Abstract

The outbreak of major health emergencies, such as the COVID-19 pandemic, has posed numerous challenges to waste management. Environmentally sound treatment of such epidemic-related municipal solid waste (MSW) plays a vital role in interrupting virus transmission. In this study, the furnace type, incineration process and control parameters of an MSW incinerator were comparatively analyzed with those of a medical waste incinerator and hazardous waste incinerator according to China’s MSW incineration pollution control standards. In addition, changes in flue gas emissions data before, during and after the outbreak of the pandemic were empirically analyzed. The study revealed the following: (1) the feasibility of MSW incinerators to meet the harmless disposal of potentially viral municipal solid waste (PVMSW); (2) the priority order of incinerator types for MSW incinerators in the disposal of potentially virulent waste was grate furnace incinerator > fluidized bed incinerator > cement kiln; and (3) when MSW incinerators treated PVMSW, the emissions of dioxin compounds in the flue gas fluctuated between 0.00052 and 0.031 ng TEQ/m3, HCl emissions fluctuated between 1.6 and 23.742 mg/m3, CO emissions fluctuated between 0.18 and 59.15 mg/m3, heavy metal emissions fluctuated between 0.000008 and 0.855 mg/m3, and particulate matter emissions fluctuated between 0.64 and 12.13 mg/m3. All emissions met the flue gas emission standards. This study verified the feasibility of using MSW incinerators to treat PVMSW during a sudden major pandemic and provided a theoretical basis for the environmentally sound collaborative treatment of PVMSW and a reference for the emergency management and sustainable development of MSW.

1. Introduction

In recent years, the infectious waste associated with the COVID-19 pandemic has caused serious environmental and health problems in many countries [1]. Empirical studies elucidated that SARS-CoV-2 can linger on various surfaces, such as cardboard, plastic and copper, for a span of up to seven days [2]. Many scholars found potential sources of SARS-CoV-2 in municipal solid waste (MSW), but there is no clear definition of such waste. Dwi Hantoko pointed out that the waste from the households of suspected or confirmed COVID-19 patients may contain viable SARS-CoV-2 and may be the source of infection [3]; Long D. Nghiem et al. suggested that viable SARS-CoV-2 may exist in the households and quarantine facilities of newly infected suspected patients [4]; Jiří Jaromír Klemeš et al. noted that mildly symptomatic patients will produce contaminated MSW when they self-isolate at home [5]; ACRPlus also pointed out that recyclable waste accumulated in households with suspected cases of COVID-19 could become a potential source of transmission [6]; Aline do Nascimento Beckert et al. pointed out that MSW collectors may be exposed to infections while collecting waste [7]; and Marcos Paulo Gomes Mol et al. suggested that SARS-CoV-2-infected patients receiving treatment at home generate potentially infected waste that may be disposed of as household waste [8]. There was research suggesting that waste contains viruses, but no clear definition of them has been given.

According to the background of SARS-CoV-2 transmission, potentially viral municipal solid waste (PVMSW) can be clearly defined as the MSW generated in risk areas where major outbreaks occur or by people associated with outbreaks in their daily lives or in activities that provide services to them.

During the pandemic, there was an increase in the use of disposable plastics and personal protective equipment, leading to an unprecedented need for medical mask disposal [9,10]. These single-use face masks are a growing source of microplastic fibers, and the plastics can potentially generate microplastics in buildings and the built environment [11]. Changes in people’s lifestyles during the pandemic, with more time spent at home [12], have resulted in a significant rise in the production of PVMSW [13]. Additionally, the quantity of meals prepared and consumed at home has notably increased, with statistics indicating a 12% rise in food waste [14]. Furthermore, the United States, Singapore, and most European countries issued notices to suspend MSW sorting during the pandemic [15,16,17]. PVMSW has not only seen a surge in quantity but has also undergone compositional changes [18,19], including higher percentages of plastics and paper [20,21], as well as increased moisture content [22,23]. This has imposed substantial pressure on MSW incineration facilities. These pose great challenges to MSW management.

PVMSW has some similarities with medical waste due to its infectious and contagious characteristics. Previous studies showed that many countries implemented policies or applied examples of using MSW incineration facilities to dispose of medical waste [24]. HCl and dioxin levels in flue gases are higher due to the high plastic content in medical waste [25,26,27]. To ensure compliance with emission standards, methods such as controlling the co-incineration ratio of medical waste and adding activated carbon during incineration have been used [24]. The “Technical Guidelines on Environmentally Sound Management of Biomedical and Healthcare Wastes under the Basel Convention” explicitly states that infectious waste can be disposed of using MSW treatment methods after disinfection [28]; medical waste generated by healthcare facilities in the United States is disinfected at the source before being transported for incineration disposal at hazardous waste incineration facilities or MSW incineration facilities [29]; in France, MSW incineration plants also co-incinerate small amounts of medical waste during the treatment process [30]; in Catalonia, some medical waste that is considered low risk is incinerated using an MSW incinerator [31]; according to the “Safe Management of Wastes From Health-Care Activities, Second Edition” published by the WHO, infectious medical waste and small amounts of pharmaceutical waste can be disposed of using MSW incinerators [32]; on January 28th, the Chinese Ministry of Ecology and Environment issued the “Technical Guidelines for Emergency Disposal of Medical Waste from COVID-19 Patients (Trial)” 2020, proposing that MSW incineration facilities can be selected for the emergency disposal of COVID-19 medical waste, provided that the disposal effectiveness is guaranteed [33]; and on 10 February 2020, the Chinese Ministry of Ecology and Environment and the Department of Solid Waste and Chemicals issued a document titled “Work and Answers Related to Emergency Disposal of Medical Wastes from COVID-19 in MSW Incineration Facilities”, which pointed out that the grate incineration furnace is feasible and effective [34]. While in previous experience, some modifications of MSW incineration facilities allowed them to treat medical waste, the feasibility of utilizing these facilities directly for the safe disposal of PVMSW remains uncertain.

Due to the high risk of virus transmission associated with PVMSW, the careful disposal of such waste is essential. Improper disposal can increase the likelihood of a widespread outbreak of infection [35]. The safe and effective management of PVMSW during an epidemic is a critical step in preventing the spread of disease. During the outbreak of the epidemic, there was a sharp increase in the quantity of PVMSW, and the demand for incineration of PVMSW far exceeded the capacity of medical waste incinerators. In this critical situation, the question of whether MSW incinerators should be used for the safe disposal of PVMSW remains unanswered. To effectively prevent the spread of viruses through waste, enhancing the flexibility of waste management systems affected by viruses is crucial, allowing them to rapidly adapt to any viral pandemic.

This study aimed to determine whether MSW incineration facilities can be directly used to treat PVMSW in a harmless way, to assess whether PVMSW incineration facilities meet the requirements of public health emergencies in terms of harmless treatment and to establish a theoretical basis for managing the new crown pandemic.

2. Materials and Methods

2.1. Data Description and Data Sources

The in situ monitoring data from incineration facilities, monitored from February 2020 to August 2023, were obtained from the Continuous Emissions Monitoring System (CEMS) for MSW incineration power plants and the Beijing Municipal Enterprises and Institutions Environmental Information Disclosure Platform [36,37]. The CEMS monitoring network, which was implemented in 2019, constitutes a direct and real-time measurement framework designed to provide more accurate and reliable daily emissions data from MSW incineration power plants across the country. It monitors parameters including furnace temperatures and key pollutants, namely, particulate matter (PM), SO2, NOx, CO and HCl. The Beijing Municipal Enterprises and Institutions Environmental Information Disclosure Platform supplemented emission data for dioxins; Hg and its compounds; and TL, Cd, Pb, As, Be, Cr, Sn, Sb, Cu, Co, Mn, Ni, V and their compounds. Relevant literature was used to supplement the limit values of flue gas emission standards.

