Green Supplier Assessment and Selection for Sea Cucumber (Apostichopus japonicus) Processing Enterprise: Case Study in China

Abstract

1. Introduction

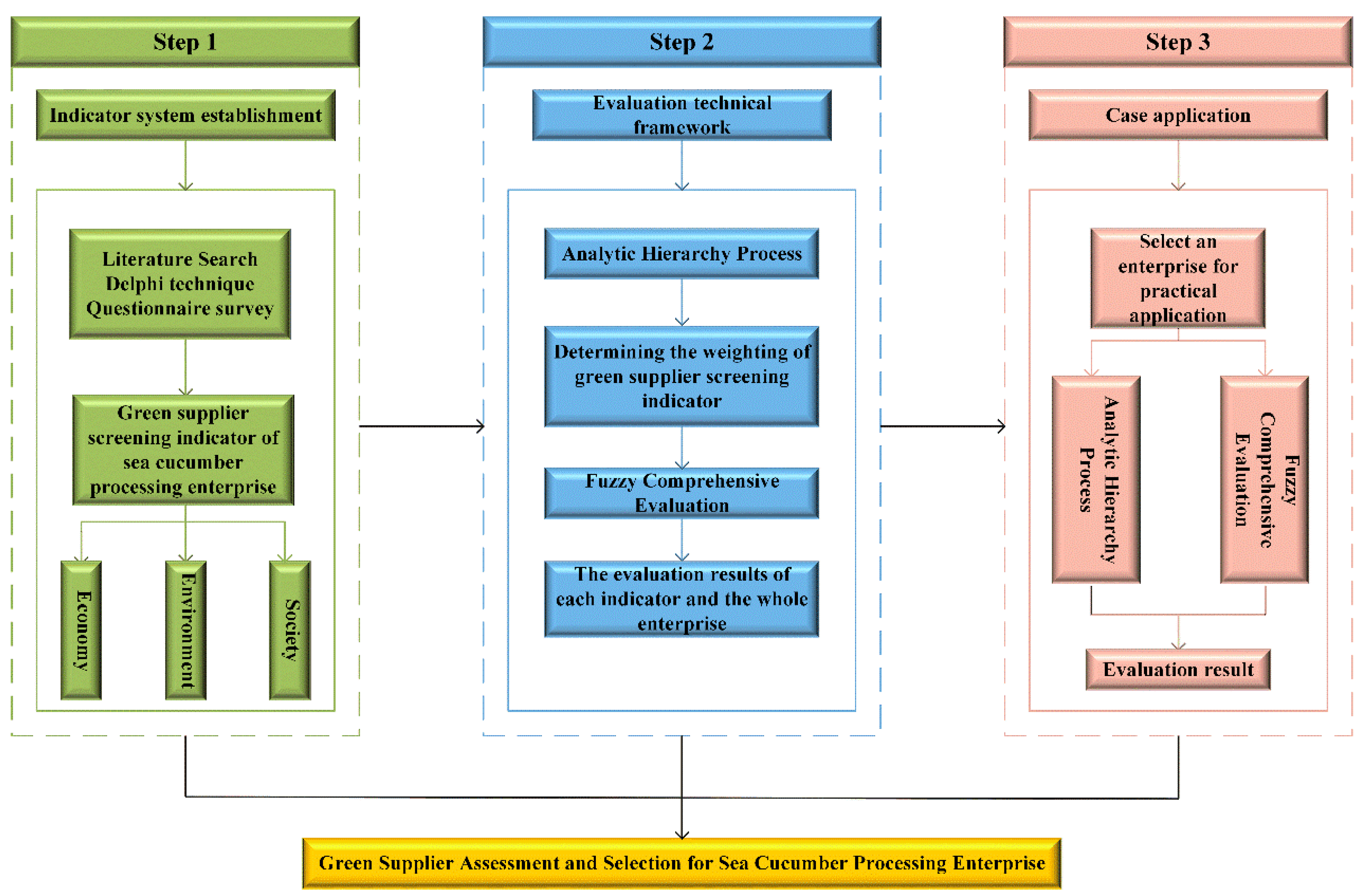

2. Material and Methods

2.1. Determination of the Indicators

2.2. Analytic Hierarchy Process

2.3. Fuzzy Comprehensive Evaluation Method

3. Results

3.1. Case Enterprise Information

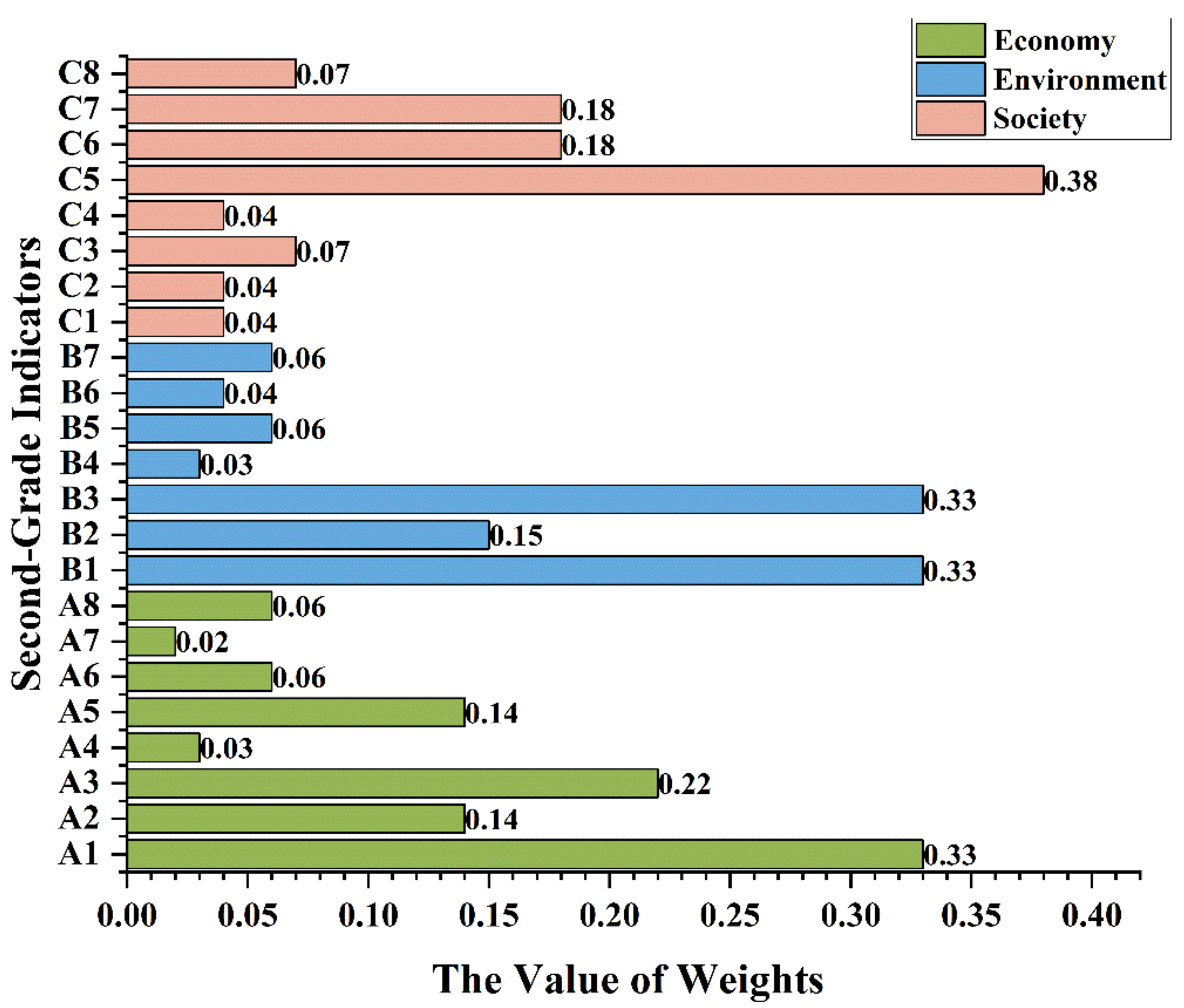

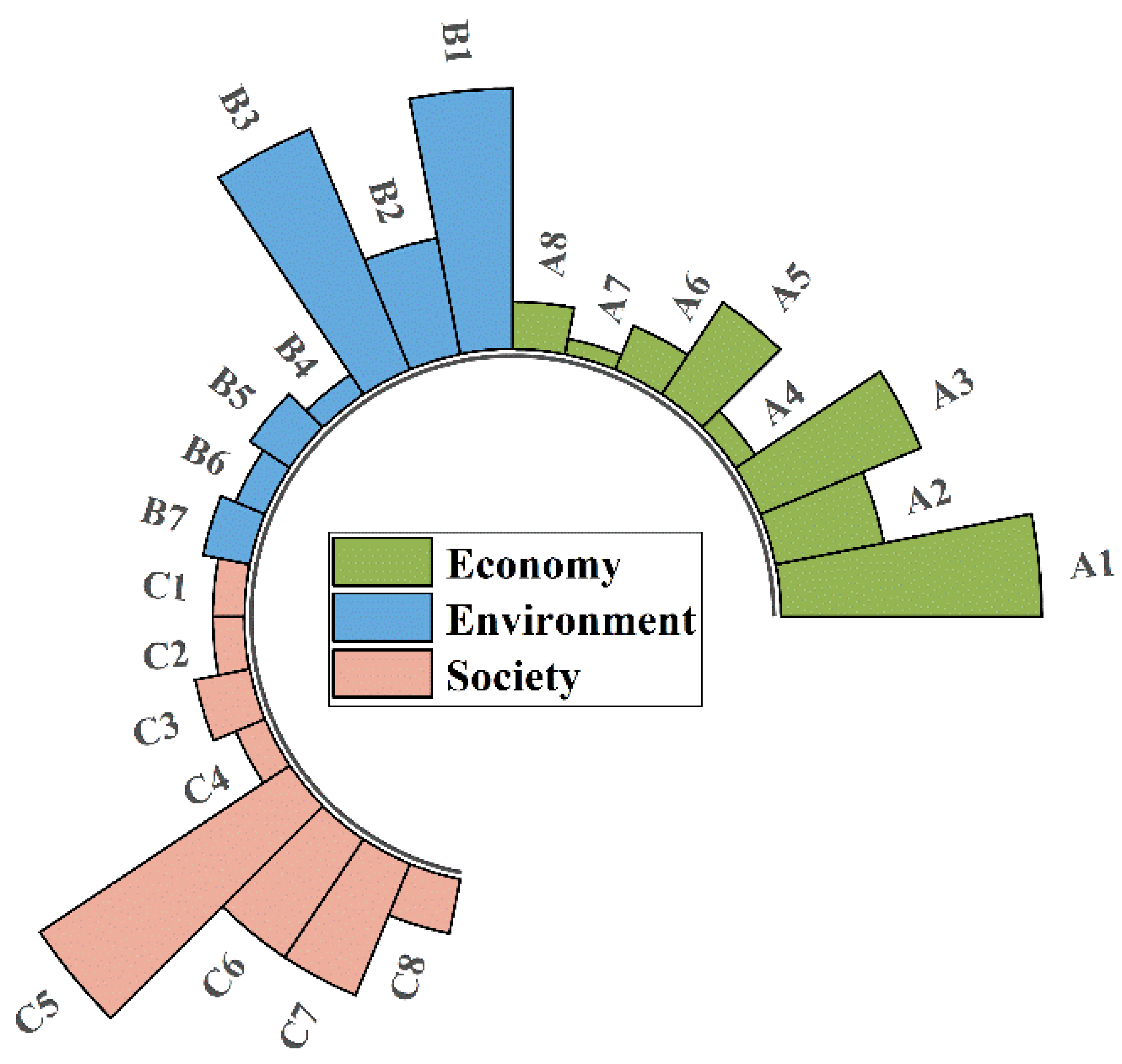

3.2. Weight Calculation Results

3.3. Green Supplier Assessment and Selection Results

4. Discussion

4.1. Key Factor Analysis

4.2. Improvement Measures and Recommendations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ekonomou, S.I.; Boziaris, I.S. Non-Thermal Methods for Ensuring the Microbiological Quality and Safety of Seafood. Appl. Sci. 2021, 11, 833. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, M.; Li, X.; Mujumdar, A. Ultrasonically Enhanced Osmotic Pretreatment of Sea Cucumber Prior to Microwave Freeze Drying. Dry. Technol. 2008, 26, 420–426. [Google Scholar] [CrossRef]

- Liang, Z.X. Exploring Safety Issues and Traceability in the Fish Supply Chain Line. Mod. Agric. Mach. 2022, 1, 103–104. [Google Scholar]

- Tang, Q.; Sun, X.Z. Analysis and Improvement of Supply Chain Inventory Management Strategies in the Aquatic Industry. China Storage Transp. 2021, 7, 173–174. [Google Scholar] [CrossRef]

- Wang, W.P. Study on Depletion Control in Cold Chain Logistics of Fresh Agricultural Products. China J. Commer. 2021, 24, 77–79. [Google Scholar] [CrossRef]

- Wang, D.; Wu, F.X. China Fishery Statistical Yearbook; China Agriculture Press: Beijing, China, 2022. [Google Scholar]

- Xu, X. Study on China’s Virtual Water Trade of Aquatic Products—Measurements, Influencing Factors and Choices of Development Path. Ph.D. Thesis, Shanghai Ocean University, Shanghai, China, 2022. [Google Scholar]

- Webb, L. Green purchasing: Forging a new link in the supply chain. Pulp Pap. Int. 1994, 36, 52–59. [Google Scholar]

- Nguyen, N.B.T.; Lin, G.H.; Dang, T.T. A Two Phase Integrated Fuzzy Decision-Making Framework for Green Supplier Selection in the Coffee Bean Supply Chain. Mathematics 2021, 9, 1923. [Google Scholar] [CrossRef]

- Song, H.H.; Gao, X.X. Green supply chain game model and analysis under revenue-sharing contract. J. Clean. Prod. 2018, 170, 183–192. [Google Scholar] [CrossRef]

- Bai, C.G.; Sarkis, J. Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 2009, 124, 252–264. [Google Scholar] [CrossRef]

