Enhancing Sustainable Dairy Industry Growth through Cold-Supply-Chain-Integrated Production Forecasting

Abstract

:1. Introduction

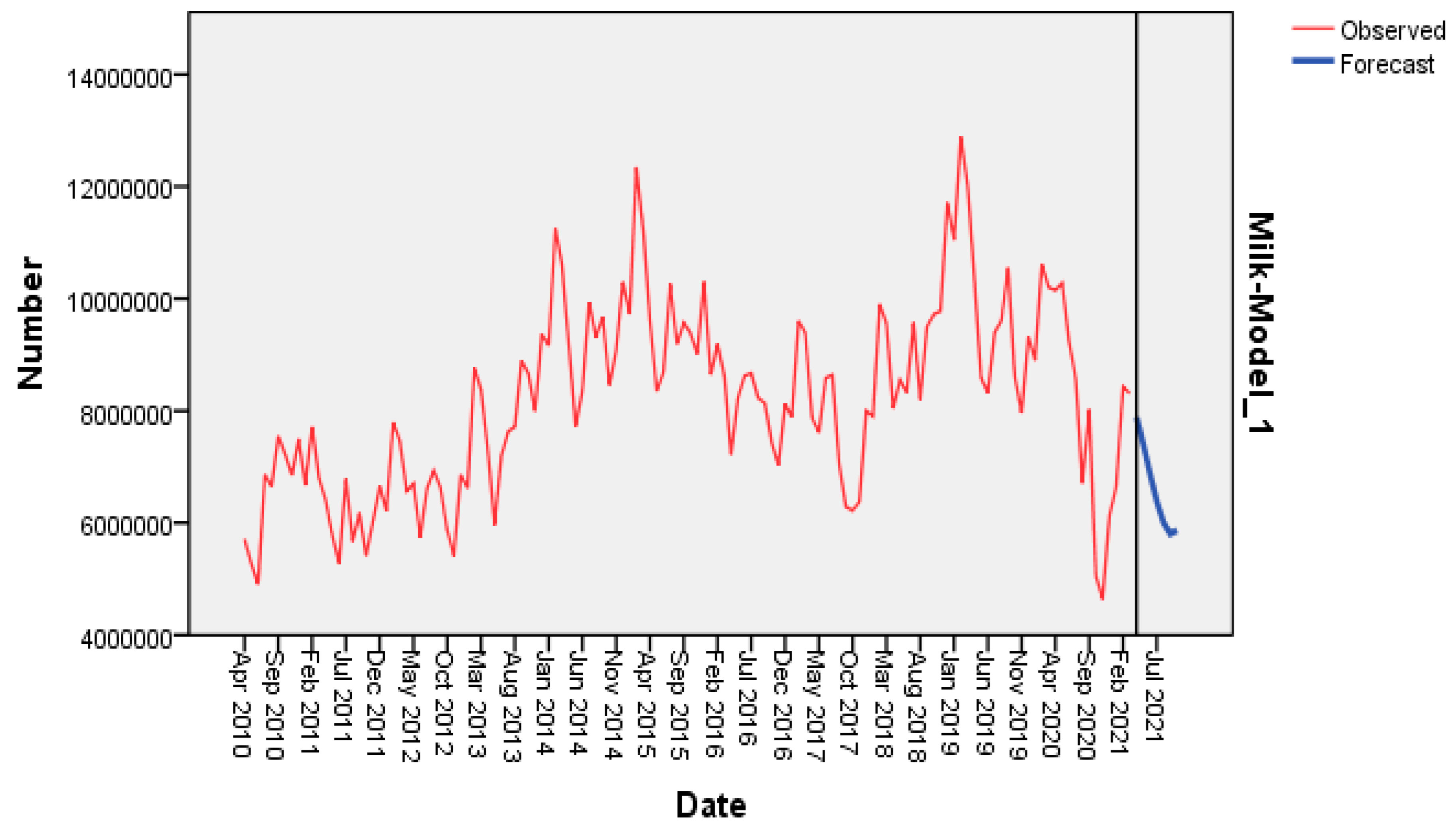

- RO1: Examine the monthly milk production trends of Company ‘X’ in North India from April 2010 to October 2021, and identify underlying patterns and trends.

- RO2: Develop ARIMA models for forecasting milk production from April 2021 to October 2021, and evaluate the precision of the forecasted values using MAPE and R2.

