2. Literature Review

Many published studies focus on the assessment of sustainability for manufacturing and service organizations. A machining process for sustainability in Indian small-scale industries was evaluated by Agrawal, Chaganti, and Nune in 2020 [

5]. They used multiple attributes decision-making methods such as technique for order of preference by similarity to an ideal solution and analytical hierarchy process. The obtained results are compared with each other, and areas of concern for sustainability are identified from the perspective of waste minimization. There are many limitations to their research. First, they’re chosen small-scale industries belong to the same area and may reflect the machining trends of that specific area. Second, they considered attributes and assigned weights that were influenced by the decision maker’s personal view and the understanding of the author, whereas Parmar and Desai [

6] evaluated sustainable lean six sigma enablers using the fuzzy decision-making trial and evaluation laboratory technique. They used a causal diagram to establish and evaluate relationships between cause-and-effect enablers. Pourvaziry et al. [reference number] evaluated the dimensions and criteria affecting the sustainable world class manufacturing model. The fuzzy decision-making trial and evaluation laboratory technique and analytic network process were chosen by them for the evaluation for Iran’s automotive industry. Thakur and Vikas [

7] identified factors under political, economic, social, technological, environmental, and legal dimensions of sustainable healthcare waste management. They classified the factors of sustainable healthcare waste management into four groups: autonomous, dependent, linkage, and independent groups using integrated total interpretive structural modeling and Fuzzy-cross-impact matrix multiplication analysis. The limitation of their study is that only the qualitative inputs were considered to represent the sustainability dimensions [

7].

Similarly, Ying Wang and Yun Yang [

8] examined green innovation practices in the Chinese manufacturing industry using sustainability performance indicators. They proposed a hybrid multi-criteria decision making model by combining the fuzzy analytical hierarchy process and fuzzy technique for order of preference by similarity to ideal solution to analyze the effects of green innovation aspects on the sustainability performance of the manufacturing industry. Their research identified several important green innovation aspects; and these were analyzed and ranked for the development of sustainable manufacturing processes and productions in the industry. Moreover, the research considered sustainability performance indicators to analyze and transform the industry’s practices. The analysis of the study showed that an industry excels in green innovation and can achieve a higher level on a sustainability performance basis. This research has several limitations as this study focuses on the garment manufacturing industry in China. It could be generalized to other garment manufacturing industries in Asia or developing countries. Moreover, only six green innovation aspects were taken into account to analyze the decision problem [

8], whereas Agrawal and Vinodh [

9] derived a conceptual model for sustainability evaluation of additive manufacturing processes using a grey-based approach. They assessed the sustainability index of additive manufacturing processes. Indeed, the grey-based approach used for evaluation was a good tool to solve uncertainty problems when there was insufficient information about the problem. They used the Euclidean distance approach to check the level of sustainability of advance manufacturing processes [

9].

Krajnc et al. [

10] presented a model for designing a sustainable index that represents the performance of companies using the three dimensions of sustainability: economic, environmental, and societal. The authors provided good guidance for decision making regarding the performance of companies along with all three aspects of sustainability through the design and analysis of a composite sustainable development index. However, the limitation in this study was the selection of criteria, considering the availability of reliable data. Since different criteria in the index for different organizations would prevent decision makers from comparing organizations in the same sector, it is required to determine how and who will select the indicators [

10]. On the other hand, Ibrahim Garbie [

11] presented full analytical and quantitative models and conferred the value of performance metrics ranging from individual indicators to the overall sustainable development index in order to achieve an optimal point for noticing the impact of them on others. Ibrahim Garbie [

11] created a sustainable development index for manufacturing enterprises by analyzing the dimensions of sustainability. Singh, Olugu, and Musa [

12] proposed a fuzzy rule-based expert system for sustainable manufacturing performance assessment in small and medium enterprises in Malaysia. Their model is to deal with the subjectivity involved in the performance evaluation of manufacturing small and medium enterprises [

12].

