Potential Integration of Bridge Information Modeling and Life Cycle Assessment/Life Cycle Costing Tools for Infrastructure Projects within Construction 4.0: A Review

Abstract

:1. Introduction

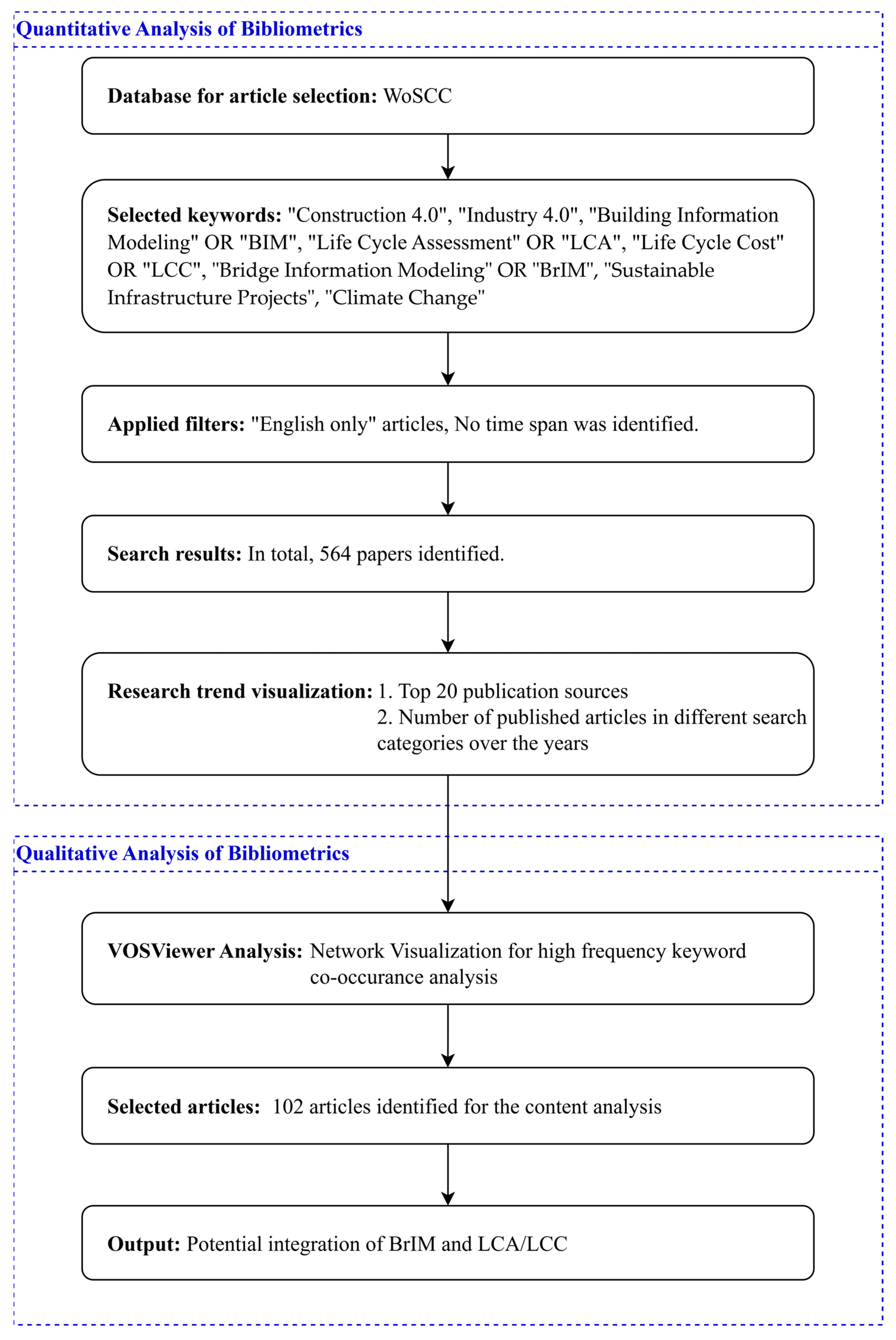

2. Materials and Methods

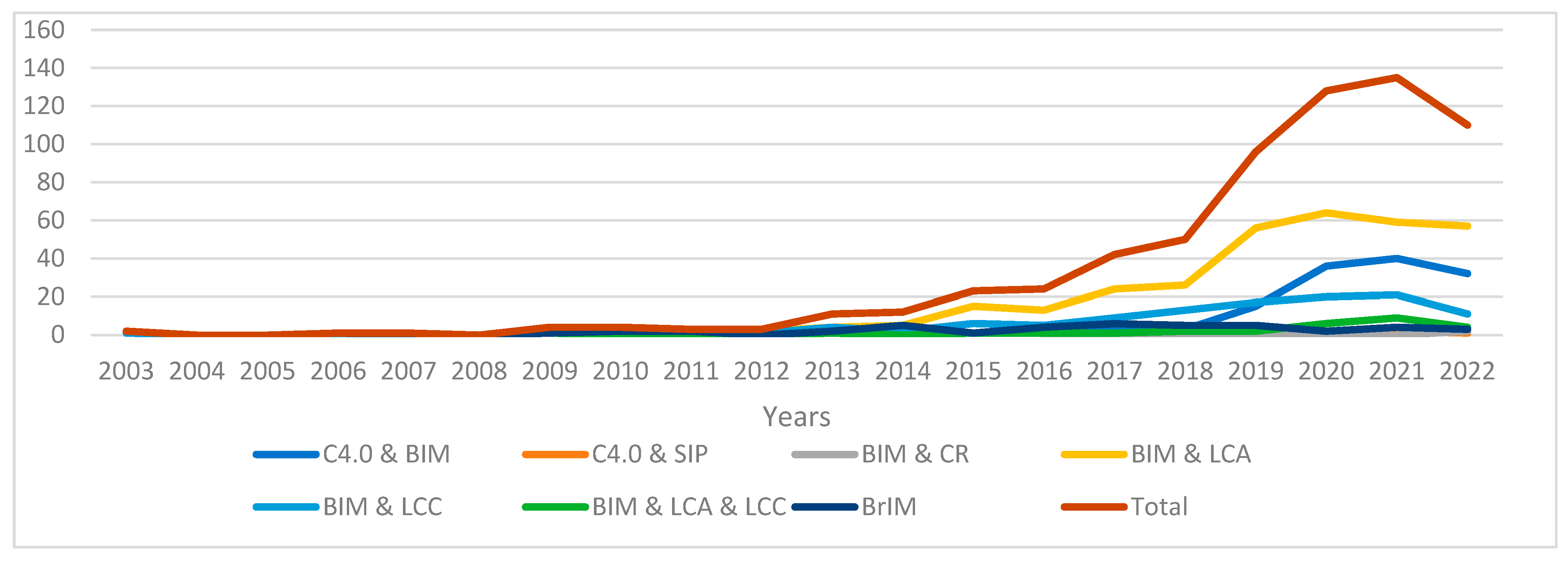

2.1. Data Collection and Bibliometric Analysis

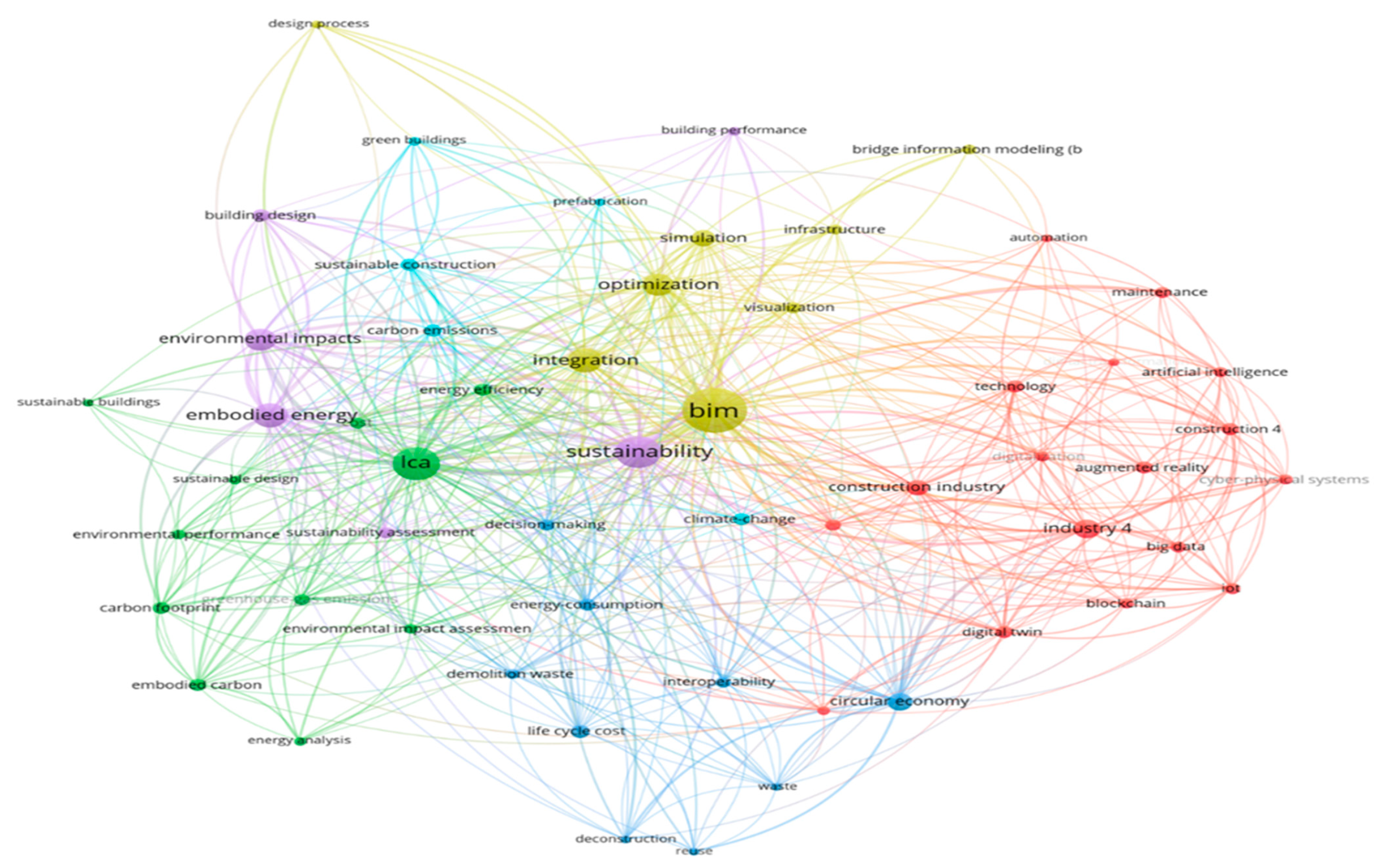

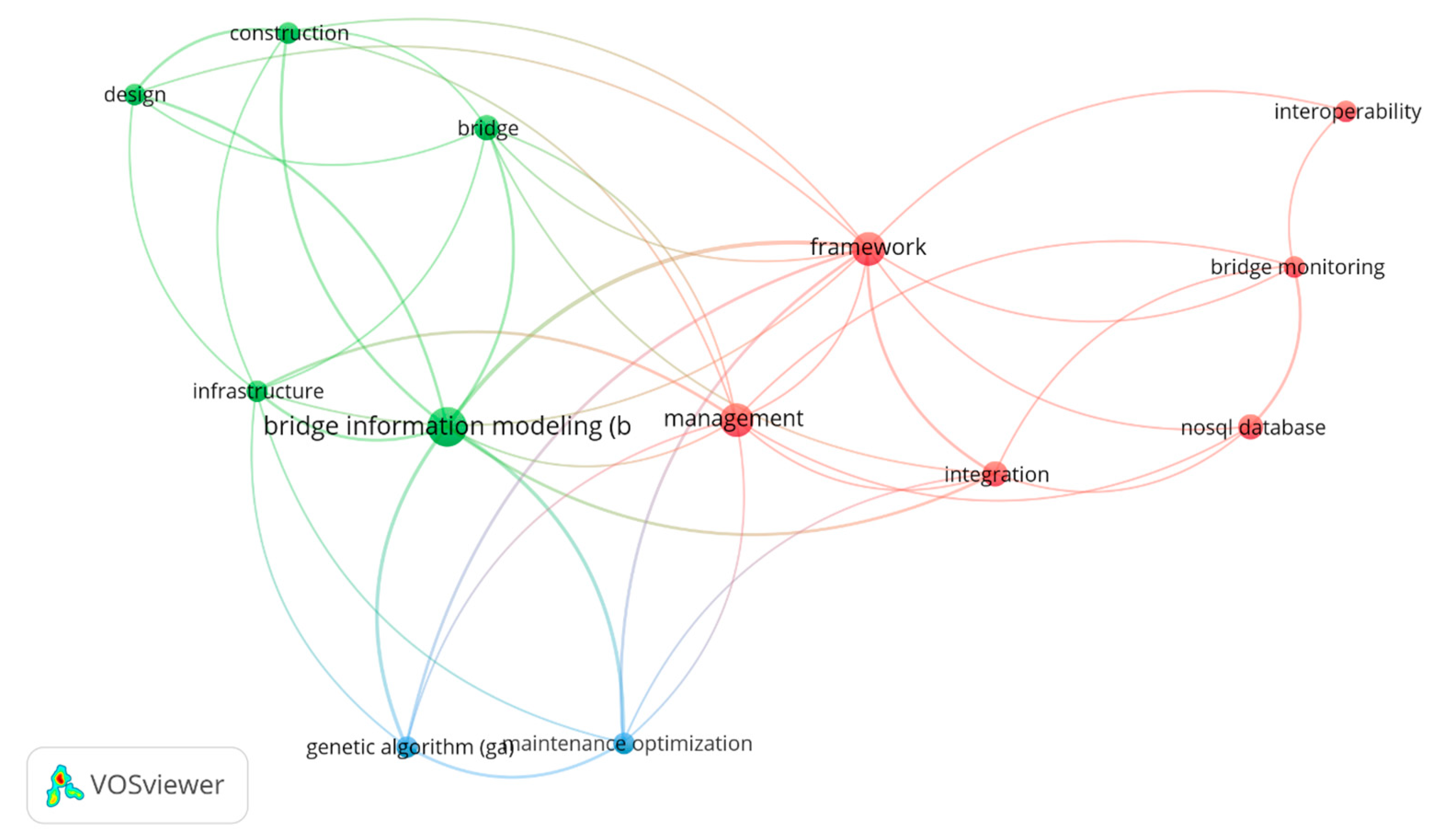

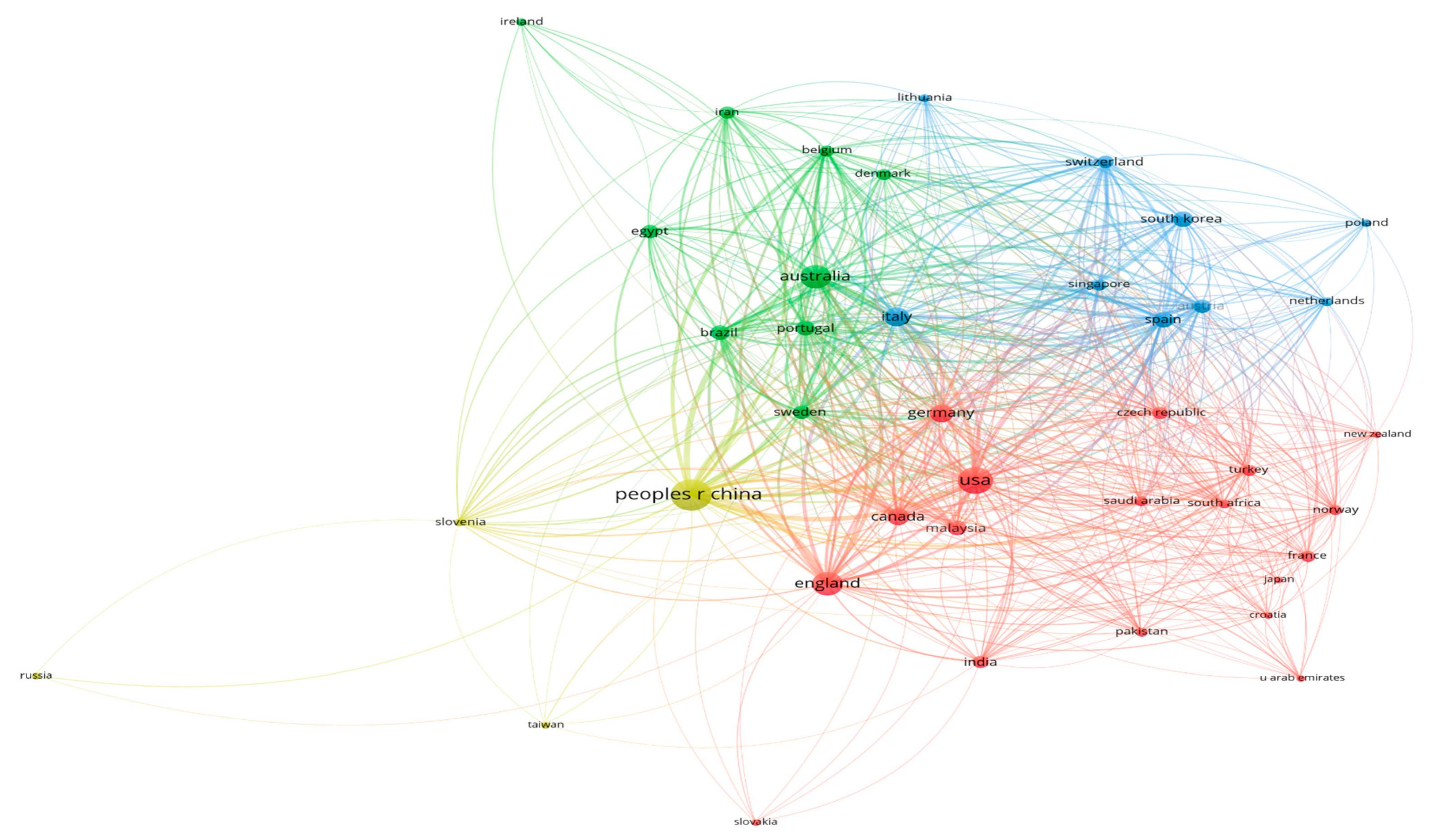

2.2. Network Visualization

2.3. Countries Engagement Analysis

3. Results

3.1. Building Information Modelling (BIM) and Life Cycle Assessment (LCA)

3.1.1. BIM Model’s Input

3.1.2. LCA Model’s Input

3.1.3. Software Integration and Data Exchange

- (i)

- Export the bill of quantities (BOQ) into Excel: it is well known that Microsoft Excel is a third-party tool that is commonly employed in many studies; thus, as part of the integration process, the quantities of materials extracted from BIM tools, like Autodesk Revit© [110] and ArchiCAD [111], are multiplied by the related emission factors provided by LCA tools, such as the Ecoinvent [95,112] and ICE [99,113] databases.

