Balancing Agriculture and Industry through Waste Utilization for Sugarcane Sustainability

Abstract

1. Introduction

2. Methodology

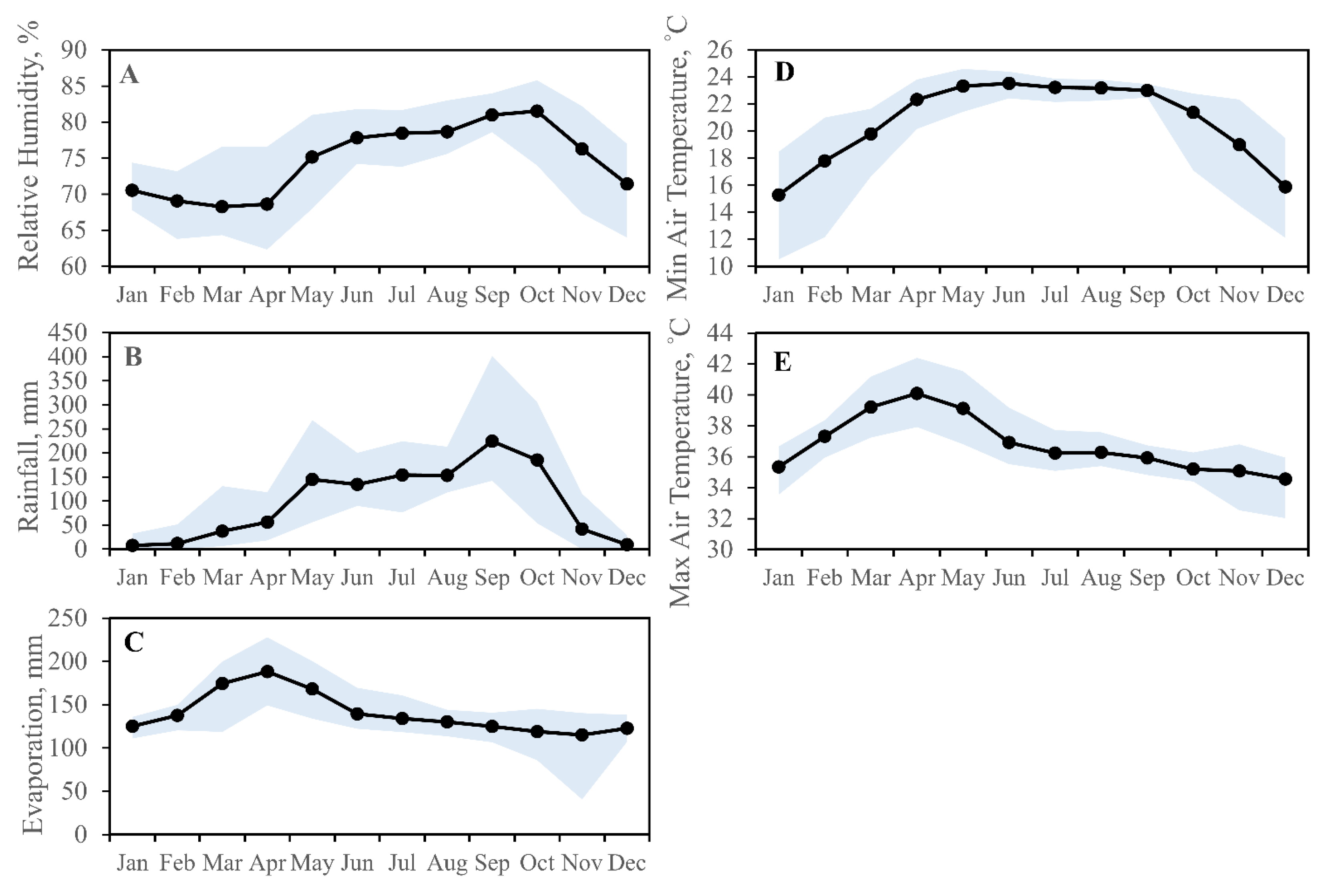

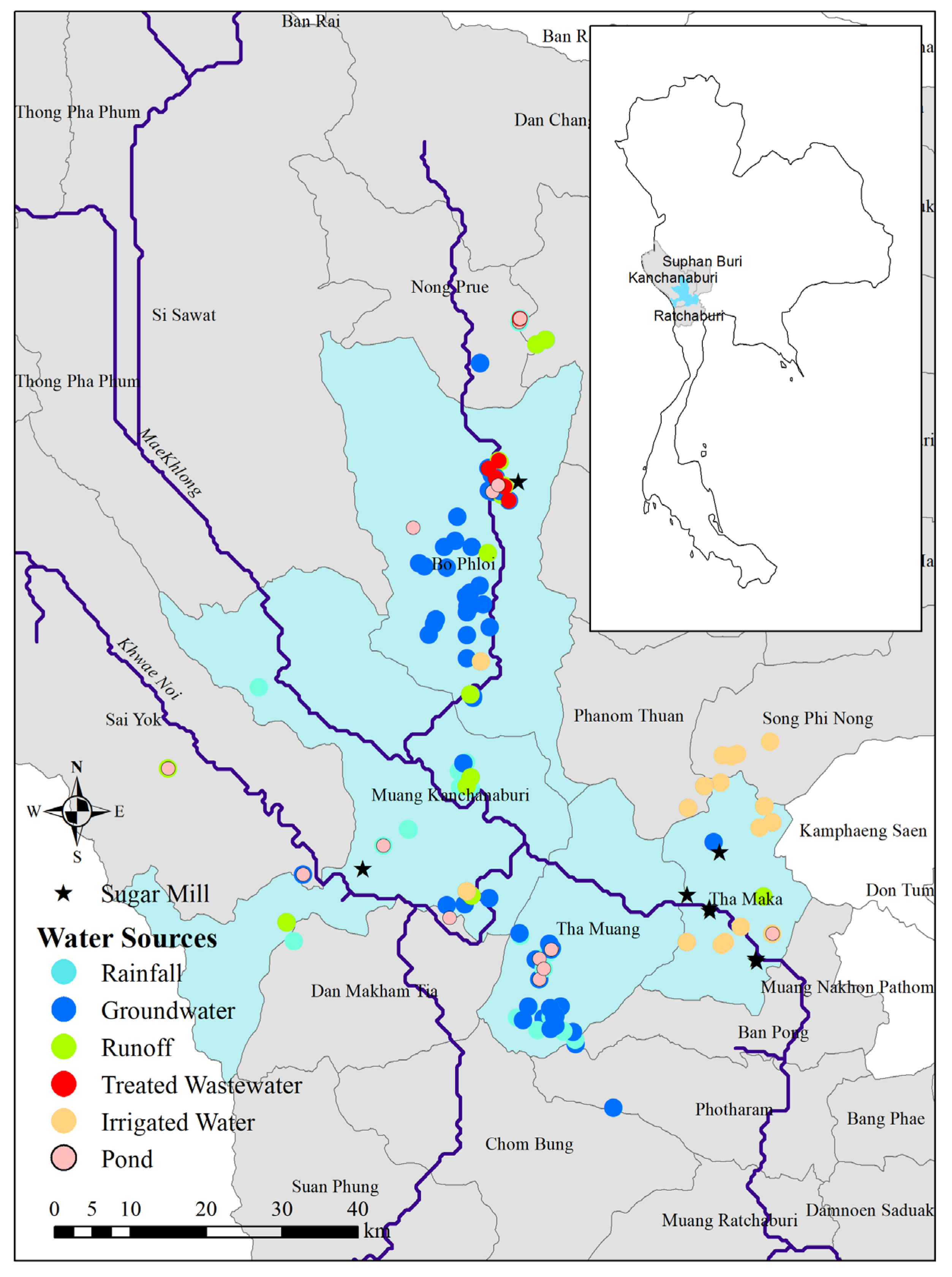

2.1. Description of the Study Area

2.2. In-Depth Interviews and Field Sampling

2.3. Sample Preparation and Analysis

2.4. Data Collection

3. Results and Discussion

- First, an analysis and review of nutrient contents and substances in the by-products and wastes from the sugar mill and distillery industry.

- Second, a discussion of the potential benefits and impacts associated with the utilization of these by-products and wastes as biofertilizers.

- Third, suggestions for the possible application of these by-products and wastes as soil conditioners.

- Fourth, an examination of the requirements and potential for using treated wastewater from the sugar mill and distillery industry for ferti-irrigation.

- Fifth, an exploration of the challenges associated with the utilization of wastes from the sugar mills and ethanol distillery industries, illustrated through the case of Kanchanaburi, Thailand.

- Sixth, a discussion of the limitations of the research implementation.

3.1. Nutrient Contents and Substances in the By-Products and Wastes

3.1.1. Treated Wastewater

3.1.2. Vinasse (Stillage, Spent Wash)

3.1.3. Filter Cake (or Press Mud)

3.2. Feasibility of Using the By-Products and Wastes as Biofertilizers

3.2.1. Current Fertilization Practices and Sugarcane Yields Based on the Interviews

3.2.2. Reviews on Using Waste from Sugar–Ethanol Industries as Fertilizer

Treated Wastewater from Sugar Mills

Vinasse (Stillage, Spent Wash)

Filter Cake (Press Mud)

