1. Introduction

Industrial modernization has brought forth detrimental impacts on the ecosystem, encompassing carbon emissions, hazardous chemical leaks, and pollution. Among the various methods devised to foster economic development and sustainable performance, Circular Economy (CE) practices stand out [

1]. In a circular economy, the emphasis lies in preserving the value of products and materials for as long as possible. This entails minimizing waste and resource consumption; ensuring resources remain within the economy even after a product’s lifecycle ends.

Firms orchestrate and synchronize organizational functions such as marketing, sales, production, logistics, IT, finance, and customer service, both within and across firms. This closure of material and energy loops reduces resource inputs, waste, and emission leakage, subsequently bolstering firm performance [

2]. Simultaneously, an escalating awareness of the ecological impacts of manufacturing is compelling producers in emerging and developed markets alike to reconsider their practices. However, the pressure for producers to contribute continuously to their countries’ economic development is also mounting. This necessitates a delicate balance between commercial growth and environmental preservation, given the predicted rapid expansion of the manufacturing industry over the next decade [

3]. Consequently, manufacturers are recognizing the urgent requirement to adopt environmentally conscious approaches, including recycling initiatives, in collaboration with consumers and suppliers, to mitigate the negative ecological consequences of their products and services [

4]. The topic of the CE is drawing increasing attention from industries, academics, policy makers, and consumers [

5]. In particular, there is a pronounced need for academic research to ascertain whether CE activities yield the desired firm performance outcomes.

Concurrently, contemporary technologies play a pivotal role in facilitating Circular Economy (CE) practices, with this study advocating for the significance of technological advancements, such as blockchain, in supporting organizational performance paradigms [

6]. These advancements are recognized as crucial enablers capable of addressing diverse firm performance challenges [

7]. Advanced technologies (AT) have the potential to drive economic transitions by amalgamating, analyzing, and integrating data [

8]. For example, the establishment of digital networks to streamline information flow in supply chain processes holds substantial potential for waste reduction, enhancing circular resource flows, and refining decision-making [

9]. Consequently, there is a pressing need to scrutinize the role played by advanced technologies, including big data, AI, and blockchain, in achieving sustainability within business operations.

Both CE and AT signify emerging concepts capable of instigating socioeconomic transformations [

10]. CE’s central goal is to elevate product value by extending their lifespans, necessitating a reshaping of business models and production systems during the transition from linear to circular economies [

11]. The confluence of AT and the CE model in augmenting firm economic and environmental performance has captivated researchers in the nascent fields of digitalization and sustainability [

12]. Clarifying these phenomena can yield a better comprehension and implementation of sustainable business models. Consequently, we formulate the following research question:

What relationship exists between advanced technology, the circular economy, and the environmental and economic performance of firms?

A plethora of research on practices and firm performance has emerged since its inception [

13]. Empirical research outcomes on the impact of CE practices on enterprise performance vary. For instance, refs. [

14,

15] found that the implementation of CE practices did not lead to financial growth for Chinese industrial enterprises. The infancy of CE practice implementation implied substantial investment costs, potentially increasing operating costs and subsequently decreasing commercial profits. However, more recent research has suggested a positive correlation between CE practices and financial benefits [

16]. Given these mixed results, our research seeks to offer deeper insights into the correlation between CE practices and enterprise performance, recognizing the intricate and multifaceted nature of CE implementation.

In this study, we employ regression analysis to explore the relationship between CE, AT, and their impact on the economic and environmental performance of Indian FMCG firms. As the Indian FMCG sector presents a unique context, we propose that digitalization holds substantial potential to enhance the sector’s transition to a circular economy. The scientific literature and public discourse underscore digital technologies’ role in promoting circular economies—economies that minimize resource use while maximizing material value through practices such as reuse, repair, refurbishment, remanufacturing, recycling, and energy recovery [

17,

18]. Industry 4.0 technologies, including IoT, big data, advanced analytics, 3D printing, additive manufacturing, blockchain, and online platforms, are expected to drive circularity in business models, products, and production processes. They also facilitate knowledge exchange and connections between stakeholders across the value chain [

19]. Additionally, digital technologies are poised to empower citizens and consumers by providing information and education, and encouraging active participation in the transition towards circular economies.

