Characteristics and Resource Recovery Strategies of Solid Waste in Sewerage Systems

Abstract

1. Introduction

| Purpose of Treatment | Processing Thoughts | Methods |

|---|---|---|

| Reduction | Reduce the generation of solid waste | Using green building materials [17,18] |

| Reduce the volume after solid waste generation | Flocculation, sedimentation, and dewatering [19,20,21] | |

| Resource utilization | Reuse as road building materials | Crushing, screening, magnetic sorting, and removal of light materials [9,10] Modified by adding lime, cement, fly ash, silica fume, blast furnace slag, steel slag, rice husk ash, etc. [22,23,24,25,26,27] |

| Reuse as concrete, brick, and ceramic | Heating and compressing [28,29,30] | |

| Converted to materials such as natural gas and fertilizer | Thermochemical treatment or anaerobic digestion [6,7,8] | |

| Harmless treatment | Remove or stabilize harmful substances | Solidification or stabilization [11] Thermal treatment [12] Separation or extraction [13] |

2. Materials and Methods

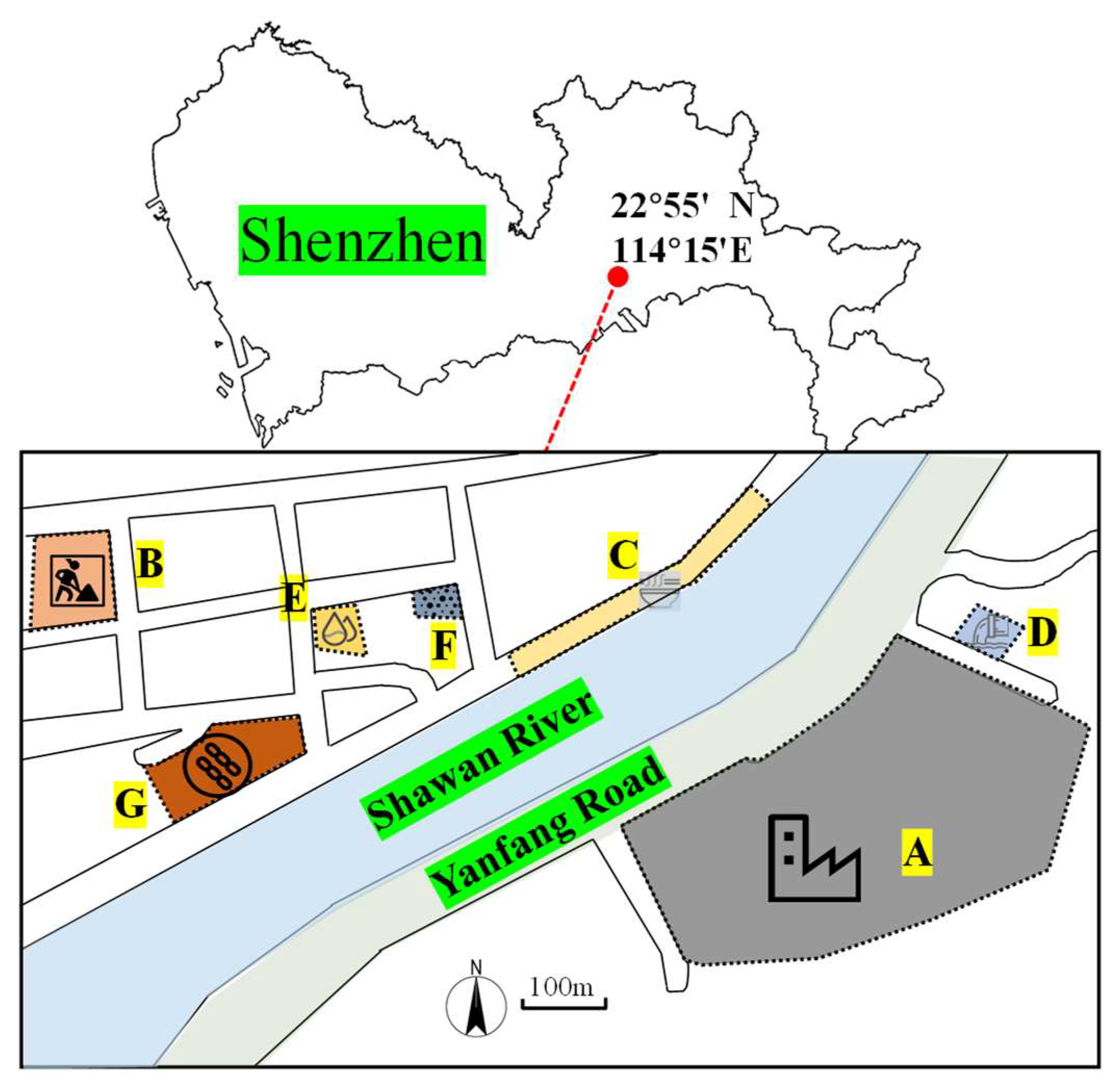

2.1. Sampling Location

2.2. Solid Waste Characterization

2.3. Codes and Standards

3. Results

3.1. Solid Waste Characterization of the Terminal

3.2. Solid Waste Characterization in Different Sewerage Facilities

