A Novel Mathematical Model for Repairing Rough Cracks Using the Microbially Induced Carbonate Precipitation (MICP)

Abstract

:1. Introduction

2. New Mathematical Model

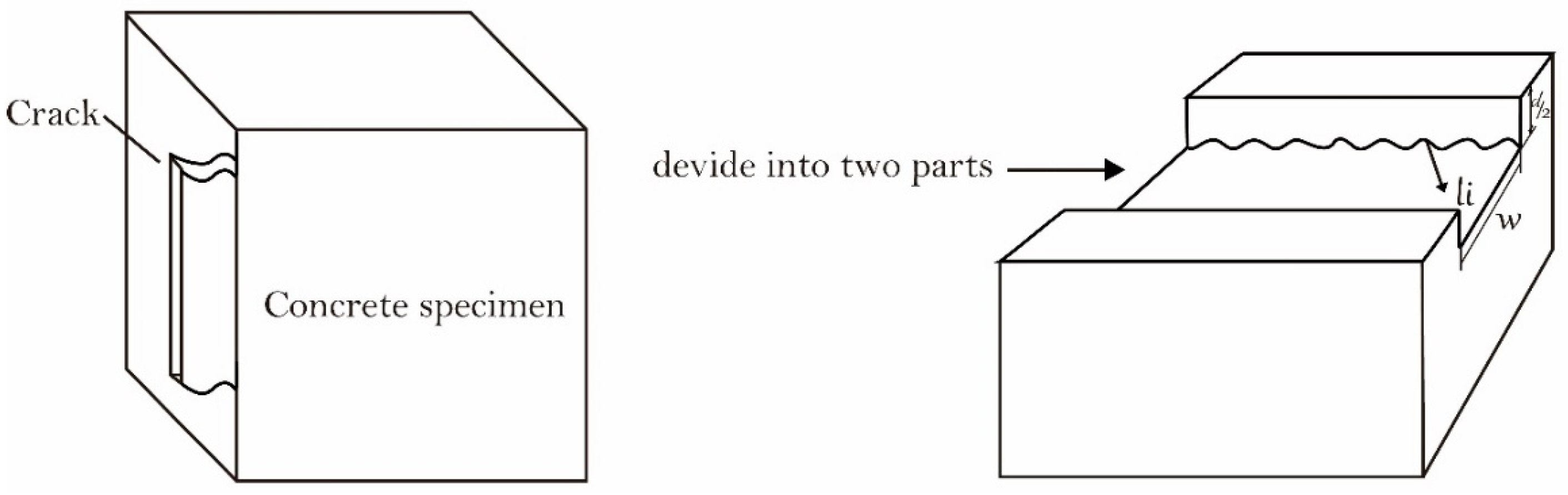

2.1. Model Generation

2.2. Transport of Solutes