Existing research on the advanced technology and circular economy has largely focused on investigating technologies’ enabling role in circular strategies [

10,

20], identifying use cases [

21,

22,

23], and addressing implementation challenges [

24]. However, the current literature lacks a comprehensive analysis of the opportunities and risks posed by AT in achieving environmental, and economic sustainability [

4]. Consequently, there is a growing call for more research on the impact of digital technology and circular economy within a specific economy context [

25,

26,

27,

28]. This article endeavors to bridge this knowledge gap by offering an investigation into the effects of AT and CE on the environmental and economic performance of the resource intensive FMCG sector within a developing economy such as India, particularly in a resource-intensive sector.

1.1. FMCG Sector

The FMCG (Fast-Moving Consumer Goods) sector, the fourth-largest contributor to the Indian economy, is on a remarkable growth trajectory. As of December 2022, the FMCG market had already surged to a valuation of US

$ 56.8 billion. Projections foresee a remarkable journey ahead, with the total revenue of the FMCG market poised to exhibit a robust Compound Annual Growth Rate (CAGR) of 27.9% between 2021 and 2027, potentially catapulting to nearly US

$ 615.87 billion by 2027 [

24]. What is particularly noteworthy is the sector’s resolute commitment to sustainability and circular economy practices. A noteworthy 60% of FMCG companies in India have embraced at least one circular economy practice, as highlighted in the FICCI Report of 2022. This dedication extends further, as a survey by the Confederation of Indian Industry (CII) revealed that an impressive 75% of FMCG companies operating in India are actively engaged in sustainability initiatives [

29,

30]. Aligned with these sustainability objectives, the Indian government has set an ambitious target to reduce waste generation by a substantial 30% by the year 2030 [

24]. To foster green manufacturing, a series of regulations have been introduced, including the Energy Conservation Act and the Water Conservation Act. FMCG companies are responding to these imperatives by integrating sustainable ingredients and materials into their product portfolios. For instance, Hindustan Unilever has committed to incorporating 100% sustainable palm oil in its products by 2023, while Nestle India is diligently working towards using 100% recycled paper in its packaging by 2025 and enhancing packaging recyclability [

31]. The tangible expression of this commitment can be observed in Coca-Cola India’s innovative introduction of a bottle crafted entirely from 100% recycled plastic and PepsiCo India’s launch of snacks thoughtfully packaged in compostable wrappers. Moreover, these companies are proactively conserving water within their operations; Dabur India, for instance, has deployed water-saving devices in its manufacturing facilities, and Godrej Consumer Products has introduced a rainwater harvesting system at its corporate headquarters.

Beyond this, significant strides are being made in enhancing energy efficiency, as exemplified by ITC’s installation of solar panels at its factories and Marico’s implementation of energy-efficient lighting within its offices. Additionally, FMCG companies are placing an emphasis on responsible waste management to minimize their environmental footprint. Notable initiatives include Procter & Gamble India’s establishment of a waste-to-energy plant at its Manesar factory and HUL’s pioneering recycling program for its shampoo bottles [

32].

These noteworthy sustainability milestones underscore the substantial progress achieved by FMCG companies in India in their unwavering commitment to sustainability. Therefore, the choice of the FMCG sector as the focal point of our study is well-justified, as it embodies the transformative journey toward sustainability and green manufacturing.