4. Discussion

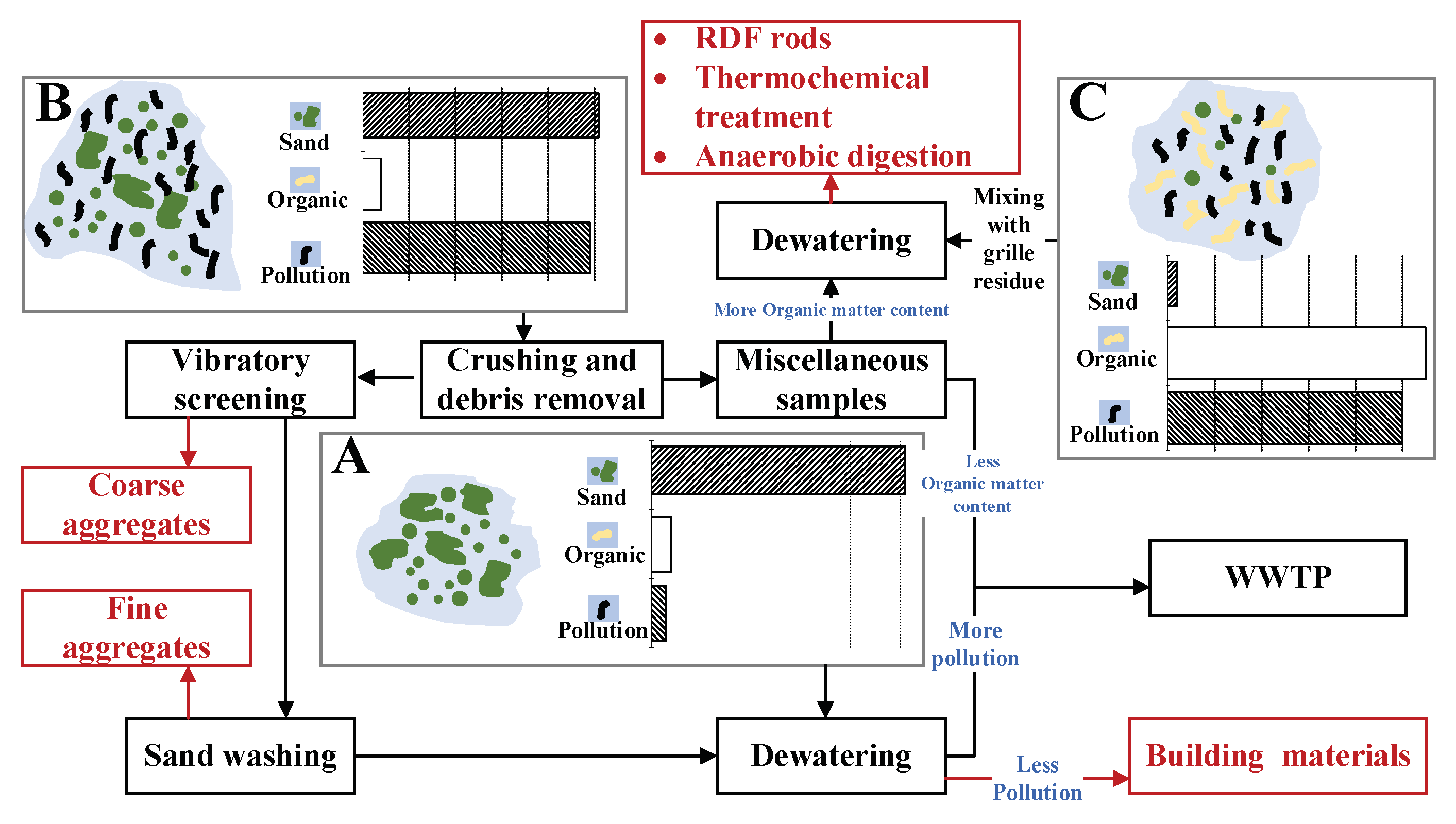

4.1. Approach of Resource Utilization for Solid Waste in Terminal

4.2. Approach of Resource Utilization for Solid Waste in Different Sewerage Facilities

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| As | Arsenic | Pb | Lead |

| Cd | Cadmium | PAHs | Polycyclic aromatic hydrocarbons |

| COD | Chemical oxygen demand | PS | The sample from pumping station |

| Cr | Chromium | RDF | Refuse derived fuel |

| Cu | Cuprum | RDP-Co | The sample from rainwater drainage pipes near the construction site |

| GC | The sample from grit chamber | RDP-Cu | The sample from rainwater drainage pipes near the cuisine street |

| GT | The sample from grease trap | ST | The sample from septic tank |

| Hg | Hydrargyrum | TN | Total nitrogen |

| LWPP | The samples from Luofang Water Purification Plant | TP | Total phosphorus |

| NH3-N | Ammonia nitrogen | TPH | Total petroleum hydrocarbon |

| Ni | Nickel | WWTP | Wastewater treatment plant |

| Zn | Zinc |

References

- Trotti, F.; Caldognetto, E.; Forte, M.; Nuccetelli, C.; Risica, S.; Rusconi, R. Estonian waterworks treatment plants: Clearance of residues, discharge of effluents and efficiency of removal of radium from drinking water. J. Radiol. Prot. 2013, 33, 809–822. [Google Scholar] [CrossRef] [PubMed]