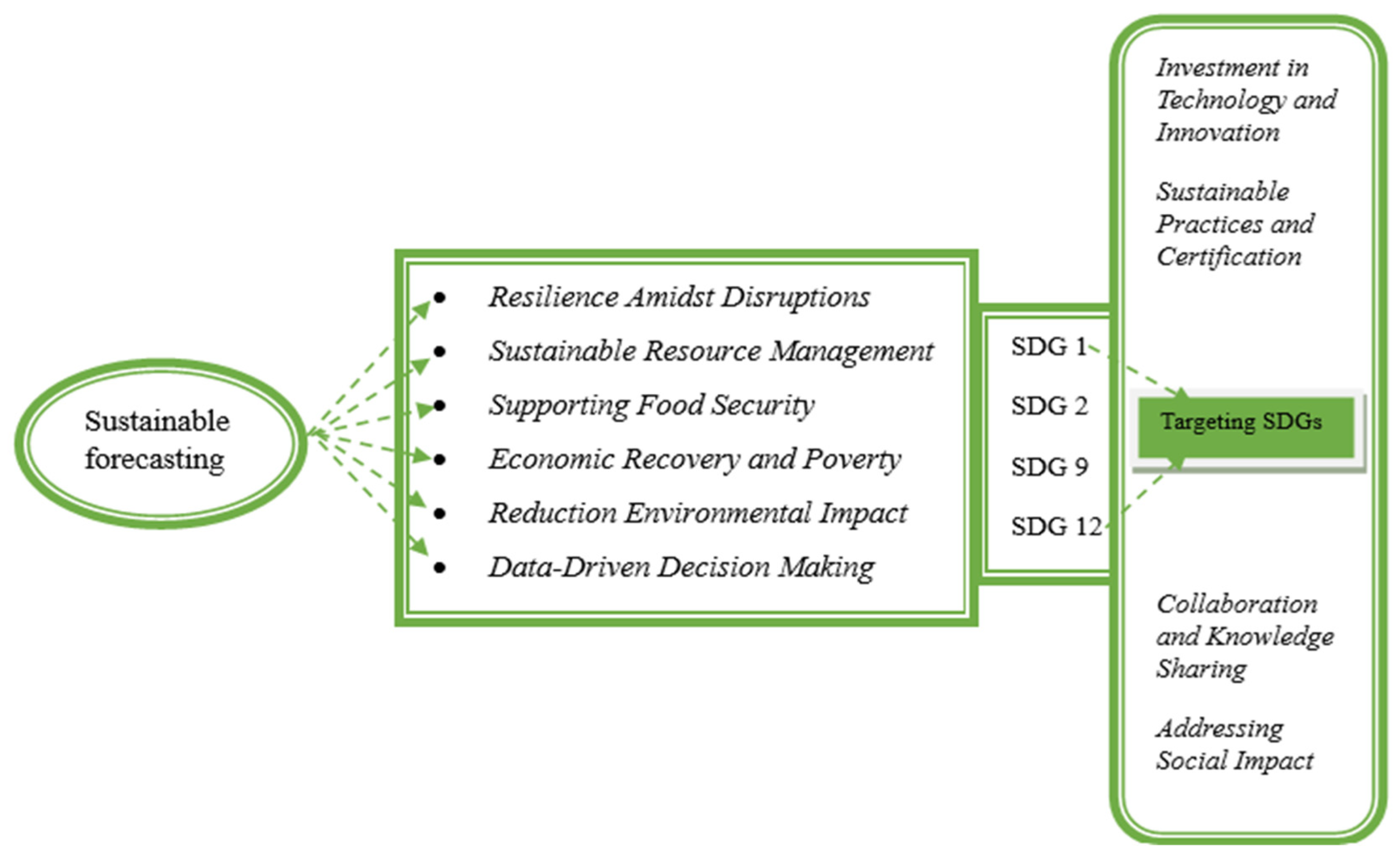

- RO3: Evaluate the implications of precise milk production forecasting for achieving SDGs in the dairy industry.