1.2. Review of Literature

1.2.1. Economic and Environmental Performance

The central focus of organizations revolves around maintaining both economic and environmental efficiency in their operations, with the aim of flourishing and competing effectively in the marketplace. The achievement of organizational performance is contingent on a multitude of factors, encompassing the optimization of economic gains, the empowerment of human resources, the cultivation of innovative expertise within the organization, and the advancement of environmentally responsible operational practices. This concept of sustainability transcends mere financial metrics such as profits and return on investment; it encompasses a holistic approach that takes into account environmental and social dimensions, as elucidated by [

33,

34]. Manufacturing enterprises are tasked with fulfilling the expectations and requirements of diverse stakeholders such as clients, customers, suppliers, society, and governments. To attain the pinnacle of sustainability, manufacturing entities must address two interconnected dimensions: the economic dimension and the environmental dimension, as coined by [

35,

36]. The economic sustainability performance (EP) holds a pivotal role in ensuring the financial well-being of a company. The ability to continuously produce goods and services while simultaneously generating profits is quintessential for the organization’s survival, a principle emphasized by [

5]. The sustenance of sound economic performance is a critical gauge of a business’s capacity to thrive in the long term, and it greatly influences a wide array of decision-making processes that reverberate across various aspects of the organization, as underscored by [

36]. The environmental sustainability performance (EVP) centers on an organization’s ecological impact arising from its routine production activities, as elucidated by [

5,

37]. Thus, to ensure environmental sustainability, an organization must endeavor to achieve either net zero emissions or a positive ecological footprint within its local ecosystem. This involves endeavors such as improving air and water quality, harnessing local waste streams, deploying renewable energy sources, and functioning as a reservoir for surplus energy, as posted by [

38].

1.2.2. Circular Economy

In alignment with other scholars [

10,

26,

39], we contend that the prevailing linear economic model, characterized by inefficient resource utilization, serves as the fundamental catalyst for numerous prevailing environmental crises. These encompass issues such as the depletion of natural habitats, scarcities in resources, unsustainable production–consumption waste, oceanic plastic pollution, and escalating health concerns arising from burgeoning waste volumes [

25,

29,

40]. As these interconnected challenges propagate across the globe via intricate supply chains, the linear economy (LE) emerges as a formidable “societal grand challenge”, a term defined by [

41] to denote global predicaments impacting vast populations across multiple nations and regions.

In response to the impending consequences of linear production–consumption patterns, a prevalent solution advocated is the transition toward a circular economy (CE). This novel economic paradigm revolves around business models that transcend the traditional “end-of-life” concept by prioritizing reduction, reuse, recycling, and resource recovery throughout production, distribution, and consumption processes. Its application spans micro-level (products, companies, consumers), meso-level (eco-industrial parks), and macro-level (city, region, nation, and beyond), with the ultimate objective of fostering sustainable development—entailing environmental integrity, economic prosperity, and social equity—for the present and future generations [

6,

31,

42]. The burgeoning interest in CE is mirrored by the surging volume of recent investigations. Initial studies in this domain [

33,

43,

44] concentrated on framing the CE concept and distinguishing it from related notions such as sustainability. More contemporary inquiries have zoomed in on specific aspects, including CE business models [

16,

45], circular supply chains [

8], digital technologies in CE [

21,

42,

46,

47], and geographical analyses of CE implementation [

35,

37]. Consistently recurring themes in the existing research spotlight various conceptualizations of CE. Some scholars view it as an overarching economic system [

48] or as a mechanism for waste elimination, while others perceive it as a holistic vision for societal transformation [

49]. Conversely, CE is also construed as an assembly of strategies [

49] or as a targeted solution to specific issues [

50]. Further conceptualizations encompass CE as a means to decouple economic growth from resource usage [

16,

44,

51], a mechanism to uphold material values, or a pathway to regeneration [

52,

53]. Despite the considerable scholarly attention lavished on this topic, a notable dearth of critical exploration persists in the domain of organizational performance concerning the influence of CE practices on economic and environmental performance. Noteworthy investigations [

5] that have linked CE to organizational performance have yielded mixed findings. For instance, authors of [

46] report a positive correlation between the adoption of green practices and firms’ economic value. Similarly, some studies posit a favorable association between green supply chain practices and firms’ profitability [

1]. Conversely, counter-evidence suggests that the embrace of green practices could lead to reduced productivity and financial pressures [

53,

54]. This incongruity underscores the need for an in-depth exploration of the role of CE practices in enhancing organizational performance. Researchers contend that contextual factors play a pivotal role in elucidating the multifaceted outcomes observed in CE-performance research. Thus, our investigation focuses on a developing economic context within the resource-intensive FMCG sector.