Trianni, Cagno, Neri, and Howard [

13] measured the industrial sustainability performance of manufacturing firms. They conducted multiple case analyses of 26 small and medium manufacturing enterprises across Germany and Italy operating in the chemical and metalworking sectors. They suggested factors influence the firms’ perspective on sustainability and the way it is managed, as well as the certifications held by firms, which influence the considered indicators. The findings provide further confirmation that some aspects of measuring sustainability are still missing in the EU manufacturing sector. In particular, they face difficulties in properly gauging sustainability performance. Ziout, Azab, Altarazi, and ElMaraghy [

14] developed a multi-criteria decision approach to assess the benefits of reusing a manufacturing system in a developing country from a sustainability point of view. Because developing countries have low labor and energy costs, reuse of manufacturing systems is more sustainable. They conducted a survey that showed economic sustainability is the main focus of decision makers in these regions, while the environment has the least significance. These findings should be considered a warning signal to promote environmental sustainability. They applied their model to a case study of a single screw extruder pelletizer [

14].

Kusi-Sarpong, Gupta, and Sarkis [

15] developed a framework and evaluation methodology for sustainable innovation advancement in the manufacturing sector and its supply chains. They investigated sustainable factors for the manufacturing industry and its associated supply chain innovation practices. The model of best–worst multi-criteria decision making was used as an assessment approach in their study. However, their study involved only the automobile, plastic, and electrical and electronics manufacturing sectors; therefore, it is difficult to generalize the results for one particular sector, whereas, Caldera, Desha, and Dawes [

16] used meta-conceptualization to assess the sustainability enablers and barriers of SMEs in Australia. Similarly, Cai and Lai [

17] presented a sustainability benchmark assessment approach related to mechanical manufacturing systems that helps improve the sustainability of manufacturing sectors and provides technical support for designing sustainable policies. The method is being tested at a small mechanical manufacturing company in China. A sustainability performance measurement model is presented by Rayhan Sharker et al. [

18] which integrates the fuzzy multiple-criteria decision-making approach and the balanced scorecard. Saad et al. [

19] presented a multi-dimensional sustainability assessment model to evaluate welding processes in the manufacturing sector. They used grey relation analysis and the complex proportional assessment method.

Thus, researchers presented a number of studies on sustainability assessment that focused on individual organizations’ performance. These studies proposed diverse sustainability indicators, which are measured in different units. One of the issues of these studies is the combination of different indicators and the difficulty of making comparisons among organizations based on a large number of performance measurements and difficulty in not allowing the organization to conduct the benchmarking. Thus, to establish a baseline for any organization’s sustainable performance and to conduct competitive benchmarking as a critical competitive factor, a sustainability index works as an important management and governance tool. To address this, the adopted research methodology to identify the sustainability dimensions and barriers, and the application of the fuzzy sustainability evaluation approach to the Saudi manufacturing organizations are presented in the subsequent sections.

4. Case Study: An Illustrative Example

The fuzzy sustainability evaluation approach was employed to measure the sustainability index of one of the manufacturing organizations in Saudi Arabia as per Steps 1 to 7. This organization is referred to as “XYZ” since its management did not consent to us revealing its identity.

To assign the performance ratings and importance weights of sustainability indicators, subject matter experts must use linguistic terms, which can be found in

Table 3 [

40]. It is unrealistic for evaluators to determine the score of an ambiguous criterion [

39]; consequently, in this research, linguistic terms were used to judge the performance ratings and importance weights of sustainability sub-criteria. The performance rating can be defined as a score or measurement of how well or successfully an organization meets particular criteria or sub-criteria [

41]. The linguistic terms and their fuzzy numbers were obtained from a previous study [

40] as per

Table 3.

In order to measure the performance ratings and importance weights, a survey was distributed to eight experts from the organization “XYZ”. Experts replied to a survey by linguistic terms which then change to its equivalent fuzzy numbers. Then, fuzzy arithmetic procedures were implemented to turn these fuzzy numbers into its equivalent fuzzy number named the Saudi manufacturing fuzzy sustainability index (SMFSI) [

42]. Responses collected from the experts of the organization “XYZ” are presented in

Table 4,

Table 5 and

Table 6.