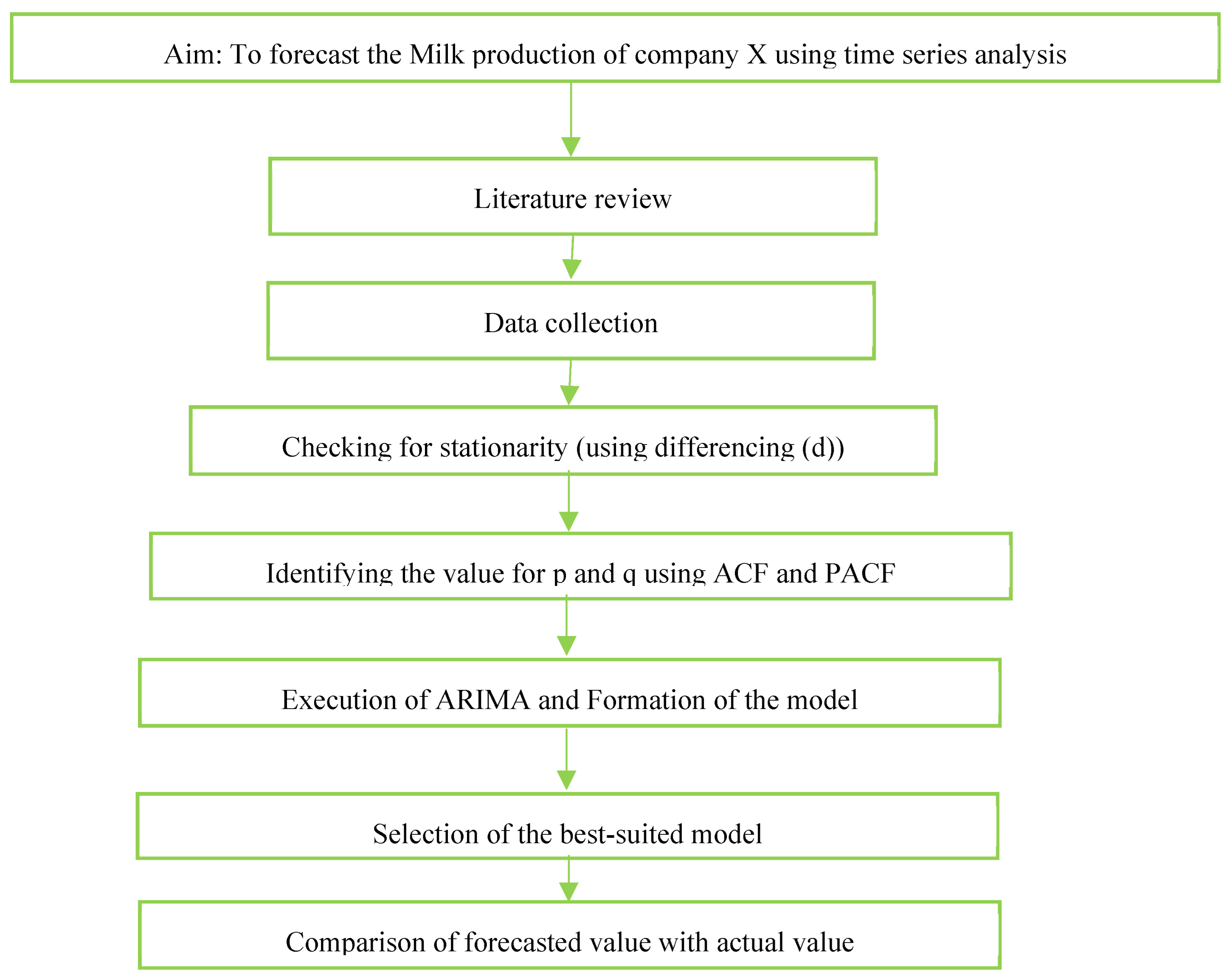

2. Materials and Methods

3. Model Formation

4. Result and Discussion, Implications, and Limitations

4.1. Results and Discussion

4.2. Implications

- Resilience amidst disruptions: The stark deviations observed between the forecasted and actual production values, particularly evident post-July 2021, attest to the dairy industry’s vulnerability to unforeseen disruptions like the COVID-19 pandemic. This pronounced impact underscores the paramount importance of accurate milk production forecasts [55,56]. Furthermore, the cold supply chain’s role in maintaining product quality and safety during such disruptions cannot be underestimated. By harnessing the insights offered by ARIMA models, stakeholders can proactively navigate challenges, restructure supply chains, and avert supply gaps, bolstering the resilience of the CSC alongside industry-wide resilience [57]. This strategic preparedness is in direct harmony with the essence of SDG 9—“Industry, Innovation, and Infrastructure”—ensuring industry resilience against unexpected upheavals.

- Sustainable resource management: A closer examination of the disparities revealed in the comparison highlights a significant area of focus for dairy sector resource management. The fluctuations between predicted and actual values underscore the criticality of judiciously managing resources such as water, energy, and feed [58,59]. Effective resource management within the CSC is vital for energy-efficient refrigeration and transportation. By narrowing the variance, dairy producers and the CSC can minimize waste, optimize resource utilization, and actively contribute to the realization of SDG 12—“Responsible Consumption and Production”. This alignment fosters a sustainable approach while balancing milk production demands [60].

- Supporting food security: The juxtaposition of forecasted and actual values accentuates the dairy industry’s crucial role in upholding food security, particularly in the face of global disruptions. The disparities between predicted and actual production patterns during challenging periods underscore the potential of precise milk production forecasts to mitigate food shortages and prevent wastage [61,62,63]. Considering SDG 2—“Zero Hunger”—this alignment becomes a cornerstone in ensuring consistent cold supply chain [64,65], supporting nutrition needs, and stabilizing communities [66].

- Economic recovery and poverty reduction: The disparities observed, particularly in times of disruption, delineate the dairy industry’s significance in promoting economic recovery and reducing poverty [67,68,69]. The accuracy of forecasts empowers decision makers to navigate uncertain terrain effectively. This strategic clarity, in alignment with SDG 1—“No Poverty”—becomes pivotal in safeguarding livelihoods, bolstering economic stability, and fostering long-term prosperity within the dairy sector.

- Environmental impact: The discernible variations between forecasted and actual values underscore the industry’s journey towards environmental stewardship. These deviations reflect the direct influence of forecasted trends on resource utilization, waste generation, and sustainability practices. By achieving a closer accord between predictions and actual outcomes, the dairy sector contributes to the principles of SDG 12, culminating in more sustainable production patterns [70].