As highlighted by [

55], Circular Economy (CE) holds a pivotal role in ensuring economic security, fostering green growth, and promoting sustainable economic development. This concept not only carries substantial potential to generate novel and unparalleled opportunities but also underscores the recommendation for nations to implement dedicated policies in support of Circular Economy principles [

26,

56]. This notion advocates circular economy practices plays a significant role in producing sustainable solutions. The concept of technological advancement and circular economy is a new research interest and needs to be explored.

1.3. Theoretical Framework and Hypothesis Development

1.3.1. Conceptual Model

This research proposed a conceptual model containing all the research variables. The conceptual model is given as under (

Figure 1).

1.3.2. Technology Advancements (TA) and the Circular Economy Practices (CP)

This section is designed to explore the relationship between technology integration and green practices or circular economy practices. Presently, digitalization has generally been considered as an essential element in every industry and has quite an impressive role in the evolution of the CE industry. These systems may be used to decrease the consumption of resources. It can be used lower logistics cost. Technology innovation encourages transparency, which enables the company to obtain information on the usage of resources for the product, assisting businesses in extending the life of their products and moving towards CE practices.

Digital technologies utilized in Industry today have been categorized by [

8,

57] into three streams of data management: collection of data, data processing, and data analysis. Data-gathering technologies include sensors (such as RFID) and devices that connect objects and people to the Internet. Data integration technologies gather and categorize data, and data analysis prepares data for decision making [

23]. The most often mentioned technologies are blockchain and the cloud [

46]. Furthermore, analyzing big data and artificial intelligence (AI) are now widely used as essential tools for analyzing data. Data are becoming a fifth factor of production, the companies dealing in this area are precious. The use of data is pervasive and essential in every field of human enquiry. Therefore, circular economy practices also suffice from it and gets heavily influenced.

According to researchers, CE models seek to build waste-reducing goods and services with the use of digital technology in order to promote sustainability [

58,

59]. Existing research has shown that the status of digital technology is having a growing impact on CE practices and innovation [

19,

39]. Additionally, efforts are being made to integrate digital technology into the industrial sector at the same time as CE development [

7]. In addition, it has been stated that cutting-edge digital technologies are swiftly taking hold in industrial transformation, including the Internet of Things (IoT), RFID, Internet-based Services (IoS), and meta cyber systems (MCS) [

20]. The retail industry and the downstream portion of the upstream supply chain depend heavily on the data generated by technologies such as RFID. Companies may evaluate the quality of returned items using these data, and return flows can be optimized over the course of the PLC [

1]. The most recent research by [

18,

27] discovered that businesses that implement circular economic concepts experience much higher value generation from technological development. Therefore, based on the aforementioned justifications, it may be concluded that:

H1. Circular Economy practices are greatly influenced by technological innovation and advancements.

1.3.3. Technological Advancements and Environmental Performance

Using Internet also showed how real-time data for decision-making may assist cyber-physical systems optimize production, supply, and maintenance [

10]. Incorporating the aforementioned technology solutions into material processes also aids in the collection, organization, and use of trash as a resource for the company [

28,

30].

H2. Environmental Performance is greatly influenced by technological innovation and advancements.

1.3.4. Technological Advancements and Economic Performance

According to studies on Industry 4.0, digital technologies also help businesses become efficient by cutting expenditure by utilizing capabilities of IT. Digital technologies not only assist companies in enhancing value generation and capture, but also influence resource flow plans. Digital solutions’ ability to automate resource management, control, and optimization may be used to develop circular business models, which also helps firms reduce supply chain costs.

H3. Economic Performance is greatly influenced by technological innovation and advancements.