Table 4 presents responses from eight experts in the Saudi manufacturing organization about each sub-criteria affecting the XYZ Saudi manufacturing organization. Both performance ratings (R

ijk) and importance weights (W

ijk) are collected from each expert. In

Table 4, for example, Expert 1 responded to the survey that sub-criteria material productivity SC1 has a very good (VG) performance rating and assign a very high (VH) importance weight for SC1, whereas

Table 5 highlights responses from eight experts in the XYZ organization about each of the criteria affecting the sustainability of the organization. Importance weights (W

ij) were collected from each expert for each criteria. Thus, in

Table 5, for example, Expert 1 responded that material criterion C1 has a high (H) importance weight while Expert 2 believed it to be very high (VH). Similarly, the above

Table 6 depicts responses from eight experts in the Saudi manufacturing organization about each of the sustainability dimensions that influence the sustainability index of the organization. In

Table 6, for example, Expert 1 responded that environmental dimension (D1) has a very high level of importance weight, while Expert 2 believes the environmental dimension (D1) has a high level of importance weight.

The linguistic terms for performance ratings and importance weights were approximated with fuzzy numbers as tabulated in

Table 3, which then had to be aggregated. Various methods can be used to combine the evaluations of various inputs, such as calculating arithmetic mean, median, and mode. In this study, the experts’ opinions were combined by using the arithmetic mean method. The average importance weights and performance ratings of sub-criteria were represented by R

ijk and W

ijk, respectively. The following Equations (1) and (2) [

42,

43] were used to compute the R

ijk and W

ijk values.

In the above Equations (1) and (2),

is overall performance rating for given sub-criteria k of criteria j for given sustainability dimension i.

is overall importance weight for given sub-criteria k of criteria j for given sustainability dimension i.

is performance rating by expert e for sustainability sub-criteria k of criteria j for given to sustainability dimension i.

is importance weight assigned by expert e for sustainability sub-criteria k of criteria j for given sustainability dimension i.

e is expert number ‘t’ from 1 to 8 in our case study.

For,

refer to above

Table 4.

is triangular fuzzy number representing performance rating by expert e for sustainability sub-criteria k of criteria j for given sustainability dimension i.

is importance weight assigned by expert e for sustainability sub-criteria k of criteria j for given sustainability dimension i.

is triangular fuzzy number representing performance rating of sub-criteria k for criteria j with respect to sustainability dimension i.

is triangular fuzzy number representing average importance weight of sub-criteria k for criteria j with respect to sustainability dimension i.

Similarly, an importance weight and corresponding triangular fuzzy number for sustainability criteria j for the given sustainability dimension i was calculated by using Equation (3), whereas an importance weight and corresponding triangular fuzzy number to sustainability dimension i was calculated by using Equation (4), respectively.

In the above Equations (3) and (4),

is importance weight assigned by expert e for sustainability criteria j for the given sustainability dimension i, and is corresponding triangular fuzzy number

is importance weight assigned by expert e to sustainability dimension i and is corresponding triangular fuzzy number

is importance weight of sustainability criteria j for given sustainability dimension i and is corresponding triangular fuzzy number.

is importance weight of sustainability dimension i and is corresponding triangular fuzzy number.

e is expert number ‘t’ from 1 to 8 in our case study. For sustainability dimension, sustainability criteria and sub-criteria refer to

Table 2, and for assigning triangular fuzzy numbers, refer to

Table 3.

As an example, for the case organization, the computation of fuzzy performance rating and importance weight for environmental dimension (i = 1), sustainability criteria energy (j = 2), and sub-criteria energy consumption (k = 4), are presented below. The fuzzy performance rating (R

124) and fuzzy importance weight (W

124) for all experts’ responses to sub-criteria energy consumption were calculated using information from

Table 4 and Equations (1) and (2), and is as presented below:

Similarly, fuzzy importance weight W

12 for environmental dimension (i = 1), sustainability criteria energy (j = 2) is calculated using Equation (3) and information in

Table 5 as below:

The calculated performance ratings and importance weights for all sub-criteria (k = 3, 4, and 5) with respect to sustainability criteria energy (j = 2), and triangular fuzzy importance weight W

12 for environmental dimension (i = 1) and sustainability criteria energy (j = 2) are presented in

Table 7.

