Examining Sustainability Alignment of Supplier Selection Criteria during Industrial Revolutions

Abstract

:1. Introduction

2. Literature Review

2.1. Part One: Overview of Sustainability

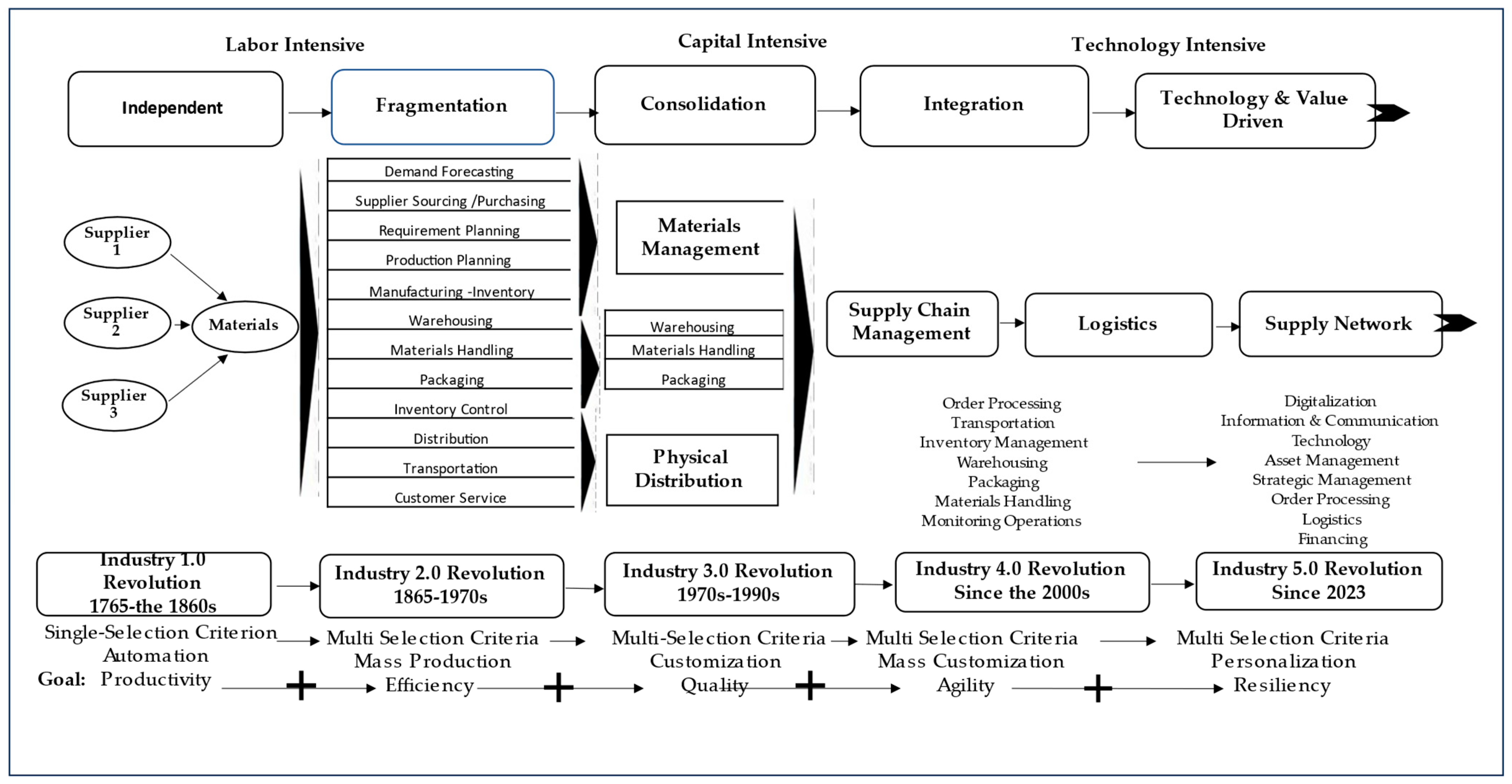

2.2. Part Two: Industrial Revolutions

2.2.1. Industry 1.0

2.2.2. Industry 2.0

2.2.3. Industry 3.0

2.2.4. Industry 4.0

2.2.5. Industry 5.0

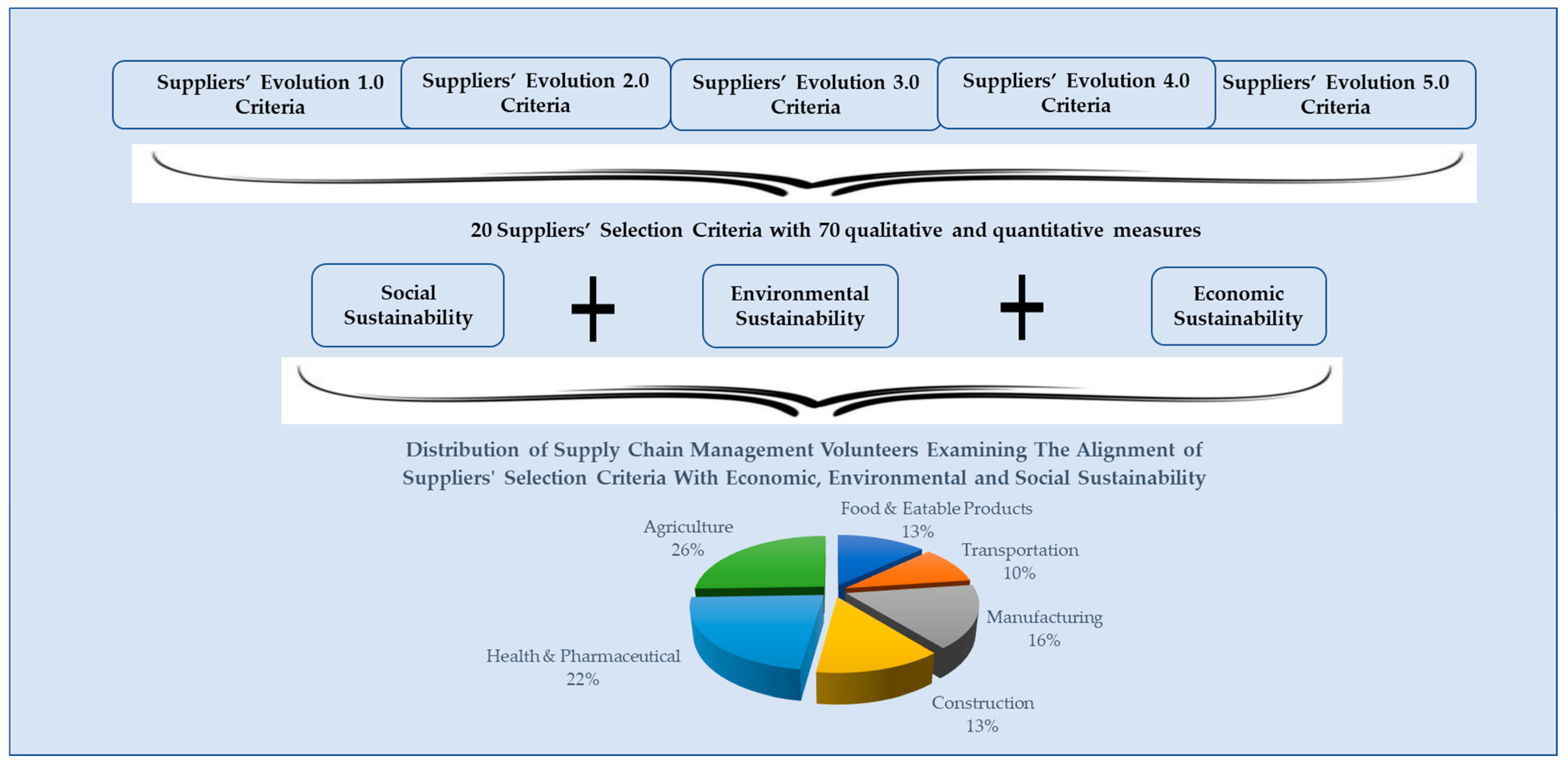

3. Research Methodology

3.1. Data Collection

3.2. Data Analysis

3.3. Discussion

3.3.1. Brief Background

3.3.2. Professional Views on Sustainability during Industrial Revolutions

- (a)

- Views on Sustainability During the First Industrial Revolution

- (b)

- Views on Sustainability During the Second Industrial Revolution

- (c)

- Views on Sustainability During the Third Industrial Revolution

- (d)

- Views on Sustainability During the Fourth and Fifth Industrial Revolutions

- (e)

