Resource Matching in the Supply Chain Based on Environmental Friendliness under a Smart Contract

Abstract

1. Introduction

2. Research Hypothesis

2.1. Establishment of a Two-Sided Matching Model

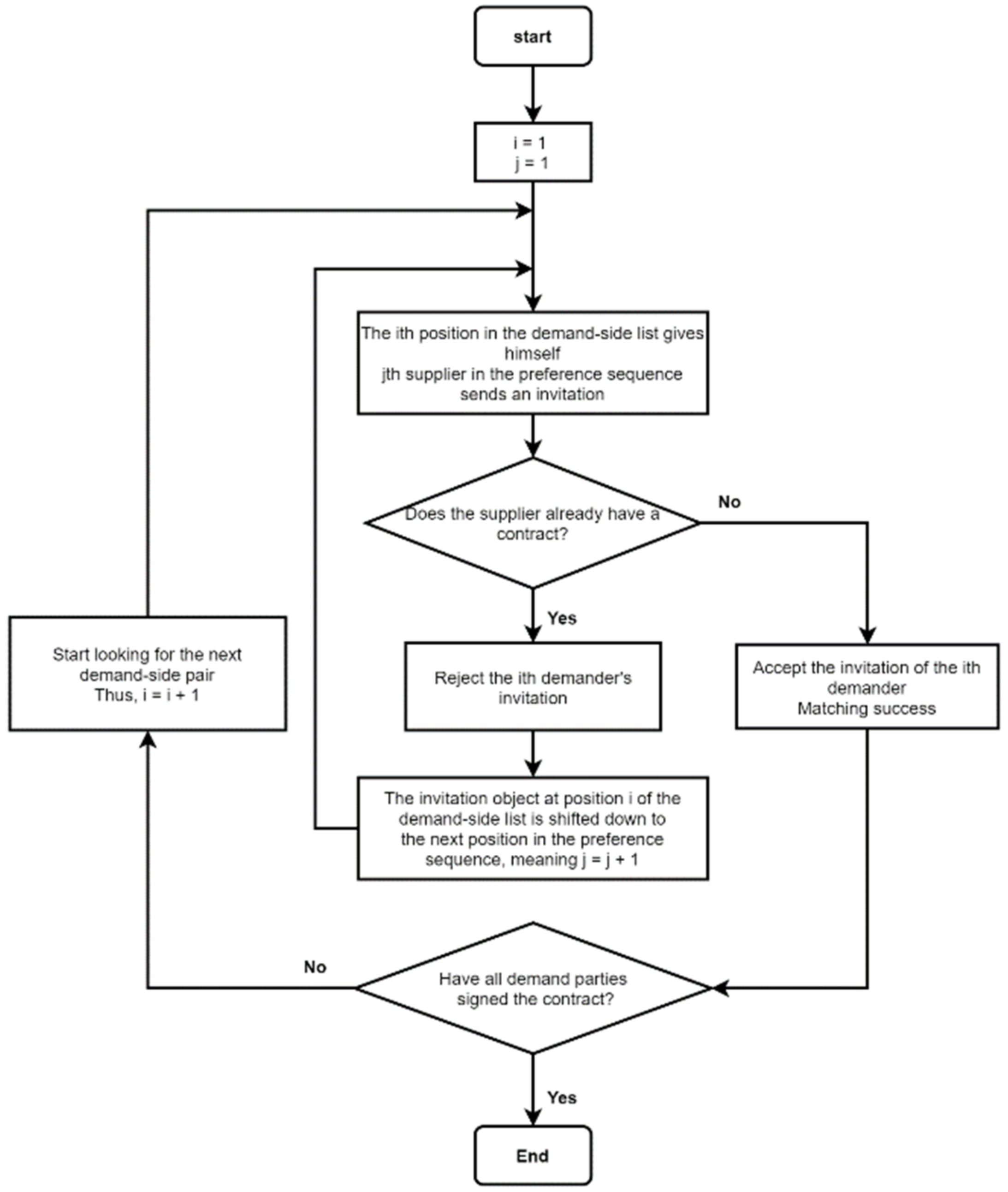

2.2. Logical Flow Design for Deploying Smart Contracts

2.3. System Flow Design of Smart Contracts

3. Matching Model Construction

3.1. Preference Calculation Based on Learning Theory

3.1.1. Cumulative Dynamic Learning Capability Calculation Based on Learning Effects on the Demand Side

3.1.2. Cumulative Dynamic Learning Capability Calculation Based on Learning Effects on the Supply Side

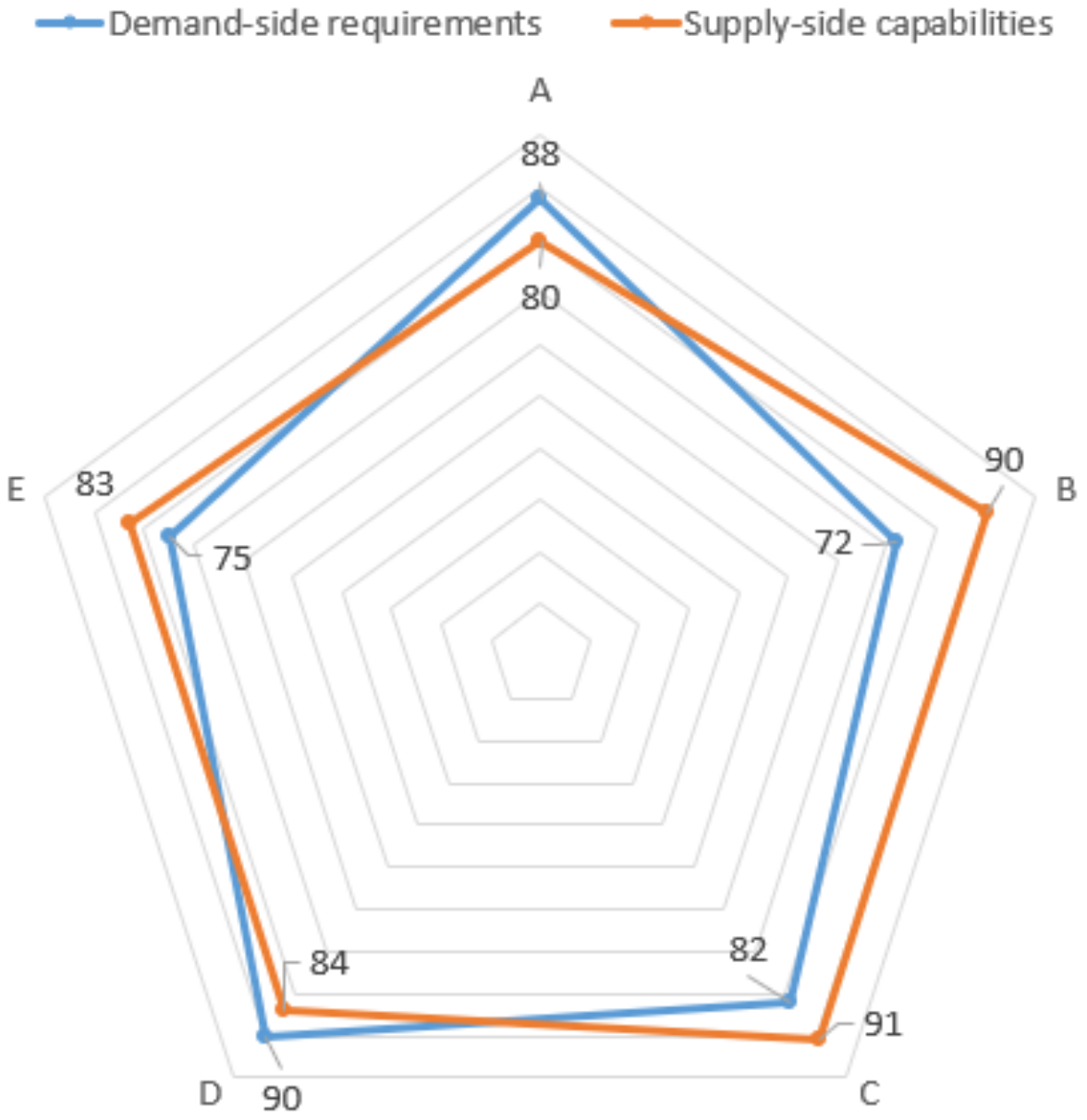

3.2. Calculation of Preference Based on Dynamic Evaluation Parameters

3.3. Multi-Dimensional Matching Model Construction

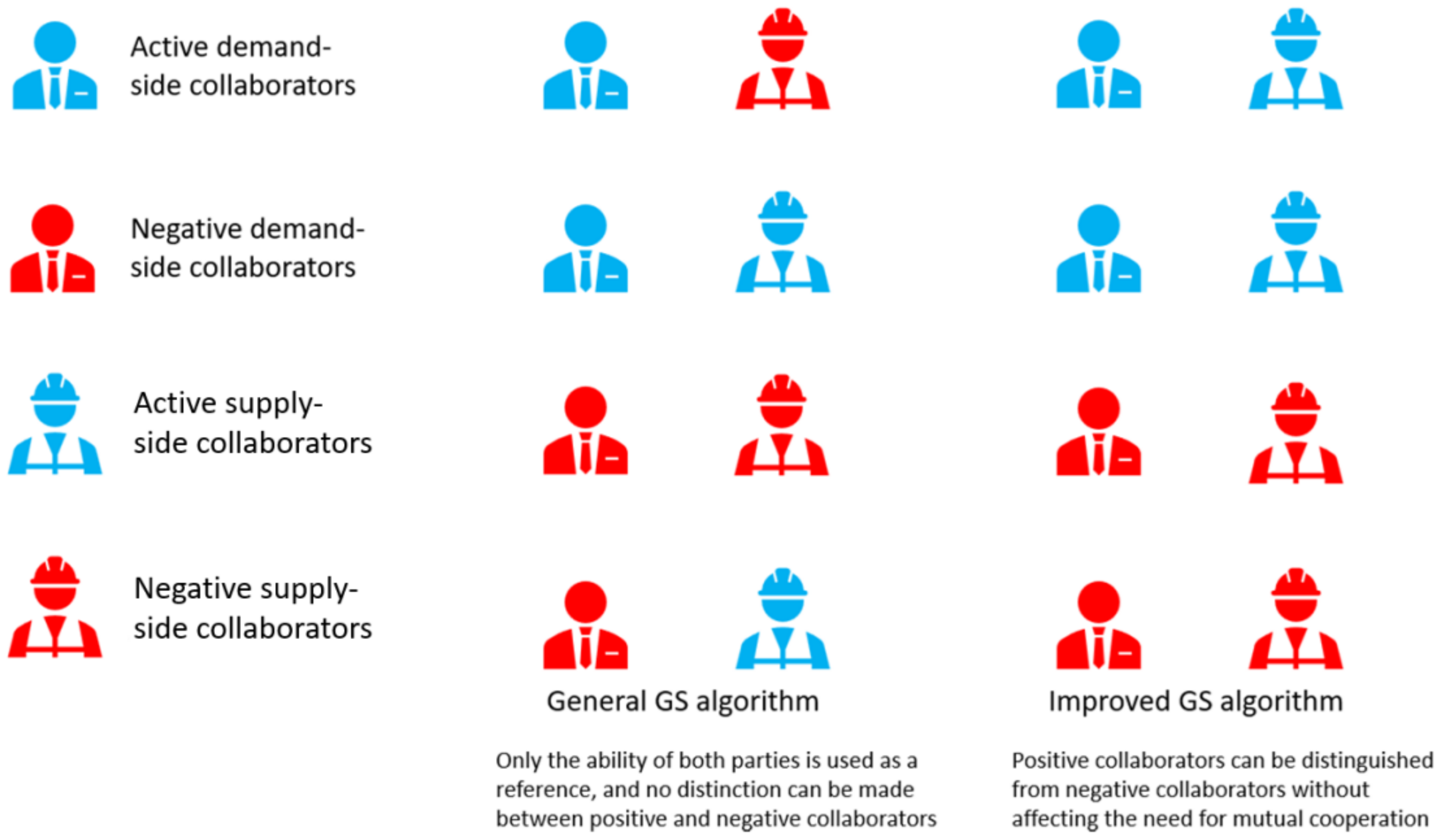

3.3.1. Establishment of Reference Sequences

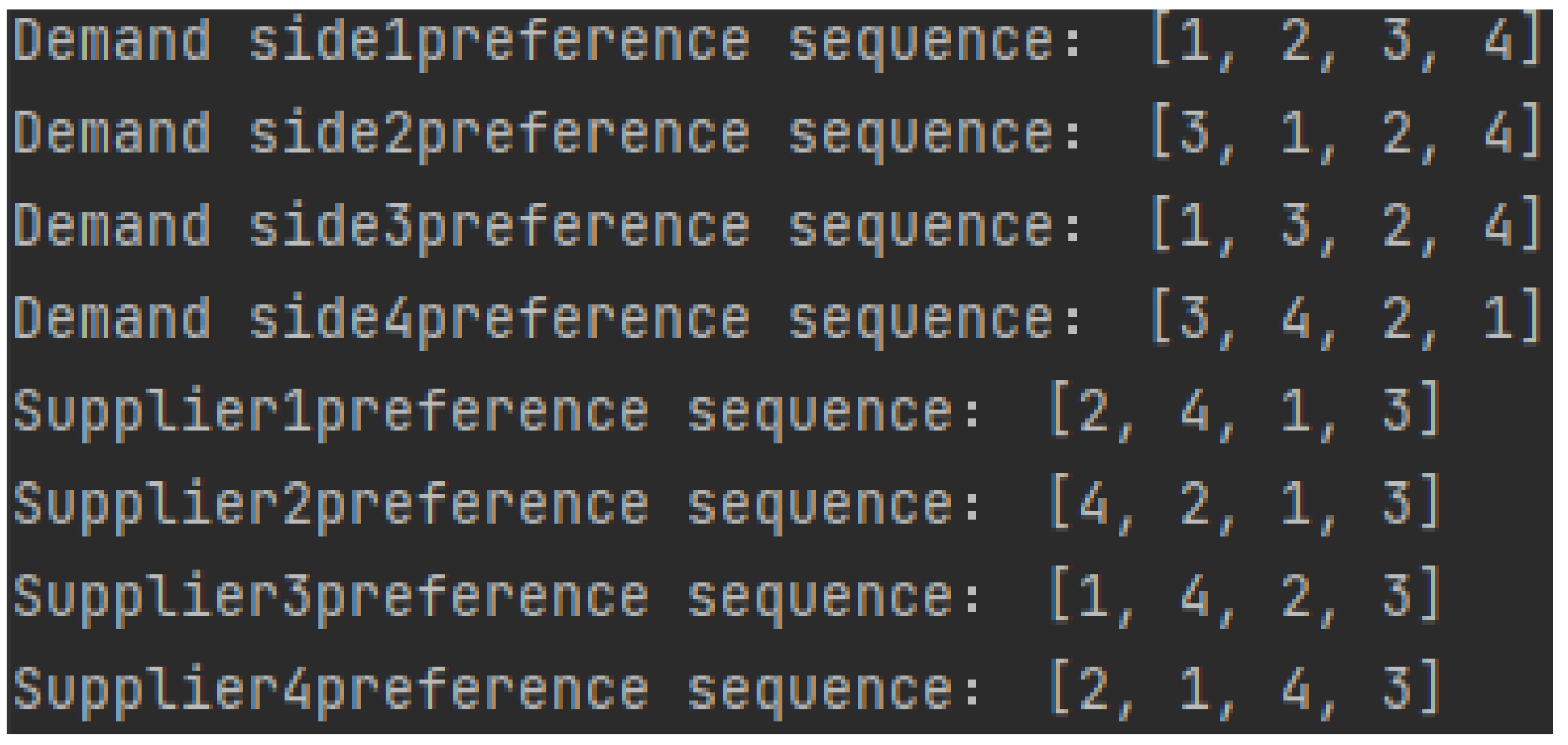

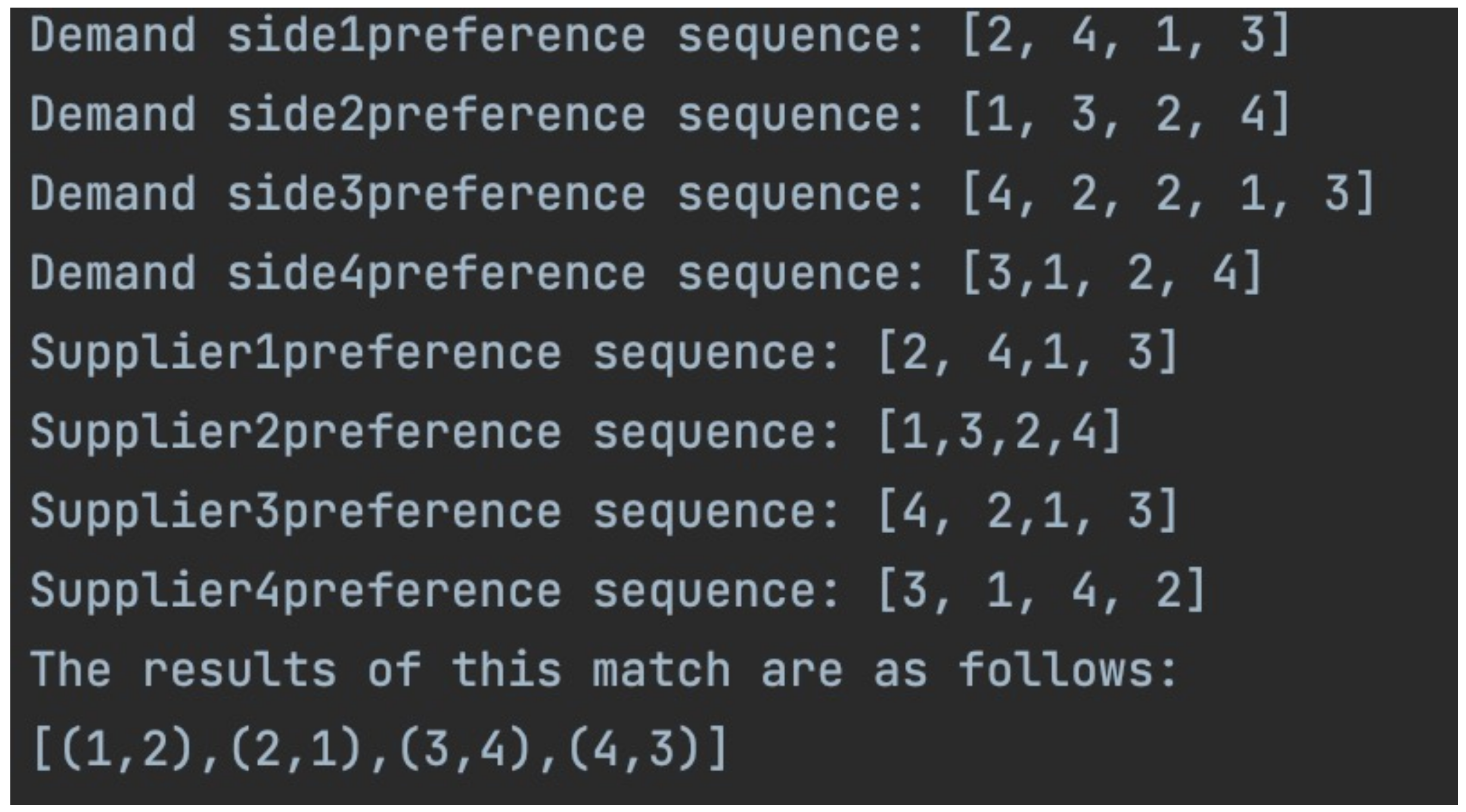

3.3.2. GS Algorithm Matching

4. Calculation Example Analysis

4.1. Introduction of Tianjin Industrial Cloud Platform