3.3. Applications of the By-Products and Wastes as Soil Conditioners

3.3.1. Vinasse (Stillage, Spent Wash)

3.3.2. Filter Cake (Press Mud)

3.4. Feasibility of Using Wastewater for Ferti-Irrigation

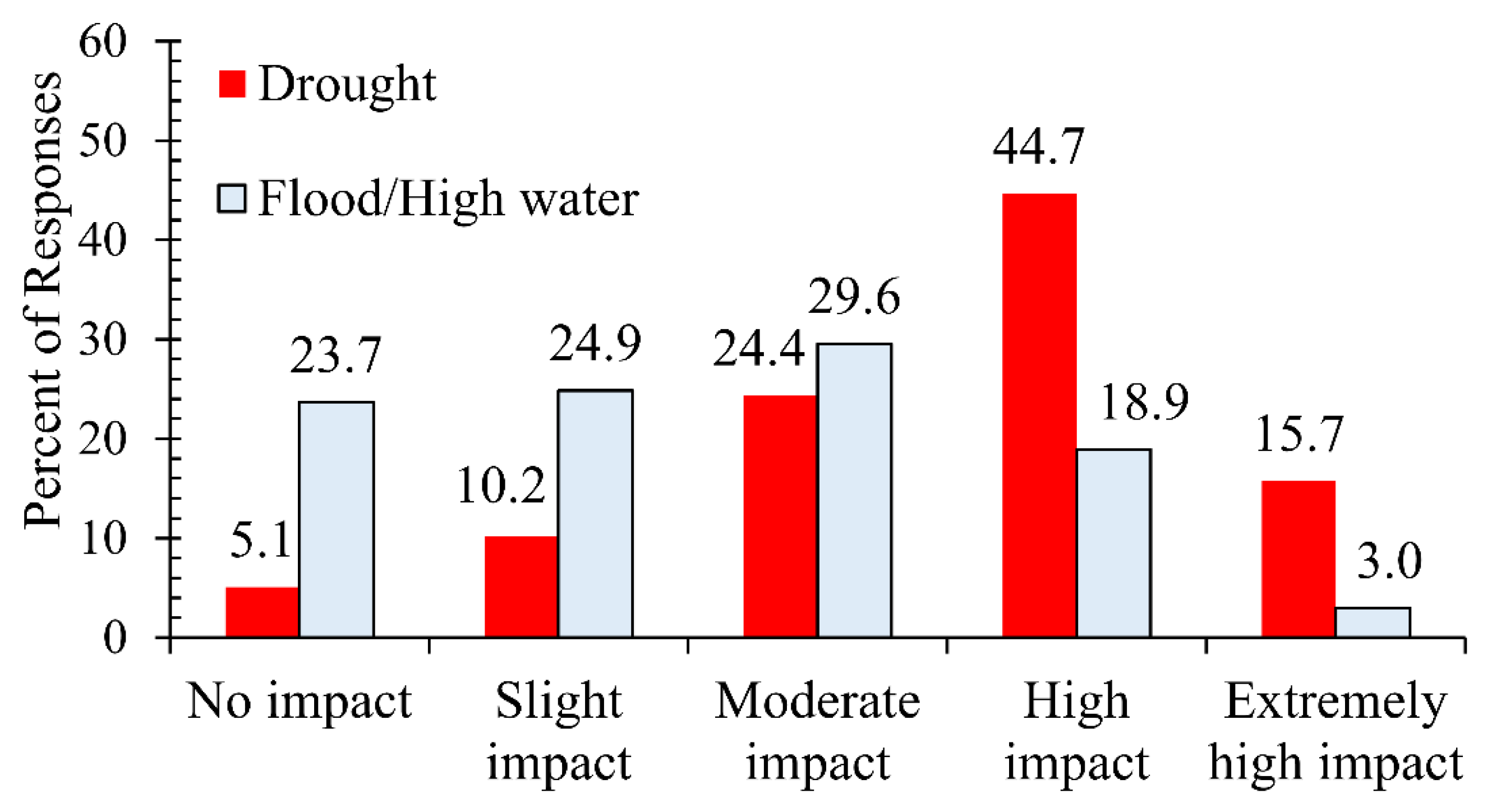

3.4.1. Prospective of Farmers and Future Projections on Drought and Flooding

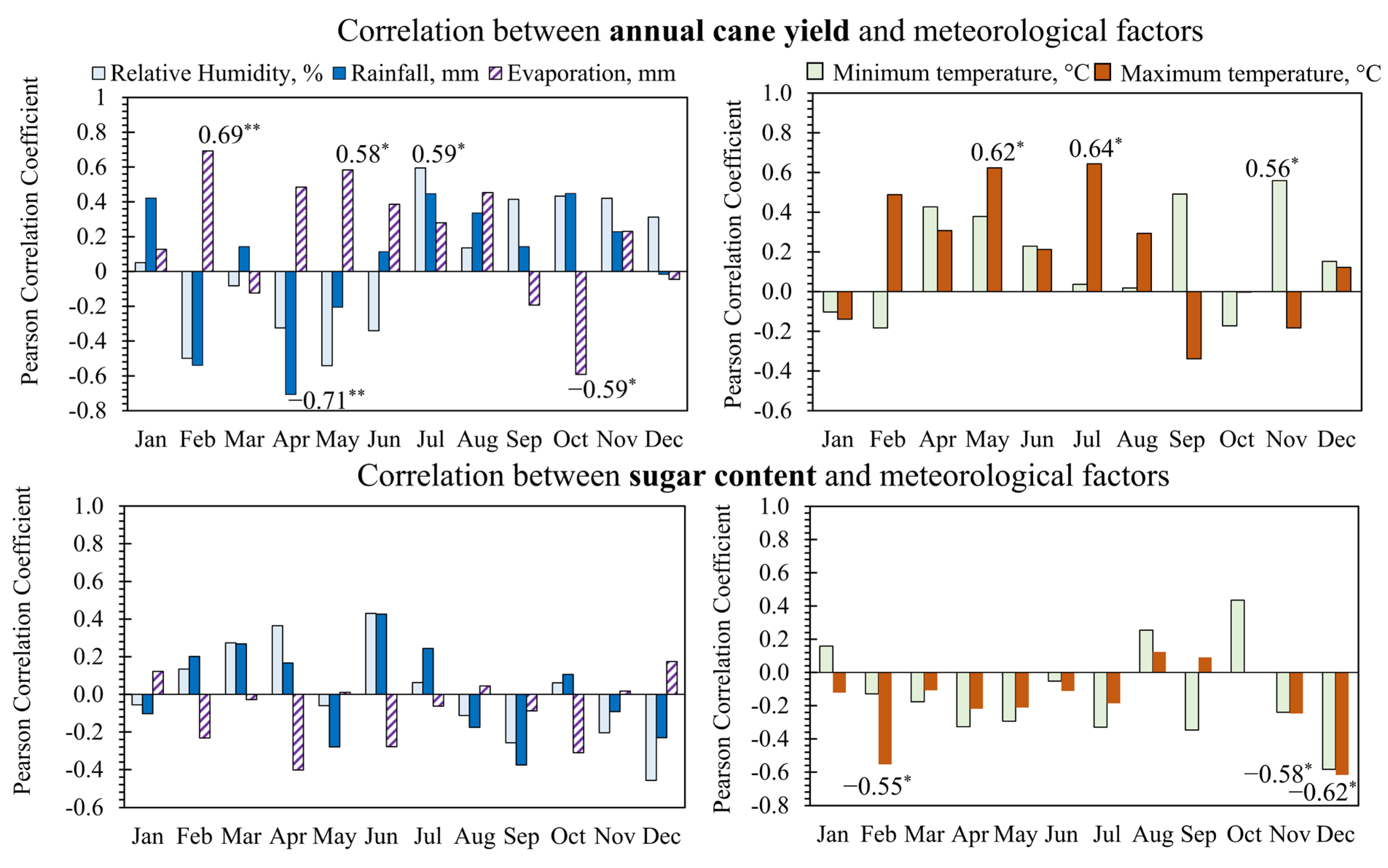

3.4.2. Association between Cane Yield and Meteorological Parameters

Annual Cane Yield vs. Meteorological Factors

Cane Sugar Content vs. Meteorological Factors

3.4.3. Water Sources for Sugarcane Cultivation Based on the Farmer Interviews

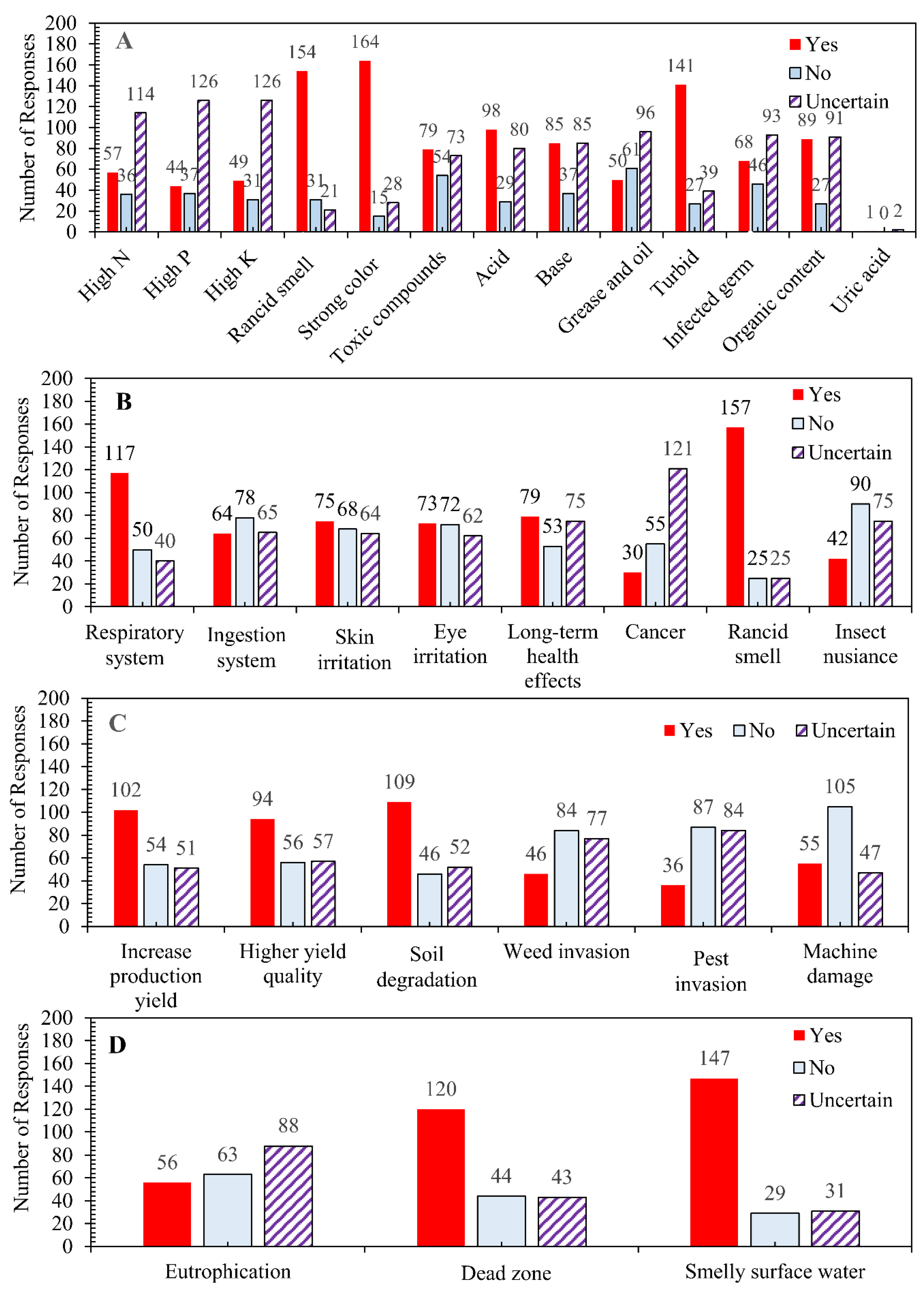

3.4.4. Perception of the Farmers on the Treated Wastewater Quality

3.4.5. Using Wastewater as Ferti-Irrigation Water Based on Literature Reviews

3.5. Challenges and Practical Implications on Waste Utilization for Agricultural Production

3.5.1. Financial Feasibility

3.5.2. Laws and Regulations

3.5.3. Farmer Perception and Practices

3.5.4. Sound Agricultural Practices

- Treated wastewater from the sugar mills can be released into the irrigated waterways and delivered to the nearby fields. The water quality must be continually monitored by relevant parties: the Department of Industry, Pollution Control Development, and the Royal Thai Irrigation Department.

