One-Dimensional Compressibility and Creep Characteristics of Unsaturated Compacted Loess Based on Incremental Loading and Constant Rate of Strain Methods

Abstract

:1. Introduction

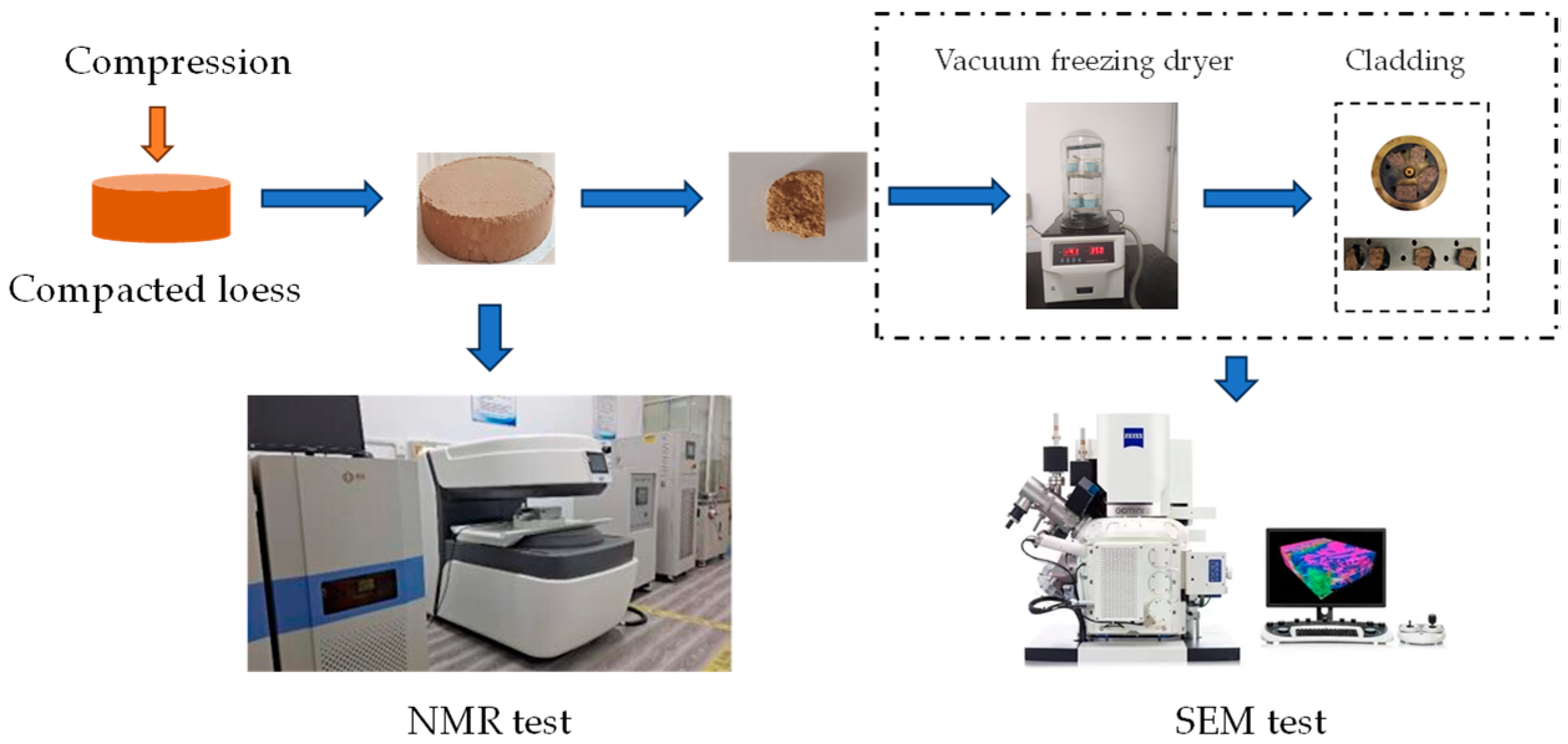

2. Material and Methodology

2.1. Sample Preparation