4.2. Tianjin Industrial Cloud Example Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Product Quality | Product Reputation | Production Scale | Registered Capital | Environmental Friendliness | |

|---|---|---|---|---|---|

| Supplier 1 | 80 | 90 | 76 | 69 | 80 |

| Supplier 2 | 74 | 86 | 75 | 81 | 75 |

| Supplier 3 | 79 | 82 | 79 | 83 | 72 |

| Supplier 4 | 75 | 87 | 92 | 89 | 91 |

| Payment Terms | Pickup Time | Demand Volume | Demand Stability | Environmental Friendliness | |

|---|---|---|---|---|---|

| Demand side 1 | 90 | 90 | 88 | 82 | 88 |

| Demand side 2 | 78 | 89 | 90 | 90 | 76 |

| Demand side 3 | 84 | 98 | 90 | 88 | 91 |

| Demand side 4 | 79 | 92 | 93 | 75 | 75 |

| Payment Terms | Pickup Time | Demand Volume | Demand Stability | Environmental Friendliness | Evaluation Parmeters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Demand side 1 | 90 | 90 | 88 | 82 | 88 | 75.24412 | 80 | 65.23 | 65.23 | 0.77 | 1 |

| Demand side 2 | 78 | 89 | 90 | 90 | 76 | 75.24412 | 78 | 65.23 | 65.23 | 0.81 | 1 |

| Demand side 3 | 84 | 98 | 90 | 88 | 91 | 75.24412 | 81 | 65.23 | 65.23 | 0.78 | 1 |

| Demand side 4 | 79 | 92 | 93 | 75 | 75 | 75.24412 | 82 | 65.23 | 65.23 | 0.79 | 1 |