- Data-driven decision making: The disparities unveiled by the comparison between forecasts and actuals substantiate the dairy industry’s progression towards data-driven decision making. These deviations act as a compass, guiding industry stakeholders to better comprehend production dynamics, identify opportunities, and address bottlenecks. This strategic transformation, in consonance with the core tenets of the SDGs, underscores the pivotal role of data-driven policies in steering the sector towards sustainable development [71,72,73].

- Investment in technology and innovation: Embracing technology and innovation can improve production efficiency and reduce the industry’s environmental footprint. For instance, advanced data analytics and IoT technologies can optimize resource utilization and enable real-time decision making.

- Sustainable practices and certification: Encouraging and incentivizing sustainable farming practices can promote responsible production. Certifications such as “organic” or “sustainable” can help consumers make more sustainable choices and contribute to achieving SDG 12.

- Collaboration and knowledge sharing: Collaborating with stakeholders, including governments, NGOs, and research institutions, can foster knowledge sharing and best practices. This collective effort can enhance the industry’s sustainability and contributions to the SDGs.

- Addressing social impact: The COVID-19 pandemic’s socioeconomic effects highlighted the importance of considering the social impact of dairy production. Ensuring fair wages, safe working conditions, and community engagement can align the industry with SDG 8—“Decent Work and Economic Growth”.

4.3. Limitations

5. Conclusions and Future Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huth, P.J.; DiRienzo, D.B.; Miller, G.D. Major Scientific Advances with Dairy Foods in Nutrition and Health. J. Dairy Sci. 2006, 89, 1207–1221. [Google Scholar] [CrossRef] [PubMed]

- Milk Products: Contribution to Nutrition and Health. Int. J. Dairy Technol. 1992, 45, 61–67. [CrossRef]

- Koç, G.; Uzmay, A. Determinants of Dairy Farmers’ Likelihood of Climate Change Adaptation in the Thrace Region of Turkey. Environ. Dev. Sustain. 2022, 24, 9907–9928. [Google Scholar] [CrossRef]

- Van der Ploeg, J.D.; Renting, H.; Brunori, G.; Knickei, K.; Mannion, J.; Marsden, T.; De Roest, K.; Sevilla-Guzmán, E.; Ventura, F. Rural Development: From Practices and Policies towards Theory. In the Rural; Routledge: London, UK, 2008; ISBN 978-1-315-23721-3. [Google Scholar]

- Juniwal, C.; Khan, A.R.; Ganesh, A.; Carvalho, R.M.; Karunamay, S. Constraints in Milk Production of Dairy Cattle: A Review. Pharma Innov. J. 2022, SP-11, 3991–3994. [Google Scholar]

- Pradhan, P.P.; Priyan, P.K. Dairy Farming: The Rural Cash Cow. GH Patel Postgraduate Institute of Business Management 1. J. Manag. 2020, 22, 1–68. [Google Scholar]

- Singh, P.; Mukesh, M.; Kumar, S. Artificial Insemination: Scope and Challenges for Indian Dairy Sector. In Advances in Animal Experimentation and Modeling; Elsevier: Amsterdam, The Netherlands, 2022; pp. 359–364. [Google Scholar]

- Subbanna, Y.B.; Kumar, S.; Puttaraju, S.K.M. Forecasting Buffalo Milk Production in India: Time Series Approach. Buffalo Bull. 2021, 40, 335–343. [Google Scholar]

- Ali, J. Livestock Sector Development and Implications for Rural Poverty Alleviation in India. Livest. Res. Rural Dev. 2007, 19, 1–15. [Google Scholar]

- Gulati, A.; Minot, N.; Delgado, C.; Bora, S. Growth in High-Value Agriculture in Asia and the Emergence of Vertical Links with Farmers. In Global Supply Chains, Standards and the Poor: How the Globalization of Food Systems and Standards Affects Rural Development and Poverty; CABI: Wallingford, UK, 2007; pp. 91–108. [Google Scholar]

- Kumar, A. Socio-Economic Scope of Agri-Business in State of Bihar: Dairy Industry a Case Study (December 5, 2020). e-Journal-First Pan IIT International Management Conference–2018. 2020. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3743430 (accessed on 18 May 2023).

- Rajak, S.K.; Panse, R.K.; Kadam, D.M. Milk Production in India and World: An Overview. Front. Crop Improv. 2019, 9, 238–242. [Google Scholar]

- Swaminathan, M.S.; Bhavani, R.V. Food Production & Availability—Essential Prerequisites for Sustainable Food Security. Indian J. Med. Res. 2013, 138, 383–391. [Google Scholar]

- Kaur, G.; Goswami, T.K. Physical and Sensory Characteristics of Low Sugar Dairy Dessert (Rasgulla) Developed at Different Level Coconut Sap Syrup. J. Food Sci. Technol. 2021, 58, 343–348. [Google Scholar] [CrossRef]

- Ravichandran, M.; Naresh, R.; Kandasamy, J. Supply Chain Routing in a Diary Industry Using Heterogeneous Fleet System: Simulation-Based Approach. J. Inst. Eng. (India) Ser. C 2020, 101, 891–911. [Google Scholar] [CrossRef]

