Hyperspectral Imaging Applied to WEEE Plastic Recycling: A Methodological Approach

Abstract

1. Introduction

2. Hyperspectral Imaging

2.1. Hyperspectral Imaging System and Data Handling

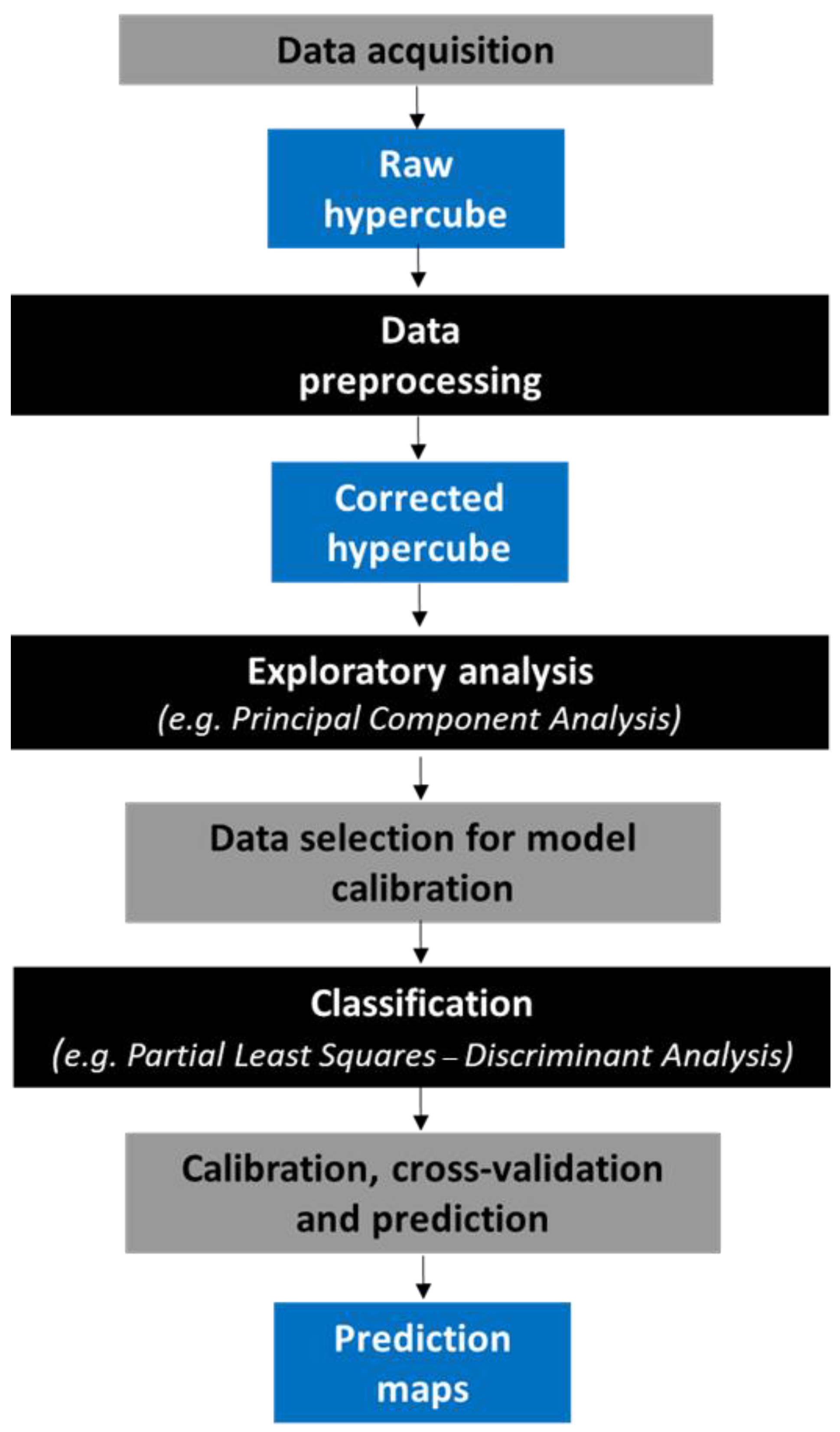

2.2. Hyperspectral Images Analysis Procedure

3. Case Studies

3.1. Plastic Flake Identification in Mixed Waste from EOL Monitors and Flat Screens

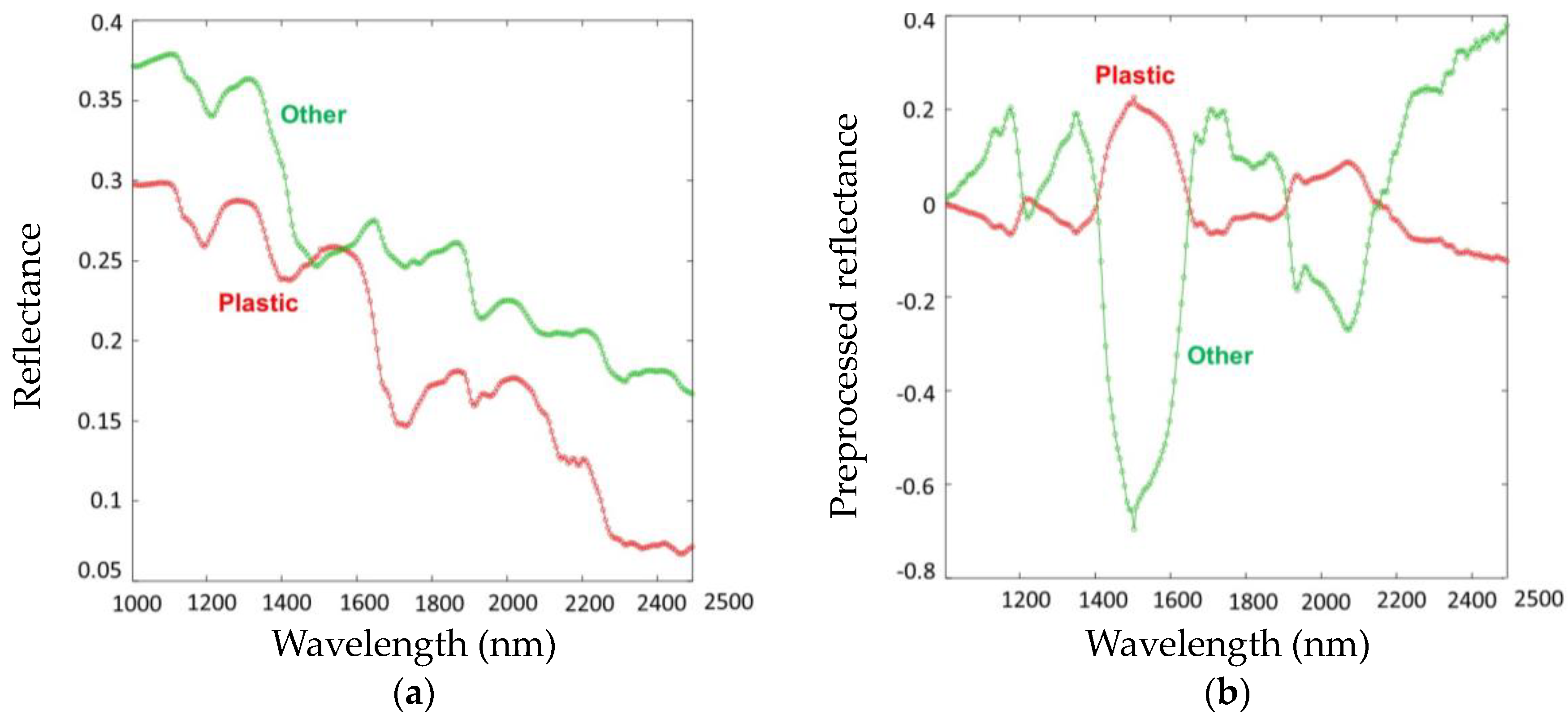

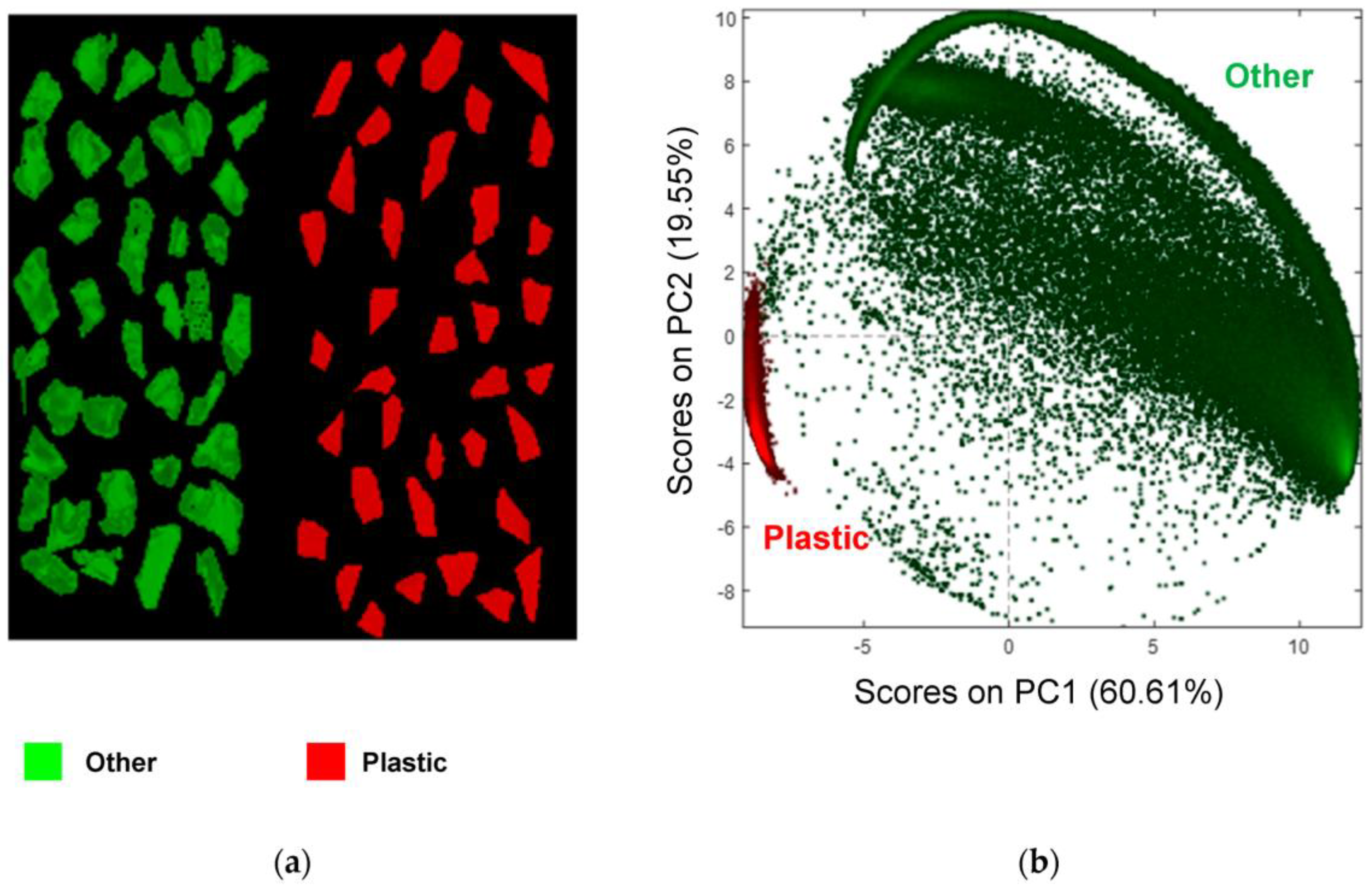

3.1.1. Analyzed Samples and Procedure Set-Up

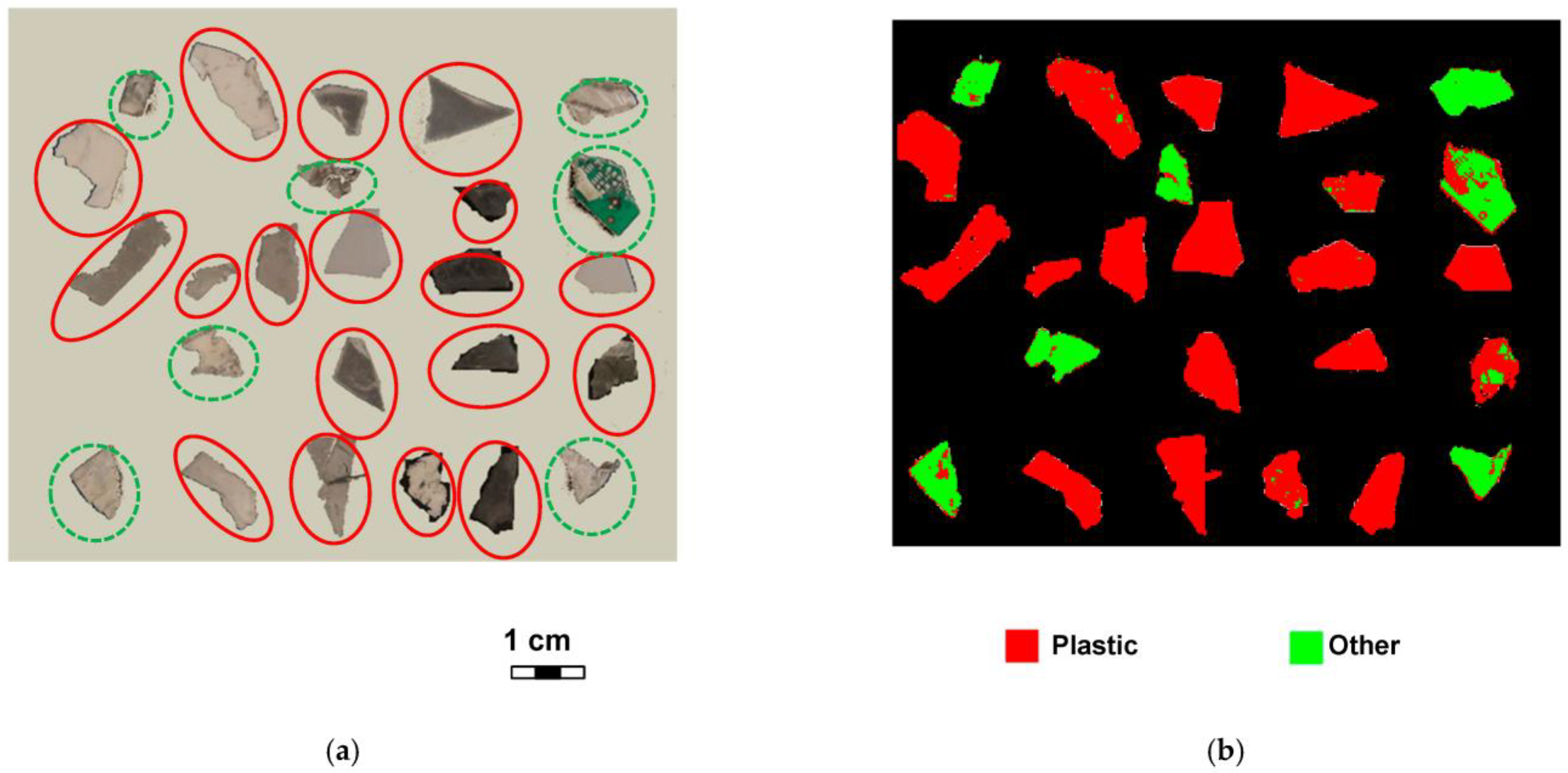

3.1.2. Results of Plastic Flake Identification

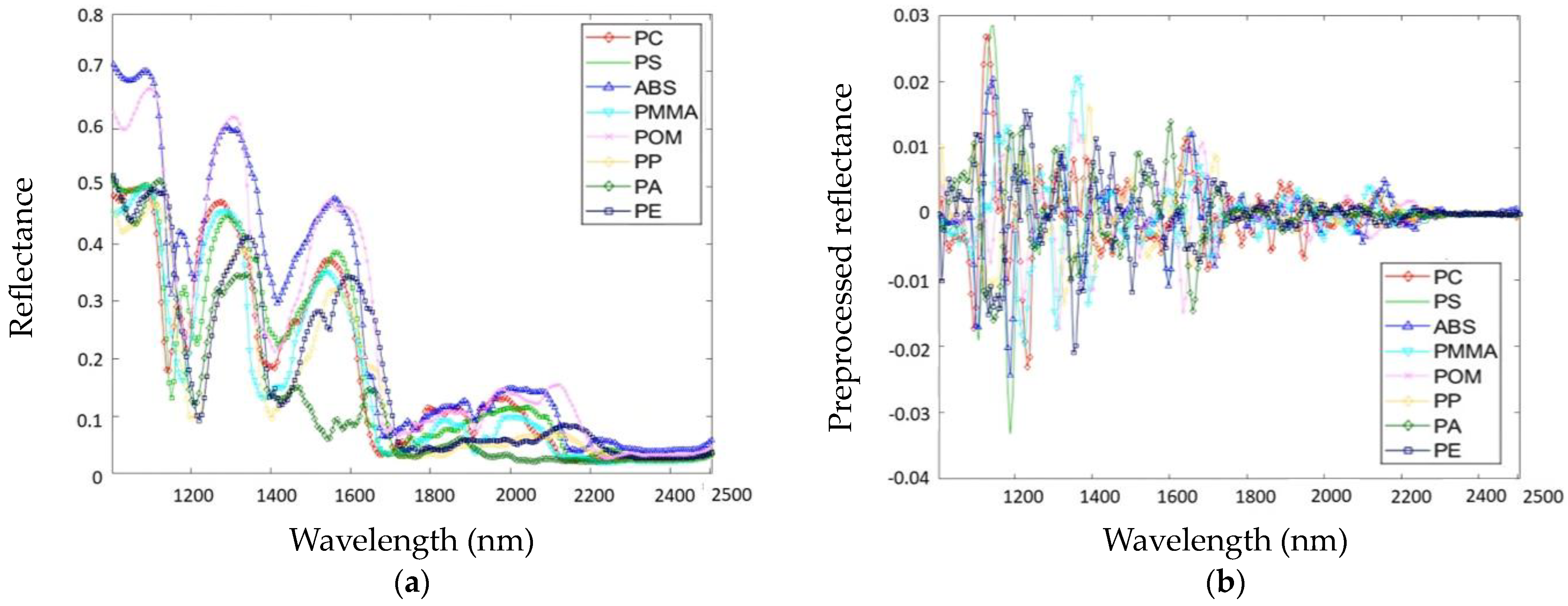