- (ii)

- Export BOQ into dedicated LCA tools: Abbasi and Noorzai [98] presented a BIM-based multi-optimization framework for determining the trade-off between embodied and operational energy. Furthermore, they provided an approach to choosing optimal solutions during the early stage of design. The geometric data and materials’ bill of quantity were extracted from Revit, a BIM tool, and subsequently inputted into Athena Impact Estimator, a LCA tool, to calculate the embodied energy of an eight-story residential building.

- (iii)

- The use of LCA plugins in BIM tools: This method has been used to a great extent since Tally, one of the LCA tools, was realized due to its user-friendly interface. Tushar et al. [97] integrated a BIM tool (Autodesk Revit©) with an energy rating tool (FirstRate5) and a Tally plugin into a BIM tool to quantify and compare different design options for a residential building. They compared various design scenarios with different options, including insulation and accessory materials. The results of their study showed that plywood walls had a lower impact on the environment compared to the other types of walls. Furthermore, some studies used sensitivity analysis to determine the factors that have a greater impact on the overall performance.

- (iv)

- The use of visual programming languages (VPL) to evaluate environmental impacts: to assess the emissions of building elements, Marzouk et al. [114] developed an interface in which building data extracted from a BIM model could be transferred to Microsoft Access through a DB link in Autodesk Revit©, a BIM tool, whereas the emission factors could be retrieved from Athena Impact Estimator, as LCA tool.

- (v)

- The use of industry foundation classes (IFC) to transfer the data exported from BIM models to an LCA tool: It is commonly known that the IFC scheme for storing LCA-related information within BIM environments is a workable method for coping with a large volume of data. However, the most recent version of IFC, IFC4, is the only version that makes use of IFC features for simple LCA but not a full LCA [115]. Therefore, more IFC properties should be created if a comprehensive LCA needs to be performed.

- (vi)

- The incorporation of LCA data into BIM objects: In this method, each building’s material data stored in the native library of the BIM tool, Autodesk Revit©, are connected to an emission factor obtained from the KBOB database using a unique ID similar to the case reported in the study conducted by Hollberg et al. [105]. The quantities of the materials are obtained using Dynamo through unique KBOB IDs. However, Dynamo is only able to retrieve volumetric data for technical routing components like pipes or ducts. However, several studies considered the creation of new and unique APIs in BIM tools (i.e., Autodesk Revit) for this purpose.

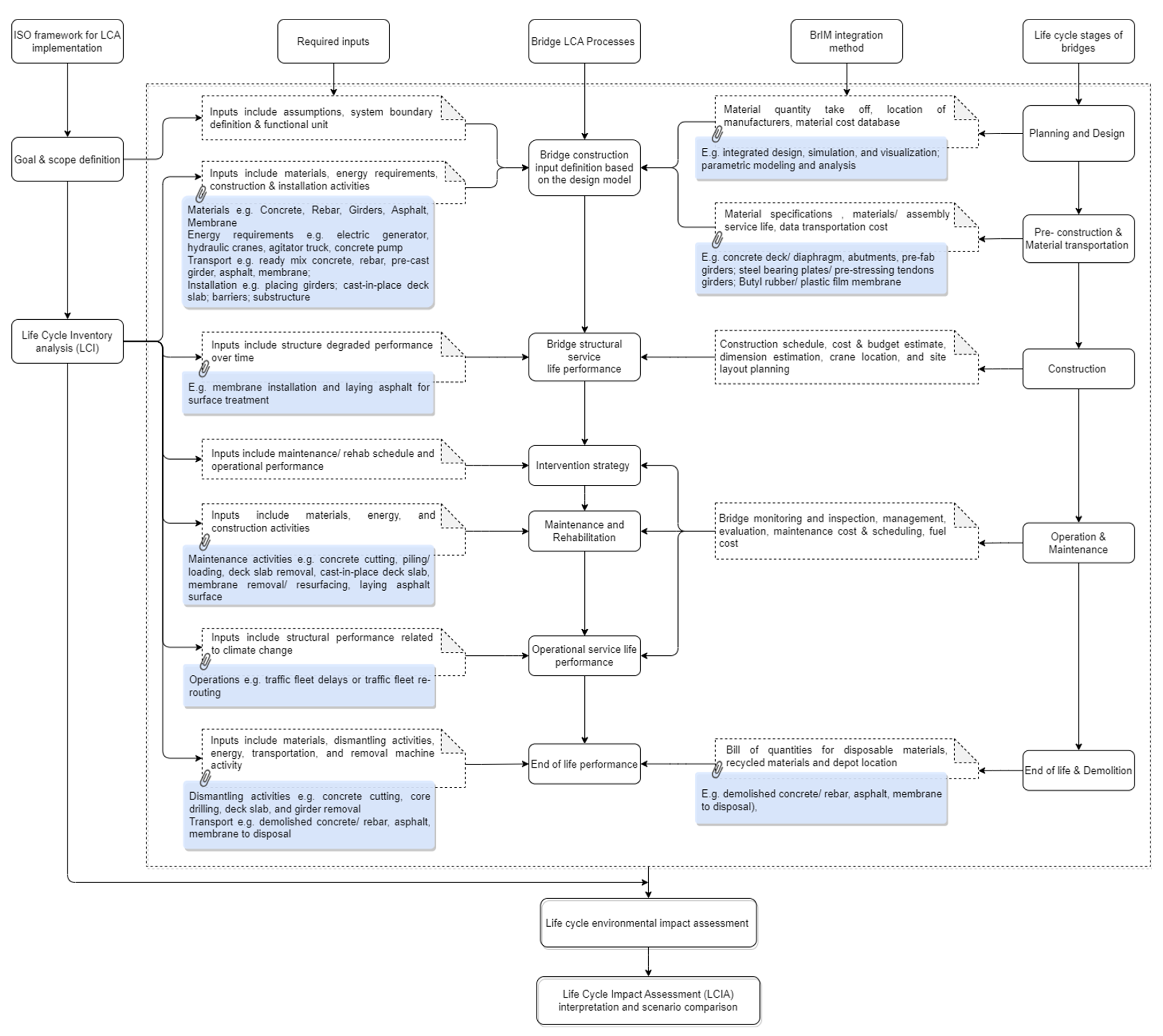

3.2. Bridge LCA Stages and Frameworks

3.2.1. Material Manufacturing Stage

3.2.2. Construction Stage

3.2.3. Operation and Maintenance Stage

3.2.4. End-of-Life and Demolition Stage

3.3. Bridge Information Modeling (BrIM)

4. Discussion

- Utilizing existing BrIM tools, such as Autodesk Revit, CSiBridge, Autodesk Infraworks, Autodesk Civil 3D CAD, and Tekla Structures to generate bills of quantities and other relevant data;

- Exporting the data from a BrIM tool to an external tool;

- Involving data and information in the BrIM environment.

5. Conclusions

- (1)

- To attain a better and more detailed understanding of the essential requirements for achieving the above-mentioned integration, a thorough evaluation of the published studies centered on the integration of BIM and LCA; BIM and LCC; and BIM, LCA, and LCC was executed. To perform an efficient LCA for bridge projects, a thorough analysis of the published methodologies was carried out with an emphasis on the objectives and scopes and the functional units to be considered at each stage of a bridge’s life, spanning from the material production stage through to its end-of-life stage (EOL). Then, the idea of BrIM was carefully reviewed based on the relevance of BIM concepts during each stage of a bridge project.

- (2)

- BrIM technology is a digital presentation of the physical and functional characteristics of a bridge that involves its geometry, materials, and behavior. BrIM can facilitate the creation of detailed digital models of bridge projects, which can be used to evaluate different design alternatives and construction successions.