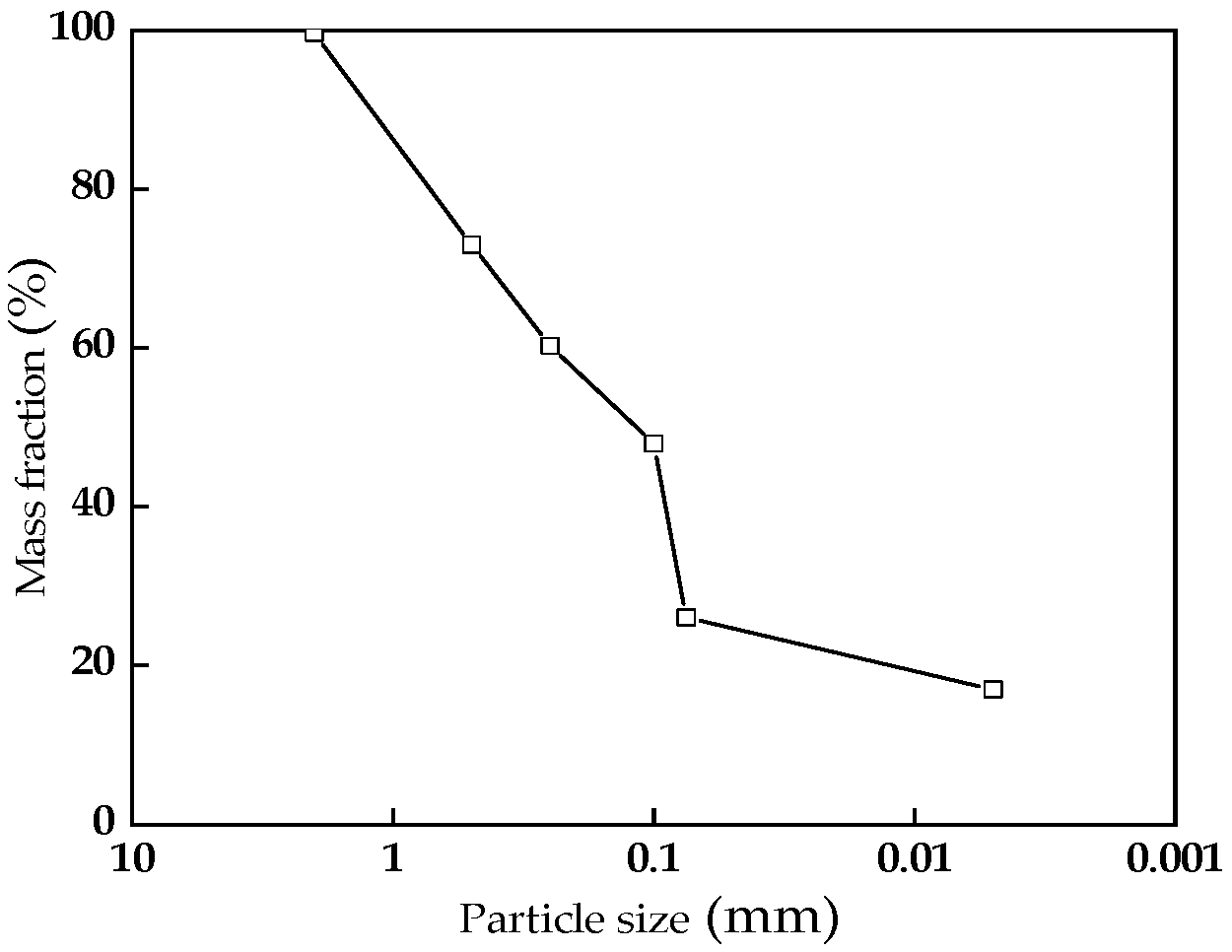

2.1.1. Physical Properties of Loess

2.1.2. Soil Sample Preparation

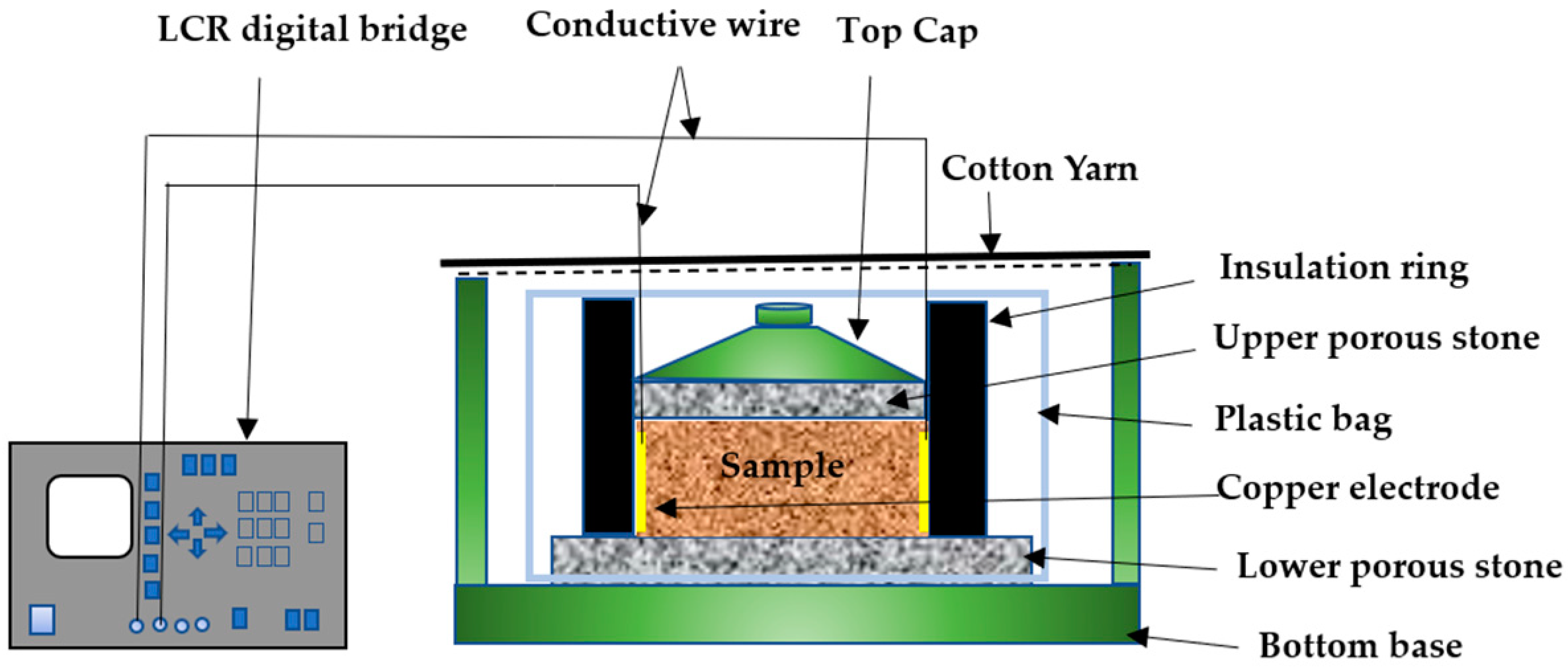

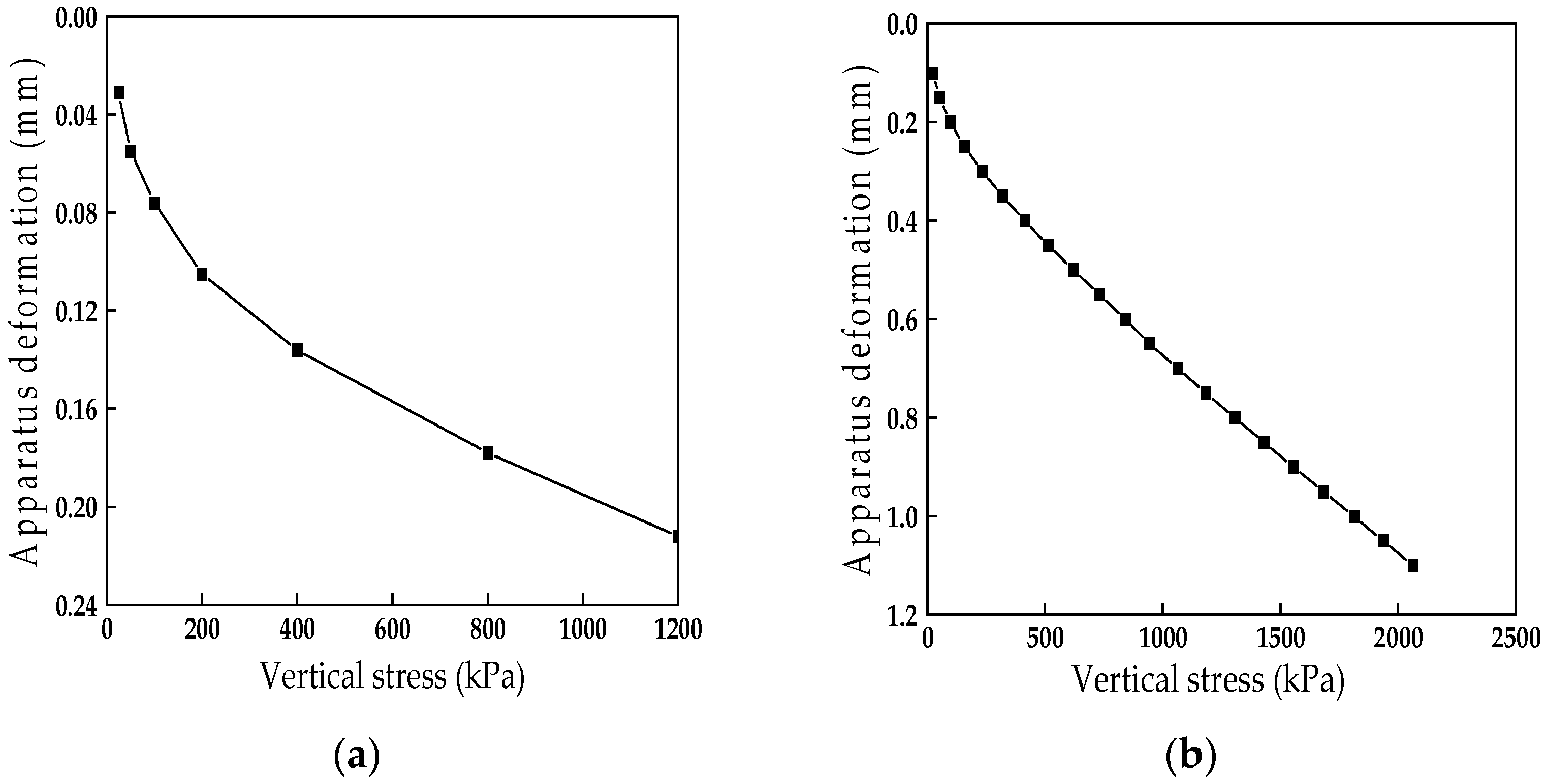

2.2. Test Apparatus

2.3. Test Scheme

3. Test Results and Analysis