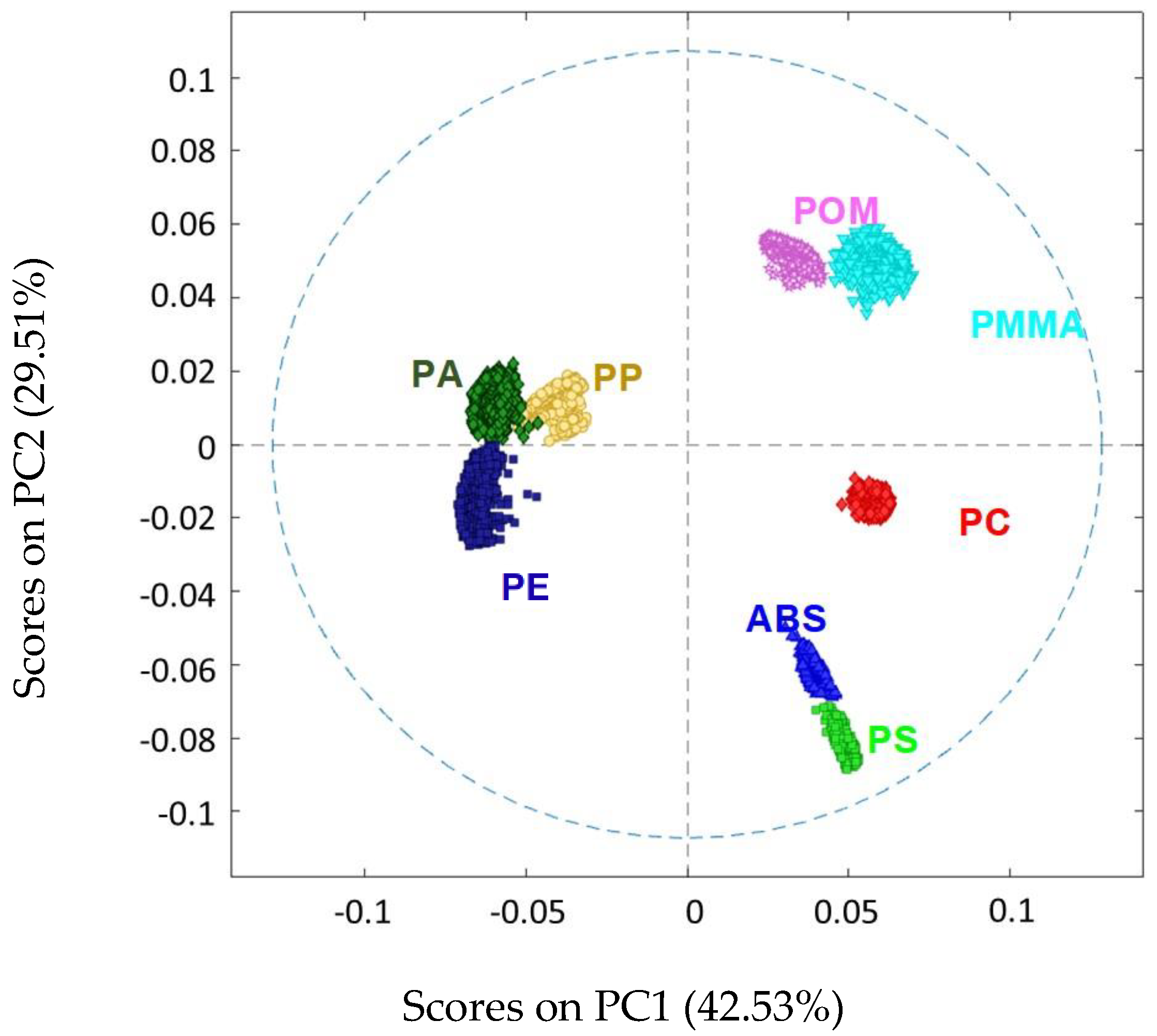

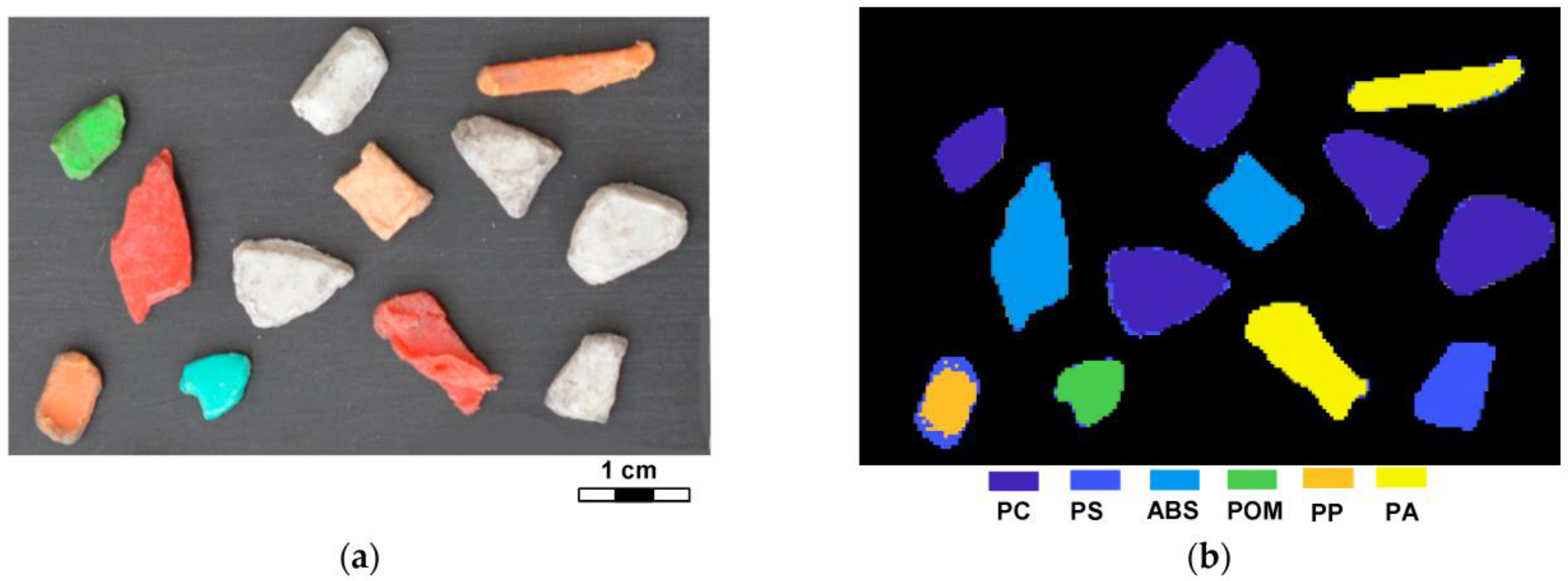

3.2. Polymer Identification Inside a Mixed Plastic Waste Stream Coming from EOL Electronic Devices

3.2.1. Analyzed Samples and Procedure Set-Up

3.2.2. Results of Polymer Identification

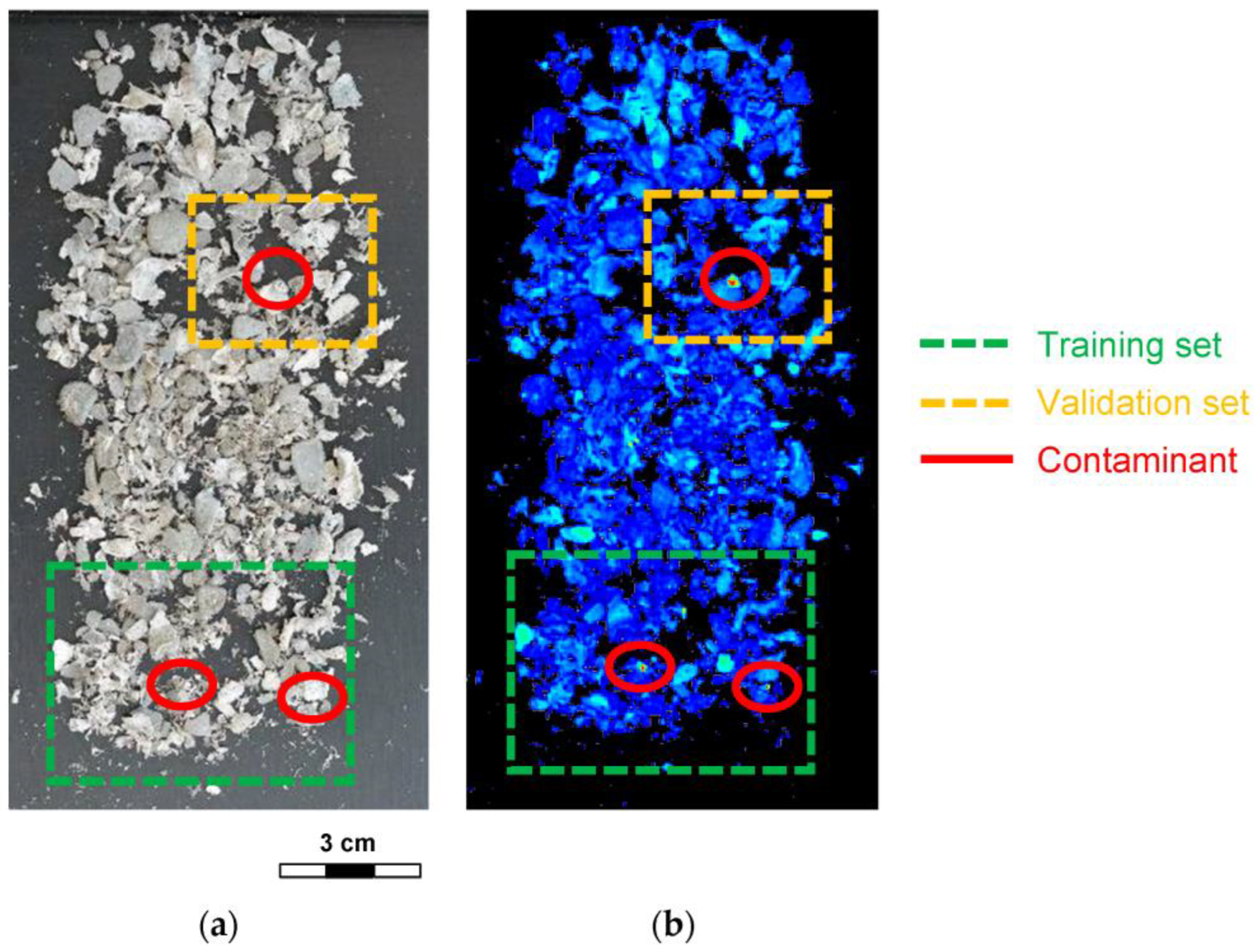

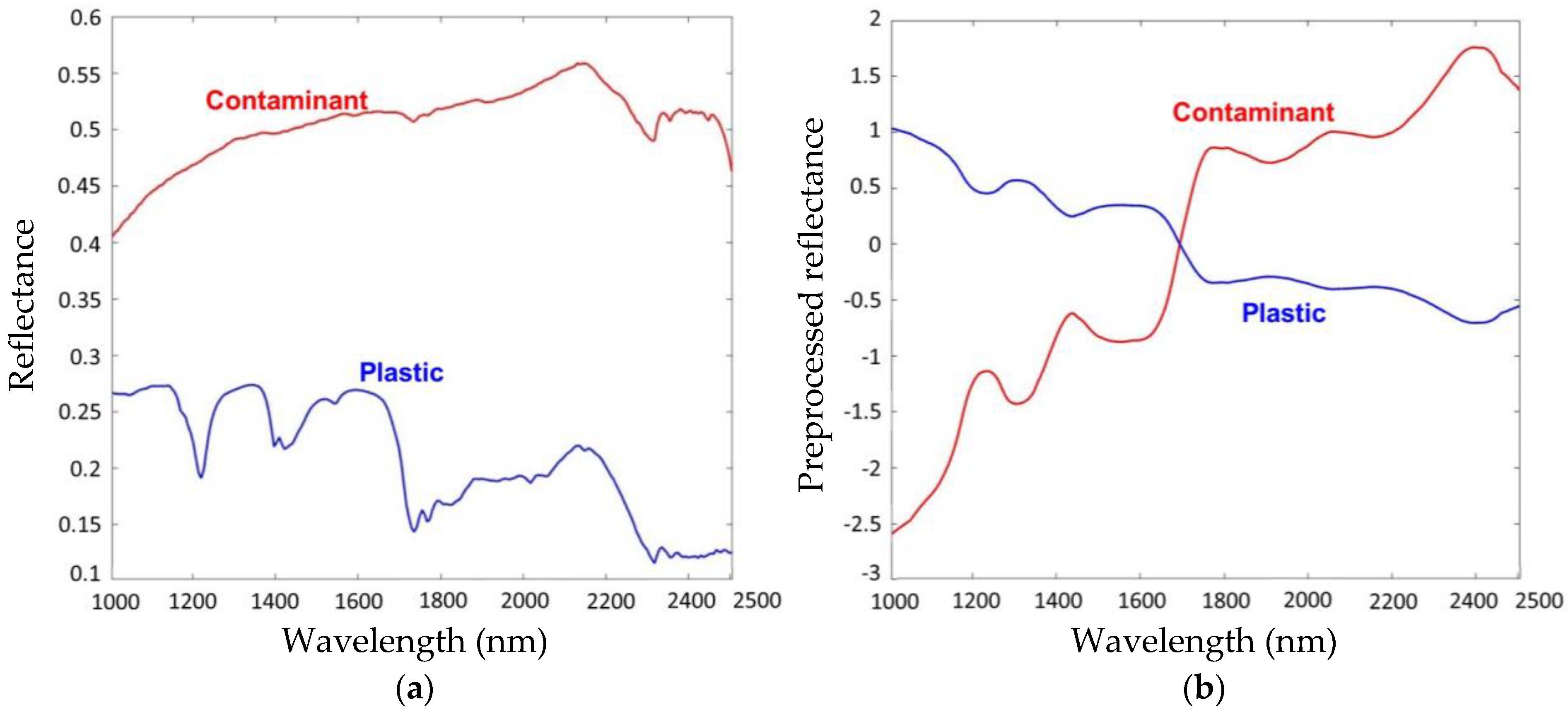

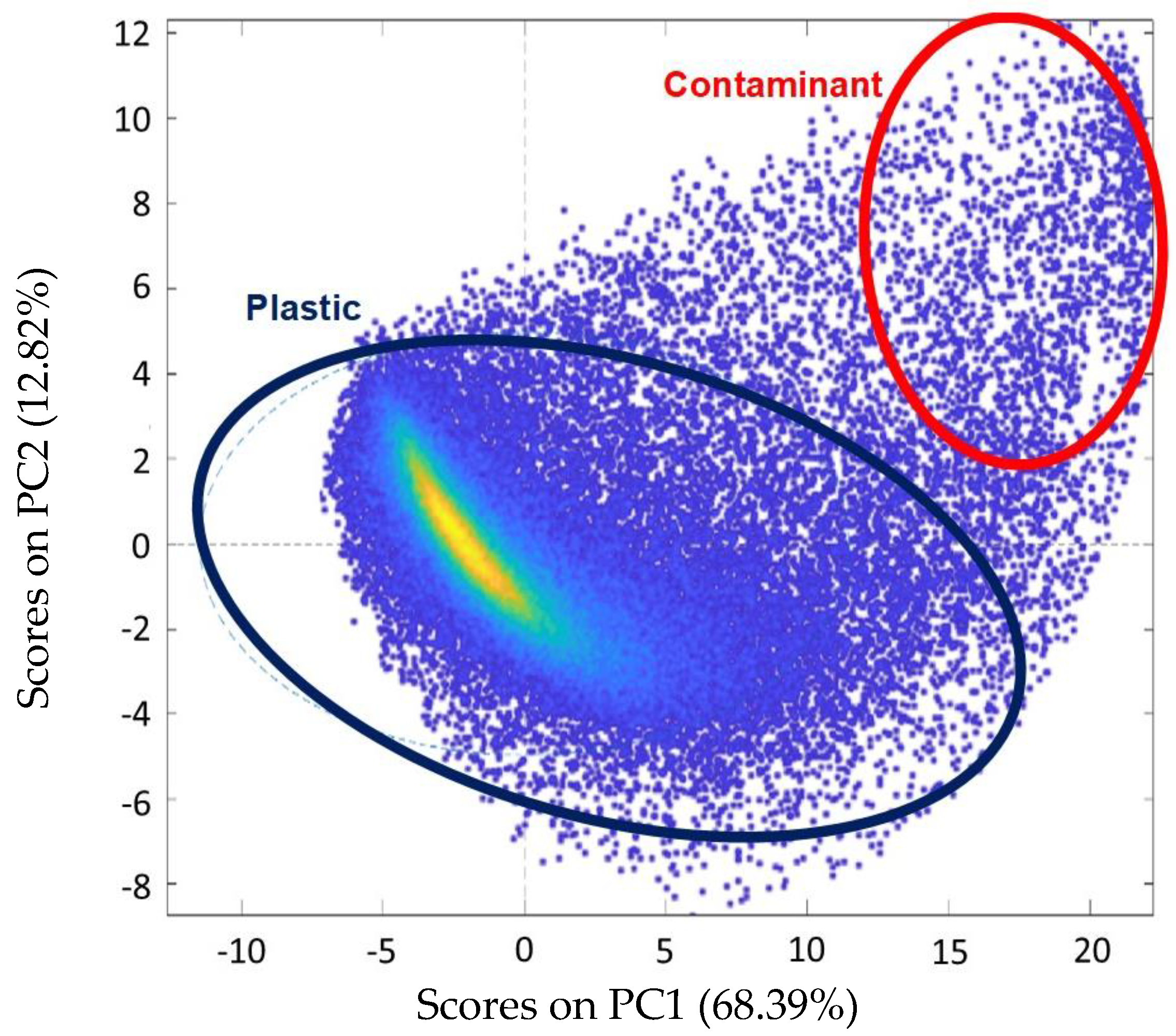

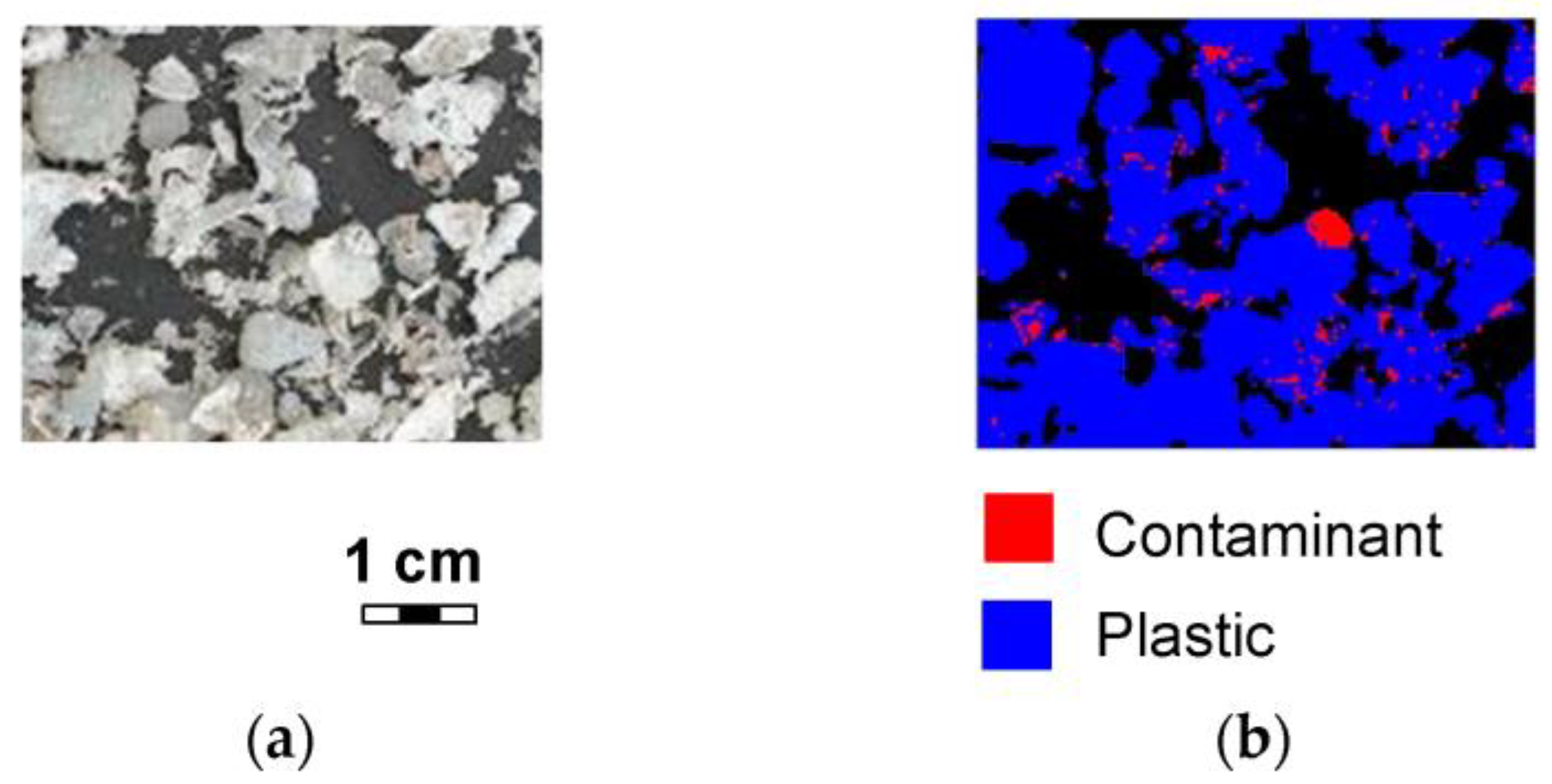

3.3. Contaminant Identification in a Mixed Plastic Waste Stream from the Recycling Line of Electrical Cables

3.3.1. Analyzed Samples and Procedure Set-Up

3.3.2. Results of Contaminant Identification