- Mokonyama, S.; Schalkwyk, M.; Rajagopaul, R. Guidelines and good practices for water treatment residues handling, disposal and reuse in South Africa. Water Res. Comm. Gezina S. Afr. 2017, 140. Available online: https://wrc.org.za/wp-content/uploads/mdocs/TT738.pdf (accessed on 13 January 2023).

- Anyakora, N.V.; Ajinomoh, C.S.; Ahmed, A.S.; Mohammed-Dabo, I.A.; Ejeh, S.P.; Okuofu, C.A.; Abba, H. Phase and Micro-Chemical Characterization of Water Works Sludge Minerals and their Thermally-Decomposed Products. J. Eng. Res. 2016, 21, 9–20. [Google Scholar]

- Titshall, L.W.; Hughes, J.C. Characterisation of some South African water treatment residues and implications for land application. Water SA 2005, 31, 299–308. [Google Scholar] [CrossRef]

- Bugajski, P.; Operacz, A.; Młyński, D.; Wałęga, A.; Kurek, K. Optimizing treatment of cesspool wastewater at an activated sludge plant. Sustainability 2020, 12, 10196. [Google Scholar] [CrossRef]

- Nandhini, R.; Berslin, D.; Sivaprakash, B.; Rajamohan, N.; Vo, D.N. Thermochemical conversion of municipal solid waste into energy and hydrogen: A review. Environ. Chem. Lett. 2022, 20, 1645–1669. [Google Scholar] [CrossRef]