2.3. Biofilm Growth and Transport of Suspended Biomass

2.4. CaCO3 Precipitation and Ureolysis

3. Crack Repair Experiments

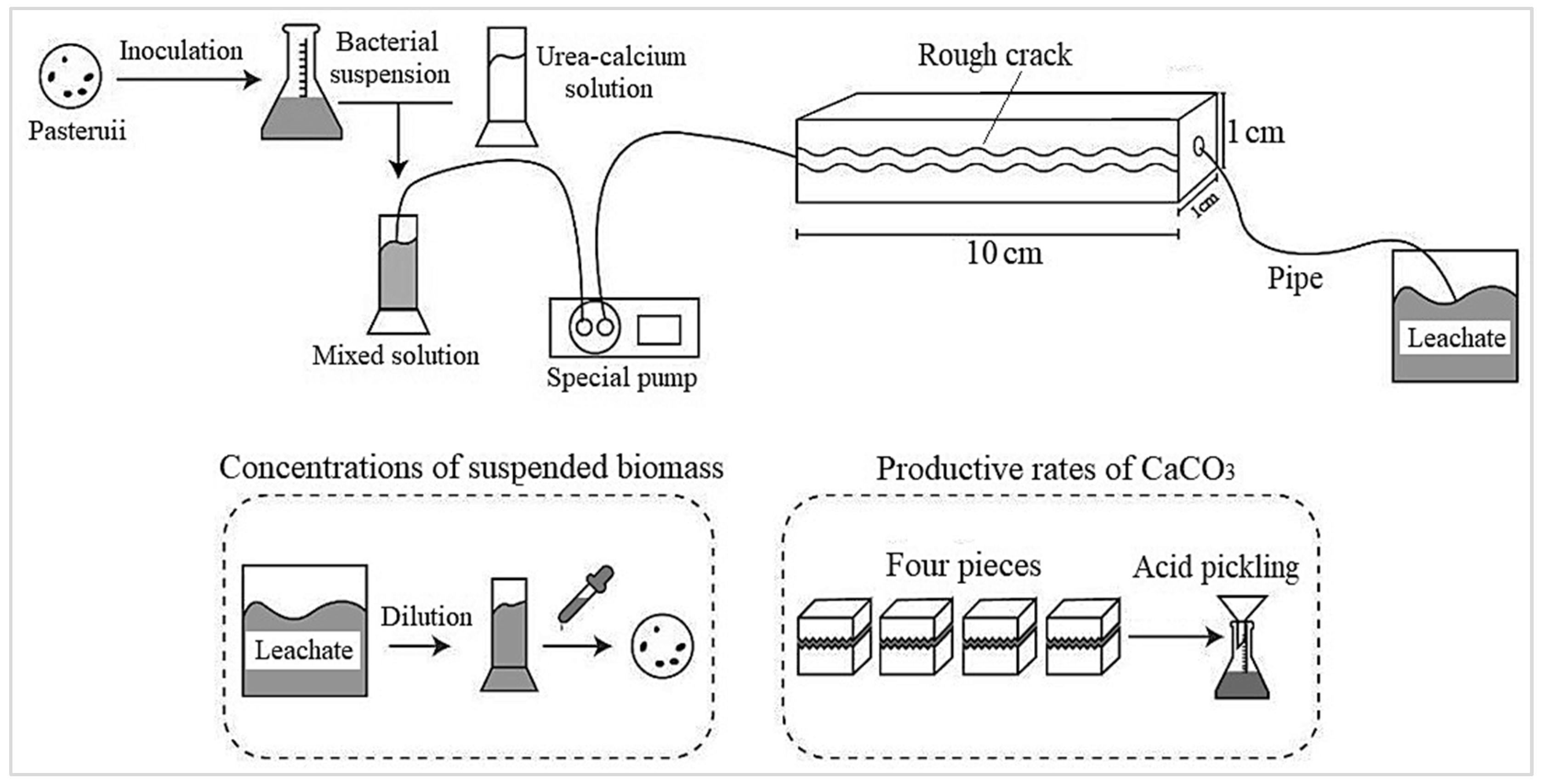

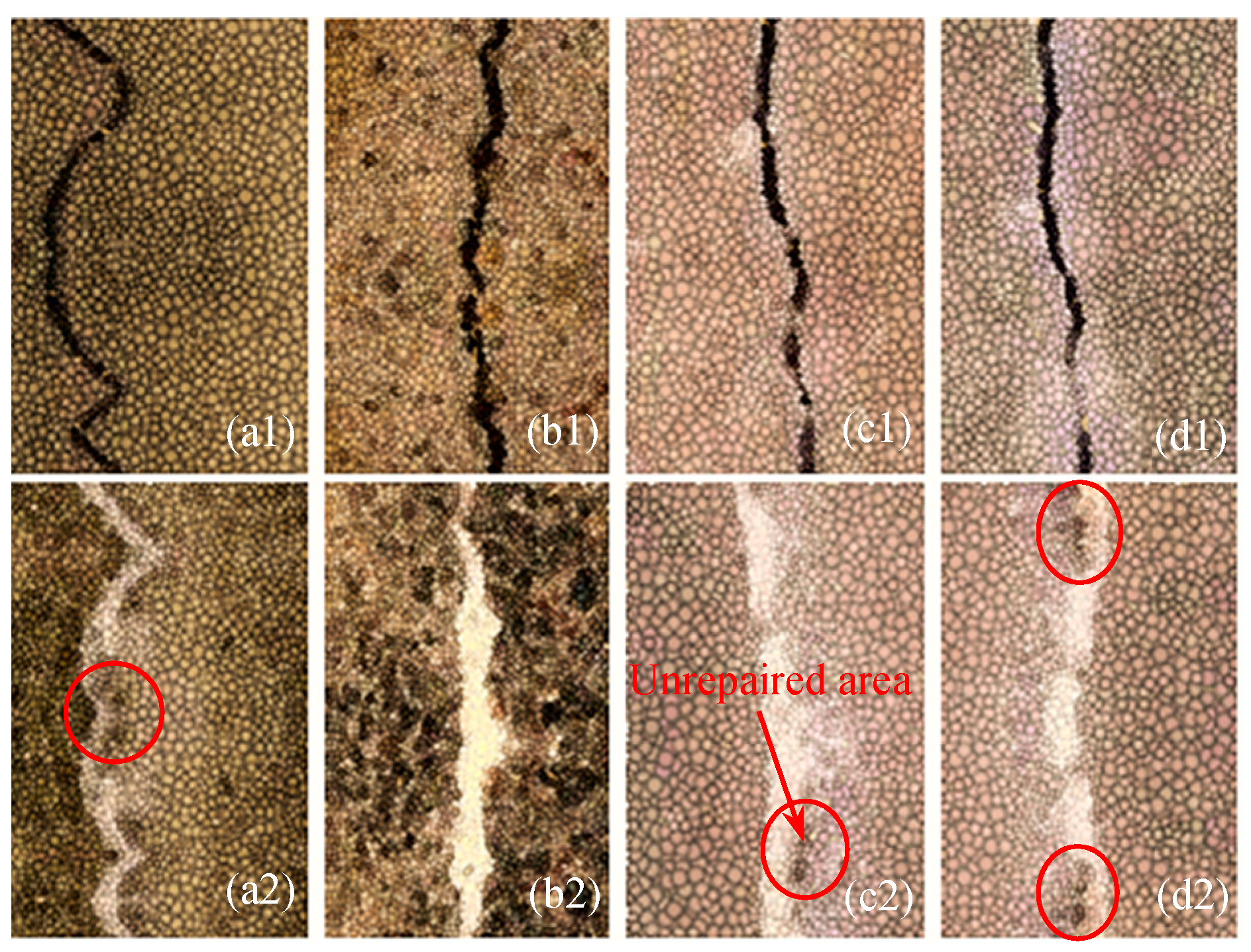

3.1. Crack Repair Using the MICP Techniques