In

Table 7, the importance weight for the sustainability criterion “energy” is (0.45, 0.65, 0.85), which falls into the high importance weight level 4 as per linguistic terms according to the fuzzy numbers (refer to

Table 3). The sustainability sub-criterion “renewable energy” had a performance rating of (0.5, 0.7, 0.9), which can be interpreted as meaning that the organization is using a very good percentage of renewable energy in their total energy mix. At the same time, both sub-criteria energy consumption and energy efficiency scored highly in the performance rating, which means XYZ needs to reduce its energy consumption compared to previous years. The company should also look at ways to reduce the quantity of energy needed per unit output to increase their energy efficiency and thus improve the “energy” sustainability criteria.

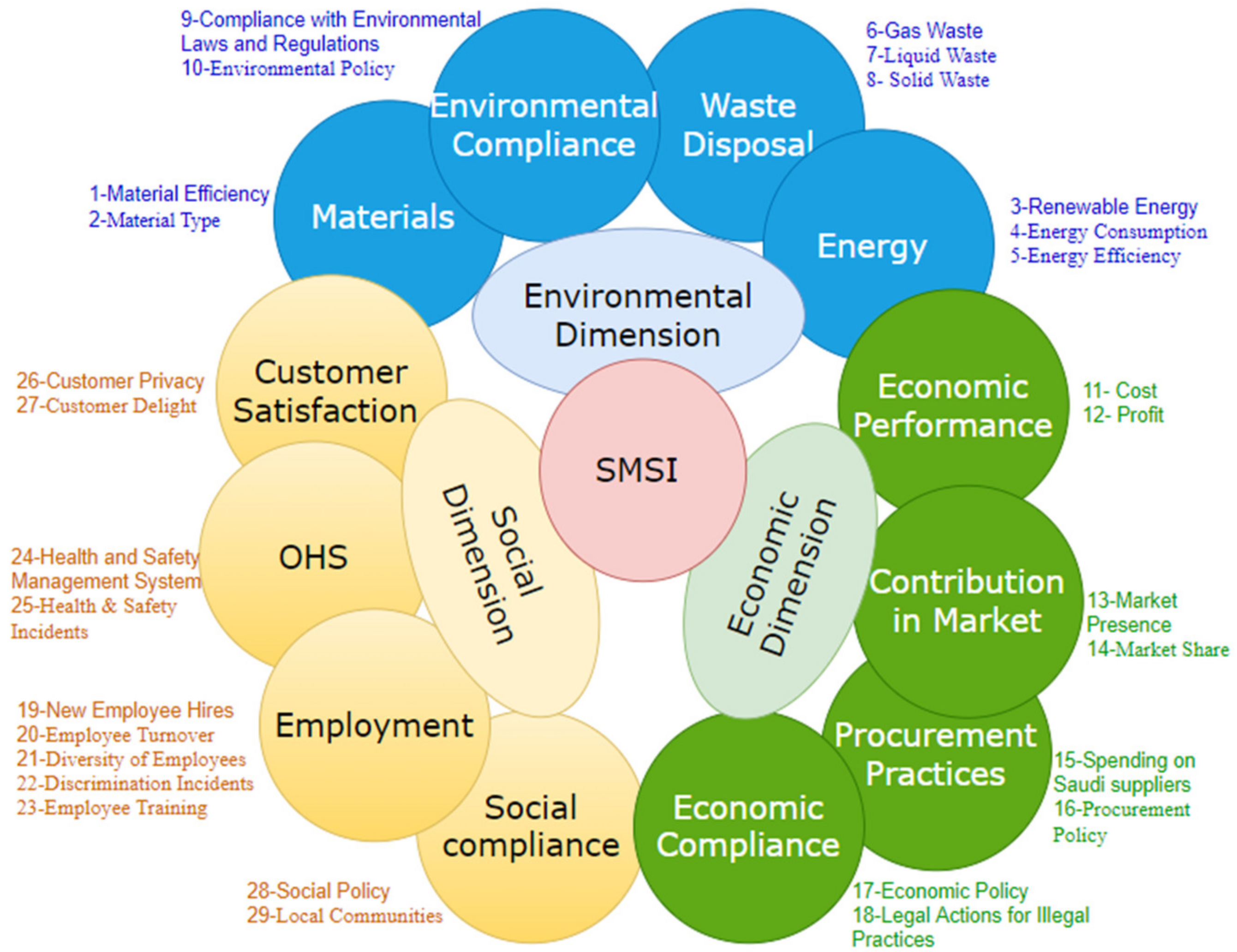

The SMFSI represents the sustainability level of the Saudi organization. To compute the SMFSI, the Saudi manufacturing sustainability index (SMSI) was calculated first at the criteria level and then calculated at the dimension level. A sustainability index at the criteria level incorporates numerous sustainability sub-criteria, and a sustainability index at the dimension level contains all sustainability criteria. The details are presented here as sub-steps.

Using combined fuzzy ratings and fuzzy weights of sustainability sub-criteria, the Saudi manufacturing sustainability index (SMSI) was calculated at the criteria level. Equation (5) was used to calculate the sustainability index at the criteria level [

43].

In Equation (5),

is Saudi manufacturing sustainability index for sustainability criteria j for given sustainability dimension i.

is importance weight for sustainability sub criteria k for sustainability criteria j for given sustainability dimension i, and

is its corresponding triangular fuzzy number (refer to

Table 7)

is performance rating for sustainability sub criteria k for sustainability criteria j for given sustainability dimension i, and

is corresponding triangular fuzzy number (refer to

Table 7)

is estimated triangular fuzzy number for sustainability criteria j for given sustainability dimension i

As an example, for the case organization, the computation of the Saudi manufacturing sustainability index for the “environmental” dimension (i = 1) and sustainability criteria “energy” (j = 2),

was calculated using Equation (5) with information in

Table 7, and is as presented below:

Thus, using Equations (1)–(5) and information in

Table 4, the Saudi manufacturing sustainability index for each sustainability criteria j for the given corresponding sustainability dimension i WAS calculated and presented in