- Hartmann, H.; Ahring, B.K. Strategies for the anaerobic digestion of the organic fraction of municipal solid waste: An overview. Water Sci. Technol. 2006, 53, 7–22. [Google Scholar] [CrossRef]

- Khan, A.H.; Sharholy, M.; Alam, P.; Al-Mansour, A.I.; Ahmad, K.; Kamal, M.A.; Alam, S.; Pervez, M.N.; Naddeo, V. Evaluation of cost benefit analysis of municipal solid waste management systems. J. King Saud Univ. 2022, 34, 101997. [Google Scholar] [CrossRef]

- Cai, X.; Wu, K.; Huang, W.; Yu, J.; Yu, H. Application of recycled concrete aggregates and crushed bricks on permeable concrete road base. Road Mater. Pavement Des. 2021, 22, 2181–2196. [Google Scholar] [CrossRef]

- Asokan, P.; Saxena, M.; Asolekar, S.R. Coal combustion residues—Environmental implications and recycling potentials. Resour. Conserv. Recycl. 2005, 43, 239–262. [Google Scholar] [CrossRef]

- Ma, W.; Chen, D.; Pan, M.; Gu, T.; Zhong, L.; Chen, G.; Yan, B.; Cheng, Z. Performance of chemical chelating agent stabilization and cement solidification on heavy metals in MSWI fly ash: A comparative study. J. Environ. Manag. 2019, 247, 169–177. [Google Scholar] [CrossRef] [PubMed]

- Lindberg, D.; Molin, C.; Hupa, M. Thermal treatment of solid residues from WtE units: A review. Waste Manag. 2015, 37, 82–94. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Cheng, Y.; He, D.; Yang, E. Review of leaching behavior of municipal solid waste incineration (MSWI) ash. Sci. Total Environ. 2019, 668, 90–103. [Google Scholar] [CrossRef]

- Yang, Y.; Liew, R.K.; Tamothran, A.M.; Foong, S.Y.; Yek, P.N.Y.; Chia, P.W.; Van Tran, T.; Peng, W.; Lam, S.S. Gasification of refuse-derived fuel from municipal solid waste for energy production: A review. Environ. Chem. Lett. 2021, 19, 2127–2140. [Google Scholar] [CrossRef]

- Hoppe, E.J.; Lane, D.S.; Fitch, G.M.; Shetty, S. Feasibility of Reclaimed Asphalt Pavement (RAP) Use as Road Base and Subbase Material. Available online: https://rosap.ntl.bts.gov/view/dot/28518 (accessed on 13 January 2023).

- Moawad, H.; Zohdy, L.I.; Badr El-Din, S.; Khalafallah, M.A.; Abdel-Maksoud, H.K. Assessment of anaerobically digested slurry as a fertilizer and soil conditioner. In Biogas Technology, Transfer and Diffusion; Springer: Berlin/Heidelberg, Germany, 1986; pp. 499–519. [Google Scholar]

- Saghafi, M.D.; Teshnizi, Z.S.H. Recycling value of building materials in building assessment systems. Energy Build. 2011, 43, 3181–3188. [Google Scholar] [CrossRef]

- Aye, L.; Hes, D. Green building rating system scores for building reuse. J. Green Build. 2012, 7, 105–112. [Google Scholar] [CrossRef]

- Ding, A.; Qu, F.; Liang, H.; Guo, S.; Ren, Y.; Xu, G.; Li, G. Effect of adding wood chips on sewage sludge dewatering in a pilot-scale plate-and-frame filter press process. RSC Adv. 2014, 4, 24762–24768. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, W.; Wu, S.; Liu, J.; Hou, H.; Lin, N. The role of lime in dredged mud dewatered by a plate and frame filter press and potential substitutes. Environ. Sci. Pollut. Res. 2021, 28, 17331–17342. [Google Scholar] [CrossRef]

