Abstract

Food waste is a serious problem worldwide, including in Europe. Research efforts are being carried out to reduce food waste. In this paper, we focus on using modern digital technologies (also known as Industry 4.0 technologies) to reduce waste in food supply chains. Based on interactions with a number of food companies in Europe over the last four years using Action Research, we provide new insights on the motivations and challenges for food companies when they are engaged in the use of technologies for reducing food waste in their supply chains. Motivations for firms include improved food quality of their produce, improved reliability, support in meeting legal requirements, a green image, and improved revenues from selling the food that has been saved. However, data security issues and trust issues posed challenges in using these technologies. Since this is an emerging area of research, we look at potential business models for technology companies for working with food companies in reducing food waste, identify value propositions and value capture, and look at how these investments in technologies can improve the sustainability of food businesses. We believe technology companies can leverage the opportunities, develop new business models with value propositions around the use of technologies, and support food companies via timely alerts in case of potential quality issues. Value capture occurs via the sale of hardware and subscriptions.

1. Introduction to Food Waste

The food sector accounts for 22 percent of global GHG emissions. The importance of reducing food waste has been well recognized in the UK, Europe and worldwide because food waste is associated with serious economic, environmental, and social impacts [1]. European statistics indicate that around 88 million tonnes or EUD 143 billion worth of food waste occurs in the EU every year (https://food.ec.europa.eu/safety/food-waste_en, accessed on 21 September 2022). The UK happens to be the largest contributor to this food waste contributing to 14.39 million tonnes (https://ourworldindata.org/grapher/food-waste-by-country-in-the-european-union, accessed on 23 September 2022). The European Food Information Council (EUFIC) estimates that around 931 million tons of food globally were wasted in 2019. According to UNDP [2], this amount increased to 1.3 billion tonnes of food waste in 2021, while nearly 2 billion people were left hungry and another 2 billion were obese. According to Eurostat, while an estimated 20% of the total food produced is lost or wasted, 36.2 million people cannot even afford a quality meal every second day, which emphasizes the social impact of food waste. The economic impact arises in two ways, (i) by preventing food waste, firms can sell more food and generate more revenue; and (ii) due to the amount of resources (water, nutrients, fertilizers, etc.) conserved, saved food waste is much more than the face value of the waste itself for the society. Further, significant carbon emissions will result in wasted food production, and the wasted food will emit more greenhouse gases in landfills, causing significant environmental impacts.

The literature on food waste sometimes uses a related term—food loss and waste. The term generally refers to “the decrease in mass (quantitative) or nutritional value (qualitative) of food—edible parts—throughout the supply chain that was intended for human consumption” (https://www.unep.org/thinkeatsave/about/definition-food-loss-and-waste accessed on 6 September 2022). Studies sometimes distinguish between the concepts of food loss and food waste (e.g., Ref. [3]). As per the above website, the former refers to the loss that takes place at production post-harvest, processing, and distribution stages of the food supply chain (which is usually considered unavoidable), while the latter term is the food that reaches the consumer but does not get consumed because it has been allowed to get spoiled (which is usually considered avoidable). However, modern literature (e.g., Ref. [4]) uses these terms interchangeably. This paper uses the term food waste consistently.

Supply chain issues are identified as one of the prominent causes based on a systematic literature review by Chauhan et al. [5]. Therefore, this paper focuses on food waste in the supply chain and deals with the use of technology in reducing food waste in agrifood supply chains.

Due to the economic, social, and environmental impacts caused by the food that is wasted, efforts must be focused on reducing this waste in all stages of the supply chain—from production to final consumption. Food waste is closely linked to several Sustainable Development Goals (SDG) of the United Nations (https://sdgs.un.org/goals, accessed on 6 September 2022). Increased food availability that results from reduced food waste will help achieve SDG 1 (no poverty), SDG 2 (zero hunger), and SDG 3 (good health and well-being). Food waste is directly linked to SDG 12 (responsible consumption and production), while it is relevant to several other SDGs.

SDG 12 focuses on responsible consumption and production for improved food security. It stresses achieving a good standard of living while reducing our ecological footprint. This goal emphasizes efficiency in all levels of production and consumption via efficient supply chains. Target 3 of SDG 12 focuses on halving per capita global food waste by 2030. This requires concerted action across all levels, from production, post-harvest processes, supply chains, retail, and consumer levels. Target 5 requires that waste generation is substantially reduced through prevention, reduction, recycling and reuse.

Lemaire and Limbourg [4] studied SDG 12 further, detailing the causes, solutions and research challenges related to managing food loss and waste. Among other categories, they highlighted the importance of efficient logistics/supply chain network design for reducing waste. Food quality tends to decline during supply chain operations, before and during production, storage in warehouses, transportation via trucks, planes, trains and ships, and consumption largely due to a lack of process control. Mena et al. [6] emphasized that inadequate process control, such as maintaining temperature and humidity levels in the food supply network, is a major cause of food waste, especially in cold chains. Appropriate quality control has been stressed as a key factor in reducing waste and improving the quality of transported food products [7]. Through appropriate mechanisms, Karki et al. [8] highlighted that food waste, food poverty and surplus food distribution could provide a win-win solution for the world. They further stress the role of the third sector in redistribution activities.

Modern digital technologies (also called as Industry 4.0 technologies) provide new opportunities to help food companies reduce waste in their supply chains [9,10,11,12]. For example, when food is transported in trucks, Internet of Things sensors can track the temperature, humidity and other relevant parameters in which the food is stored and send the details to cloud storage for remote access. If the food is stored in sub-optimal conditions (for example, when the storage temperature is above the maximum threshold), then decision-makers who remotely access the temperature can take appropriate action to correct the temperature rapidly. This will help prevent the food from becoming waste. In general, food companies are unaware of such promises of digital technologies. In recent years, some efforts have been made to promote digital technologies among food companies [12].

