Management of Postharvest Losses and Wastages in the Indian Tomato Supply Chain—A Temperature-Controlled Storage Perspective

Abstract

1. Introduction

- First, this study analyzes PHL in Indian tomato supply chains and identifies the fundamental causes.

- Second, technologies such as temperature-controlled chains or cold chains used for managing the PHL are identified from the literature.

- Third, the feasibility of adapting the identified technologies in the Indian food supply chain and the challenges are discussed in detail.

- Fourth, this study suggests a temperature-controlled storage system as a feasible opportunity to reduce the PHL.

- Fifth, this study suggests how supply chain entities can collaborate and share information with the help of technologies to reduce PHL.

2. Background

2.1. Indian Tomato Supply Chain

2.2. Causes of PHL

2.3. Impact of PHL

- Increased availability and access due to decreased losses.

- Farmers benefit from lower harvest losses by earning more money.

- Lower prices throughout the supply chain, in local areas, and distant urban areas result from increased supply throughout the state due to reduced losses.

2.4. Opportunities to Minimize PHL

2.4.1. Forced Air Cooling Treatment

2.4.2. Ethylene Treatment

2.4.3. Evaporative Cooling of Tomato

2.4.4. Modified Atmospheric Storage Using a Silicone Membrane

2.4.5. Blast Freezing

2.5. Research Gap

3. Methodology

3.1. Sample Selection

3.2. Data Collection

4. Data Analysis and Research Findings

4.1. Details of the Supply Chain Operation of the Case Study Considered

4.2. PHL across the Stages and Ways to Minimize Losses

4.3. Difficulties in Implementing Temperature-Controlled Storage Technologies

- a.

- 25% of the share comes from the National Horticulture Board (NHB), and 50% comes from the National Bank for Agriculture and Rural Development (NABARD) as a loan.

- b.

- 33%, which is up to 50 lakh rupees (60 lakh in the northeastern states), from the National Cooperative Development Corporation (NCDC).

- c.

- 10% of the stock is owned by cooperatives.

- d.

- NCDC approval is needed for cooperative-based cold storage.