| Product Quality | Product Reputation | Production Scale | Registered Capital | Environmental Friendliness | Evaluation Parameters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier 1 | 80 | 90 | 76 | 69 | 80 | 75.24412 | 82 | 65.23 | 65.23 | 0.75 | 1 |

| Supplier 2 | 74 | 86 | 75 | 81 | 75 | 75.24412 | 81 | 65.23 | 65.23 | 0.69 | 1 |

| Supplier 3 | 79 | 82 | 79 | 83 | 72 | 75.24412 | 75 | 65.23 | 65.23 | 0.73 | 1 |

| Supplier 4 | 75 | 87 | 92 | 89 | 91 | 75.24412 | 77 | 65.23 | 65.23 | 0.78 | 1 |

| Score | Score | ||

|---|---|---|---|

| Demand side 1 | 95 | Supplier 1 | 70 |

| Demand side 2 | 60 | Supplier 2 | 88 |

| Demand side 3 | 89 | Supplier 3 | 65 |

| Demand side 4 | 40 | Supplier 4 | 87 |

| Payment Terms | Pickup Time | Demand Volume | Demand Stability | Environmental Friendliness | Evaluation Parameters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Demand side 1 | 90 | 90 | 88 | 82 | 88 | 81.0301054 | 80 | 65.23 | 84.71429 | 0.77 | 2 |

| Demand side 2 | 78 | 89 | 90 | 90 | 76 | 76.5165612 | 78 | 65.23 | 86.97333 | 0.81 | 2 |

| Demand side 3 | 84 | 98 | 90 | 88 | 91 | 70.2036125 | 81 | 65.23 | 85.82895 | 0.78 | 2 |