Despite the importance of reducing food waste and the efforts to promote the use of digital technologies for reducing waste in food supply chains, there has been very little effort to understand the motivations and barriers for food companies in using modern digital technologies for reducing food waste reduction. We attempt to fill this research gap by undertaking research activities by engaging with several food companies in Europe on the use of technology for reducing food waste. We share our experience from the last five years, as we worked with several European food companies on the use of technology for supporting food waste reduction (FWR). Therefore, the research questions for this paper are: (i) what are the motivations for food companies to use digital technologies for food waste in their supply chains and what are the challenges? (ii) what is the best business model for commercially exploiting the power of digital technologies for FWR? We find answers in this paper based on the action research methodology. The novelty of this study is in the appropriate use of technologies and the significance of these technologies can help save huge amounts of food waste. By understanding the motivations and challenges and analyzing business models, this paper contributes to achieving several SDGs.

This paper is organized as follows. The next section discusses the literature on FWR in food supply chains, emphasizing the use of modern digital technologies. We collected relevant data via action research through numerous meetings with relevant stakeholders, field visits, installations, and observations. The research approach and details of the data collection are presented in Section 3. The data analysis and findings are presented in Section 4. Our views on the motivations and challenges are presented in detail in this section. These findings are used to develop some future scenarios in the form of road maps. The last section presents a summary and conclusions.

2. Literature Review—Minimizing Food Waste in Agrifood Supply Chains

Food waste occurs in all parts of agrifood supply chains and can be minimized in various ways and approaches. Mena et al. [6] analyzed causes of food waste using case studies of selected supply chain networks of 15 food commodities (fruits, vegetables, and meat) and found that inadequate temperature control in supply chains was one of the most significant causes of waste of fruits and vegetables. For meat products, they stressed contamination, weather variations and damages in transit were found to be some of the main reasons for waste. Table 1 shows some prominent causes of food waste in agrifood supply chains.

Table 1.

Some prominent causes of food waste in agrifood supply chains (Adapted from Refs. [6,13,14]).

Table 1 covers the entire spectrum of food supply chains. However, the focus of this paper will be the first three stages shown in Table 1—farm, packaging, and transportation and storage. Table 1 shows that food waste in these stages is caused by various factors, including workforce, quality management techniques, processing techniques, supply chain coordination, and storage/transport conditions. Hence, efforts to reduce food waste should consider various options for avoiding the causes shown in Table 1. These options include technological and non-technological options [14,15,16]. For example, a skilled workforce can help improve efficiencies in farming/abattoirs, processing and transport efficiencies, and reduce waste. Early detection of pests and other diseases can reduce waste. Effective (non-destructive) quality control techniques can save food. There are technological options [15], especially by exploiting the power of modern digital technologies. This is the focus of this paper. These technological remedies are discussed in the next section.

Technological Options

Over the last few years, various digital technologies have been developed to increase the efficiencies of various stages of food supply chains [12,15]. This includes advanced digital technologies, for example, the use of drones and robots that can help improve farming efficiency. Modern scheduling, forecasting and supply chain collaboration tools can help improve operational efficiencies. Using the Internet of Things (IoT), sensors can help measure temperature and other parameters to maintain the freshness of food for longer. When the outputs from sensors are connected to the cloud and monitored via smartphone-based applications, timely warning signals can be sent to owners of food. In the case of a malfunction of temperature control systems, such a warning system can lead to rapid actions for reducing food waste. Other ways of using technology to support reducing food waste include real-time information-sharing using data collected with IoT networks, optimization of food delivery points based on real-time food-quality monitoring, and increased food shelf life using real-time cold-chain monitoring and control. For example, automated algorithms can help identify reductions in food quality sufficiently early, and food can be redirected to nearby demand points for sale before the food becomes a waste. Developing early detection algorithms based on sensor data and a platform linking suppliers and customers so that the nearest demand point can be located in the event of an unexpected reduction in food quality can also help make use of food that would otherwise become a waste. Further, when the data from IoT sensors are monitored and combined with externally available data (such as local weather) and the resulting big data is analyzed using modern data analytics techniques, more detailed understandings of the patterns and causes of food waste can emerge, leading to better solutions to reduce food waste.

Table 2 provides a brief overview of some important modern digital technologies and their use to support food waste applications. Please note that Table 2 provides a long list of prominent modern digital technologies, but not all of them are considered in the subsequent sections of this paper.

Table 2.

Prominent modern digital technologies and their applications in food supply chains.

3. Methodology

This paper focuses on using innovative modern digital technologies to improve supply chain resource efficiency and reduce food waste in food supply chains. It draws heavily on our work in a transnational–European territorial cooperation project co-funded by the Interreg North-West Europe Programme [12].

Due to the extensive involvement in the preliminary discussion, implementation, making observations, data collection, and analysis, our approach to this research could be termed Action Research [34,35]. Erro-Garcés and Alfaro-Tanco [36] defined action research as research applied in business and management and involves researchers and organizations who collaboratively undertake research in a practical setting. The research and the action become part of the results of action research. Erro-Garcés and Alfaro-Tanco [36] further cited Ref. [37], who claims that the collaboration increases the authenticity and trustworthiness of the results. Accordingly, researchers (academic experts) and practitioners (agribusiness organizations) have worked together to learn more about the issues related to the implementation of modern digital technologies (MDT) in agribusiness organizations. Our action research involves the intervention and transformation in a dynamic process through the collaboration of researchers and practitioners in a business setting. The learnings discussed in the next few sections are the results of our action research.

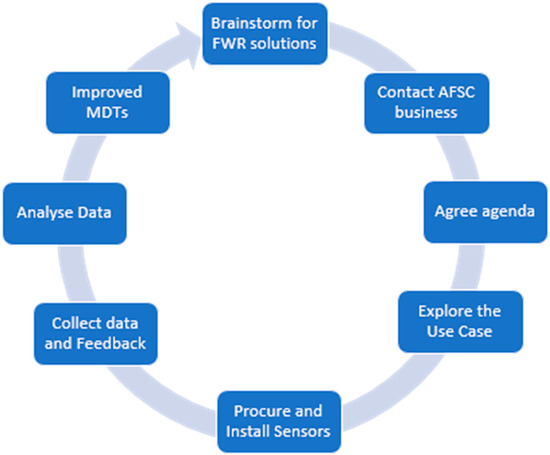

The central part of the action research methodology is the demonstrations of the MDT in multiple agribusiness organizations. Figure 1 illustrates the approach adopted to work with agribusiness organizations.

Figure 1.

Approach adopted to collaborate with relevant agribusiness organizations.