4.4. Temperature-Controlled Storage Systems—A Feasible Opportunity to Reduce PHL

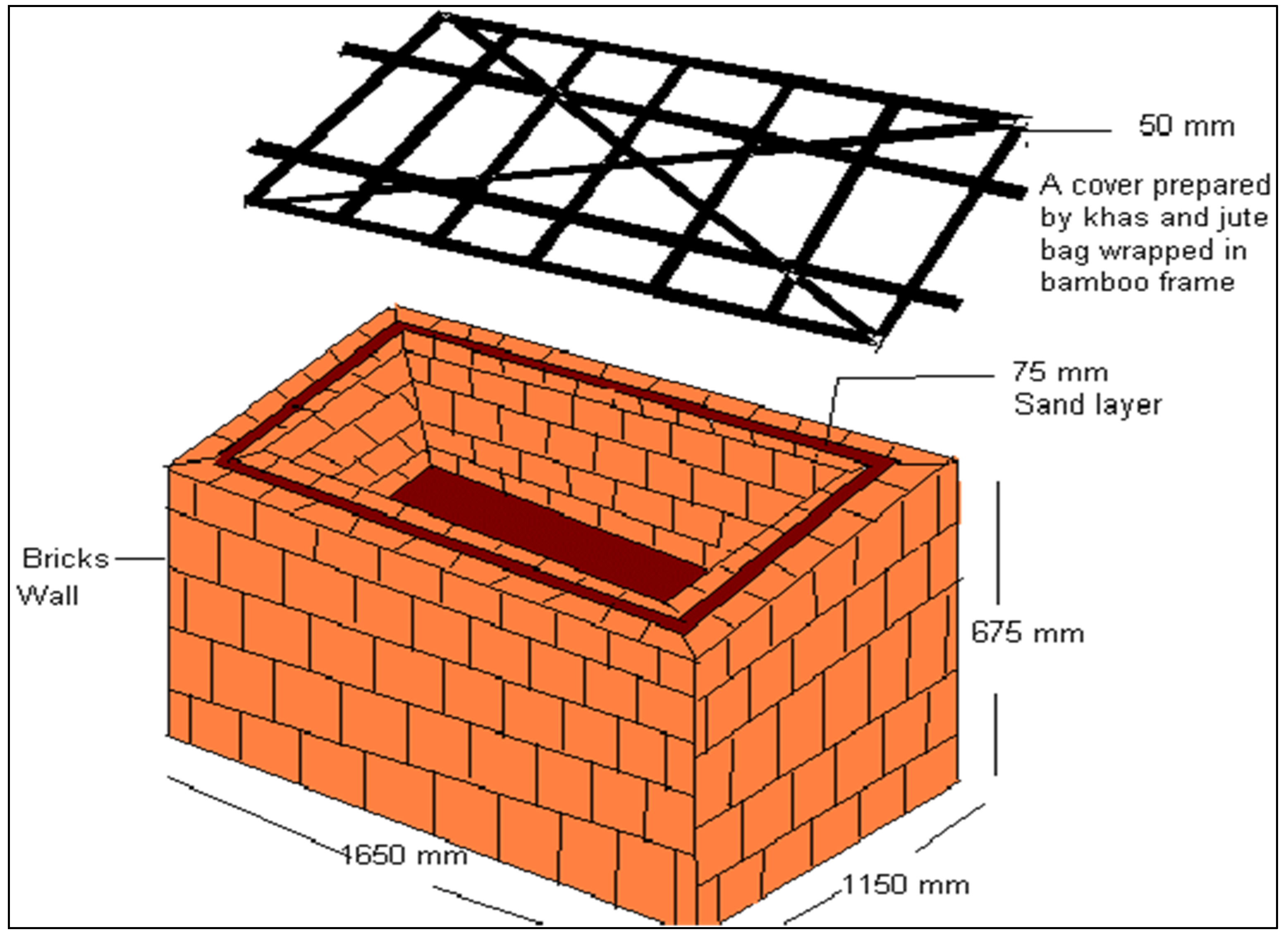

4.4.1. Low-Cost Cold Chamber by the National Board of Horticulture

4.4.2. ColdHubs by Nigerian-Based Start-Up

4.4.3. Mini Mobile Cold Storage by CRS Group—UK

4.5. Supply Chain Collaboration for PHL Reduction

5. Contributions and Policy Implications

Policy Implications

- This study shows that the entities of the tomato supply chain lack awareness of the loss happening at every checkpoint and the techniques to overcome them. Thus, more awareness campaigns must be created among the supply chain entities to introduce them to the available technologies and their benefits.

- The Government provides various subsidy schemes for establishing individual and joint cold storage facilities. However, across the region of this study, farmers need to be made aware of these schemes and the potential of establishing a cold storage facility. Hence, initiatives should implement cold storage facilities at a small-scale level and the benefits of potential benefits that farmers can realize demonstrated.

- Since collaboration reduces PHL, initiatives to implement cold storage facilities in collaborative environments such as farmer–producer organizations could be encouraged.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Data Collection Questionnaires

- I.

- Farmer-related

- 1.

- Tell me about yourself.

- 2.

- What type (variety) of tomato are you growing?

- 3.

- On how many acres are you growing tomatoes?

- 4.

- What is the timeline for overall tomato cultivation?

- 5.

- What process is involved, and what resources are consumed in tomato cultivation?

- 6.

- What time of the day (usually) do you harvest the tomato?

- 7.

- On what basis do you harvest the tomato? In terms of color/size/days?

- 8.

- How do you pack the tomato after harvesting it for transportation?

- 9.

- How do you keep the tomatoes on the farm after harvesting, and how long do you keep the tomatoes on the farm?

- 10.

- Where do you sell your tomatoes? (agents/wholesalers/retailers/customers)

- 11.

- How do you transport tomatoes to agents/wholesalers/retailers/customers?