3.2. Modified Cubic Law for Rough Cracks

3.3. Determination of Suspended Biomass Concentrations

3.4. Productive Rates of CaCO3

3.5. Sonic Time Values

4. Results

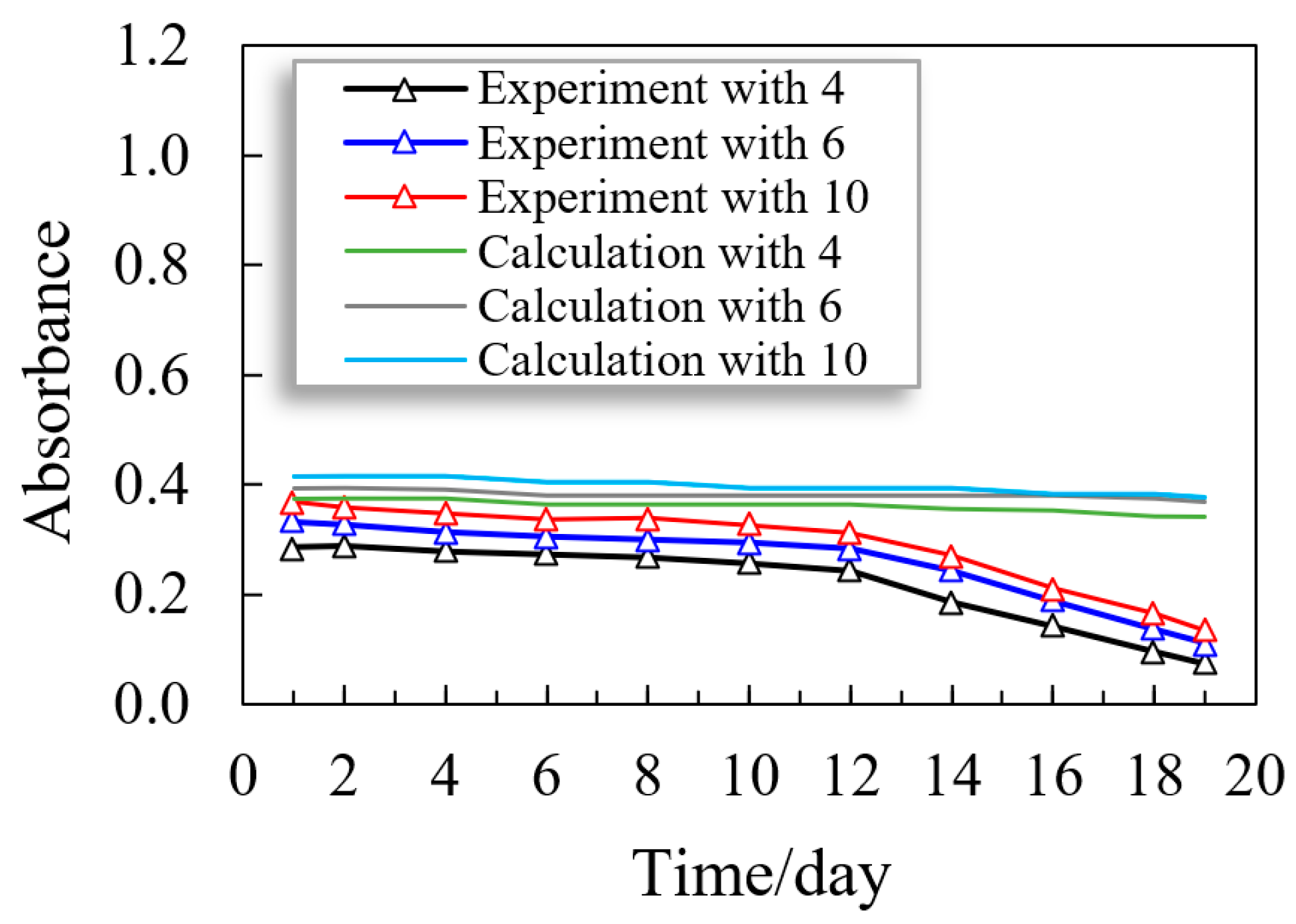

4.1. Concentrations of Suspended Biomass