- Filter cake is typically applied to improve soil physical properties and also reduce fertilizer use. Filter cake must be biodegraded and fermented, probably with vinasse, before being applied to the field, which can increase bioavailability, increasing nutrient availability, and avoid negative impacts to the soil and plant [15,30]. Since it has comparatively low available N, the treated filter cake should be applied together with urea fertilizer, cow manure, or bagasse [31,40,42].

- Vinasse is K- and N-rich. Thus, it has been recommended as an alternative source of plant nutrients. Nonetheless, it should not be used without being pre-treated, probably by anaerobic fermentation to reduce organic loading. Dilution is strictly recommended to avoid negative impacts on soil quality and to enhance soil microbial activity [27,53]. Furthermore, its application to sandy soils could be of the greatest benefit as suggested by the farmer survey.

3.5.5. Environmental Health

3.5.6. Value-Added Products

3.5.7. Comprehensive Sustainability Assessment

3.6. Research Limitations

4. Conclusions and Prospects

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Definition |

| BCG | Bio-Circular-Green Economy |

| GDP | Gross Domestic Product |

| CCS | Commercial Cane Sugar |

| pH | Power of Hydrogen Ion |

| TDS | Total Dissolved Solid |

| DO | Dissolved Oxygen |

| EC | Electroconductivity |

| TN | Total Nitrogen |

| TOC | Total Organic Carbon |

| IC | Inorganic Carbon |

| BOD | Biochemical Oxygen Demand |

| COD | Chemical Oxygen Demand |

| TKN | Total Kjeldahl Nitrogen |

| C | Carbon |

| N | Nitrogen |

| Fe | Iron |

| Mn | Manganese |

| Zn | Zinc |

| Cu | Copper |

| Cr | Chromium |

| Pb | Lead |

| Cd | Cadmium |

| Hg | Mercury |

| As | Arsenic |

| Ca | Calcium |

| Mg | Magnesium |

| K | Potassium |

| P | Phosphorus |

| Si | Silica |

| Al | Aluminum |

| FeSO4 | Ferrous Sulfate |

| ZnSO4 | Zinc Sulfate |

| CaCO3 | Calcium Carbonate |

| PCU | Platinum Cobalt Unit |

| NTU | Nephelometric Turbidity Unit |

| r | Pearson correlation coefficient |

| p | p-value |

| B.E. | Buddhist Era |

References

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Meiksin, J. EU and Thailand address bio-circular-green-economy. MRS Bull. 2020, 45, 419. [Google Scholar] [CrossRef]