Pollution control of waste incineration in China relies primarily on standards such as the “Standard for pollution control on the municipal solid waste incineration” (GB 18485-2014) [38], “Municipal solid waste incinerator and boiler” (GB/T 18750-2008) [39], “Standard for pollution control on hazardous waste incineration” (GB 18484-2020) [40], “Environmental Protection Technical Specification for co-disposal of solid wastes in cement kiln” (HJ 662-2013) [41] and “Standard for pollution control on medical waste treatment and disposal” (GB 39707-2020) [42]. In China, regulations governing the process control parameters for MSW incineration primarily focus on incineration control parameters and the characteristics of incoming waste. The key incineration control parameters are the incineration temperature, flue gas residence time, thermal decomposition rate, waste residence time, etc. The specific requirements for these primary parameters are outlined in the “Standard for pollution control on the municipal solid waste incineration” (GB 18485-2014), as detailed in Table 1.

Table 1.

Summary of incineration control parameters for MSW incinerators in China.

2.2. Analysis Methods

Similar to medical waste, PVMSW contains a higher proportion of plastic and disinfectant materials. In certain countries, MSW incinerators and hazardous waste incinerators have been employed in emergencies to manage medical waste during pandemics. Therefore, parameters relevant to the incineration of medical waste and hazardous waste can offer valuable insights into the disposing of PVMSW during significant disease outbreaks. To synthesize the crucial aspects of the incineration process, we conducted a comprehensive review and analysis of thirteen relevant standards and five journal articles. These sources encompassed incineration process flows, incineration process control parameters, incinerator technical performance indicators, and exhaust gas emission standards outlined in MSW, medical waste and hazardous waste incineration practices in China. This study primarily focused on the MSW incineration process, incinerator control parameters, flue gas emission control parameters and standards. Medical waste served as a comparative reference, while hazardous waste provided a supplementary control. We analyzed MSW incinerator types and process flows, and compared the differences and similarities between grate furnace incinerators, fluidized bed incinerators and cement kilns concerning the types of waste, mixing levels of incoming waste, particle size and the need for pre-treatment in MSW incineration. These were contrasted with the incinerator types, process flows and incineration parameters for medical waste and hazardous waste while considering the conditions for viral inactivation. The objective was to assess the theoretical feasibility of using MSW incinerators for the safe disposal of PVMSW.

In China, the process control parameters for MSW incinerators are determined based on incineration control parameters and the characteristics of the waste being fed into the incinerator. To achieve this, we selected typical MSW incineration treatment facilities and collected data on the furnace temperature monitoring during the MSW incineration process. These data were compared with temperatures during normal operation in various waste incineration plants. The flue gas emission parameters for the MSW incineration process in China encompassed nine indicators, namely, PM; NOX (NO2 for cement kilns); SO2; HCl; dioxins; CO; Hg and its compounds; Tl, Cd, Pb, As, Be, Cr, Sn, Sb, Cu, Co, Mn, Ni, V and their compounds; and Sb, As, Pb, Cr, Cu, Mn, Ni and their compounds. We conducted a thorough quantitative data analysis of data from three typical MSW incineration plants in China, covering the mid-period of the epidemic and the periods before and after its outbreak. This analysis involved a comprehensive review, comparison and compliance assessment of MSW incineration process parameters according to legal regulations. The results of this study confirm the practical feasibility of using MSW incineration facilities for PVMSW treatment.

3. Results and Discussion

3.1. Incineration Furnace Type and Flow

3.1.1. MSW Incinerator Type and Process Flow

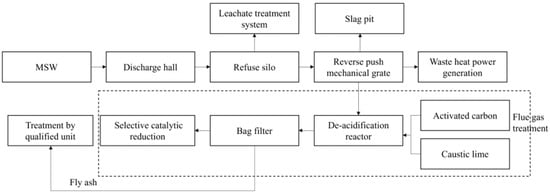

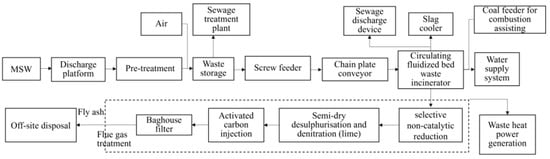

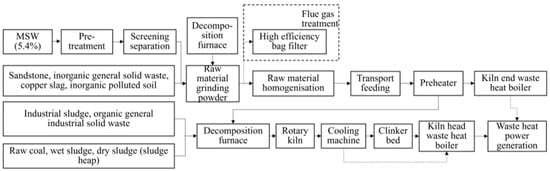

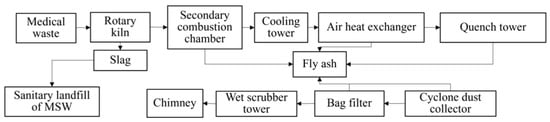

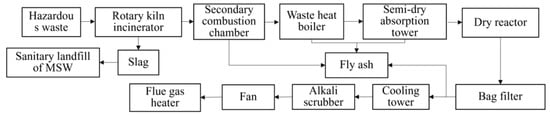

The primary types of incinerators used in MSW incineration facilities in China are mechanical grate furnace incinerators, circulating fluidized bed incinerators and cement kilns. In this study, three typical MSW incineration treatment plants were selected for comparison: Beijing Nangong Waste Incineration Plant [43], Hangzhou Xiaoshan Jinjiang MSW Incineration Plant and Chibi Cement Kiln Co-Disposal MSW. The aim was to compare the differences in the process of MSW treatment between different types of incinerators. The comparison and analysis of the three MSW incineration process flows and incineration processes are presented in Figure 1, Figure 2 and Figure 3.

Figure 1.

Incineration process flow of Beijing Nangong MSW incineration plant [43].

Figure 2.

Incineration process flow of Hangzhou Xiaoshan Jinjiang MSW incineration plant [44].

Figure 3.

Process flow of Chibi cement kiln co-processing MSW [45].

According to the “Municipal solid waste incinerator and boiler” (GB/T 18750-2008), “Standard for pollution control on the municipal solid waste incineration” (GB 18485-2014) and “Municipal solid waste fluidized bed incineration boiler” (GB/T 34552-2017) [46] standards, the acceptable waste for a grate furnace incinerator includes general industrial solid waste, composting sieves, infectious waste that meets inspection criteria and sludge. A fluidized bed incinerator can include sludge and general solid waste and a rotary kiln incinerator can accommodate solid, gas, liquid and slurry wastes. In terms of the mixing degree of incoming waste, the waste for the grate furnace incinerator remains unchanged; the fluidized bed incinerator requires a smaller particle size, preferably less than 150 mm. However, for a cement kiln incinerator, the incoming waste must be pre-treated, screened and homogenized with other general solid waste, such as limestone, copper slag, inorganic contaminated soil, sandstone and inorganic categories, and the particle size requirements are more stringent [47]. Additionally, a cement kiln incinerator does not produce residues, while both the grate furnace incinerator and fluidized bed incinerator generate residues, with the grate furnace incinerator producing a significantly higher proportion of residues than the fluidized bed incinerator.

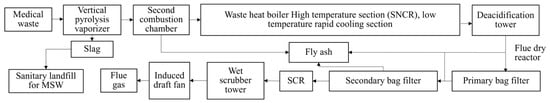

3.1.2. Medical Waste Furnace Type and Process Flow

Medical waste incineration technologies in China include rotary kiln incineration, fixed bed furnace incineration, pyrolysis incineration, chemical disinfection, autoclaving and secure landfill. Among them, rotary kiln incineration is the primary disposal technology. Different disposal technologies are suitable for different types of medical waste. For example, high-temperature incineration and plasma are suitable for all medical waste except for chemical waste, while chemical disinfection, autoclaving and microwave sterilization can only treat infectious and pathological waste. Incineration is considered to be the safest, most thorough, simple and most widely used method for treating medical waste [48].