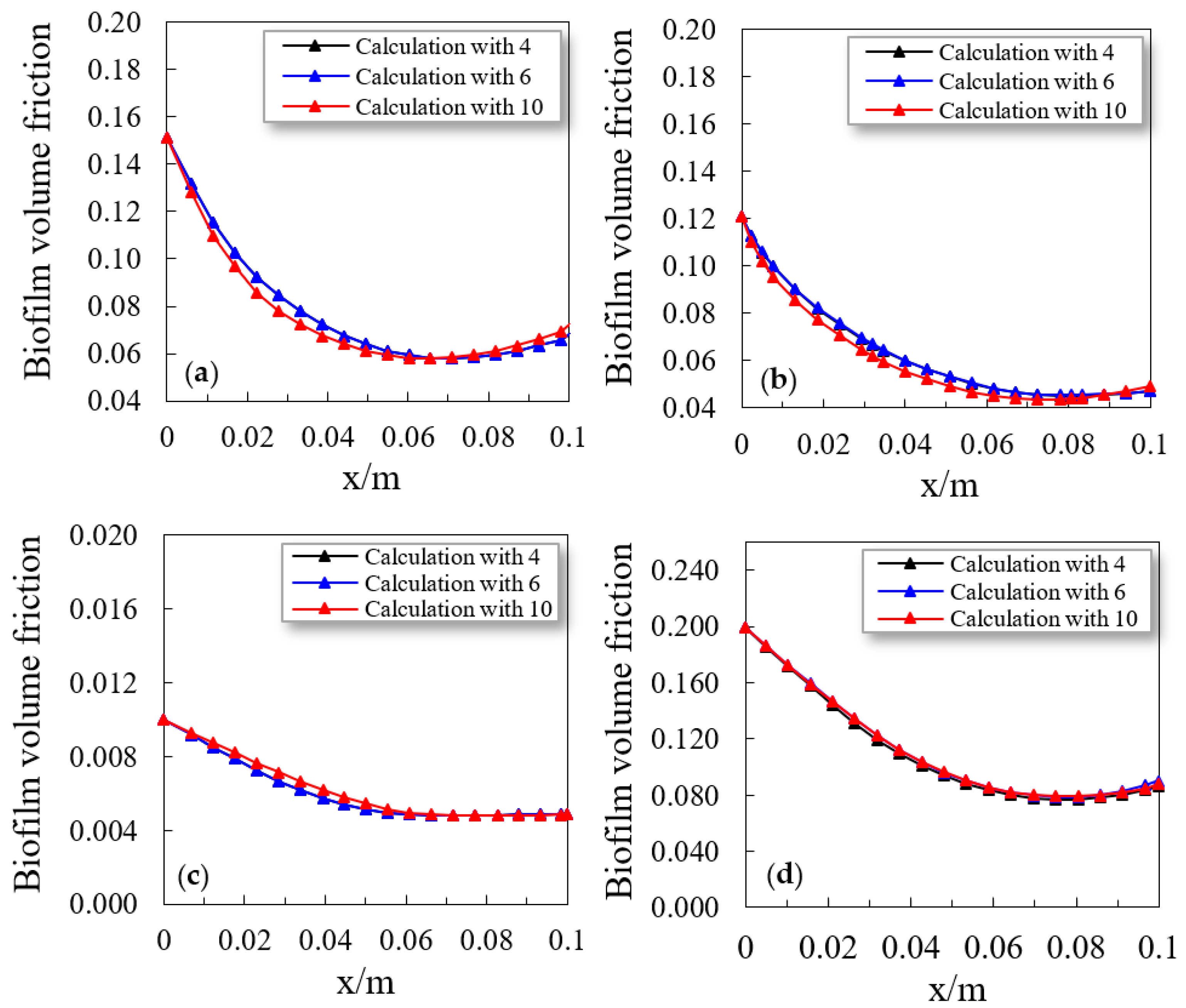

4.2. Biofilm Evolution

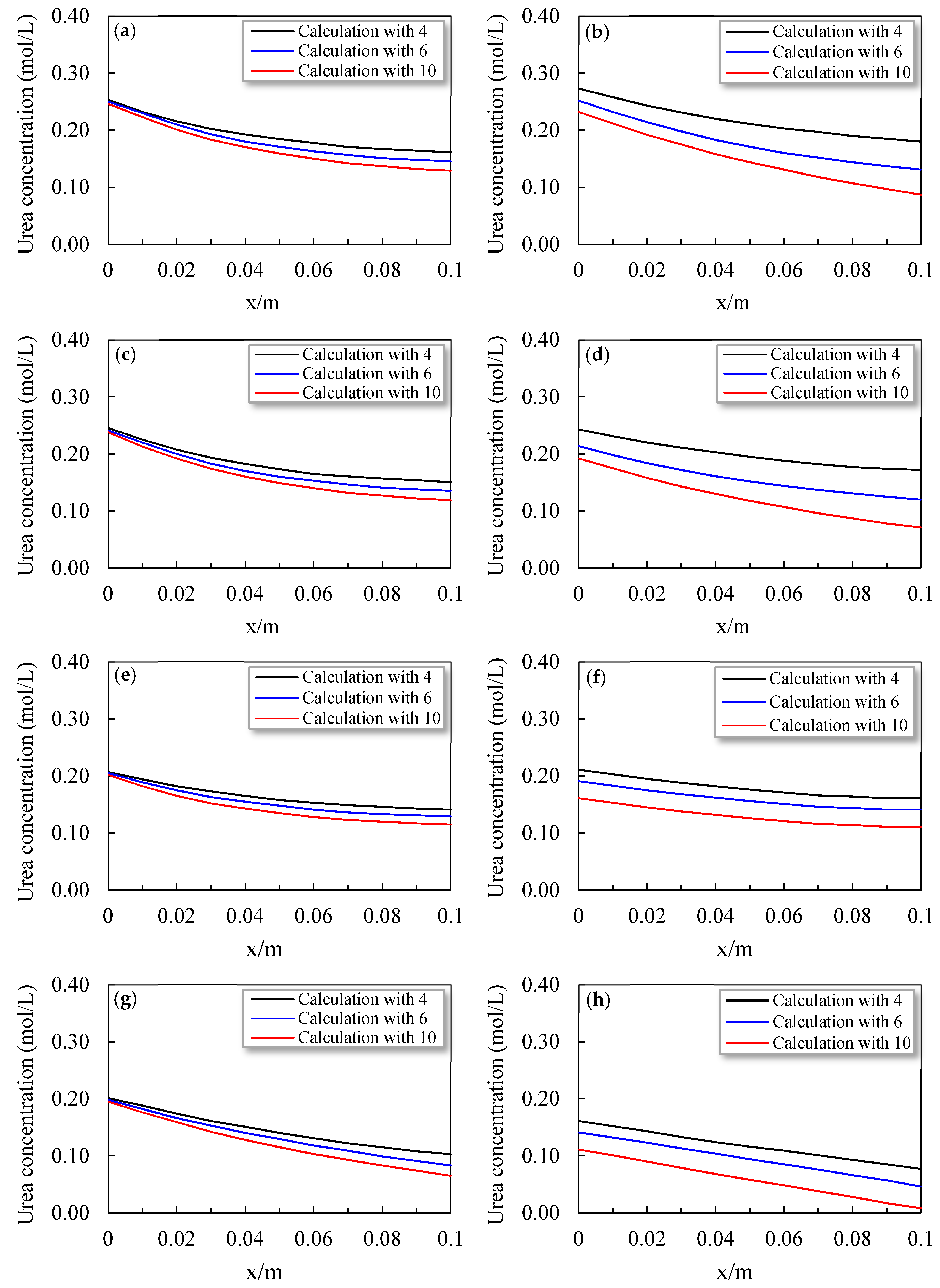

4.3. Concentrations of Solutes

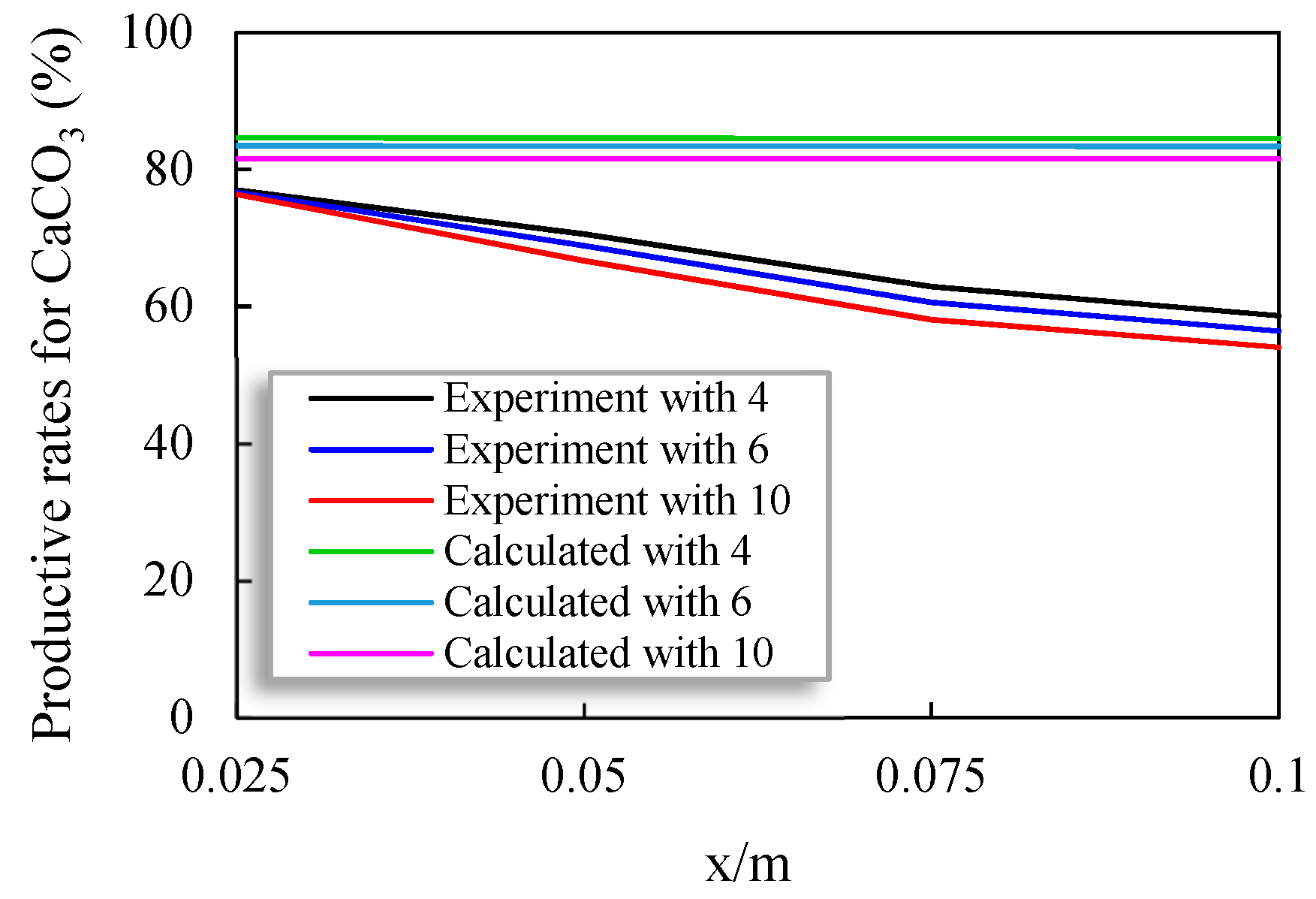

4.4. Productive Rates of CaCO3

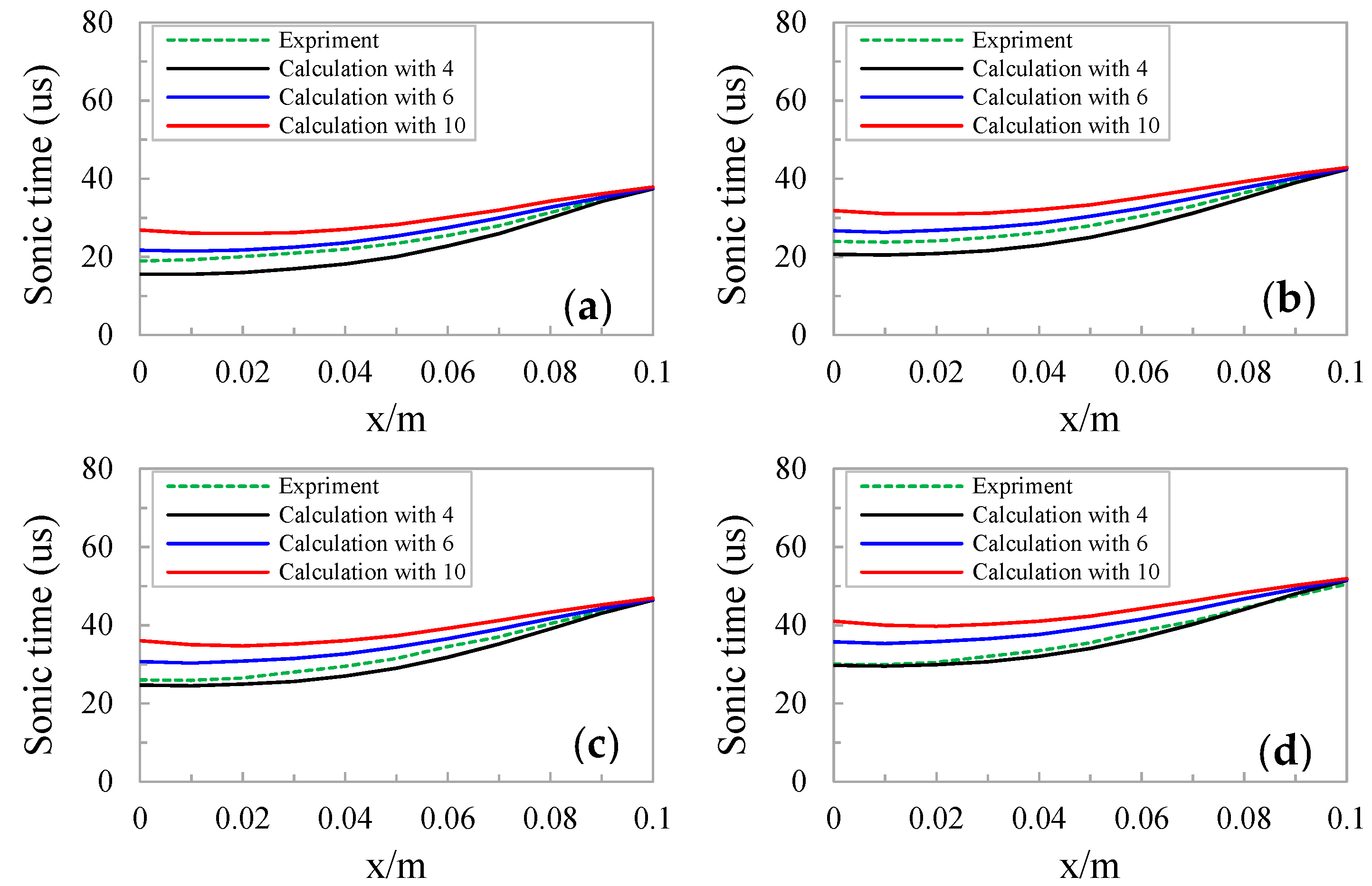

4.5. Sonic Time Values