| Demand side 4 | 79 | 92 | 93 | 75 | 75 | 73.9450121 | 82 | 65.23 | 82.56962 | 0.79 | 2 |

| Product Quality | Product Reputation | Production Scale | Registered Capital | Environmental Friendliness | Evaluation Parameters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier 1 | 80 | 90 | 76 | 69 | 80 | 77.84233573 | 82 | 65.23 | 86.97333 | 0.75 | 2 |

| Supplier 2 | 74 | 86 | 75 | 81 | 75 | 80.15539656 | 81 | 65.23 | 89.35616 | 0.69 | 2 |

| Supplier 3 | 79 | 82 | 79 | 83 | 72 | 77.1227818 | 75 | 65.23 | 89.35616 | 0.73 | 2 |

| Supplier 4 | 75 | 87 | 92 | 89 | 91 | 79.92748577 | 77 | 65.23 | 83.62821 | 0.78 | 2 |

References

- Mao, T. Research on China’s Industrial Low-carbon Transformation Under the Goal of Carbon Emission Peak and Carbon Neutralization. Reform 2022, 8, 67–75. [Google Scholar]

- Chen, J.; Zhao, C.; Gao, G.; Zhao, Z. Research on Dynamic Emission Reduction of Vertical Cooperation in Dual-channel Supply Chain under Carbon Cap and Trade Policy. Chin. J. Manag. Sci. 2022. Available online: https://kns.cnki.net/kcms/detail/11.2835.G3.20220916.1034.001.html (accessed on 1 November 2022).