Our efforts in reaching out to agribusinesses resulted in technology demonstrations in multiple food businesses across Europe. The demonstrations primarily focused on food production and transport/storage stages of the food supply chains. Table 3 provides more details of the technology demonstrations. All the demonstrations used IoT, CCT, and BDA-AI.

Table 3.

A listing of Technology Demonstrations of modern digital technologies for reducing food waste in European businesses.

Of the companies approached, nine agreed to participate in technology demonstrations. The discussion in the rest of the paper is based on these nine demonstrations. Two papers [38,39] published in the same special issue as this paper described two of these nine technology demonstrations in detail. As per Figure 1, the next stage was to procure and install the sensors. The use case of the company, defined in Table 3, determined what modern digital technology was most appropriate for the successful execution of the technology demonstration. For example, if the company was focused on monitoring the storage stage of the food supply chain, a LoRaWAN (Long Range Wide Area Network) sensor could be deployed, which are widely known for its long transmission range and low power consumption, making them very popular for IoT applications. While these sensors have the benefit of minimal maintenance and upkeep due to their long battery life, they are best suited for fixed locations as they require a LoRa network to connect to the cloud. In the UK, this network is generally facilitated by privately owned gateway devices, and the coverage is very sporadic. Alternatively, if the company was focused on monitoring at the transport stage, GPRS loggers could be used, operating on the telecommunication networks already in place by mobile phone operators. While GPRS loggers, therefore, benefit from remote cloud connectivity, essential while monitoring cargo during transportation, they also have more demanding energy requirements. This results in a monitoring system that requires more maintenance in the form of battery replacements from the company.

4. Results—Insights on the Motivations of Businesses

As specified in Figure 1, the first step in reaching out to potential businesses is to prepare posters and flyers to bring out the benefits of FWR. Multiple stakeholders, stated below, were consulted in preparing the posters: IoT sensor technology firms, agribusiness SMEs and companies, farmers, processors, and wholesalers involved in FWR in food supply chains, public bodies and NGOs to help reach potential stakeholders, big data agritech firms, and research and policy institutions.

4.1. Benefits to Organizations in Food Supply Chains

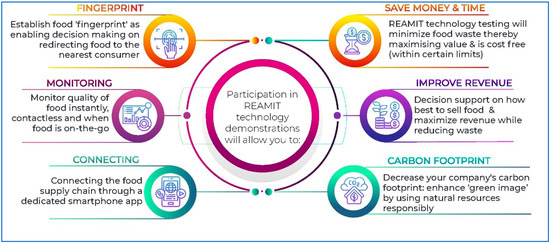

Interactions with these stakeholders have resulted in interesting findings, depicted via the infographics shown in Figure 2.

Figure 2.

Potential benefits to agribusiness organizations in engaging in FWR using modern digital technologies. Source: Ref. [12]. (Reprinted with permission from authors of Ref. [12])

As can be seen in Figure 2, a technology-based approach to reducing food waste can help food companies in multiple ways. They will get access to valuable sensor technology to measure their food waste fingerprint. If necessary, the food which would otherwise go to waste can be redirected to needy people nearby. This helps measure their carbon footprint as well. Wi-Fi-enabled IoT sensors can connect to systems via the internet for remote monitoring. This will avoid frequent manual intervention and hence can save money and time. Reducing food waste would mean a better carbon footprint. Table 4 provides an overview of the key benefits and the associated impact areas.

Table 4.

An overview of the impact and associated key benefits.

We interacted with multiple food companies in Europe for more than years on using modern digital technologies in FWR in their organizations. While food companies recognized the need for FWR and to improve their carbon footprint, not all of them were prepared to engage with using modern digital technologies for FWR. The food companies we contacted did not have prior experience using technologies, such as the Internet of Things sensors and big data for real-time information on the quality parameters (such as temperature and humidity). Some of them have been using thermometers and refrigerated trucks for transporting food but did not attempt to track quality parameters in real-time. Thus, if the refrigeration system does not work properly, they will only know this problem when the truck reaches its destination, and by then, the food will have become a waste. The companies did provide some examples of food loss in this way. Hence, they generally valued the use of Internet of Things sensors and other technologies so that quality parameters could be tracked in real-time. Detailed information on the technology demonstrations in at least two food companies has been discussed in other papers in this special issue (Ref. [38] for food—human milk transport and Ref. [39] for food storage). While a detailed discussion of our experience on all the technology demonstrations is beyond the scope of this paper due to lack of space, the discussions in this section are based on our experience in all the technology demonstrations.

It must be noted here that software also plays an important role in ensuring that the data from sensors are collected in the cloud and analyzed via dedicated software to identify anomalies and send alerts to food companies. Technology providers usually handle this software. Food companies are given access to a user-friendly graphical interface called a dashboard. The detailed case studies show more details of the dashboards [38,39].

Our interactions revealed that while there were several factors for companies to use modern digital technologies for FWR, there were also some issues that would prevent food firms from using modern digital technologies. In the next few subsections, we present our understanding of these motivators (drivers) and challenges (barriers).

4.2. Motivations

Based on our experience working with these technology demonstration cases, the following prominent motivators that would encourage them to use technology for FWR are identified.

4.2.1. Food Quality

Several firms realized that using technology for continuous monitoring is a very useful way of maintaining food quality while benefiting from FWR. Several food companies engaged in TDs are reporting that they do not incur food waste anymore after the sensor technology is installed and continuously monitored. Technologies have primarily helped these companies improve the quality of their produce, as they can track performance in terms of quality-related variables. Since improving quality can help in multiple ways (e.g., Ref. [40]), these firms enjoy improving productivity, reduced waste, and increased revenue via higher prices.

4.2.2. Reliability

Food firms have experienced increased reliability of their food processing systems due to the measurement of quality parameters (e.g., temperature and humidity) and continuous monitoring of these parameters. Potential failure issues can be better predicted with these real-time data for increased reliability of their production processes [41].