- Sowcharoensuk, C. Business/Industry Trends 2021–2023: Sugar Industry. Available online: https://www.krungsri.com/th/research/industry/industry-outlook/agriculture/sugar/IO/io-sugar- (accessed on 3 February 2021).

- Aguilar-Rivera, N.; Khan, M.T.; Khan, I.A.; Iqbal, R.; Aslam, M.M. Sustainable Conversion of Wastes into Green Bioproducts to Introduce Diversification and Green Economy in the Sugar Industry. A Review. Sugar Tech 2022, 24, 1198–1211. [Google Scholar] [CrossRef]

- Kushwaha, J.P. A review on sugar industry wastewater: Sources, treatment technologies, and reuse. Desalin. Water Treat. 2015, 53, 309–318. [Google Scholar] [CrossRef]

- Contreras, A.M.; Rosa, E.; Pérez, M.; Van Langenhove, H.; Dewulf, J. Comparative life cycle assessment of four alternatives for using by-products of cane sugar production. J. Clean. Prod. 2009, 17, 772–779. [Google Scholar] [CrossRef]

- Gonçales Filho, M.; Nunhes, T.V.; Barbosa, L.C.F.M.; de Campos, F.C.; de Oliveira, O.J. Opportunities and challenges for the use of cleaner production to reduce water consumption in Brazilian sugar-energy plants. J. Clean. Prod. 2018, 186, 353–363. [Google Scholar] [CrossRef]

- Fito, J.; Tefera, N.; Van Hulle, S.W. Sugarcane biorefineries wastewater: Bioremediation technologies for environmental sustainability. Chem. Biol. Technol. Agric. 2019, 6, 1–13. [Google Scholar] [CrossRef]

- Chunhawong, K.; Chaisan, T.; Rungmekarat, S.; Khotavivattana, S. Sugar industry and utilization of its by-products in Thailand: An overview. Sugar Tech 2018, 20, 111–115. [Google Scholar] [CrossRef]

- International Atomic Energy Agency (IAEA), Country Nuclear Power Profiles 2017 Edition. 2023. Available online: https://www-pub.iaea.org/MTCD/publications/PDF/cnpp2017/countryprofiles/Thailand/Thailand_tables.htm (accessed on 23 September 2023).

- Nguyen, T.L.T.; Gheewala, S.H.; Garivait, S. Full chain energy analysis of fuel ethanol from cane molasses in Thailand. Appl. Energy 2008, 85, 722–734. [Google Scholar] [CrossRef]

- Ministry of Energy. Department of Alternative Energy Development and Energy Conservation, Renewable and Alternative Energy Development Plan 2018 to 2037; Ministry of Energy: Bangkok, Thailand, 2020.

- Murugaragavan, R.; Mahimairaja, S. Problems and prospects of agricultural use of distillery spentwash in India. J. Ecotoxicol. Environ. Monit. 2009, 19, 375–382. [Google Scholar]

- Murillo, J.M.; Cabrera, F.; López, R. Effect of beet vinasse on germination and seedling performance of ryegrass (Lolium multiflorum Lam cv Barwoltra). J. Sci. Food Agric. 1993, 61, 155–160. [Google Scholar] [CrossRef][Green Version]

- Dotaniya, M.; Datta, S.; Biswas, D.; Dotaniya, C.; Meena, B.; Rajendiran, S.; Regar, K.; Lata, M. Use of sugarcane industrial by-products for improving sugarcane productivity and soil health. Int. J. Recycl. Org. Waste Agric. 2016, 5, 185–194. [Google Scholar] [CrossRef]

- Fuess, L.T.; Garcia, M.L. Implications of stillage land disposal: A critical review on the impacts of fertigation. J. Environ. Manag. 2014, 145, 210–229. [Google Scholar] [CrossRef] [PubMed]

- Saranraj, P.; Stella, D. Impact of sugar mill effluent to environment and bioremediation: A review. World Appl. Sci. J. 2014, 30, 299–316. [Google Scholar]

- Sousa, R.M.O.; Amaral, C.; Fernandes, J.M.; Fraga, I.; Semitela, S.; Braga, F.; Coimbra, A.M.; Dias, A.A.; Bezerra, R.M.; Sampaio, A. Hazardous impact of vinasse from distilled winemaking by-products in terrestrial plants and aquatic organisms. Ecotoxicol. Environ. Saf. 2019, 183, 109493. [Google Scholar] [CrossRef] [PubMed]

- Moran-Salazar, R.; Sanchez-Lizarraga, A.; Rodriguez-Campos, J.; Davila-Vazquez, G.; Marino-Marmolejo, E.; Dendooven, L.; Contreras-Ramos, S. Utilization of vinasses as soil amendment: Consequences and perspectives. SpringerPlus 2016, 5, 1007. [Google Scholar] [CrossRef] [PubMed]

- Silalertruksa, T.; Wirodcharuskul, C.; Gheewala, S.H. Environmental Sustainability of Waste Circulation Models for Sugarcane Biorefinery System in Thailand. Energies 2022, 15, 9515. [Google Scholar] [CrossRef]

- Kanchanaburi Provincial Statistical Office, Kanchanaburi Provincial Statistical Report: 2022. National Statistical Office, Ministry of Digital Economy and Society (in Thai). Available online: https://kanchanaburi.nso.go.th/index.php?option=com_content&view=article&id=957:2565&catid=120&Itemid=579 (accessed on 24 November 2022).