Table 8.

As shown in

Table 8, the sustainability criteria “economic performance”, “contribution to the market”, “employment”, “occupational health and safety”, “customer satisfaction”, and “social compliance” had the lowest sustainability index values. Therefore, XYZ should concentrate on these criteria to improve its sustainability index and become an extremely sustainable organization.

Using the sustainability index at the criteria level, a calculation of the sustainability index at dimension level was carried out. The Saudi manufacturing sustainability index at the dimension level was calculated by Equation (6) [

42].

where

is Saudi manufacturing sustainability index for sustainability criteria j for given sustainability dimension i.

is importance weight for sustainability criteria j for given sustainability dimension i, and

is corresponding triangular fuzzy number (refer to

Table 8)

is estimated triangular fuzzy number for sustainability criteria j for given sustainability dimension i (refer to

Table 8)

is triangular fuzzy number representing Saudi manufacturing sustainability for given sustainability dimension i

is Saudi manufacturing sustainability index for ith sustainability dimension.

As an example, for the case organization, the computation of the Saudi manufacturing sustainability index for environmental dimension (i = 1)

was calculated using information from

Table 8 and Equation (6), and is as presented below:

Using Equations (4) and (6), triangular fuzzy importance weight

and Saudi manufacturing sustainability index

for the sustainability dimension i were calculated and presented in

Table 9.

As shown in

Table 9, the Saudi manufacturing sustainability index for economic and social sustainability dimensions has low fuzzy scores compared to the environmental dimension. Therefore, XYZ should pay more attention to the economic and social dimensions to achieve a better balance between the dimensions of sustainability.

The Saudi manufacturing fuzzy sustainability index (SMFSI) can be calculated using the following Equation (7) [

20]:

In Equation (7),

is importance weight for sustainability dimension i, and

is corresponding fuzzy number (refer to above

Table 9)

is Saudi manufacturing sustainability index for ith sustainability dimension and

is corresponding fuzzy number (refer to

Table 9)

is Saudi manufacturing fuzzy sustainability index and is corresponding triangular fuzzy number

Thus, for the case organization, the

is the Saudi manufacturing fuzzy sustainability index calculated using Equation (7) and

Table 9.