- Verma, S.; Klima, M.S. Evaluation of a pilot-scale, plate-and-frame filter press for dewatering thickener underflow slurries from bituminous coal-cleaning plants. Int. J. Coal Prep. Util. 2010, 30, 1–19. [Google Scholar] [CrossRef]

- Oggeri, C.; Fenoglio, T.M.; Vinai, R. Tunnel spoil classification and applicability of lime addition in weak formations for muck reuse. Tunn. Undergr. Space Techcol. 2014, 44, 97–107. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Lin, X.; Su, S.; Zhao, B. To ameliorate the performance of recycled aggregate concrete (RAC) by pre-treating aggregate in sulfoaluminate cement slurry and water glass solution. J. Build. Eng. 2021, 44, 103364. [Google Scholar] [CrossRef]

- Dave, S.; Raj, D.; Raval, J. To Study the Characteristics of Recycled Concrete Aggregates upon Their Treatment with a Weak Acid and Geopolymer Slurry. Available online: http://ir.pdpu.ac.in:8080/jspui/handle/123456789/173 (accessed on 13 January 2023).

- Li, H.; Tong, Y.; Zhang, H.; Zhang, X.; Duan, J. Study on road performance of cement fly ash stabilized steel slag—Concrete recycled macadam. Materials 2021, 14, 7530. [Google Scholar] [CrossRef]

- Yan, K.; Lan, H.; Li, Q.; Ge, D.; Li, Y. Optimum utilization of recycled aggregate and rice husk ash stabilized base material. Constr. Build. Mater. 2022, 348, 128627. [Google Scholar] [CrossRef]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.; Mukherjee, A.; Barai, S.V. A review on different treatment methods for enhancing the properties of recycled aggregates for sustainable construction materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Constr. Build. Mater. 2011, 25, 4037–4042. [Google Scholar] [CrossRef]

- Boarder, R.; Owens, P.L.; Khatib, J.M. The sustainability of lightweight aggregates manufactured from clay wastes for reducing the carbon footprint of structural and foundation concrete. In Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 209–244. [Google Scholar]

- Hossain, S.S.; Roy, P.K. Sustainable ceramics derived from solid wastes: A review. J. Asian Ceram. Soc. 2020, 8, 984–1009. [Google Scholar] [CrossRef]

- Ministry of Agriculture of the PRC. Method for Determination of Soil Organic Matter. China Agriculture Press: Beijing, China, 2010. Available online: https://www.doc88.com/p-4921296827978.html (accessed on 14 November 2022).

- Ministry of Environmental Protection of the People’s Republic of China. Solid Waste—Determination of Mercury, Arsenic, Selenium, Bismuth, Antimony—Microwave Dissolution/Atomic Fluorescence Spectrometry. China Environmental Press: Beijing, China, 2014. Available online: https://www.doc88.com/p-68939064249582.html (accessed on 14 November 2022).

- Ministry of Environmental Protection of the People’s Republic of China. Solid Waste—Determination of Lead, Zinc and Cadmium-Flame atomic absorption spectrometry. China Environmental Press: Beijing, China, 2016. Available online: https://www.doc88.com/p-9922568892068.html (accessed on 14 November 2022).

- Ministry of Environmental Protection of the People’s Republic of China. Solid Waste—Determination of Metals—Inductively Coupled Plasma Mass Spectrometry (ICP-MS). China Environmental Press: Beijing, China, 2015. Available online: https://www.doc88.com/p-9048715200664.html (accessed on 14 November 2022).

- Ministry of Ecology and Environment of the People’s Republic of China. Soil and Sediment—Determination of Petroleum Hydrocarbons (C10-C40)—Gas Chromatography. China Environment Publishing Group: Beijing, China, 2019. Available online: https://www.doc88.com/p-60529008112529.html (accessed on 14 November 2022).

- Ministry of Construction of the People’s Republic of China. Determination Method for Municipal Sludge in Wastewater Treatment Plant. Standards Press of China: Beijing, China, 2005. Available online: https://www.doc88.com/p-1186038269.html (accessed on 14 November 2022).