High-temperature incineration is the predominant method of medical waste disposal in China, accounting for 70% of the total disposal volume. After collection, transportation and temporary storage at the treatment plant, medical waste undergoes high-temperature decomposition through incineration. The incineration flue gas is treated by the purification system to meet emission standards before being discharged. Both the “Technical standard for medical waste incinerator (Trial)” (GB 19218-2003) [49] and “Technical specifications for Centralized Incineration Facility Construction on Medical Waste” (HJ/T 177-2023) [50] require that a medical waste incinerator be equipped with a secondary combustion chamber. Based on these standards, the EIA reports of the Jinan Medical Centralized Disposal Project (Jinan Qidian Environmental Development Co., Ltd., Jinan, China) and the Beijing Medical Waste Treatment Project (Beijing Runtai Environmental Protection Technology Co., Ltd., Beijing, China) were selected, and their medical waste incineration process flows are shown in Figure 4 and Figure 5. According to the “Environmental Protection Technical Specification for co-disposal of solid wastes in cement kiln” (HJ 662-2013), medical waste is prohibited from being crushed or otherwise pre-treated before entering a kiln for disposal.

Figure 4.

Incineration process of Jinan medical waste centralized disposal project [51].

Figure 5.

Beijing Medical Waste Treatment Project treatment process flow [52].

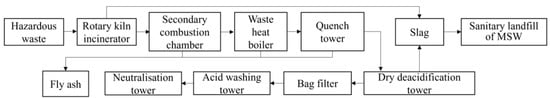

3.1.3. Hazardous Waste Furnace Type and Process Flow

For solid hazardous waste, the treatment processes include incineration, pyrolysis and other thermal treatments, and solidification methods. Incineration is currently the most mature, widely applicable and safest method for hazardous waste treatment. Some special organic hazardous waste can only be treated via incineration, which serves as an important consideration treatment of PVMSW during major epidemics. The rotary kiln incinerator is the preferred choice for processing hazardous waste due to its wide adaptability. According to the “Technical specifications for Centralized Incineration Facility” (HJ/T 176-2005) [53], a hazardous waste incinerator should be equipped with a secondary combustion chamber. Therefore, the environmental impact assessment reports of the Fuzhou Hongmiaoling comprehensive waste treatment site and the Yangzhou hazardous waste disposal project were selected to sort out their incineration processes, as shown in Figure 6 and Figure 7. As can be seen from the process flow diagrams, the hazardous waste incinerators used are generally rotary kiln incinerators, and the incineration process includes the incinerator, secondary combustion chamber and flue gas cleaning system. The secondary combustion chamber purifies the flue gas, effectively controlling the production of toxic and hazardous substances and dioxins in the flue gas. The composition of the flue gas purification system varies in the two examples, but their purpose remains the same.

Figure 6.

Incineration process of Fuzhou hazardous waste comprehensive disposal project [54].

Figure 7.

Incineration process of Yangzhou hazardous waste comprehensive disposal project [55].

3.1.4. Comparative Discussion of Three Types of Solid Waste Incineration Processes

The main technical requirements of MSW incinerators, medical waste incinerators and hazardous waste incinerators are the same, and their working conditions are similar. There are several pollutants that are incinerated, including PM, NOX, SO2, HCl, dioxins, CO, Hg and its compounds, Cd + Tl and their compounds, and Sb + As + Pb + Cr + Cu + Mn + Ni and their compounds. The main devices are waste-feeding devices, incineration devices, residue devices, combustion air devices, auxiliary combustion devices and other auxiliary devices. The three main types of solid waste incineration processes are summarized in Table 2.

Table 2.

Solid waste incinerator difference.

3.1.5. Comparative Discussion of Process Parameters for Three Types of Solid Waste Incineration Processes

In China, the process parameters for solid waste incineration should comply with the “Standard for pollution control on medical waste treatment and disposal” (GB 39707-2020) and “Technical standard for medical waste incinerator (Trial)” (GB 19218-2003). When using cement kiln treatment, it should meet the relevant requirements of the “Environmental Protection Technical Specification for co-disposal of solid wastes in cement kiln” (HJ 662-2013), and the process parameters for hazardous waste incinerators should be set in accordance with the provisions of the “Standard for pollution control on hazardous waste incineration” (GB 18484-2020). The parameters of the solid waste incinerator are summarized in Table 3.

Table 3.

Solid waste incinerator parameters.

Both MSW and medical waste incinerators must operate at temperatures ≥850 °C with a minimum flue gas residence time in the furnace chamber of ≥2 s. For MSW incinerators, there is a requirement for the slag’s thermal scorching rate to be ≤5%. However, medical waste incinerators have slightly different criteria, with the thermal scorch rate of incinerator slag set at <5%. MSW incinerators do not have specific requirements for flue gas oxygen content, combustion efficiency or destruction removal efficiency. The stringency of setting indicators and parameters for incinerators follows the order of hazardous waste > medical waste > MSW.

According to the “Pneumonia diagnosis and treatment protocol for novel coronavirus infection (trial fifth edition)” (National Health Office Medical Letter [2020] No. 103), SARS-CoV-2 is heat sensitive and can be effectively inactivated by maintaining a temperature of 56 °C for 30 min. The temperature in the MSW incinerator chamber is 850 °C, with a residence time of generally 1 to 1.5 h; under these conditions, the novel coronavirus can be completely inactivated. Therefore, from the perspective of the incineration parameters, all three types of solid waste incinerators can meet the requirements for PVMSW incineration.

3.1.6. Empirical Analysis of MSW Incinerator Burning

Based on data from the CEMS on 1 March 2023 (within 24 h), this study selected a typical MSW incineration treatment facility. The monitoring data for a furnace chamber temperature during the MSW incineration process are summarized in Table 4. According to practical application cases [56], the material temperature and gas temperature during MSW treatment in cement kilns typically fall within the ranges of 1400–1500 °C and 1700–1800 °C, respectively.

Table 4.

Summary of incinerator temperatures for a typical MSW incineration facility.

Table 4 presents a summary of typical MSW incinerator temperatures. A vertical comparison reveals the normal operating temperature range for incinerators in various waste incineration plants is 860.27–1054.21 °C for the low-temperature range and 921.26–1119.56 °C for the high-temperature range. Both the low- and high-temperature differentials of these incinerators are relatively large, at 198.3 °C and 193.94 °C, respectively. Horizontally, the temperature differentials of these incinerators range from 56.23 °C to 206.79 °C. It can be illustrated that in terms of temperature, the three types of incinerators rank as follows: cement kiln > grate furnace incinerator > fluidized bed incinerator. Their furnace temperatures all exceed 850 °C, which is significantly higher than the virus inactivation temperature, effectively eliminating pathogens. It can be seen that the MSW incinerator meets the performance requirements for incinerating medical waste. Given that PVMSW exhibits characteristics between MSW and medical waste, MSW incinerators also fulfill the performance requirements for PVMSW incineration. Considering the substantial increase in PVMSW generation during a pandemic and the minimal pre-treatment applied, the preferred order for furnace selection from a process perspective is as follows: grate furnace incinerator > fluidized bed incinerator > cement kiln.