- National Statistical Office, Statistics of Temperature at Meteorology Station, Kanchanaburi Province: 2003–2015. Available online: http://service.nso.go.th/nso/web/statseries/statseries27.html (accessed on 24 November 2022).

- Camargo, J.M.d.O.; Ríos, J.M.G.; Antonio, G.C.; Leite, J.T. Physicochemical properties of sugarcane industry residues aiming at their use in energy processes. In Sugarcane-Biotechnology for Biofuels; IntechOpen: London, UK, 2021. [Google Scholar]

- Fito, J.; Tefera, N.; Kloos, H.; Van Hulle, S.W. Physicochemical properties of the sugar industry and ethanol distillery wastewater and their impact on the environment. Sugar Tech 2019, 21, 265–277. [Google Scholar] [CrossRef]

- Talang, R.P.N.; Sirivithayapakorn, S. Environmental impacts and economic benefits of different wastewater management schemes for molasses-based ethanol production: A case study of Thailand. J. Clean. Prod. 2020, 247, 119141. [Google Scholar] [CrossRef]

- Royal Thai Irrigation Department, Order of the Royal Thai Irrigation Department No. 18/2561 BE on Prevention and Correction of Drainage Discharging Low-Quality Water into Irrigation Waterways and Waterways That Connects to the Irrigation Waterways in the Areas Covering the Irrigation Project. Available online: http://hydrology.rid.go.th/sediment-wq/index.php/th/water-quality/wastewaterrid (accessed on 24 November 2022).

- Satyawali, Y.; Balakrishnan, M. Wastewater treatment in molasses-based alcohol distilleries for COD and color removal: A review. J. Environ. Manag. 2008, 86, 481–497. [Google Scholar] [CrossRef]

- Tg, I.; Haq, I.; Kalamdhad, A.S. 14-Factors affecting anaerobic digestion for biogas production: A review. In Advanced Organic Waste Management; Hussain, C., Hait, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Rajkishore, S.; Vignesh, N. Distillery spentwash in the context of crop production-a review. Bioscan 2012, 7, 369–375. [Google Scholar]

- Raza, Q.-U.-A.; Bashir, M.A.; Rehim, A.; Sial, M.U.; Ali Raza, H.M.; Atif, H.M.; Brito, A.F.; Geng, Y. Sugarcane industrial byproducts as challenges to environmental safety and their remedies: A review. Water 2021, 13, 3495. [Google Scholar] [CrossRef]

- Prado, R.d.M.; Caione, G.; Campos, C.N.S. Filter cake and vinasse as fertilizers contributing to conservation agriculture. Appl. Environ. Soil Sci. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Kuziemska, B.; Wysokinski, A.; Klej, P. The Content, Uptake and Bioaccumulation Factor of Copper and Nickel in Grass Depending on Zinc Application and Organic Fertilization. Agriculture 2023, 13, 1676. [Google Scholar] [CrossRef]

- Land Development Department. Land Development Regulations Regarding the Use of Agricultural Production Standard Certification Marks, B.E. 2556. Available online: http://web.krisdika.go.th/data//document/ext825/825514_0001.pdf (accessed on 23 September 2023).

- Poddar, P.K.; Sahu, O. Quality and management of wastewater in sugar industry. Appl. Water Sci. 2017, 7, 461–468. [Google Scholar] [CrossRef]

- Singh, P.K.; Tripathi, M.; Singh, R.P.; Singh, P. Treatment and recycling of wastewater from sugar mill. In Advances in Biological Treatment of Industrial Waste Water and their Recycling for a Sustainable Future; Springer: Singapore, 2019; pp. 199–223. [Google Scholar]

- Carpanez, T.; Moreira, V.; Assis, I.; Amaral, M. Sugarcane vinasse as organo-mineral fertilizers feedstock: Opportunities and environmental risks. Sci. Total Environ. 2022, 832, 154998. [Google Scholar] [CrossRef]

- Moraes, B.S.; Zaiat, M.; Bonomi, A. Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: Challenges and perspectives. Renew. Sustain. Energy Rev. 2015, 44, 888–903. [Google Scholar] [CrossRef]

- Júnior, A.D.N.F.; Koyama, M.H.; de Araújo Júnior, M.M.; Zaiat, M. Thermophilic anaerobic digestion of raw sugarcane vinasse. Renew. Energy 2016, 89, 245–252. [Google Scholar] [CrossRef]

- Wongkoon, T.; Boonlue, S.; Riddech, N. Effect of compost made from filter cake and distillery slop on sugarcane growth. Asia-Pac. J. Sci. Technol. 2014, 19, 250–255. [Google Scholar]

- Sharma, B.; Singh, S.; Sharma, S.; Prakash, V.; Singh, R. Integrated response of press mud cake and urea on sugarcane in calcareous soil. Coop. Sugar 2002, 33, 1001–1004. [Google Scholar]

- Patil, N.N.; Jadhav, S.; Ghorpade, S.S.; Sharma, A.B. Isolation and enrichment of sugar press mud (SPM) adapted microorganism for production of biofertilizer by using sugar press mud. Int. J. Adv. Biotechnol. Res. 2013, 14, 96–104. [Google Scholar]

- Prakash, M.; Karmegam, N. Vermistabilization of pressmud using Perionyx ceylanensis Mich. Bioresour. Technol. 2010, 101, 8464–8468. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Marañón, M.; Romero-Freire, A.; Martín-Peinado, F.J. Soil-color changes by sulfuricization induced from a pyritic surface sediment. Catena 2015, 135, 173–183. [Google Scholar] [CrossRef]

- Owens, P.; Rutledge, E. Morphology. Encyclopedia of Soils in the Environment. In Encyclopedia of Soils in the Environment; Academic Press: Cambridge, MA, USA, 2005; pp. 511–520. [Google Scholar]

- Vongvisessomjai, S. Effect of global warming in Thailand. Songklanakarin J. Sci. Technol. 2010, 32, 431–444. [Google Scholar]