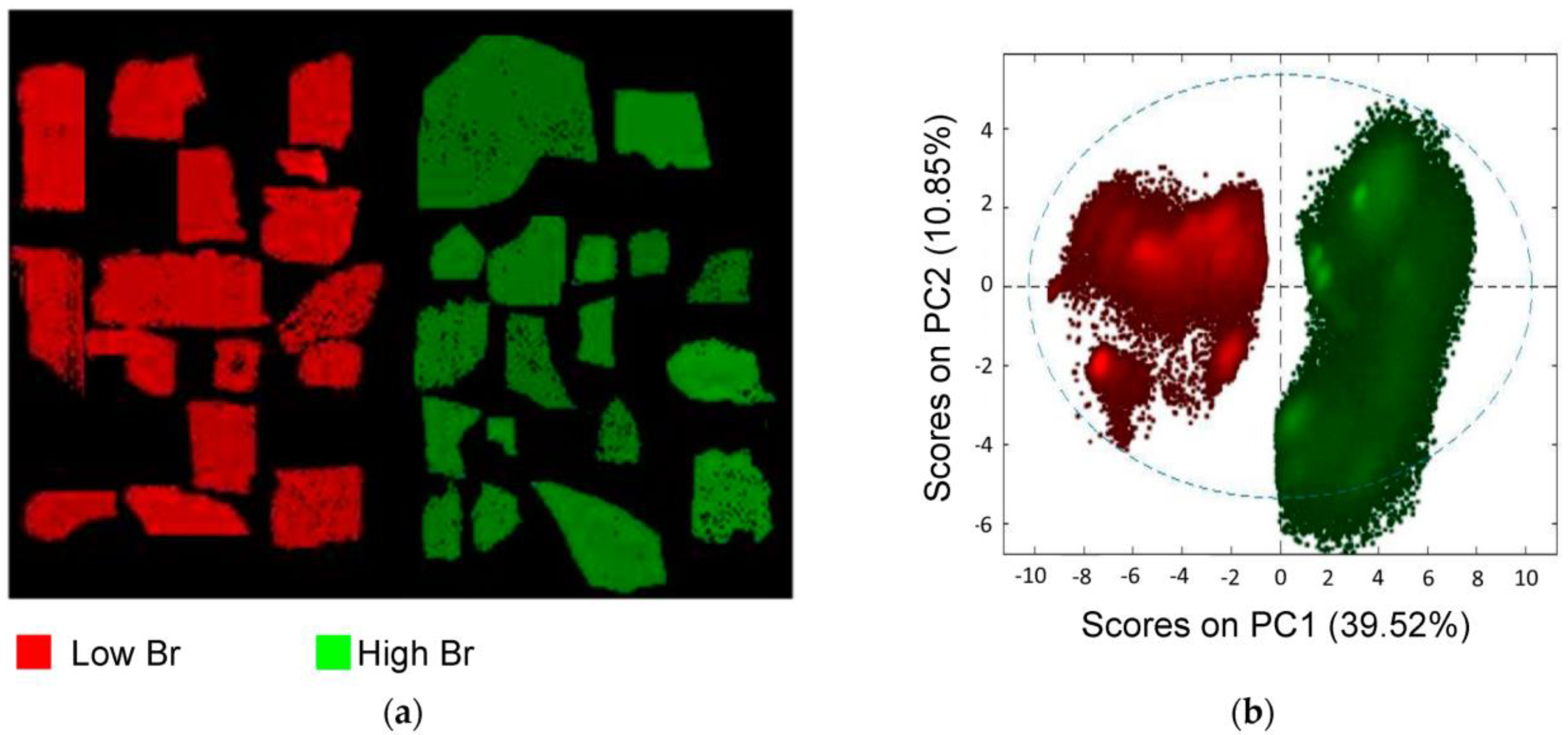

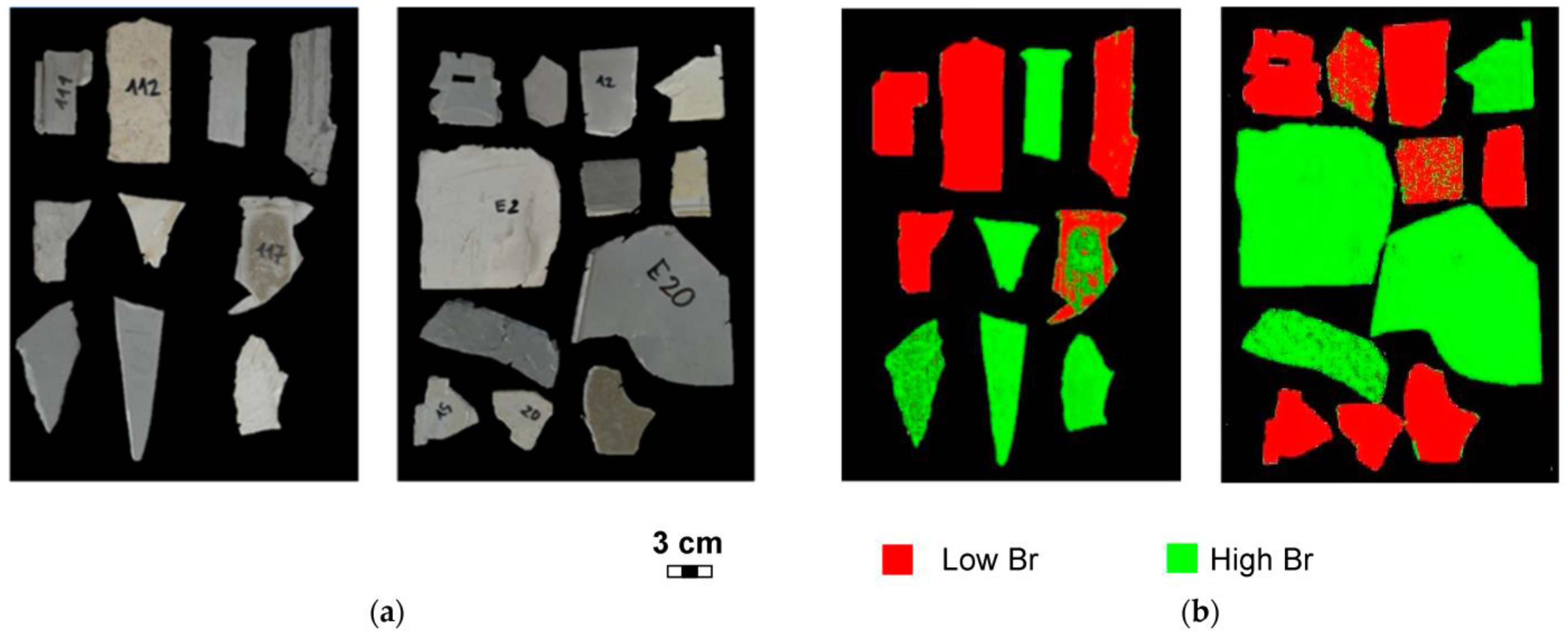

3.4. Identification of WEEE Plastics with Brominated Flame Retardants

3.4.1. Analyzed Samples and Procedure Set-Up

3.4.2. Results of Plastic with Brominated Flame Retardants Identification

4. Conclusions and Future Perspectives

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential. 2020. Available online: https://ewastemonitor.info/wp-content/uploads/2020/11/GEM_2020_def_july1_low.pdf (accessed on 19 July 2023).

- Buekens, A.; Yang, J. Recycling of WEEE plastics: A review. J. Mater. Cycles Waste Manag. 2014, 16, 415–434. [Google Scholar] [CrossRef]