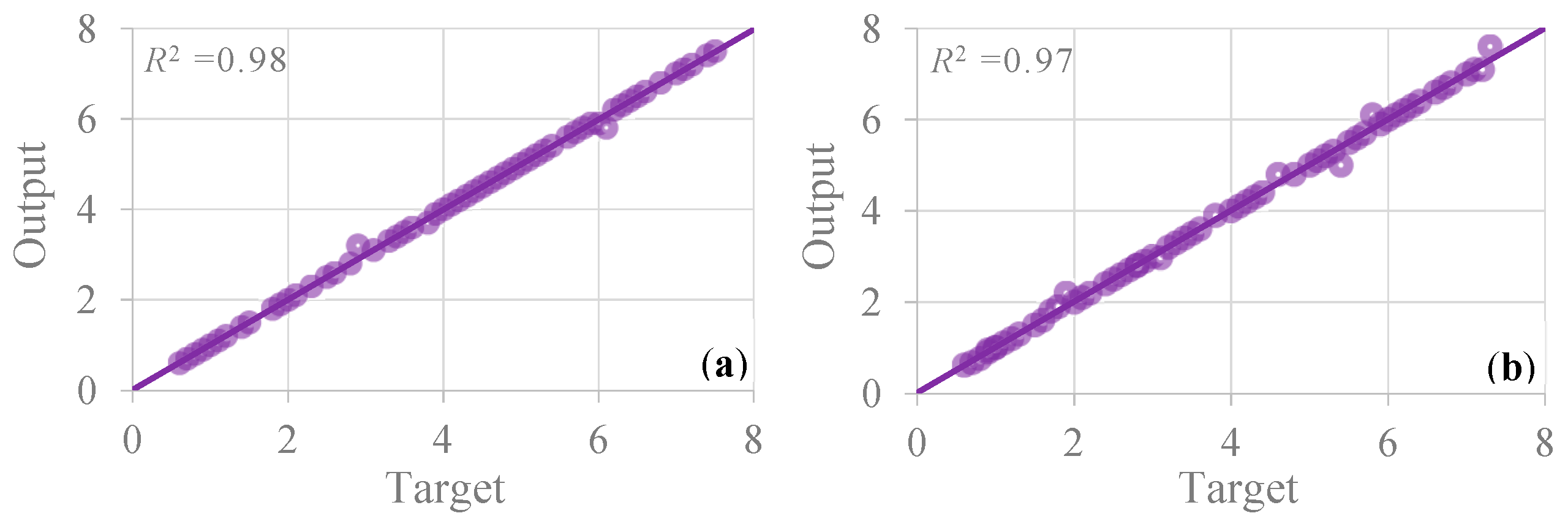

5. Model Accuracy and Application

6. Conclusions

- (1)

- In different rough cracks, the concentrations of suspended biomass changed significantly, and the suspended biomass concentrations diminished slowly during the experiments. The suspended biomass concentration for the rougher crack (crack 10#) was higher. The experimental results were in line with the calculated results, which validated that the transport model of suspended biomass is feasible and precise.