- Ministry of Environmental Protection of the People’s Republic of China. Solid Waste—Determination of Polycyclic Aromatic Hydrocarbons—High Performance Liquid Chromatography. China Environmental Press: Beijing, China, 2017. Available online: https://www.doc88.com/p-9099672501868.html (accessed on 14 November 2022).

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. Proximate Analysis of Coal. Standards Press of China: Beijing, China, 2009. Available online: https://www.doc88.com/p-1933807965091.html (accessed on 14 November 2022).

- Ministry of Environmental Protection of the People’s Republic of China. Water Quality—Determination of pH—Electrode Method. China Environmental Press: Beijing, China, 2020. Available online: https://www.doc88.com/p-99599060330118.html (accessed on 14 November 2022).

- Ministry of Environmental Protection of the People’s Republic of China. Water Quality—Determination of the Chemical Oxygen Demand—Dichromate Method. China Environmental Press: Beijing, China, 2017. Available online: https://www.doc88.com/p-7794991208370.html (accessed on 14 November 2022).

- State Environmental Protection Administration; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Environmental Quality Standards for Surface Water. China Environmental Press: Beijing, China, 2002. Available online: https://www.doc88.com/p-7763822545075.html (accessed on 14 November 2022).

- Ministry of Construction of the People’s Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Code for Design of Municipal Wastewater Reclamation and Reuse. China Environmental Press: Beijing, China, 2016. Available online: https://www.doc88.com/p-6488418465814.html (accessed on 14 November 2022).

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Planting Soil for Greening. Standards Press of China: Beijing, China, 2016. Available online: https://www.doc88.com/p-34087139088771.html (accessed on 15 November 2022).

- Ministry of Transport of the People’s Republic of China. Specifications for Design of Highway Subgrades. China Communications Press: Beijing, China, 2004. Available online: https://www.doc88.com/p-3874248635707.html (accessed on 14 November 2022).

- Shenzhen Administration for Market Regulation. Risk Screening Values and Intervention Values for Soil Contamination of Development Land. Shenzhen Publishing Group: Shenzhen, China, 2020. Available online: https://www.doc88.com/p-24359487432786.html (accessed on 14 November 2022).

- Ministry of Construction of the People’s Republic of China. Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2006. Available online: https://www.doc88.com/p-135711922595.html (accessed on 14 November 2022).

- Oelkers, E.H.; Benning, L.G.; Lutz, S.; Mavromatis, V.; Pearce, C.R.; Plümper, O. The efficient long-term inhibition of forsterite dissolution by common soil bacteria and fungi at Earth surface conditions. Geochim. Cosmochim. Acta 2015, 168, 222–235. [Google Scholar] [CrossRef]

- Khan, A.H.; López-Maldonado, E.A.; Khan, N.A.; Villarreal-Gómez, L.J.; Munshi, F.M.; Alsabhan, A.H.; Perveen, K. Current solid waste management strategies and energy recovery in developing countries—State of art review. Chemosphere 2022, 291, 133088. [Google Scholar] [CrossRef]

- Świerczek, L.; Cieślik, B.M.; Konieczka, P. The potential of raw sewage sludge in construction industry—A review. J. Clean. Prod. 2018, 200, 342–356. [Google Scholar] [CrossRef]

| Sample Type | Test Items | Reference Standards |

|---|---|---|

| All solid waste | Organic matter | Method for determination of soil organic matter (GB 9834-88) [31] |

| As | Solid Waste—Determination of Mercury, Arsenic, Selenium, Bismuth, Antimony—Microwave Dissolution/Atomic Fluorescence Spectrometry (HJ 702-2014) [32] Solid waste—Determination of Lead, Zinc and Cadmium- Flame atomic absorption spectrometry (HJ 786-2016) [33] Solid waste—Determination of metals- Inductively Coupled Plasma Mass Spectrometry (ICP- MS) (HJ766-2015) [34] | |