- Sustainability During the Fifth Industrial Revolution

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Che, H.; Wang, S. Supplier selection and supply quantity allocation of common and non-common parts with multiple criteria under multiple products. Comput. Ind. Eng. 2008, 55, 110–133. [Google Scholar] [CrossRef]

- Nath, D.; Eweje, G.; Sajjad, A. The hidden side of sub-supplier firms’ sustainability—An empirical analysis. Int. J. Oper. Prod. Manag. 2020, 40, 1771–1799. [Google Scholar] [CrossRef]

- Ripple, W.J.; Wolf, C.; Gregg, J.W.; Levin, K.; Rockström, J.; Newsome, T.M.; Betts, M.G.; Huq, S.; Law, B.E.; Kemp, L.; et al. World Scientists’ Warning of a Climate Emergency 2022. BioScience 2022, 72, 1149–1155. [Google Scholar] [CrossRef]

- Tobin, E.; Kottasová, I. 11,000 Scientists Warn of ‘Untold Suffering’ Caused by Climate Change. CNN. 2019. Available online: https://www.cnn.com/2019/11/05/world/climate-emergency-scientists-warning-intl-trnd/index.html (accessed on 10 March 2023).

- The US Environmental Protection Agency. Sustainability and the U.S. EPA. 2011. Available online: https://nap.nationalacademies.org/catalog/13152/sustainability-and-the-us-epa (accessed on 10 April 2023).

- McKinsey & Company. Starting at the Source: Sustainability in Supply Chains. 2016. Available online: https://www.mckinsey.com/~/media/McKinsey/Business%20Functions/Sustainability/Our%20Insights/Starting%20at%20the%20source%20sustainability%20in%20the%20supply%20chain/Starting-at-the-source-Sustainability-in-supply-chains.pdf (accessed on 10 January 2023).

- Environmental and Society Portal. 2013. Available online: https://www.environmentandsociety.org/tools/keywords/hans-carl-von-carlowitz-and-sustainability. (accessed on 5 October 2023).

- Van Weenen, H. Towards a vision of a sustainable university. Int. J. Sustainability. 2000, 1, 20–34. [Google Scholar] [CrossRef]

- Costanza, R. Ecological Economics: All scientific analysis is based on a “pre-analytic vision”, the major source of uncertainty about current environmental policies results from differences in visions and world views. BioScience 2001, 51, 459–468. [Google Scholar] [CrossRef]

- Henriques, A.; Richardson, J. The Triple Bottom Line. Does it All Add Up? Taylor & Francis Group: Abingdon, UK, 2004. [Google Scholar] [CrossRef]

- Werbach, A. Strategy for Sustainability: A Business Manifesto; Harvard Business; Springer: Berlin/Heidelberg, Germany, 2009; Available online: https://store.hbr.org/product/strategy-for-sustainability-a-business-manifesto/12169 (accessed on 14 May 2023).

- Hasna, M. Sustainability classifications in engineering: Discipline and approach. Int. J. Sustain. Eng. 2010, 3, 258–276. [Google Scholar] [CrossRef]

- Moldan, B.; Janouskova, S.; Hak, T. How to understand and measure environmental sustainability: Indicators and targets. Ecol. Indic. 2012, 17, 4–13. [Google Scholar] [CrossRef]

- Slimane, M. Role and the relationship between leadership and sustainable development to release social, human, and cultural dimension. Procedia-Soc. Behav. Sci. 2012, 41, 92–99. [Google Scholar] [CrossRef]

- The Earth Summit on Environmental. 1992. Available online: https://www.un.org/en/conferences/environment/rio1992 (accessed on 6 April 2023).

- The United Nations’ Sustainable Development. Open SDG Data Hub. 2015. Available online: https://sdgs.un.org/goals#icons (accessed on 11 May 2023).

- Basiago, D. Economic, social, and environmental sustainability in development theory and urban planning practice. Environmentalist 1998, 19, 145–161. [Google Scholar] [CrossRef]

- Brundtland Commission. Our Common Future. 1987. Available online: https://sustainabledevelopment.un.org/content/documents/5987our-common-future.pdf. (accessed on 29 May 2023).

- The United Nations, Department of Economic and Social Affairs Sustainable Development. 17 Goals. 2015. Available online: https://sdgs.un.org/goals#icons (accessed on 1 February 2023).