- Zheng, H.; Yang, S.; Lou, S.; Gao, Y.; Feng, Y. Knowledge-based integrated product design framework towards sustainable low-carbon manufacturing. Adv. Eng. Inform. 2021, 48, 101258. [Google Scholar] [CrossRef]

- Guo, J.; Sun, L.; Zhang, C.; Nie, M.; Zhu, J. Evolutionary Game Analysis of Duopoly Enterprise’s Emission Reduction Decision under Cap-and-Trade Mechanism. Soft Sci. 2019, 32, 54–60. [Google Scholar]

- Xu, X.; Xu, X.; He, P. Joint production and pricing decisions for multiple products with cap-and-trade and carbon tax regulations. J. Clean. Prod. 2016, 112, 4093–4106. [Google Scholar] [CrossRef]

- Tao, Z. Review of Supply Chain Emission Reduction Decision and Coordination under the Background of Low Carbon. Econ. Res. Guide 2021, 8, 73–75. [Google Scholar]

- Yu, W.; Shang, H.; Han, R. The impact of carbon emissions tax on vertical centralized supply chain channel structure. Comput. Ind. Eng. 2020, 141, 106303. [Google Scholar] [CrossRef]

- Wei, F.; Xiong, Z.; Rong, L.; Wang, W. Research on the choice of green supply chain coordination mechanism in manufacturing industre. Price Theory Pract. 2021, 12, 471. [Google Scholar]

- Li, B.; Zhang, L.; Wang, S.; Tao, F.; Cao, J.; Jiang, X.; Song, X.; Chai, X. Cloud manufacturing: A new service-oriented networked manufacturing model. Comput. Integr. Manuf. Syst. 2010, 16, 1–16. [Google Scholar]

- Meng, K.; Wu, Z.; Huang, S.; Wang, Z.; Yan, X.; Sun, Y. Novel cloud manufacturing service selection method based on blockchain. Comput. Integr. Manuf. Syst. 2022. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=JSJJ2022061000D&DbName=CAPJ2022 (accessed on 25 August 2022).

- Zhou, L. Research on resource endowment, service model and development path of digitaltransformation of industrial park in the context of yangtze river delta integration. Future Dev. 2022, 46, 16–20. [Google Scholar]

- Zhang, D.; Sun, T.; Yan, C.; Chen, Y.; Wan, L. Two-sided matching method considering psychological behavior of agents based on multi-form preference information. Comput. Intergreated Manuf. Syst. 2018, 24, 3136–3143. [Google Scholar]

- Wang, J.; Ye, N.; Ge, L. Steady-State Power Quality Synthetic Evaluation Based on the Triangular Fuzzy BW Method and Interval VIKOR Method. Appl. Sci. 2020, 10, 2839. [Google Scholar] [CrossRef]

- Yue, Q.; Yu, B.; Peng, Y.; Zhang, L.; Yu, H. Hesitant fuzzy linguistic two-sided matching decision making. Filomat 2018, 32, 1853–1860. [Google Scholar] [CrossRef]

- Morizumi, Y.; Hayashi, T.; Ishida, Y. A network visualization of stable matching in the stable marriage problem. Artif. Life Robot. 2011, 16, 40–43. [Google Scholar] [CrossRef]

- Knoblauch, V. Marriage matching and gender satisfaction. Soc. Choice Welf. 2009, 32, 15–27. [Google Scholar] [CrossRef]

- Liang, R.; Wu, C.; Sheng, Z.; Wang, X. Multi-Criterion Two-Sided Matching of Public–Private Partnership Infrastructure Projects: Criteria and Methods. Sustainability 2018, 10, 1178. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, J.; Liu, X.; Cao, C.; Zhang, W. A Two-Sided Matching Model for Task Distribution in Ridesharing: A Sustainable Operations Perspective. Sustainability 2019, 11, 2187. [Google Scholar] [CrossRef]

- Aghamohammadzzadeh, E.; Fatahi Valilai, O. A novel cloud manufacturing service composition platform enabled by Blockchain technology. Int. J. Prod. Res. 2020, 58, 5280–5298. [Google Scholar] [CrossRef]

- Li, X.; Zheng, Z.; Dai, H.N. When services computing meets blockchain:Challenges and opportunities. J. Parallel Distrib. Comput. 2021, 150, 1–14. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, C.; Jiang, P.; Liu, Q.; Zhou, X. Blockchain-empowered sustainable manufacturing and product lifecycle management inindustry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, L.; Zhao, W.; Zhang, S. A blockchain-based service composition architecture in cloud manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 701–715. [Google Scholar] [CrossRef]

- Li, Z.; Ali, V.B.; Huang, G.Q. Toward a blockchain cloud manufacturing system as a peer to peer distributed network platform. Robot. Comput. Integr. Manuf. 2018, 54, 133–144. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, C.; Zhou, B. Trusted transaction method of manufacturing services based on blockchain. Comput. Integr. Manuf. Syst. 2019, 25, 3247–3257. [Google Scholar]

- Kshetri, N. Can blockchain strengthen the internet of things? IT Prof. 2017, 19, 68–72. [Google Scholar] [CrossRef]

- Zhang, P.; Qin, G.; Wang, Y. Optimal Maintenance Decision Method for Urban Gas Pipelines Based on as Low as Reasonably Practicable Principle. Sustainability 2019, 11, 153. [Google Scholar] [CrossRef]

- Gou, Z.H. Promoting and implementing urban sustainability in China: An integration of sustainable initiatives at different urban scales. Habitat Int. 2018, 82, 83–93. [Google Scholar]

- Cheng, T.C.E.; Wang, G. Single Machine Scheduling with Learning Effect Considerations. Ann. Oper. Res. 2000, 98, 273–290. [Google Scholar] [CrossRef]

- Niu, G. Grasp the opportunity of Beijing-Tianjin-Hebei synergistic development to promote the construction of “one base and three districts” in Tianjin. Tianjin Econ. 2017, 5, 3–8. [Google Scholar]

| Condition Acs | Condition Bcs | Condition Ccs | Condition Dcs | Environmental Friendliness | Evaluation Parameters | Service Rate | Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|

| Demand side |

| Acr | Bcr | Ccr | Dcr | |

|---|---|---|---|---|

| Demand side |

| Condition Ass | Condition Bss | Condition Css | Condition Dss | Environmental Friendliness | Evaluation Parameters | Service Rate | Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|

| Supply side |

| Asr | Bsr | Csr | Dsr | |

|---|---|---|---|---|

| Supply side |

| Acw | Bcw | Ccw | Dcw | Environmental Friendliness | Evaluation Parameters | Service Level | |

|---|---|---|---|---|---|---|---|

| Demand side |

| Asw | Bsw | Csw | Dsw | Environmental Friendliness | Evaluation Parameters | Service Level | |

|---|---|---|---|---|---|---|---|

| Supply side |

| Product Quality | Product Reputation | Production Scale | Registered Capital | Environmental Friendliness | Evaluation Parameters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier 1 | 80 | 73 | 95 | 77 | 92 | 81.2 | 95 | 65 | 273.9094 | 0.75 | 32 |