- (3)

- LCC is the basis for evaluating the costs of different design and construction options over the whole life cycle of projects, including their operation and maintenance costs. LCA is an efficient context for analyzing the environmental impact of a project over its entire life cycle, including the impact of the materials used, the energy consumed, and the waste generated. The integration of LCC and LCA with BrIM helps designers, engineers, and contractors to conduct accurate evaluations of a bridge’s performance and assessments of its environmental impact over its anticipated life. This integration can facilitate the decision-making act during the design and construction phases and lead to better maintenance and repair strategies throughout the bridge’s service life.

- (4)

- Furthermore, integrating LCC, LCA, and BrIM can enhance the collaboration and communication between various stakeholders who are involved in the design and construction of a bridge project. BrIM provides a platform for stakeholders to share and visualize data that can support the process of making efficient decisions. Joining LCC and LCA with BrIM assists decision makers in evaluating different scenarios and alternatives in a virtual environment to determine the most cost-effective and sustainable options. Overall, the integration of LCC, LCA, and BrIM helps individuals make better decisions, thereby decreasing the environmental impact and improving the performance of bridge projects.

- (5)

- With respect to the abovementioned review of the literature, which focused on the evaluation of integrating BrIM with LCA and LCC, we recommended that researchers proceed with an additional evaluation and analysis that would be centered as a roadmap for developing a prototype model for bridge LCA and LCC within a BrIM platform. This roadmap can guide the way for the implementation of a standalone integrated model that acts as a platform for integrating BrIM, LCA, and LCC, but this was not the focus, to the best of our knowledge, of any of the previous studies. Furthermore, using optimization frameworks that incorporate BrIM, LCC, and LCA can be considered for future studies as well. The proposed framework permits the development of a more detailed approach to making accurate and effective decisions related to the construction of bridge projects by considering both the costs and the environmental impact over the long term. To further enrich the scope of future research in this domain, the potential implications of capital investment required for the adoption of digital technologies like the proposed framework can be investigated. While this study has explored the integration of BrIM with LCA and LCC, its future expansion will concern understanding the impact of capital investment on construction projects and its importance. The extended framework will also consider budget constraints and financial conditions, ultimately leading to more sustainable and cost-effective measures. Optimization frameworks that incorporate BrIM, LCC, and LCA can be used to assess different design and construction options and determine cost-effective and sustainable measures based on budget limitations and financial conditions for such types of projects.

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tay, S.; Te Chuan, L.; Aziati, A.; Ahmad, A.N.A. An Overview of Industry 4.0: Definition, Components, and Government Initiatives. J. Adv. Res. Dyn. Control. Syst. 2018, 10, 14. [Google Scholar]

- Craveiro, F.; Duarte, J.; Bártolo, H.; Bartolo, P. Additive Manufacturing as an Enabling Technology for Digital Construction: A Perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.d.F.R.; Ramos, L.F.P. Past, Present and Future of Industry 4.0—A Systematic Literature Review and Research Agenda Proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Schneider, P. Managerial Challenges of Industry 4.0: An Empirically Backed Research Agenda for a Nascent Field. Rev. Manag. Sci. 2018, 12, 803–848. [Google Scholar] [CrossRef]

- Nakayama, R.S.; de Mesquita Spínola, M.; Silva, J.R. Towards I4.0: A Comprehensive Analysis of Evolution from I3.0. Comput. Ind. Eng. 2020, 144, 106453. [Google Scholar] [CrossRef]

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28, 689–711. [Google Scholar] [CrossRef]

- Liu, Y.; van Nederveen, S.; Hertogh, M. Understanding Effects of BIM on Collaborative Design and Construction: An Empirical Study in China. Int. J. Proj. Manag. 2017, 35, 686–698. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the Implications of Digitisation and Automation in the Context of Industry 4.0: A Triangulation Approach and Elements of a Research Agenda for the Construction Industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Lee, M.L.; Cheah, W.T.; Lau, S.H.; Lee, X.S.; Abdullahi, A.M.; Wong, S.Y. Evaluation of Practicality of Virtual Design and Construction (VDC) with 5D Building Information Modelling (BIM) through a Case Study. IOP Conf. Ser. Mater. Sci. Eng. 2020, 943, 12058. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, Y.; Sun, C. Emerging Information Technology Acceptance Model for the Development of Smart Construction System. J. Civ. Eng. Manag. 2018, 24, 457–468. [Google Scholar] [CrossRef]

- Chowdhury, T.; Adafin, J.; Wilkinson, S. Review of Digital Technologies to Improve Productivity of New Zealand Construction Industry. J. Inf. Technol. Constr. 2019, 24, 569–587. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Mohammed, B.S. Industry Revolution IR 4.0: Future Opportunities and Challenges in Construction Industry. MATEC Web Conf. 2018, 203, 02010. [Google Scholar] [CrossRef]

- Zabidin, N.S.; Belayutham, S.; Ibrahim, C.K.I.C. A Bibliometric and Scientometric Mapping of Industry 4.0 in Construction. J. Inf. Technol. Constr. 2020, 25, 287–307. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A Literature Review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Bock, T. The Future of Construction Automation: Technological Disruption and the Upcoming Ubiquity of Robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Yidong, Q.; Rucheng, X.; Yang, W.; Law, K.H. A Bridge Information Modeling Framework for Model Interoperability. Comput. Civ. Eng. 2019, 2022, 447–454. [Google Scholar]

- McGuire, B.; Atadero, R.; Clevenger, C.; Ozbek, M.E. Bridge Information Modeling for Inspection and Evaluation. J. Bridge Eng. 2016, 21, 4015076. [Google Scholar] [CrossRef]

- Shim, C.S.; Yun, N.R.; Song, H.H. Application of 3D Bridge Information Modeling to Design and Construction of Bridges. Procedia Eng. 2011, 14, 95–99. [Google Scholar] [CrossRef]

- Elbeltagi, E.; Dawood, M. Integrated Visualized Time Control System for Repetitive Construction Projects. Autom. Constr. 2011, 20, 940–953. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, Y.B.; Shim, C.S.; Park, K.L. Bridge Information Models for Construction of a Concrete Box-Girder Bridge. Struct. Infrastruct. Eng. 2012, 8, 687–703. [Google Scholar] [CrossRef]

- Ding, L.; Zhou, Y.; Akinci, B. Building Information Modeling (BIM) Application Framework: The Process of Expanding from 3D to Computable ND. Autom. Constr. 2014, 46, 82–93. [Google Scholar] [CrossRef]

- Jeong, S.; Hou, R.; Lynch, J.P.; Sohn, H.; Law, K.H. An Information Modeling Framework for Bridge Monitoring. Adv. Eng. Softw. 2017, 114, 11–31. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, D.; Liu, Z.; Osmani, M.; Demian, P. Construction 4.0, Industry 4.0, and Building Information Modeling (BIM) for Sustainable Building Development within the Smart City. Sustainability 2022, 14, 10028. [Google Scholar] [CrossRef]

- Teng, Y.; Xu, J.; Pan, W.; Zhang, Y. A Systematic Review of the Integration of Building Information Modeling into Life Cycle Assessment. Build. Environ. 2022, 221, 109260. [Google Scholar] [CrossRef]

- Olawumi, T.; Chan, D.; Wong, J. Evolution in the intellectual structure of BIM research: A bibliometric analysis. J. Civ. Eng. Manag. 2017, 23, 1060–1081. [Google Scholar] [CrossRef]

- Wang, X.; Fang, Z.; Sun, X. Usage Patterns of Scholarly Articles on Web of Science: A Study on Web of Science Usage Count. Scientometrics 2016, 109, 917–926. [Google Scholar] [CrossRef]

- Xu, J.; Teng, Y.; Pan, W.; Zhang, Y. BIM-integrated LCA to automate embodied carbon assessment of prefabricated buildings. J. Clean. Prod. 2022, 374, 133894. [Google Scholar] [CrossRef]

- Morsi, D.M.; Ismaeel, W.S.; Ehab, A.; Othman, A.A. BIM-based life cycle assessment for different structural system scenarios of a residential building. Ain Shams Eng. J. 2022, 13, 101802. [Google Scholar] [CrossRef]

- Lee, S.; Tae, S.; Jang, H.; Chae, C.U.; Bok, Y. Development of Building Information Modeling Template for Environmental Impact Assessment. Sustainability 2021, 13, 3092. [Google Scholar] [CrossRef]

- Abouhamad, M.; Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13, 461. [Google Scholar] [CrossRef]

- Sameer, H.; Bringezu, S. Building information modelling application of material, water, and climate footprint analysis. Build. Res. Inf. 2021, 49, 593–612. [Google Scholar] [CrossRef]

- Jalaei, F.; Zoghi, M.; Khoshand, A. Life cycle environmental impact assessment to manage and optimize construction waste using Building Information Modeling (BIM). Int. J. Constr. Manag. 2019, 21, 784–801. [Google Scholar] [CrossRef]