- The United Nations Environmental Programme, Emissions Gap Report. 2022. Available online: https://www.unep.org/resources/emissions-gap-report-2022?gclid=CjwKCAjwrdmhBhBBEiwA4Hx5gxUtxyaMMltoEktFB3uJWle5-DY-r5BjmgEAjT1gQtpHyWLtukIFbhoChJsQAvD_BwE (accessed on 10 March 2023).

- Stoddart, H.; Bottero, M.; Cornforth, J.; Dodds, F.; Lingan, J.; Schneeberger, K.; Shaw, A.; Smith, N.; Strachan, J.; White, R. A Pocket Guide to Sustainable Development Governance. Stakeholder Forum. 2011. Available online: https://sustainabledevelopment.un.org/index.php?menu=35&nr=147&page=view&type=400 (accessed on 29 May 2023).

- Brodhag, C.; Talière, S. Sustainable development strategies: Tools for policy coherence. Nat. Resour. Forum 2006, 30, 136–145. [Google Scholar] [CrossRef]

- Holden, E.; Linnerud, K.; Banister, D. The imperatives of sustainable development. Sustain. Dev. 2017, 25, 213–226. [Google Scholar] [CrossRef]

- Guo, F. The spirit and characteristics of the general provisions of civil law. Law Econ. 2017, 3, 5–16. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C48&q=Guo%2C+F.+%282017%29.+The+spirit+and+characteristics+of+the+general+provisions+of+civil+law.+&btnG= (accessed on 9 May 2023).

- Gray, R. Is accounting for sustainability, and how would we know? An exploration of narratives of organizations and the planet. Account. Organ. Soc. 2010, 35, 47–62. Available online: https://www-sciencedirect-com.proxy.seattleu.edu/science/article/pii/S0361368209000427 (accessed on 1 February 2023). [CrossRef]

- Morelli, J. Environmental sustainability: A definition for environmental professionals. J. Environ. Sustain. 2017, 1, 2. Available online: https://scholarworks.rit.edu/cgi/viewcontent.cgi?article=1007&context=jes (accessed on 1 February 2023).

- Daily, G.; Matson, P. Ecosystem services: From theory to implementation. Proc. Natl. Acad. Sci. USA 2008, 105, 9455–9456. [Google Scholar] [CrossRef]

- Mathis, W.; Beyers, B. Ecological Footprint: Managing Our Biocapacity Budget; New Society Publishers: Gabriola Island, BC, Canada, 2019; Available online: https://books.google.com/books?hl=en&lr=&id=TzCEDwAAQBAJ&oi=fnd&pg=PP1&dq=Mathis,+W.+Ecological+footprint:+managing+our+biocapacity+budget.+&ots=QULQbqsqql&sig=WKbRUI62GAJSrvT_eKS8sxA5mNY#v=onepage&q=Mathis%2C%20W.%20Ecological%20footprint%3A%20managing%20our%20biocapacity%20budget.&f=false (accessed on 1 March 2023).

- Global Footprint Network. 2016. Available online: http://www.footprintnetwork.org/en/index.php/GFN/ (accessed on 1 March 2023).

- Henfrey, T.; Penha-Lopes, G. Policy and community-led action on sustainability and climate change: Paradox and possibility in the interstices. Environ. Innov. Soc. Transit. 2018, 29, 52–54. [Google Scholar] [CrossRef]

- Pincetl, S. Cities in the age of the Anthropocene: Climate change agents and the potential for mitigation. Anthropocene 2017, 20, 74–82. [Google Scholar] [CrossRef]

- Bruhwiler, L.; Basu, S.; Butler, J.H.; Chatterjee, A.; Dlugokencky, E.; Kenney, M.A.; McComiskey, A.; Montzka, S.A.; Stanitski, D. Observations of greenhouse gases as climate indicators. Clim. Chang. 2021, 165, 12. [Google Scholar] [CrossRef]

- Wall, C.J.; Norris, J.R.; Possner, A.; McCoy, D.T.; McCoy, I.L.; Lutsko, N.J. Assessing effective radiative forcing from aerosol-cloud interactions over the global ocean. Proc. Natl. Acad. Sci. USA 2022, 119, e2210481119. [Google Scholar] [CrossRef]

