Abstract

The connection of universities with new knowledge in various sciences leads to entrepreneurship and the progress of the economic development of universities. Countries with higher education institutions, in the shadow of practical research and development, are trying to strengthen the economic structure and entrepreneurship, and conduct basic research. Besides, higher education institutions are building science parks and implementing high-tech projects jointly with industry. New materials such as PVC and concrete have been created through scientific evolution between innovators and industry workers, which can be used as one of the most useful building materials. Among the advantages of these materials, we can point out their low cost compared to the high volume of their use, which has attracted the attention of most engineers, designers, employers, innovators and entrepreneurs. In this regard, the construction industry is also a huge consumer of natural resources and at the same time a waste producer, which is solved by this number of graduate students. In this article, we intend to investigate the engineering properties and environmental effects of green materials prepared with PVC waste powder using designers, innovators and entrepreneurial ideas. Many studies have been conducted on the chemical decomposition of PVC to transform PVC into other products, so investigating the possibility of recycling PVC and reusing it in the production cycle is an important issue in the discussion of waste. One of the proposed ways is to replace river sand with PVC waste to prepare concrete, which can be considered one of the environmentally friendly activities of employers, innovators and entrepreneurs. The obtained results show that there is a great demand for the production of natural materials as non-renewable materials with better support for the economy of countries such as China or with high waste.

1. Introduction

The expansion of industries and the movement towards industrialization require that comprehensive research be done on the consumption of construction and industrial waste. The ever-increasing amount of materials and urban waste, especially the debris resulting from the demolition of buildings, is such that it is considered a social and environmental problem in all countries, especially developed countries [1,2]. Among the most important problems of construction waste, we can mention the environmental problems and health problems caused by dumping them on the side or bed of rivers. The lack of places to bury has caused a bad and unnatural landscape [3]. On the other hand, due to the expansion of construction in the world and since the construction industry is the largest harvester and consumer of materials from the earth, excessive exploitation of natural resources for the production of construction materials leads to a shortage of natural materials [4]. Moreover, the extraction of natural resources that are often found along the rivers has led to dangerous floods.

In recent years, attention to environmental issues and the approach to the technology of recycling waste materials and their reuse in developed countries have received a huge investment. One of the methods of using waste materials is to use them in concrete and other building materials [3,4,5]. Using some waste materials in concrete to reduce environmental pollution can be achieved concrete-positive properties [5]. The use of waste materials and recycling in many third-world countries is still in its infancy and requires encouragement and coercion from the government. In some areas, governments accumulate waste materials in the deserts, which become habitats for insects and animals, or they may burn the waste materials resulting in smoke pollutes in the environment that is known as a dangerous phenomenon for global warming [6]. Therefore, the laws of some countries prohibit the burning of waste materials and make the recycling of some wastes mandatory in certain industries in which the science of law and management can be effective. Recycling some waste materials for concrete is a good solution to achieve the two goals of disposing of waste materials and preserving natural resources [7,8,9]. Therefore, the importance of using waste materials in concrete has emerged.

In general, the wastes used in concrete are divided into two groups of wastes such as havuing pozzolanic properties and replacing part of the cement materials in concrete, and having a filling role and replacing aggregates in concrete. In order to use the recycling of PVC materials in the construction of green concrete, therefore, one should have a complete understanding of these waste materials [7]. It is important to find out how much the use of green concrete materials is used in the construction industry that can promote our goal of reducing harmful environmental effects [8]. To achieve green or sustainable construction, green concrete is the best choice. Using green technology in the production of materials, energy resources, and natural materials can be saved for future generations. By replacing waste materials with natural raw materials, environmental problems are reduced and the emission of greenhouse gases is prevented [9,10,11,12,13,14]. In fact, sustainable materials are used instead of non-sustainable materials in the production of green concrete. With the production of green concrete, the wastes created from the destruction of concrete structures are reused.

The aluminum cans are converted into fibers and can be effective in increasing concrete reinforcement. The objective of this transformation is to emphasize the locality, reinforce normality, foster applicable abilities, and serve the local economic and social growth of both peoples and industries. Enrich the theoretical research of higher education and make up for the lack of research on the development of these products in China’s regular universities is widely observed [10,15,16,17,18,19,20,21]. Therefore, further guiding and standardizing the school running behavior is required. The existing research mainly reviews the school running concept and characteristics, school positioning, discipline, and professional development, scientific research and science, technology management, and the relationship that should be handled well in school management. There are few strategic studies on the development of new regular colleges, and inaccurate and unsystematic overviews. Combined with the school running practice of several newly-built colleges in China, which have achieved early success, and the questionnaire analysis, this study puts forward the sustainable development (SD) path and strategy for newly-built regular colleges. To examine, develop, and modify ordinary colleges, key theoretical issues such as why, where, and how ordinary colleges are transformed, are considered [6,7,8,9,10,11,12]. At the same time, based on the model of policy coordination, the specific policy tools to provide policy suggestions for the relevant stakeholders of the transformation and the development of local colleges, especially to provide a reference for the transformation and development of China’s regular colleges are needed. Preparing the teacher education policy system, and solving the confusion of the development of China’s regular colleges have certain research value and practical significance [13,14,15,16,17,18,19,20,21,22,23,24,25,26,27]. UN Sustainable Development Goals (SDGs) adopted the 2030 agenda for sustainable development, which includes a set of 17 SDGs to end poverty, fight inequality and injustice, and tackle climate change by 2030. SDGs are also known as Global Goals (GGs). SDGs aimed at an array of issues that included slashing poverty, hunger, disease, gender inequality, and access to water and sanitation [27,28].

Despite these achievements, the indignity of poverty has not been ended for all [29,30,31,32]. The researchers pointed to the importance of China’s policy of boosting science, technology, and education while ensuring SD, as well as the active growth of vocational-technical education and adult education in various fields. In 1999, the plan to deepen educational reforms and promote educational capacity was approved by National Assembly. The decree emphasized the establishment of an education system following the socialist trade economy, and development of vocational-technical education, especially in secondary level. The design and implementation of such policies have not led to the creation of a suitable social environment for the development of vocational training [32,33,34,35,36]. The establishment of a macro-management system was used to improve the quality of higher education and create sustainable progress. Therefore, by the implementation of the mentioned plan, the educational quality of the country may continuously improve and the effectiveness of the university may increase [37,38,39,40,41,42]. Assessing education at the undergraduate level is based on the principle of advancing reform and building a university at the same time as measuring it [43,44,45,46,47,48]. The emphasis is on the importance of theoretical research in higher education and correcting the orientation of theoretical education with scientific education [49,50,51]. The plan was implemented with an emphasis on providing higher education programs in Chinese characters and establishing, such an education system. All research teams must conduct theoretical research on socialist higher education in Chinese characters. The key to success in today’s highly competitive world is innovation and entrepreneurship [52,53,54,55,56,57,58].