- 12.

- Do you incur any wastages in the entire process, and how do you manage them?

- 13.

- Mention your supply chain structure (number of suppliers/customers, areas of collaboration, requirements). Has it changed in recent years? What are the drivers for the above changes, if any?

- II.

- Agent-related

- 1.

- Tell me about yourself.

- 2.

- From which region do your procur tomatoes? Seasonwise.

- 3.

- In what form do you buy tomatoes—fully ripened / half-ripened / unripe?

- 4.

- Do farmers hold the tomato for a few days or supply it straight after the harvest?

- 5.

- How do you manage the fluctuation in supply?

- 6.

- How do you transport tomatoes from farmers to wholesalers?

- 7.

- What time of the day do you transport the tomato?

- 8.

- How is the packaging done?

- 9.

- Do you send tomatoes directly to wholesalers from farmers or store them somewhere?

- 10.

- How long does it take to send tomatoes to wholesalers?

- 11.

- Do you incur any wastages in the entire process, and how do you manage them?

- 12.

- Is there any collaboration with wholesalers or other enterprises?

- III.

- Wholesaler-related

- 1.

- Tell me about yourself.

- 2.

- From which regions do you procur tomatoes? Seasonwise.

- 3.

- In what form do you buy tomatoes—fully ripened / half-ripened / unripe?

- 4.

- How do you transport tomatoes from agents?

- 5.

- How is the packaging done?

- 6.

- How long does it take to receive supply from wholesalers of different regions?

- 7.

- Do you own any storage facilities for storing tomatoes?

- 8.

- Do you incur any wastages in the entire process, and how do you manage them?

- IV.

- Retailer-related

- 1.

- Tell me about yourself.

- 2.

- From which region do you procur tomatoes? Seasonwise.

- 3.

- In what form do you buy tomatoes—fully ripened / half-ripened / unripe?

- 4.

- How do you transport tomatoes from wholesalers?

- 5.

- How is the packaging done?

- 6.

- Do you own any storage facilities for storing tomatoes?

- 7.

- Do you incur any wastages in the entire process, and how do you manage them?

References

- Manida, M.; Nedumaran, G. Agriculture in India: Information About Indian Agriculture & Its Importance. Aegaeum J. 2020, 8, 729–736. [Google Scholar]

- Biswas, A.K.; Tortajada, C. India Must Tackle Food Waste. 2014. Available online: https://www.weforum.org/agenda/2014/08/india-perishable-food-waste-population-growth/ (accessed on 5 May 2021).

- Chauhan, C. India Wastes More Farm Food than China: UN. Hindustan Times, 12 September 2013. [Google Scholar]

- Srikanta, R.; Astajyoti, B. Agriculture Supply Chain: A Systematic Review of Literature and Implications for Future Research. J. Agribus. Dev. Emerg. Econ. 2017, 7, 275–302. [Google Scholar]

- Statista Gross Value Output of Tomatoes in India from Financial Year 2012 to 2019. Available online: https://www.statista.com/statistics/1080566/india-economic-contribution-of-tomatoes/ (accessed on 6 September 2022).

- Arun Kumar, S. Supply Chain Management of Tomato Based Food Processing Industries. Int. J. Sci. Eng. Res. 2017, 8, 97–102. [Google Scholar]

- Fernandes, S. Rotten tomatoes? A Mumbai start-up will now keep them for over a month. Hindustan Time, 11 January 2017. [Google Scholar]

- Narula, S.A. Reinventing cold chain industry in India: Need of the hour. Interview with Mr Sanjay Aggarwal. J. Agribus. Dev. Emerg. Econ. 2011, 1, 1–8. [Google Scholar] [CrossRef]

- Chakraborty, M. Cold Storage in India: Challenges and Prospects. Agriculture & Food: E-Newsletter, October 2020, pp. 458–460. Available online: https://www.researchgate.net/publication/344441289_Cold_Storage_in_India_Challenges_and_Prospects (accessed on 30 November 2022).