- (2)

- The biofilm volume fractions in the mathematical model decreased after increasing the distance from the crack inlet. The distributions of the concentrations of urea in the rough concrete cracks had similar laws, finally causing an increase in the productive rates of calcium carbonate. For the smoother cracks (4# and 6#), the reducing limits were higher after the daily cycle. In the smoother cracks, the productive rates of calcium carbonate were very similar to the experimental outcomes. The variation between the experimental and calculated outcomes was in an acceptable range.

- (3)

- The value of sonic time in all cracks diminished after increasing the repair time. The smoother cracks had lower values of sonic time and showed excellent repair effects as compared to the rougher crack. As well, near the inlet, the sonic time values for cracks 4# and 6# were small due to the precipitation of CaCO3.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameter | Value |

|---|---|

| Yield coefficient Y | 0.5 |

| The mass of oxygen consumed per unit mass of nutrient F | 0.5 |

| Biofilm density | 2.0 g/L |

| Maximum substrate utilization rate | 4.1667 × 10−5 L/s |

| Half-saturation constant of oxygen | 2.0 × 10−5 g/L |

| Half-saturation constant of nutrient | 7.99 × 10−4 g/L |

| Empirical parameter | 6.15 × 10−10 |

| Endogenous decay rate | 3.18 × 10−7 g/L |

| Decay rate due to calcite precipitation | 1.0 |

| Biomass attachment rate | 6.15 × 10−7 mm/s |

| Biofilm detachment 1 | 3.0 × 10−9 mm/Pa s |

| Biofilm detachment 2 | 0.0 dm/Pa |

| Urea growth rate | 0.7067 mol/g s |

| Urease content in biofilm | 0.001 |

| Half-saturation constant of urea | 0.355 mol/kgw |

| Calcite precipitation 1 | 8.9 × 10−7 mol/mm2 s |

| Calcite precipitation 2 | 5.01 × 10−10 mol/mm2 s |

| Calcite precipitation 3 | 6.6 × 10−13 mol/mm2 s |

| Component diffusivity | 1.0 × 10−3 mm2/s |

| Calcite density | 2710 g/L |

| Molecular weight of calcite | 100.09 g/mol |

| Exponent for calcite precipitation rate | 1.0 |

| Constant coefficient | 0.1 |

| Temperature | 25 °C |

| Initial Conditions | Value |

|---|---|

| Nutrient concentration | 0 kg/m3 |

| Oxygen concentration | 0 kg/m3 |

| Biomass concentration | 0 kg/m3 |

| Biofilm volume fraction | 0 |

| Calcite volume fraction | 0.0 |

| pH | 8.2 |

| Total carbon CT | 1.318 × 10−5 mol/L |

| Total nitrogen NT | 0.187 mol/L |

| Total calcium CaT | 0.0 mol/L |

| Inlet Boundary Conditions | Value |

|---|---|

| Nutrient concentration | 3.0 kg/m3 |

| Oxygen concentration | 8.0 × 10−3 kg/m3 |

| Biomass concentration | 7.44 × 10−8 kg/m3 |

| Urea concentration | 30 kg/m3 |

| Calcium concentration | 20 kg/m3 |

| Total carbon CT | 1.318 × 10−5 mol/L |

| Total nitrogen NT | 0.187 mol/L |

| Total calcium CaT | 0.0 mol/Ls |

| Injection speed | 4 mL/min |

References

- Du, W.; Qian, C.; Xie, Y. Demonstration application of microbial self-healing concrete in sidewall of underground engineering: A case study. J. Build. Eng. 2023, 63, 105512. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wu, L.; Wang, H. Theoretical quantification for cracks repair based on microbially induced carbonate precipitation (MICP) method. Cem. Concr. Compos. 2021, 118, 103950. [Google Scholar] [CrossRef]

- Jiang, L.; Han, Q.; Wang, W.; Zhang, Y.; Lu, W.; Li, Z. A sugar-coated microbial agent for self-healing cracks in concrete. J. Build. Eng. 2023, 66, 105890. [Google Scholar] [CrossRef]

- Fan, S.; Li, M. Understanding intrinsic healing process in cementitious cracks through modeling and experiments. Cem. Concr. Res. 2022, 162, 106931. [Google Scholar] [CrossRef]

- Jogi, P.K.; Lakshmi, T.V. Self healing concrete based on different bacteria: A review. Mater. Today Proc. 2021, 43, 1246–1252. [Google Scholar] [CrossRef]

- Zhu, J.; Shen, D.; Jin, B.; Wu, S. Theoretical investigation on the formation mechanism of carbonate ion in microbial self-healing concrete: Combined QC calculation and MD simulation. Constr. Build. Mater. 2022, 342, 128000. [Google Scholar] [CrossRef]

- Wen, C.; Shen, D.; Luo, Y.; Wang, W.; Liu, C.; Li, M. Early-age autogenous shrinkage and tensile creep of concrete reinforced with polypropylene macro fiber. J. Sustain. Cem.-Based Mater. 2023, 12, 1255–1269. [Google Scholar] [CrossRef]

- Wen, C.; Luo, Y.; Wang, W.; Yao, P.; Shen, D. Early-Age Cracking Potential of Fly Ash High Performance Concrete Internally Cured with Super Absorbent Polymers. J. Test. Eval. 2023, 51, 2422–2441. [Google Scholar] [CrossRef]

- Goushis, R.; Mini, K. Effectiveness of polymeric and cementitious materials to secure cracks in concrete under diverse circumstances. Int. J. Adhes. Adhes. 2022, 114, 103099. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, C.; Xue, H.; Yi, K.; Liu, S. Rheological Properties of Epoxy-Grouting Materials for Early Cracks of Cast-In-Situ Concrete on Bridge Deck. J. Mater. Civ. Eng. 2023, 35, 04023282. [Google Scholar] [CrossRef]