| Supplier 2 | 96.4 | 72 | 94 | 81 | 76 | 89.3 | 88 | 75 | 263.4757 | 0.77 | 29 |

| Supplier 3 | 79 | 79 | 79 | 83 | 81 | 82 | 80 | 72 | 306.8538 | 0.69 | 16 |

| Supplier 4 | 85 | 87 | 75 | 89 | 82 | 77 | 90 | 83 | 310.397 | 0.75 | 25 |

| Supplier 5 | 82 | 88 | 80 | 88 | 84 | 71 | 87 | 71.5 | 294.4248 | 0.74 | 27 |

| Supplier 6 | 71 | 82 | 91 | 80 | 90 | 65 | 73 | 82 | 260.7033 | 0.79 | 31 |

| Supplier 7 | 77 | 73 | 90 | 75 | 82 | 84 | 90 | 81 | 254.4274 | 0.8 | 35 |

| Supplier 8 | 80 | 90 | 75 | 89 | 83 | 83.5 | 85 | 77 | 322.0914 | 0.65 | 11 |

| Supplier 9 | 82 | 80 | 77 | 72 | 75 | 86.7 | 91 | 75 | 294.5309 | 0.75 | 28 |

| Supplier 10 | 82 | 85 | 75 | 79 | 95 | 80 | 90 | 66 | 303.4389 | 0.72 | 26 |

| Payment Terms | Pickup Time | Demand Volume | Demand Stability | Environmental Friendliness | Evaluation Parameters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Demand side 1 | 92 | 90 | 88 | 82 | 88 | 82 | 88 | 82 | 211.595 | 0.85 | 58 |

| Demand side 2 | 89 | 89 | 90 | 90 | 76 | 89 | 94 | 64 | 279.9149 | 0.75 | 35 |

| Demand side 3 | 82 | 98 | 90 | 77 | 77 | 76.8 | 89 | 85 | 306.8382 | 0.69 | 12 |

| Demand side 4 | 79 | 92 | 93 | 75 | 71 | 87.5 | 87 | 74 | 295.0235 | 0.75 | 29 |

| Demand side 5 | 70 | 73 | 91 | 96 | 75 | 60.2 | 91 | 77 | 257.0367 | 0.76 | 21 |

| Demand side 6 | 72 | 82 | 80 | 70 | 72 | 69.9 | 90 | 86 | 283.9475 | 0.78 | 29 |

| Demand side 7 | 79 | 89 | 75 | 79 | 78 | 81.8 | 82 | 60 | 316.7637 | 0.71 | 30 |

| Demand side 8 | 80 | 91 | 79 | 82 | 80 | 83.5 | 85 | 59 | 267.8598 | 0.73 | 29 |

| Demand side 9 | 78 | 81 | 79 | 87 | 70 | 88 | 87 | 85 | 276.4568 | 0.8 | 40 |

| Demand side 10 | 82 | 86 | 93 | 81 | 81 | 81.7 | 86 | 70 | 291.118 | 0.75 | 32 |

| Payment Terms | Pickup Time | Demand Volume | Demand Stability | Environmental Friendliness | |

|---|---|---|---|---|---|

| Supplier 1 | 81 | 90 | 91 | 81 | 79 |

| Supplier 2 | 82 | 88 | 92 | 75 | 79 |

| Supplier 3 | 89 | 92 | 87 | 79 | 72 |

| Supplier 4 | 84 | 91 | 88 | 85 | 75 |

| Supplier 5 | 88 | 91 | 85 | 80 | 76 |

| Supplier 6 | 80 | 88 | 86 | 87 | 76 |

| Supplier 7 | 68 | 75 | 94 | 96 | 72 |

| Supplier 8 | 79 | 83 | 83 | 86 | 75 |

| Supplier 9 | 76 | 86 | 86 | 90 | 79 |

| Supplier 10 | 90 | 82 | 85 | 82 | 71 |

| Product Quality | Product Reputation | Production Scale | Registered Capital | Environmental Friendliness | |

|---|---|---|---|---|---|

| Demand side 1 | 83 | 91 | 72 | 80 | 84 |

| Demand side 2 | 95 | 75 | 90 | 67 | 73 |

| Demand side 3 | 80 | 90 | 75 | 76 | 79 |

| Demand side 4 | 84 | 88 | 86 | 85 | 80 |

| Demand side 5 | 88 | 89 | 77 | 84 | 79 |

| Demand side 6 | 82 | 83 | 80 | 90 | 82 |

| Demand side 7 | 81 | 82 | 85 | 92 | 83 |

| Demand side 8 | 89 | 89 | 81 | 82 | 86 |

| Demand side 9 | 90 | 75 | 83 | 79 | 81 |

| Demand side 10 | 80 | 71 | 98 | 76 | 94 |

| Payment Terms | Pickup Time | Demand Volume | Demand Stability | Environmental Friendliness | Evaluation Parameters | Service Level | |

|---|---|---|---|---|---|---|---|

| Supplier 1 | 0.1 | 0.2 | 0.2 | 0.3 | 0.2 | 0.2 | 0.2 |

| Supplier 2 | 0.25 | 0.15 | 0.3 | 0.1 | 0.2 | 0.2 | 0.2 |

| Supplier 3 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Supplier 4 | 0.2 | 0.15 | 0.25 | 0.3 | 0.1 | 0.2 | 0.2 |

| Supplier 5 | 0.3 | 0.3 | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 |

| Supplier 6 | 0.15 | 0.32 | 0.13 | 0.18 | 0.22 | 0.2 | 0.2 |

| Supplier 7 | 0.15 | 0.1 | 0.35 | 0.35 | 0.05 | 0.2 | 0.2 |

| Supplier 8 | 0.18 | 0.26 | 0.19 | 0.21 | 0.16 | 0.2 | 0.2 |

| Supplier 9 | 0.32 | 0.17 | 0.21 | 0.19 | 0.11 | 0.2 | 0.2 |

| Supplier 10 | 0.21 | 0.25 | 0.17 | 0.17 | 0.2 | 0.2 | 0.2 |

| Product Quality | Product Reputation | Production Scale | Registered Capital | Environmental Friendliness | Evaluation Parameters | Service Level | |

|---|---|---|---|---|---|---|---|

| Demand side 1 | 0.2 | 0.1 | 0.3 | 0.2 | 0.2 | 0.2 | 0.2 |

| Demand side 2 | 0.4 | 0.2 | 0.35 | 0.05 | 0.2 | 0.2 | 0.2 |

| Demand side 3 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Demand side 4 | 0.4 | 0.1 | 0.4 | 0.1 | 0.2 | 0.2 | 0.2 |