- Statista. Production Volume of Tomatoes across India from Financial Year 2015 to 2021, with an Estimate for 2022. Available online: https://www.statista.com/statistics/1039712/india-production-volume-of-tomatoes/ (accessed on 23 December 2022).

- ABC Fruits Tomato Varieties in India, Production in India and Season. Available online: https://www.abcfruits.net/tomato-varieties-in-india-production-and-season/ (accessed on 23 December 2022).

- Vala, K.V.; Kumpavat, M.T.; Datta, S. Long Distance Supply of Tomato: A Case Study of Anand (Gujarat). Int. J. Res. Agric. Sci. 2021, 8, 127–131. [Google Scholar]

- Negi, S.; Anand, N.; Trivedi, S. Factors that impact Quality during the Transportation of Tomatoes. Int. J. Appl. Logist. 2017, 7, 49–63. [Google Scholar] [CrossRef]

- Gustavsson, J.; Stage, J. Retail waste of horticultural products in Sweden. Resour. Conserv. Recycl. 2011, 55, 554–556. [Google Scholar] [CrossRef]

- Lebersorger, S.; Schneider, F. Food loss rates at the food retail, influencing factors and reasons as a basis for waste prevention measures. Waste Manag. 2014, 34, 1911–1919. [Google Scholar] [CrossRef]

- Sanyaolu, A.A.A. Postharvest Fungal Deterioration of Tomato (Lycopersicum Esculentum Mill) and Pepper (Capsicum Annum L): The “Esa” Connection. Sci. World J. 2016, 11, 1–10. [Google Scholar]

- Hegazy, R. Post-harvest Situation and Losses in India. Figshare 2016, 1–21. [Google Scholar] [CrossRef]

- Yahaya, S. Review of Post-Harvest Losses of Fruits and Vegetables. Biomed. J. Sci. Tech. Res. 2019, 13, 10192–10200. [Google Scholar] [CrossRef]

- FAO. Value of Agricultural Production—Tomato. Available online: https://www.fao.org/faostat/en/#data/QV (accessed on 6 September 2022).

- Sharma, S.; Shukla, R. Economic analysis of post harvest losses in onion in Ajmer district of Rajasthan. Int. J. Commer. Bus. Manag. 2018, 11, 19–23. [Google Scholar] [CrossRef] [PubMed]

- Elik, A.; Aysar, N. Strategies to Reduce Post-Harvest Losses for Fruits and Vegetables. Int. J. Sci. Technol. Res. 2019, 5, 29–39. [Google Scholar] [CrossRef]

- Deltsidis, A.I.; Brecht, J.K.; Bai, J.; Baldwin, E.A. Tomato chilling injury threshold defined by the volatile profiles of pink harvested tomato fruit. Acta Hortic. 2016, 1120, 143–149. [Google Scholar] [CrossRef]

- Li, L.; Lichter, A.; Chalupowicz, D.; Gamrasni, D.; Goldberg, T.; Nerya, O.; Ben-Arie, R.; Porat, R. Effects of the Ethylene-Action Inhibitor 1-Methylcyclopropene on Postharvest Quality of Non-Climacteric Fruit Crops. Postharvest Biol. Technol. 2016, 111, 322–329. [Google Scholar] [CrossRef]

- El-Ramady, H.R.; Domokos-szabolcsy, E.; Abdalla, N.A.; Taha, H.S.; Fári, M. Postharvest Management of Fruits and Vegetables Storage. In Sustainable Agriculture Reviews; Springer: Cham, Switzerland, 2015; ISBN 9783319091327. [Google Scholar]

- NHB, National Horticulture Board Storage Methode Cold Storage. Available online: http://www.nhb.gov.in/ (accessed on 9 May 2021).