- Robinson, B.H. E-waste: An assessment of global production and environmental impacts. Sci. Total Environ. 2009, 408, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-de-los-Mozos, E.; Rentería-Bilbao, A.; Díaz-Martín, F. WEEE recycling and circular economy assisted by collaborative robots. Appl. Sci. 2020, 10, 4800. [Google Scholar] [CrossRef]

- Maisel, F.; Chancerel, P.; Dimitrova, G.; Emmerich, J.; Nissen, N.F.; Schneider-Ramelow, M. Preparing WEEE plastics for recycling–How optimal particle sizes in pre-processing can improve the separation efficiency of high quality plastics. Resour. Conserv. Recycl. 2020, 154, 104619. [Google Scholar] [CrossRef]

- Chaine, C.; Hursthouse, A.S.; McLean, B.; McLellan, I.; McMahon, B.; McNulty, J.; Miller, J.; Viza, E. Recycling Plastics from WEEE: A Review of the Environmental and Human Health Challenges Associated with Brominated Flame Retardants. Int. J. Environ. Res. Public Health 2022, 19, 766. [Google Scholar] [CrossRef]

- Makenji, K.; Savage, M. 10—Mechanical methods of recycling plastics from WEEE. In Waste Electrical and Electronic Equipment (WEEE) Handbook; Goodship, V., Stevels, A., Eds.; Woodhead Publishing: Soston, UK, 2012; pp. 212–238. [Google Scholar] [CrossRef]

