholar] [CrossRef]

- Afzali, S.F.; Mahalec, V. Optimal design, operation and analytical criteria for determining optimal operating modes of a CCHP with fired HRSG, boiler, electric chiller and absorption chiller. Energy 2017, 139, 1052–1065. [Google Scholar] [CrossRef]

- Lin, H.S.; Yang, C.Z.; Xu, X.Q. A new optimization model of CCHP system based on genetic algorithm. Sustain. Cities Soc. 2020, 52, 10. [Google Scholar] [CrossRef]

- Song, Z.H.; Liu, T.; Liu, Y.J.; Jiang, X.D.; Lin, Q.Z. Study on the optimization and sensitivity analysis of CCHP systems for industrial park facilities. Int. J. Electr. Power Energy Syst. 2020, 120, 12. [Google Scholar] [CrossRef]

- Kotzur, L.; Markewitz, P.; Robinius, M.; Stolten, D. Time series aggregation for energy system design: Modeling seasonal storage. Appl. Energy 2018, 213, 123–135. [Google Scholar] [CrossRef]

- Poncelet, K.; Höschle, H.; Delarue, E.; Virag, A.; D’haeseleer, W. Selecting representative days for capturing the implications of integrating intermittent renewables in generation expansion planning problems. IEEE Trans. Power Syst. 2016, 32, 1936–1948. [Google Scholar] [CrossRef]

- Hassan, M.A.; Khalil, A.; Abubakr, M. Selection methodology of representative meteorological days for assessment of renewable energy systems. Renew. Energy 2021, 177, 34–51. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, M.L.; Wang, P.H.; Gu, J.Q.; Zheng, W.D.; Dong, Y.H. Bi-stage stochastic model for optimal capacity and electric cooling ratio of CCHPs—A case study for a hotel. Energy Build. 2019, 194, 113–122. [Google Scholar] [CrossRef]

- Hu, M.Q.; Cho, H.J. A probability constrained multi-objective optimization model for CCHP system operation decision support. Appl. Energy 2014, 116, 230–242. [Google Scholar] [CrossRef]

- Qin, C.K.; Tang, J.X.; Zhang, Y. An efficient algorithm for CCHP system sizing and an operational optimization model based on LP. J. Nat. Gas Sci. Eng. 2015, 25, 189–196. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Q.F.; Wang, Z.J.; Jermsittiparsert, K.; Shafiee, M. A new optimized configuration for capacity and operation improvement of CCHP system based on developed owl search algorithm. Energy Rep. 2020, 6, 315–324. [Google Scholar] [CrossRef]

- China Society for Hydropower Engineering. Discussion on Carbon Emission Intensity in Power Generation Industry during the 13th Five-Year Plan Period. 2017. Available online: http://www.hydropower.org.cn/showNewsDetail.asp?nsId=20181 (accessed on 6 August 2023).

- Jiang, J.M.; Gao, W.J.; Wei, X.D.; Li, Y.X.; Kuroki, S. Reliability and cost analysis of the redundant design of a combined cooling, heating and power (CCHP) system. Energy Convers. Manag. 2019, 199, 13. [Google Scholar] [CrossRef]

- Ahn, H.; Rim, D.; Pavlak, G.S.; Freihaut, J.D. Uncertainty analysis of energy and economic performances of hybrid solar photovoltaic and combined cooling, heating, and power (CCHP + PV) systems using a Monte-Carlo method. Appl. Energy 2019, 255, 113753. [Google Scholar] [CrossRef]

- Sanjari, M.J.; Gooi, H.B.; Nair, N.-K.C. Power generation forecast of hybrid PV–wind system. IEEE Trans. Sustain. Energy 2019, 11, 703–712. [Google Scholar] [CrossRef]

- Huang, C.; Ding, Q.; Qian, G.; Chen, X.; Chen, X. Robust Planning Method for Integrated Energy Systems with the Consideration of multiple energy uncertainties. In Proceedings of the 2020 IEEE Sustainable Power and Energy Conference (iSPEC), Chengdu, China, 23–25 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1499–1504. [Google Scholar]

| Scenarios | Model | Advantage | Outlook |

|---|---|---|---|

| Residential building [12] | Maximum rectangle method (MRM) | This paper explores the benefits of using a hybrid-CCHP system instead of a basic-CCHP system. The solar collector orientation and type is optimized. | Choosing the best solar strategy to design a collector. |

| Energy community [13] | MRM, Particle Swarm Optimization (PSO) | The study combines hydrogen energy and thermal energy storage to streamline device configuration | The analysis of detailed thermodynamic energy flow. |

| Sea island [14,15,16] | Traversing method Branch-and-bound method | The study offered valuable insights into the integration of desalination with the CCHP system. | Multi-objective method is used to solve the conflict problem |