3.2. Flue Gas Emission Control Parameters and Standards

3.2.1. Control Standards for MSW Incineration Flue Gas Emissions

China has set parameters for flue gas emissions from MSW incineration processes, including PM; NOX (NO2 for cement kilns); SO2; HCl; dioxins; Hg and its compounds; Tl, Cd, Pb, As, Be, Cr, Sn, Sb, Cu, Co, Mn, Ni, V and their compounds; and Sb, As, Pb, Cr, Cu, Mn, Ni and their compounds [57]. These parameters include different time spans, such as 1 h average and 24 h average, or a measured average. They mainly refer to the “Standard for pollution control on the municipal solid waste incineration” (GB 18485-2014), which applies to grate furnace incinerators and fluidized bed incinerators. For cement kiln incinerators, their flue gas emission standards should comply with the “Standard for pollution control on co-processing of solid wastes in Cement kiln” (GB 30485-2013) [58] and the “Emission standard of air pollutants for cement industry” (GB 4915-2013) [59]. As shown in Table 5, the emission limits of flue gas (air) pollutants from MSW incinerators are modified by the introduction of NH₃ and fluoride and the exclusion of CO.

Table 5.

MSW incinerator flue gas (atmospheric) pollutant limits.

Table 5 reveals that the emission standards for cement kiln flue gas (excluding HCl content) are relatively lenient compared with those for grate furnace incinerators and fluidized bed incinerators. To compare the actual operation and flue gas emissions of different MSW incineration treatment facilities, monitoring data on pollutants in incinerator flue gases of typical MSW incineration plants were collected based on the data from 17 April 2021 (within 24 h) from the CEMS on 7 June 2021 from the Department of Ecology and Environment of Jiangsu Province [60], as shown in Table 6.

Table 6.

Typical MSW incinerator flue gas pollutant concentrations.

Table 6 shows that the concentration of various pollutants in the flue gas produced by the grate furnace incinerator was significantly lower than that produced by the fluidized bed incinerator. This was directly related to the higher average temperature of the grate furnace incinerator, which resulted in more complete waste combustion and gas decomposition [61]. The concentration of pollutants in the flue gas of cement kiln incinerators was basically 30% or less of the limit value. Furthermore, the dioxin-like concentrations (with a limit value of 0.1 ng TEQ/m3) at Everbright Renewable Energy (Nanjing, China) Co., Ltd. (11 May 2021), and Everbright Environmental Energy (Nanjing) Co., Ltd. (21 June 2021), were 0.044 ng TEQ/m3 and 0.0035 ng TEQ/m3, respectively. Thus, from the perspective of the flue gas pollutant emission concentrations of MSW incineration, the grate furnace incinerator was superior to the fluidized bed incinerator and cement kiln.

3.2.2. Comparison of Control Parameters of the Three Types of Solid Waste Flue Gas Emissions

The control parameters and flue gas emission control parameters of MSW, medical waste and hazardous waste incineration processes in China are presented in Table 7. From the perspective of setting pollutant indicators and their limits, the indicator requirements for PM, NOX, SO2, HCl, HF and CO are the same for medical waste, hazardous waste and MSW incineration. However, the dioxin class MSW indicators are higher than those for medical waste and hazardous waste. Regarding heavy metals, the stringency of the limit values follows the order of medical waste = hazardous waste > MSW. Therefore, the optimal approach for PVMSW incineration in terms of process and emission control parameters aligns with the standards applied to medical waste or hazardous waste incineration. If MSW incineration facilities are utilized for MSW treatment, a thorough assessment is required.

Table 7.

Control parameters of solid waste flue gas emissions.

3.3. Empirical Analysis of Flue Gas Emission Control

3.3.1. Asuwei Waste Incineration Plant Empirical Analysis of Flue Gas Emission Control

The Asuwei waste incineration plant, located in Changping, Beijing, is responsible for treating MSW from the northern part of Dongcheng District, the northern part of Xicheng District and the entire Changping District. The plant has a designed processing capacity of 3000 t/d and is equipped with four incinerators. It employs a flue gas purification process that includes “Selective Non-Catalytic Reduction De-NOx Process (SNCR) + Semi-dry Acid Gas Removal Process + Baghouse Filter + Selective Catalytic Reduction De-NOx Process (SCR)” [37].

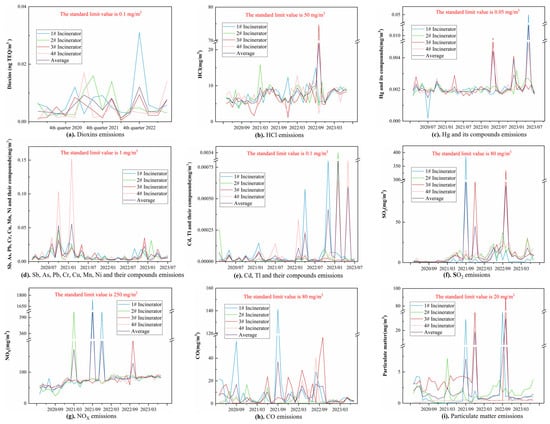

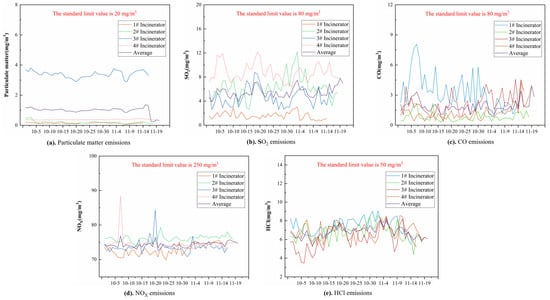

This study gathered data on the concentrations of dioxins in the flue gas emissions from the Asuwei MSW incineration plant between March 2020 and July 2023 (a time span of 3 months). The concentrations of other flue gas components, including HCl, SO2, NOX, CO and PM, were also collected during the same period (a one-month time span). The compliance of flue gas emissions at the Asuwei waste incineration plant is presented in Figure 8.

Figure 8.

Flue gas emissions compliance of Asuwei waste incineration plant.

Based on Figure 8, it is evident that the flue gas emissions of the Asuwei Waste Incineration Plant remained within the emission standards from March 2020 to July 2023. Notably, HCl (Figure 8b), CO (Figure 8h) and PM (Figure 8i) emissions exhibited significant fluctuations compared with before the end of the outbreak on 9 December 2022. Several factors contributed to these variations [62]: Because PVMSW does not segregate waste, PVMSW incineration primarily involves bagged or boxed man-overs, making incineration difficult. This can potentially result in increased CO emissions, and particulate matter concentrations can vary greatly depending on the degree of waste segregation [63]; the higher content of plastics and disinfectant solutions in PVMSW can contribute to increased HCl emissions in the exhaust gases [64]. During the COVID-19 pandemic, the extensive use of medical masks led to their incineration alongside other solid waste, causing a sudden increase in CO emissions [65,66]. The SO2 (Figure 8f) and NOX (Figure 8g) emissions remained relatively stable.

HCl (Figure 8b) and PM (Figure 8i) in February 2021, Hg and its compounds (Figure 8c) in May 2022; cadmium, Sb, As, Pb, Cr, Cu, Mn, Ni and their compounds (Figure 8d) in March 2022 and May 2022; and Cd, Tl and their compounds (Figure 8e) in August 2020, October 2020, and February 2021 were monitored and fluctuated within the range of the emission standards. These changes were due to an unexpected COVID-19 outbreak in Beijing Changping District during these periods, prompting partial lockdown measures. And there were more medium to high-risk areas around the Asuwei waste incineration plant, such as the Hongfuyuan community in Beiqijia Town, the Baigezhuang New Village community and the Forest Dadi Home community in Dongxiaokou Town. Furthermore, dioxins (Figure 8a); Hg and its compounds (Figure 8c); Sb, As, Pb, Cr, Cu, Mn, Ni and their compounds (Figure 8d); and Cd, Tl and their compounds (Figure 8e) all exhibited fluctuations in November 2022. During this period, Beijing experienced a severe SARS-CoV-2 outbreak, and the entire city essentially went into a pandemic condition. This resulted in a significant increase in the production of PVMSW. Due to the absence of prior classification of PVMSW before entering the incinerator, some waste with a high content of heavy metal, such as rubber, newspapers, plastics and batteries, were incinerated together [67]. Heavy metals can be converted to a gaseous form or attached to particles in the flue gas at high temperatures, leading to an increase in heavy metal content in the flue gas [64]. Therefore, it is reasonable to observe certain fluctuations in the emission standards of flue gas indicators during the operation of the Asuwei Waste Incineration Plant during a major outbreak period.