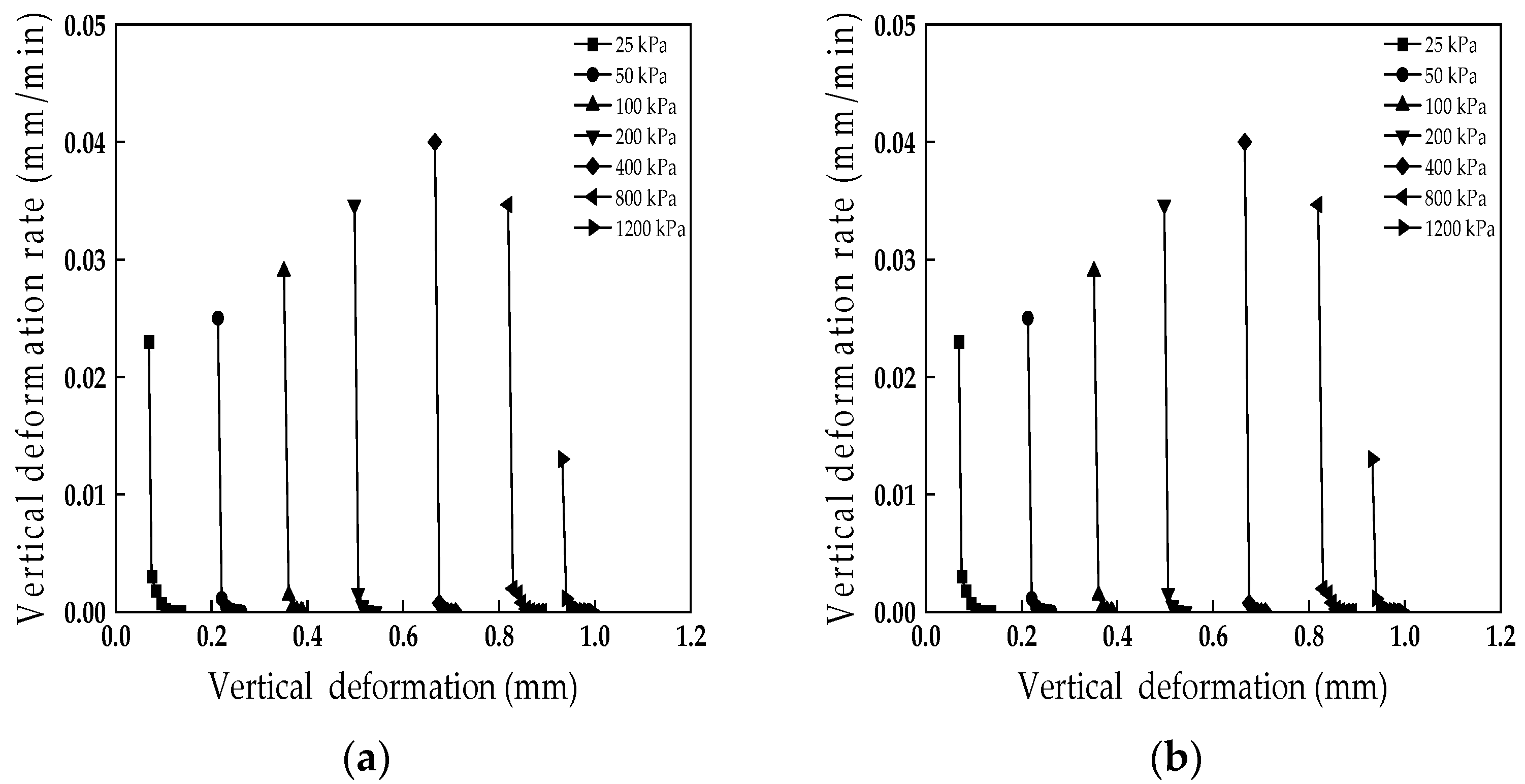

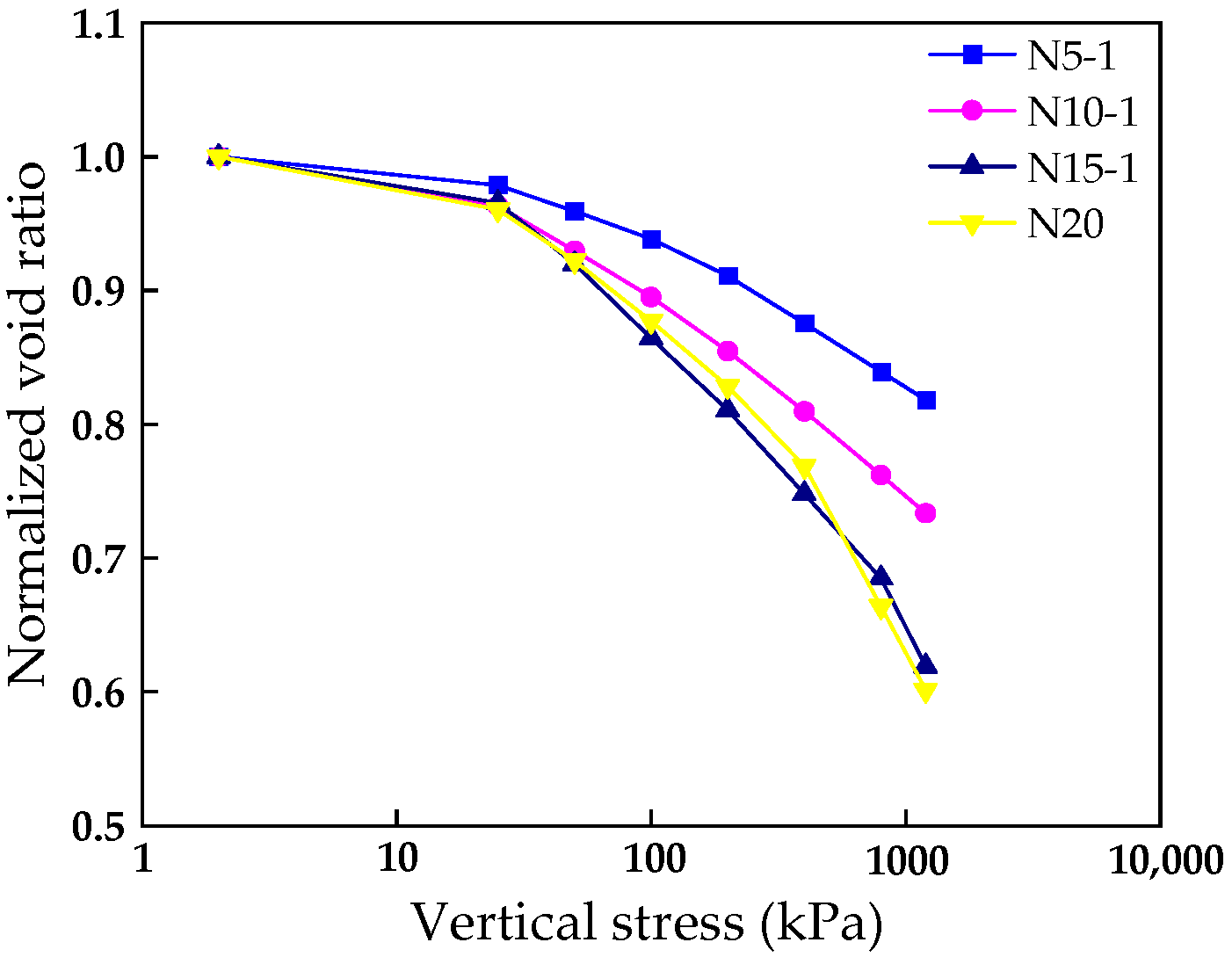

3.1. Incremental Loading Tests

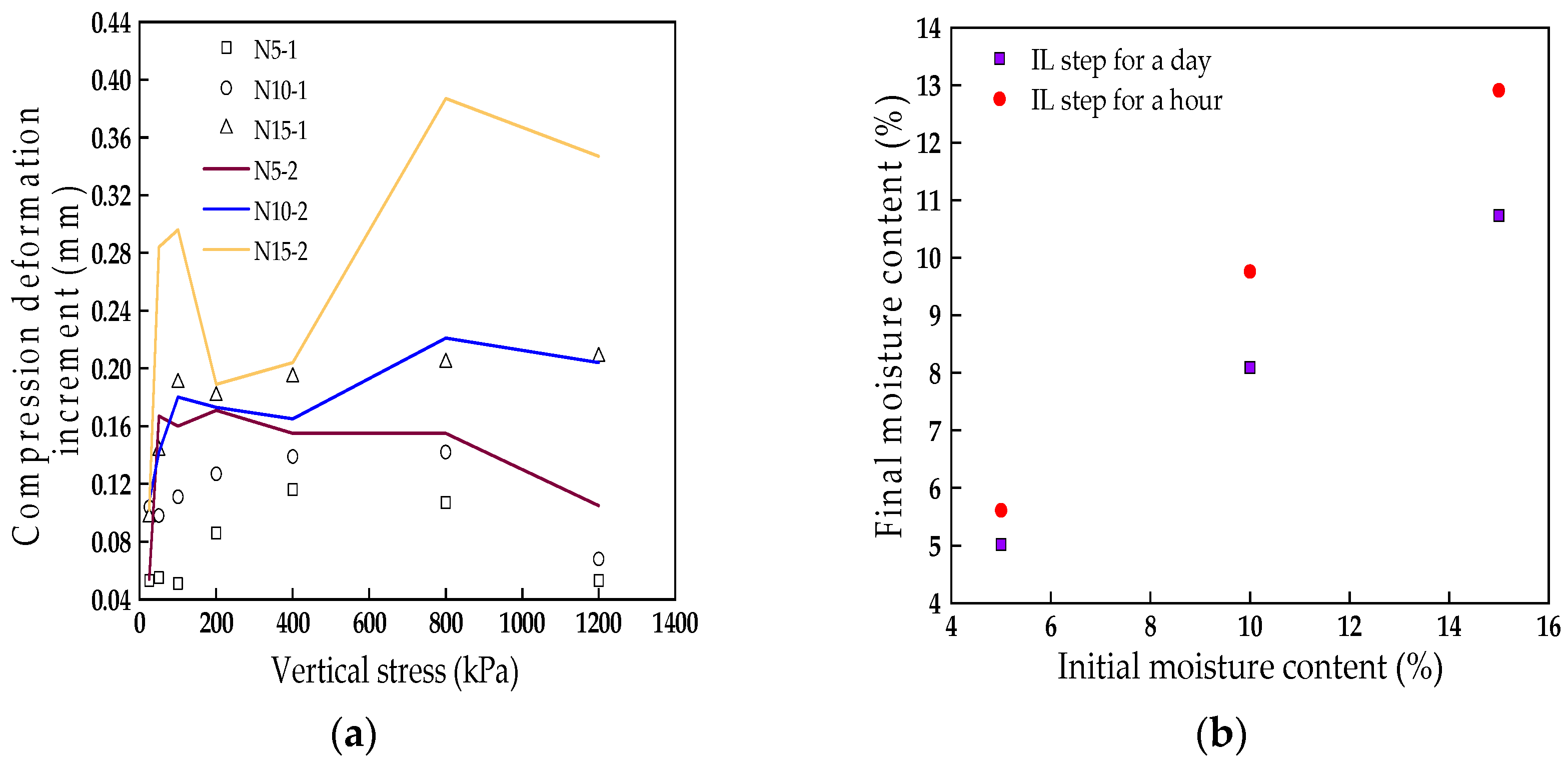

3.1.1. Compression Deformation

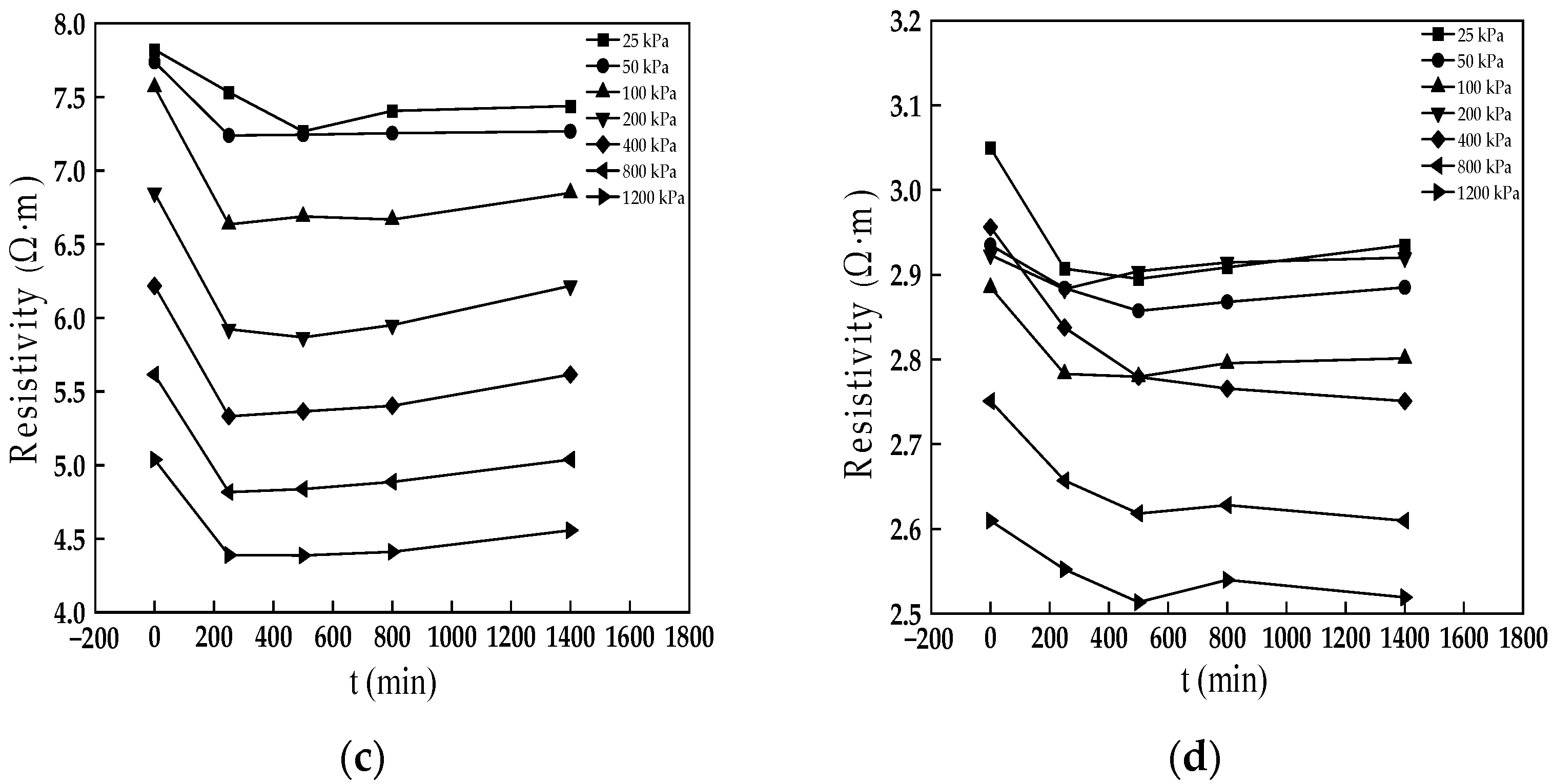

3.1.2. Resistivity Properties

3.2. CRS Tests