4.2.3. Legal

Food safety regulations are an important reason companies try to use modern digital technologies to continuously monitor food quality to prevent waste in their organizations. Several companies cited the regulatory requirement on food quality as a main reason for using technology, supporting FWR. Specifically, the Hazard Analysis & Critical Control Point (HACCP) directive, introduced in the EU in the 1990s and modified in subsequent years, expects EU food business operators to implement and maintain a permanent procedure or procedures based on the HACCP principles. The plan should protect food against contamination with bacteria, fungi, viruses and parasites. Maintaining correct atmospheric conditions (temperature, humidity, etc.) that would keep the shelf life of food long enough could be a good plan, which is better served using IoT sensors and other technologies, which would, in turn, help avoid FWR. Thus, some organizations decided that installing sensors can help their adherence to food safety regulations while at the same time helping them in FWR, as echoed in the literature (e.g., Ref. [42]).

4.2.4. Green Image

Engaging in activities that create waste can be used by firms to project a green image and competitive advantage [43,44]. They can use these efforts to show that they are contributing to improving overall sustainability and helping to save the planet. Explicit associations with established food charities can also be a good motivator for a green image.

4.2.5. Pressures from Stakeholders

Commitment from top management and commitment from employees plays a strong role in reducing food waste. Other downstream supply chain partners, by virtue of their position as customers, also exert pressure on reducing food waste. Pressures from other stakeholders, such as the media or the general public, are apparent, considering the higher emphasis on reducing food waste and adopting sustainable food practices in modern days compared to a few decades earlier. These observations are consistent with the tenets of the stakeholder theory [45].

4.2.6. Economic Factors and Survival

The economic dimension of the additional value derived from the food that has been prevented from going to waste is an important motivator for businesses to use modern technologies. In addition, the reduction in waste disposal costs due to FWR led to more cost efficiency. Some firms realized that their quest to reduce food waste has helped them find new ways to improve the operational efficiency of their operations, which in turn further reduced costs. The economic dimension manifested in an opposite way when food companies prioritized their survival and were hesitant to engage in innovative technologies during the COVID-19 pandemic, even though they knew the benefits of working on the project. This is consistent with similar observations in the literature [46]. In principle, it is important to ensure that the costs invested in technologies for FWR should compare favorably to the cost of food waste saved. The economic analysis is not so straightforward considering the multiple benefits (discussed above) of these technologies for the companies. However, it is important to ensure that the resources spent in producing and installing these technologies should be much lower than the resources saved by the avoided food waste avoided, which can be confirmed using life cycle analysis (LCA).

4.3. Challenges

While the above motivators did help us reach out to more companies for successful technology demonstrations, some challenges emerged. These challenges revolved primarily around the collection of sensitive data using IoT sensors.

4.3.1. Data Security, Data Sharing, Threat from Hackers

As explained previously, one of the first steps in our approach to technology demonstrations is to assure the companies that their data will be kept safely and securely. In spite of this promise, we found that data sharing and security issues could be important barriers on why companies might not be willing to use technology. For example, data that could help measure waste in their system can be potentially used to project the level of inefficiency, which can affect the company’s brand image. This fear was a main barrier in this context. The threat of hacking contributed to this challenge. Shared sensor data to multiple entities in the supply chain (e.g., data analytics companies) could create opportunities for malicious agents to disrupt the food chain via cyberattacks. It is important to ensure that suitable data management plans (e.g., blockchain) are available to minimize data security issues.

4.3.2. Privacy

The perception that using modern digital technologies might infringe on the privacy of potential users was witnessed in our discussion with some food companies. For example, there was hesitation from drivers of trucks to install a gateway in their cabins due to privacy concerns and also other concerns such as exposure to radioactivity. In another case, some drivers were not happy to track the location of their vehicles, as it was deemed an invasion of privacy. This adequate consideration of privacy issues could pose challenges to large-scale adoption of the technologies [47].

4.3.3. Technological Challenges

Though significant technological developments helped produce relatively inexpensive systems for measuring and monitoring quality parameters, our technology demonstrations did bring more challenging situations that tend to extend the current capabilities. For example, one company wanted to track the temperature of fruits during international flights, which could not be completed cost-effectively with the current technologies available in the market.

4.3.4. Trust Issues

A general negative perception from some companies on any IT projects could be seen during the interactions [48]. Given that several IT projects overpromise and under-deliver, we also witnessed the negative perception during our work’s early stages. However, as we could show successful TDs over time, trust issues became more positive.

5. Exploring the Future of Use of Modern Digital Technologies for FWR—Business Models, Sustainability Plans and Roadmaps

In this section, we use our experience with multiple food companies to explore the future development of modern digital technologies for FWR.

5.1. Business Models for Supporting the Use of Digital Technologies in Food Supply Chain Companies

In the long run, large-scale commercialization of modern digital technologies for supporting food waste depends on developing suitable business models. Business Model (BM) is a term normally used to understand how commercial entities can exploit a unique capability to address a business need and develop appropriate revenue mechanisms to survive in the marketplace [49]. The literature on BMs provides multiple definitions for the term [49,50,51]. While addressing the business needs of a firm’s internal and external stakeholders, business models need to clearly identify the underlying value proposition, value delivery, value creation, and value capture [52,53]. Nine building blocks of a typical BM have been specified by Osterwalder and Pigneur [53]. The nine building blocks are value proposition, customer segments, customer relationships, channels, key partners, key activities, key resources, cost structure, and revenue streams. However, modern discussions of a typical BM usually consider four more prominent of the nine blocks—value proposition (the value embedded in the products/services offered by the firm), supply chain (the relationships with suppliers), customer interface (the relationships with customers); financial model (costs and benefits and their distribution among stakeholders).

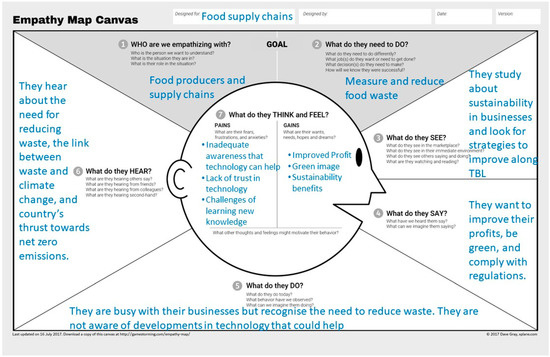

An empathy map canvas [54] is sometimes used to explain business models. Standard versions of the canvas (e.g., https://gamestorming.com/empathy-mapping/ accessed on 27 September 2022) outline some of the building blocks identified by Osterwalder & Pigneur [53]. Figure 2 gives an example of an empathy map canvas for the business model based on modern digital technologies for FWR in food supply chains.