2. Research Methodology of Educational Priorities in China

A series of articles by innovative Chinese universities such as Yancheng Teachers University were reviewed and analyzed. A review of the university’s activities may support an understanding of innovation and entrepreneurship in academia and prepare a better understand of the key role of intellectual property in this area. Innovation and technology for China’s greater prosperity and global development are growing every year. Among the most important educational priorities of preschool education in China, the development of foreign investments (especially for children aged 1–6 years) is facing a bright future. According to statistics, more than 20 preschools have been established in Beijing. Eastern Child Care Center, which was established in 1998 as the only private specialized center for child education in Beijing has five branches throughout Beijing, with four centers for the care and education of children aged 1–6 years, and one center dedicated to the education of pregnant women. So far, an amount of 10 million Yuan (equivalent to 1.2 million US dollars) was invested in the establishment and operation of these centers. In 1999, the institute established the first child nutrition and health-counseling center to expand childcare activities. The institute established two centers for educating parents on nutrition, intelligence, and child psychology in Beijing. The teachers of these centers are women with health and child education degrees. Using educational entertainment for children to enhance their educational workforce forms a large part of the institute’s teaching method. All the following improvements in these years showed that using innovation from university new technologies in universities could be improved. Therefore, all these improvements affect the future of students in universities and industries.

2.1. Domestic Research Status

Many scholars have studied the transformation of local colleges and universities in contemporary China from the aspects of talent training objectives and the essence of university education [10,26,27,28,29,30,31]. Moreover, some scholars studied the same issue, but from the perspectives of education management, resource allocation, operation mechanism, and enrollment system reform. Other scholars have investigated and discussed the internal driving force and interest game of the transformation and development of local colleges from the perspectives of economics and sociology, which provides a new research perspective for the transformation and development of local colleges [26,27,28,29,30,31,32,33,34,35,36].

A review of successful universities’ performance indicates that the actors of the innovation ecosystem for providing a suitable environment for “education”, “research”, is adding “entrepreneurship and innovation” to their functions and creating added value from basic and applied research [45,46,47,48,49,50,51,52,53,54,55]. Meanwhile, the success of academic entrepreneurship depends on the proper protection of inventions and innovations. Therefore, universities have became active actors in the innovation system; For instance, green product has been developed in the university by mechanical, textile, medical civil engineers. The registration and acquisition of intellectual property rights, particularly in the innovation system, not only helps in the protection of inventions, but also in the creation of money via the issuing of licenses, and the patent may be a useful indication for assessment [46,47,48,49,50,51,52]. In recent years, China has developed its universities and adapted them to the world’s top universities, and improved the higher education process. According to the country’s exports, leading universities are required to strengthen their research institutions, acquire the latest educational concepts of the international community, and strengthen their role in the process of globalization of the economy.

2.2. Research on the Transformation and Development of Regular University

Firstly, this paper studies the transformation of regular colleges and makes a comparative study on the transformation of regular colleges in China and western countries. Secondly, taking a new regular college as the starting point, this paper studies the ideas and strategies for the transformation and development of a new regular college. Then, it deals with the transformation of new regular colleges from the aspects of economic transformation, difficulties of college students employment, and talent needs of employers. Finally, this paper studies the specialty and curriculum of the transformation of the new regular university and the reform of talent training mode, and puts forward the specific strategies and methods of the transformation of the regular university.

In western countries, the industrialization process began earlier, and higher education development is considerably advanced [29,30,31]. From the perspective of strategic management theory and based on the diversified educational needs of society in the late 20th century, scholars discussed the innovation of the organizational model, the construction of a diversified funding base, and the integration of innovative culture that has great guiding significance for the transformation and development of universities. The US and European countries have more research on the transformation of regular universities, comparing to Japan and South Korea. Firstly, scholars have studied the history of American regular education, investigated the problems of the American teacher recruitment system, qualification certification system, teacher feminization, the establishment and transformation of state regular schools and colleges, and analyzed the main characteristics, development, and transformation of American regular education in different stages [32,33,34,35,36,37]. Second, the structure of British higher education is relatively single. From the overall situation of the transformation and development of higher education at home and abroad, the transformation of regular colleges is the objective requirement to realize the connotative development, high-quality development, and SD of regular colleges. Regular college transformation is a challenge of educational reform with a constrained problem scope. From expansion to connotation, and from study to application, many domestic academics have researched the transition and development of new regular colleges. In western countries, as there are few new regular colleges, the transformation problem is not obvious, and the research results are relatively few [37,38,39]. Overall, domestic scholars mostly study the transformation of regular colleges from the micro-level and practical level. Most scholars advocate that highlighting school running characteristics, innovating educational ideas, innovating teaching models, and building brand majors should be taken as the focus of the school’s transformation and development. Few scholars have studied the transformation and development of newly-built regular colleges with holistic and systematic thinking, and cannot comprehensively analyze and evaluate various factors affecting the transformation of regular colleges. Questionnaire surveys, field visits, and individual interviews are the most common research methodologies used by domestic researchers to undertake a specific study on the transition of a regular university.

2.3. Research Difficulties and Expected Innovations

Since the popularization of higher education was launched, there were many studies on the development of newly-built application-oriented undergraduate colleges, but there is a lack of theoretical research on the SD of regular colleges. The present studies mainly evaluate the school running concept, school positioning, school running characteristics, discipline and professional development, scientific research or science and technology management, and academic team construction. There are also few macro strategic studies on the growth of new regular colleges, and some are simply fragmented, imprecise, and unsystematic summaries [41,42,43,44,45,46,47,48], in terms of the connection that should be managed properly in school administration or building [44,45,46,47,48,49].