1.3.5. Circular Economy Practices (CP) and Environmental Performance (EP)

Circular Economy Practices such as procurement or design are two environmental projects that are frequently recognized as good strategies to significantly minimize waste output and decrease the overall ecological footprint [

1]. The future of supply chains using digital technologies and circular economy principles asserts that the introduction of CP is a crucial first step in the development of a fully green supply chain process. Environmentally friendly design and operating practices significantly reduce harmful environmental effects and may increase the viability of the business. The ecological design makes it easier to disassemble and recycle items, which will enable the company to use fewer dangerous chemicals and use less raw resources in manufacturing. When refs. [

47,

60] looked at several environmental performance factors, they also discovered that eco design is strongly and directly connected to socio-environmental sustainability.

The researchers contend that selecting the appropriate suppliers is just as crucial for businesses as adopting sustainable green management [

26]. Having an extraordinarily wide selection of environmentally friendly providers is crucial in a difficult, cutthroat market, impacting production choices both fundamentally and psychologically. In their study of UK businesses, ref. [

12] found a significant and positive correlation between eco-practices and environmental performance. By implementing green practices at various points throughout the supply chain, businesses may be able to increase income while reducing waste and improving processing efficiency. Every attempt is made to reduce the unfavorable environmental effects of a company’s products and services as part of its GSCM operations. According to [

26], these initiatives help reduce material and water use, as well as trash production, to the absolute minimum. Therefore, based on the aforementioned justifications, it may be concluded that:

H4. The Circular economy Practices influence positively to Environmental Performance.

1.3.6. Circular Economy Practices (CP) and Economic Performance (ECP)

Organizations benefit economically from implementing technology-based systems to advance the circular economy in numerous ways, some of which were already discussed in the introduction section. According to the growing body of research on the circular economy, the inclusion of technology may lower long-term costs related to environmental risks associated with corporate operations [

1]. The use of CE-accredited methods helps to conserve natural resources, reduce wasteful spending, and keep money in the general economy [

47]. Eco-friendly practices assistin the reduction of waste throughout whole operations, increasing profits [

45]. According to the literature, green practices and business performance are related. Two methods in which GSCM may improve economic performance are as follows: first, enterprises can gain an economic advantage by using less resources and energy. Second, businesses may obtain indirect economic benefits by improving their brand recognition and customer loyalty [

61]. According to these studies’ findings [

24,

27], applying Green SCM approaches positively affects a company’s total productivity. Additionally, market-driven circular economy initiatives such as creating more sustainable products may expand sales opportunities and increase profitability [

52,

53]. The research by [

62], also advocated the similar perception, validated this earlier research. Green management practices have been shown to improve public perception and reputation, which might lead to increased demand for goods [

21,

63]. Increasing operational efficiency through waste reduction is also thought to improve environmental performance, which, in turn, leads to better financial performance [

64]. As a result, it is implied that based on the reason and previous arguments.

H5. The Circular economy Practices influence positively to Economic Performance.