- Aytekin, B.; Mardani, A.; Yazıcı, Ş. State-of-art review of bacteria-based self-healing concrete: Biomineralization process, crack healing, and mechanical properties. Constr. Build. Mater. 2023, 378, 131198. [Google Scholar] [CrossRef]

- Liu, N.; Haugen, M.; Benali, B.; Landa-Marbán, D.; Fernø, M.A. Pore-scale spatiotemporal dynamics of microbial-induced calcium carbonate growth and distribution in porous media. Int. J. Greenh. Gas Control 2023, 125, 103885. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, L.; Zeng, W.; sun Poon, C.; Lu, Z. Improvement in properties of concrete with modified RCA by microbial induced carbonate precipitation. Cem. Concr. Compos. 2021, 124, 104251. [Google Scholar] [CrossRef]

- Tamayo-Figueroa, D.P.; Meneses-Martínez, H.O.; Darghan-Contreras, A.E.; Lizarazo-Marriaga, J.; Brandão, P.F. A comparison index in mortar repair treatments by microbiologically induced carbonate precipitation and its evaluation by a non-destructive technique. Eur. J. Environ. Civ. Eng. 2023. [Google Scholar] [CrossRef]

- Feng, J.; Chen, B.; Sun, W.; Wang, Y. Microbial induced calcium carbonate precipitation study using Bacillus subtilis with application to self-healing concrete preparation and characterization. Constr. Build. Mater. 2021, 280, 122460. [Google Scholar] [CrossRef]

- Rauf, M.; Khaliq, W.; Khushnood, R.A.; Ahmed, I. Comparative performance of different bacteria immobilized in natural fibers for self-healing in concrete. Constr. Build. Mater. 2020, 258, 119578. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Riofrio, A.; Baykara, H.; Soleymani, A.; Mahdi, H.A.; Jahangir, H.; Ibe, K. Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures. Sustainability 2022, 14, 9573. [Google Scholar] [CrossRef]

- Omoregie, A.I.; Palombo, E.A.; Nissom, P.M. Bioprecipitation of calcium carbonate mediated by ureolysis: A review. Environ. Eng. Res. 2021, 26, 200379. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Tong, T.; Wang, C. Improvement of microbial-induced calcium carbonate precipitation technology for sand solidification. J. Mater. Civ. Eng. 2018, 30, 04018301. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; Alsulamy, S.; Martínez-García, R.; de Prado-Gil, J.; Arbili, M.M. Experimental study on the properties of ultra-high-strength geopolymer concrete with polypropylene fibers and nano-silica. PLoS ONE 2023, 18, e0282435. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; Alsulamy, S.; Martínez-García, R.; de Prado Gil, J.; Arbili, M.M. Determining engineering properties of ultra-high-performance fiber-reinforced geopolymer concrete modified with different waste materials. PLoS ONE 2023, 18, e0285692. [Google Scholar] [CrossRef] [PubMed]

- Althoey, F.; Zaid, O.; Martínez-García, R.; de Prado-Gil, J.; Ahmed, M.; Yosri, A.M. Ultra-high-performance fiber-reinforced sustainable concrete modified with silica fume and wheat straw ash. J. Mater. Res. Technol. 2023, 24, 6118–6139. [Google Scholar] [CrossRef]

- Sidhu, N.; Goyal, S.; Reddy, M.S. Self-healing by biocomposite containing metakaolin immobilized bacterial spores in concrete using low-cost corn steep liquor media. J. Sustain. Cem.-Based Mater. 2023. [Google Scholar] [CrossRef]

- Bagga, M.; Hamley-Bennett, C.; Alex, A.; Freeman, B.L.; Justo-Reinoso, I.; Mihai, I.C.; Gebhard, S.; Paine, K.; Jefferson, A.D.; Masoero, E. Advancements in bacteria based self-healing concrete and the promise of modelling. Constr. Build. Mater. 2022, 358, 129412. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wang, C. Glucose addition improves the bio-remediation efficiency for crack repair. Mater. Struct. 2019, 52, 111. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Wang, Z.; Yao, W. Use of recycled concrete aggregates as carriers for self-healing of concrete cracks by bacteria with high urease activity. Constr. Build. Mater. 2022, 337, 127581. [Google Scholar] [CrossRef]

- Algaifi, H.A.; Bakar, S.A.; Sam, A.R.M.; Abidin, A.R.Z.; Shahir, S.; AL-Towayti, W.A.H. Numerical modeling for crack self-healing concrete by microbial calcium carbonate. Constr. Build. Mater. 2018, 189, 816–824. [Google Scholar] [CrossRef]

- Castro-Alonso, M.J.; Montañez-Hernandez, L.E.; Sanchez-Muñoz, M.A.; Macias Franco, M.R.; Narayanasamy, R.; Balagurusamy, N. Microbially induced calcium carbonate precipitation (MICP) and its potential in bioconcrete: Microbiological and molecular concepts. Front. Mater. 2019, 6, 126. [Google Scholar] [CrossRef]

- Reshma, T.; Kumar, P.C.; Khalid, S. Influence of self-healing behavior of bacteria & e-waste incorporated concrete on its mechanical properties. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, Y.; Xu, X.; Yuan, W.; Yang, L.; Shao, Q.; Guo, Z.; Ding, T.; Huang, Y. Efficient intrinsic self-healing epoxy acrylate formed from host-guest chemistry. Polymer 2019, 164, 79–85. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, M.; Liu, R.; Li, X.; Yan, J.; Du, H. Enhancing self-healing efficiency of concrete using multifunctional granules and PVA fibers. J. Build. