An Automated Classification of Recycled Aggregates for the Evaluation of Product Standard Compliance

Abstract

:1. Introduction

- The relatively low values of the materials that are potentially recoverable from C&DW flow streams. The development of low-cost processes is thus linked to the production of large quantities of material per time unit, which must also be of high quality;

- The dimensions of the enterprises involved in this business. Usually, in fact, they are of small or medium size, and normally, they want to perform the job as quickly and as cheaply as possible, utilizing simple technologies and thus causing an important loss of recoverable materials and a corresponding reduction in revenues [19].

2. Materials and Methods

2.1. Selected Samples

- Rc: Concrete, concrete products, mortar, and concrete masonry units;

- Ru: Unbound aggregates, natural stones, and hydraulically bound aggregates;

- Rb: Clay masonry units (i.e., brick and tiles), calcium silicate masonry units, and aerated non-floating concrete;

- Ra: Bituminous materials;

- Rg: Glass;

- X: Other cohesive materials (i.e., clay and soil) and miscellaneous materials, such as metals (ferrous and non-ferrous metals), non-floating wood, plastic and rubber, and gypsum plaster.

- X1: Metals (ferrous and non-ferrous);

- X2: Non-floating wood;

- X3: Cardboard;

- X4: Parget and gypsum plaster.

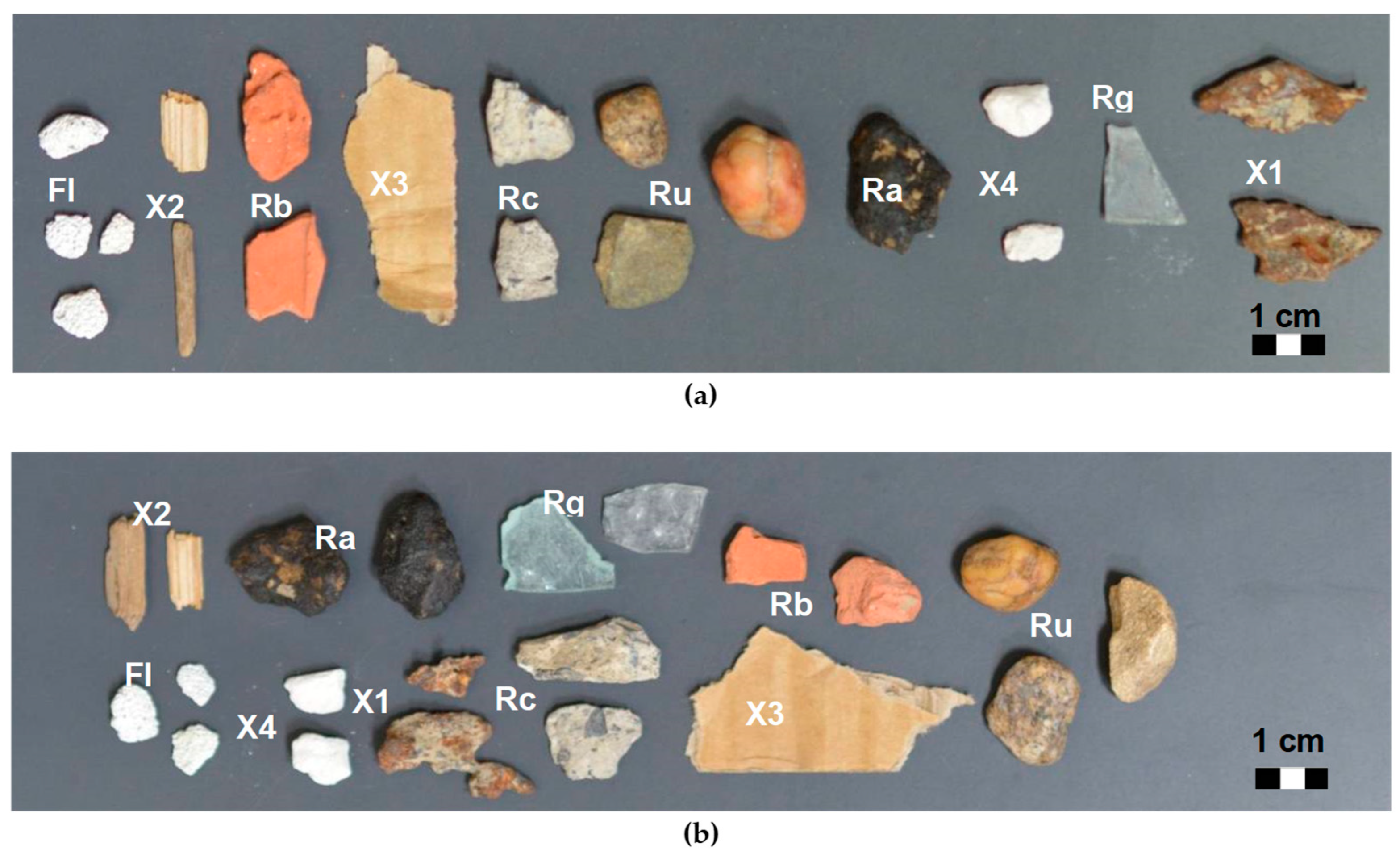

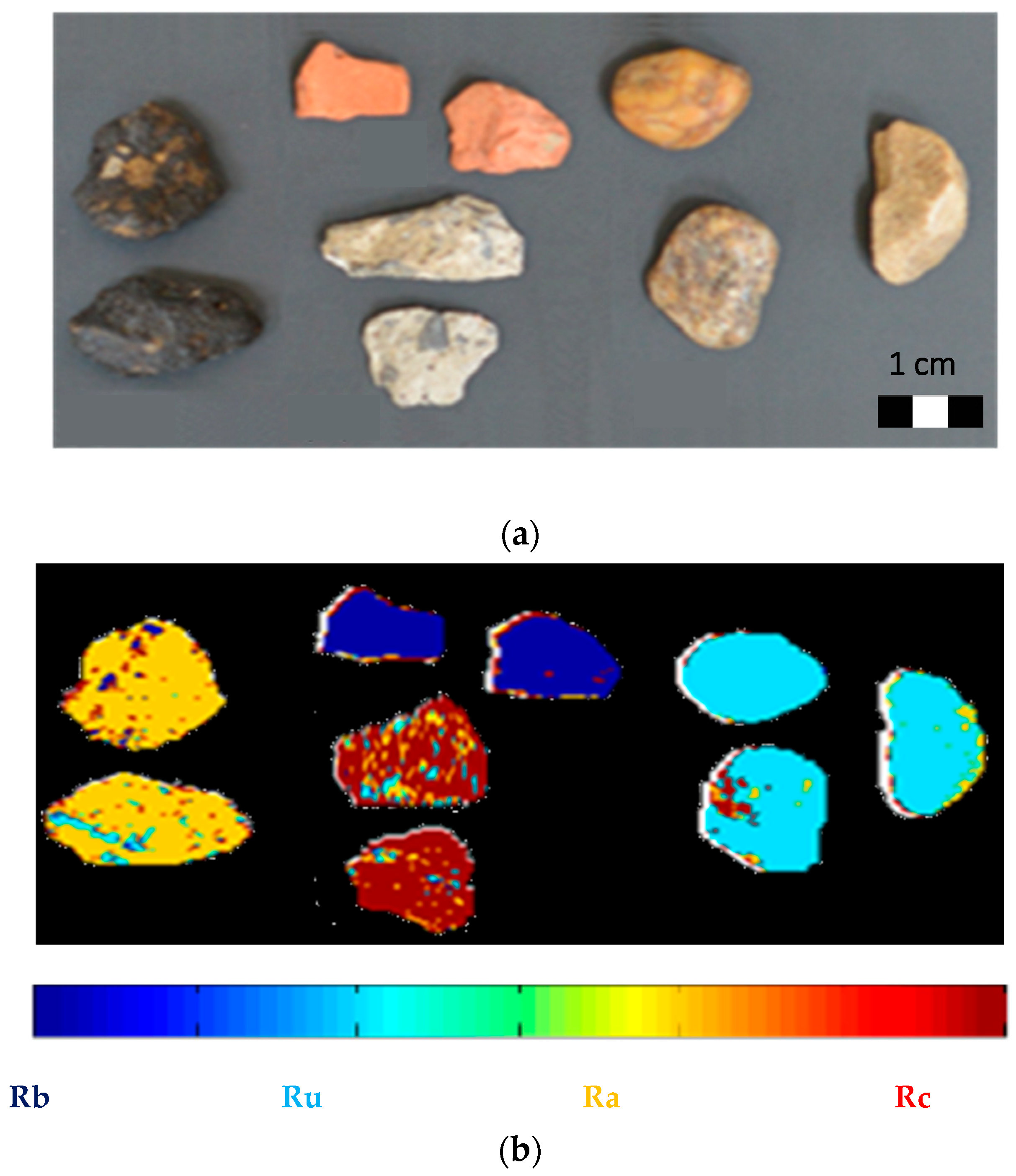

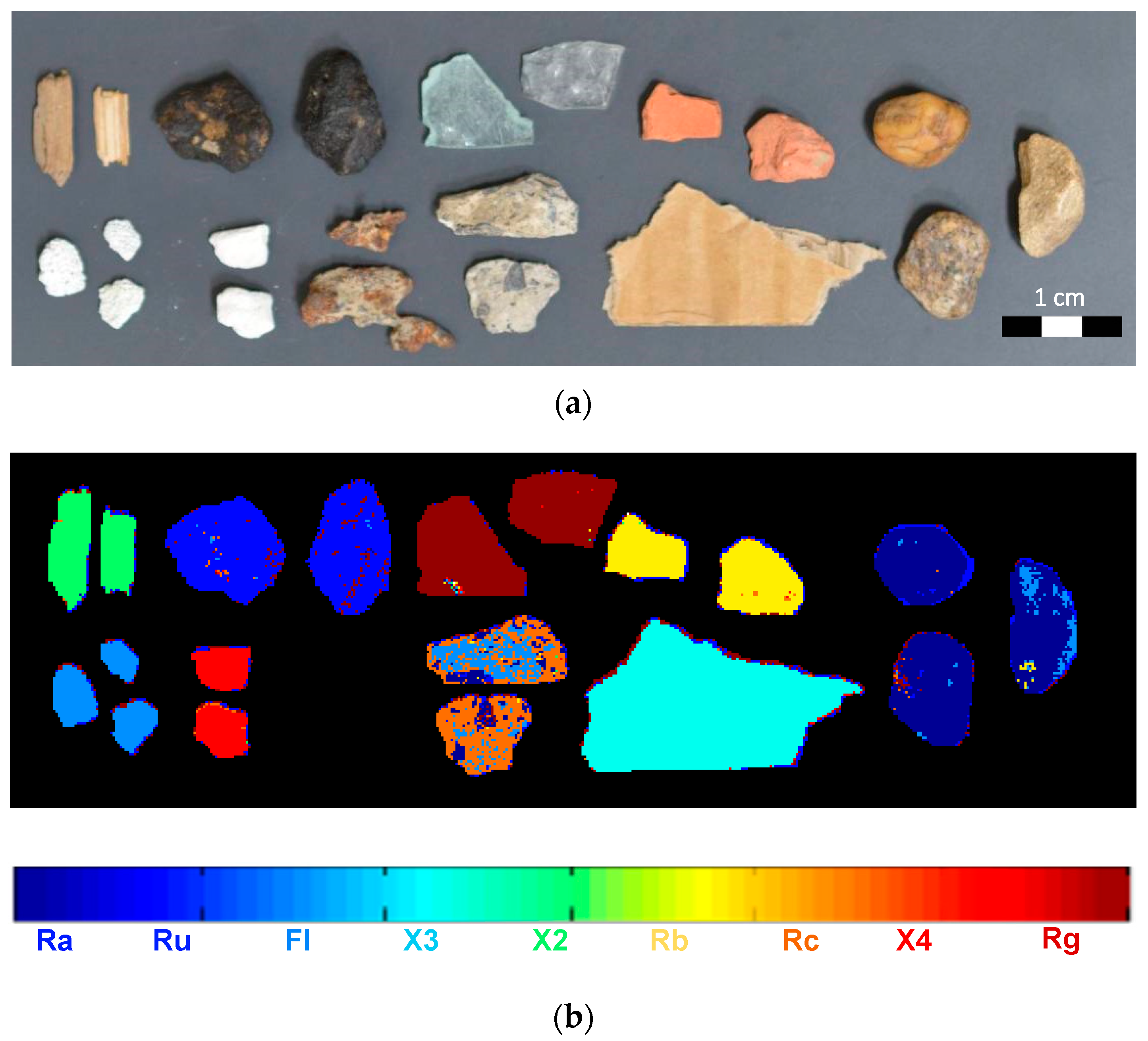

- 1st set-up. A training image to be utilized for the classification stage was generated (Figure 1a). More specifically, a set of 20 particles clearly identified as floating materials (4 particles), wood (2 particles), masonry (2 particles), paperboard (1 particle), concrete (2 particles), aggregates (3 particles), hydrocarbons (1 particle), parget (2 particles), glass (1 particle), and metals (2 particles) were used in order to build the classification model.

- 2nd set-up. A validation image, constituted by particles of the same materials but different from those utilized for training, was then created to perform the validation (Figure 1b).

2.2. Hyperspectral Imaging System

2.3. The Developed HSI Procedures

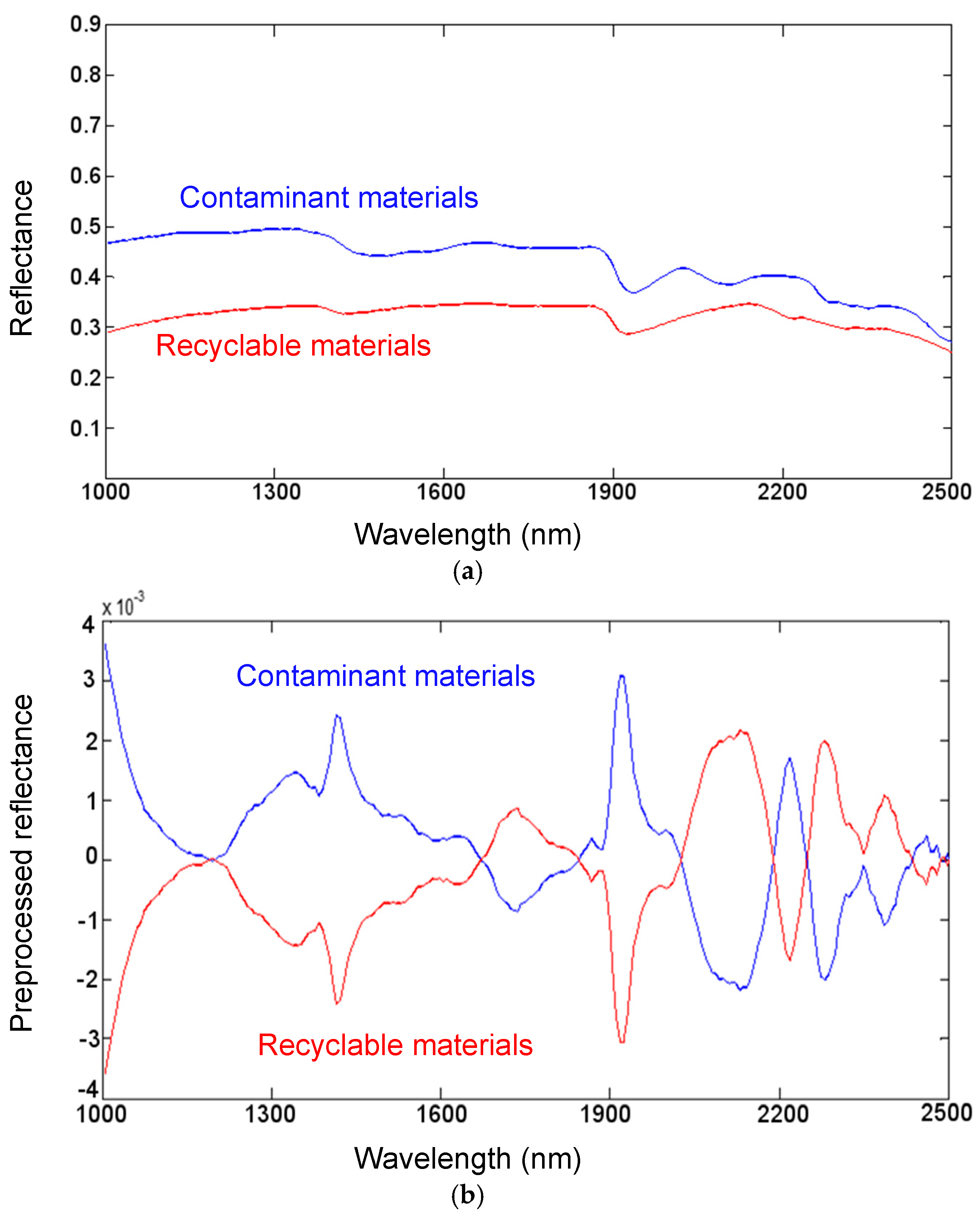

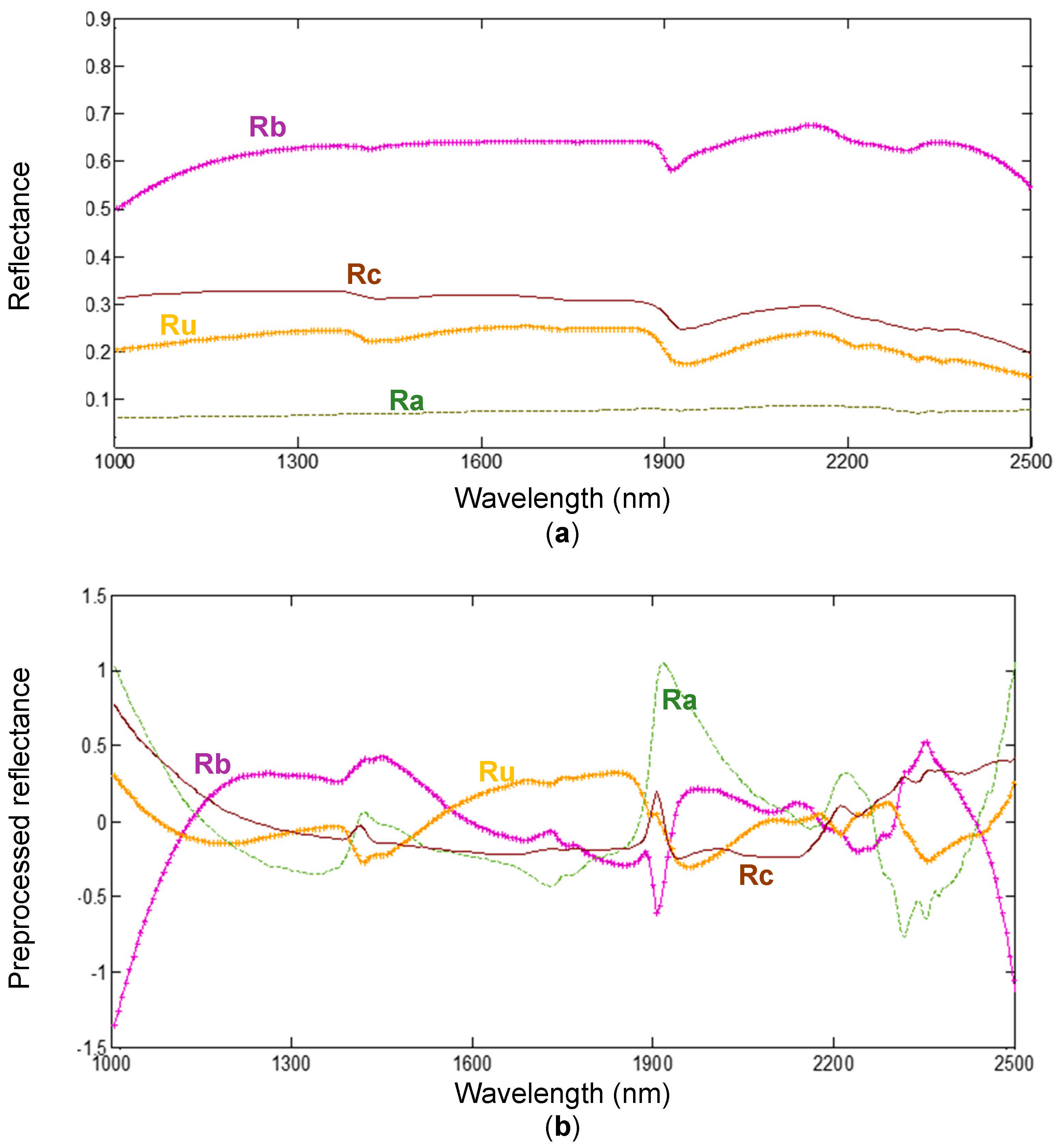

- Two-classes model. In the first strategy, a two-classes model was built to identify recyclable (Class 1: Rc, Ru, Rb, and Ra) and contaminant (Class 2: Fl, Rg, X1, X2, X3, and X4) materials. Two classification models were then developed to recognize the single materials of Class 1 (4-classes model) and of Class 2 (5-classes model), assuming that the X1 class was removed during a metal removal step (i.e., magnetic separation).

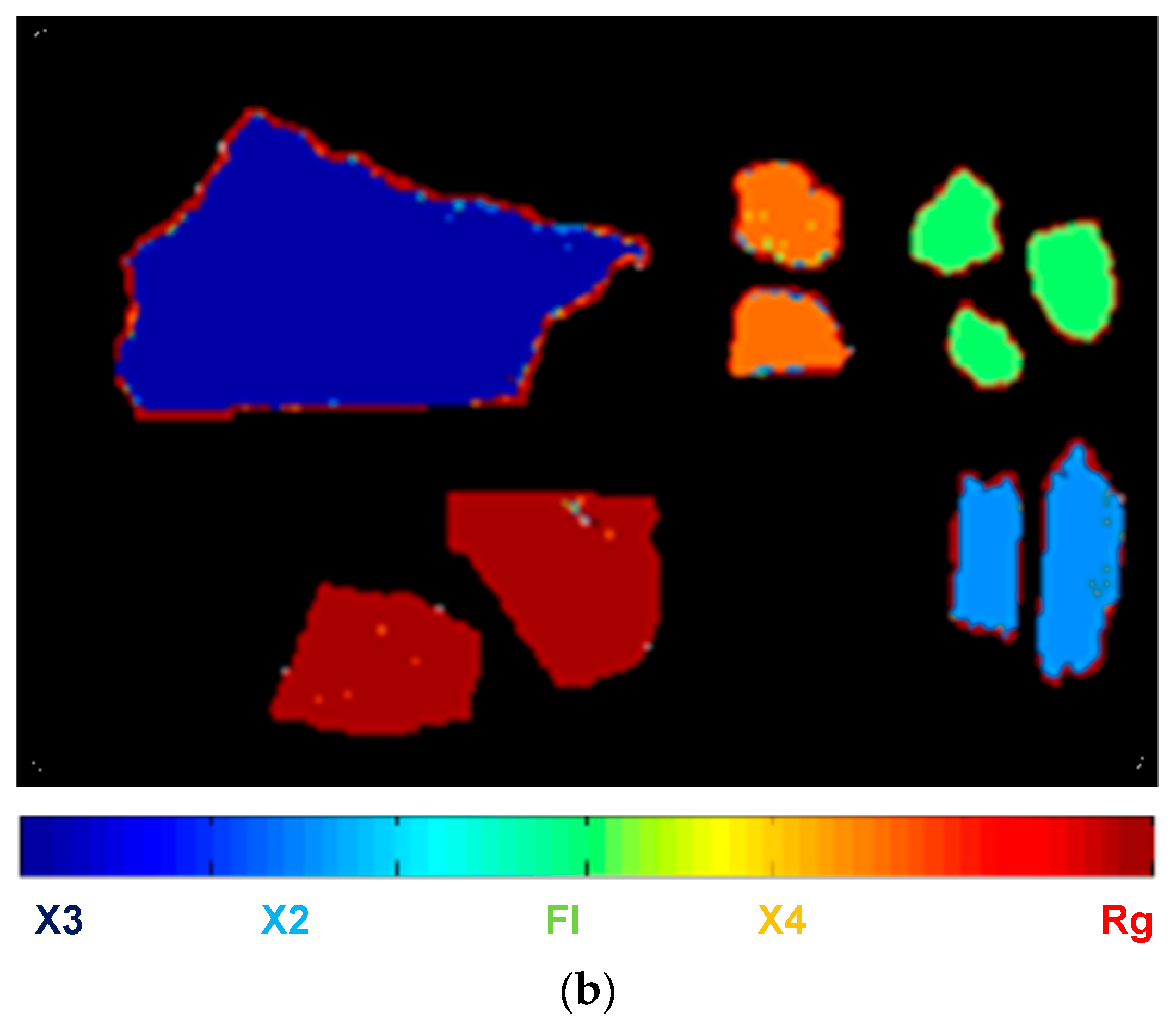

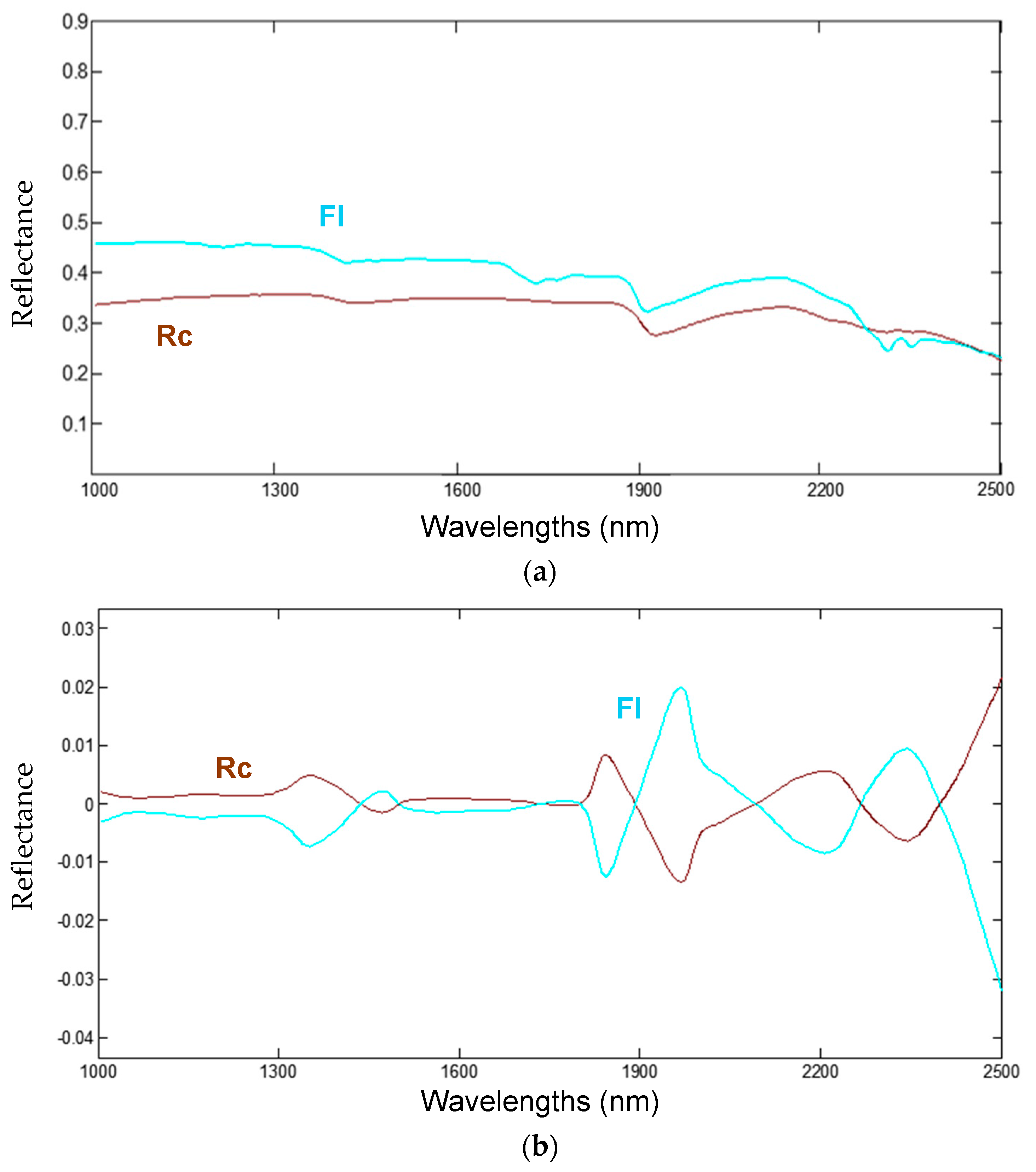

- Nine-classes model. In the second strategy, a metal removal step (i.e., magnetic separation of X1) was firstly assumed, and then the remaining 9 categories of materials (i.e., Rc, Ru, Rb, Ra, Fl, Rg, X2, X3, and X4) were classified individually by a single model. Since Rc (i.e., concrete) is sometimes misclassified with Fl (i.e., floating materials/autoclaved aerated concrete), a 2-classes model to discriminate only these two concrete categories was built.

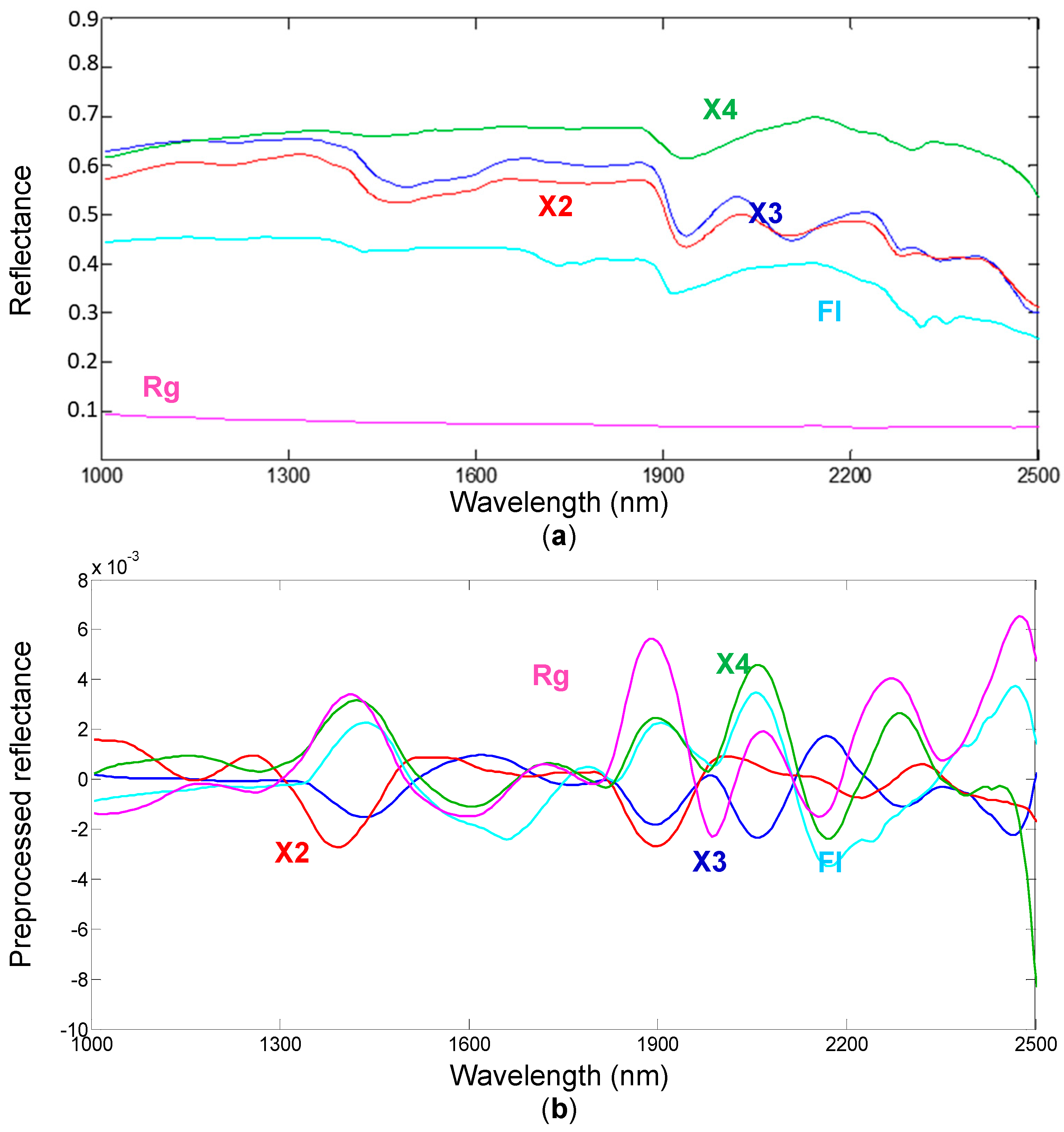

2.3.1. Spectra Preprocessing

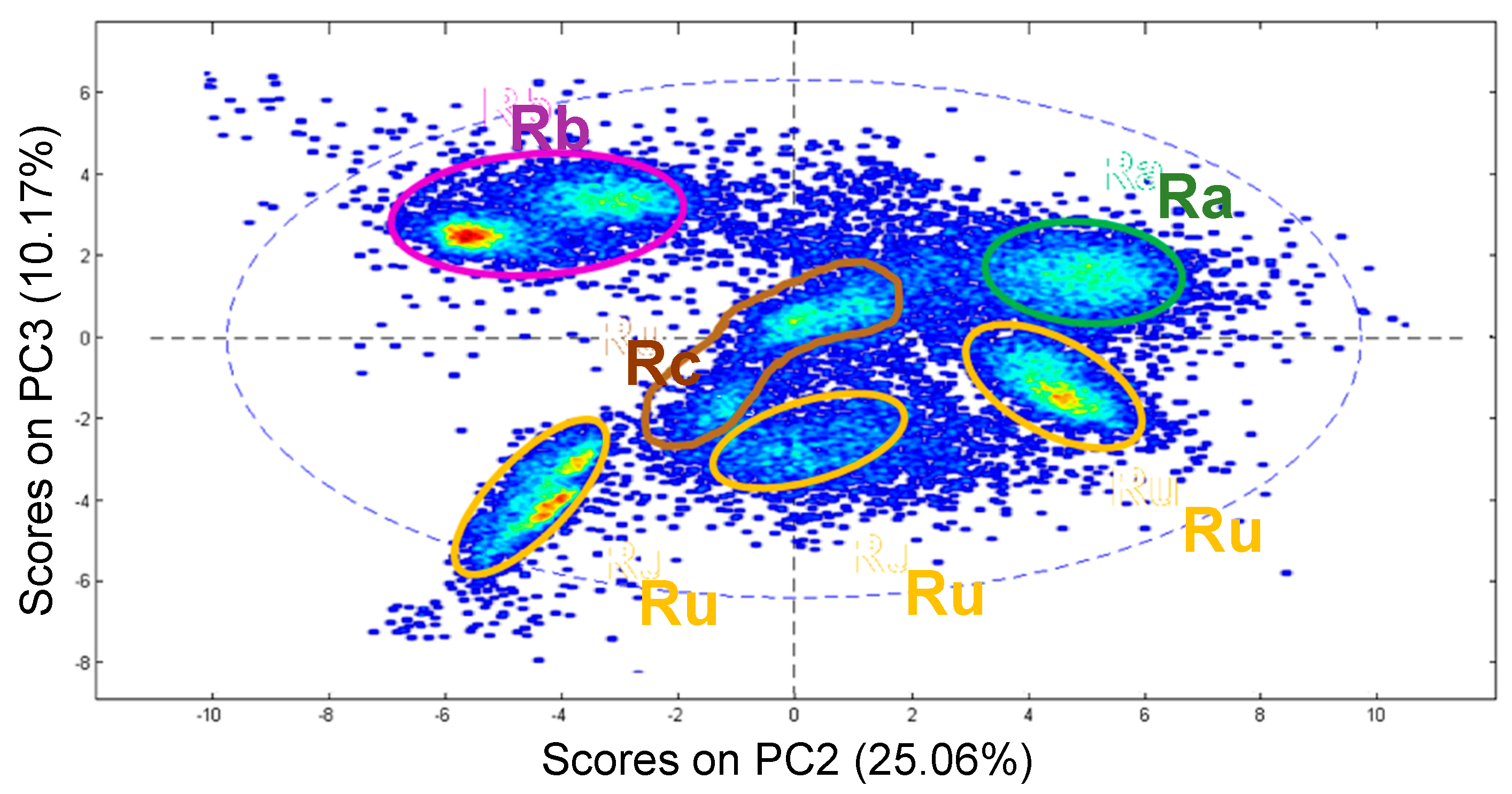

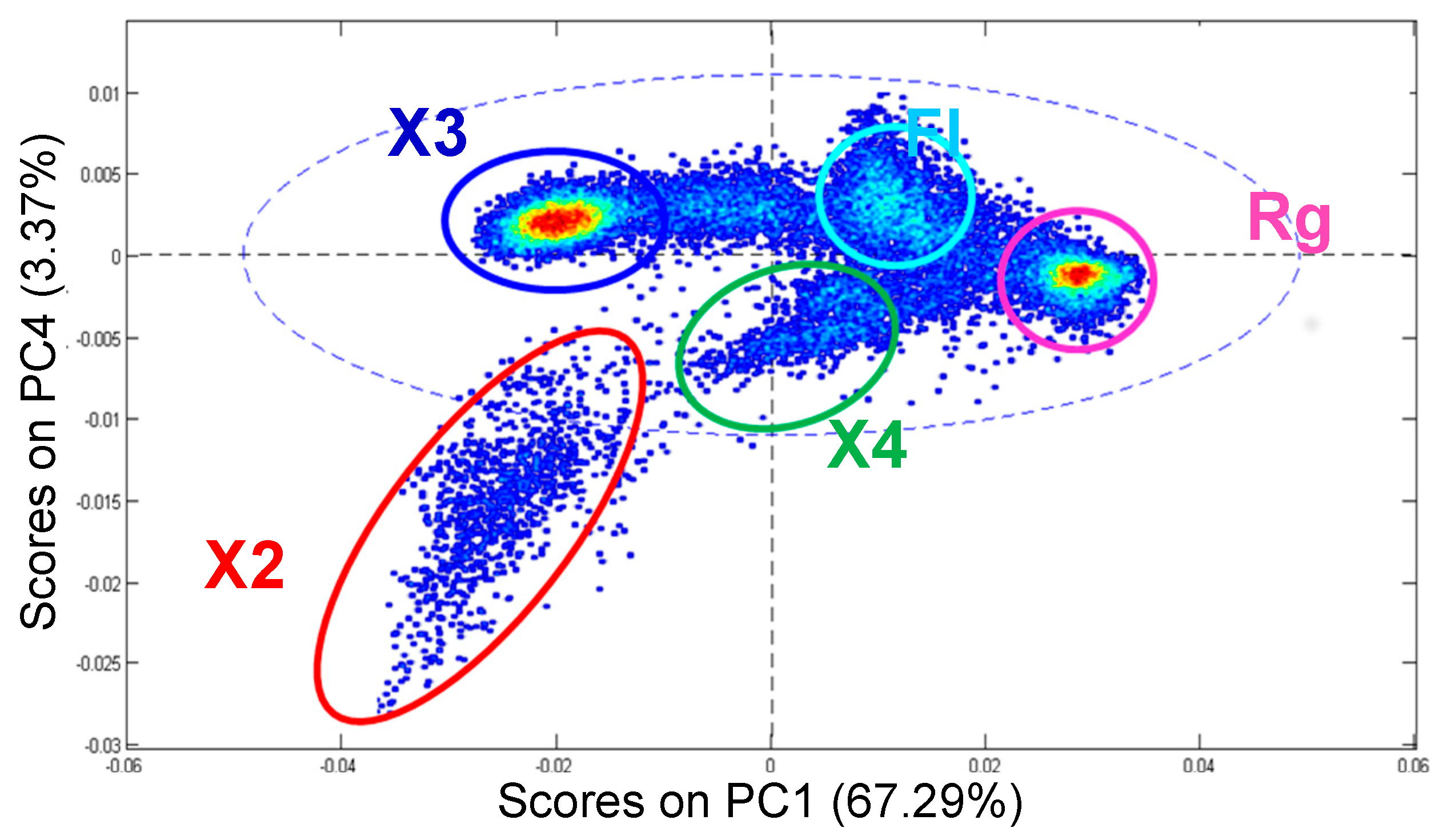

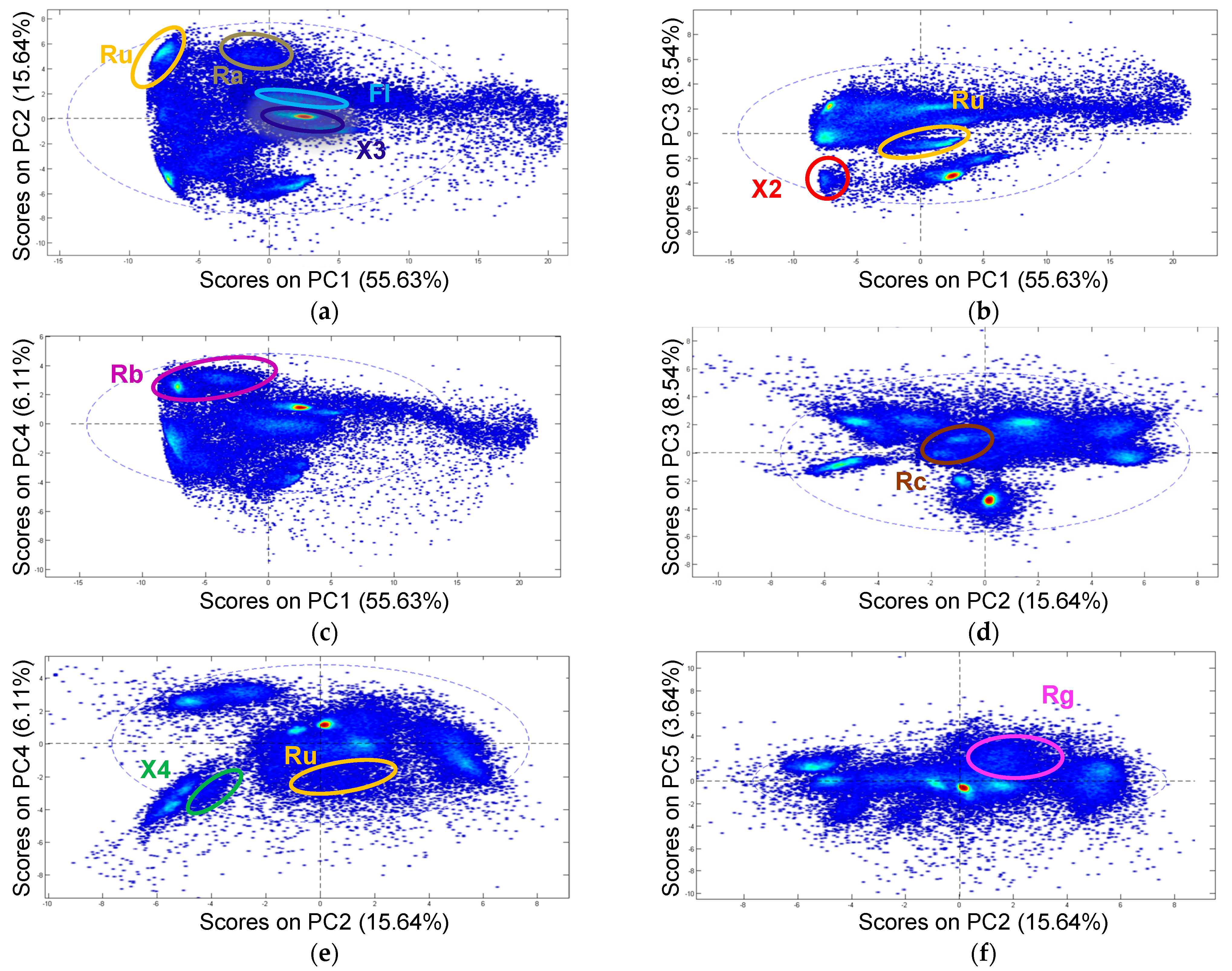

2.3.2. Principal Component Analysis (PCA)

2.3.3. Partial Least-Squares–Discriminant Analysis (PLS-DA)

3. Experimental Results

3.1. Recyclable and Contaminant Materials Recognition (First Classification Strategy)

3.1.1. Recyclable Materials Four-Classes Model

3.1.2. Contaminant Materials Five-Classes Model

3.2. Single Material Classes Recognition (Second Classification Strategy)

Concrete and Floating Materials Model

3.3. Results Comparison with Previous Benchmark Studies

4. Conclusions

- Samples were first classified as recyclable (Class 1: Rc, Ru, Rb, and Ra) and contaminant (Class 2: Fl, Rg, X1, X2, X3, and X4) materials. Then, in a cascade detection perspective, the Rc, Ru, Rb, and Ra categories were correctly identified in the recyclable set and Fl, Rg, X1, X2, X3, and X4 were recognized in the contaminant material group.

- All the samples (i.e., nine categories) were involved in the same classification model. Since some pixel misclassifications occur between concrete and floating materials, a two-classes model was built to recognize them.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eurostat. Waste Statistics in Europe. 2020. Available online: https://ec.europa.eu/eurostat/databrowser/view/cei_wm040/default/table?lang=en (accessed on 14 December 2022).

- Ossa, A.; García, J.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Wang, T.; Wang, J.; Wu, P.; Wang, J.; He, Q.; Wang, X. Estimating the environmental costs and benefits of demolition waste using life cycle assessment and willingness-to-pay: A case study in Shenzhen. J. Clean. Prod. 2018, 172, 14–26. [Google Scholar] [CrossRef]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in Building and Construction within the Framework of Circular Cities and European New Green Deal. The Contribution of Concrete Recycling. Sustainability 2021, 13, 2139. [Google Scholar]

- European Commission. The European Green Deal; European Council: Brussels, Belgium, 2019.

- Ulsen, C.; Kahn, H.; Hawlitschek, G.; Masini, E.A.; Angulo, S.C. Separability studies of construction and demolition waste recycled sand. Waste Manag. 2013, 33, 656–662. [Google Scholar] [CrossRef]

- BRE. Recycled Aggregates. In BRE Digest 433, CI/SfB P(T6); Building Research Establishment: Watford, UK, 1998; p. 6. [Google Scholar]

- Silva, R.; De Brito, J.; Dhir, R. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Silva, R. Use of Recycled Aggregates from Construction and Demolition Waste in the Production of Structural Concrete. Ph.D. Thesis, Instituto Superior Tecnico, Lisboa, Portugal, 2015. [Google Scholar]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Mrad, C.; Frölén Ribeiro, L. A Review of Europe’s Circular Economy in the Building Sector. Sustainability 2022, 14, 14211. [Google Scholar] [CrossRef]

- Joseph, H.S.; Pachiappan, T.; Avudaiappan, S.; Maureira-Carsalade, N.; Roco-Videla, Á.; Guindos, P.; Parra, P.F. A Comprehensive Review on Recycling of Construction Demolition Waste in Concrete. Sustainability 2023, 15, 4932. [Google Scholar] [CrossRef]

- Angulo, S.C.; Carrijo, P.M.; Figueiredo, A.D.; Chaves, A.P.; John, V.M. On the classification of mixed construction and demolition waste aggregate by porosity and its impact on the mechanical performance of concrete. Mater. Struct. 2010, 43, 519–528. [Google Scholar] [CrossRef]

- Pereira, P.M.; Vieira, C.S. A Literature Review on the Use of Recycled Construction and Demolition Materials in Unbound Pavement Applications. Sustainability 2022, 14, 13918. [Google Scholar] [CrossRef]

- Dosho, Y. Development of a sustainable concrete waste recycling system-Application of recycled aggregate concrete produced by aggregate replacing method. J. Adv. Concr. Technol. 2007, 5, 27–42. [Google Scholar] [CrossRef]

- Eguchi, K.; Teranishi, K.; Nakagome, A.; Kishimoto, H.; Shinozaki, K.; Narikawa, M. Application of recycled coarse aggregate by mixture to concrete construction. Constr. Build. Mater. 2007, 21, 1542–1551. [Google Scholar] [CrossRef]

- Lotfi, S.; Deja, J.; Rem, P.; Mróz, R.; van Roekel, E.; van der Stelt, H. Mechanical recycling of EOL concrete into high-grade aggregates. Resour. Conserv. Recycl. 2014, 87, 117–125. [Google Scholar] [CrossRef]

- Chini, A.R.; Bruening, S. Deconstruction and materials reuse in the United States. Future Sustain. Constr. 2003, 14, 1–22. [Google Scholar]

- Gebremariam, A.T.; Di Maio, F.; Vahidi, A.; Rem, P. Innovative technologies for recycling End-of-Life concrete waste in the built environment. Resour. Conserv. Recycl. 2020, 163, 104911. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Zaragoza-Benzal, A.; Zúñiga-Vicente, J.A. Towards a more sustainable environmentally production system for the treatment of recycled aggregates in the construction industry: An experimental study. Heliyon 2023, 9, e16641. [Google Scholar] [CrossRef]

- NBN EN 933-11:2009; Tests for Geometrical Properties of Aggregates—Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate. Comité Européen de Normalisation: Brussels, Belgium, 2009.

- Hyvarinen, T.S.; Herrala, E.; Dall’Ava, A. Direct sight imaging spectrograph: A unique add-in component brings spectral imaging to industrial applications. In Digital Solid State Cameras: Designs and Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 1998. [Google Scholar]

- Geladi, P.; Grahn, H.; Burger, J. Multivariate images, hyperspectral imaging: Background and equipment. In Techniques and Applications of Hyperspectral Image Analysis; Wiley: Hoboken, NJ, USA, 2007; pp. 1–15. [Google Scholar]

- Bonifazi, G.; Palmieri, R.; Serranti, S. Hyperspectral imaging applied to end-of-life (EOL) concrete recycling. Tm-Tech. Mess. 2015, 82, 616–624. [Google Scholar] [CrossRef]

- Xiao, W.; Yang, J.; Fang, H.; Zhuang, J.; Ku, Y.; Zhang, X. Development of an automatic sorting robot for construction and demolition waste. Clean Technol. Environ. Policy 2020, 22, 1829–1841. [Google Scholar] [CrossRef]

- Hollstein, F.; Cacho, Í.; Arnaiz, S.; Wohllebe, M. Challenges in automatic sorting of construction and demolition waste by hyperspectral imaging. In Advanced Environmental, Chemical, and Biological Sensing Technologies; SPIE: Baltimore, MD, USA, 2016; Volume 9862, pp. 73–82. [Google Scholar]

- Trotta, O.; Bonifazi, G.; Capobianco, G.; Serranti, S. Recycling-Oriented Characterization of Post-Earthquake Building Waste by Different Sensing Techniques. J. Imaging 2021, 7, 182. [Google Scholar] [CrossRef]

- Rinnan, Å.; Van Den Berg, F.; Engelsen, S.B. Review of the most common pre-processing techniques for near-infrared spectra. TrAC Trends Anal. Chem. 2009, 28, 1201–1222. [Google Scholar] [CrossRef]

- Tauler, R.; Peré-Trepat, E.; Lacorte, S.; Barceló, D. Chemometrics modelling of environmental data. In Proceedings of the 2nd International Congress on Environmental Modelling and Software, Osnabrück, Germany, 14–17 June 2004. [Google Scholar]

- Wise, B.M.; Gallagher, N.B.; Bro, R.; Shaver, J.M.; Windig, W.; Koch, R.S. Chemometrics Tutorial for PLS_Toolbox and Solo; Eigenvector Research, Inc.: Wenatchee, WA, USA, 2006; Volume 3905, pp. 102–159. [Google Scholar]

- Martens, H.; Høy, M.; Wise, B.M.; Bro, R.; Brockhoff, P.B. Pre-whitening of data by covariance-weighted pre-processing. J. Chemom. J. Chemom. Soc. 2003, 17, 153–165. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Gewali, U.B.; Monteiro, S.T.; Saber, E. Machine learning based hyperspectral image analysis: A survey. arXiv 2018, arXiv:1802.08701. [Google Scholar]

- Paoletti, M.E.; Haut, J.M.; Plaza, J.; Plaza, A. Deep learning classifiers for hyperspectral imaging: A review. ISPRS J. Photogramm. Remote Sens. 2019, 158, 279–317. [Google Scholar] [CrossRef]

- Manna, T.; Anitha, A. Deep Ensemble-Based Approach Using Randomized Low-Rank Approximation for Sustainable Groundwater Level Prediction. Appl. Sci. 2023, 13, 3210. [Google Scholar] [CrossRef]

- Anitha, A.; Shivakumara, P.; Jain, S.; Agarwal, V. Convolution Neural Network and Auto-encoder Hybrid Scheme for Automatic Colorization of Grayscale Images. In Smart Computer Vision; Springer: Berlin/Heidelberg, Germany, 2023; pp. 253–271. [Google Scholar]

- Barker, M.; Rayens, W. Partial least squares for discrimination. J. Chemom. J. Chemom. Soc. 2003, 17, 166–173. [Google Scholar] [CrossRef]

- Fawcett, T. An introduction to ROC analysis. Pattern Recognit. Lett. 2006, 27, 861–874. [Google Scholar] [CrossRef]

- Crowley, J.; Williams, D.; Hammarstrom, J.; Piatak, N.; Chou, I.-M.; Mars, J. Spectral reflectance properties (0.4–2.5 μm) of secondary Fe-oxide, Fe-hydroxide, and Fe-sulphate-hydrate minerals associated with sulphide-bearing mine wastes. Geochem. Explor. Environ. Anal. 2003, 3, 219–228. [Google Scholar] [CrossRef]

- Schwanninger, M.; Rodrigues, J.C.; Fackler, K. A review of band assignments in near infrared spectra of wood and wood components. J. Near Infrared Spectrosc. 2011, 19, 287–308. [Google Scholar] [CrossRef]

- Bonifazi, G.; Palmieri, R.; Serranti, S. Evaluation of attached mortar on recycled concrete aggregates by hyperspectral imaging. Constr. Build. Mater. 2018, 169, 835–842. [Google Scholar] [CrossRef]

- Bonifazi, G.; Capobianco, G.; Palmieri, R.; Serranti, S.S. Hyperspectral imaging applied to the waste recycling sector. Spectrosc. Eur. 2019, 31, 8–11. [Google Scholar] [CrossRef]

| Identification Code | Condition | Description | |

|---|---|---|---|

| Recyclables | Rc | Non-floating | Concrete and mortar |

| Ru | Non-floating | Natural stones and aggregates | |

| Rb | Non-floating | Masonry (i.e., bricks, tiles, ceramics, etc.) | |

| Ra | Non-floating | Hydrocarbons | |

| Contaminants | Rg | Non-floating | Glass |

| X1 | Non-floating | Metals (ferrous and non-ferrous) | |

| X2 | Non-floating | Non-floating wood | |

| X3 | Non-floating | Cardboard | |

| X4 | Non-floating | Parget, gypsum plaster | |

| Fl | Floating | Autoclaved aerated concrete |

| Contaminant Materials | Recyclable Materials | ||

|---|---|---|---|

| Sensitivity | Calibration | 0.964 | 0.974 |

| Cross-validation | 0.942 | 0.962 | |

| Specificity | Calibration | 0.974 | 0.964 |

| Cross-validation | 0.962 | 0.942 |

| Rc | Ru | Rb | Ra | ||

|---|---|---|---|---|---|

| Sensitivity | Calibration | 0.974 | 0.982 | 1.000 | 1.000 |

| Cross-validation | 0.973 | 0.981 | 1.000 | 1.000 | |

| Specificity | Calibration | 0.986 | 0.994 | 1.000 | 0.981 |

| Cross-validation | 0.985 | 0.995 | 1.000 | 0.981 |

| Fl | Rg | X2 | X3 | X4 | ||

|---|---|---|---|---|---|---|

| Sensitivity | Calibration | 1.000 | 1.000 | 0.999 | 1.000 | 1.000 |

| Cross-validation | 1.000 | 1.000 | 0.999 | 1.000 | 1.000 | |

| Specificity | Calibration | 1.000 | 1.000 | 0.993 | 1.000 | 0.997 |

| Cross-validation | 1.000 | 1.000 | 0.992 | 1.000 | 0.997 |

| Rc | Ru | Rb | Ra | Fl | Rg | X2 | X3 | X4 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Sensitivity | Calibration | 0.983 | 0.997 | 0.994 | 1.000 | 0.986 | 0.998 | 0.999 | 0.975 | 0.995 |

| Cross-validation | 0.983 | 0.997 | 0.992 | 1.000 | 0.986 | 0.998 | 0.999 | 0.975 | 0.995 | |

| Specificity | Calibration | 0.997 | 0.988 | 0.996 | 1.000 | 0.995 | 0.999 | 0.989 | 0.975 | 0.994 |

| Cross-validation | 0.997 | 0.988 | 0.996 | 1.000 | 0.995 | 0.999 | 0.989 | 0.975 | 0.994 |

| Rc | Fl | ||

|---|---|---|---|

| Sensitivity | Calibration | 0.999 | 0.997 |

| Cross-validation | 0.999 | 0.997 | |

| Specificity | Calibration | 0.997 | 0.999 |

| Cross-validation | 0.997 | 0.999 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serranti, S.; Palmieri, R.; Bonifazi, G.; Gasbarrone, R.; Hermant, G.; Bréquel, H. An Automated Classification of Recycled Aggregates for the Evaluation of Product Standard Compliance. Sustainability 2023, 15, 15009. https://doi.org/10.3390/su152015009

Serranti S, Palmieri R, Bonifazi G, Gasbarrone R, Hermant G, Bréquel H. An Automated Classification of Recycled Aggregates for the Evaluation of Product Standard Compliance. Sustainability. 2023; 15(20):15009. https://doi.org/10.3390/su152015009

Chicago/Turabian StyleSerranti, Silvia, Roberta Palmieri, Giuseppe Bonifazi, Riccardo Gasbarrone, Gauthier Hermant, and Herve Bréquel. 2023. "An Automated Classification of Recycled Aggregates for the Evaluation of Product Standard Compliance" Sustainability 15, no. 20: 15009. https://doi.org/10.3390/su152015009

APA StyleSerranti, S., Palmieri, R., Bonifazi, G., Gasbarrone, R., Hermant, G., & Bréquel, H. (2023). An Automated Classification of Recycled Aggregates for the Evaluation of Product Standard Compliance. Sustainability, 15(20), 15009. https://doi.org/10.3390/su152015009