This study refers to regular universities and focuses on their connotation development. The purpose is to highlight the locality, strengthen the normality, cultivate applied talents, and serve the local economic and social development via the transformation and development. In addition, this study analyzes the difficulties encountered in the transformation and development of regular universities from three aspects of theoretical research, empirical research, and countermeasure research. The first is to analyze the economic and social background of the transformation and development of regular colleges at home and abroad, especially in the popularization of higher education, diversification of teachers’ education, and the situation faced by the transformation of regular colleges, and the internal and external causes of the transformation. The second is to clarify the school running concept and its orientation in the process of transformation and development of China’s regular universities, the characteristics and key problems of regular discipline majors in talent training, discipline construction, and teacher team construction. Third, refine the relevant theories on the transformation and development of regular colleges in pedagogy, management, and economics [59,60,61,62,63,64].

Based on the grounded theory, first, a preliminary survey is conducted on the transformation and development of regular colleges from 2000 to 2019, and then, a follow-up survey from 2020 to 2021 is provided. The investigated cases involve transitional universities of different types and regions. It is planned to select regular colleges in Northeast (Liaoning), Northwest (Shaanxi), Southwest (Sichuan), and other provinces to carry out extensive research, and select 10 representative colleges for key analysis. Additionally, NVIVO qualitative analysis software is used to clarify the main elements of the transformation and development of regular colleges in China. A questionnaire survey (300 relevant personnel) is adopted to obtain effective data on the transformation and development of regular universities, and finally, structural equation model (SEM) is used to mine the leading factors affecting the transformation and development.

3. Review of Chemical Materials Used in Green Concrete

Civil engineers along with material and metallurgical engineers in the world have made efforts to create sustainable materials, which has led to the creation of a product called green concrete, made from concrete waste materials. In its production, less energy is used and it produces less carbon dioxide than ordinary concrete [1,2,3]. The production of cement and concrete creates a large amount of carbon gas and by polluting the air, it leads to damage to the environment. But in making green concrete, processes are used that have no harm to the environment [5]. Concrete waste such as slag, recycled concrete, fly ash, aluminum can strings, power plant waste, waste glass, red mud, burnt clay, sawdust, combustion ash and foundry sand are ingredients of green concrete. Due to the unique advantages of this type of material, its use has become popular in recent years and it has become a popular concrete among builders. Green concrete is a good opportunity to buy cheaper concrete that is safe for the environment. Green concrete or eco concrete is the same as normal concrete, but it is made of environmentally friendly materials, and there is no difference between its color and normal concrete [6,7,8,9]. This type of concrete is made by adding environmentally friendly materials, so it is known as environmentally friendly concrete. The production of eco-concrete is very cheap because a partial substitute for cement and aggregates is used to make it [10]. The use of this type of concrete in the construction industry is growing at a faster rate, and the development of urban society increases the demand for this type of concrete. Today, the construction industry is looking for an alternative material due to the reduction of pollution and lack of construction materials, therefore green concrete is a new type of concrete in line with SD [11,12].

This concrete is a revolutionary concept in the construction industry that was first made in Denmark in 1998 [7]. Materials often used in eco-concrete include blast furnace slag, fly ash, silica fume, recycled glass, and wood ash as a substitute for cement in the production of green concrete. Some applications of green concrete can be seen in the construction of bridges, urban buildings, road construction, dam construction, and construction of concrete platforms [13]. Regarding the types of materials used in green concrete, it can be said that they are divided into two parts, substitute materials in cement and substitute materials in aggregates. We can refer to the materials that replace cement with green concrete [14,15]. Granular blast furnace slag, which is a waste material of steel and iron production in the factory. Replacing zero to 80% of granulated blast furnace slag in different grades of concrete gives more compressive strength and bending strength [16]. In addition, granular blast furnace slag in concrete provides about 40% replacement, 9% higher strength at 7 days, and 6% increase in strength with percent replacement at 28 days [10,11,12,13,14,15,16].

Fly ash is another alternative that is obtained from the combustion of pulverized coal. In other words, the waste material is a coal-based power plant. Concrete with high compressive strength and fracture resistance is possible by replacing cement with fly ash by weight, fly ash can be used up to 30% in concrete instead of cement. Silica fume is one of the side products in the production process of silicon and ferrosilicon and consists of spherical particles with an average diameter of 150 nm. Researchers have said that this mixture improves the strength and durability of concrete [12,13,14,15,16]. The use of silica fume also reduces harmful environmental impacts and leads to a 30% reduction in cement consumption. Recycled glass also helps to produce this product in concrete blocks, self-compacting concrete, and architectural mortar [17].

Concrete samples with mortar based on palm leaf ash with 10, 20, and 30% replacement in cement are used. Now we refer to alternative materials that can be used as a substitute for aggregates in concrete. Fly ash is a very soft powder that disperses in the air. When coal is used for heat generation, the residue contains 80% light ash and 20% heavy bottom ash. The fly ash produced in the power plant is light to medium gray in color and has the appearance of cement powder [8,9,10]. Using fly ash in concrete instead of PCC not only saves cement and energy but is also economical. Theoretically, 100% replacement of Portland cement with fly ash is possible, but at replacement levels above 80%, a chemical activator is generally required. In addition, fly ash can improve certain properties of cement such as durability [14].