| Commercial region [18] | Mixed-integer linear programming model (MILP) | This project employs consistent energy demands and average seasonal weather conditions for IES design. | Focus on uncertainties in renewable energy sources and energy demands. |

| Zagreb [26] | EnergyPLAN (simulation study) | This article compares two approaches to achieve a 100% renewable energy system in a city: traditional and smart systems. | Impact of some primary factors on intermittent renewable energy production. |

| Hotel building [31] | Moth Flame Optimization algorithm | It provides a reference for the study of equipment operating under off-design performance conditions in IES. | The impact of key parameter settings on system and equipment performance. |

| Central business district [33] | Multi-objective genetic algorithm | Proposes a new CCHP system model that segments operating conditions and integrates the part-load performance of power generation unit. | Energy storage devices can be added to the energy system. |

| Industrial Park [34] | GA | Proposes an integrated method to optimize configuration and strategy of CCHP systems. | The study needs to incorporate multi-objective optimization thoroughly. |

| Item | Type | Parameter |

|---|---|---|

| electrical efficiency of gas turbine (%) | 0.35 | |

| thermal efficiency of boiler (%) | 0.85 | |

| refrigeration coefficient of absorption refrigerator | 1.2 | |

| refrigeration coefficient of electric refrigerator | 4.8 | |

| waste heat recovery rate of gas turbine [39] | 0.8 | |

| cut-in wind speed (m/s) | 3 | |

| cut-out wind speed (m/s) | 20 | |

| rated wind speed (m/s) | 10 | |

| rated solar radiation intensity (Ix) | 1000 | |

| electrical efficiency of power plant | 0.40 | |

| transmission efficiency of electric grid [39] | 0.92 | |

| emission factor—natural gas (g/kWh) [40] | 220 | |

| emission factor—power plant (g/kWh) [41] | 600 | |

| ambient temperature (K) | 273.15 |

| Item | Type | Parameter |

|---|---|---|

| Designed life of system (Year) | y | 20 |

| Annual interest rate (%) | i | 4.2 |

| Initial cost per unit capacity of gas turbine (CNY/kW) | 6500 | |

| Initial cost per unit capacity of absorption refrigerator (CNY/kW) | 1200 | |

| Initial cost per unit capacity of electric refrigerator (CNY/kW) | 1000 | |

| Initial cost per unit capacity of boiler (CNY/kW) | 900 | |

| Initial cost per unit capacity of photovoltaics system (CNY/kW) | 5000 | |

| Initial cost per unit capacity of wind turbine (CNY/kW) | 8000 | |

| Initial cost per unit capacity of storage battery (CNY/kWh) | 6000 | |

| Initial cost per unit capacity of thermal storage system (CNY/kWh) | 6000 | |

| Unit output maintenance cost of gas turbine (CNY/kWh) | 0.025 | |

| Unit output maintenance cost of absorption refrigerator (CNY/kWh) | 0.015 | |

| Unit output maintenance cost of electric refrigerator (CNY/kWh) | 0.015 | |

| Unit output maintenance cost of boiler (CNY/kWh) | 0.015 | |

| Unit output maintenance cost of photovoltaics system (CNY/kWh) | 0.025 | |

| Unit output maintenance cost of wind turbine (CNY/kWh) | 0.015 | |

| Unit output maintenance cost of storage battery (CNY/kWh) | 0.025 | |

| Unit output maintenance cost of thermal storage system (CNY/kWh) | 0.025 | |

| Gas prices (CNY/kWh) | 0.35 | |

| Purchase price of electricity (CNY/kWh) | 0.85 | |

| Sale price of electricity (CNY/kWh) | 0.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Ji, Y.; Guo, Z.; Yuan, S.; Chen, Y.; Zhang, W. Study of Key Parameters and Uncertainties Based on Integrated Energy Systems Coupled with Renewable Energy Sources. Sustainability 2023, 15, 16266. https://doi.org/10.3390/su152316266

Liu X, Ji Y, Guo Z, Yuan S, Chen Y, Zhang W. Study of Key Parameters and Uncertainties Based on Integrated Energy Systems Coupled with Renewable Energy Sources. Sustainability. 2023; 15(23):16266. https://doi.org/10.3390/su152316266

Chicago/Turabian StyleLiu, Xin, Yuzhang Ji, Ziyang Guo, Shufu Yuan, Yongxu Chen, and Weijun Zhang. 2023. "Study of Key Parameters and Uncertainties Based on Integrated Energy Systems Coupled with Renewable Energy Sources" Sustainability 15, no. 23: 16266. https://doi.org/10.3390/su152316266

APA StyleLiu, X., Ji, Y., Guo, Z., Yuan, S., Chen, Y., & Zhang, W. (2023). Study of Key Parameters and Uncertainties Based on Integrated Energy Systems Coupled with Renewable Energy Sources. Sustainability, 15(23), 16266. https://doi.org/10.3390/su152316266