| Demand side 5 | 0.25 | 0.25 | 0.1 | 0.1 | 0.3 | 0.2 | 0.2 |

| Demand side 6 | 0.33 | 0.22 | 0.2 | 0.1 | 0.15 | 0.2 | 0.2 |

| Demand side 7 | 0.15 | 0.21 | 0.32 | 0.15 | 0.17 | 0.2 | 0.2 |

| Demand side 8 | 0.35 | 0.22 | 0.18 | 0.11 | 0.14 | 0.2 | 0.2 |

| Demand side 9 | 0.2 | 0.18 | 0.2 | 0.24 | 0.18 | 0.2 | 0.2 |

| Demand side 10 | 0.05 | 0.05 | 0.45 | 0.05 | 0.4 | 0.2 | 0.2 |

| Supplier 1 | Supplier 2 | Supplier 3 | Supplier 4 | Supplier 5 | Supplier 6 | Supplier 7 | Supplier 8 | Supplier 9 | Supplier 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Demand side 1 | 23.96288 | 28.88614 | 24.85176 | 23.4604 | 19.16596 | 20.46166 | 20.09648 | 25.03928 | 23.30718 | 24.51878 |

| Demand side 2 | 11.7011 | 7.14784 | 16.38778 | 21.29642 | 15.80198 | 17.35232 | 10.9475 | 23.5053 | 10.5832 | 22.0048 |

| Demand side 3 | 17.08576 | 26.3325 | 5.00312 | 4.91176 | 6.68268 | 19.20698 | 19.96216 | 5.04064 | 6.74146 | 7.57986 |

| Demand side 4 | 13.22282 | 18.26956 | 7.16606 | 8.7747 | 2.71974 | 15.47404 | 15.43922 | 10.09358 | 7.75852 | 13.18308 |

| Demand side 5 | 15.97454 | 14.7478 | 14.76342 | 13.97206 | 11.42762 | 12.73332 | 11.55186 | 17.50094 | 13.91884 | 17.33044 |

| Demand side 6 | 12.50762 | 18.60436 | 7.78126 | 8.9899 | 4.14546 | 12.89884 | 14.20402 | 11.01878 | 8.83668 | 11.99828 |

| Demand side 7 | 17.47086 | 23.9176 | 6.38198 | 7.87334 | 7.41778 | 17.96208 | 19.27726 | 5.30554 | 12.84656 | 12.81496 |

| Demand side 8 | 11.00992 | 13.83682 | 13.3988 | 14.20744 | 8.613 | 11.7113 | 12.45648 | 16.48632 | 13.53422 | 14.11582 |

| Demand side 9 | 8.90948 | 10.70622 | 10.6794 | 14.38804 | 10.9436 | 14.0107 | 9.78588 | 18.74692 | 10.07482 | 15.49642 |

| Demand side 10 | 5.14172 | 17.53846 | 12.74716 | 20.3558 | 11.41136 | 13.87294 | 12.95812 | 17.48468 | 11.28258 | 14.16418 |

| Demand Side 1 | Demand Side 2 | Demand Side 3 | Demand Side 4 | Demand Side 5 | Demand Side 6 | Demand Side 7 | Demand Side 8 | Demand Side 9 | Demand Side 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Supplier 1 | 16.26288 | 14.32614 | 22.25176 | 23.5604 | 27.26596 | 18.68166 | 15.31648 | 25.18928 | 23.72718 | 20.31878 |

| Supplier 2 | 7.3011 | 7.88784 | 8.58778 | 8.34642 | 14.00198 | 11.26232 | 13.0475 | 13.6753 | 11.3932 | 6.7948 |

| Supplier 3 | 11.58576 | 11.9225 | 4.60312 | 5.51176 | 16.58268 | 17.50698 | 16.78216 | 8.36064 | 11.27146 | 6.80986 |

| Supplier 4 | 8.72282 | 9.15956 | 6.56606 | 8.8747 | 11.11974 | 15.94404 | 15.86922 | 9.27358 | 6.53852 | 6.08308 |

| Supplier 5 | 7.57454 | 4.3378 | 14.36342 | 16.62206 | 20.67762 | 9.34332 | 6.02186 | 16.65094 | 15.64884 | 14.32044 |

| Supplier 6 | 7.90762 | 7.99436 | 9.98126 | 11.9399 | 11.19546 | 12.48884 | 12.90402 | 11.42878 | 6.07668 | 8.02828 |

| Supplier 7 | 22.57086 | 20.6076 | 14.98198 | 12.67334 | 6.56778 | 20.55208 | 28.41726 | 14.45554 | 13.74656 | 12.87496 |

| Supplier 8 | 8.70992 | 6.97682 | 14.9988 | 16.05744 | 12.813 | 6.7313 | 8.68648 | 15.50632 | 7.57422 | 12.24582 |

| Supplier 9 | 7.50948 | 8.09622 | 13.4794 | 15.33804 | 11.1936 | 10.9507 | 12.90588 | 14.31692 | 8.13482 | 9.77642 |

| Supplier 10 | 9.24172 | 10.12846 | 11.14716 | 11.6558 | 12.16136 | 11.81294 | 14.58812 | 12.91468 | 7.01258 | 8.67418 |

| The preference sequence for demand side 1 is: [5, 7, 6, 9, 4, 1, 10, 3, 8, 2] |

| The preference sequence for demand side 2 is: [2, 9, 7, 1, 5, 3, 6, 4, 10, 8] |

| The preference sequence for demand side 3 is: [4, 3, 8, 5, 9, 10, 1, 6, 7, 2] |

| The preference sequence for demand side 4 is: [5, 3, 9, 4, 8, 10, 1, 7, 6, 2] |

| The preference sequence for demand side 5 is: [5, 7, 6, 9, 4, 2, 3, 1, 10, 8] |

| The preference sequence for demand side 6 is: [5, 3, 9, 4, 8, 10, 1, 6, 7, 2] |

| The preference sequence for demand side 7 is: [8, 3, 5, 4, 10, 9, 1, 6, 7, 2] |

| The preference sequence for demand side 8 is: [5, 1, 6, 7, 3, 9, 2, 10, 4, 8] |

| The preference sequence for demand side 9 is: [1, 7, 9, 3, 2, 5, 6, 4, 10, 8] |

| The preference sequence for demand side 10 is: [1, 9, 5, 3, 7, 6, 10, 8, 2, 4] |