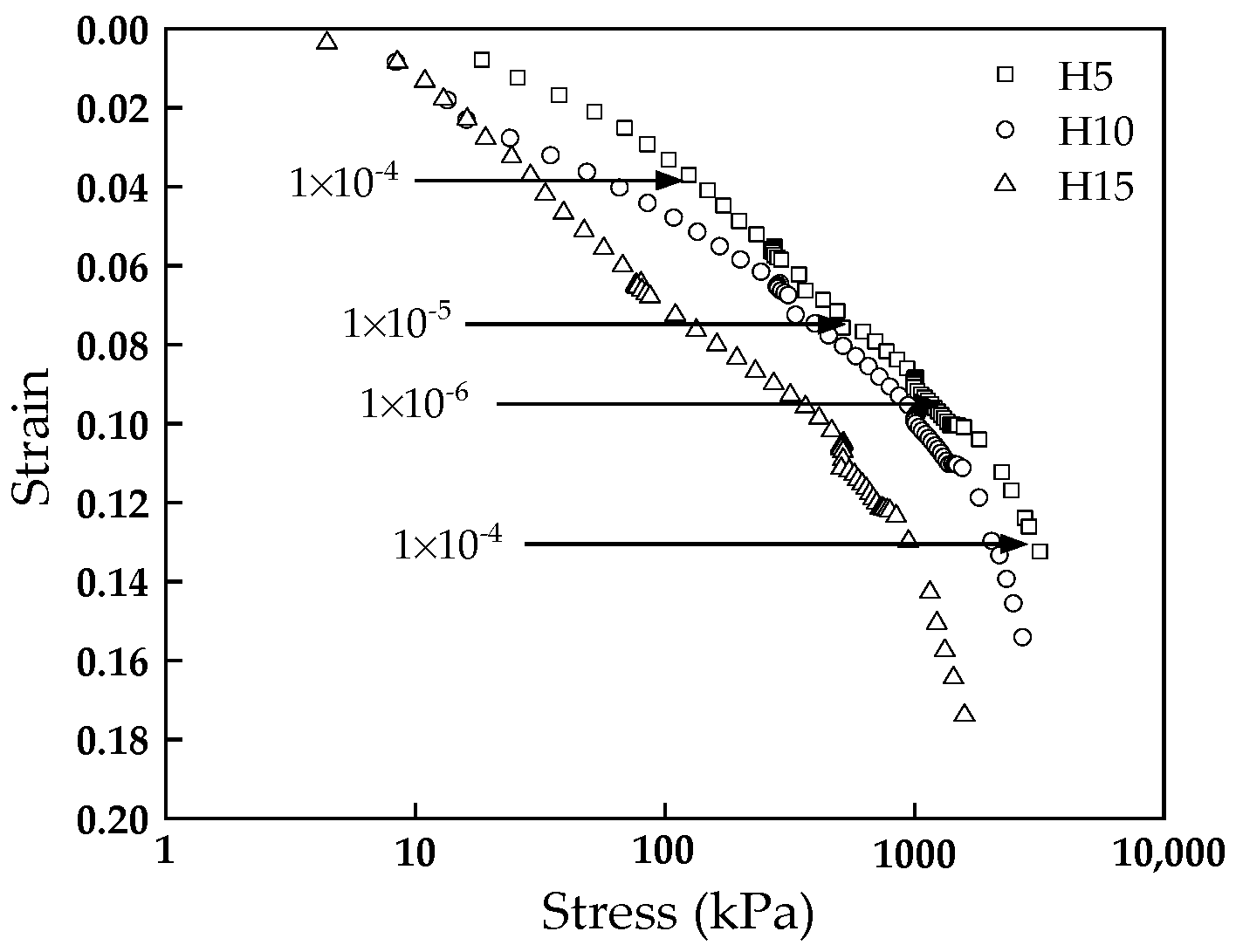

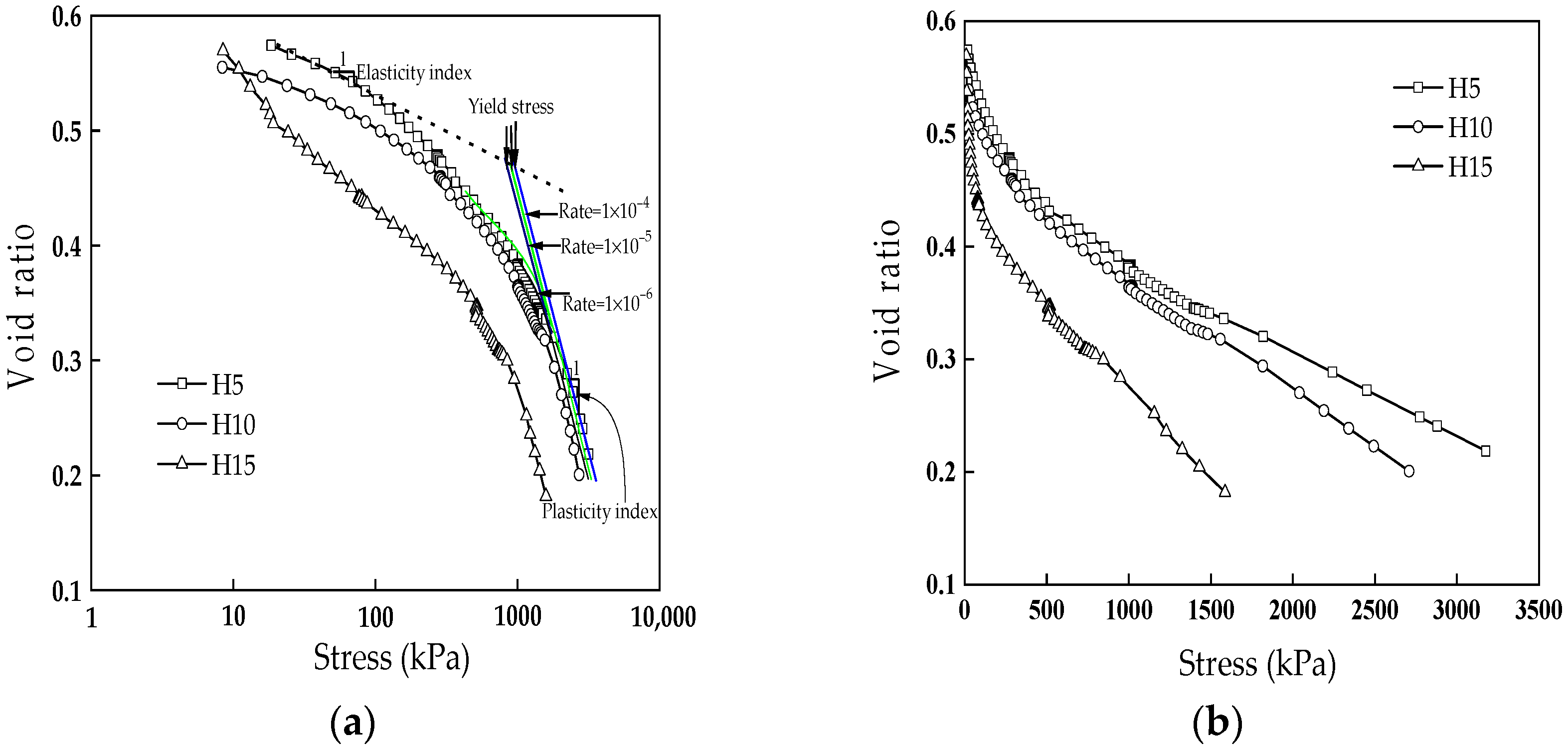

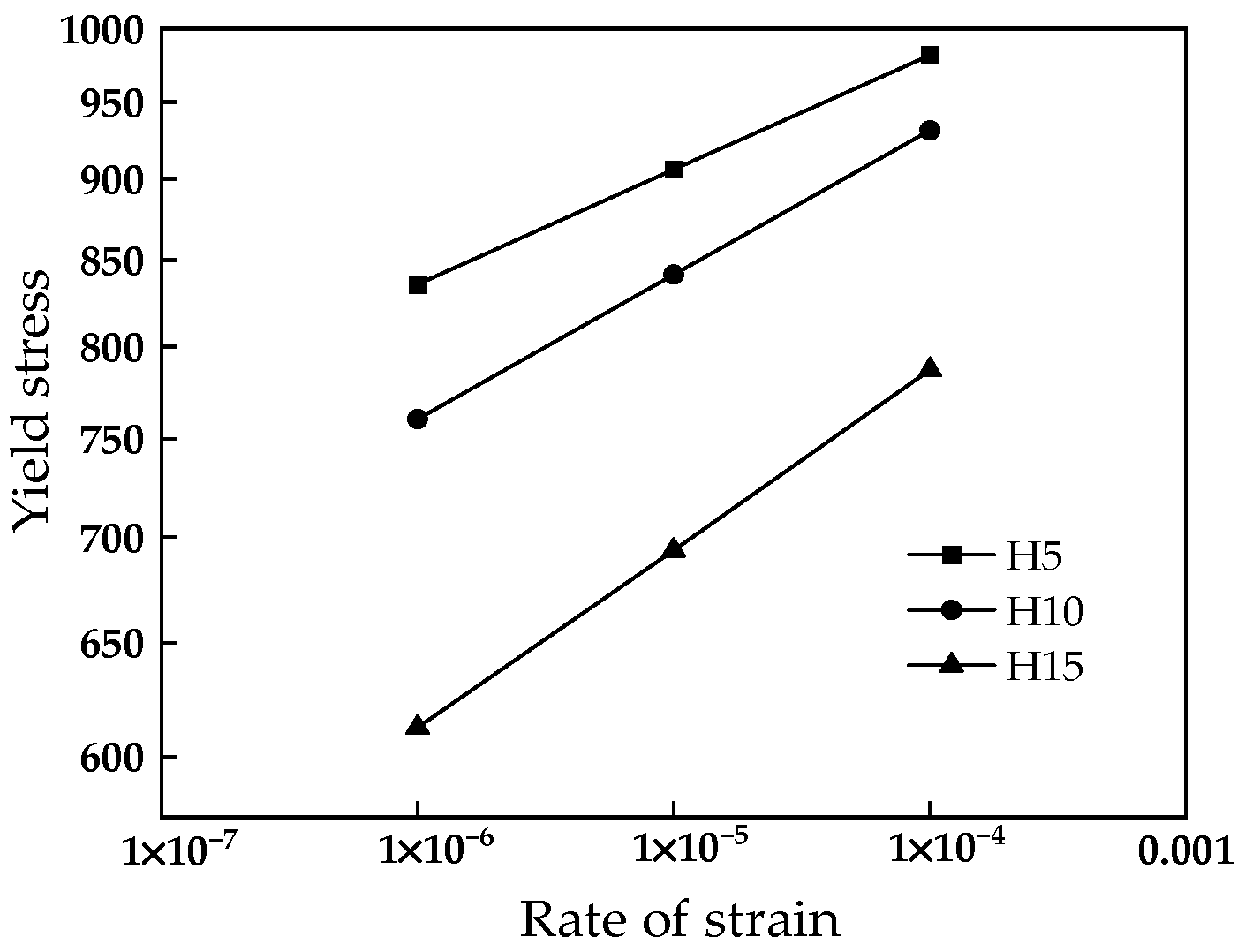

3.2.1. Compression Deformation

3.2.2. Resistivity

3.3. Microstructural Tests

3.3.1. NMR Tests

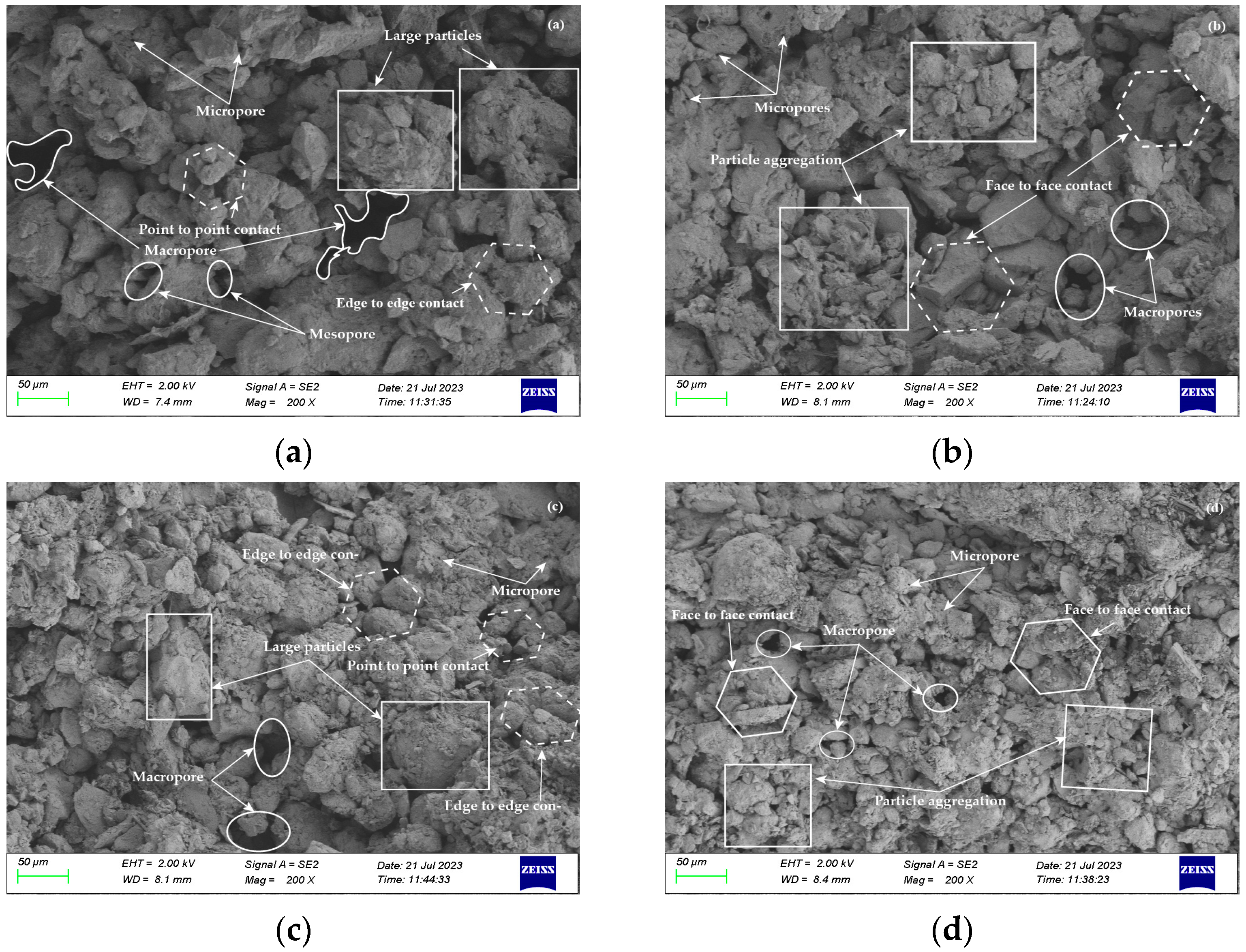