Having calculated the Saudi manufacturing fuzzy sustainability index (SMFSI), it was aligned with linguistic terms (refer to

Table 10). For this case, the Euclidean distance technique was implemented because it is the best logical technique for observing closeness [

40].

Table 10 lists the linguistic terms and fuzzy numbers that were used to determine the Saudi Manufacturing Sustainability Level (SMSL) [

42]. There are five sustainability levels (r = 1 to 5) with their five linguistic terms, while

are the corresponding sustainability fuzzy numbers for the given level r.

By implementing the Euclidean distance technique, the Euclidean distance D between SMFSI and SMSL (sustainability level) can be found by Equation (8) [

43].

In Equation (8), represents the corresponding fuzzy number for the Saudi manufacturing sustainability level linguistic variable for each level r ranging from one to five.

The shortest Euclidean distance between SMFSI and SMSL was recognized between five calculated distances using Equation (8). For example, by using SMFSI where (h, o, p)

(0.51, 0.71, 0.91) and SMSLr where level r = 5, SMSL

5 [ Extremely Sustainable,

(0.7,0.85,1)] for XYZ, the Euclidean distance (D) was calculated for r = 5 as follows:

Similarly, other Euclidean distances for sustainability level (for r = 1 to 5) were calculated and are presented in

Table 11.

D (SMFSI, SMSL

r) represents minimum distance of sustainability level r, here for the case minimum distance is 0.07 of sustainability level of 4. It means that the XYZ organization reaches a highly sustainable level. Accordingly, the sustainability index level of the case organization (XYZ) is assessed as “highly sustainable,” by matching a linguistic label with the minimum Euclidean distance as shown in

Figure 2.

To improve the sustainability level of a manufacturing organization, sustainability barriers need to be identified and analyzed. Such barriers will impact the sustainability level. The target is to reach the “extremely sustainable” level, which is the highest possible level. The Saudi manufacturing fuzzy performance index (SMFPI) can be used to identify such barriers. Equation (9) was used to calculate the SMFPI [

42,

43].

A sample calculation of SMFPI of sustainability sub-criteria “material productivity” is as shown below:

Thus, for all 29 sustainability sub-criteria, the SMFPI was calculated and presented in

Table 12. However, the SMFPIs had to be ranked, because fuzzy numbers do not always produce an ordered set as real numbers do [

40]. There are several existing ways in the literature to rank fuzzy numbers. In this study, the centroid technique was implemented to rank the SMFPIs because the centroid technique is simple and easy to implement. Equation (10) was used to calculate the ranking score base on the centroid technique.

A sample calculation of ranking score of SMFPI for sustainability sub-criteria “material productivity” was calculated using Equation (10) as here below.

Ranking score for material productivity = = 0.197

The ranking score of the sub-criterion titled material productivity is 0.197. Furthermore, the same equation was used to calculate other sustainability sub-criteria ranking scores and presented in

Table 12 and accordingly ranked.

Thus, a threshold value needs to be calculated to identify sustainability barriers. Equation (11) is used to calculate the threshold value as calculated below.

Sustainability barriers are those sustainability sub-criteria with a ranking lower than the threshold value assigned and are thus problems to the company’s sustainability. In the case study, the median ranking score was 0.21, the maximum ranking score was 0.27, and the minimum ranking score was 0.16.

The threshold value for XYZ company = 0.19

The threshold value for XYZ is 0.19. Thus, using this threshold value as benchmark and the Saudi manufacturing sustainability sub criteria fuzzy ranking score from

Table 12 were compared and eight sustainability sub-criteria were identified whose performance was lower than the threshold value and are listed in the

Table 13. These eight sustainability sub-criteria can thus be considered barriers to sustainability. Addressing these barriers to improving the weaker areas of the sustainability sub-criteria will improve sustainability levels.