- Plastics Europe Plastics—The Facts 2022. 2022. Available online: https://plasticseurope.org/wp-content/uploads/2022/10/PE-PLASTICS-THE-FACTS_V7-Tue_19-10-1.pdf (accessed on 19 July 2023).

- Calvini, R.; Ulrici, A.; Amigo, J.M. Growing applications of hyperspectral and multispectral imaging. Data Handl. Sci. Technol. 2020, 32, 605–629. [Google Scholar]

- Bonifazi, G.; Palmieri, R.; Serranti, S. Short wave infrared hyperspectral imaging for recovered post-consumer single and mixed polymers characterization. In Image Sensors and Imaging Systems 2015; International Society for Optics and Photonics: Bellingham, WA, USA, 2015. [Google Scholar]

- Neo, E.R.K.; Yeo, Z.; Low, J.S.C.; Goodship, V.; Debattista, K. A review on chemometric techniques with infrared, Raman and laser-induced breakdown spectroscopy for sorting plastic waste in the recycling industry. Resour. Conserv. Recycl. 2022, 180, 106217. [Google Scholar] [CrossRef]

- Zheng, Y.; Bai, J.; Xu, J.; Li, X.; Zhang, Y. A discrimination model in waste plastics sorting using NIR hyperspectral imaging system. Waste Manag. 2018, 72, 87–98. [Google Scholar] [CrossRef]

- Bonifazi, G.; Palmieri, R.; Serranti, S. Concrete drill core characterization finalized to optimal dismantling and aggregates recovery. Waste Manag. 2017, 60, 301–310. [Google Scholar] [CrossRef]