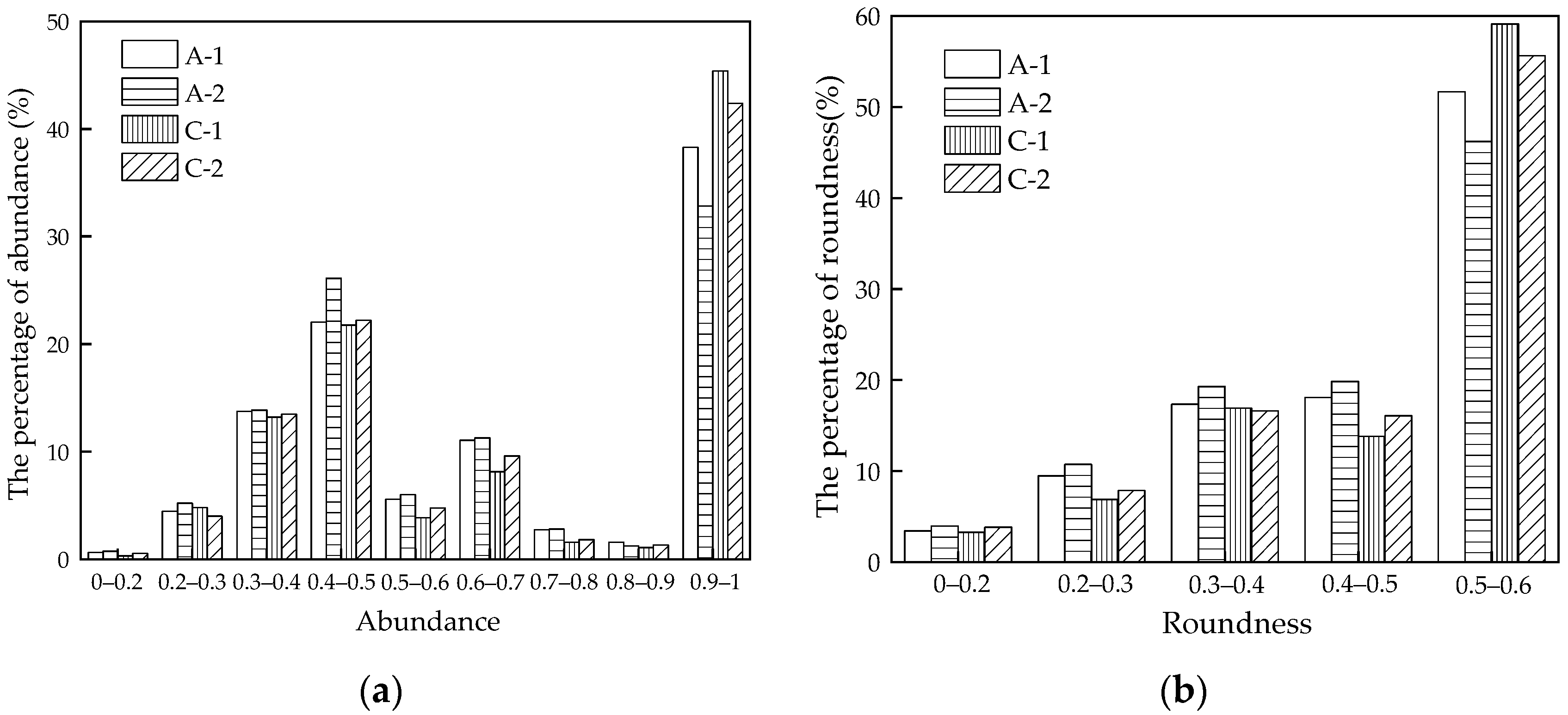

3.3.2. SEM Tests

4. Discussion

4.1. Compression Properties

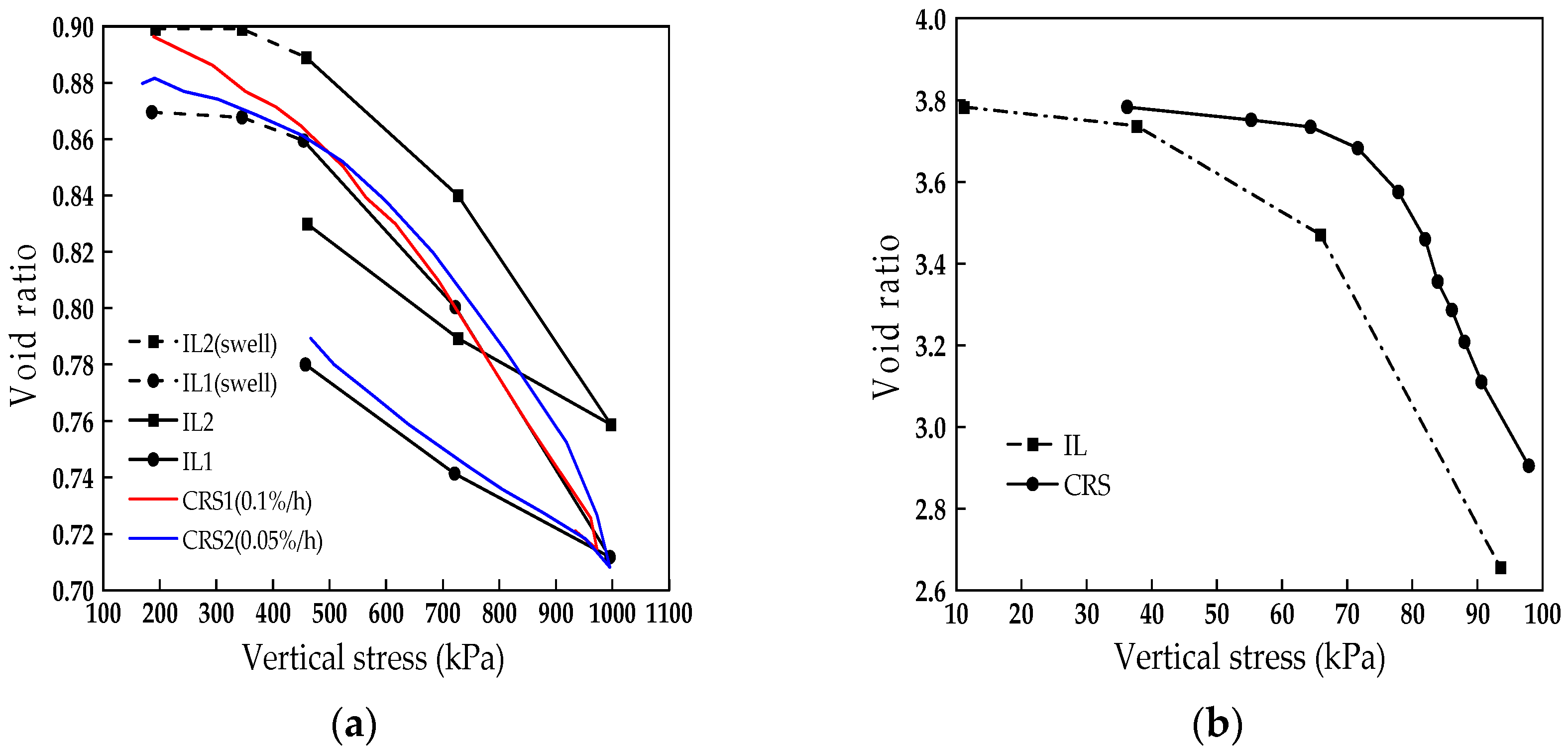

4.2. Comparison of IL and CRS Tests

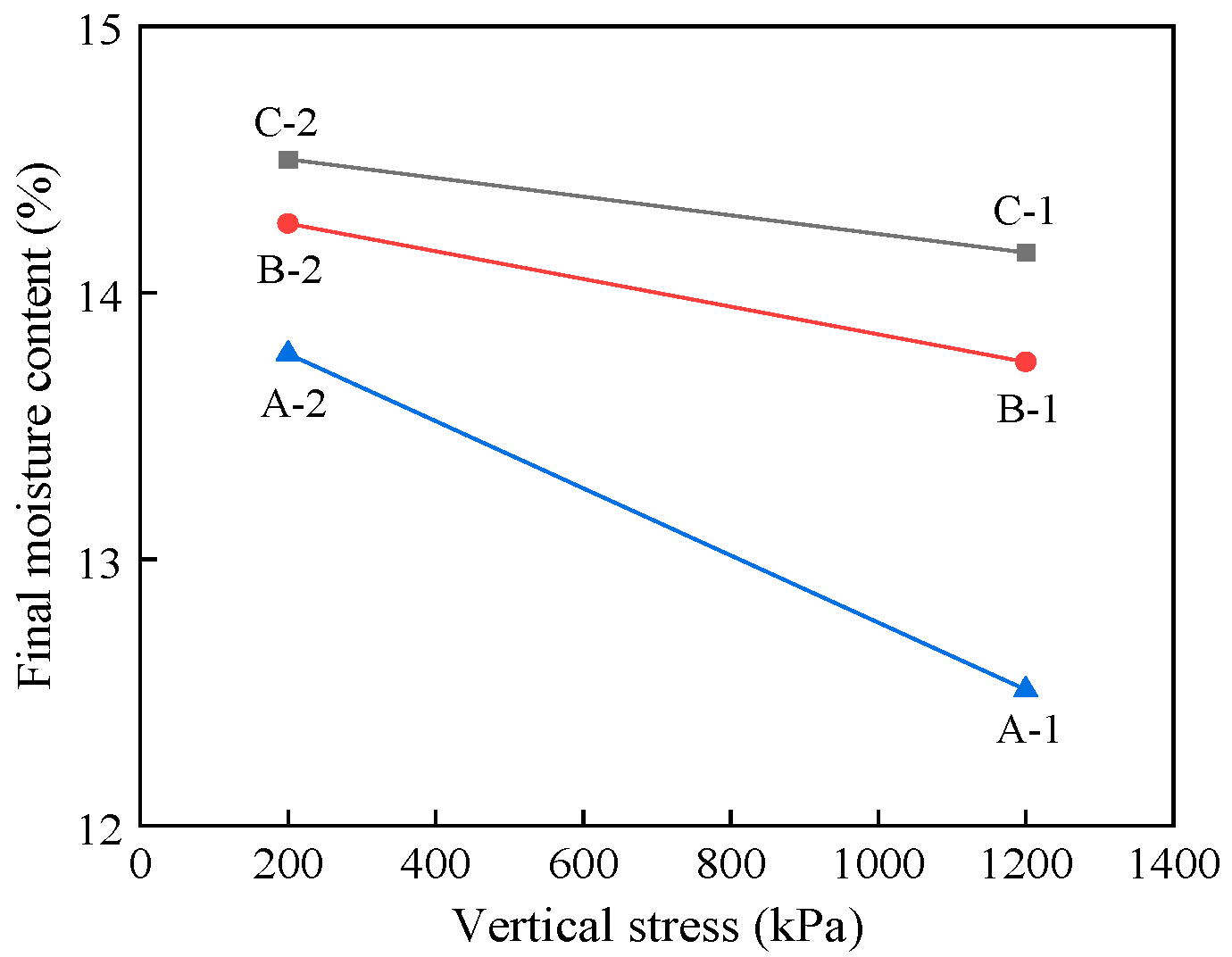

4.2.1. Compressibility

4.2.2. Resistivity

5. Conclusions

- (1)