- Naneva, A.; Bonanomi, M.; Hollberg, A.; Habert, G.; Hall, D. Integrated BIM-Based LCA for the Entire Building Process Using an Existing Structure for Cost Estimation in the Swiss Context. Sustainability 2020, 12, 3748. [Google Scholar] [CrossRef]

- Vilutiene, T.; Kumetaitis, G.; Kiaulakis, A.; Kalibatas, D. Assessing the Sustainability of Alternative Structural Solutions of a Building: A Case Study. Buildings 2020, 10, 36. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Development of a BIM-based Environmental and Economic Life Cycle Assessment tool. J. Clean. Prod. 2020, 265, 121705. [Google Scholar] [CrossRef]

- Wang, N.; Satola, D.; Wiberg, A.H.; Liu, C.; Gustavsen, A. Reduction Strategies for Greenhouse Gas Emissions from High-Speed Railway Station Buildings in a Cold Climate Zone of China. Sustainability 2020, 12, 1704. [Google Scholar] [CrossRef]

- Kiss, B.; Szalay, Z. Modular approach to multi-objective environmental optimization of buildings. Autom. Constr. 2020, 111, 103044. [Google Scholar] [CrossRef]

- Feng, H.; Liyanage, D.R.; Karunathilake, H.; Sadiq, R.; Hewage, K. BIM-based life cycle environmental performance assessment of single-family houses: Renovation and reconstruction strategies for aging building stock in British Columbia. J. Clean. Prod. 2019, 250, 119543. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, S.; Wang, E. Integration of BIM and Energy Consumption Modelling for Manufacturing Prefabricated Components: A Case Study in China. Adv. Civ. Eng. 2019, 2019, 1609523. [Google Scholar] [CrossRef]

- Lu, K.; Jiang, X.; Tam, V.W.Y.; Li, M.; Wang, H.; Xia, B.; Chen, Q. Development of a Carbon Emissions Analysis Framework Using Building Information Modeling and Life Cycle Assessment for the Construction of Hospital Projects. Sustainability 2019, 11, 6274. [Google Scholar] [CrossRef]

- Nilsen, M.; Bohne, R. Evaluation of BIM Based LCA in Early Design Phase (Low LOD) of Buildings; Passer, A., Lutzkendorf, T., Habert, G., KrompKolb, H., Monsberger, M., Eds.; IOP Publishing: Bristol, UK, 2019; Volume 323. [Google Scholar]

- Najjar, M.; Figueiredo, K.; Hammad, A.W.; Haddad, A. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382. [Google Scholar] [CrossRef]

- Najjar, M.K.; Figueiredo, K.; Evangelista, A.C.J.; Hammad, A.W.A.; Tam, V.W.Y.; Haddad, A. Life cycle assessment methodology integrated with BIM as a decision-making tool at early-stages of building design. Int. J. Constr. Manag. 2019, 22, 541–555. [Google Scholar] [CrossRef]

- Sharif, S.A.; Hammad, A. Simulation-Based Multi-Objective Optimization of institutional building renovation considering energy consumption, Life-Cycle Cost and Life-Cycle Assessment. J. Build. Eng. 2019, 21, 429–445. [Google Scholar] [CrossRef]

- Castro, R.; Pasanen, P. How to design buildings with Life Cycle Assessment by accounting for the material flows in refurbishment. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012019. [Google Scholar] [CrossRef]

- Hasik, V.; Escott, E.; Bates, R.; Carlisle, S.; Faircloth, B.; Bilec, M.M. Comparative whole-building life cycle assessment of renovation and new construction. J. Affect. Disord. 2019, 161, 106218. [Google Scholar] [CrossRef]

- Stevanovic, M.; Allacker, K.; Vermeulen, S. Development of an Approach to Assess the Life Cycle Environmental Impacts and Costs of General Hospitals through the Analysis of a Belgian Case. Sustainability 2019, 11, 856. [Google Scholar] [CrossRef]

- Shadram, F.; Mukkavaara, J. An integrated BIM-based framework for the optimization of the trade-off between embodied and operational energy. Energy Build. 2018, 158, 1189–1205. [Google Scholar] [CrossRef]

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. J. Affect. Disord. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Nizam, R.S.; Zhang, C.; Tian, L. A BIM based tool for assessing embodied energy for buildings. Energy Build. 2018, 170, 1–14. [Google Scholar] [CrossRef]

- Yang, X.; Hu, M.; Wu, J.; Zhao, B. Building-Information-Modeling Enabled Life Cycle Assessment, a Case Study on Carbon Footprint Accounting for a Residential Building in China. J. Clean. Prod. 2018, 183, 729–743. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A.; de Cózar, J.C.G. BIM-Based LCA Method to Analyze Envelope Alternatives of Single-Family Houses: Case Study in Uruguay. J. Arch. Eng. 2018, 24. [Google Scholar] [CrossRef]

- Bueno, C.; Fabricio, M.M. Comparative analysis between a complete LCA study and results from a BIM-LCA plug-in. Autom. Constr. 2018, 90, 188–200. [Google Scholar] [CrossRef]

- Bueno, C.; Pereira, L.M.; Fabricio, M.M. Life cycle assessment and environmental-based choices at the early design stages: An application using building information modelling. Arch. Eng. Des. Manag. 2017, 14, 332–346. [Google Scholar] [CrossRef]

- Crippa, J.; Boeing, L.C.; Caparelli, A.P.A.; da Costa, M.d.R.d.M.M.; Scheer, S.; Araujo, A.M.F.; Bem, D. A BIM–LCA integration technique to embodied carbon estimation applied on wall systems in Brazil. Built Environ. Proj. Asset Manag. 2018, 8, 491–503. [Google Scholar] [CrossRef]

- Najjar, M.; Figueiredo, K.; Palumbo, M.; Haddad, A. Integration of BIM and LCA: Evaluating the environmental impacts of building materials at an early stage of designing a typical office building. J. Build. Eng. 2017, 14, 115–126. [Google Scholar] [CrossRef]

- Schultz, J.; Ku, K.; Gindlesparger, M.; Doerfler, J. A benchmark study of BIM-based whole-building life-cycle assessment tools and processes. Int. J. Sustain. Build. Technol. Urban Dev. 2016, 7, 219–229. [Google Scholar] [CrossRef]

- Shadram, F.; Johansson, T.D.; Lu, W.; Schade, J.; Olofsson, T. An integrated BIM-based framework for minimizing embodied energy during building design. Energy Build. 2016, 128, 592–604. [Google Scholar] [CrossRef]

- Santos, R.; Aguiar Costa, A. BIM in LCA/LCEA Analysis: Comparative Analysis of Multi-Family House and Single-Family. In Proceedings of the CIB World Building Congress, Tampere, Finland, 30 May–3 July 2016. [Google Scholar]

- Peng, C. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Ceranic, B.; Gallanagh, M.; Kadiri, K.O. Life cycle environmental performance of material specification: A BIM-enhanced comparative assessment. Int. J. Sustain. Build. Technol. Urban Dev. 2015, 6, 14–24. [Google Scholar] [CrossRef]

- Lee, S.; Tae, S.; Roh, S.; Kim, T. Green Template for Life Cycle Assessment of Buildings Based on Building Information Modeling: Focus on Embodied Environmental Impact. Sustainability 2015, 7, 16498–16512. [Google Scholar] [CrossRef]

- Shafiq, N.; Nurrudin, M.F.; Gardezi, S.S.S.; Bin Kamaruzzaman, A. Carbon footprint assessment of a typical low rise office building in Malaysia using building information modelling (BIM). Int. J. Sustain. Build. Technol. Urban Dev. 2015, 6, 157–172. [Google Scholar] [CrossRef]

- Wiberg, A.H.; Georges, L.; Dokka, T.H.; Haase, M.; Time, B.; Lien, A.G.; Mellegård, S.; Maltha, M. A net zero emission concept analysis of a single-family house. Energy Build. 2014, 74, 101–110. [Google Scholar] [CrossRef]

- Jalaei, F.; Jrade, A. An Automated BIM Model to Conceptually Design, Analyze, Simulate, and Assess Sustainable Building Projects. J. Constr. Eng. 2014, 2014, 672896. [Google Scholar] [CrossRef]

- Jrade, A.; Jalaei, F. Integrating building information modelling with sustainability to design building projects at the conceptual stage. Build. Simul. 2013, 6, 429–444. [Google Scholar] [CrossRef]

- Liu, S.; Meng, X.; Tam, C. Building information modeling based building design optimization for sustainability. Energy Build. 2015, 105, 139–153. [Google Scholar] [CrossRef]

- Kehily, D.; Underwood, J. Embedding Life Cycle Costing in 5D BIM. J. Inf. Technol. Constr. 2017, 22, 145–167. [Google Scholar]

- Juan, Y.-K.; Hsing, N.-P. BIM-Based Approach to Simulate Building Adaptive Performance and Life Cycle Costs for an Open Building Design. Appl. Sci. 2017, 7, 837. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-based approach for optimizing life cycle costs of sustainable buildings. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- Saridaki, M.; Haugbølle, K. Implementing Life-Cycle Costing: Data Integration between Design Models and Cost Calculations. Electron. J. Inf. Technol. Constr. 2019, 24, 14–32. [Google Scholar]

- Raposo, C.; Rodrigues, F.; Rodrigues, H. BIM-based LCA assessment of seismic strengthening solutions for reinforced concrete precast industrial buildings. Innov. Infrastruct. Solutions 2019, 4, 1–10. [Google Scholar] [CrossRef]

- Lee, J.; Yang, H.; Lim, J.; Hong, T.; Kim, J.; Jeong, K. BIM-based preliminary estimation method considering the life cycle cost for decision-making in the early design phase. J. Asian Arch. Build. Eng. 2020, 19, 384–399. [Google Scholar] [CrossRef]

- Le, H.T.T.; Likhitruangsilp, V.; Yabuki, N. A BIM-Integrated Relational Database Management System for Evaluating Building Life-Cycle Costs. Eng. J. 2020, 24, 75–86. [Google Scholar] [CrossRef]

- Rad, M.A.H.; Jalaei, F.; Golpour, A.; Varzande, S.S.H.; Guest, G. BIM-based approach to conduct Life Cycle Cost Analysis of resilient buildings at the conceptual stage. Autom. Constr. 2021, 123, 103480. [Google Scholar] [CrossRef]

- Zhuang, D.; Zhang, X.; Lu, Y.; Wang, C.; Jin, X.; Zhou, X.; Shi, X. A performance data integrated BIM framework for building life-cycle energy efficiency and environmental optimization design. Autom. Constr. 2021, 127, 103712. [Google Scholar] [CrossRef]

- Tian, H.; Wang, J.; Cao, S.; Chen, Y.; Li, L. Probabilistic Assessment of the Safety of Main Cables for Long-Span Suspension Bridges considering Corrosion Effects. Adv. Civ. Eng. 2021, 2021, 6627762. [Google Scholar] [CrossRef]

- Wang, Q.; Sohn, H.; Cheng, J.C.P. Automatic As-Built BIM Creation of Precast Concrete Bridge Deck Panels Using Laser Scan Data. J. Comput. Civ. Eng. 2018, 32, 04018011. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Butler, L.J.; Brilakis, I.; Elshafie, M.Z.E.B.; Middleton, C.R. Structural Performance Monitoring Using a Dynamic Data-Driven BIM Environment. J. Comput. Civ. Eng. 2018, 32. [Google Scholar] [CrossRef]

- Xia, Y. Research on dynamic data monitoring of steel structure building information using BIM. J. Eng. Des. Technol. 2020, 18, 1165–1173. [Google Scholar] [CrossRef]

- Mawlana, M.; Vahdatikhaki, F.; Doriani, A.; Hammad, A. Integrating 4D modeling and discrete event simulation for phasing evaluation of elevated urban highway reconstruction projects. Autom. Constr. 2015, 60, 25–38. [Google Scholar] [CrossRef]

- Nettis, A.; Saponaro, M.; Nanna, M. RPAS-Based Framework for Simplified Seismic Risk Assessment of Italian RC-Bridges. Buildings 2020, 10, 150. [Google Scholar] [CrossRef]

- Shim, C.; Kang, H.; Dang, N.S.; Lee, D. Development of BIM-Based Bridge Maintenance System for Cable-Stayed Bridges. Smart Struct. Syst. 2017, 20, 697–708. [Google Scholar]

- Parlikad, A.K.; Catton, P. Infrastructure information management of bridges at local authorities in the UK. Infrastruct. Asset Manag. 2018, 5, 120–131. [Google Scholar] [CrossRef]

- Isailović, D.; Stojanovic, V.; Trapp, M.; Richter, R.; Hajdin, R.; Döllner, J. Bridge damage: Detection, IFC-based semantic enrichment and visualization. Autom. Constr. 2020, 112, 103088. [Google Scholar] [CrossRef]

- Floros, G.S.; Boyes, G.; Owens, D.; Ellul, C. Developing IFC for Infrastructure: A Case Study of Three Highway Entities. ISPRS Ann. Photogramm. Remote. Sens. Spat. Inf. Sci. 2019, IV-4/W8, 59–66. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management–Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 31 July 2023).

- ISO 14044:2006; The International Standards Organisation, ISO 14044: Environmental Management-Life Cycle Assessment-Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 31 July 2023).

- Succar, B. Building Information Modelling Framework: A Research and Delivery Foundation for Industry Stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of Life-Cycle Assessment to Early Stage Building Design for Reduced Embodied Environmental Impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Eleftheriadis, S.; Duffour, P.; Mumovic, D. BIM-Embedded Life Cycle Carbon Assessment of RC Buildings Using Optimised Structural Design Alternatives. Energy Build. 2018, 173, 587–600. [Google Scholar] [CrossRef]

- Mostafazadeh, F.; Eirdmousa, S.J.; Tavakolan, M. Energy, Economic and Comfort Optimization of Building Retrofits Considering Climate Change: A Simulation-Based NSGA-III Approach. Energy Build. 2023, 280, 112721. [Google Scholar] [CrossRef]

- Tavakolan, M.; Mostafazadeh, F.; Jalilzadeh Eirdmousa, S.; Safari, A.; Mirzaei, K. A Parallel Computing Simulation-Based Multi-Objective Optimization Framework for Economic Analysis of Building Energy Retrofit: A Case Study in Iran. J. Build. Eng. 2022, 45, 103485. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; Garcia-Martinez, A. Critical Review of Bim-Based LCA Method to Buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; Moya, L. Comparative BIM-Based Life Cycle Assessment of Uruguayan Timber and Concrete-Masonry Single-Family Houses in Design Stage. J. Clean. Prod. 2020, 277, 121958. [Google Scholar] [CrossRef]

- Rezaei, F.; Bulle, C.; Lesage, P. Integrating Building Information Modeling and Life Cycle Assessment in the Early and Detailed Building Design Stages. Build. Environ. 2019, 153, 158–167. [Google Scholar] [CrossRef]

- Tushar, Q.; Bhuiyan, M.; Zhang, G.; Maqsood, T. An Integrated Approach of BIM-Enabled LCA and Energy Simulation: The Optimized Solution towards Sustainable Development. J. Clean. Prod. 2021, 289, 125622. [Google Scholar] [CrossRef]

- Abbasi, S.; Noorzai, E. The BIM-Based Multi-Optimization Approach in Order to Determine the Trade-off between Embodied and Operation Energy Focused on Renewable Energy Use. J. Clean. Prod. 2021, 281, 125359. [Google Scholar] [CrossRef]

- Ansah, M.; Chen, X.; Yang, H.; Lu, L.; Lam, P. An Integrated Life Cycle Assessment of Different Facade Systems for a Typical Residential Building in Ghana. Sustain. Cities Soc. 2020, 53, 101974. [Google Scholar] [CrossRef]

- Abanda, F.; Oti, A.; Tah, J. Integrating BIM and New Rules of Measurement for Embodied Energy and CO2 Assessment. J. Build. Eng. 2017, 12, 288–305. [Google Scholar] [CrossRef]

- Carvalho, J.; Alecrim, I.; Braganca, L.; Mateus, R. Integrating BIM-Based LCA and Building Sustainability Assessment. Sustainability 2020, 12, 7468. [Google Scholar] [CrossRef]

- Jalaei, F.; Guest, G.; Gaur, A.; Zhang, J. Exploring the Effects That a Non-Stationary Climate and Dynamic Electricity Grid Mix Has on Whole Building Life Cycle Assessment: A Multi-City Comparison. Sustain. Cities Soc. 2020, 61, 102294. [Google Scholar] [CrossRef]

- Cheng, B.; Li, J.; Tam, V.; Yang, M.; Chen, D. A BIM-LCA Approach for Estimating the Greenhouse Gas Emissions of Large-Scale Public Buildings: A Case Study. Sustainability 2020, 12, 685. [Google Scholar] [CrossRef]

- Cavalliere, C.; Habert, G.; Dell’Osso, G.; Hollberg, A. Continuous BIM-Based Assessment of Embodied Environmental Impacts throughout the Design Process. J. Clean. Prod. 2019, 211, 941–952. [Google Scholar] [CrossRef]

- Hollberg, A.; Genova, G.; Habert, G. Evaluation of BIM-Based LCA Results for Building Design. Autom. Constr. 2020, 109, 102972. [Google Scholar] [CrossRef]

- Kiamili, C.; Hollberg, A.; Habert, G. Detailed Assessment of Embodied Carbon of HVAC Systems for a New Office Building Based on BIM. Sustainability 2020, 12, 3372. [Google Scholar] [CrossRef]

- Su, S.; Wang, Q.; Han, L.; Hong, J.; Liu, Z. BIM-DLCA: An Integrated Dynamic Environmental Impact Assessment Model for Buildings. Build. Environ. 2020, 183, 107218. [Google Scholar] [CrossRef]

- Obrecht, T.; Rock, M.; Hoxha, E.; Passer, A. BIM and LCA Integration: A Systematic Literature Review. Sustainability 2020, 12, 5534. [Google Scholar] [CrossRef]