Because it produces less heat of hydration, this type of concrete is particularly well suited for mass concrete applications as shown in Table 1. Silica sand is good quality, clean, and of the uniform size used in casting processes. Sand is used to make molds or patterns used for casting ferrous (iron and steel) and non-ferrous (copper, aluminum, brass) metals [18]. Foundry sand is used as a substitute for fine aggregates with different weight percentages and is made for water absorption and quick chloride permeability. Concrete made with cast sand will last 30% better. Plastic and rubber wastes are also one of the most important substitutes for aggregates in concrete. Due to the rapid population growth, urbanization, and industrialization of cities, a large amount of solid waste is produced daily in developing countries, and the management of this waste has become a major concern for environmental activists and city officials [19]. A significant part of this waste is plastic waste, only a small part of which is recycled. One of the alternative solutions for the indirect recycling of these wastes is to use them in concrete production. Plastic waste leads to a 16% increase in strength and rubber materials lead to a 50% increase in concrete strength [20]. Agricultural waste is another example of producing better-performance concrete. Agricultural waste from bamboo, corn, wheat, olives, and seashells can be used. However, these waste materials must be produced by appropriate treatment methods [22,23]. Ore dust can be defined as the residue, tailings, or other worthless waste after the extraction and processing of rocks to form fine particles less than 4.75 mm. Mines’ dust is created during the blasting, crushing, and screening of coarse grains. Mine’s dust is rough, sharp, and angular particles, and because of these reasons [20,21,22]. It achieves more strength due to better interlocking. The use of sand substitute materials in construction works requires attention or their availability and practicality [24]. The use of mining dust sometimes increases the amount of cement required to maintain efficiency. Ore round concrete has better acid and sulfate resistance compared to normal concrete and its permeability is less. However, the water absorption of round ore concrete is slightly higher than that of ordinary concrete. Coarse and construction-recycled concrete is considered as materials produced from cleaned and stored concrete and masonry waste, usually for road construction applications [25]. These materials may contain a small amount of brick, gravel, crushed stone, or other forms of stone material as mixed materials. The use of green concrete also has disadvantages. High water absorption rate by green concrete. The amount of creep and shrinkage of green concrete is higher than normal concrete. Flexural strength in green concrete is lower than in normal concrete [20,21,22]. Structures built with green concrete usually have a shorter lifespan than structures built with concrete. Among the advantages of using green concrete, we can mention these things, the strength of green concrete is 30% higher compared to normal concrete, and the amount of cement used in its production is less. This type of concrete plays an important role in the life of the building and its resistance is very high [26]. Green concrete is produced with the aim of increasing the durability and strength of the building and is a new technology to protect the environment and avoid harming it [27]. One of the greenhouse gases that play an important role in global warming is carbon dioxide. Ordinary concrete produces a lot of this gas. But the process used in the production of green concrete minimizes the production of this gas. Green concrete has good quality and due to low energy consumption and the use of affordable methods, its purchase price is also suitable. The reasonable cost of this product makes its use in construction popular and has many fans as an ideal product. By using green concrete, the number of environmental pollutants can be minimized [18,19,20,21,22,23,24,25]. This material has a very high resistance to temperature changes and acid substances. Researchers have found that the compressive strength of this product is twice that of normal concrete. The use of green concrete in the construction industry is economically very affordable and due to its significant advantages, this material can be introduced as a sustainable and environmentally friendly material [10,11,12,13,14,15]. Green concrete is concrete with high strength, whose use in structural members reduces the consumption of concrete and rebar in reinforced concrete buildings. This concrete reduces the consumption of reinforcement by 20%. Green concrete requires little maintenance.

Table 1.

Alternative materials for green concrete.

Methodology for This Study

In recent years, researchers have witnessed the growing trend of the development of cities in most smart countries of the world, which is the result of the age of knowledge and technology. The world’s population has increased sixfold since the beginning of the industrial revolution. As a result of these developments, the increase in consumption and population has caused the loss of resources and increase in waste materials, and this has reduced the index of environmental qualities. In an era where people are facing an energy crisis and environmental pollution, sustainable development (SD) is one of the main goals and pillars to reach a world without environmental pollution and without destruction of natural resources [12,13,14,15,16,17,18,65]. Therefore, for instance concrete is the most widely used material after water in the construction industry. According to the global website of the phenomenon of greenhouse warming, almost 7% of the total amount of greenhouse gas emissions was related to the production of concrete cement. The production of cement in concrete is associated with high energy consumption, the release of a large amount of carbon dioxide and high-water consumption has harmful effects on the environment. The solution to these problems is the use of green concrete, which minimizes the environmental impact of the cement industry. The purpose of this article was to introduce green concrete as a way to achieve sustainable construction using new science and innovated technology. The method of this research was based on the purpose of an applied research and based on the nature of a descriptive-review research [65]. From the findings of the research, it is possible to understand the production and use of green concrete technology in line with the macro concepts of environmental protection. Researchers mentioned SD and the results of the research may be used in civil engineering, architecture, sustainable energy, energy management, and building green buildings. In order to collect information, the methods of documentary and library studies and through reliable sites have been used in relation to similar studies conducted in previous researches [59,60,61,62,63,64,65,66].

4. Result and Discussion

By taking advantage of new science, technologies and human resources for the development and innovation of transforming science into industrial infrastructure and service design in universities, various sciences such as civil engineering and green engineering can be used and applied. Among the things that can be used is the use of dissolvable and decaying materials in nature. These materials can be recycled materials that can be prepared by combining them together or prevent the creation of waste to improve the mechanical and chemical properties of products for use in green engineering [10,11,12]. Materials are classified as miscodifying concrete additives according to their physical activity in concrete with different five classes. Class A. Water-soluble natural and synthetic inorganic polymers that increase the viscosity of the mixing water. Class B. Mineral water-soluble substances that are absorbed on cement particles and increase viscosity with an increase in interparticle absorption. These materials are copolymer styrene with carboxyl groups, artificial polyelectrolytes and natural gums. Class C. Emulsions of various mineral materials that increase interparticle attraction which provide ultrafine grain nanoparticles in cement paste. These materials consist of acrylic emulsions and dispersed clay particles in the aqueous phase. Non-mineral materials with high surface area or unusual surface characteristics increase the water holding capacity of the mixture [28,29,30,31]. These materials include very soft clays (bentonites), exothermic silica, dense silica foam, ground asbestos, and other fibrous materials. Class E. Inorganic materials that provide additional fine particles in mortar pastes and therefore shake They increase thixotropy—the tendency of some jellies and emulsions to become watery due to shaking and harden again due to lack of movement, translator). These materials are diverse such as fly ash, hydrated lime, kaolin, siliceous soil and other raw or oxidized pozzolanic materials. Nanoparticles used in self-compacting concrete industry [32,65].

4.1. Carbon Nanotubes

Carbon nanotubes (CNTs) and carbon nanofibers (CNFs) are proposed as the main choice of nanotechnology to reinforce cements. The high elastic modulus and resistance of these nanomaterials have an excellent tensile strength, unique electrical and chemical features which show favorable ability to create a new generation of building materials. The use of these nanomaterials leads to the improve mechanical characteristics, resistance to the expansion of cracks, protection against electromagnetic waves, and the creation of self-healing capabilities in cement materials. Unlike nanotubes, carbon nanofibers are much easier to distribute in the cement mixture [41]. One of the main problems of these nanomaterials is the impossibility of their uniform distribution in the cement mixture due to their high hydrophobicity and high internal gravity of these nanomaterials. Another problem of these nanomaterials is the lack of proper adhesion between them and the cement paste [42]. In this research, it was found that in order to improve the performance of self-compacting concrete, the effect of adding industrial additives (steel industry waste, silica foam, basalt powder, limestone powder, ash, and marble powder) and various nanoparticles and nano oxides were studied [43,44,45,46,47,48,49].