4. Discussion and Implications

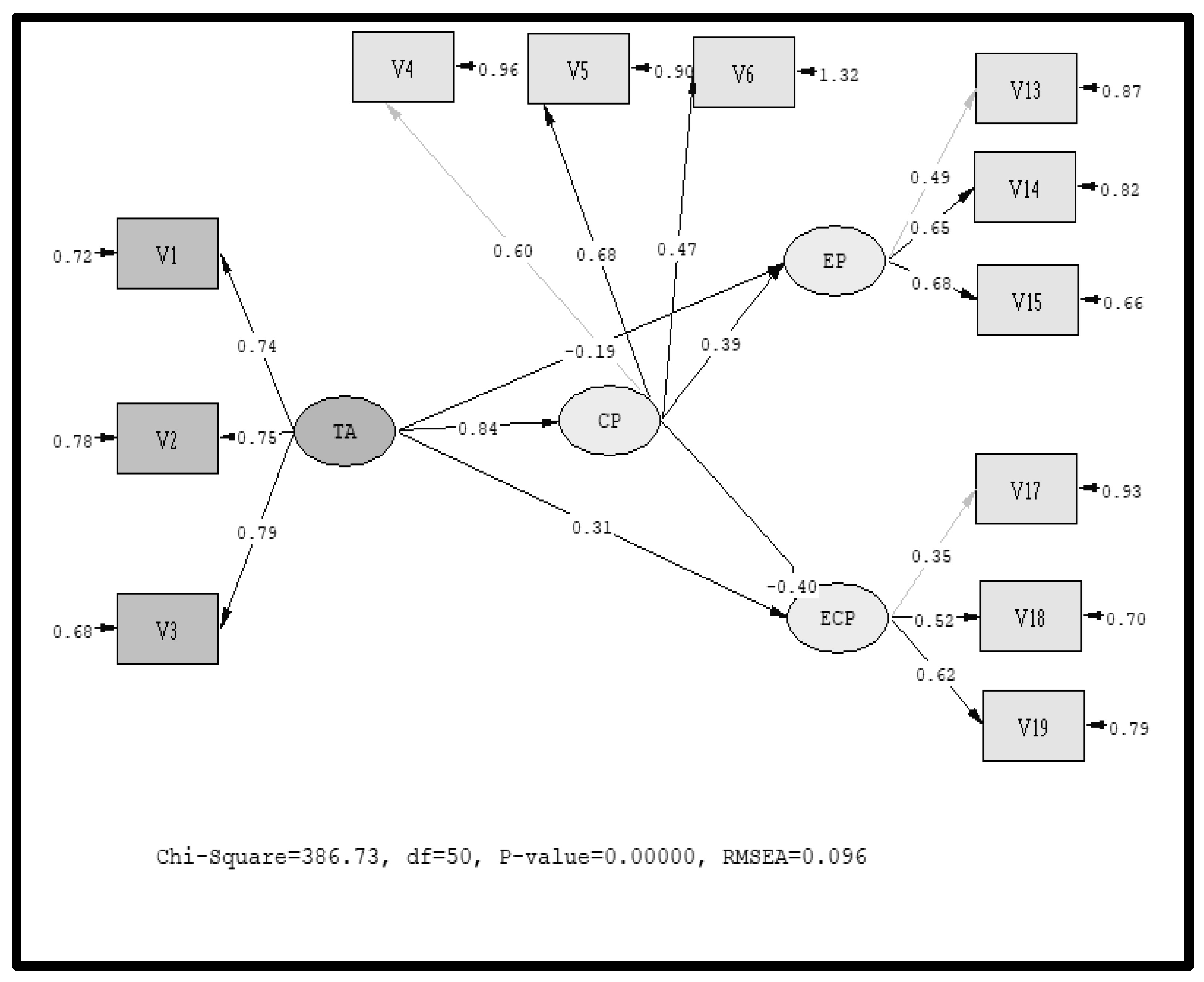

The findings of the present study underscore the significant influence of Advanced Technologies (AT) on Circular Economy (CE) practices. These results align with earlier investigations by [

22,

47], corroborating the substantial impact of AT on CE practices. These studies also emphasized the challenges of technological security and interoperability faced by this technology. In a similar vein, ref. [

22] positioned AT, such as blockchain, as an emerging facilitator of CE practices, supporting information systems and enhancing CE performance. Ref. [

72] conducted a case study that reinforced the idea that AT fosters energy and material traceability, streamlining reuse and recycling planning, making it a feasible strategy for CE adoption. Researchers stressed the pivotal role of AT in implementing CE, particularly through digitization, integration, and automation during the current era of industrial revolution.

Remarkably, our findings indicate that the advancement of technology does not significantly impact environmental performance, in accordance with recent work by [

7]. Nevertheless, this conclusion contrasts with the study by [

19] conducted within the context of Mexican SMEs. This inconsistency may arise from the fact that Indian technologies are not tailored to enhance environmental performance. Alternatively, the impact of AT on environmental performance might be indirect, warranting further investigation. This outcome enriches the literature by suggesting that the direct impact of AT on environmental performance within India’s FMCG sector is not prominent.