- Alshammari, I.; Parimala, M.; Ozel, C.; Riaz, M. Spherical Linear Diophantine Fuzzy TOPSIS Algorithm for Green Supply Chain Management System. J. Funct. Spaces 2022, 2022, 3136462. [Google Scholar] [CrossRef]

- Amarasinghe, U.A.; Hoanh, C.T.; D’haeze, D.; Hung, T.Q. Toward sustainable coffee production in Vietnam: More coffee with less water. Agric. Syst. 2015, 136, 96–105. [Google Scholar] [CrossRef]

- Stević, Ž.; Pamučar, D.; Vasiljević, M.; Stojić, G.; Korica, S. Novel Integrated Multi-Criteria Model for Supplier Selection: Case Study Construction Company. Symmetry 2017, 9, 279. [Google Scholar] [CrossRef]

- Sarwar, A.; Xu, J.P.; Zeng, Z.Q.; Hashim, M. Ahp And Fuzzy Topsis Methods for Green Supplier Selection And Evaluation. Int. J. Adv. Res. 2017, 5, 625–635. [Google Scholar] [CrossRef]

- Tseng, M.L. Green supply chain management with linguistic preferences and incomplete information. Appl. Soft Comput. 2011, 11, 4894–4903. [Google Scholar] [CrossRef]

- Zhu, Q.H.; Feng, Y.T.; Choi, S.B. The role of customer relational governance in environmental and economic performance improvement through green supply chain management. J. Clean. Prod. 2016, 155, 46–53. [Google Scholar] [CrossRef]

- Lima Junior, F.R.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Lakshmanpriya, C.; Kumaravel, A.; Saravanan, M.; Kumar, P.M. Selecting the Optimal Green Supplier and Order Allocation under Linear Discount. Math. Probl. Eng. 2022, 2022, 2453703. [Google Scholar] [CrossRef]

- Verma, M.; Prem, P.R.; Ren, P.J.; Liao, H.C.; Xu, Z.S. Green supplier selection with a multiple criteria decision-making method based on thermodynamic features. Environ. Dev. Sustain. 2022, 2022, 1–33. [Google Scholar] [CrossRef]

- Kang, X.; Xu, X.J.; Yang, Z.L. Evaluation and selection of green suppliers for papermaking enterprises using the interval basic probability assignment-based intuitionistic fuzzy set. Complex Intell. Syst. 2022, 8, 4187–4203. [Google Scholar] [CrossRef]

- Segura, M.; Maroto, C. A multiple criteria supplier segmentation using outranking and value function methods. Expert Syst. Appl. 2017, 69, 87–100. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Gurel, O.; Acar, A.Z.; Onden, I.; Gumus, I. Determinants of the Green Supplier Selection. Procedia—Soc. Behav. Sci. 2015, 181, 131–139. [Google Scholar] [CrossRef]

- Giannakis, M.; Dubey, R.; Vlachos, I.; Ju, Y.B. Supplier sustainability performance evaluation using the analytic network process. J. Clean. Prod. 2018, 247, 119439. [Google Scholar] [CrossRef]

- Ghamari, R.; Mahdavi, M.M.; Ghannadpour, S.F. Resilient and sustainable supplier selection via a new framework: A case study from the steel industry. Environ. Dev. Sustain. 2021, 24, 10403–10441. [Google Scholar] [CrossRef]

- Izadikhah, M.; Saen, R.F.; Ahmadi, K.; Shamsi, M. How to use fuzzy screening system and data envelopment analysis for clustering sustainable suppliers? A case study in Iran. J. Enterp. Inf. Manag. 2020, 34, 199–229. [Google Scholar] [CrossRef]

- Majumdar, A.; Sinha, S. Modeling the barriers of green supply chain management in small and medium enterprises: A case of Indian clothing industry. Manag. Environ. Qual. 2018, 29, 1110–1122. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Vaish, A. Suppliers’ green performance evaluation using fuzzy extended ELECTRE approach. Clean Technol. Environ. Policy 2018, 19, 809–821. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Hashemkhani Zolfani, S. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Liang, R.; Chong, H.Y. A hybrid group decision model for green supplier selection: A case study of megaprojects. Eng. Constr. Archit. Manag. 2019, 26, 1712–1734. [Google Scholar] [CrossRef]

- Yang, Z.J.; Guo, X.T.; Sun, J.; Zhang, Y.L. Contextual and organizational factors in sustainable supply chain decision making: Grey relational analysis and interpretative structural modeling. Environ. Dev. Sustain. 2021, 23, 12056–12076. [Google Scholar] [CrossRef]

- Peng, C.; Feng, D.Z.; Guo, S.D. Material Selection in Green Design: A Method Combining DEA and TOPSIS. Sustainability 2021, 13, 5497. [Google Scholar] [CrossRef]