4.2. Iron Oxide Nanoparticles

Researchers conducted a research on the addition of iron oxide nanoparticles on the properties of self-compacting concrete. They found that an increase in the weight percentage of iron oxide nanoparticles with 4 wt% can increases the compressive strength, cracking and twisting of self-compacting concrete [44,45,46,47,48]. They also found that these nanoparticles can act as fillers and increase the resistance of concrete against water penetration, which occurs for sample with 4 wt% iron oxide nanoparticles.

4.3. Titanium Nano Oxide

Research has proven that the use of titanium nanoparticles in addition to the self-cleaning property of concrete, increases the rate of hydration and reduces the setting time of concrete [44]. Also, the use of these nanoparticles increases the bending strength and compressive strength of concrete. As it is known, by adding titanium oxide nanoparticles, the microstructure of concrete is improved and the internal voids of concrete are smaller. This improves mechanical properties. and durability of concrete. To improve the mechanical properties and increase the durability of concrete, the use of microsilica is increasing in developed countries [43]. The use of microsilica in concrete has many benefits, including: reducing cracks caused by cement hydration, better durability against sulfate attack, acid rain, and achieving high resistance. Another advantage of using microsilica is reducing the mobility of chlorine ions and thus reducing the depth of chlorine penetration in concrete, especially in coastal areas. It can be used in concreting related to the construction of sea piers, piles, columns and prefabricated parts, foundations. Machines and all concrete structures that are exposed to chemical attacks, especially chlorine ions and sulfates. The addition of nano silica to concrete increases the compressive, tensile and bending resistances, reduces the setting time of concrete and reduces the permeability of water inside the concrete and also increases the resistance of concrete against the attacks of chemical agents [46]. Concrete reduces its hydration time and increases the peak temperature of hydration. There are two possible mechanical reactions during the hydration of concrete in the presence of nanosilica particles. Cement hydration can be accelerated in the presence of nanosilica particles. When nanosilica is added to cement particles, it forms and starts to react with the existing Ca2+, which causes the production of additional calcium-silicate-hydrate (C-S-H). Then these created C-S-H particles in water are spread between cement particles and play the role of a source to create C-S-H compact phase. The formation of C-S-H phase helps to fill the pores of concrete. The formation of a large number of these particles accelerates the hydration time of concrete [45,46,47]. By adding 10% of nano silica, the compressive strength of concrete increases by 26%, but by adding the same amount of micron silica, the compressive strength of concrete increases by 30%. Nano silica in a very small amount equal to 0.25%, the compressive strength increases by 10% and the bending strength by 25%.

4.4. Nano Aluminum Oxide

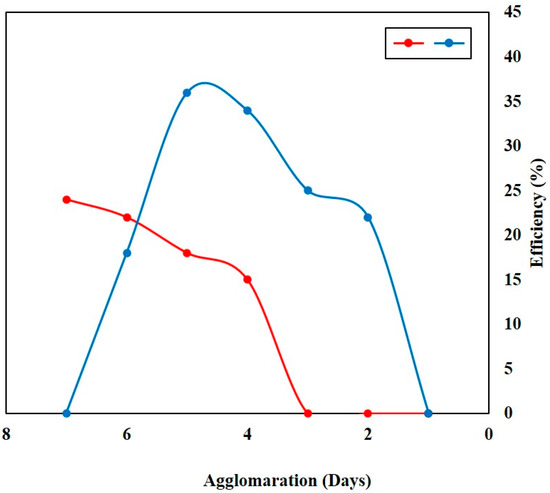

Addition of aluminum nanoparticles to the concrete mixture significantly increases the elastic modulus of concrete. Experience has proven that addition of 5 wt% nano aluminum oxide, increases the elastic modulus of concrete by 143%. However, it does not have a significant effect on the strength of concrete. Researchers studied the effect of adding aluminum oxide nanoparticles on concrete hydration and observed that addition of these particles reduces the released heat and accelerates the time peak of this heat release [62,63,64,65,66]. Therefore, addition of 3 wt% of aluminum nanoparticles to concrete, the amount of released heat may decrease the most. Researchers studied the effect of workability of concrete modified with aluminum nanoparticles for 0.5, 1.0, 1.5 and 2 wt% and the results indicated that increasing the amount of aluminum nanoparticles decreases the workability of the concrete. As it is clear from the Figure 1 and Figure 2, the use of the minimum standard amount of water slightly reduces the workability of concrete [42,43,44,45,46,47,67,68,69].

Figure 1.

Rate of agglomeration versus the efficiency in the PVC-CNT.

Figure 2.

Deformation versus mechanical properties of samples.

4.5. Nano Clays

The use of nanoclay particles enhances the behavior of concrete such as creating self-compacting concrete, increasing compressive strength, reducing permeability, resistance to chloride penetration, and reducing shrinkage in concrete [45].

4.6. Concrete Additives for Special Concretes

To produce colloidal non-dispersible concrete under water, the minimum ratio of water to cement should be in the range of 0.36 to 0.6, and the amount of cement and fine grains is usually higher than the corresponding mixtures on the ground. Often the hardness of the mix proportions is adjusted to achieve the desired design parameters for all concrete properties. As a result, the underwater properties of colloidal concrete are controlled by the addition of three chemical additives. For example, silica foam can be used in conjunction with an AWA and a super-lubricant to reduce separation.

5. Theoretical Analysis

As mentioned before, in this study, three different types of samples have been made. Then, the prepared samples have been examined to find their specifications related to their specifications. Some parameters like mechanical properties, the day of destroy, agglomeration, and their efficiencies have been examined afterward. The results are shown in Table 2.

Table 2.

Alternative materials for green concrete.

In this table, it is seen that, for instance, by increasing the mechanical properties, the efficiency is not increased necessarily; or there is not a clear relation between agglomeration and efficiencies. Therefore, to find an optimum sample, containing the best properties of what has been considered in this study, the well-known technique of global criterion methods has been used. This method, which is known as GCM, tries to minimize the difference between the objective function value of each parameter, and its optimum value, in total [48,49,50]. Equation (1) shows the GCM formula.

There are some parameters in Equation (1) such as , and that are related to the input value, objective function number, the value of the objective function, the value of the equation that should be minimized, and an integer, which increasing it from one to a higher number, increases the difference between the obtained objective function values and their optimal amounts. In the literature, the is considered a number among 2 to 4, which is considered equal to three in this study [51,52,53,54].