- Kiguchi, M.; Takata, K.; Hanasaki, N.; Archevarahuprok, B.; Champathong, A.; Ikoma, E.; Jaikaeo, C.; Kaewrueng, S.; Kanae, S.; Kazama, S. A review of climate-change impact and adaptation studies for the water sector in Thailand. Environ. Res. Lett. 2021, 16, 023004. [Google Scholar] [CrossRef]

- Prabnakorn, S.; Maskey, S.; Suryadi, F.; de Fraiture, C. Rice yield in response to climate trends and drought index in the Mun River Basin, Thailand. Sci. Total Environ. 2018, 621, 108–119. [Google Scholar] [CrossRef] [PubMed]

- Samui, R.; John, G.; Kulkarni, M. Impact of weather on yield of sugarcane at different growth stages. J. Agric. Phys. 2003, 3, 119–125. [Google Scholar]

- Scarpari, M.S.; de Beauclair, E.G.F. Estimativa da maturação da cana-de-açúcar por meio de parâmetros edafoclimáticos. Sci. Agric. 2004, 61, 486–491. [Google Scholar] [CrossRef]

- Muñoz, C.A.U.; Trujillo, F.d.J.V. Efeitos de variáveis meteorológicas no amadurecimento de cana-de-açúcar no vale do rio Cauca, Colômbia. Pesqui. Agropecuária Trop. 2020, 50, e60815. [Google Scholar] [CrossRef]

- Uehara, N.; Sasaki, H.; Aoki, N.; Ohsugi, R. Effects of the temperature lowered in the daytime and night-time on sugar accumulation in sugarcane. Plant Prod. Sci. 2009, 12, 420–427. [Google Scholar] [CrossRef]

- Chooyok, P.; Pumijumnog, N.; Ussawarujikulchai, A. The water footprint assessment of ethanol production from molasses in Kanchanaburi and Supanburi province of Thailand. APCBEE Procedia 2013, 5, 283–287. [Google Scholar] [CrossRef]

- Kumar, V.; Chopra, A. Fertigation effect of distillery effluent on agronomical practices of Trigonella foenum-graecum L. (Fenugreek). Environ. Monit. Assess. 2012, 184, 1207–1219. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, J.J.; da Silva, B.F.; Stradiotto, N.R.; Petrović, M.; Gros, M.; Gago-Ferrero, P. Identification of organic contaminants in vinasse and in soil and groundwater from fertigated sugarcane crop areas using target and suspect screening strategies. Sci. Total Environ. 2021, 761, 143237. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Deng, C.-B.; Wang, X.-F.; Chen, G.-l.; Mihucz, V.G.; Xu, G.-P.; Deng, Q.-C. Effects of long-term application of vinasse on physicochemical properties, heavy metals content and microbial diversity in sugarcane field soil. Sugar Tech 2019, 21, 62–70. [Google Scholar] [CrossRef]

- Bordonal, R.d.O.; Carvalho, J.L.N.; Lal, R.; de Figueiredo, E.B.; de Oliveira, B.G.; La Scala, N. Sustainability of sugarcane production in Brazil. A review. Agron. Sustain. Dev. 2018, 38, 1–23. [Google Scholar] [CrossRef]

- Oliveira, B.G.; Carvalho, J.L.N.; Chagas, M.F.; Cerri, C.E.P.; Cerri, C.C.; Feigl, B.J. Methane emissions from sugarcane vinasse storage and transportation systems: Comparison between open channels and tanks. Atmos. Environ. 2017, 159, 135–146. [Google Scholar] [CrossRef]

- De Oliveira, B.G.; Carvalho, J.L.N.; Cerri, C.E.P.; Cerri, C.C.; Feigl, B.J. Greenhouse gas emissions from sugarcane vinasse transportation by open channel: A case study in Brazil. J. Clean. Prod. 2015, 94, 102–107. [Google Scholar] [CrossRef]

- Patil, S.; Konde, K.; Behera, S. Bio-circular economy: An opportunity for diversification for sugar industries in compressed biogas (CBG) and organic fertilizer production. Sugar Tech 2022, 24, 1079–1092. [Google Scholar] [CrossRef]

- Santos, F.; Eichler, P.; Machado, G.; De Mattia, J.; De Souza, G. By-products of the sugarcane industry. In Sugarcane Biorefinery, Technology and Perspectives; Elsevier: Amsterdam, The Netherlands, 2020; pp. 21–48. [Google Scholar] [CrossRef]

- Montiel-Rosales, A.; Montalvo-Romero, N.; García-Santamaría, L.E.; Sandoval-Herazo, L.C.; Bautista-Santos, H.; Fernández-Lambert, G. Post-industrial use of sugarcane ethanol vinasse: A systematic review. Sustainability 2022, 14, 11635. [Google Scholar] [CrossRef]

- Cronjé, Y.; Farzad, S.; Mandegari, M.; Görgens, J.F. A critical review of multiple alternative pathways for the production of a high-value bioproduct from sugarcane mill byproducts: The case of adipic acid. Biofuel Res. J. 2023, 10, 1933–1947. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Hosseinzadeh-Bandbafha, H.; Shahbeik, H.; Tabatabaei, M. The role of sustainability assessment tools in realizing bioenergy and bioproduct systems. Biofuel Res. J. 2022, 9, 1697–1706. [Google Scholar] [CrossRef]