- Bonifazi, G.; Palmieri, R.; Serranti, S. Hyperspectral imaging applied to end-of-life (EOL) concrete recycling. tm-Tech. Mess. 2015, 82, 616–624. [Google Scholar] [CrossRef]

- Bonifazi, G.; Gasbarrone, R.; Palmieri, R.; Serranti, S. Near infrared hyperspectral imaging-based approach for end-of-life flat monitors recycling. At—Automatisierungstechnik 2020, 68, 265–276. [Google Scholar] [CrossRef]

- Bonifazi, G.; Gasbarrone, R.; Palmieri, R.; Serranti, S. Hierarchical modelling for recycling-oriented classification of shredded spent flat monitor products based on HyperSpectral Imaging. Detritus 2020, 2020, 122–130. [Google Scholar] [CrossRef]

- Geladi, P.; Grahn, H.; Burger, J. Multivariate images, hyperspectral imaging: Background and equipment. In Techniques and Applications of Hyperspectral Image Analysis; Wiley: Hoboken, NJ, USA, 2007; pp. 1–15. [Google Scholar]

- Hyvarinen, T.S.; Herrala, E.; Dall’Ava, A. Direct sight imaging spectrograph: A unique add-in component brings spectral imaging to industrial applications. In Digital Solid State Cameras: Designs and Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 1998. [Google Scholar]

- Amigo, J.M.; Babamoradi, H.; Elcoroaristizabal, S. Hyperspectral image analysis. A tutorial. Anal. Chim. Acta 2015, 896, 34–51. [Google Scholar] [CrossRef] [PubMed]

- Bonifazi, G.; Capobianco, G.; Palmieri, R.; Serranti, S. Hyperspectral imaging applied to the waste recycling sector. Spectrosc. Eur. 2019, 31, 8–11. [Google Scholar] [CrossRef]

- Burger, J. Replacement of hyperspectral image bad pixels. NIR News 2009, 20, 19–21. [Google Scholar] [CrossRef]

- Burger, J.; Gowen, A. Data handling in hyperspectral image analysis. Chemom. Intell. Lab. Syst. 2011, 108, 13–22. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Barker, M.; Rayens, W. Partial least squares for discrimination. J. Chemom. J. Chemom. Soc. 2003, 17, 166–173. [Google Scholar] [CrossRef]

- Fawcett, T. An introduction to ROC analysis. Pattern Recognit. Lett. 2006, 27, 861–874. [Google Scholar] [CrossRef]

- Barnes, R.; Dhanoa, M.S.; Lister, S.J. Standard normal variate transformation and de-trending of near-infrared diffuse reflectance spectra. Appl. Spectrosc. 1989, 43, 772–777. [Google Scholar] [CrossRef]

- Weyer, L. Practical Guide to Interpretive Near-Infrared Spectroscopy; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Workman, J., Jr.; Weyer, L. Practical Guide and Spectral Atlas for Interpretive Near-Infrared Spectroscopy; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Leitner, R.; McGunnigle, G.; Kraft, M.; De Biasio, M.; Rehrmann, V.; Balthasar, D. Real-time detection of flame-retardant additives in polymers and polymer blends with NIR imaging spectroscopy. In Advanced Environmental, Chemical, and Biological Sensing Technologies VI; International Society for Optics and Photonics: Bellingham, WA, USA, 2009; pp. 114–122. [Google Scholar]

- Schlummer, M. Recycling of postindustrial and postconsumer plastics containing flame retardants. In Polymer Green Flame Retardants; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Wu, X.; Li, J.; Yao, L.; Xu, Z. Auto-sorting commonly recovered plastics from waste household appliances and electronics using near-infrared spectroscopy. J. Clean. Prod. 2020, 246, 118732. [Google Scholar] [CrossRef]

| Polymer | Typical Applications |

|---|---|

| Acrylonitrile styrene acrylonitrile (ASA) | Housings, trim |

| Acrylonitrile butadiene styrene (ABS) | Housings, trim |

| Polymethylmethacrylate (PMMA) | Lenses, lighting |

| Polytetrafluoroethylene (PTFE) | Gears, bearings |

| Liquid crystal polymer (LCP) | Coatings, radio frequency (RF) shielding |

| Polyacetal/acetal (POM) | Gears, bearings, insulators |

| Polyamide/nylon (PA) | Structures, clips, casings |

| Polyamide-imide (PAI) | Bearings, insulators, connectors |

| Polybutylene terephthalate (PBT) | Switches, connectors, insulators |

| Polyethylene terephthalate (PET) | Films, screens |

| Polycarbonate (PC) | Screens, casings |

| Polyethylene (PE) | Packaging |

| Polyetheretherketone (PEEK) | Hinges, switches, membranes |

| Polyetherimide (PEI) | Sensors, connectors |

| Polyphenylene oxide (PPO) | Housings, valves |

| Polyphenylene sulfide (PPS) | Connectors, housings |

| Polypropylene (PP) | Packaging, cases |

| Polystyrene (PS) | Housings, trim |

| Polysulfone (PSU) | High temperature applications |

| Polyurethane (PU) | Connectors, coatings |

| Polyvinyl chloride (PVC) | Seals, trim |

| Styrene/acrylonitrile (SAN) | Housings, trim |

| Class: | Sensitivity | Specificity | Sensitivity | Specificity |

|---|---|---|---|---|

| (Calibration) | (Calibration) | (Cross-Validation) | (Cross-Validation) | |

| Plastic | 0.921 | 0.813 | 0.921 | 0.813 |

| Other | 0.813 | 0.921 | 0.813 | 0.921 |

| Class: | Sensitivity | Specificity | Sensitivity | Specificity |

|---|---|---|---|---|

| (Calibration) | (Calibration) | (Cross-Validation) | (Cross-Validation) | |

| PC | 1.000 | 1.000 | 1.000 | 1.000 |

| PS | 1.000 | 1.000 | 1.000 | 1.000 |

| ABS | 1.000 | 1.000 | 1.000 | 1.000 |

| PMMA | 1.000 | 1.000 | 1.000 | 1.000 |

| POM | 1.000 | 1.000 | 1.000 | 1.000 |

| PP | 1.000 | 1.000 | 1.000 | 1.000 |

| PA | 1.000 | 1.000 | 1.000 | 1.000 |

| PE | 1.000 | 1.000 | 1.000 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonifazi, G.; Fiore, L.; Gasbarrone, R.; Palmieri, R.; Serranti, S. Hyperspectral Imaging Applied to WEEE Plastic Recycling: A Methodological Approach. Sustainability 2023, 15, 11345. https://doi.org/10.3390/su151411345

Bonifazi G, Fiore L, Gasbarrone R, Palmieri R, Serranti S. Hyperspectral Imaging Applied to WEEE Plastic Recycling: A Methodological Approach. Sustainability. 2023; 15(14):11345. https://doi.org/10.3390/su151411345

Chicago/Turabian StyleBonifazi, Giuseppe, Ludovica Fiore, Riccardo Gasbarrone, Roberta Palmieri, and Silvia Serranti. 2023. "Hyperspectral Imaging Applied to WEEE Plastic Recycling: A Methodological Approach" Sustainability 15, no. 14: 11345. https://doi.org/10.3390/su151411345

APA StyleBonifazi, G., Fiore, L., Gasbarrone, R., Palmieri, R., & Serranti, S. (2023). Hyperspectral Imaging Applied to WEEE Plastic Recycling: A Methodological Approach. Sustainability, 15(14), 11345. https://doi.org/10.3390/su151411345