- Boyd, P. Toward quantifying the response of the oceans’ biological pump to climate change. Front. Mar. Sci. 2015, 2, 77. Available online: https://www.frontiersin.org/articles/10.3389/fmars.2015.00077/full (accessed on 16 January 2023). [CrossRef]

- Kar, A.; Pani, A. Exploring the importance of different supplier selection criteria. Manag. Res. Rev. 2014, 37, 89–105. [Google Scholar] [CrossRef]

- Freeman, C.; Soete, L. The Economics of Industrial Innovation; Psychology Press: London, UK, 1997. [Google Scholar] [CrossRef]

- Jensen, C. The modern industrial revolution, exit, and the failure of internal control systems. J. Financ. 1993, 48, 831–880. [Google Scholar] [CrossRef]

- Chen, L.; Nan, G.; Liu, Q.; Peng, J.; Ming, J. How do consumer fairness concerns affect an E-commerce Platform’s choice of selling scheme? J. Theor. Appl. Electron. Commer. Res. 2022, 17, 1075–1106. Available online: https://www.mdpi.com/0718-1876/17/3/55 (accessed on 1 March 2023). [CrossRef]

- Thompson, H. Industrial Purchasing; Principles and Practice; Richard D. Irwin, Inc.: Washington, DC, USA, 1947; Available online: https://books.google.com/books/about/Industrial_Purchasing.html?id=lIPVAAAAMAAJ (accessed on 1 March 2023).

- The History and the Evolution of Global Supply Chain. Blume Global. 2023. Available online: https://www.blumeglobal.com/learning/history-of-supply-chain/ (accessed on 1 March 2023).

- Rodrigue, P. The Geography of Transport Systems; Routledge: London, UK, 2020. [Google Scholar] [CrossRef]

- Kaplan, M.; Haenlein, M. Toward a parsimonious definition of traditional and electronic mass customization. J. Prod. Innov. Manag. 2006, 23, 168–182. [Google Scholar] [CrossRef]

- Alavudeen, A.; Venkateshwaran, N. Computer-Integrated Manufacturing; PHI Learning Pvt. Ltd.: Delhi, India, 2008; Available online: https://books.google.com/books?hl=en&lr=&id=GlL0TO6n320C&oi=fnd&pg=PR2&dq=Alavudeen+A.,++Venkateshwaran+N.,+Computer+integrated+manufacturing,+2008&ots=9a5ghsvjqM&sig=iQA6j4LY1tFSl6 (accessed on 1 February 2023).

- Kennard, W.; Stone, A. Computer-aided design of experiments. Technometrics 1969, 11, 137–148. Available online: https://www.tandfonline.com/doi/abs/10.1080/00401706.1969.10490666 (accessed on 7 January 2023). [CrossRef]

- Stephenson, N. Snow Crash: A Novel; Spectra: New York, NY, USA, 2003; Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C48&q=44.%09Stephenson%2C+N.+Snow+crash%3A+A+novel.+Spectra.+2003&btnG (accessed on 12 February 2023).

- Lee, L.; Billington, C. The evolution of supply-chain-management models and practice at Hewlett-Packard. Interfaces 1995, 25, 42–63. [Google Scholar] [CrossRef]

- Singh, N. Emerging technologies to support supply chain management. Commun. ACM 2003, 46, 243–247. Available online: https://dl.acm.org/doi/fullHtml/10.1145/903893.903943 (accessed on 12 February 2023). [CrossRef]

- Kemppainen, K.; Vepsäläinen, P. Trends in industrial supply chains and networks. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 701–719. Available online: https://www.emerald.com/insight/content/doi/10.1108/09600030310502885/full/html (accessed on 12 February 2023). [CrossRef]

- Weber, A.; Current, R.; Benton, C. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Gereffi, G.; Fernandez-Stark, K. Global Value Chain Analysis: A Primer. 2016. Available online: https://dukespace.lib.duke.edu/dspace/bitstream/handle/10161/12488/2016-07-28_GVC%20Primer%202016_2nd%20edition.pdf (accessed on 12 February 2023).