Additionally, our research underscores the positive influence of AT on the economic performance of Indian FMCG companies, consistent with earlier studies. Moreover, we find that circular economy practices yield a positive impact on the environmental performance of Indian FMCG firms, aligning with existing research [

47] However, it is worth noting that our findings do not reveal a significant impact of circular economy practices on economic performance, which diverges from prior studies [

47]. This unexpected outcome may arise from two factors. Firstly, Indian FMCG companies might not have fully embraced CE practices to enhance economic efficiency. Secondly, due to the resource-intensive nature of the FMCG sector, its efficiency may be more dependent on resource availability rather than CE practices. This finding contradicts prior conclusions suggesting that CE practices boost economic performance. Consequently, we recommend further research to delve into the underlying causes of this inconclusive outcome.

The study’s contributions are manifold. It provides a contextual understanding of CE practices and organizational performance within the framework of a developing economy such as India, addressing a gap in a literature predominantly focused on Western developed nations. Additionally, the intriguing disparity in findings regarding the connection between CE practices and organizational efficiency is highlighted. Our study highlights that technological advancements primarily impact economic efficiency, while CE practices predominantly influence environmental efficiency. These revelations pave the way for future research and the need for further validation. This study also provides a clearer understanding of FMCG sector of Indian economy which extremely important from CE perspective as it is resource intensive sector. Lastly, our study responds to the call for exploring the nexus between CE practices and firm performance, contributing to the development of a more robust framework and theory-building process.