Additionally, maintenance or repairs were conducted on the 1# incinerator in September 2021 and September 2022; the 2# incinerator in March 2021 and December 2021; and the 3# incinerator in December 2021, May 2022 and October 2022 (official website data sources are labeled). The sudden fluctuations in indicators were due to the frequent startups and shutdowns of the incinerators, resulting in higher pollutant concentrations, and were unrelated to the occurrence of a major outbreak.

According to the time frame of the first non-local COVID-19-related case in Changping District, which occurred from 22 October 2021 to 17 November 2021, we conducted an analysis of changes in flue gas emission concentrations before (1 October to 21 October), during (22 October to 17 November) and after (18 November and after) the epidemic. The results are shown in Figure 9.

Figure 9.

Flue gas emissions compliance of Asuwei waste incineration plant, October–November 2021.

Figure 9 shows the flue gas emissions from the incineration plant during the selected testing period. While most of the emissions remained within the standard limits, there were also sudden increases in the concentration of some flue gas components. In terms of changes in flue gas emissions, dioxins, HCl, heavy metals (Hg and its compounds, Cd, Tl and its compounds, Sb, As, Pb, Cr, Cu, Mn, Ni and its compounds) and SO2 showed minor fluctuations. In contrast, NOX, CO and PM exhibited significant fluctuations, which coincided with the operation changes of the incinerators. The fluctuations were notably associated with the shutdown and restart of the 3# incinerator in April 2020 and the 2# incinerator in July 2020. The 3# incinerator underwent a cooling shutdown on 10 April, followed by a restart on 19–20 April, while the 2# incinerator was shut down on 1 July and restarted on 2 July.

Figure 9 shows that the flue gas emissions before, during and after the outbreak all remained within the standard limits with no notable abrupt changes. These emission concentrations were notably lower than those of MSW flue gas emissions and even lower than medical waste flue gas emissions. This suggests that during this outbreak, if the Asuwei waste incineration plant had accepted PVMSW, the emissions from the incineration plant would have fully complied with the emission standards.

3.3.2. Gaoantun Waste Incineration Plant Empirical Analysis of Flue Gas Emission Control

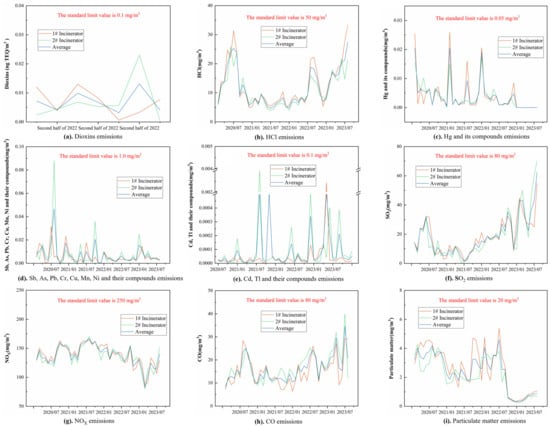

The Gaoantun waste incineration plant is located in Chaoyang District, Beijing, and is responsible for treating MSW in Chaoyang District. The plant has a designed processing capacity of 1800 t/d and is equipped with two incinerators. It employs a flue gas purification process that includes “humidifying ash recirculation, activated carbon injection, bag filter, and in-furnace denitrification” [37].

The concentrations of dioxins were analyzed over 6 months. Additionally, other flue gas components (HCl, SO2, NOX, CO, PM, etc.) were examined over 1-month intervals in the flue gas emissions from this incineration plant between March 2020 and August 2023. This study involved data gathering.

Figure 10 illustrates that the flue gas emissions of the Gaoantun Waste Incineration Plant remained within the emission standards from February 2020 to August 2023. HCl (Figure 10b) exhibited notable fluctuations within the emission standards during the periods of March to June 2020 and August to October 2022, which were likely due to variations in the MSW composition, especially its moisture content, coinciding with the rainy season [68]. Hg and its compounds (Figure 10c) in February 2021, August 2021 and January 2022; Sb, As, Pb, Cr, Cu, Mn, Ni and their compounds (Figure 10d) in July 2020; and Cd, Tl and their compounds (Figure 10e) in January 2021, May 2021 and November 2022 exhibited significant fluctuations within the emission standards. These fluctuations could be attributed to a sudden and severe SARS-CoV-2 outbreak in Beijing’s Chaoyang District during the mentioned time frames. Some communities implemented comprehensive containment measures, and several areas, such as the Xiaohongmen (area) Township of Chaoyang District and Shibalidian (area) Township of Chaoyang District, were designated as middle–high-risk areas. This led to an increase in PVMSW production and significant alterations in pollutant emission concentrations. Specifically, for Hg and its compounds (Figure 10c); Sb, As, Pb, Cr, Cu, Mn, Ni and their compounds (Figure 10d); and PM (Figure 10i), their emission levels exhibited larger fluctuations compared with the period before the pandemic’s end on 9 December 2022, possibly due to changes in household waste composition [69,70]. SO2 (Figure 10f) emissions displayed varying fluctuation patterns, while dioxin (Figure 10a) and NOx (Figure 10g) emissions remained relatively stable throughout the monitoring period.

Figure 10.

Flue gas emissions compliance at the Gaoantun Waste Incineration Plant.

Furthermore, maintenance or repairs were conducted on the 2# incinerator in December 2020, January 2021 and February 2022, as well as on the 4# incinerator in April 2021 (official website data sources are labeled). The abrupt fluctuations in indicators were due to higher pollutant concentrations resulting from the frequent startups and shutdowns of the incinerators and were unrelated to the occurrence of a major outbreak.

In summary, during the major epidemic outbreak, the flue gas emission indicators of MSW incineration at the Gaoantun Waste Incineration Plant remained within the emission standards but exhibited some degree of fluctuation. The concentrations of each air pollutant were significantly lower than China’s national standards and also below the emission standards for medical waste. This indicates that during this outbreak, if the Gaoantun waste incineration plant had accepted PVMSW, the emissions from the incineration plant would have been in full compliance with the emission standards.

3.3.3. Lujiashan Waste Incineration Plant Empirical Analysis of Flue Gas Emission Control

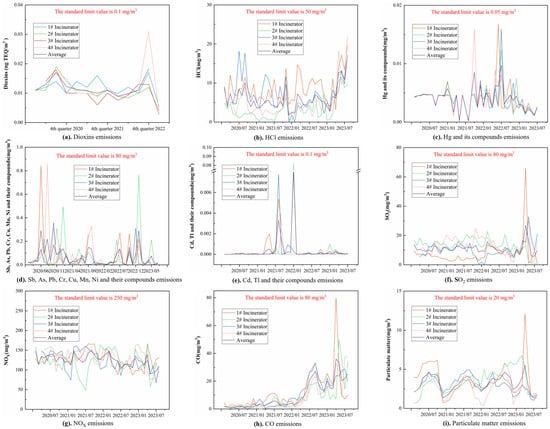

The Lujiashan waste incineration plant is located in Mentougou District, Beijing, and is responsible for treating MSW in western Beijing. The plant has a designed processing capacity of 3000 t/d and is equipped with four incinerators. It employs a flue gas purification process that includes “SNCR, rotary atomization semi-dry deacidification, bag filter and SCR” [71].