- Gheewala, S.H. Life cycle assessment for sustainability assessment of biofuels and bioproducts. Biofuel Res. J. 2023, 10, 1810–1815. [Google Scholar] [CrossRef]

| Treated Sugar Mill’s Wastewater | Treated Sugar Mill’s Wastewater | Anaerobically Treated Vinasse from Molasses-Based Ethanol Production | Surface Runoff in the Agricultural Area Near Plant A | Standard of Water Quality Discharged into the IrrigationWaterway | |

|---|---|---|---|---|---|

| Plant | A | B | B | ||

| pH | 8.48 | 7.68 | 8.06 | 7.27–7.49 | 6.5–8.5 |

| Dissolved oxygen, DO (mg L−1) | 4.48 | 5.03 | 1.10 | 5.55–7.56 | >2 |

| Turbidity (NTU) | 48.2 | 23.9 | 158 | 4.61–5.75 | NR |

| Electroconductivity, EC (μS cm−1) | 987 | 19.7 | 6140 | 84.7–661 | <2000 |

| Color (PCU) | 320 | 10 | 16,000 | 110 | NR |

| Total Nitrogen, TN (mg L−1) | 4.42 | 0.69 | 808.1 | 0.43 | TKN < 35 |

| Total Organic Carbon, TOC (mg L−1) | 23.73 | 9.42 | 9040 | 9.66 | NR |

| Inorganic Carbon, IC (mg L−1) | 125 | 21.57 | 1440 | 24.93 | NR |

| C/N ratio | 33.65 | 44.91 | 12.97 | 80.44 | NR |

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Growth stage | Land Preparation/Sprouting | Tillering | Elongation | Ripening | ||||||||

| Percentage of farmers applied fertilizers | 23.7 | 12.7 | 18.2 | 17.7 | 40.3 | 13.8 | 10.5 | 13.3 | 12.1 | 7.2 | 2.2 | 1.1 |

| Fertilizer application rate (kg ha−1) | ||||||||||||

| Chemical fertilizer | 156–625 | 187.5–1250 | 62.5–937.5 | 104–625 | 104–937.5 | 156–469 | 156–625 | 156–625 | 156–1562.5 | 156–625 | 156–625 | 312.5–625 |

| N:P:K formula | 15:15:15, 16:8:8, 18:8:8, 21:0:0, 24:8:7, 25:7:7, 46:0:0 | 15:15:15, 16:20:0, 16:8:8, 21:0:0, 21:21:21, 30:0:0, 46:0:0 | 15:15:15, 16:20:0, 16:8:8, 21:0:0, 25:7:7, 30:10:10, 46:0:0 | 15:15:15, 16:8:8, 21:0:0, 46:0:0 | 12:20:0, 15:15:15, 16:16:16, 16:8:8, 21:0:0, 27:12:6, 30:0:0, 46:0:0 | 15:15:15, 16:16:16, 16:8:8, 21:0:0, 23:16:0, 30:0:0, 46:0:0 | 15:15:15, 16:20:0, 21:0:0, 46:0:0 | 15:15:15, 16:16:16, 16:8:8, 18:8:8, 21:0:0, 25:5:15, 30:0:0, 46:0:0 | 16:8:8, 21:0:0, 46:0:0 | 21:0:0, 21:21:21, 24:8:7, 46:0:0 | 21:0:0, 21:21:21, 24:8:7, 46:0:0 | 16:8:8, 46:0:0 |

| Manure (Chicken, Goat, Swine) | 312.5–3125 | 312.5–3125 | 312.5–46,870 | 312.5 | 312.5–3125 | Co-applied with chemical fertilizers | 312.5 | Co-applied with chemical fertilizers | Co-applied with chemical fertilizers | 312.5–3125 | NR | NR |

| Filter Cake | 310–156,000 | 120–156,000 | NR | NR | 250 | NR | NR | NR | NR | NR | NR | NR |

| Other organic fertilizer | 312.5 | 312.5 | NR | 312.5 | 156–625 | 625 | 156 | 625 | NR | NR | NR | NR |

| Dominant Soil Texture | Fertilizer Amount, kg ha−1 year−1 | Median | Number of Observations | |

|---|---|---|---|---|

| Cane Yield, Ton ha−1 | Crop Area Per Farmer Household, ha | |||

| Sand | <312.5 | 81.3 | 625 | 5 |

| 312.5–625 | 62.5 | 1250 | 9 | |

| 625–937.5 | 62.5 | 2500 | 3 | |

| >937.5 | 62.5 | 1875 | 4 | |

| Loam | <312.5 | 64.4 | 1250 | 7 |

| 312.5–625 | 75.0 | 1250 | 14 | |

| 625–937.5 | 62.5 | 1250 | 7 | |

| >937.5 | 62.5 | 1875 | 5 | |

| Clay | <312.5 | 75.0 | 844 | 22 |

| 312.5–625 | 75.0 | 938 | 25 | |

| 625–937.5 | 81.3 | 1875 | 10 | |

| >937.5 | 68.8 | 1250 | 17 | |

| Major Water Sources for Sugarcane Cultivation | Percentage (N = 207) |

|---|---|

| Rainfall | 38.65 |

| Groundwater | 63.77 |

| Surface Runoff | 14.98 |

| Industrial Wastewater | 4.35 |

| Irrigated Water | 13.53 |

| Pond | 14.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bridhikitti, A.; Kaewsuk, J.; Karaket, N.; Friend, R.; Sallach, B.; Chong, J.P.J.; Redeker, K.R. Balancing Agriculture and Industry through Waste Utilization for Sugarcane Sustainability. Sustainability 2023, 15, 14711. https://doi.org/10.3390/su152014711

Bridhikitti A, Kaewsuk J, Karaket N, Friend R, Sallach B, Chong JPJ, Redeker KR. Balancing Agriculture and Industry through Waste Utilization for Sugarcane Sustainability. Sustainability. 2023; 15(20):14711. https://doi.org/10.3390/su152014711

Chicago/Turabian StyleBridhikitti, Arika, Jutamas Kaewsuk, Netiya Karaket, Richard Friend, Brett Sallach, James P. J. Chong, and Kelly R. Redeker. 2023. "Balancing Agriculture and Industry through Waste Utilization for Sugarcane Sustainability" Sustainability 15, no. 20: 14711. https://doi.org/10.3390/su152014711

APA StyleBridhikitti, A., Kaewsuk, J., Karaket, N., Friend, R., Sallach, B., Chong, J. P. J., & Redeker, K. R. (2023). Balancing Agriculture and Industry through Waste Utilization for Sugarcane Sustainability. Sustainability, 15(20), 14711. https://doi.org/10.3390/su152014711