- Qu, G.H.; Zhang, Z.J.; Qu, W.H.; Xu, Z.S. Green Supplier Selection Based on Green Practices Evaluated Using Fuzzy Approaches of TOPSIS and ELECTRE with a Case Study in a Chinese Internet Company. Int. J. Environ. Res. Public Health 2020, 17, 3268. [Google Scholar] [CrossRef] [PubMed]

- Li, Y. Quality Evaluation of Environmental Accounting Information Disclosure of Y Nonferrous Metal Company Based on AHP-FCE Model. Discret. Dyn. Nat. Soc. 2022, 2022, 1549611. [Google Scholar] [CrossRef]

- Yan, G. Research on Green Suppliers’ Evaluation Based on AHP & Genetic Algorithm. In Proceedings of the International Conference on Signal Processing Systems, Singapore, 15–17 May 2009. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.F.; Li, M.; Liu, X. Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int. J. Rock Mech. Min. Sci. 2012, 52, 50–55. [Google Scholar] [CrossRef]

- Wang, X.C.; Zhang, H.S.; Li, M.; Li, Y. Research on Interference Optimization Mechanism of Wireless Routing Signal Transmission Based on Fuzzy Comprehensive Evaluation Method. Int. J. Online Biomed. Eng. 2017, 13, 136–148. [Google Scholar] [CrossRef][Green Version]

- Zhang, R.X.; Zhao, B. Research on Location Selection of Shared Vehicle Charging Station Based on Analytic Hierarchy Process and Fuzzy Evaluation Method. Open Access Libr. J. 2018, 5, 87593. [Google Scholar] [CrossRef]

- Li, Y.W.; Sun, Z.W.; Song, W.W. Prestressed Concrete Bridge Bearing Capacity Evaluation Based on Analytic Hierarchy Process and Fuzzy Evaluation Method. Adv. Mater. Res. 2011, 368–373, 2006–2010. [Google Scholar] [CrossRef]

- Liu, Q. Research on Investment Decision of Green Public Building Based on Analytic Hierarchy Process and Fussy Evaluation. Open Cybern. Syst. J. 2015, 9, 909–914. [Google Scholar] [CrossRef][Green Version]

- Wang, R.G.; Liu, G.; Zhou, L.; Yang, Z.N.; Tang, Z.C.; Lu, S.J.; Zhao, M.J.; Sun, H.W.; Ma, C.; Cheng, G.Y. Quantifying food loss along the animal products supply chain in China with large-scale field-survey based primary data. Resour. Conserv. Recycl. 2023, 188, 106685. [Google Scholar] [CrossRef]

- Ren, A.Q.; Hou, H.C.; Wang, H.H.; Ma, Z.; Zhang, Y.; Liu, Y. Review on aquaculture green supply chain management in China. Environ. Pollut. Control 2023, 45, 1164–1168. [Google Scholar] [CrossRef]

- Liu, M.L.; Yang, B.C. Study on Cold Chain Technology Investment Decision of Dual Channel Aquatic Supply Chain Under the Background of Hayes Road. Eur. Bus. Manag. 2018, 4, 80. [Google Scholar] [CrossRef]

- Kwong, C.K.; Bai, H. A fuzzy AHP approach to the determination of importance weights of customer requirements in quality function deployment. J. Intell. Manuf. 2002, 13, 367–377. [Google Scholar] [CrossRef]

- Zhang, K.; Si, B.F. The Application of Fuzzy Comprehensive Evaluation Method Based on AHP on the Distribution of Rail Transport. Appl. Mech. Mater. 2014, 2916, 1379–1382. [Google Scholar] [CrossRef]

- Hou, H.C. Study on Evaluation and Application of Cleaner Production in Sea Cucumber Industry Based on Life Cycle Assessment. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2020. [Google Scholar]

- Li, P.; Chen, H.Z. Evaluation of green building suppliers based on IVPLTS-CBR decision-making method. Int. J. Intell. Comput. Cybern. 2021, 15, 17–40. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Memari, A.; Dargi, A.; Jokar, M.R.A.; Ahmad, R.; Rahim, A.R.A. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Olson, J.; Clay, P.M.; Silva, P.P.D. Putting the seafood in sustainable food systems. Mar. Policy 2014, 43, 104–111. [Google Scholar] [CrossRef]

- Hewawitharana, S.C.; Webb, K.L.; Strochlic, R.; Gosliner, W. Comparison of Fruit and Vegetable Prices between Farmers’ Markets and Supermarkets: Implications for Fruit and Vegetable Incentive Programs for Food Assistance Program Participants. Nutrients 2022, 14, 1842. [Google Scholar] [CrossRef]