In this study, data were collected from the incineration plant for dioxin emissions over 6 months, as well as for other flue gas components (HCl, SO2, NOX, CO, PM, etc.) over a time span of 1 month, covering the period from March 2020 and August 2023. The flue gas emissions from the Lujiashan waste incineration plant are presented in Figure 11.

Figure 11.

Flue gas emissions compliance of Lujiashan waste incineration plant.

As depicted in Figure 11, from February 2020 to December 2022, the flue gas emission indicators of the Lujiashan Waste Incineration Plant consistently remained within the emission standards. Nevertheless, significant fluctuations were observed in the monitoring indicators for dioxins (Figure 11a) in the fourth quarter of 2022; Hg and its compounds (Figure 11c) in June–July 2022; and Cd, Tl and their compounds (Figure 11e) in July–August 2021. It is noteworthy that these fluctuations also fell within the emission standards. During the mentioned period, the areas served by the Lujiashan incineration plant, including Shijingshan, Fengtai, Mentougou and Xicheng Districts, experienced varying degrees of SARS-CoV-2 outbreaks, such as in Babaoshan and Laoshan streets in Shijingshan District; Xiluoyuan and Lugouqiao streets in Fengtai District; and Yongding Town in Mentougou District. In PVMSW, a significant portion consists of plastic products, with polyvinyl chloride being the main component, serving as a major source of dioxins in the incineration flue gas [72]. The fluctuations in the compounds of Sb, As, Pb, Cr, Cu, Mn, Ni and their compounds (Figure 11d) were inconsistent, possibly due to the increased maintenance frequency during this period, resulting in higher pollutant concentrations as the incineration furnace frequently started and shut down [70]. CO (Figure 11f) did not exhibit a uniform correlation with the occurrence of the epidemic. HCl (Figure 11b), SO2 (Figure 11f) and PM (Figure 11i) showed relatively small fluctuations in emission concentrations during the pandemic, remaining close to their respective averages.

Furthermore, maintenance or repairs were conducted on the 1# incinerator in October 2021 and April 2023, the 2# incinerator in December 2020, and the 3# and 4# incinerators in February 2020 and March 2020 (official website data sources are labeled). The abrupt fluctuations in indicators were attributed to higher pollutant concentrations resulting from the frequent startups and shutdowns of the incinerators and were unrelated to the occurrence of a major outbreak.

It can be observed that the flue gas emission indicators of the waste incineration plant exhibited some fluctuations within the emission standards during a major outbreak. The concentration of each air pollutant was considerably lower than China’s national standard and even lower than the flue gas emission indicators of medical waste. This suggests that during this outbreak, if the Lujiashan Waste Incineration Plant had accepted the PVMSW, it would have been in full compliance with the emission standards for treating flue gas.

4. Conclusions

The outbreak of SARS-CoV-2 presented new challenges for the environmentally sound and harmless treatment of MSW. It is crucial to assess the feasibility of using MSW incineration for the environmentally sound and harmless treatment of PVMSW to effectively prevent the spread of the epidemic and ensure the sustainable development of the urban environment [30]. Based on the characteristics of PVMSW during the epidemic, this study compared the pollution control standards for MSW incineration with those for medical and hazardous waste, clarified the requirements of incinerator furnace types for pre-treatment of incoming MSW and for process parameters during incineration, and analyzed the monitoring data on actual flue gas emission concentrations during pandemic periods across 23 incinerators from 16 urban MSW incineration plants.

It was concluded that the preferred order of incineration furnace types for MSW treatment facilities disposing of PVMSW was as follows: grate furnace incinerator > fluidized bed incinerator > cement kiln; when MSW incinerators treated PVMSW, the emissions of dioxin compounds in the flue gas fluctuated between 0.00052 and 0.031 ng TEQ/m3, HCl emissions fluctuated between 1.6 and 23.742 mg/m3, CO emissions fluctuated between 0.18 and 59.15 mg/m3, heavy metal emissions fluctuate between 0.000008 and 0.855 mg/m3, and particulate matter emissions fluctuated between 0.64 and 12.13 mg/m3; all emissions met the flue gas emission standards. Ultimately, using MSW incineration furnaces to incinerate PVMSW is feasible during major pandemics. Moving forward, this study provides a theoretical basis for researching the coordinated treatment of urban PVMSW for harmless disposal, among other aspects.

Author Contributions

Y.L.: conceptualization, methodology, project administration, writing—review and editing, and funding acquisition. R.Z.: methodology, investigation, data curation, formal analysis and writing—original draft. H.L.: writing—review and editing and supervision. W.S.: writing—review and editing and supervision. H.C.: writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the R&D Program of the Beijing Municipal Education Commission, grant number SZ202110016008.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All datasets used of our proposed approach are publicly available and can be accessed from [36,37].

Conflicts of Interest

The authors declare no conflict of interest.

References

- Saadat, S.; Rawtani, D.; Hussain, C. Mustansar, Environmental perspective of COVID-19. Sci. Total Environ. 2020, 728, 138870. [Google Scholar] [CrossRef]

- Kampf, G.; Todt, D.; Pfaender, S.; Steinmann, E. Persistence of coronaviruses on inanimate surfaces and their inactivation with biocidal agents. J. Hosp. Infect. 2020, 104, 246–251. [Google Scholar] [CrossRef] [PubMed]

- Hantoko, D.; Li, X.; Pariatamby, A.; Yoshikawa, K.; Horttanainen, M.; Yan, M. Challenges and practices on waste management and disposal during COVID-19 pandemic. J. Environ. Manag. 2021, 286, 112140. [Google Scholar] [CrossRef] [PubMed]

- Nghiem, L.D.; Morgan, B.; Donner, E.; Short, M.D. The COVID-19 pandemic: Considerations for the waste and wastewater services sector. Case Stud. Chem. Environ. Eng. 2020, 1, 100006. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Van Fan, Y.; Tan, R.R.; Jiang, P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew. Sustain. Energy Rev. 2020, 127, 109883. [Google Scholar] [CrossRef]

- ACRPlus-Association of Cities and Regions for Sustainable Resource Management. Municipal Waste Management and COVID-19. Available online: https://www.acrplus.org/en/municipal-waste-management-covid-19 (accessed on 1 November 2022).

- Do Nascimento Beckert, A.; Barros, V.G. Waste management, COVID-19 and occupational safety and health: Challenges, insights and evidence. Sci. Total Environ. 2022, 831, 154862. [Google Scholar] [CrossRef] [PubMed]

- Mol, M.P.G.; Caldas, S. Can the human coronavirus epidemic also spread through solid waste? Waste Manag. Res. 2020, 38, 485–486. [Google Scholar] [CrossRef]

- Ajaj, R.; Shahin, S.; Moda, H.; Ahmed Syed Ali, S. Knowledge, Attitude, and Practices of Face Mask Use among University Students during the COVID-19 Pandemic: A Cross-Sectional Study. Sustainability 2023, 15, 2868. [Google Scholar] [CrossRef]

- Thwe Win, T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Ferdous, W.; Kamchoom, V. Microplastics in construction and built environment. Dev. Built Environ. 2023, 15, 100188. [Google Scholar] [CrossRef]

- Rachmawati, R.; Mei, E.T.; Nurani, I.W.; Ghiffari, R.A.; Rohmah, A.A.; Sejati, M.A. Innovation in Coping with the COVID-19 Pandemic: The Best Practices from Five Smart Cities in Indonesia. Sustainability 2021, 13, 12072. [Google Scholar] [CrossRef]