- Workineh, M.; Lemma, H. Post Harvest Loss Management and Quality Control of Fruits and Vegetables in Ethiopia for Securing Food and nutrition—A review. Food Sci. Qual. Manag. 2020, 100, 21–28. [Google Scholar] [CrossRef]

- Dempsey, P.; Bansal, P. The art of air blast freezing: Design and efficiency considerations. Appl. Therm. Eng. 2012, 41, 71–83. [Google Scholar] [CrossRef]

- Foster Refrigerator Blast Chilling and Freezing-Learn the Basics of Blast Chilling and Blast Freezing. Available online: https://www.fosterrefrigerator.com/en/blast-chilling-and-freezing (accessed on 8 May 2021).

- Yin, R.K. Case Study Research: Design and Methods; Sage: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Nardi, P.M. Doing Survey Research: A Guide to Quantitative Methods, 4th ed.; Routledge: London, UK, 2018; ISBN 9781315172231. [Google Scholar]

- Aschemann-Witzel, J.; de Hooge, I.E.; Rohm, H.; Normann, A.; Bossle, M.B.; Grønhøj, A.; Oostindjer, M. Key characteristics and success factors of supply chain initiatives tackling consumer-related food waste—A multiple case study. J. Clean. Prod. 2017, 155, 33–45. [Google Scholar] [CrossRef]

- Bakshi, A.; Shemansky, J.M.; Chang, C.; Binder, B.M. History of Research on the Plant Hormone Ethylene. J. Plant Growth Regul. 2015, 34, 809–827. [Google Scholar] [CrossRef]

- Sualeh, A.; Daba, A.; Kiflu, S.; Mohammed, A. Effect of Storage Conditions and Packing Materials on Shelf life of Tomato. Food Sci. Qual. Manag. 2016, 56, 60–67. [Google Scholar]

- Ali, S.S.; Kaur, R.; Khan, S. Evaluating sustainability initiatives in warehouse for measuring sustainability performance: An emerging economy perspective. Ann. Oper. Res. 2022, 1–40. [Google Scholar] [CrossRef]

- Karthiga. Capital Investment Subsidy Scheme for Horticulture. Available online: https://www.indiafilings.com/learn/capital-investment-subsidy-scheme-for-horticulture/ (accessed on 30 November 2022).

- Dew, R.; Seal, C.J.; Brandt, K. Effects of temperature conditions during transport and storage on tomato fruit quality. Acta Hortic. 2016, 1120, 317–322. [Google Scholar] [CrossRef]

- Firdous, N. Post-harvest losses in different fresh produces and vegetables in Pakistan with particular focus on tomatoes. J. Hortic. Postharvest Res. 2020, 2021, 71–86. [Google Scholar] [CrossRef]

- Energypedia Cold Storage for Agricultural Products. Available online: https://energypedia.info/wiki/Cold_Storage_of_Agricultural_Products (accessed on 24 February 2022).

- Usall, J.; Ippolito, A.; Sisquella, M.; Neri, F. Physical treatments to control postharvest diseases of fresh fruits and vegetables. Postharvest Biol. Technol. 2016, 122, 30–40. [Google Scholar] [CrossRef]

- Barkai-Golan, R. Postharvest Disease Initiation. In Postharvest Diseases of Fruits and Vegetables; Elsevier Science: Amsterdam, The Netherlands, 2001; pp. 3–24. [Google Scholar] [CrossRef]

- Tigist, M.; Workneh, T.S.; Woldetsadik, K. Effects of variety on the quality of tomato stored under ambient conditions. J. Food Sci. Technol. 2013, 50, 477–486. [Google Scholar] [CrossRef] [PubMed]

- Cherono, K.; Sibomana, M.; Workneh, T.S. Effect of infield handling conditions and time to pre-cooling on the shelf-life and quality of tomatoes. Braz. J. Food Technol. 2018, 21, e2017016. [Google Scholar] [CrossRef]

- Ikegwuonu, N.C. The Solution: Walk-in, Solar-Powered Cold Stations for 24/7 Storage and Preservation. Available online: https://www.coldhubs.com/ (accessed on 8 May 2021).

- CRS Mini Mobile Cold Stores. Available online: https://www.crscoldstorage.co.uk/specialist/mini-mobile-cold-stores.html (accessed on 18 October 2021).