- van Asselt, E.D.; Capuano, E.; van der Fels-Klerx, H.J. Sustainability of Milk Production in the Netherlands—A Comparison between Raw Organic, Pasteurised Organic and Conventional Milk. Int. Dairy J. 2015, 47, 19–26. [Google Scholar] [CrossRef]

- McLaughlin, D.; Kinzelbach, W. Food Security and Sustainable Resource Management. Water Resour. Res. 2015, 51, 4966–4985. [Google Scholar] [CrossRef]

- Mishra, P.; Fatih, C.; Niranjan, H.K.; Tiwari, S.; Devi, M.; Dubey, A. Modelling and Forecasting of Milk Production in Chhattisgarh and India. IJAR 2020, 54, 912–917. [Google Scholar] [CrossRef]

- Singh, S.P.; Tegegne, F.; Ekanem, E.P.; Singh, S.P.; Tegegne, F.; Ekanem, E.P. The Food Processing Industry in India: Challenges and Opportunities. J. Food Distrib. Res. 2012, 43, 81–89. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Cerchione, R. The Digital and Sustainable Transition of the Agri-Food Sector. Technol. Forecast. Soc. Chang. 2023, 187, 122222. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Joshi, L. Understanding Implications of Dairy Sector Development to Sustainable Development Goals (SDGs); National Council of Applied Economic Research: New Delhi, India, 2022. [Google Scholar]

- Kim, S.; Kim, H. A New Metric of Absolute Percentage Error for Intermittent Demand Forecasts. Int. J. Forecast. 2016, 32, 669–679. [Google Scholar] [CrossRef]

- Song, X.; Liu, Y.; Xue, L.; Wang, J.; Zhang, J.; Wang, J.; Jiang, L.; Cheng, Z. Time-Series Well Performance Prediction Based on Long Short-Term Memory (LSTM) Neural Network Model. J. Pet. Sci. Eng. 2020, 186, 106682. [Google Scholar] [CrossRef]

- Choudhury, A.; Jones, J. Crop Yield Prediction Using Time Series Models. J. Econ. Econ. Educ. Res. 2014, 15, 53–67. [Google Scholar]

- Elhag, M.; Gitas, I.; Othman, A.; Bahrawi, J.; Psilovikos, A.; Al-Amri, N. Time Series Analysis of Remotely Sensed Water Quality Parameters in Arid Environments, Saudi Arabia. Env. Dev. Sustain. 2021, 23, 1392–1410. [Google Scholar] [CrossRef]

- Makridakis, S.; Wheelwright, S.C.; Hyndman, R.J. Forecasting Methods and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Fradinata, E.; Suthummanon, S.; Sirivongpaisal, N.; Suntiamorntuthq, W. ANN, ARIMA and MA Timeseries Model for Forecasting in Cement Manufacturing Industry: Case Study at Lafarge Cement Indonesia—Aceh. In Proceedings of the 2014 International Conference of Advanced Informatics: Concept, Theory and Application (ICAICTA), Bandung, Indonesia, 20–21 August 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 39–44. [Google Scholar]

- Veerendra, G.T.N.; Kumaravel, B.; Rao, P.K.R.; Dey, S.; Manoj, A.V.P. Forecasting Models for Surface Water Quality Using Predictive Analytics. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Taye, B.A.; Alene, A.A.; Nega, A.K.; Yirsaw, B.G. Time Series Analysis of Cow Milk Production at Andassa Dairy Farm, West Gojam Zone, Amhara Region, Ethiopia. Model. Earth Syst. Environ. 2021, 7, 181–189. [Google Scholar] [CrossRef]

- Yadav, A.K.; Das, K.K.; Das, P.; Raman, R.K.; Kumar, J.; Das, B.K. Growth Trends and Forecasting of Fish Production in Assam, India Using ARIMA Model. J. Appl. Nat. Sci. 2020, 12, 415–421. [Google Scholar] [CrossRef]

- Rabbani, M.B.A.; Musarat, M.A.; Alaloul, W.S.; Rabbani, M.S.; Maqsoom, A.; Ayub, S.; Bukhari, H.; Altaf, M. A Comparison Between Seasonal Autoregressive Integrated Moving Average (SARIMA) and Exponential Smoothing (ES) Based on Time Series Model for Forecasting Road Accidents. Arab. J. Sci. Eng. 2021, 46, 11113–11138. [Google Scholar] [CrossRef]

- Almasarweh, M.; Alwadi, S. ARIMA Model in Predicting Banking Stock Market Data. Mod. Appl. Sci. 2018, 12, 309. [Google Scholar] [CrossRef]

- Minhas, K.S.; Sidhu, J.S.; Mudahar, G.S.; Singh, A.K. Flow Behavior Characteristics of Ice Cream Mix Made with Buffalo Milk and Various Stabilizers. Plant Foods Hum. Nutr. 2002, 57, 25–40. [Google Scholar] [CrossRef]