The main and key point about non-collapsed concrete with self-leveling characteristics is the successful optimization of AWA with concrete additives such as superplasticizer used to increase slump. Support agents react with the polymer in AWA to increase the apparent molecular weight of the polymer, thereby improving the cohesive properties of the polymer can increase the scour resistance of cement with AWA. These factors also make possible a 0.8% reduction in weight, without having an adverse effect on resistance (Table 3).

Table 3.

Test results for concrete containing polymer and glutaraldehyde reducing agent.

All of the single objective functions, one function for each parameter, make a multi-objective function problem in total. Using Equation (1), the multi-objective problem is converted to a single-objective function again. This function is coded in the CPLEX application and the optimal answer is found by the branch and bound method [55,56,57,58]. It is mentioned that using average of the data, each sample will be an input for the problem. After solving the provided problem, in the first step, the following functions, Equations (2)–(5) are found for each parameter, respectively.

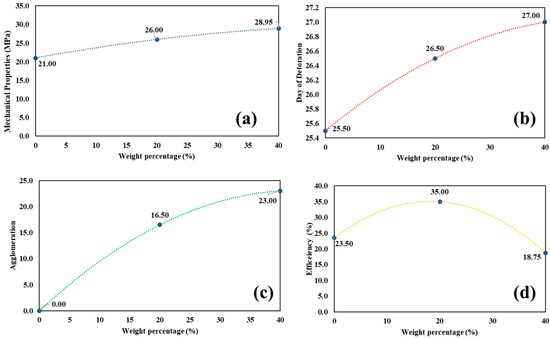

In Equations (2)–(5), is the percentage of the sample, such as 0, 20 and 40 percent, and to are the objective functions for each parameter, respectively. Figure 3a–d depicts the plotted function, given by Equations (2)–(4), respectively. It is mentioned that the value of the squared error for each of the function is equal to one, which shows the complete conformity. The least value obtained for Equation (1) is 0.135 for the sample with 28.5%. For such a sample, the mechanical properties, the day of destroy, agglomeration, and the efficiency will be 27.5, 26.8, 20.5, and 31.5, respectively.

Figure 3.

The curves of the (a) mechanical properties, (b) day of destroy, (c) agglomeration, and (d) efficiency, based on the weigh percentage variations of the samples.

Figure 3a–c, similarly present fast increases in the outputs, by increasing the input at first, and afterward, the increment will be continued but with lower increments. Opposite to the other graphs, shown in Figure 3, Figure 3d illustrates an increment at first and a drop immediately thereafter. First, the efficiency starts with 23.5% and increases to 35%. However, after increasing the weight percentage of the sample, in drops to 18.75%, which is less than the value of the starting point.

6. Conclusions

In recent years, attention to environmental issues, the approach to the technology of recycling waste materials, and their reuse in developed countries have received a huge investment. One of the methods of using waste materials is to use them in concrete and other building materials. In this research, after reviewing the effect of PVC and PVC-CNT, it was found that these materials might increase the strength of mechanical properties of green concrete. In this regard, green concrete technology is one of the basic steps that the construction industry can provide to achieve sustainable construction with the aforementioned various resources. Green concrete technology can save natural materials for the use of future generations to preserve and deliver them for a good time. The raw materials can end and therefore the price of the materials may increase. The countries with higher education institutions have conducted practical research and development in the shadow of the country’s economy to use new technology combined with conventional industries. Meanwhile, major efforts were made to strengthen the economic structure and basic research. Besides, higher education institutions are building science parks and implementing high-tech projects jointly with industry. The number of students in colleges and universities has sharply decreased, and many new regular universities are facing the problem of enrollment. As most of the newly-built regular colleges are ordinary colleges with short running times, insufficient teachers, low popularity, and poor education quality. Establishing an information service system consisting of the World Wide Web, databases, and digital libraries in the country’s universities were emphasized. With waste materials as an alternative approach, one can help to reduce environmental problems and preserve naturally occurring materials for future generations. Green concrete has a reduced environmental impact with a 30% reduction in CO2 emissions from the concrete industry. Concrete waste such as slag, recycled concrete, fly ash, aluminum can string, power plant waste, waste glass, red mud, burnt clay, sawdust, combustion ash, and foundry sand are ingredients of green concrete. However, concrete as a green product produced today reduces environmental damage and solves the problem of lack of aggregate.

Author Contributions

Methodology, X.D.; Investigation, S.Q. and X.D.; Data curation, A.S.K. and S.A.; Funding acquisition, S.Q. and A.S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not available.

Informed Consent Statement

Not available.

Data Availability Statement

Not available.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liew, K.; Sojobi, A.; Zhang, L. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- Sivakrishna, A.; Adesina, A.; Awoyera, P.; Kumar, K.R. Green concrete: A review of recent developments. Mater. Today Proc. 2019, 27, 54–58. [Google Scholar] [CrossRef]

- Suhendro, B. Toward Green Concrete for Better Sustainable Environment. Procedia Eng. 2014, 95, 305–320. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green Concrete: By-Products Utilization and Advanced Approaches. Sustainability 2019, 11, 5145. [Google Scholar] [CrossRef]

- Obla Karthik, H. What is green concrete? Indian Concr. J. 2009, 24, 26–28. [Google Scholar]

- Błaszczyński, T.; Król, M. Usage of Green Concrete Technology in Civil Engineering. Procedia Eng. 2015, 122, 296–301. [Google Scholar] [CrossRef]

- Mette, G.; Munch-Petersen, C. Green’concrete in Denmark. Struct. Concr. 2000, 1, 19–25. [Google Scholar]

- Chirag, G.; Jain, A. Green concrete: Efficient & eco-friendly construction materials. Int. J. Res. Eng. Technol. 2014, 2, 259–264. [Google Scholar]

- Sellami, A.; Merzoud, M.; Amziane, S. Improvement of mechanical properties of green concrete by treatment of the vegetals fibers. Constr. Build. Mater. 2013, 47, 1117–1124. [Google Scholar] [CrossRef]

- Ostrom, A.L.; Bitner, M.J.; Brown, S.W.; Burkhard, K.A.; Goul, M.; Smith-Daniels, V.; Demirkan, H.; Rabinovich, E. Moving Forward and Making a Difference: Research Priorities for the Science of Service. J. Serv. Res. 2010, 13, 4–36. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Uthaman, S. Environmental Impact of Sustainable Green Concrete. In Smart Nanoconcretes and Cement-Based Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 241–255. [Google Scholar] [CrossRef]