- Ponte, S.; Gereffi, G.; Raj-Reichert, G. Introduction to the handbook on global value chains. In Handbook on Global Value Chains; Edward Elgar Publishing: Cheltenham, UK, 2019; pp. 1–27. [Google Scholar] [CrossRef]

- Dickson, G. An analysis of vendor selection systems and decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Wilson, E.J. The relative importance of supplier selection criteria: A review and update. Int. J. Purch. Mater. Manag. 1994, 30, 34–41. [Google Scholar] [CrossRef]

- Menon, M.; McGinnis, A.; Ackerman, B. Selection criteria for providers of third-party logistics services: An exploratory study. J. Bus. Logist. 1998, 19, 121. Available online: https://www.library.northwestern.edu/find-borrow-request/requests-interlibrary-loan/lending-institutions.html (accessed on 18 April 2023).

- Lee, A.; Seshia, S. Introduction to Embedded Systems—A Cyber-Physical Systems Approach, 2nd ed; MIT Press: Cambridge, MA, USA, 2016; Available online: https://ptolemy.berkeley.edu/books/leeseshia/ (accessed on 18 April 2023).

- Ibarra, D.; Ganzarain, J.; Igartua, I. Business model innovation through Industry 4.0: A Review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Frank, A.; Dalenogare, L.; Ayala, N. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Valeske, B.; Osman, A.; Römer, F.; Tschuncky, R. Next Generation NDE Sensor System as Industrial Internet-of-Things Elements of Industry 4.0. Res. Nondestruct. Eval. 2020, 31, 340–369. [Google Scholar] [CrossRef]

- Muthuswamy, P.; Shunmugesh, K. Artificial intelligence-based tool condition monitoring for digital twins and industry 4.0 applications. Int. J. Interact. Des. Manuf. 2023, 17, 1067–1087. [Google Scholar] [CrossRef]

- Xu, D. Industry 4.0—Frontiers of the Fourth Industrial Revolution. Syst. Res. Behav. Sci. 2020, 37, 531–534. [Google Scholar] [CrossRef]

- Santhi, A.; Muthuswamy, P. Industry 5.0 or Industry 4.0S? Introduction to Industry 4.0 and a Peek into the prospective Industry 5.0 technologies. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 947–979. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, maturity, and research agenda. Supply Chain. Manag. Int. J. 2020, 25, 262–282. [Google Scholar] [CrossRef]

- European Commission. Research and Innovation Industry: 5. 2022. Available online: https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/industry-50_en (accessed on 9 January 2023).

- De Giovanni, P. Leveraging the circular economy with a closed-loop supply chain and a reverse omnichannel using blockchain technology and incentives. Int. J. Oper. Prod. Manag. 2022, 42, 959–994. Available online: https://www.emerald.com/insight/content/doi/10.1108/IJOPM-07-2021-0445/full/html (accessed on 9 January 2023). [CrossRef]

- Vishkaei, B. Metaverse: A New Platform for Circular Smart Cities. In Cases on Circular Economy in Practice; IGI Global: Hershey, PA, USA, 2022; Available online: https://www.igi-global.com/chapter/metaverse/312035 (accessed on 16 April 2023).

- Queiroz, M.M.; Wamba, S.F.; Pereira, S.C.F.; Jabbour, C.J.C. The metaverse as a breakthrough for operations and supply chain management: Implications and call for action. Int. J. Oper. Prod. Manag. 2023, 43, 1539–1553. Available online: https://www.emerald.com/insight/content/doi/10.1108/IJOPM-01-2023-0006/full/html (accessed on 1 May 2023). [CrossRef]

- Fu, Y.; Li, C.; Yu, F.R.; Luan, T.H.; Zhao, P.; Liu, S. A survey of blockchain and intelligent networking for the metaverse. IEEE Internet Things J. 2023, 10, 3587–3610. [Google Scholar] [CrossRef]

- Yu, R.; Yu, A. The Metaverse and the Real-World Universe. In A Brief History of Intelligence: From the Big Bang to the Metaverse; Springer International Publishing: Cham, Switzerland, 2022; pp. 5–109. Available online: https://link.springer.com/chapter/10.1007/978-3-031-15951-0_9 (accessed on 22 January 2023).

- Rowling, J.; Ménard, J.; Ménard, J. Harry Potter à L’école des Sorciers; Gallimard Jeunesse: Paris, France, 2000; Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C48&q=70.%09Rowling%2C+J.+%281998%29.+Harry+Potter+%C3%A0+l%27%C3%A9cole+des+sorciers.+Triangle&btnG (accessed on 13 April 2023).