- Hou, H.C.; Shao, S.; Zhang, Y.; Sun, D.L.; Yang, Q.Y.; Qin, C.L.; Sun, X.Y. Cleaner Production assessment for sea cucumber aquaculture: Methodology and case studies in Dalian, China. Clean Technol. Environ. Policy 2019, 21, 1751–1763. [Google Scholar] [CrossRef]

- Heng, X. The Development of Microecologics for Industrialized Mariculture. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2017. [Google Scholar]

- Senapati, T.; Yager, R.R. Fermatean fuzzy sets. J. Ambient Intell. Humaniz. Comput. 2020, 11, 663–674. [Google Scholar] [CrossRef]

- Senapati, T.; Yager, R.R. Fermatean fuzzy weighted averaging/geometric operators and its application in multi-criteria decision-making methods. Eng. Appl. Artif. Intell. 2019, 85, 112–121. [Google Scholar] [CrossRef]

| Aspect | Criterion | Definition |

|---|---|---|

| Economy (A) | A1: Sea cucumber farming price | Production cost that determines the final price of the product. |

| A2: Size of sea cucumber farming enterprises | Judge the supply capacity of suppliers. | |

| A3: Quality of fresh sea cucumber | Ensure the quality control of sea cucumber products. | |

| A4: Sea cucumber transportation cost | Transportation cost from the supplier to the manufacturer. | |

| A5: Qualified rate of transport quality | The probability of transportation product quality, transportation service quality, and transportation work quality meeting the requirements. | |

| A6: Order fulfillment rate | Supplier order completion. | |

| A7: Sea cucumber inventory cost | Cost of storing sea cucumber products. | |

| A8: Sea cucumber traceability | Material tracking technology between suppliers and customers. | |

| Environment (B) | B1: Clean production level of sea cucumber farming | Judgment is based on elements such as resource and energy consumption, product characteristics, pollutant generation, integrated resource use, and cleaner production management. |

| B2: Green supply chain management commitment for sea cucumber farming enterprises | The willingness of enterprises to implement green supply chain management. | |

| B3: Environmental awareness | The consciousness of saving and protecting natural resources. | |

| B4: Geographical location | Whether the location of the supplier’s farming workshop has a negative impact on the surrounding environment, such as pollution. | |

| B5: Environmental management system | The determination of the environmental management system includes ISO 14000 environmental management system certification, ecological label, supplier environmental assessment, and environmental management information system. | |

| B6: Food safety management system certification | A necessary requirement for safety and quality management in the food industry. | |

| B7: Mastery of new environmental technology | The extent of research and innovation into environmental technology. | |

| Society (C) | C1: Cooperation with green seed enterprises | Guarantee product quality from the source. |

| C2: Protection of employee rights | Fully mobilize the enthusiasm and creativity of the staff. | |

| C3: Green technology talent | Talents with a strong concept of sustainable development and corresponding ability. | |

| C4: Employee training | Improve staff efficiency and quality. | |

| C5: Long-term cooperation | Examining enterprise stability. | |

| C6: Green image of farming enterprises | A high-quality corporate image with green as the core. | |

| C7: Social responsibility of farming enterprises | Enterprises should bear the responsibility for consumers, communities, and the environment while paying attention to economic interests. | |

| C8: Brand effect | The value a brand brings to a business. |

| Importance Level | Implication | Description |

|---|---|---|

| 1 | Equally important | Factor i is equally important to factor j |

| 3 | Slightly important | Factor i is slightly more important than factor j |

| 5 | Clearly important | Factor i is clearly more important than factor j |

| 7 | Strongly important | Factor i is strongly more important than factor j |

| 9 | Extremely important | Factor i is extremely more important than factor j |

| 2, 4, 6, 8 | —— | Intermediate values |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|

| Registered capital (USD) | 1,450,150 | 1,232,628 | 725,075 | 7,975,825 | 290,030 |

| Farming scale (USD) | 5,095,465 | 5,485,917 | 2,050,150 | 7,635,040 | 4,809,437 |

| Aquaculture technology | Pond and cage farming | Pond and cage farming | Pond and cage farming | Pond and cage farming | Pond farming |

| Aquaculture production (t) | 234.25 | 242.5 | 94.25 | 337.5 | 252 |

| Sea cucumber farming price (USD/t) | 21,752.3 | 22,622.3 | 21,752.3 | 22,622.3 | 17,404.3–23,205.8 |

| Indicator | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | Normalization Result |