- Everitt, H.; van der Werf, P.; Gilliland, J.A. A Review of Household Food Waste Generation during the COVID-19 Pandemic. Sustainability 2023, 15, 5760. [Google Scholar] [CrossRef]

- Leal Filho, W.; Lange Salvia, A.; Sierra, J.; Fletcher, C.A.; Banks, C.E.; Velazquez, L.; Anholon, R.; Rampasso, I.S.; Maclean, C.; Barbir, J.; et al. COVID-19 and Households Waste in Hispanic America: An Assessment of Trends. Sustainability 2022, 14, 16552. [Google Scholar] [CrossRef]

- Kahlert, S.; Bening, C.R. Plastics recycling after the global pandemic: Resurgence or regression? Resour. Conserv. Recycl. 2020, 160, 104948. [Google Scholar] [CrossRef]

- Fan, Y.V.; Jiang, P.; Hemzal, M.; Klemeš, J.J. An update of COVID-19 influence on waste management. Sci. Total Environ. 2021, 754, 142014. [Google Scholar] [CrossRef] [PubMed]

- Zambrano-Monserrate, M.A.; Ruano, M.A.; Sanchez-Alcalde, L. Indirect effects of COVID-19 on the environment. Sci. Total Environ. 2020, 728, 138813. [Google Scholar] [CrossRef]

- Ganguly, R.K.; Chakraborty, S.K. Integrated approach in municipal solid waste management in COVID-19 pandemic: Perspectives of a developing country like India in a global scenario. Case Stud. Chem. Environ. Eng. 2021, 3, 100087. [Google Scholar] [CrossRef]

- Jassim, M.S.; Coskuner, G.; Sultana, N.; Hossain, S.M. Zakir, Forecasting domestic waste generation during successive COVID-19 lockdowns by Bidirectional LSTM super learner neural network. Appl. Soft Comput. 2023, 133, 109908. [Google Scholar] [CrossRef]

- Ardusso, M.; Forero-López, A.D.; Buzzi, N.S.; Spetter, C.V.; Fernández-Severini, M.D. COVID-19 pandemic repercussions on plastic and antiviral polymeric textile causing pollution on beaches and coasts of South America. Sci. Total Environ. 2021, 763, 144365. [Google Scholar] [CrossRef] [PubMed]

- Benson, N.U.; Bassey, D.E.; Palanisami, T. COVID pollution: Impact of COVID-19 pandemic on global plastic waste footprint. Heliyon 2021, 7, e06343. [Google Scholar] [CrossRef]

- Leal Filho, W.; Salvia, A.L.; Minhas, A.; Paço, A.; Dias-Ferreira, C. The COVID-19 pandemic and single-use plastic waste in households: A preliminary study. Sci. Total Environ. 2021, 793, 148571. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.D.T.; Kawai, K.; Nakakubo, T. Estimation of COVID-19 waste generation and composition in Vietnam for pandemic management. Waste Manag. Res. 2021, 39, 1356–1364. [Google Scholar] [CrossRef] [PubMed]

- Lan, D.-Y.; Zhang, H.; Wu, T.-W.; Lü, F.; Shao, L.-M.; He, P.-J. Repercussions of clinical waste co-incineration in municipal solid waste incinerator during COVID-19 pandemic. J. Hazard. Mater. 2022, 423, 127144. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.; Wei, G.; Zhang, N.; Qiao, H.; Gong, Y.; Yu, X.; Zhou, J.; Wu, Y. A review on emergency disposal and management of medical waste during the COVID-19 pandemic in China. Sci. Total Environ. 2022, 810, 152302. [Google Scholar] [CrossRef]

- Mazzei, H.G.; Specchia, S. Latest insights on technologies for the treatment of solid medical waste: A review. J. Environ. Chem. Eng. 2023, 11, 109309. [Google Scholar] [CrossRef]

- Das, A.K.; Islam, M.N.; Billah, M.M.; Sarker, A. COVID-19 pandemic and healthcare solid waste management strategy—A mini-review. Sci. Total Environ. 2021, 778, 146220. [Google Scholar] [CrossRef]

- UNEP Basel Conventio: Technical Guidelines for the Environmentally Sound Management of Biomedical and Health Care Waste. Available online: http//www.basel.int/Implementation/TechnicalMatters/DevelopmentofTechnicalGuidelines/TechnicalGuidelines/tabid/8025/Default.aspx (accessed on 7 August 2023).

- United States Environmental Protection Agency. Title 40 Protection of Environment: Part 266 Standards for the Management of Specific Hazardous Waste and Specific Types of Hazardous Waste Management Facilities; United States Environmental Protection Agency: Washington, DC, USA, 2013.

- Beylot, A.; Hochar, A.; Michel, P.; Descat, M.; Menard, Y.; Villeneuve, J. Municipal Solid Waste Incineration in France: An Overview of Air Pollution Control Techniques, Emissions and Energy Efficiency. J. Ind. Ecol. 2018, 22, 1016–1026. [Google Scholar] [CrossRef]

- Ilyas, S.; Srivastava, R.R.; Kim, H. Disinfection technology and strategies for COVID-19 hospital and bio-medical waste management. Sci. Total Environ. 2020, 749, 141652. [Google Scholar] [CrossRef]

- Asian Development Bank. Managing Infectious Medical Waste during the COVID-19 Pandemic. Available online: https://www.adb.org/publications/managing-medical-waste-covid19 (accessed on 5 August 2023).

- Ministry of Ecology and Environment. Management and Technical Guidelines for Emergency Disposal of Medical Wastes Induced by the Novel Coronavirus Pneumonia Epidemic (Trial). Available online: http://www.mee.gov.cn/ywdt/hjywnews/202001/t20200129_761043.shtml (accessed on 7 August 2023). (In Chinese)

- Ministry of Ecology and Environment. Questionsand Answers Related to the Emergency Treatment of Medical Waste from Pneumonia in Domestic Garbage Incineration Facilities. Available online: http//sthjt.jl.gov.cn/zwzx/qghb/202002/t20200227_6862133.html (accessed on 7 August 2023). (In Chinese)

- Nzediegwu, C.; Chang, S.X. Improper solid waste management increases potential for COVID-19 spread in developing countries. Resour. Conserv. Recycl. 2020, 161, 104947. [Google Scholar] [CrossRef] [PubMed]

- Continuous Emissions Monitoring System. Available online: http://ljgk.envsc.cn/ (accessed on 14 July 2023).

- Beijing Environmental Information Disclosure Platform for Enterprises and Institutions. Available online: http://xxgk.bevoice.com.cn/index.do (accessed on 7 August 2023).

- GB 18485-2014; Standard for Pollution Control on the Municipal Solid Waste Incineration. Environmental Science Press: Beijing, China, 2014.

- GB/T 18750-2008; Municipal Solid Waste Incinerator and Boiler. Standard Press: Beijing, China, 2008.

- GB 18484-2020; Standard for Pollution Control on Hazardous Waste Incineration. Environmental Science Press: Beijing, China, 2020.

- HJ 662-2013; Environmental Protection Technical Specification for Co-Disposal of Solid Wastes in Cement Kiln. Environmental Science Press: Beijing, China, 2013.

- GB 39707-2020; Standard for Pollution Control on Medical Waste Treatment and Disposal. Environmental Science Press: Beijing, China, 2020. (In Chinese)

- Beijing Muncipal Commission of Urban Management. Publicity of “Special Monitoring Report on Environmental Protection Acceptance of Beijing Nangong Domestic Waste Incineration Plant Project”; Beijing Muncipal Commission of Urban Management: Beijing, China, 2018.