| Hg | ||

| Zn | ||

| Pb | ||

| Cd | ||

| Cr | ||

| Ni | ||

| Cu | ||

| TPH | Soil and sediment—Determination of petroleum hydrocarbons (C10- C40)—gas chromatography (HJ 1021-2019) [35] | |

| Bacteria | Determination method for municipal sludge in wastewater treatment plant (CJ/T 221-2005) [36] | |

| PAHs | Solid waste—Determination of polycyclic aromatic hydrocarbons—High performance liquid chromatography (HJ 892-2017) [37] | |

| Grille residue | Volatile substances, Ash, and Solid carbon | Proximate analysis of coal (GB/T 212-2008) [38] |

| Sewage | pH | Water quality—Determination of pH—Electrode method (HJ 1147-2020) [39] |

| COD | Water quality—Determination of the Chemical Oxygen Demand—Dichromate Method (HJ 828-2017) [40] | |

| TN | Environmental quality standards for surface water (GB3838-2002) [41] | |

| TP | ||

| NH3-N |

| Sample Type | Related Codes and Standards |

|---|---|

| Sewage | Environmental quality standards for surface water (GB 3838-2002) [41] |

| Code for design of municipal wastewater reclamation and reuse (GB50335-2016) [42] | |

| Coarse aggregates | Planting soil for greening (CJ/T340-2016) [43] |

| Specifications for Design of Highway Subgrades (JTG D30-2004) [44] | |

| Risk screening values and intervention values for soil contamination of development land (DB4430/T 67-2020) [45] | |

| Fine aggregates | Standard for technical requirements and test method of sand and crushed stone (or gravel) for ordinary concrete (JGJ 52-2006) [46] |

| Test Items | Coarse Aggregates | Fine Aggregates | Grille Residue | Substrate |

|---|---|---|---|---|

| pH | 8.5 | 8.3 | 6.8 | 6.9 |

| Water content (%) | 8 | 12.8 | 40 | 92 |

| Organic matter (%) | 1.77 | 8 | 76 | 34.8 |

| PAHs (µg/L) | ND * | ND | ND | ND |

| Bacteria (pcs/g) | 2.1 × 107 | 1.7 × 106 | 1.7 × 108 | 3.6 × 108 |

| pH | Organic Matter (%) | COD (mg/L) | TN (mg/L) | NH3-N (mg/L) | TP (mg/L) | TPH (mg/L) |

|---|---|---|---|---|---|---|

| 6.1 | 30 | 8.45 × 103 | 457 | 334 | 57.7 | 2.13 |

| Volatile Substances (%) | Ash (%) | Solid Carbon (%) |

|---|---|---|

| 73.71 | 15.80 | 10.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; He, J.; Lv, W.; Wu, S.; Peng, Y.; Peng, Y.; Fei, J.; Wu, Z. Characteristics and Resource Recovery Strategies of Solid Waste in Sewerage Systems. Sustainability 2023, 15, 1662. https://doi.org/10.3390/su15021662

Sun X, He J, Lv W, Wu S, Peng Y, Peng Y, Fei J, Wu Z. Characteristics and Resource Recovery Strategies of Solid Waste in Sewerage Systems. Sustainability. 2023; 15(2):1662. https://doi.org/10.3390/su15021662

Chicago/Turabian StyleSun, Xiaohui, Junpei He, Wei Lv, Silin Wu, Yongshen Peng, Yuansheng Peng, Jianbo Fei, and Zezhou Wu. 2023. "Characteristics and Resource Recovery Strategies of Solid Waste in Sewerage Systems" Sustainability 15, no. 2: 1662. https://doi.org/10.3390/su15021662

APA StyleSun, X., He, J., Lv, W., Wu, S., Peng, Y., Peng, Y., Fei, J., & Wu, Z. (2023). Characteristics and Resource Recovery Strategies of Solid Waste in Sewerage Systems. Sustainability, 15(2), 1662. https://doi.org/10.3390/su15021662