| The preference sequence for supplier 1 is: [2, 7, 1, 6, 10, 3, 4, 9, 8, 5] |

| The preference sequence for supplier 2 is: [10, 1, 2, 4, 3, 6, 9, 7, 8, 5] |

| The preference sequence for supplier 3 is: [3, 4, 10, 8, 9, 1, 2, 5, 7, 6] |

| The preference sequence for supplier 4 is: [10, 9, 3, 1, 4, 2, 8, 5, 7, 6] |

| The preference sequence for supplier 5 is: [2, 7, 1, 6, 10, 3, 9, 4, 8, 5] |

| The preference sequence for supplier 6 is: [9, 1, 2, 10, 3, 5, 8, 4, 6, 7] |

| The preference sequence for supplier 7 is: [5, 4, 10, 9, 8, 3, 6, 2, 1, 7] |

| The preference sequence for supplier 8 is: [6, 2, 9, 7, 1, 10, 5, 3, 8, 4] |

| The preference sequence for supplier 9 is: [1, 2, 9, 10, 6, 5, 7, 3, 8, 4] |

| The preference sequence for supplier 10 is: [9, 10, 1, 2, 3, 4, 6, 5, 8, 7] |

| Score | Score | ||

|---|---|---|---|

| Demand side 1 | 65 | Suppliers 1 | 60 |

| Demand side 2 | 79 | Suppliers 2 | 41 |

| Demand side3 | 45.5 | Suppliers 3 | 47 |

| Demand side4 | 52 | Suppliers 4 | 68 |

| Demand side5 | 39 | Suppliers 5 | 90 |

| Demand side6 | 77 | Suppliers 6 | 40 |

| Demand side7 | 90 | Suppliers 7 | 62 |

| Demand side8 | 58 | Suppliers 8 | 61.5 |

| Demand side9 | 41 | Suppliers 9 | 42 |

| Demand side10 | 40 | Suppliers 10 | 84 |

| Product Quality | Product Reputation | Production Scale | Registered Capital | Environmental Friendliness | Evaluation Parameters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier 1 | 80 | 73 | 95 | 77 | 92 | 81.43437838 | 95 | 65 | 273.9095 | 0.75 | 33 |

| Supplier 2 | 96.4 | 72 | 94 | 81 | 76 | 89.06499412 | 88 | 75 | 266.9852 | 0.77 | 30 |

| Supplier 3 | 79 | 79 | 79 | 83 | 81 | 81.884 | 80 | 72 | 317.7008 | 0.69 | 17 |

| Supplier 4 | 85 | 87 | 75 | 89 | 82 | 77.4932 | 90 | 83 | 315.7008 | 0.75 | 26 |

| Supplier 5 | 82 | 88 | 80 | 88 | 84 | 71.9675 | 87 | 71.5 | 299.2916 | 0.74 | 28 |

| Supplier 6 | 71 | 82 | 91 | 80 | 90 | 64.81055556 | 73 | 82 | 263.6267 | 0.79 | 32 |

| Supplier 7 | 77 | 73 | 90 | 75 | 82 | 84.2592 | 90 | 81 | 254.4274 | 0.8 | 36 |

| Supplier 8 | 80 | 90 | 75 | 89 | 83 | 84.10446875 | 85 | 77 | 341.7466 | 0.65 | 12 |

| Supplier 9 | 82 | 80 | 77 | 72 | 75 | 86.48564848 | 91 | 75 | 299.0103 | 0.75 | 29 |

| Supplier 10 | 82 | 85 | 75 | 79 | 95 | 81.19225806 | 90 | 66 | 309.132 | 0.72 | 27 |

| Payment Terms | Pickup Time | Demand Volume | Demand Stability | Environmental Friendliness | Evaluation Parmeters | Service Rate | Initial Service Level | Current Service Level | Learning Rate | Number of Matches | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Demand side 1 | 92 | 90 | 88 | 82 | 88 | 82.20095238 | 88 | 82 | 212.4596414 | 0.85 | 59 |

| Demand side 2 | 89 | 89 | 90 | 90 | 76 | 89.65975 | 94 | 64 | 279.9149626 | 0.75 | 36 |

| Demand side 3 | 82 | 98 | 90 | 77 | 77 | 76.58378824 | 89 | 85 | 321.4688469 | 0.69 | 13 |

| Demand side 4 | 79 | 92 | 93 | 75 | 71 | 87.55135294 | 87 | 74 | 299.3516992 | 0.75 | 30 |

| Demand side 5 | 70 | 73 | 91 | 96 | 75 | 59.89318462 | 91 | 77 | 257.0367731 | 0.75 | 22 |

| Demand side 6 | 72 | 82 | 80 | 70 | 72 | 70.51893529 | 90 | 86 | 287.5416898 | 0.78 | 30 |

| Demand side 7 | 79 | 89 | 75 | 79 | 78 | 82.69788324 | 82 | 60 | 322.114489 | 0.71 | 31 |

| Demand side 8 | 80 | 91 | 79 | 82 | 80 | 83.69788235 | 85 | 59 | 272.1616691 | 0.73 | 30 |

| Demand side 9 | 78 | 81 | 79 | 87 | 70 | 87.8248 | 87 | 85 | 278.7193026 | 0.8 | 41 |

| Demand side 10 | 82 | 86 | 93 | 81 | 81 | 81.47454054 | 86 | 70 | 294.9794239 | 0.75 | 33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Liang, Z.; Liu, Y.; Yang, X. Resource Matching in the Supply Chain Based on Environmental Friendliness under a Smart Contract. Sustainability 2023, 15, 1505. https://doi.org/10.3390/su15021505

Wei J, Liang Z, Liu Y, Yang X. Resource Matching in the Supply Chain Based on Environmental Friendliness under a Smart Contract. Sustainability. 2023; 15(2):1505. https://doi.org/10.3390/su15021505

Chicago/Turabian StyleWei, Jinyu, Zihan Liang, Yaoxi Liu, and Xin Yang. 2023. "Resource Matching in the Supply Chain Based on Environmental Friendliness under a Smart Contract" Sustainability 15, no. 2: 1505. https://doi.org/10.3390/su15021505

APA StyleWei, J., Liang, Z., Liu, Y., & Yang, X. (2023). Resource Matching in the Supply Chain Based on Environmental Friendliness under a Smart Contract. Sustainability, 15(2), 1505. https://doi.org/10.3390/su15021505