Figure 3 explains many aspects that would make a business (Business A) engaged in using technology for FWR in food supply chains commercially viable. Business A serves food producers and supply chains to help FWR, the customers. The business highlights that there must be an approach to measure waste generated and reduce food waste in their operations. The strong point is that all businesses, including food businesses, are aware of the need to reduce waste and improve sustainability. In addition, existing governmental policies (e.g., the goal for net-zero carbon emissions by the UK government) also provide additional incentives for food companies to engage in FWR. Business A should inform their potential customers about the win-win strategy; that is, reducing food waste helps them economically (increased revenues and reduced waste disposal costs) but also help them comply with regulations and improve their green image and sustainability plans. Unfortunately, Business A’s customers (who are food companies) consider waste in their supply chain unavoidable and are internalizing it. However, Business A should demonstrate that newer developments in modern digital technologies can help reduce this waste by developing demonstrations and use cases.

Figure 3.

Empathy canvas outlines the business model of using modern digital technologies for FWR in food supply chains.

The literature on business models distinguishes between traditional and newer business models [55]. While traditional business models rely on incremental innovations, new business models are based on radical and disrupting innovations. Sometimes business models dealing with sustainable solutions are called sustainable business models, while business models focusing on minimizing waste and reusing waste in other processes for zero waste are called circular business models [49]. Due to the focus on sustainability and FWR, any business model developed using modern digital technologies will belong to the categories of sustainable and circular business models. In general, Industry 4.0 technologies [9,10] belong to disruptive or radical innovation category, and hence the business models using modern digital technologies are newer business models.

The literature outlines at least four categories of sustainable business models [49]—circular business models, social enterprises, the bottom of the pyramid solutions and product service systems. Of these, a profit-making business model that uses technology for FWR in food companies can be termed a circular business model. Servitization-based business models (also called product-service business models) rely on developing a tangible product but selling the integrated product-service offerings to improve customer experience. While Business A can sell simple hardware, such as IoT sensors, it will reap better rewards if it can link the sensors to CCT and BDA-AI and offer the integrated solution to customers. This vertical integration will help customers enjoy the service better and improve revenue generation. Business A can offer a subscription-based revenue model that measures the extent of use by customers and charges them accordingly.

A successful business model should specify at least four major dimensions—value proposition, value delivery, value creation and value capture [51]. The business model that uses technology for FWR can be characterized in terms of these dimensions, as shown in Table 5.

Table 5.

Dimensions of a business model for technology companies that support the use of technology for FWR in food supply chains.

5.2. Sustainability Plans

This section looks at the sustainability impacts of using technology for FWR and develops a plan for future large-scale diffusion that would help avoid significant quantities of food waste. As highlighted earlier, the concept of sustainability can be viewed in multiple dimensions—economic, environmental and social. A business that uses technology for FWR can contribute in terms of all these dimensions.

Economic dimension: The economic impact of food waste is well-known in the literature. As highlighted in the introduction, huge amounts of food are wasted across nations, continents, and, in fact, the globe (1.3 billion tonnes of food in 2021 as per UNDP [2]). Literature highlights that food waste occurs in all stages of the food supply chain—production, processing, transport, storage, retail, and consumer end. There is scope for reducing food waste in all of these stages. Mena et al. [6] estimated the level of food waste in various stages in the supply chain for fruits and vegetables and meat products. For example, waste occurs during grading, storage, packing and retail for fruits and vegetables, while waste occurs for meat products during slaughtering, processing, packing and retail. They also highlight that improper temperature and humidity conditions during storage and transport are crucial causes of food waste in food supply chains. Other studies, such as [56], have highlighted that supply chain stages account for as much as 28% of food waste that occurs during the supply chain stages (food services, production, wholesale, and retail). Unlike food waste in households, food waste at supply chain stages occurs primarily due to improper storage conditions. It hence can be tackled by continuously monitoring the storage conditions using MDTs. Even if one assumes that about 10% of the food waste in supply chain stages can be avoided using MDTs, it amounts to huge savings in food waste reduction. Thus, the scope for the positive economic impact of using technology for FWR is huge at 10% of 28% of 1.3 billion tonnes per year or 36.68 million tonnes of food per year.

Social dimension: As mentioned earlier, food waste has significant social impacts too. While a significant amount of food is wasted by a section of the world’s population, nearly 2 billion people are hungry [2]. Thus, if the food that normally gets wasted is avoided and the resulting excess food is sent to feed those in need will help avoid several social problems (e.g., crime). We highlight the social benefits of saving food waste here, though we recognize the logistical complications involved in feeding hungry people with the food waste avoided. Another social benefit of saving food waste can also be highlighted. If food is wasted, all resources (e.g., water, labor, electricity and fertilizer) that were used in producing the food would also become waste. This will result in additional adverse social impacts.

Environmental dimension: Environmental impacts of food waste have been well-researched in the literature. Food waste adversely impacts the environment in at least two ways. (i) Wasted food that ends in a landfill will be a source of greenhouse gas emissions. It has been estimated that greenhouse gases from food waste are approximately 4.4 gigatons (Gt) of carbon dioxide equivalents (CO2 e) per year. Comparisons with national emissions have been made (that is, if food waste were a country, it would rank as the third-highest emitter after the United States and China) (Ref. [57], quoting data from Emissions Database for Global Atmospheric Research at https://data.jrc.ec.europa.eu/collection/edgar) (accessed on 01 December 2022).

There are several ways of valorizing waste [56]. For example, food waste can be used as feed for animals, sent to anaerobic digestion to produce biogas or sent straight to the landfill). While these activities help reduce the impact of food waste once occurred, the best way to avoid the adverse impact of food waste is to prevent it from occurring. For example, Parry et al. [56] estimated that nearly 3090 kg of CO2e can be avoided if food waste is redistributed to people from manufacturing/retail. This value is much higher compared to other waste disposal options. For example, using food waste as feed for animals would avoid only 220 kg of CO2e in comparison.