- Siami-Namini, S.; Tavakoli, N.; Namin, A.S. A Comparison of ARIMA and LSTM in Forecasting Time Series. In Proceedings of the 2018 17th IEEE International Conference on Machine Learning and Applications (ICMLA), Orlando, FL, USA, 17–20 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1394–1401. [Google Scholar]

- Zhang, X. Forecasting Short-Term Electricity Load with Combinations of Singular Spectrum Analysis. Arab. J. Sci. Eng. 2023, 48, 1609–1624. [Google Scholar] [CrossRef]

- Schaffer, A.L.; Dobbins, T.A.; Pearson, S.-A. Interrupted Time Series Analysis Using Autoregressive Integrated Moving Average (ARIMA) Models: A Guide for Evaluating Large-Scale Health Interventions. BMC Med. Res. Methodol. 2021, 21, 1–12. [Google Scholar] [CrossRef]

- Sharma, A.K.; Punj, P.; Kumar, N.; Das, A.K.; Kumar, A. Lifetime Prediction of a Hydraulic Pump Using ARIMA Model. Arab. J. Sci. Eng. 2023. [Google Scholar] [CrossRef]

- Argyrous, G. Statistics for Research: With a Guide to SPSS; Sage Publications Ltd.: New York, NY, USA, 2011; 608p. [Google Scholar]

- Bryman, A.; Cramer, D. Quantitative Data Analysis with IBM SPSS 17, 18 & 19: A Guide for Social Scientists; Routledge: London, UK, 2012. [Google Scholar]

- Levesque, R. SPSS Programming and Data Management: A Guide for SPSS and SAS Users; SPSS: Armonk, NY, USA, 2005. [Google Scholar]

- Perone, G. An ARIMA Model to Forecast the Spread and the Final Size of COVID-2019 Epidemic in Italy. MedRxiv 2020. [Google Scholar] [CrossRef]

- Alizadeh, M.; Rahimi, S.; Ma, J. A Hybrid ARIMA–WNN Approach to Model Vehicle Operating Behavior and Detect Unhealthy States. Expert Syst. Appl. 2022, 194, 116515. [Google Scholar] [CrossRef]

- Nath, B.; Dhakre, D.S.; Bhattacharya, D. Forecasting Wheat Production in India: An ARIMA Modelling Approach. J. Pharmacogn. Phytochem. 2019, 8, 2158–2165. [Google Scholar]

- Abdel-Aal, R.E.; Al-Garni, A.Z. Forecasting Monthly Electric Energy Consumption in Eastern Saudi Arabia Using Univariate Time-Series Analysis. Energy 1997, 22, 1059–1069. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, Y.; Zhang, Y.; Sun, Y.; Yang, H. Impacts of the COVID-19 Pandemic on Fish Trade and the Coping Strategies: An Initial Assessment from China’s Perspective. Mar. Policy 2021, 133, 104748. [Google Scholar] [CrossRef]

- Mor, R.S.; Jaiswal, S.K.; Singh, S.; Bhardwaj, A. Demand Forecasting of the Short-Lifecycle Dairy Products. In Understanding the Role of Business Analytics; Springer: Singapore, 2019; pp. 87–117. [Google Scholar]

- Chang, Y.-S.; Chiao, H.-T.; Abimannan, S.; Huang, Y.-P.; Tsai, Y.-T.; Lin, K.-M. An LSTM-Based Aggregated Model for Air Pollution Forecasting. Atmos. Pollut. Res. 2020, 11, 1451–1463. [Google Scholar] [CrossRef]

- Khin, A.A.; Thambiah, S.; Teng, K.L.L. Short-Term and Long-Term Price Forecasting Models for the Future Exchange of Malaysian Natural Rubber Market. Int. J. Agric. Resour. Gov. Ecol. 2017, 13, 21–42. [Google Scholar] [CrossRef]

- Farajian, L.; Moghaddasi, R.; Hosseini, S. Agricultural Energy Demand Modeling in Iran: Approaching to a More Sustainable Situation. Energy Rep. 2018, 4, 260–265. [Google Scholar] [CrossRef]

- Govindan, K. Sustainable Consumption and Production in the Food Supply Chain: A Conceptual Framework. Int. J. Prod. Econ. 2018, 195, 419–431. [Google Scholar] [CrossRef]

- Pawlak, K.; Ko\lodziejczak, M. The Role of Agriculture in Ensuring Food Security in Developing Countries: Considerations in the Context of the Problem of Sustainable Food Production. Sustainability 2020, 12, 5488. [Google Scholar] [CrossRef]

- Edwards, J. New Zealand Aid and Dairy Development in Sri Lanka. 2020. Available online: https://researcharchive.vuw.ac.nz/handle/10063/8886 (accessed on 18 May 2023).