- Nielsen, C.V.; Glavind, M. Danish Experiences with a Decade of Green Concrete. J. Adv. Concr. Technol. 2007, 5, 3–12. [Google Scholar] [CrossRef]

- Golewski, G.L. Green concrete composite incorporating fly ash with high strength and fracture toughness. J. Clean. Prod. 2018, 172, 218–226. [Google Scholar] [CrossRef]

- Panesar, D.K.; Seto, K.E.; Churchill, C.J. Impact of the selection of functional unit on the life cycle assessment of green concrete. Int. J. Life Cycle Assess. 2017, 22, 1969–1986. [Google Scholar] [CrossRef]

- Zhang, L.V.; Nehdi, M.L.; Suleiman, A.R.; Allaf, M.M.; Gan, M.; Marani, A.; Tuyand, M. Crack self-healing in bio-green concrete. Compos. Part B Eng. 2021, 227, 109397. [Google Scholar] [CrossRef]

- Petek, G.A.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar]

- Zeyad, A.M.; Johari, M.A.M.; Alharbi, Y.R.; Abadel, A.A.; Amran, Y.M.; Tayeh, B.A.; Abutaleb, A. Influence of steam curing regimes on the properties of ultrafine POFA-based high-strength green concrete. J. Build. Eng. 2021, 38, 102204. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Ferrara, L.; Martinelli, E. Recent Advances on Green Concrete for Structural Purposes; The Contribution of the Eu-fp7 Project Encore; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Alani, A.H.; Bunnori, N.M.; Noaman, A.T.; Majid, T. Durability performance of a novel ultra-high-performance PET green concrete (UHPPGC). Constr. Build. Mater. 2019, 209, 395–405. [Google Scholar] [CrossRef]

- Golewski, G. Green Concrete Based on Quaternary Binders with Significant Reduced of CO2 Emissions. Energies 2021, 14, 4558. [Google Scholar] [CrossRef]

- Manjunatha, M.; Seth, D.; Kvgd, B. Engineering properties and environmental impact assessment of green concrete prepared with PVC waste powder: A step towards sustainable approach. Case Stud. Constr. Mater. 2022, 17, e01404. [Google Scholar] [CrossRef]

- Vikram, K.; Gangurde, A.; Pawar, A. Green concrete using plastic waste. Int. J. Eng. Trends Technol. 2015, 19, 214–216. [Google Scholar]

- Manjunatha, M.; Seth, D.; Kvgd, B.; Srilakshmi, C. Influence of PVC waste powder and silica fume on strength and microstructure properties of concrete: An experimental study. Case Stud. Constr. Mater. 2021, 15, e00610. [Google Scholar]

- Manjunatha, M.; Seth, D.; Balaji, K. Role of engineered fibers on fresh and mechanical properties of concrete prepared with GGBS and PVC waste powder—An experimental study. Mater. Today Proc. 2021, 47, 3683–3693. [Google Scholar] [CrossRef]

- Sangtani, H.; Jain, B.; Shenoy, K.N. Replacement of Sand by PVC Pipe Waste in Pavement Blocks. Int. J. Emerg. Res. Manag. Technol. 2018, 6, 282–285. [Google Scholar] [CrossRef]

- Jaksland, C.; Rasmussen, E.; Rohde, T. A new technology for treatment of PVC waste. Waste Manag. 2000, 20, 463–467. [Google Scholar] [CrossRef]

- Keane, M.A. Catalytic conversion of waste plastics: Focus on waste PVC. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2007, 82, 787–795. [Google Scholar] [CrossRef]

- Kim, S. Pyrolysis kinetics of waste PVC pipe. Waste Manag. 2001, 21, 609–616. [Google Scholar] [CrossRef]

- Braun, D. Recycling of PVC. Prog. Polym. Sci. 2002, 27, 2171–2195. [Google Scholar] [CrossRef]

- Jurate, M.-P.; Fråne, A.; Almasi, A.M. Overview of polyvinyl chloride (PVC) waste management practices in the Nordic countries. Clean. Eng. Technol. 2021, 4, 100246. [Google Scholar]

- Gao, L. Cultural context of school science teaching and learning in the People’s Republic of China. Sci. Educ. 1998, 82, 1–13. [Google Scholar] [CrossRef]

- La Mantia, F.P. Recycling of PVC and Mixed Plastic Waste; ChemTec Publishing: Scarborough, ON, Canada, 1996. [Google Scholar]

- Correa, C.A.; de Santi, C.R.; Leclerc, A. Green-PVC with full recycled industrial waste and renewably sourced content. J. Clean. Prod. 2019, 229, 1397–1411. [Google Scholar] [CrossRef]

- Suresh, S.S.; Mohanty, S.; Nayak, S.K. Composition analysis and characterization of waste polyvinyl chloride (PVC) recovered from data cables. Waste Manag. 2017, 60, 100–111. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Ma, X. A new approach to transforming PVC waste into energy via combined hydrothermal carbonization and fast pyrolysis. Energy 2017, 141, 1156–1165. [Google Scholar] [CrossRef]

- Owen, J. (Ed.) Degradation and Stabilisation of PVC; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Caraculacu, A.A.; Bezdadea, E.C.; Istrate, G. Structure of Branching in PVC. J. Polym. Sci. Part A-1 Polym. Chem. 1970, 8, 1239–1246. [Google Scholar] [CrossRef]

- Elashmawi, I.; Hakeem, N.; Marei, L.; Hanna, F. Structure and performance of ZnO/PVC nanocomposites. Phys. B Condens. Matter 2010, 405, 4163–4169. [Google Scholar] [CrossRef]

- Titow, M.V. PVC Technology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Lai, H.; Wang, Z.; Wu, P.; Chaudhary, B.I.; Sengupta, S.S.; Cogen, J.M.; Li, B. Structure and Diffusion Behavior of Trioctyl Trimellitate (TOTM) in PVC Film Studied by ATR-IR Spectroscopy. Ind. Eng. Chem. Res. 2012, 51, 9365–9375. [Google Scholar] [CrossRef]

- Sarde, B.; Patil, Y. Recent Research Status on Polymer Composite Used in Concrete-An Overview. Mater. Today Proc. 2019, 18, 3780–3790. [Google Scholar] [CrossRef]

- Mechtcherine, V. Use of superabsorbent polymers (SAP) as concrete additive. RILEM Tech. Lett. 2016, 1, 81–87. [Google Scholar] [CrossRef]