Thus, modern digital technologies can play a crucial role in FWR by ensuring appropriate storage conditions (temperature and humidity) in food supply chains. By measuring these parameters, a warning signal can be sent when these parameters exceed acceptable storage conditions and thus help in appropriate immediate corrective actions. By ensuring optimal storage conditions, technology can thus be used to avoid significant carbon emissions. Using life-cycle emissions, we estimated that about 0.84 tonnes of CO2 can be avoided every time a warning alert is sent for fruits/vegetables or frozen food, while as much as 107 tonnes of CO2e can be avoided in meat industries for each warning signal. In this special issue, they will be explained in greater detail in subsequent papers.

5.3. Roadmaps

We illustrated in this paper that modern digital technologies could play a crucial role in FWR in food supply chains. By continuously monitoring food environment conditions (temperature, humidity, etc.) along the supply chains, sensors can help ensure that food is stored and transported in optimal conditions during supply chain processes. Warning signals in the case of non-optimal conditions can be used to rapidly identify problems and retain optimal storage conditions. Significant food waste and equally significant carbon emissions can thus be avoided.

However, there are challenges to employing technologies for FWR. As the business models have highlighted, companies specializing in technology must make efforts to publicize the value of these technologies for FWR. We have so far approached a handful of food companies and demonstrated the benefits of using technology for FWR. However, significant efforts are required to scale up these technologies.

The following roadmap strategies are recommended to achieve a substantial target of reducing food waste.

- Keep abreast of the latest developments in modern digital technologies and utilize the most cost-effective technologies.

- Showcase a number of demonstrator applications of the use of modern digital technologies for FWR in selected companies. Bring out all the elements of a sustainable business model (including the value proposition, creation and delivery dimensions).

- Use the success of the demonstrators to reach out to more food companies. Explain the food waste saved, the carbon emissions avoided, and the social benefits derived from each demonstration case.

- Reach out to more food companies. There is potential to reduce 107 tonnes of carbon emissions by working with meat companies each time a warning signal is sent. This can translate to significant tons of carbon emissions over a year. By reaching more meat companies, this saving can be much larger. For example, if 100 such companies are reached in one year, there is a potential saving of 10,700 tonnes of carbon emissions per year. Therefore, it is imperative to scale up the technology adoption by involving more companies in the next few years and save as much carbon emissions as possible.

- Work with policymakers to incentivize food companies to use modern digital technologies to reduce food waste in their supply chains. This can be done, for example, by formulating guidelines, policy briefs, regulations, taxes and incentives and via appropriate labeling mechanisms confirming ‘pro-active food waste reduction status’. This will encourage much wider deployment of modern digital technologies in food supply chains and will help avoid more food waste and reduce more carbon emissions in the future.

6. Conclusions

This paper has demonstrated the value of modern digital technologies in helping to reduce waste in food supply chains. Based on the experience gained in reaching out to food businesses across northwest Europe over the last four years, it analyzed the motivations and challenges for companies, discussed potential business models for supporting the use of digital technologies in food supply chain companies and highlighted the roadmaps for avoiding a significant amount of food waste and carbon emissions. For example, improved food quality and the ability to meet some legal requirements are important motivations, while there are challenges in the form of trust and security issues. Technology companies can create value for food companies around reduced waste via timely alerts. In return, they can generate revenues by charging food companies for the sale of hardware and subscriptions.

The paper has theoretical and practical implications. This paper contributes to the theory and practice by discussing the motivations and challenges. Theoretical implications arise because the motivations and challenges provide an opportunity to utilize established theories, such as the technology assessment models, technology–organization–environment theory, the resource-based view, t institutional theory, and transaction cost theory for further understanding how food firms can be supported towards the cause of food waste reduction [58]. Practical implications arise because this study provides important factors (quality issues, legal issues, trust issues, etc.) that managers of food firms need to be aware of for engaging in the use of technologies for FWR. The roadmap described in Section 5.3 provides more practical implications on working with food companies and policy-makers.

It is hoped that more companies will take advantage of the power of technologies to help reduce waste in food supply chains, thereby supporting a number of the UN’s sustainable development goals. The field of digital technology is continuously evolving. It is quite possible that the trust or security issues can be addressed by more promising technologies (e.g., blockchain) or by hitherto undiscovered technologies. Technology companies should keep abreast of the latest technological developments and support food companies to reduce food waste.

Author Contributions

Conceptualization, R.R., Y.D., T.A. and J.C.; methodology, R.R., Y.D. and T.A.; validation, R.R., K.P., J.G. and I.H.; formal analysis, R.R., Y.D. and T.A.; investigation, R.R., K.P., J.G, I.H. and S.A.; resources, R.R., Y.D., T.A., K.P., J.G., S.A., J.C., I.H. and U.R.; writing—original draft preparation, R.R., Y.D., J.C. and T.A.; writing—review and editing, R.R., Y.D., S.A., T.A. and U.R.; visualization, S.A.; supervision, R.R., Y.D., J.C. and T.A.; project administration, R.R., Y.D., J.C., K.P. and T.A.; funding acquisition, R.R., Y.D., J.C. and T.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Interreg North-West Europe (NWE831).

Institutional Review Board Statement

The study was conducted after gaining ethical approval (ref BMRI/Ethics/Staff/2018-19/005) from the University of Bedfordshire, UK.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

REAMIT project and case-study videos are available at www.reamit.eu (accessed on 01 December 2022).

Acknowledgments

We acknowledge our project team and administrative team for conducting case studies and collecting information.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cattaneo, A.; Federighi, G.; Vaz, S. The environmental impact of reducing food loss and waste: A critical assessment. Food Policy 2021, 98, 101890. [Google Scholar] [CrossRef]

- UNDP. Sustainable Development Goal 12—Responsible Consumption and Production; UNDP: New York, NY, USA, 2022; Available online: https://www.undp.org/sustainable-development-goals#responsible-consumption-and-production (accessed on 6 September 2022).