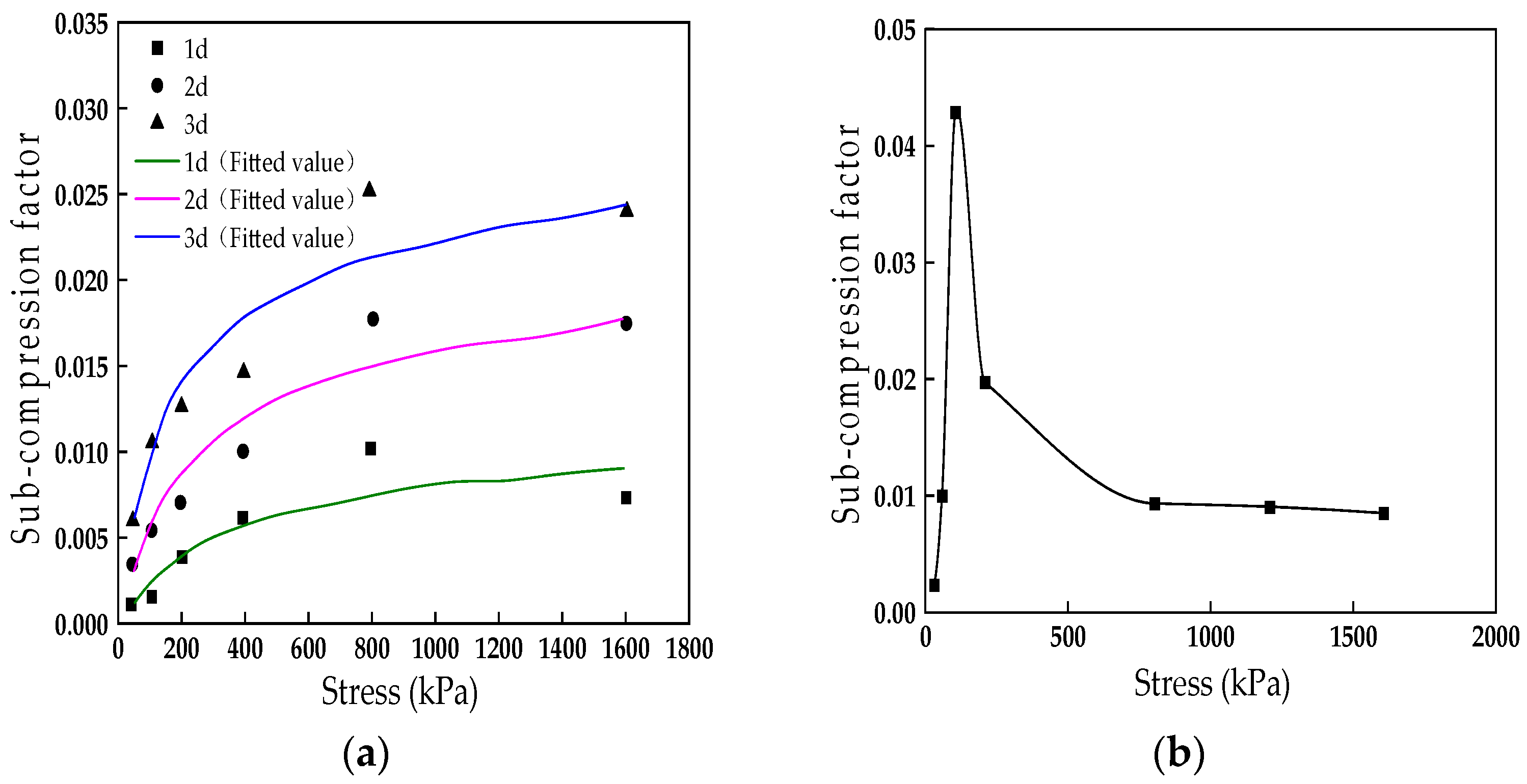

- Cc and Cα of unsaturated compacted loess increase with the increase in vertical stress and moisture content. Cα increases linearly with Cc, which is distributed in a narrow range. Cα/Cc increases with the increase in moisture content.