- Hangzhou Xiaoshan Jinjiang Green Energy Co., Ltd. Environmental Impact Assessment Form for Construction Projects. Available online: http://www.cnshidai.cn/ubb/attached/file/20200302/20200302181291909190.pdf (accessed on 3 August 2023).

- Huaxin Environmental Engineering Co. Ltd. Environmental Impact Assessment Report for the Integrated Project of Pre-Treatment of Municipal Solid Waste and Comprehensive Utilization in Cement Kilns in Chibi City. Available online: https://max.book118.com/html/2015/0404/14303427.shtm (accessed on 1 August 2023).

- GB/T 34552-2017; Municipal Solid Waste Fluidized Bed Incineration Boiler. Standard Press: Beijing, China, 2017.

- Chen, C.; Wang, H.; Liu, G.; Lin, B.; Yang, L.; Jin, R.; Sun, Y.; Guo, J.; Li, Y.; Yang, N.; et al. Concentrations, congener patterns, and correlations of unintentional persistent organic pollutants in cement kilns co-processing hazardous waste. Sci. Total Environ. 2023, 854, 158793. [Google Scholar] [CrossRef] [PubMed]

- Yoon, C.-W.; Kim, M.-J.; Park, Y.-S.; Jeon, T.-W.; Lee, M.-Y. A Review of Medical Waste Management Systems in the Republic of Korea for Hospital and Medical Waste Generated from the COVID-19 Pandemic. Sustainability 2022, 14, 3678. [Google Scholar] [CrossRef]

- GB 19218-2003; Technical Standard for Medical Waste Incinerator. Environmental Science Press: Beijing, China, 2003.

- HJ 177-2023; Technical Specifications for Centralized Incineration Engineering on Medical Waste. Environmental Science Press: Beijing, China, 2023.

- Jinan Municipal Ecological Environment Bureau. Public Announcement by Jinan Municipal Ecological Environment Bureau Regarding the Acceptance of the “Environmental Impact Assessment Report for the Jinan Qidi Environmental Development Co. Ltd. Medical Waste Central Disposal Project in Jinan City”. Available online: http://www.jncq.gov.cn/art/2019/6/18/art_21721_3024605.html (accessed on 7 August 2023).

- Beijing Ruentex Environmental Technology Co. Medical Waste Disposal. Available online: http://www.bjruentex.com/yfcz.aspx (accessed on 7 August 2023).

- HJ/T 176-2005; Technical Specifications for Centralized Incineration Facility. Environmental Science Press: Beijing, China, 2005.

- Fuzhou Municipal Urban Management Committee. Second Public Notice for the Environmental Impact Assessment of the Fuzhou Hazardous Waste Comprehensive Disposal Project. Available online: http://zfj.fuzhou.gov.cn/zz/zwgk/tzgg/201711/t20171114_1831829.htm (accessed on 7 August 2023).

- Yangzhou Shoutuo Environmental Technology Co. Ltd. Second Public Notice of the Environmental Impact Assessment for the Hazardous Waste Disposal Project in Yangzhou. Available online: http://www.d1ea.com/front/eia/28442.html (accessed on 7 August 2023).

- Nanjing Lishui District People’s Government. Announcement on the Acceptance of Environmental Impact Assessment Documents for Construction Projects by the Lishui Ecological Environment Bureau of Nanjing City on May 21, 2020. Available online: http://www.njls.gov.cn/jrs/gggs/202005/t20200521_1883586.html (accessed on 4 July 2023).

- Wen, Z.; Di, J.; Liu, S.; Han, J.; Lee, J.C.K. Evaluation of flue-gas treatment technologies for municipal waste incineration: A case study in Changzhou, China. J. Clean. Prod. 2018, 184, 912–920. [Google Scholar] [CrossRef]

- GB 30485—2013; Standard for pollution control on co-processing of solid wastes in Cement kiln. China Environmental Science Press: Beijing, China, 2013.

- GB 4915-2013; Emission standard of air pollutants for cement industry. China Environmental Science Press: Beijing, China, 2013.

- Jiangsu Provincial Department of Ecology and Environment. Monitoring Results of Key Pollutant Discharge Units in Jiangsu Province in the Second Quarter of 2021. Available online: http://hbt.jiangsu.gov.cn/art/2021/7/30/art_80478_9956470.html (accessed on 7 August 2023).

- Leckner, B.; Lind, F. Combustion of municipal solid waste in fluidized bed or on grate—A comparison. Waste Manag. 2020, 109, 94–108. [Google Scholar] [CrossRef]

- Tang, L.; Guo, J.; Wan, R.; Jia, M.; Qu, J.; Li, L.; Bo, X. Air pollutant emissions and reduction potentials from municipal solid waste incineration in China. Environ. Pollut. 2023, 319, 121021. [Google Scholar] [CrossRef]

- Heidari, M.; Garnaik, P.P.; Dutta, A. 11—The Valorization of Plastic Via Thermal Means: Industrial Scale Combustion Methods. In Plastics to Energy; Al-Salem, S.M., Ed.; William Andrew Publishing: Norwich, NY, USA, 2019; pp. 295–312. [Google Scholar]

- Wang, L.; Zhong, R.; Hu, Y.; Kong, H.; Shen, H. Discussion on emergency disposal of medical waste during epidemic period. In Proceedings of the 2020 Annual Meeting of Science and Technology of Chinese Society of Environmental Sciences, Nanjing, China, 21 September 2020; pp. 1291–1295. [Google Scholar]

- Idowu, G.A.; Olonimoyo, E.A. How has COVID-19 medical face mask altered the dynamics of pollutants from incinerated wastes? J. Hazard. Mater. Adv. 2023, 11, 100351. [Google Scholar] [CrossRef]

- Pujara, Y.; Govani, J.; Patel, H.T.; Pathak, P.; Mashru, D.; Ganesh, P. Sankar, Quantification of environmental impacts associated with municipal solid waste management in Rajkot city, India using Life Cycle Assessment. Environ. Adv. 2023, 12, 100364. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Xiao, Y.; Sun, M.; Gao, X.; Su, J. Evaluation of a flue gas cleaning system of a circulating fluidized bed incineration power plant by the analysis of pollutant emissions. Powder Technol. 2015, 286, 9–15. [Google Scholar] [CrossRef]

- Dan, Z.; Zhou, W.; Zhou, P.; Che, Y.; Han, Z.; Qiong, A.; Duo, B.; Lv, X.; Zhuoma, Q.; Wang, J.; et al. Characterization of municipal solid waste incineration and flue gas emission under anoxic environment in Tibet Plateau. Environ. Sci. Pollut. Res. 2022, 29, 6656–6669. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Liu, Q.; Luo, H.; Li, B.; Cheng, J.; Huang, Y. Emission characteristics and impact factors of air pollutants from municipal solid waste incineration in Shanghai, China. J. Environ. Manag. 2022, 310, 114732. [Google Scholar] [CrossRef]

- Li, M.; Wang, C.; Cen, K.; Ni, M.; Li, X. PCDD/F emissions during startup and shutdown of a hazardous waste incinerator. Chemosphere 2017, 181, 645–654. [Google Scholar] [CrossRef]

- Beijing Shougang Bioenergy Science & Technolongy Co. Ltd. Process Introduction. Available online: http://www.sgswz.com/xtgy0/gyjs0/cindex1.html (accessed on 3 August 2023).

- Patrício Silva, A.L.; Prata, J.C.; Walker, T.R.; Duarte, A.C.; Ouyang, W.; Barcelò, D.; Rocha-Santos, T. Increased plastic pollution due to COVID-19 pandemic: Challenges and recommendations. Chem. Eng. J. 2021, 405, 126683. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).