- Ivankova, N.V. Mixed Methods Applications in Action Research: From Methods to Community Action; Sage Publications: Washington, DC, USA, 2015; Available online: https://books.google.com/books?hl=en&lr=&id=RNQ5DQAAQBAJ&oi=fnd&pg=PP1&dq=71.%09Ivankova+N.+V.+Mixed+methods+applications+in+action+research:+From+methods+to+community+action,+2015.+Sage,+ISBN+978-1-4522-2003.++&ots=pv76FhMC2X&sig=fO9jmlnLmxdjQGX_fCGq4xmiVlM#v=onepage&q&f=false (accessed on 22 October 2023).

- Christensen, R. Analysis of Variance, Design, and Regression: Linear Modeling for Unbalanced Data; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- The Richmond Vale Academy. The Second Industrial Revolution: The Technological Revolution. Global Issue. World History. 2022. Available online: https://richmondvale.org/blog/second-industrial-revolution/#What (accessed on 29 January 2023).

- Nardinelli, C. Child labor and the Factory Acts. J. Econ. Hist. 2010, 40, 739–755. [Google Scholar] [CrossRef]

- Saeed, F.; Malik, M. Oceanic pollution; A threat to life. Pure Appl. Biol. 2022, 11, 483–490. [Google Scholar] [CrossRef]

- Cocks, D. Use with Care: Managing Australia’s Natural Resources in the 21st Century; University of New South Wales Press: Kensington, NSW, Australia, 1992; Available online: http://dougcocks.labshop.com.au/MAKEWINFINAL.pdf (accessed on 14 January 2023).

- Flannery, T. The Future Eaters: An Ecological History of the Australasian Lands and People; Reed New Holland: Sydney, NSW, Australia, 1994. Available online: https://catalogue.nla.gov.au/Record/2197719 (accessed on 10 May 2023).

- Rees, W. Ecological footprints and appropriated carrying capacity: What urban economics leaves out. Environ. Urban. 1992, 4, 121–130. [Google Scholar] [CrossRef]

- Karampournioti, E.; Wiedmann, K. Storytelling in online shops: The impacts on explicit and implicit user experience, brand perceptions, and behavioral intention. Internet Res. 2022, 32, 228–259. [Google Scholar] [CrossRef]

- Shen, B.; Tan, W.; Guo, J.; Zhao, L.; Qin, P. How to promote user purchases in the metaverse? A systematic literature review on consumer behavior research and virtual commerce application design. Appl. Sci. 2021, 11, 11087. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. The race between man and machine: Implications of technology for growth, factor shares, and employment. Am. Econ. Rev. 2018, 108, 1488–1542. Available online: https://www.nber.org/system/files/working_papers/w22252/w22252.pdf (accessed on 18 January 2023). [CrossRef]

- Dhelim, S.; Kechadi, T.; Chen, L.; Aung, N.; Ning, H.; Atzori, L. Edge-enabled metaverse: The convergence of metaverse and mobile edge computing. arXiv 2022, arXiv:2205.02764. [Google Scholar] [CrossRef]

- Sisi, Z.; Souri, A. Blockchain technology for energy-aware mobile crowd sensing approaches in the Internet of Things. Trans. Emerg. Telecommun. Technol. 2021, e4217. [Google Scholar] [CrossRef]

- World Health Organization. Solid Waste—Compendium of WHO and Other UN Guidance on Health and Environment. 2021. Available online: https://cdn.who.int/media/docs/default-source/who-compendium-on-health-and-environment/who_compendium_chapter4_v2_01092021.pdf?sfvrsn=b4e99edc_5 (accessed on 18 January 2023).

- Sinha, S. State of IoT 2023: Number of Connected IoT Devices Growing 18% to 14.4 Billion Globally. IoT Analytics. 2023. Available online: https://iot-analytics.com/number-connected-iot-devices/ (accessed on 2 June 2023).