- (2)

- For the IL tests, the void ratio decreases rapidly after the loading is imposed on the soil sample. The amount of electrical connected channels increases; thus, the resistivity of the soil sample decreases rapidly in the early loading stage. As the deformation of the soil sample stabilizes, the void ratio decreases slowly, and the number of connected channels decreases slightly. Importantly, the loss of water during compression dominates the increase in resistivity of the soil sample. For CRS tests, the resistivity of the soil sample decreases with increasing strain at a constant rate of strain. The resistivity rapidly decreases with the large strain rate. The resistivity decreases slowly at the latter loading stage than at the former stage for a given strain rate. However, as the strain rate is relatively small, the resistivity increases, intricating the significant impact of water loss on the resistivity. Meanwhile, the void ratio of soil samples slows down at the later loading stage due to the increased resistance to deformation of the soil particles.

- (3)

- In the NMR tests, it was found that there were three peaks in the T2 distribution curves of unsaturated compacted loess, corresponding to different pore sizes. The spectral peaks in the T2 curves shifted to the left when the vertical stress increased. The area enclosed by the spectral curve around the peak of the larger macropore sizes decreased while that of the smaller pore sizes increased, indicating that the larger macropores transformed into the small pores due to the compression of the soil samples. In addition, through the qualitative and quantitative analysis of the SEM images, it was found that with the increase in vertical stress, the pore area of soil samples decreased, the coarse particles were crushed, the fine particles were inlaid with each other and became agglomerates, the contact relationship between particles changed from point-to-point contact and edge to edge contact to face to face contact. The abundance and roundness of loess particles tended to build up with the increase in vertical stress and loading rate.

- (4)

- The primary and secondary compression indexes obtained when using the CRS tests have the same variation trends as those obtained using the IL tests. However, due to the fast loading rate, the drainage of the soil sample is less, and its corresponding moisture content is high. Hence, the compression parameters and compression deformation of the soil samples obtained using CRS tests are a little higher than those obtained when using the IL tests for a given vertical stress.

- (5)

- The moisture content has a significant impact on the creep characteristics of compacted loess. Therefore, it is necessary to strictly control the moisture content of the subgrade, roadbed, and slope in practical engineering to prevent the settlement of roadbeds and subgrades and landslide failure. Meanwhile, the duration of compression also has an impact on the deformation of compacted soil. Thus, it is necessary to consider the construction speed. For example, it is better to quickly process the ground through the means of compression or impact, but it is risky to quickly load the ground and slope during engineering construction, especially due to the fact that the moisture content of the loess is high. Moreover, the soil structure gradually stabilizes with the increase in vertical stress, and the post-construction creep deformation can be reduced through the pre-compression of the roadbed and subgrade. Therefore, this work could provide a theoretical and experimental basis for improving ground stability and preventing landslide disasters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, J.Z.; Wu, W.J. Loessology, 1st ed.; Hong Kong Archaeological Society Press: Hong Kong, China, 2005. [Google Scholar]

- Wu, P. Application of compaction technology in earth filling construction. China High Tech. Enterp. 2009, 22, 39–40. [Google Scholar]

- Wu, Z.J.; Chen, T.; Ma, W. Creep analysis of plain fill embankment at permafrost regions along Qinghai-Tibet Railway under train dynamic load. Geotech. Mech. 2011, 32, 82–87. [Google Scholar]

- Wang, L.; Qiu, H.; Zhou, W.; Zhu, Y.; Liu, Z.; Ma, S.; Yang, D.; Tang, B. The post-failure spatiotemporal deformation of certain translational landslides may follow the pre-failure pattern. Remote Sens. 2022, 14, 2333. [Google Scholar] [CrossRef]

- Ma, S.; Qiu, H.; Zhu, Y.; Yang, D.; Tang, B.; Wang, D.; Wang, L.; Cao, M. Topographic Changes, Surface Deformation and Movement Process before, during and after a Rotational Landslide. Remote Sens. 2023, 15, 662. [Google Scholar] [CrossRef]

- Nash, D. Precompression design for secondary settlement reduction. Ground Soil Improv. 2004, 94, 822–826. [Google Scholar]

- Zhang, W.B.; Xie, Y.L.; Yang, X.H. Study of one-dimensional sub-consolidation characteristics of compacted loess. J. Geotech. Eng. 2007, 29, 765–768. [Google Scholar]

- Wang, S.H.; Luo, Y.S.; Li, Y. Experimental study of consolidation creep properties of loess. J. Eng. Geol. 2009, 17, 643–647. [Google Scholar]

- Ye, W.M.; Lai, X.L.; Wang, Q.; Chen, Y.G.; Chen, B.; Cui, Y.J. An experimental investigation on the secondary compression of unsaturated GMZ01 bentonite. Appl. Clay Sci. 2014, 97–98, 104–109. [Google Scholar] [CrossRef]

- Ge, M.M.; Li, N.; Zheng, J.G.; Zhu, C.H.; Bo, Y.Y. Prediction of post-construction settlement of high filled embankment with considering the time depending deformation of compacted loess. China Civ. Eng. J. 2015, 48, 262–266. [Google Scholar]

- Ajdari, M.; Niknam, E.; Bahmyari, H.; Esfandiari, Z. Consolidation and creep phenomena in a sand-bentonite mixture under controlled suctions. Geomech. Geoengin. 2020, 17, 106–117. [Google Scholar] [CrossRef]

- Wang, F.; Pang, W.; Li, Z.; Wei, H.; Han, L. Experimental Study on Consolidation-Creep Behavior of Subgrade Modified Soil in Seasonally Frozen Areas. Materials 2021, 14, 5138. [Google Scholar] [CrossRef] [PubMed]

- Sheahan, T.C.; Watters, P.J. Experimental verification of CRS consolidation theory. J. Geotech. Geoenviron. Eng. 1997, 123, 430–437. [Google Scholar] [CrossRef]

- Yin, J.H.; Tong, F. Constitutive modeling of time-dependent stress–strain behavior of saturated soils exhibiting both creep and swelling. Can. Geotech. J. 2011, 48, 1870–1885. [Google Scholar] [CrossRef]

- Qin, P.J.; Ye, W.M.; Chen, Y.G.; Chen, B.; Cui, Y.J. Influence of strain-rate on hydromechanical behavior of highly compacted GMZ01 bentonite. Eng. Geol. 2015, 195, 85–92. [Google Scholar] [CrossRef]

- Díaz-Rodríguez, J.A.; Tonix, W.; Carrizales, P. Constant rate of strain consolidation of Maxico City Soil. In Proceedings of the 19th International Conference on Soil Mechanics and Geotechnical Engineering, Seoul, Republic of Korea, 17–22 September 2017. [Google Scholar]

- Li, F.L.; Yang, J.; Liu, W.Q.; Fan, Z.H.; Yang, Y.G. Effect of loading rate changing on the mechanical properties of mudstone under uniaxial compression. Rock Soil Mech. 2021, 42, 369–378. [Google Scholar]

- Zhu, C.H.; Li, N. Mesoscopic deformation mechanism of loess high fill foundation based on soil electrical resistivity. Chin. J. Rock Mech. Eng. 2013, 32, 640–648. [Google Scholar]

- Dong, X.Q.; Huang, F.F.; Su, N.N.; Zhou, W.; Zhang, J.; Bai, X.H. Experimental study of AC electrical resistivity of unsaturated loess during compression. Chin. J. Rock Mech. Eng. 2015, 34, 189–197. [Google Scholar]

- Badrzadeh, Y.; Ghorbani, A.; Ansari, A.; Fatehi Maraji, M. Study of the electrical resistivity changes in soils during consolidation testing. Iran. J. Geophys. 2016, 5, 102–110. [Google Scholar]

- Qin, P.J.; Song, Z.W.; Wang, Y.B.; Miao, C.X.; Ma, F.L.; Dong, X.Q. Experimental study on structural properties of compacted loess during constant rate of strain compaction. J. Taiyuan Univ. Technol. 2020, 51, 620–626. [Google Scholar]

- Duan, Z.; Yan, X.; Sun, Q.; Tan, X.; Dong, C. Effects of water content and salt content on electrical resistivity of loess. Environ. Earth Sci. 2021, 80, 1–15. [Google Scholar] [CrossRef]

- Li, Z.X.; Wang, J.D.; Yang, S.; Liu, S.H.; Li, Y.W. Characteristics of Microstructural Changes of Malan Loess in Yanan Area during Creep Test. Water 2022, 14, 438. [Google Scholar] [CrossRef]

- Casini, F.; Vaunat, J.; Romero, E.; Desideri, A. Consequences on water retention properties of double-porosity features in a compacted silt. Acta Geotech. 2012, 7, 139–150. [Google Scholar] [CrossRef]