- Mönnig, S.; Lura, P. Superabsorbent Polymers—An Additive to Increase the Freeze-Thaw Resistance of High Strength Concrete. In Advances in Construction Materials; Springer: Berlin/Heidelberg, Germany, 2007; pp. 351–358. [Google Scholar] [CrossRef]

- Son, S.-W.; Yeon, J.H. Mechanical properties of acrylic polymer concrete containing methacrylic acid as an additive. Constr. Build. Mater. 2012, 37, 669–679. [Google Scholar] [CrossRef]

- Vaganov, V.; Popov, M.; Korjakins, A.; Šahmenko, G. Effect of CNT on Microstructure and Minearological Composition of Lightweight Concrete with Granulated Foam Glass. Procedia Eng. 2017, 172, 1204–1211. [Google Scholar] [CrossRef]

- Gao, Y.; Jing, H.; Zhou, Z.; Shi, X.; Li, L.; Fu, G. Roles of carbon nanotubes in reinforcing the interfacial transition zone and impermeability of concrete under different water-to-cement ratios. Constr. Build. Mater. 2020, 272, 121664. [Google Scholar] [CrossRef]

- Singh, N.; Kalra, M.; Saxena, S. Nanoscience of Cement and Concrete. Mater. Today Proc. 2017, 4, 5478–5487. [Google Scholar] [CrossRef]

- Mosallaeipour, S.; Nejad, M.G.; Shavarani, S.M.; Nazerian, R. Mobile robot scheduling for cycle time optimization in flow-shop cells, a case study. Prod. Eng. 2018, 12, 83–94. [Google Scholar] [CrossRef]

- Nejad, M.G.; Güden, H.; Vizvári, B. Time minimization in flexible robotic cells considering intermediate input buffers: A comparative study of three well-known problems. Int. J. Comput. Integr. Manuf. 2019, 32, 809–819. [Google Scholar] [CrossRef]

- Ghadirinejad, N.; Nejad, M.G.; Alsaadi, N. A fuzzy logic model and a neuro-fuzzy system development on supercritical CO2 regeneration of Ni/Al2O3 catalysts. J. CO2 Util. 2021, 54, 101706. [Google Scholar] [CrossRef]

- Nejad, M.G.; Kashan, A.H. An Effective Grouping Evolution Strategy Algorithm Enhanced with Heuristic Methods for Assembly Line Balancing Problem. J. Adv. Manuf. Syst. 2019, 18, 487–509. [Google Scholar] [CrossRef]

- Ghasemi, M.; Nejad, M.G.; Alsaadi, N.; Abdel-Jaber, M.; Ab Yajid, M.S.; Habib, M. Performance Measurment and Lead-Time Reduction in EPC Project-Based Organizations: A Mathematical Modeling Approach. Math. Probl. Eng. 2022, 5767356. [Google Scholar] [CrossRef]

- Mosallaeipour, S.; Nazerian, R.; Ghadirinejad, M. A Two-Phase Optimization Approach for Reducing the Size of the Cutting Problem in the Box-Production Industry: A Case Study. In Industrial Engineering in the Industry 4.0 Era; Springer: Cham, Switzerland, 2017; pp. 63–81. [Google Scholar] [CrossRef]

- Golabi, M.; Nejad, M.G. Intelligent and Fuzzy UAV Transportation Applications in Aviation 4.0. In Intelligent and Fuzzy Techniques in Aviation 4.0; Springer: Cham, Switzerland, 2021; pp. 431–458. [Google Scholar] [CrossRef]

- Davani, P.P.; Kloub, A.W.M.; Nejad, M.G. Optimizing the first type of U-shaped assembly line balancing problems. Ann. Optim. Theory Pract. 2020, 3, 65–82. [Google Scholar] [CrossRef]

- Vizvari, B.; Guden, H.; Nejad, M.G. Local search based meta-heuristic algorithms for optimizing the cyclic flexible manufacturing cell problem. Ann. Optim. Theory Pract. 2018, 1, 15–32. [Google Scholar] [CrossRef]

- Nejad, M.G.; Banar, M. Emergency response time minimization by incorporating ground and aerial transportation. Ann. Optim. Theory Pract. 2018, 1, 43–57. [Google Scholar] [CrossRef]

- Mirzaei, N.; Nejad, M.G.; Fernandes, N.O. Combining Line Balancing Methods and Discrete Event Simulation: A Case Study from a Metalworking Company. Int. J. Ind. Eng. Manag. 2021, 12, 14. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M.; Moshtagh, A. On the post-heat performance of cement mortar containing silica fume or Granulated Blast- Furnace Slag. J. Build. Eng. 2019, 24, 100757. [Google Scholar] [CrossRef]

- Seddighi, F.; Pachideh, G.; Salimbahrami, S.B. A study of mechanical and microstructures properties of autoclaved aerated concrete containing nano-graphene. J. Build. Eng. 2021, 43, 103106. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M. An experimental investigation into effect of temperature rise on mechanical and visual characteristics of concrete containing recycled metal spring. Struct. Concr. 2020, 22, 550–565. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M. Assessment of post-heat behavior of cement mortar incorporating silica fume and granulated blast-furnace slag. J. Struct. Fire Eng. 2020, 11, 221–246. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M. An Experimental Study on the Effects of Adding Steel and Polypropylene Fibers to Concrete on Its Resistance after Different Temperatures. J. Test. Eval. 2018, 47, 20170145. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Qin, S.; Duan, X.; Al-Hourani, A.F.; Alsaadi, N. Evaluation of Total Quality Management in Turkish Pharmaceutical Companies: A Case Study. Sustainability 2022, 14, 10181. [Google Scholar] [CrossRef]

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132. [Google Scholar] [CrossRef]

- Behfarnia, K.; Salemi, N. The effects of nano-silica and nano-alumina on frost resistance of normal concrete. Constr. Build. Mater. 2013, 48, 580–584. [Google Scholar] [CrossRef]

- Shokravi, H.; Mohammadyan-Yasouj, S.; Koloor, S.; Petrů, M.; Heidarrezaei, M. Effect of Alumina Additives on Mechanical and Fresh Properties of Self-Compacting Concrete: A Review. Processes 2021, 9, 554. [Google Scholar] [CrossRef]

- Jaishankar, P.; Karthikeyan, C. Characteristics of Cement Concrete with Nano Alumina Particles. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristok, UK, 2017; p. 80. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).