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Towards transparent valorization of food surplus, waste and loss: Clarifying definitions, food waste hierarchy, and role in the circular economy. Sci. Total Environ. 2020, 706, 136033. [Google Scholar] [CrossRef] [PubMed]

- Lemaire, A.; Limbourg, S. How can food loss and waste management achieve sustainable development goals? J. Clean. Prod. 2019, 234, 1221–1234. [Google Scholar] [CrossRef]

- Chauhan, C.; Dhir, A.; Akram, M.U.; Salo, J. Food loss and waste in food supply chains. A systematic literature review and framework development approach. J. Clean. Prod. 2021, 295, 126438. [Google Scholar] [CrossRef]

- Mena, C.; Terry, L.A.; Williams, A.; Ellram, L. Causes of waste across multi-tier supply networks: Cases in the UK food sector. Int. J. Prod. Econ. 2014, 152, 144–158. [Google Scholar] [CrossRef]

- van der Vorst, J.G.; van Kooten, O.; Luning, P.A. Towards a diagnostic instrument to identify improvement opportunities for quality controlled logistics in agrifood supply chain networks. Int. J. Food Syst. Dyn. 2011, 2, 94–105. [Google Scholar]

- Karki, S.T.; Bennett, A.C.; Mishra, J.L. Reducing food waste and food insecurity in the UK: The architecture of surplus food distribution supply chain in addressing the sustainable development goals (Goal 2 and Goal 12.3) at a city level. Ind. Mark. Manag. 2021, 93, 563–577. [Google Scholar] [CrossRef]

- Ali, I.M.; Satie, S.A.; Thai, V.I. Adopting Industry 4.0 technologies in agri-food supply chains. In Supply Chain 4.0: Improving Supply Chains with Analytics and Industry 4.0 Technologies; Kogan Page: London, UK, 2021; Volume 3, p. 209. [Google Scholar]

- Attaran, M. Digital technology enablers and their implications for supply chain management. In Supply Chain Forum: An International Journal; Taylor & Francis: Abingdon, UK, 2020; Volume 21, pp. 158–172. [Google Scholar]

- da Costa, T.P.; Gillespie, L.; Cama-Moncunill, X.; Ward, S.; Condell, J.; Ramanathan, R.; Murphy, F. A systematic review of real-time monitoring technologies and its potential application to reduce food loss and waste: Key elements of food supply chains and IoT technologies. Sustainability 2023, 15, 614. [Google Scholar] [CrossRef]

- REAMIT. Benefits to Stakeholders for Participating in the REAMIT Project. 2022. Available online: https://www.nweurope.eu/projects/project-search/reamit-improving-resource-efficiency-of-agribusiness-supply-chains-by-minimising-waste-using-big-data-and-internet-of-things-sensors/#tab-7 (accessed on 29 August 2022).

- Kayıkcı, Y.; Gözaçan, N.; Lafcı, Ç.; Kazançoğlu, Y. A conceptual framework for food loss and waste in agri-food supply chains: Circular economy perspective. In Challenges and Opportunities of Circular Economy in Agri-Food Sector; Springer: Singapore, 2021; pp. 41–53. [Google Scholar]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef]

- Aramyan, L.; Grainger, M.; Logatcheva, K.; Piras, S.; Setti, M.; Stewart, G.; Vittuari, M. Food waste reduction in supply chains through innovations: A review. Meas. Bus. Excell. 2021, 25, 475–492. [Google Scholar] [CrossRef]

- Martin-Rios, C.; Demen-Meier, C.; Gössling, S.; Cornuz, C. Food waste management innovations in the foodservice industry. Waste Manag. 2018, 79, 196–206. [Google Scholar] [CrossRef]

- Yadav, V.S.; Singh, A.R.; Raut, R.D.; Mangla, S.K.; Luthra, S.; Kumar, A. Exploring the application of Industry 4.0 technologies in the agricultural food supply chain: A systematic literature review. Comput. Ind. Eng. 2022, 169, 108304. [Google Scholar] [CrossRef]

- Li, X.; Liu, P.C. Based on RFID Food Supply Chain Traceability System Framework Design. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; Volume 474, pp. 2150–2154. [Google Scholar]

- Sparrow, R.; Howard, M. Robots in agriculture: Prospects, impacts, ethics, and policy. Precis. Agric. 2021, 22, 818–833. [Google Scholar] [CrossRef]

- Tiwari, U. Application of blockchain in agri-food supply chain. Br. Int. Exact Sci. (BIoEx) J. 2020, 11, 574–589. [Google Scholar] [CrossRef]

- Kopanaki, E.; Stroumpoulis, A.; Oikonomou, M. The impact of blockchain technology on food waste management in the hospitality industry. ENTRENOVA-Enterp. Res. Innov. 2021, 7, 428–437. [Google Scholar] [CrossRef]

- Marin, M.P.; Marin, I.; Vidu, L. Learning about the reduction of food waste using blockchain technology. arXiv 2021, arXiv:2101.02026. [Google Scholar]

- Panghal, A.; Vern, P.; Mor, R.S.; Panghal, D.; Sindhu, S.; Dahiya, S. A study on adoption enablers of 3D printing technology for sustainable food supply chain. Manag. Environ. Qual. Int. J. 2022; ahead-of-print. [Google Scholar]

- Prakash, S.; Bhandari, B.R.; Godoi, F.C.; Zhang, M. Future outlook of 3D food printing. In Fundamentals of 3D Food Printing and Applications; Academic Press: Cambridge, MA, USA, 2019; pp. 373–381. [Google Scholar]

- Verdouw, C.N.; Robbemond, R.M.; Verwaart, T.; Wolfert, J.; Beulens, A.J. A reference architecture for IoT-based logistic information systems in agri-food supply chains. Enterp. Inf. Syst. 2018, 12, 755–779. [Google Scholar] [CrossRef]

- Kumar, T.B.; Prashar, D. Review on efficient food waste management system using internet of things. Int. J. Cur Res. Rev. 2021, 13, 143. [Google Scholar] [CrossRef]

- Singh, A.; Kumari, S.; Malekpoor, H.; Mishra, N. Big data cloud computing framework for low carbon supplier selection in the beef supply chain. J. Clean. Prod. 2018, 202, 139–149. [Google Scholar] [CrossRef]

- Mustapha, U.F.; Alhassan, A.W.; Jiang, D.N.; Li, G.L. Sustainable aquaculture development: A review on the roles of cloud computing, internet of things and artificial intelligence (CIA). Rev. Aquac. 2021, 13, 2076–2091. [Google Scholar] [CrossRef]

- Funchal, G.; Melo, V.; Leitão, P. Cloud-enabled Integration of IoT Applications within the Farm to Fork to Reduce the Food Waste. In Proceedings of the 2022 IEEE 31st International Symposium on Industrial Electronics (ISIE), Anchorage, AK, USA, 1–3 June 2022; pp. 824–829. [Google Scholar]

- Misra, N.N.; Dixit, Y.; Al-Mallahi, A.; Bhullar, M.S.; Upadhyay, R.; Martynenko, A. IoT, big data and artificial intelligence in agriculture and food industry. IEEE Internet Things J. 2020, 9, 6305–6324. [Google Scholar] [CrossRef]

- Sharma, S.; Gahlawat, V.K.; Rahul, K.; Mor, R.S.; Malik, M. Sustainable innovations in the food industry through artificial intelligence and big data analytics. Logistics 2021, 5, 66. [Google Scholar] [CrossRef]

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C. Study and analysis of the implementation of 4.0 technologies in the agri-food supply chain: A state of the art. Agronomy 2021, 11, 2526. [Google Scholar] [CrossRef]

- Seiler, R.; Fankhauser, D.; Keller, T. Reducing food waste with virtual reality (VR) training—A prototype and A/B-test in an online experiment. In Proceedings of the 20th International Conference e-Society 2022, Virtual, 12–14 March 2022; IADIS. pp. 179–186. [Google Scholar]

- Elg, M.; Gremyr, I.; Halldorsson, Á.; Wallo, A. Service action research: Review and guidelines. J. Serv. Mark. 2020, 34, 87–99. [Google Scholar] [CrossRef]

- Ivankova, N.; Wingo, N. Applying mixed methods in action research: Methodological potentials and advantages. Am. Behav. Sci. 2018, 62, 978–997. [Google Scholar] [CrossRef]

- Erro-Garcés, A.; Alfaro-Tanco, J.A. Action research as a meta-methodology in the management field. Int. J. Qual. Methods 2020, 19. [Google Scholar] [CrossRef]

- Argyris, C.; Schön, D.A. Participatory action research and action science compared: A commentary. In Participatory Action Research; Whyte, W.F., Ed.; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 1991; pp. 85–96. [Google Scholar] [CrossRef]

- Ramanathan, U.; Pelc, K.; da Costa, T.P.; Ramanathan, R.; Shenker, N. A Case Study of Human Milk Banking with Focus on the Role of IoT Sensor Technology. Sustainability 2023, 15, 243. [Google Scholar] [CrossRef]

- Ramanathan, U.; Ramanathan, R.; Adefisan, A.; da Costa, T.P.; Cama, X.; Samriya, G. Adapting digital technologies to reduce food waste and improve operational efficiency of a frozen food company—The case of Yumchop Foods in the UK. Sustainability 2022, 14, 16614. [Google Scholar] [CrossRef]

- Powell, T.C. Total quality management as competitive advantage: A review and empirical study. Strateg. Manag. J. 1995, 16, 15–37. [Google Scholar] [CrossRef]

- Angelopoulos, A.; Michailidis, E.T.; Nomikos, N.; Trakadas, P.; Hatziefremidis, A.; Voliotis, S.; Zahariadis, T. Tackling faults in the industry 4.0 era—A survey of machine-learning solutions and key aspects. Sensors 2019, 20, 109. [Google Scholar] [CrossRef]

- Chauhan, N.; Jain, U.; Soni, S. Sensors for food quality monitoring. In Nanoscience for Sustainable Agriculture; Springer: Cham, Switzerland, 2019; pp. 601–626. [Google Scholar]

- Lopez-Torres, G.C.; Montejano-García, S.; Alvarez-Torres, F.J.; Perez-Ramos, M.d.J. Sustainability for competitiveness in firms—A systematic literature review. Meas. Bus. Excell. 2022, 26, 433–450. [Google Scholar] [CrossRef]

- Vrchota, J.; Pech, M.; Rolínek, L.; Bednář, J. Sustainability outcomes of green processes in relation to industry 4.0 in manufacturing: Systematic review. Sustainability 2020, 12, 5968. [Google Scholar] [CrossRef]

- Freudenreich, B.; Lüdeke-Freund, F.; Schaltegger, S. A stakeholder theory perspective on business models: Value creation for sustainability. J. Bus. Ethics 2020, 166, 3–18. [Google Scholar] [CrossRef]

- Ramanathan, U.; Aluko, O.; Ramanathan, R. Supply chain resilience and business responses to disruptions of the COVID-19 pandemic. Benchmarking Int. J. 2022, 29, 2275–2290. [Google Scholar] [CrossRef]

- Tawalbeh, L.A.; Muheidat, F.; Tawalbeh, M.; Quwaider, M. IoT Privacy and security: Challenges and solutions. Appl. Sci. 2020, 10, 4102. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 innovation ecosystems: An evolutionary perspective on value cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Haaker, T.; Ly, P.T.M.; Nguyen-Thanh, N.; Nguyen, H.T.H. Business model innovation through the application of the Internet-of-Things: A comparative analysis. J. Bus. Res. 2021, 126, 126–136. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M. A review and typology of circular economy business model patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef]

- Foss, N.J.; Saebi, T. Fifteen years of research on business model innovation: How far have we come, and where should we go? J. Manag. 2017, 43, 200–227. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, And Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 1. [Google Scholar]

- Pileggi, S.F. Knowledge interoperability and re-use in Empathy Mapping: An ontological approach. Expert Syst. Appl. 2021, 180, 115065. [Google Scholar] [CrossRef]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Parry, A.; James, K.; LeRoux, S. Strategies to Achieve Economic and Environmental Gains by Reducing Food Waste; Waste & Resources Action Programme (WRAP): Banbury, UK, 2015; ISBN 978-1-84405-473-2. Available online: https://wrap.org.uk/sites/default/files/2020–12/Strategies-to-achieve-economic-and-environmental-gains-by-reducing-food-waste.pdf (accessed on 4 January 2022).

- Bravard, C.; Babladelis, C.; Coleman, M.; Genser, J. Assessment of Food Waste Reduction Strategies, University of Michgan. 2022. Available online: https://deepblue.lib.umich.edu/bitstream/handle/2027.42/172144/Food%20Waste%20Reduction%20Strategies_402.pdf (accessed on 30 September 2022).

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).