- Chiang, C.-T.; Kou, T.-C.; Koo, T.-L. A Systematic Literature Review of the IT-Based Supply Chain Management System: Towards a Sustainable Supply Chain Management Model. Sustainability 2021, 13, 2547. [Google Scholar] [CrossRef]

- Keller, J.; Jung, M.; Lasch, R. Sustainability Governance: Insights from a Cocoa Supply Chain. Sustainability 2022, 14, 10763. [Google Scholar] [CrossRef]

- Nchanji, E.B.; Lutomia, C.K. Sustainability of the Agri-Food Supply Chain amidst the Pandemic: Diversification, Local Input Production, and Consumer Behavior. In Advances in Food Security and Sustainability; Elsevier: Amsterdam, The Netherlands, 2021; Volume 6, pp. 211–229. [Google Scholar]

- Sharma, M.; Joshi, S.; Luthra, S.; Kumar, A. Managing Disruptions and Risks amidst COVID-19 Outbreaks: Role of Blockchain Technology in Developing Resilient Food Supply Chains. Oper. Manag. Res. 2021, 15, 268–281. [Google Scholar] [CrossRef]

- Barbosa-Povoa, A.P.; Pinto, J.M. Process Supply Chains: Perspectives from Academia and Industry. Comput. Chem. Eng. 2020, 132, 106606. [Google Scholar] [CrossRef]

- Aarts, H.F.M.; Habekotte, B.; Hilhorst, G.J.; Koskamp, G.J.; Van Der Schans, F.C.; De Vries, C.K. Efficient Resource Management in Dairy Farming on Sandy Soil. Neth. J. Agric. Sci. 1999, 47, 153–167. [Google Scholar] [CrossRef]

- Nahed, J.; Castel, J.M.; Mena, Y.; Caravaca, F. Appraisal of the Sustainability of Dairy Goat Systems in Southern Spain According to Their Degree of Intensification. Livest. Sci. 2006, 101, 10–23. [Google Scholar] [CrossRef]

- Faye, B.; Konuspayeva, G. The Sustainability Challenge to the Dairy Sector—The Growing Importance of Non-Cattle Milk Production Worldwide. Int. Dairy J. 2012, 24, 50–56. [Google Scholar] [CrossRef]

- Benyam, A.A.; Soma, T.; Fraser, E. Digital Agricultural Technologies for Food Loss and Waste Prevention and Reduction: Global Trends, Adoption Opportunities and Barriers. J. Clean. Prod. 2021, 323, 129099. [Google Scholar] [CrossRef]

- Duncan, E.; Abdulai, A.-R.; Fraser, E.D. Modernizing Agriculture through Digital Technologies: Prospects and Challenges. In Handbook on the Human Impact of Agriculture; Edward Elgar Publishing: Cheltenham, UK, 2021; pp. 138–161. [Google Scholar]

- National Academies of Sciences. Medicine a National Strategy to Reduce Food Waste at the Consumer Level; National Academies Press: Washington, DC, USA, 2020. [Google Scholar]

- López-Gálvez, F.; Gómez, P.A.; Artés, F.; Artés-Hernández, F.; Aguayo, E. Interactions between Microbial Food Safety and Environmental Sustainability in the Fresh Produce Supply Chain. Foods 2021, 10, 1655. [Google Scholar] [CrossRef]

- Bottani, E.; Casella, G.; Nobili, M.; Tebaldi, L. An Analytic Model for Estimating the Economic and Environmental Impact of Food Cold Supply Chain. Sustainability 2022, 14, 4771. [Google Scholar] [CrossRef]

- Augustin, M.A.; Udabage, P.; Juliano, P.; Clarke, P.T. Towards a More Sustainable Dairy Industry: Integration across the Farm–Factory Interface and the Dairy Factory of the Future. Int. Dairy J. 2013, 31, 2–11. [Google Scholar] [CrossRef]

- Atieno, R.; Kanyinga, K. The Revitalisation of Kenya Cooperative Creameries: The Politics of Policy Reforms in the Dairy Sector in Kenya. 2008. Available online: http://erepository.uonbi.ac.ke/bitstream/handle/11295/39683/Kanyinga_The%20Revitalisation%20of%20Kenya%20Cooperative%20Creameries.pdf?sequence=1 (accessed on 18 May 2023).

- Rob, V.O.S.; Cattaneo, A. Poverty Reduction through the Development of Inclusive Food Value Chains. J. Integr. Agric. 2021, 20, 964–978. [Google Scholar]

- Upton, M. The Role of Livestock in Economic Development and Poverty Reduction. 2004. Available online: https://ageconsearch.umn.edu/record/23783/ (accessed on 18 May 2023).