- Tam, V.; Zhou, Y.; Illankoon, C.; Le, K. A Critical Review on BIM and LCA Integration Using the ISO 14040 Framework. Build. Environ. 2022, 213, 108865. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. A Validation Study of a Semi-Automatic BIM-LCA Tool: 2o Congresso Português de Building Information Modelling. In 2° Congresso Português de Building Information Modelling; Instituto Superior Técnico Universidade de Lisboa: Lisbon, Portugal, 2018. [Google Scholar]

- Shin, Y.; Cho, K. BIM Application to Select Appropriate Design Alternative with Consideration of LCA and LCC. Math. Probl. Eng. 2015, 2015, 281640. [Google Scholar] [CrossRef]

- Georges, L.; Haase, M.; Houlihan Wiberg, A.; Kristjansdottir, T.; Risholt, B. Life Cycle Emissions Analysis of Two NZEB Concepts. Build. Res. Inf. 2015, 43, 82–93. [Google Scholar] [CrossRef]

- Iddon, C.; Firth, S. Embodied and Operational Energy for New-Build Housing: A Case Study of Construction Methods in the UK. Energy Build. 2013, 67, 479–488. [Google Scholar] [CrossRef]

- Marzouk, M.; Abdelkader, E.M.; Al-Gahtani, K. Building Information Modeling-Based Model for Calculating Direct and Indirect Emissions in Construction Projects. J. Clean. Prod. 2017, 152, 351–363. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.; Silvestre, J.; Pyl, L. Integration of LCA and LCC Analysis within a BIM-Based Environment. Autom. Constr. 2019, 103, 127–149. [Google Scholar] [CrossRef]

- Guest, G.; Zhang, J.; Kadhom, B.; Singh, J. Incorporating the Impacts of Climate Change into a Life Cycle Assessment of a Slab-on-Girder Highway Bridge. In Pavement, Roadway, and Bridge Life Cycle Assessment 2020; Harvey, J., Al-Qadi, I.L., Ozer, H., Flintsch, G., Eds.; Taylor & Francis Group: London, UK, 2020; pp. 40–50. ISBN 9780367551667. [Google Scholar]

- Ma, M.; Li, Z.; Xue, K.; Liu, M. Exergy-Based Life Cycle Assessment Model for Evaluating the Environmental Impact of Bridge: Principle and Case Study. Sustainability 2021, 13, 11804. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; García-Segura, T.; Martí, J.V.; Yepes, V. An Optimization-LCA of a Prestressed Concrete Precast Bridge. Sustainability 2018, 10, 685. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; Martí, J.V.; García-Segura, T.; Yepes, V. Life-Cycle Assessment: A Comparison between Two Optimal Post-Tensioned Concrete Box-Girder Road Bridges. Sustainability 2017, 9, 1864. [Google Scholar] [CrossRef]

- Peñaloza, D.; Erlandsson, M.; Pousette, A. Climate Impacts from Road Bridges: Effects of Introducing Concrete Carbonation and Biogenic Carbon Storage in Wood. Struct. Infrastruct. Eng. 2018, 14, 56–67. [Google Scholar] [CrossRef]

- Shi, C.; Wang, Y.; Chen, B.; Liu, Y.; Li, K.; Luo, W. Life-Cycle Environmental and Economic Benefits of Jointless Bridges Considering Climate Change. Struct. Infrastruct. Eng. 2023, 19, 745–759. [Google Scholar] [CrossRef]

- Kripka, M.; Yepes, V.; Milani, C.J. Selection of Sustainable Short-Span Bridge Design in Brazil. Sustainability 2019, 11, 1307. [Google Scholar] [CrossRef]

- Lee, H.R.; Yu, J.; Yun, W.G.; Nam, J.; Kim, K.J. Estimating Environmental Load of PSC Beam Bridge Using Standard Quantities and Resource DB Model. KSCE J. Civ. Eng. 2019, 23, 958–972. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Wu, W.J.; Wang, Y.F. Bridge Life Cycle Assessment with Data Uncertainty. Int. J. Life Cycle Assess. 2016, 21, 569–576. [Google Scholar] [CrossRef]

- Fifer Bizjak, K.; Lenart, S. Life Cycle Assessment of a Geosynthetic-Reinforced Soil Bridge System—A Case Study. Geotext. Geomembr. 2018, 46, 543–558. [Google Scholar] [CrossRef]

- Pang, B.; Yang, P.; Wang, Y.; Kendall, A.; Xie, H.; Zhang, Y. Life Cycle Environmental Impact Assessment of a Bridge with Different Strengthening Schemes. Int. J. Life Cycle Assess. 2015, 20, 1300–1311. [Google Scholar] [CrossRef]

- Du, G.; Pettersson, L.; Karoumi, R. Soil-Steel Composite Bridge: An Alternative Design Solution for Short Spans Considering LCA. J. Clean. Prod. 2018, 189, 647–661. [Google Scholar] [CrossRef]

- Kim, H.; Tae, S.; Ahn, Y.; Yang, J. Scenarios for Life Cycle Studies of Bridge Concrete Structure Maintenance. Sustainability 2020, 12, 29557. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V.; González-Vidosa, F. Life Cycle Impact Assessment of Corrosion Preventive Designs Applied to Prestressed Concrete Bridge Decks. J. Clean. Prod. 2018, 196, 698–713. [Google Scholar] [CrossRef]

- Du, G.; Safi, M.; Pettersson, L.; Karoumi, R. Life Cycle Assessment as a Decision Support Tool for Bridge Procurement: Environmental Impact Comparison among Five Bridge Designs. Int. J. Life Cycle Assess. 2014, 19, 1948–1964. [Google Scholar] [CrossRef]

- Habert, G.; Arribe, D.; Dehove, T.; Espinasse, L.; Roy, R. Le Reducing Environmental Impact by Increasing the Strength of Concrete: Quantification of the Improvement to Concrete Bridges. J. Clean. Prod. 2012, 35, 250–262. [Google Scholar] [CrossRef]

- Martínez-Muñoz, D.; Martí, J.V.; Yepes, V. Comparative Life Cycle Analysis of Concrete and Composite Bridges’ Varying Steel Recycling Ratio. Materials 2021, 14, 4218. [Google Scholar] [CrossRef]

- O’Born, R. Life Cycle Assessment of Large Scale Timber Bridges: A Case Study from the World’s Longest Timber Bridge Design in Norway. Transp. Res. Part D Transp. Environ. 2018, 59, 301–312. [Google Scholar] [CrossRef]

- Hammervold, J.; Reenaas, M.; Brattebø, H. Environmental Life Cycle Assessment of Bridges. J. Bridge Eng. 2013, 18, 153–161. [Google Scholar] [CrossRef]

- Kim, K.J.; Yun, W.G.; Cho, N.; Ha, J. Life Cycle Assessment Based Environmental Impact Estimation Model for Pre-Stressed Concrete Beam Bridge in the Early Design Phase. Environ. Impact Assess. Rev. 2017, 64, 47–56. [Google Scholar] [CrossRef]

- Marzouk, M.; Hisham, M. Implementing Earned Value Management Using Bridge Information Modeling. KSCE J. Civ. Eng. 2014, 18, 1302–1313. [Google Scholar] [CrossRef]

- Shim, C.-S.; Lee, K.-M.; Kang, L.S.; Hwang, J.; Kim, Y. Three-Dimensional Information Model-Based Bridge Engineering in Korea. Struct. Eng. Int. 2012, 22, 8–13. [Google Scholar] [CrossRef]

- Vilventhan, A.; Rajadurai, R. 4D Bridge Information Modelling for Management of Bridge Projects: A Case Study from India. Built Environ. Proj. Asset Manag. 2020, 10, 423–435. [Google Scholar] [CrossRef]

- Markiz, N.; Jrade, A. Integrating fuzzy-logic decision support with a bridge information management system (BrIMS) at the conceptual stage of bridge design. J. Inf. Technol. Constr. 2018, 23, 92–121. [Google Scholar]

- Tanner, P.; Bellod, J.L.; Sanz, D. Paper and Pencil in the Age of BIM. Struct. Eng. Int. 2018, 28, 396–407. [Google Scholar] [CrossRef]

- Dang, N.-S.; Rho, G.-T.; Shim, C.-S. A Master Digital Model for Suspension Bridges. Appl. Sci. 2020, 10, 7666. [Google Scholar] [CrossRef]

- Hautala, K.; Järvenpää, M.-E.; Pulkkinen, P. Digitalization Transforms the Construction Sector throughout Asset’s Life-Cycle from Design to Operation and Maintenance. Stahlbau 2017, 86, 340–345. [Google Scholar] [CrossRef]

- Fanning, B.; Clevenger, C.M.; Ozbek, M.E.; Mahmoud, H. Implementing BIM on Infrastructure: Comparison of Two Bridge Construction Projects. Pract. Period. Struct. Des. Constr. 2015, 20, 04014044. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Zhou, Z. Sustainability-Based Lifecycle Management for Bridge Infrastructure Using 6D BIM. Sustainability 2020, 12, 2436. [Google Scholar] [CrossRef]