| Environmental | Economic | Social |

|---|---|---|

| Global warming | Gross domestic product | Health |

| Acidification potential | Trade balance | Education |

| Ozon depletion | Government revenue | Income |

| Aerosol optical depth | Profit | Living standards |

| Eutrophication | Productivity Value | Equity |

| Ionization radiation potential | Tax | Community cohesion |

| Waste production treatment | Equality | Social security |

| Freshwater use | Inflation | |

| Energy resources use | Government debt | |

| Level of Biodiversity |

| Selection Criteria | Qualitative and Quantitative Indicators During Each Industrial Revolution | Industry 1.0 1765–1860s | Industry 2.0 1865–1930s | Industry 3.0 1930–2000s | Industry 4.0 2011–2020s | Industry 5.0 After 2022 |

|---|---|---|---|---|---|---|

| Price | Lowest price, transportation cost, and ordering cost | 3 | ||||

| Productivity | Quantity, production capacity, and outputs/inputs | 3 | ||||

| Performance history | Compliance, control variability, adapting to changes, and fulfillment rate | 4 | ||||

| Warranty policy | Repairs, replacement, duration of warranty, and frequency of maintenance | 3 | ||||

| Two-way delivery and logistics | Right product, right quantity, right place, right schedule, and right price | 5 | ||||

| Proximity | Geographical locations, capacity of distribution centers, capability of delivery | 3 | ||||

| Reliability | Accepted delivery/total orders ratio, responsiveness, and collaboration | 3 | ||||

| Quality | % of rework and returned items, commitments to TQM, and Six Sigma | 3 | ||||

| Service and responsiveness | After-sales dependability, return policy, responsiveness, and transparency | 4 | ||||

| Financial stability | Revenue, profit, financial resources, and investment-to-loan ratio | 3 | ||||

| Efficiency | Output/inputs and resource utilization | 2 | ||||

| Safety and security | Environmental, building, equipment, human resources, and cyber | 5 | ||||

| Agility and flexibility | Speed in responding to unpredictable events/changes and coordination | 2 | ||||

| Repair services | On-call repair, no delays, speedy recovery, and no repair charges | 4 | ||||

| Continuity of operations | Backup: building, hardware, software, human resource skills, and digital platform | 5 | ||||

| Technical capability | Hardware, software, human skills, and network | 4 | ||||

| Infrastructure capability | Physical assets, hardware, software, robots, and human resource development | 5 | ||||

| Hyper-connectivity | Digital platforms, information and communication technologies: AI, IoT, 3D, and RFID | 2 | ||||

| Labor relations and business reputation | Customer relations, safety, and labor legal complains | 3 | ||||

| Intercreditor agreement | Price, quantity, % of rejection, and delivery | 4 | ||||

| 20 criteria | 70 indicators from Industry 1.0 to 5.0 |

| Summary | ||||||

|---|---|---|---|---|---|---|

| Groups | Count | Sum | Average | Variance | ||

| Environmental Sustainability | 20 | 1551 | 77.55 | 382.7868 | ||

| Economic Sustainability | 20 | 232 | 11.6 | 106.6737 | ||

| Social Sustainability | 20 | 498 | 24.9 | 335.4632 | ||

| ANOVA | ||||||

| Source of Variation | SS | df | MS | F | p-Value | F Crit |

| Between Groups | 48,655.43333 | 2 | 24,327.72 | 88.47261 | 3.33 × 10−18 | 3.158843 |

| Within Groups | 1567.55 | 57 | 274.9746 | |||

| Total | 64,328.98333 | 59 | ||||

| Groups | Economic Sustainability | Environmental Sustainability | Social Sustainability |

|---|---|---|---|

| Economic sustainability | 1 | ||

| Environmental sustainability | −0.378342641 | 1 | |

| Social sustainability | −0.853764998 | −0.1588105532 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modarress-Fathi, B.; Ansari, A.; Ansari, A. Examining Sustainability Alignment of Supplier Selection Criteria during Industrial Revolutions. Sustainability 2023, 15, 15930. https://doi.org/10.3390/su152215930

Modarress-Fathi B, Ansari A, Ansari A. Examining Sustainability Alignment of Supplier Selection Criteria during Industrial Revolutions. Sustainability. 2023; 15(22):15930. https://doi.org/10.3390/su152215930

Chicago/Turabian StyleModarress-Fathi, Batoul, Al Ansari, and Alexander Ansari. 2023. "Examining Sustainability Alignment of Supplier Selection Criteria during Industrial Revolutions" Sustainability 15, no. 22: 15930. https://doi.org/10.3390/su152215930

APA StyleModarress-Fathi, B., Ansari, A., & Ansari, A. (2023). Examining Sustainability Alignment of Supplier Selection Criteria during Industrial Revolutions. Sustainability, 15(22), 15930. https://doi.org/10.3390/su152215930