- Hurduzeu, G.; Pânzaru, R.L.; Medelete, D.M.; Ciobanu, A.; Enea, C. The Development of Sustainable Agriculture in EU Countries and the Potential Achievement of Sustainable Development Goals Specific Targets (SDG 2). Sustainability 2022, 14, 15798. [Google Scholar] [CrossRef]

- Ali, Z.A.; Zain, M.; Pathan, M.S.; Mooney, P. Contributions of Artificial Intelligence for Circular Economy Transition Leading toward Sustainability: An Explorative Study in Agriculture and Food Industries of Pakistan. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Cabrera, V.E.; Fadul-Pacheco, L. Future of Dairy Farming from the Dairy Brain Perspective: Data Integration, Analytics, and Applications. Int. Dairy J. 2021, 121, 105069. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Achieving Sustainable Performance in a Data-Driven Agriculture Supply Chain: A Review for Research and Applications. Int. J. Prod. Econ. 2020, 219, 179–194. [Google Scholar] [CrossRef]

| Model | Equations | Explanation | Meaning of Terms |

|---|---|---|---|

| AR (p) | Yt = c + ϕ1Yt−1 + ϕ2Yt−2 + … + ϕpYt−p + ε | In the AR model, the current value Yt is a linear combination of its past values up to order p. | Yt—current value of the time-series; c—constant; ϕ1, ϕ2, …, ϕp—autoregressive coefficients; ε—white noise error terms. |

| MA (q) | Yt = c − θ1εt−1 − θ2εt−2 − … − θqεt−q + ε | In the MA model, the current value Yt depends on a linear combination of past white noise error terms up to order q. | Yt—current value of the time-series; c—constant; θ1, θ2, …, θq—moving average coefficients; εt−1, εt−2, …, εt−q—white noise error terms. |

| ARMA | Yt = c + ϕ1Yt−1 + ϕ2Yt−2 + … + ϕpYt−p + ε − θ1εt−1 − θ2εt−2 − … − θqεt−q | The ARMA model combines both AR and MA components, expressing the current value Yt as a combination of past values and past error terms. | Yt—current value of the time-series; c—constant; ϕ1, ϕ2, …, ϕp—autoregressive coefficients; ε—white noise error term; θ1, θ2, …, θq—moving average coefficients; εt−1, εt−2, …, εt−q—white noise error terms. |

| ACF | PACF | Model | |

|---|---|---|---|

| AR (p) | Geometric | Significant until p lags | (p, d, 0) |

| MA (q) | Significant until q lags | Geometric | (0, d, q) |

| AR (p) MA (q) | Significant until q lags | Significant until p lags | (p, d, q) |

| AR (p) | I (d) | MA (q) | ARIMA (p, d, q) |

|---|---|---|---|

| 1 | 2 | 1 | ARIMA (1, 2, 1) |

| 2 | 2 | 1 | ARIMA (2, 2, 1) |

| 2 | 2 | 2 | ARIMA (2, 2, 2) |

| 1 | 2 | 2 | ARIMA (1, 2, 2) |

| Month | Actual Production (Kgs) | ARIMA (1, 2, 1) | ARIMA (2, 2, 1) | ARIMA (2, 2, 2) | ARIMA (1, 2, 2) |

| April 2021 | 7,276,530 | 7,915,560 | 7,883,079 | 7,990,791 | 7,995,746 |

| May 2021 | 7,284,150 | 7,420,933 | 7,401,705 | 7,844,204 | 7,577,291 |

| June 2021 | 7,428,660 | 6,885,345 | 6,874,768 | 7,500,731 | 7,134,018 |

| July 2021 | 6,240,510 | 6,385,984 | 6,383,390 | 7,278,260 | 6,714,827 |

| August 2021 | 4,304,730 | 6,385,984 | 6,002,114 | 7,057,491 | 6,390,933 |

| September 2021 | 4,006,170 | 5,793,478 | 5,804,899 | 6,943,595 | 6,216,954 |

| October 2021 | 3,665,070 | 5,849,720 | 5,865,956 | 6,947,270 | 6,259,852 |

| Model | MAPE | |

|---|---|---|

| ARIMA (1, 2, 1) | 22.6 | 0.739 |

| ARIMA (2, 2, 1) | 21.3 | 0.790 |

| ARIMA (2, 2, 2) | 37.4 | 0.818 |

| ARIMA (1, 2, 2) | 28.4 | 0.793 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kashyap, A.; Shukla, O.J.; Jha, B.K.; Ramtiyal, B.; Soni, G. Enhancing Sustainable Dairy Industry Growth through Cold-Supply-Chain-Integrated Production Forecasting. Sustainability 2023, 15, 16102. https://doi.org/10.3390/su152216102

Kashyap A, Shukla OJ, Jha BK, Ramtiyal B, Soni G. Enhancing Sustainable Dairy Industry Growth through Cold-Supply-Chain-Integrated Production Forecasting. Sustainability. 2023; 15(22):16102. https://doi.org/10.3390/su152216102

Chicago/Turabian StyleKashyap, Abhishek, Om Ji Shukla, Bal Krishna Jha, Bharti Ramtiyal, and Gunjan Soni. 2023. "Enhancing Sustainable Dairy Industry Growth through Cold-Supply-Chain-Integrated Production Forecasting" Sustainability 15, no. 22: 16102. https://doi.org/10.3390/su152216102

APA StyleKashyap, A., Shukla, O. J., Jha, B. K., Ramtiyal, B., & Soni, G. (2023). Enhancing Sustainable Dairy Industry Growth through Cold-Supply-Chain-Integrated Production Forecasting. Sustainability, 15(22), 16102. https://doi.org/10.3390/su152216102