- Kaipia, R.; Dukovska-popovska, I.; Loikkanen, L. Creating sustainable fresh food supply chains through waste reduction. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 262–276. [Google Scholar] [CrossRef]

- Lee, H.L.; Whang, S. Information sharing in a supply chain. Int. J. Manuf. Technol. Manag. 2000, 1, 79–93. [Google Scholar] [CrossRef]

- Mishra, N.; Singh, A. Use of twitter data for waste minimisation in beef supply chain. Ann. Oper. Res. 2018, 270, 337–359. [Google Scholar] [CrossRef]

- Sharma, G.; Singh, S.P. Economic Analysis of Post-harvest Losses in Marketing of. Agric. Econ. Res. Rev. 2011, 24, 309–315. [Google Scholar]

- DTE Staff. As told to Parliament (November 30, 2021): 5,579 Indian farmers died by suicide in 2020. 2021. Available online: https://www.downtoearth.org.in/news/agriculture/as-told-to-parliament-november-30-2021-5-579-indian-farmers-died-by-suicide-in-2020-80453 (accessed on 1 December 2021).

| Category of Causes | Specific Causes |

|---|---|

| Physical causes | Heating of fruits Cooling and freezing Water loss Reduction in relative humidity |

| Physiological causes | Ethylene production Transpiration and respiration Senescence Sprouting and rooting |

| Mechanical causes | Damages due to cuts and bruises Scrapings Shrinkage |

| Hygiene-related causes | Dampness during storage Microbial action and pest infestation Rodent action |

| Activity | Causes of Losses | Possible Solutions | Current Status and Implementation Challenges |

|---|---|---|---|

| Harvesting | Common causes of losses are: mechanical damage to the crop, such as scratches, punctures, and bruises, as well as weight loss and wilting due to heat. |

| Yes, this practice is generally followed. |

| Handling | Mechanical injury paves the way for pest attack and increases physiological losses. |

| Yes. This solution is followed. |

| Sorting and cleaning | Low-grade fruits do not bring market value. |

| Farmers do systematic sorting and grading before sending to the agents, but ethylene treatment is not followed. |

| Packaging | Damage due to long-distance travel, stacking, and improper air conditioning |

| No. This is not followed, although a feasible solution. Instead, fruits are transported in crates. |

| Storage | Reduced shelf life due to improper or no storage options. |

| None of the techniques is followed since the structures are not constructed owing to high maintenance. |

| Transport | Damaged rotten fruits due to watering fresh produce and rough loading and unloading. |

| Transport loss minimization requires paying close attention to the vehicles, equipment, infrastructure, and handling. It is not implemented because it is expensive to maintain. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohan, A.; Krishnan, R.; Arshinder, K.; Vandore, J.; Ramanathan, U. Management of Postharvest Losses and Wastages in the Indian Tomato Supply Chain—A Temperature-Controlled Storage Perspective. Sustainability 2023, 15, 1331. https://doi.org/10.3390/su15021331

Mohan A, Krishnan R, Arshinder K, Vandore J, Ramanathan U. Management of Postharvest Losses and Wastages in the Indian Tomato Supply Chain—A Temperature-Controlled Storage Perspective. Sustainability. 2023; 15(2):1331. https://doi.org/10.3390/su15021331

Chicago/Turabian StyleMohan, Aishwarya, Ramesh Krishnan, Kaur Arshinder, John Vandore, and Usha Ramanathan. 2023. "Management of Postharvest Losses and Wastages in the Indian Tomato Supply Chain—A Temperature-Controlled Storage Perspective" Sustainability 15, no. 2: 1331. https://doi.org/10.3390/su15021331

APA StyleMohan, A., Krishnan, R., Arshinder, K., Vandore, J., & Ramanathan, U. (2023). Management of Postharvest Losses and Wastages in the Indian Tomato Supply Chain—A Temperature-Controlled Storage Perspective. Sustainability, 15(2), 1331. https://doi.org/10.3390/su15021331