- Zheng, J.; Yang, Z.; Gao, H.; Lai, X.Y.; Wu, X.; Huang, Y.L. Experimental study on microstructure characteristics of saturated remolded cohesive soil during consolidation. Sci. Rep. 2022, 12, 18378. [Google Scholar] [CrossRef]

- Sun, W.; Zuo, Y.J.; Wu, Z.H.; Liu, H.; Xi, S.J.; Shui, Y.; Wang, J.; Liu, R.B.; Lin, J.Y. Fractal analysis of pores and the pore structure of the Lower Cambrian Niutitang shale in northern Guizhou province: Investigations using NMR, SEM and image analyses. Mar. Pet. Geol. 2018, 99, 416–428. [Google Scholar] [CrossRef]

- Chen, L. Experimental Study on Consolidation-Creep Properties of Dredger Soft Soil. Master’s Thesis, Tianjin University, Tianjin, China, 2013. [Google Scholar]

- Ge, M.M.; Li, N.; Zheng, J.G.; Zhang, J.W.; Zhu, C.H. A creep model for compacted loess based on 1D oedometer test. Rock Soil Mech. 2015, 36, 3164–3170. [Google Scholar]

- Hu, S.X.; Zhang, D.; Yang, R.; Yao, Z.H. Experimental study on consolidation characteristics of unsaturated disturbed loess. J. Water Resour. Archit. Eng. 2016, 14, 55–58. [Google Scholar]

- Tang, D.Q.; Peng, J.B.; Sun, W.Q. Matrix suction test based on the filter paper method for unsaturated loess. Coal Geol. Explor. 2012, 40, 37–41. [Google Scholar]

- Mesri, G.; Godlewski, P.M. Time- and stress-compressibility interrelationship. J. Geotech. Eng. Div. 1977, 103, 417–430. [Google Scholar] [CrossRef]

- Fukue, M.; Minato, T.; Horibe, H.; Taya, N. The micro-structures of clay given by resistivity measurements. Eng. Geol. 1999, 54, 43–53. [Google Scholar] [CrossRef]

- Cha, F.S.; Liu, S.Y.; Du, Y.J.; Cui, K.R.; Xu, L. Quantitative assessment on change in microstructure of loess during collapsing using electrical resistivity measurement. Rock Soil Mech. 2010, 31, 1692–1698. [Google Scholar]

- De Gennaro, V.; Pereira, J.M. A viscoplastic constitutive model for unsaturated geomaterials. Comput. Geotech. 2013, 54, 143–151. [Google Scholar] [CrossRef]

- Sun, B.; Gu, T.F.; Sun, J.X.; Zhang, F.S.; Sun, J.X. Experimental research on the relationship between resistivity and moisture content of unsaturated loess. Northwest Geol. 2020, 53, 216–222. [Google Scholar]

- Cha, F.S.; Liu, S.Y.; Du, Y.J.; Cui, K.R. Experimental study of resistivity properties of compacted loess. Geotech. Mech. 2011, 32, 155–158. [Google Scholar]

- Jaeger, F.; Bowe, S.; Van As, H.; Schaumann, G.E. Evaluation of 1H NMR relaxometry for the assessment of pore size distribution in soil samples. Eur. J. Soil Sci. 2010, 60, 1052–1064. [Google Scholar] [CrossRef]

- Zhang, X.W.; Wang, C.M. Microstructural change of soft clay before and after one-dimensional compression creep. Chin. J. Geotech. Eng. 2010, 32, 1688–1694. [Google Scholar]

- Fang, X.W.; Shen, C.N.; Chen, Z.H.; Cheng, P.J. Research on microstructure of Q2 loess before and after wetting. Rock Soil Mech. 2013, 34, 1319–1324. [Google Scholar]

- Gao, X.G.; Zhang, Z.X.; Huang, X. Research on Mesomechanical Properties of Rock and Soil Considering Shape Factors. Hans J. Civ. Eng. 2021, 10, 216–226. [Google Scholar] [CrossRef]

- Peng, J.Y.; Zhang, J.F.; Shen, Z.Z.; Ye, J.B. Effect of grain shape on pore characteristics and permeability of coarse-grained soil. Rock Soil Mech. 2020, 41, 592–600. [Google Scholar]

- Zhou, Q.J.; Chen, X.P. Test study on of secondary consolidation of soft soils. Rock Soil Mech. 2006, 27, 404–408. [Google Scholar]

- Jiang, Q. Study on the Secondary Consolidation Property and Forecasting Model for Marine Sedimental Clay. Master’s Thesis, Tianjin University, Tianjin, China, 2015. [Google Scholar]

- Yin, Z.Z.; Zhang, H.B.; Zhu, J.G.; Li, G.W. Secondary-consolidation of soft soils. Chin. J. Geotech. Eng. 2003, 25, 521–526. [Google Scholar]

- Yu, X.J.; Yin, Z.Z.; Dong, W.J. Influence of load on secondary consolidation deformation of soft soils. Chin. J. Geotech. Eng. 2007, 29, 913–916. [Google Scholar]

- Nguyen, C.O.; Tran, T.T.; Dao, V.T.T. Consolidation analysis with application of constant rate of strain consolidation tests for Vietnam clays. Geotech. Geol. Eng. 2020, 38, 833–847. [Google Scholar] [CrossRef]

- Andries, J.; Verastegui, D.; De Beule, K.; Baertsoen, A. One-Dimensional Consolidation of Overconsolidated Clay Using Con-stant Rate of Strain Testing. In E3S Web of Conferences; EDP Sciences: Glasgow, Scotland, 2019. [Google Scholar]

- Leroueil, S. The Isotache approach. Where are we 50 years after its development by Professor Šuklje? 2006 Prof. Šuklje’s Memorial Lecture. In Proceedings of the XIII Danube-European Conference on Geotechnical Engineering, Ljubljana, Slovenia, 29–31 May 2006. [Google Scholar]

- Cui, Y.; Delage, P. Yielding and plastic behavior of an unsaturated compacted silt. Géotechnique 1996, 46, 291–311. [Google Scholar] [CrossRef]

| Specific Gravity Gs | Maximum Dry Density ρmax (g·cm−3) | Optimum Moisture Content ωopt (%) | Liquid Limit ωL (%) | Plastic Limit ωP (%) | Plasticity Index IP | Collapsibility Coefficient ∆s |

|---|---|---|---|---|---|---|

| 2.77 | 1.72 | 15.3 | 22.8 | 13.1 | 9.71 | 0.02 |

| Loading Method | Number | Water Content ω | Initial Dry Density ρd (g·cm−3) | Initial Pore Ratio eo | Initial Height of Soil Sample (mm) |

|---|---|---|---|---|---|

| IL | N5-1 | 5% | 1.698 | 0.5901 | 10.01 |

| N10-1 | 10% | 1.675 | 0.6119 | 10.15 | |

| N15-1 | 15% | 1.667 | 0.6197 | 10.20 | |

| N5-2 | 5% | 1.693 | 0.5948 | 10.04 | |

| N10-2 | 10% | 1.693 | 0.5948 | 10.04 | |

| N15-2 | 15% | 1.698 | 0.5901 | 10.01 | |

| N20 | 20% | 1.667 | 0.6197 | 10.20 | |

| A-1 | 15% | 1.710 | 0.5789 | 9.940 | |

| A-2 | 15% | 1.698 | 0.5901 | 10.01 | |

| B-1 | 15% | 1.695 | 0.5929 | 10.03 | |

| B-2 | 15% | 1.690 | 0.5976 | 10.06 | |

| CRS | H5 | 5% | 1.682 | 0.6052 | 10.11 |

| H10 | 10% | 1.670 | 0.6168 | 10.06 | |

| H15 | 15% | 1.703 | 0.5854 | 9.980 | |

| C-1 | 15% | 1.702 | 0.5864 | 9.988 | |

| C-2 | 15% | 1.687 | 0.6008 | 10.08 |

| Loading Method | Number | Loading Steps | Duration of Every Loading Stage |

|---|---|---|---|

| IL | A-1 | 25 kPa→50 kPa→100 kPa→200 kPa→400 kPa→800 kPa→1200 kPa | 1 day |

| A-2 | 25 kPa→50 kPa→100 kPa→200 kPa | ||

| B-1 | 25 kPa→50 kPa→100 kPa→200 kPa→400 kPa→800 kPa→1200 kPa | 1 h | |

| B-2 | 25 kPa→50 kPa→100 kPa→200 kPa | ||

| CRS | C-1 | 0.06 mm/min—1200 kPa | _____ |

| C-2 | 0.06 mm/min—200 kPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, P.; Yan, Q.; Lu, Y.; Yang, C.; Song, Z.; Li, C. One-Dimensional Compressibility and Creep Characteristics of Unsaturated Compacted Loess Based on Incremental Loading and Constant Rate of Strain Methods. Sustainability 2023, 15, 13854. https://doi.org/10.3390/su151813854

Qin P, Yan Q, Lu Y, Yang C, Song Z, Li C. One-Dimensional Compressibility and Creep Characteristics of Unsaturated Compacted Loess Based on Incremental Loading and Constant Rate of Strain Methods. Sustainability. 2023; 15(18):13854. https://doi.org/10.3390/su151813854

Chicago/Turabian StyleQin, Pengju, Qingchen Yan, Yu Lu, Chungang Yang, Zhiwei Song, and Chunbao Li. 2023. "One-Dimensional Compressibility and Creep Characteristics of Unsaturated Compacted Loess Based on Incremental Loading and Constant Rate of Strain Methods" Sustainability 15, no. 18: 13854. https://doi.org/10.3390/su151813854

APA StyleQin, P., Yan, Q., Lu, Y., Yang, C., Song, Z., & Li, C. (2023). One-Dimensional Compressibility and Creep Characteristics of Unsaturated Compacted Loess Based on Incremental Loading and Constant Rate of Strain Methods. Sustainability, 15(18), 13854. https://doi.org/10.3390/su151813854