- Marzouk, M.; Hisham, M. A Hybrid Model for Selecting Location of Mobile Cranes in Bridge Construction Projects. Balt. J. Road Bridge Eng. 2013, 8, 184–189. [Google Scholar] [CrossRef]

- Xu, Y.; Turkan, Y. BrIM and UAS for Bridge Inspections and Management. Eng. Constr. Archit. Manag. 2020, 27, 785–807. [Google Scholar] [CrossRef]

- Almomani, H.; Almutairi, O.N. Life-Cycle Maintenance Management Strategies for Bridges in Kuwait. J. Environ. Treat. Tech. 2020, 8, 1556–1562. [Google Scholar] [CrossRef]

- Park, S.I.; Park, J.; Kim, B.-G.; Lee, S.-H. Improving Applicability for Information Model of an IFC-Based Steel Bridge in the Design Phase Using Functional Meanings of Bridge Components. Appl. Sci. 2018, 8, 2531. [Google Scholar] [CrossRef]

- Wan, C.; Zhou, Z.; Li, S.; Ding, Y.; Xu, Z.; Yang, Z.; Xia, Y.; Yin, F. Development of a Bridge Management System Based on the Building Information Modeling Technology. Sustainability 2019, 11, 4583. [Google Scholar] [CrossRef]

- Zhang, Z.; Hamledari, H.; Billington, S.; Fischer, M. 4D beyond Construction: Spatio-Temporal and Life-Cyclic Modeling and Visualization of Infrastructure Data. Electron. J. Inf. Technol. Constr. 2018, 23, 285–304. [Google Scholar]

- Hüthwohl, P.; Brilakis, I.; Borrmann, A.; Sacks, R. Integrating RC Bridge Defect Information into BIM Models. J. Comput. Civ. Eng. 2018, 32, 04018013. [Google Scholar] [CrossRef]

- Costin, A.; Adibfar, A.; Hu, H.; Chen, S.S. Building Information Modeling (BIM) for Transportation Infrastructure–Literature Review, Applications, Challenges, and Recommendations. Autom. Constr. 2018, 94, 257–281. [Google Scholar] [CrossRef]

- Markiz, N.; Jrade, A. Integrating a Fuzzy-Logic Decision Support System with Bridge Information Modelling and Cost Estimation at Conceptual Design Stage of Concrete Box-Girder Bridges. Int. J. Sustain. Built Environ. 2014, 3, 135–152. [Google Scholar] [CrossRef]

- Nikolaos, F.; Sergios, L.; George, T. Parametric Model for Conceptual Cost Estimation of Concrete Bridge Foundations. J. Infrastruct. Syst. 2011, 17, 66–74. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Vandenbergh, T.; Pyl, L. BIM-Based Life Cycle Assessment and Life Cycle Costing of an Office Building in Western Europe. Build. Environ. 2020, 169, 106568. [Google Scholar] [CrossRef]

- Guest, G.; Zhang, J.; Atadero, R.; Shirkhani, H. Incorporating the Effects of Climate Change into Bridge Deterioration Modeling: The Case of Slab-on-Girder Highway Bridge Deck Designs across Canada. J. Mater. Civ. Eng. 2020, 32, 04020175. [Google Scholar] [CrossRef]

| Web of Science Core Collection | SCI-EXPANDED, SSCI, CPCI-S, CPCI-SSH, CCR-EXPANDED, IC | No. of Results |

|---|---|---|

| Search steps | #1 = (“building information modeling” or “BIM”) (Topic) and (“climate resiliency” or “climate resilience”) | 2 |

| #2 = (“construction 4.0” OR “industry 4.0”) AND (“infrastructure projects” OR “sustainable infrastructure”) | 5 | |

| #3 = (“construction 4.0” OR “industry 4.0”) AND (“building information modeling” OR “BIM”) | 118 | |

| #4 = (“building information modeling” OR “BIM”) AND (“life cycle assessment” OR “LCA”) | 329 | |

| #5 = (“building information modeling” OR “BIM”) AND (“life cycle cost” OR “LCC”) | 114 | |

| #6 = (“building information modeling” OR “BIM”) AND (“life cycle assessment” OR “LCA”) AND (“life cycle cost” OR “LCC”) | 28 | |

| #7 = (“bridge information modeling” OR “BrIM”) | 43 | |

| #8 = (“bridge information modeling” OR “BrIM”) AND (“construction 4.0” OR “industry 4.0”) | 1 | |

| #9 = (“bridge information modeling” OR “BrIM”) AND (“life cycle assessment” OR “LCA”) | 0 | |

| #10 = (“bridge information modeling” OR “BrIM”) AND (“life cycle cost” OR “LCC”) | 0 | |

| #11 = #8 OR #7 OR #6 OR #5 OR #4 OR #3 OR #2 OR #1 | 564 | |

| Qualified Records | 102 | |

| Timespan | 2003–2022 | |

| Ranking | Source Titles (Journals) | No. of Publications |

|---|---|---|

| Top 1 | Sustainability | 63 |

| Top 2 | Journal of Cleaner Production | 32 |

| Top 3 | Buildings | 26 |

| Top 4 | Automation in Construction | 24 |

| Top 5 | Journal of Building Engineering | 21 |

| Top 6 | Iop Conference Series Earth and Environmental Science | 20 |

| Top 7 | Building and Environment | 16 |

| Top 8 | Energy and Buildings | 16 |

| Top 9 | Sustainable Built Environment Conference | 15 |

| Top 10 | International Journal of Construction Management | 12 |

| Top 11 | Journal of Information Technology in Construction | 11 |

| Top 12 | Procedia Engineering | 10 |

| Top 13 | Applied Sciences Basel | 8 |

| Top 14 | Life Cycle Analysis and Assessment in Civil Engineering Towards an Integrated Vision | 8 |

| Top 15 | Sustainable Cities and Society | 8 |

| Top 16 | Energies | 7 |

| Top 17 | Construction Innovation England | 6 |

| Top 18 | Smart and Sustainable Built Environment | 6 |

| Top 19 | Advanced Engineering Informatics | 5 |

| Top 20 | Built Environment Project and Asset Management | 5 |

| Country | Documents | Citations | Total Link Strength |

|---|---|---|---|

| Peoples R China | 103 | 1933 | 914 |

| Australia | 62 | 1795 | 663 |

| USA | 77 | 1906 | 631 |

| England | 61 | 1253 | 541 |

| Spain | 28 | 454 | 485 |

| Portugal | 24 | 604 | 441 |

| Austria | 20 | 375 | 424 |

| Italy | 41 | 411 | 419 |

| Belgium | 15 | 466 | 406 |

| Brazil | 22 | 427 | 395 |

| Switzerland | 17 | 436 | 392 |

| Sweden | 20 | 415 | 378 |

| Germany | 34 | 911 | 329 |

| Canada | 30 | 518 | 313 |

| South Korea | 26 | 485 | 242 |

| Iran | 16 | 209 | 198 |

| Turkey | 15 | 135 | 169 |

| Malaysia | 22 | 158 | 161 |

| Czech Republic | 16 | 105 | 156 |

| South Africa | 9 | 184 | 155 |

| Slovenia | 7 | 87 | 143 |

| Egypt | 21 | 251 | 141 |

| Denmark | 13 | 90 | 127 |

| Norway | 11 | 62 | 120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jrade, A.; Jalaei, F.; Zhang, J.J.; Jalilzadeh Eirdmousa, S.; Jalaei, F. Potential Integration of Bridge Information Modeling and Life Cycle Assessment/Life Cycle Costing Tools for Infrastructure Projects within Construction 4.0: A Review. Sustainability 2023, 15, 15049. https://doi.org/10.3390/su152015049

Jrade A, Jalaei F, Zhang JJ, Jalilzadeh Eirdmousa S, Jalaei F. Potential Integration of Bridge Information Modeling and Life Cycle Assessment/Life Cycle Costing Tools for Infrastructure Projects within Construction 4.0: A Review. Sustainability. 2023; 15(20):15049. https://doi.org/10.3390/su152015049

Chicago/Turabian StyleJrade, Ahmad, Farnaz Jalaei, Jieying Jane Zhang, Saeed Jalilzadeh Eirdmousa, and Farzad Jalaei. 2023. "Potential Integration of Bridge Information Modeling and Life Cycle Assessment/Life Cycle Costing Tools for Infrastructure Projects within Construction 4.0: A Review" Sustainability 15, no. 20: 15049. https://doi.org/10.3390/su152015049

APA StyleJrade, A., Jalaei, F., Zhang, J. J., Jalilzadeh Eirdmousa, S., & Jalaei, F. (2023). Potential Integration of Bridge Information Modeling and Life Cycle Assessment/Life Cycle Costing Tools for Infrastructure Projects within Construction 4.0: A Review. Sustainability, 15(20), 15049. https://doi.org/10.3390/su152015049