|---|---|---|---|---|---|---|---|---|---|

| A1 | 1 | 3 | 2 | 7 | 3 | 6 | 9 | 6 | 0.32857 |

| A2 | 1/3 | 1 | 1/2 | 5 | 1 | 3 | 6 | 3 | 0.13954 |

| A3 | 1/2 | 2 | 1 | 6 | 2 | 5 | 7 | 5 | 0.22447 |

| A4 | 1/7 | 1/5 | 1/6 | 1 | 1/5 | 1/2 | 2 | 1/2 | 0.03458 |

| A5 | 1/3 | 1 | 1/2 | 5 | 1 | 3 | 6 | 3 | 0.13954 |

| A6 | 1/6 | 1/3 | 1/5 | 2 | 1/3 | 1 | 3 | 1 | 0.05476 |

| A7 | 1/9 | 1/6 | 1/7 | 1/2 | 1/6 | 1/3 | 1 | 1/3 | 0.02379 |

| A8 | 1/6 | 1/3 | 1/5 | 2 | 1/3 | 1 | 3 | 1 | 0.05476 |

| Second-Grade Indicator | Normalization Results of Membership Degree Value | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | |||||||||||||

| S1 | S2 | S3 | S4 | S5 | S1 | S2 | S3 | S4 | S5 | S1 | S2 | S3 | S4 | S5 | |

| A1: Sea cucumber farming price | 0.2 | 0 | 0.2 | 0 | 0.8 | 0.7 | 0.4 | 0.7 | 0.4 | 0.2 | 0.1 | 0.6 | 0.1 | 0.6 | 0 |

| A2: Size of sea cucumber farming enterprises | 0.6 | 0.8 | 0 | 1 | 0.2 | 0.3 | 0.2 | 0.4 | 0 | 0.5 | 0.1 | 0 | 0.6 | 0 | 0.3 |

| A3: Quality of fresh sea cucumber | 0.6 | 0.2 | 0 | 0.8 | 1 | 0.3 | 0.5 | 0.4 | 0.2 | 0 | 0.1 | 0.3 | 0.6 | 0 | 0 |

| A4: Sea cucumber transportation cost | 0.2 | 0.2 | 0 | 0.2 | 0.2 | 0.7 | 0.7 | 0.4 | 0.7 | 0.7 | 0.1 | 0.1 | 0.6 | 0.1 | 0.1 |

| A5: Qualified rate of transport quality | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| A6: Order fulfillment rate | 0.7 | 0.7 | 0.2 | 0.7 | 0.7 | 0.3 | 0.3 | 0.8 | 0.3 | 0.3 | 0 | 0 | 0 | 0 | 0 |

| A7: Sea cucumber inventory cost | 0.3 | 0.8 | 0.3 | 0.3 | 0.3 | 0.6 | 0.2 | 0.6 | 0.6 | 0.6 | 0.1 | 0 | 0.1 | 0.1 | 0.1 |

| A8: Sea cucumber traceability | 0.2 | 0.2 | 0 | 0.8 | 0 | 0.7 | 0.7 | 0.4 | 0.2 | 0.4 | 0.1 | 0.1 | 0.6 | 0 | 0.6 |

| B1: Clean production level of sea cucumber farming | 0.3 | 0.3 | 0.3 | 0.3 | 0 | 0.6 | 0.6 | 0.6 | 0.6 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.8 |

| B2: Green supply chain management commitment for sea cucumber farming enterprises | 0.2 | 0.2 | 0 | 0.8 | 0.2 | 0.7 | 0.7 | 0.4 | 0.2 | 0.7 | 0.1 | 0.1 | 0.6 | 0 | 0.1 |

| B3: Environmental awareness | 0.8 | 0.3 | 0 | 0.3 | 0.3 | 0.2 | 0.6 | 0.4 | 0.6 | 0.6 | 0 | 0.1 | 0.6 | 0.1 | 0.1 |

| B4: Geographical location | 0.8 | 0.8 | 0.2 | 0.8 | 0.2 | 0.2 | 0.2 | 0.7 | 0.2 | 0.7 | 0 | 0 | 0.1 | 0 | 0.1 |

| B5: Environmental management system | 0.3 | 0.3 | 0 | 0.3 | 0 | 0.5 | 0.5 | 0.4 | 0.5 | 0.4 | 0.2 | 0.2 | 0.6 | 0.2 | 0.6 |

| B6: Food safety management system certification | 0.3 | 0.3 | 0 | 0 | 0 | 0.5 | 0.5 | 0.4 | 0.4 | 0.4 | 0.2 | 0.2 | 0.6 | 0.6 | 0.6 |

| B7: Mastery of new environmental technology | 0 | 0.2 | 0 | 0.2 | 0 | 0.4 | 0.7 | 0.4 | 0.7 | 0.4 | 0.6 | 0.1 | 0.6 | 0.1 | 0.6 |

| C1: Cooperation with green seed enterprises | 0.7 | 0.7 | 0.2 | 0.7 | 0.2 | 0.2 | 0.2 | 0.6 | 0.2 | 0.6 | 0.1 | 0.1 | 0.2 | 0.1 | 0.2 |

| C2: Protection of employee rights | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| C3: Green technology talent | 0 | 0.8 | 0 | 0.8 | 0 | 0.4 | 0.2 | 0.4 | 0.2 | 0.4 | 0.6 | 0 | 0.6 | 0 | 0.6 |