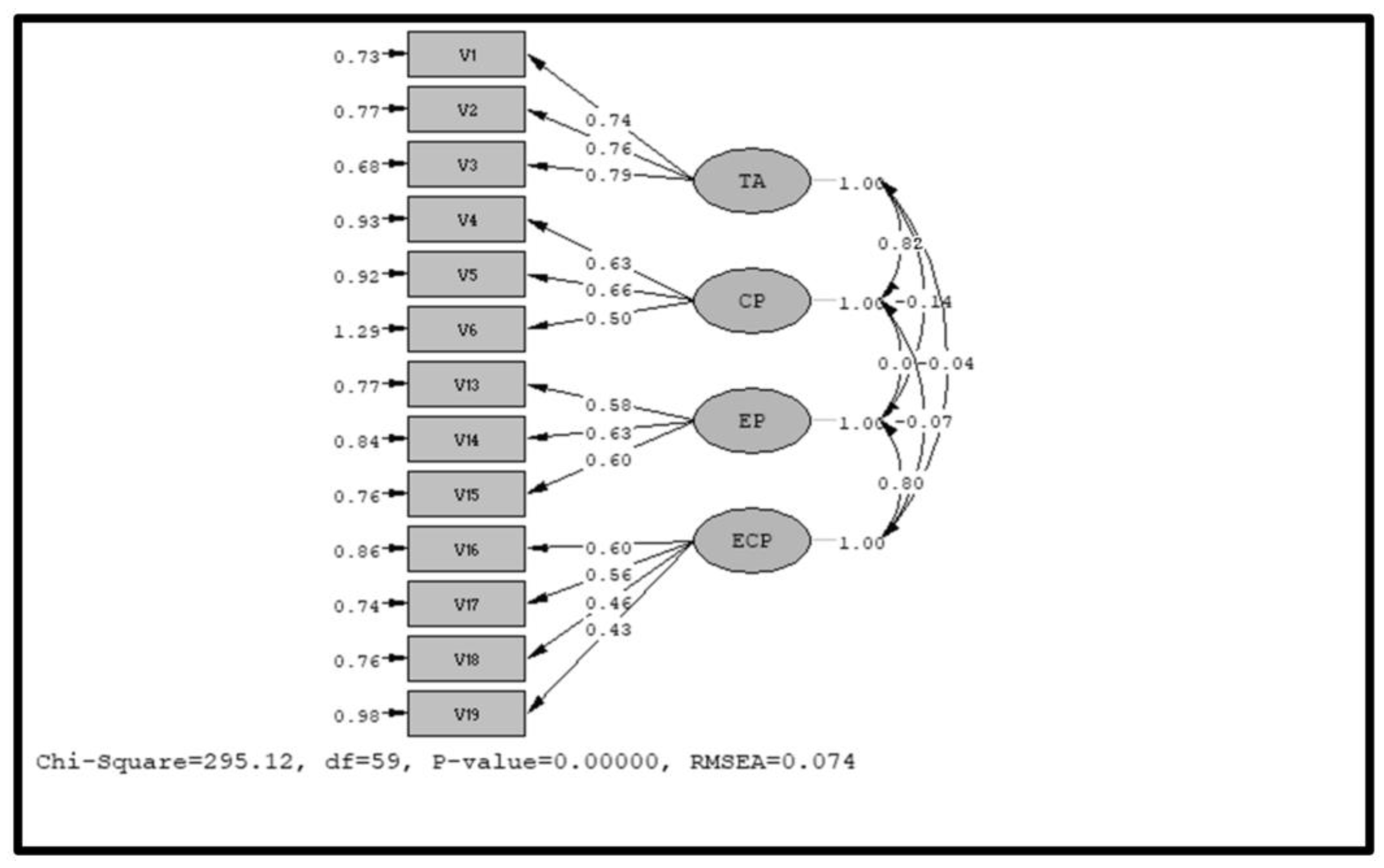

The goal of the current research is to improve organizational economic and environmental performance by examining the impact of digitalization on CE practices. Through various channels of contact, questionnaires were used to gather cross-sectional data from Indian FMCG Companies. The SEM method was utilized for analysis. The analysis’ results were found to be internally consistent and to have both convergent and discriminant validity. The findings demonstrate that digitalization has a favorable impact on CE practices. The results also show that the firm’s performance in terms of the environment is significantly improved by CE practices. The study’s findings also show a strong relation between technological advancements economic performance. The study also reveals a negligible impact of circular economy practices on economic performance of these firms. The relationship between technological advancements and environmental performance found to be insignificant.

4.1. Theoretical Implications

The findings demonstrate that technological advancements have a favorable impact on CE practices. This indicates that technology advancements helped East European automakers accelerate their adoption of CE. The results also show that CE practices are shown to significantly improve a company’s operational, economic, and environmental performance making those businesses more sustainable as a consequence. The study’s findings also show a strong correlation between technological advancements, CE Practices, and economic and environmental performance of an organization. This is not unexpected because companies that adopt technology and CE practices usually perform well in economic and environmental areas.

4.2. Managerial Implications

A deliberate endeavor on the part of FMCG company administrations to seamlessly integrate technologies into their operational and logistical frameworks emerges as essential. This strategic move promises the dual advantage of reducing workforce requirements, thereby augmenting both economic and environmental performance. Furthermore, it serves as a pivotal step towards embracing digitalization and harnessing the potential of Artificial Intelligence, which is widely recognized as the future trajectory for the FMCG industry.

Simultaneously, significant attention must be directed towards embracing circular practices. An illustrative example includes the adoption of recycled materials for packaging purposes. The promotion and affordability of products adhering to circular norms could be facilitated by offering them at reduced prices.

These implications, stemming from the current study, carry policy implications for managerial decision-makers and stakeholders. The integration of technologies within Circular Economy practices to curtail carbon footprint while safeguarding financial stability has been endorsed by the study. Managers are encouraged to draw inspiration from this research, translating it into the implementation of technologies to reap operational, environmental, and financial benefits.

In the Indian context, governmental entities are urged to foster the adoption of technological infrastructure to support environmental legislation. This proactive stance aligns with the effective management of businesses in alignment with their ecological commitments. The study underscores the potential efficacy of providing businesses with tax exemptions and interest-free loans as incentives for adeptly incorporating technology into their operations, a measure that could be envisaged by legislators based on the study’s findings.

More recently, Industry 4.0 has had a positive impact on the environment [

17]; hence, government should also design policies aimed at promoting industry 4.0.