| C4: Employee training | 0.3 | 0.3 | 0.1 | 0.6 | 0.1 | 0.6 | 0.6 | 0.5 | 0.2 | 0.5 | 0.1 | 0.1 | 0.4 | 0.2 | 0.4 |

| C5: Long-term cooperation | 0.8 | 0.8 | 0.8 | 0.3 | 0.8 | 0.2 | 0.2 | 0.2 | 0.6 | 0.2 | 0 | 0 | 0 | 0.1 | 0 |

| C6: Green image of farming enterprises | 0.2 | 0.2 | 0.2 | 0.7 | 0.2 | 0.5 | 0.5 | 0.5 | 0.1 | 0.5 | 0.3 | 0.3 | 0.3 | 0.2 | 0.3 |

| C7: Social responsibility of farming enterprises | 0.2 | 0.2 | 0.8 | 0.8 | 0.2 | 0.7 | 0.7 | 0.2 | 0.2 | 0.7 | 0.1 | 0.1 | 0 | 0 | 0.1 |

| C8: Brand effect | 0.8 | 0.8 | 0.3 | 0.8 | 0 | 0.2 | 0.2 | 0.6 | 0.2 | 0.4 | 0 | 0 | 0.1 | 0 | 0.6 |

| Fuzzy Comprehensive Evaluation Result | First-Grade Indicators | ||

|---|---|---|---|

| Economy | Environment | Society | |

| S1 | (0.488 0.432 0.080) | (0.447 0.449 0.104) | (0.480 0.394 0.126) |

| S2 | (0.372 0.355 0.273) | (0.294 0.599 0.107) | (0.536 0.380 0.084) |

| S3 | (0.224 0.471 0.305) | (0.105 0.475 0.420) | (0.525 0.344 0.131) |

| S4 | (0.558 0.239 0.203) | (0.372 0.520 0.108) | (0.556 0.354 0.090) |

| S5 | (0.706 0.211 0.083) | (0.135 0.454 0.411) | (0.396 0.420 0.184) |

| Assessment Level (L) | Score (Q) | Fuzzy Vector Uniformization Result Interval (V) |

|---|---|---|

| L1: high level | 3 | 3.00–2.34 |

| L2: mid level | 2 | 2.33–1.67 |

| L3: low level | 1 | 1.66–1.00 |

| Supplier | Comprehensive Evaluation Result | Ranking | Assessment Level |

|---|---|---|---|

| S1 | 2.37 | 1 | L1: high level |

| S2 | 2.19 | 3 | L2: mid level |

| S3 | 1.87 | 5 | L2: mid level |

| S4 | 2.33 | 2 | L2: mid level |

| S5 | 2.18 | 4 | L2: mid level |

| Supplier | Economy | Environment | Society | |||

|---|---|---|---|---|---|---|

| Calculation Result | Assessment Level | Calculation Result | Assessment Level | Calculation Result | Assessment Level | |

| S1 | 2.41 | L1 | 2.34 | L1 | 2.35 | L1 |

| S2 | 2.10 | L2 | 2.19 | L2 | 2.45 | L1 |

| S3 | 1.92 | L2 | 1.65 | L3 | 2.39 | L1 |

| S4 | 2.36 | L1 | 2.26 | L2 | 2.47 | L1 |

| S5 | 2.62 | L1 | 1.72 | L2 | 2.21 | L2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, A.; Zhao, X.; Liu, Q.; Yu, L.; Han, F.; Jia, F.; Hou, H.; Liu, Y. Green Supplier Assessment and Selection for Sea Cucumber (Apostichopus japonicus) Processing Enterprise: Case Study in China. Sustainability 2023, 15, 15368. https://doi.org/10.3390/su152115368

Ren A, Zhao X, Liu Q, Yu L, Han F, Jia F, Hou H, Liu Y. Green Supplier Assessment and Selection for Sea Cucumber (Apostichopus japonicus) Processing Enterprise: Case Study in China. Sustainability. 2023; 15(21):15368. https://doi.org/10.3390/su152115368

Chicago/Turabian StyleRen, Anqi, Xintao Zhao, Qi Liu, Lixingbo Yu, Fengfan Han, Fei Jia, Haochen Hou, and Ying Liu. 2023. "Green Supplier Assessment and Selection for Sea Cucumber (Apostichopus japonicus) Processing Enterprise: Case Study in China" Sustainability 15, no. 21: 15368. https://doi.org/10.3390/su152115368

APA StyleRen, A., Zhao, X., Liu, Q., Yu, L., Han, F., Jia, F., Hou, H., & Liu, Y. (2023). Green Supplier Assessment and Selection for Sea Cucumber (Apostichopus japonicus) Processing Enterprise: Case Study in China. Sustainability, 15(21), 15368. https://doi.org/10.3390/su152115368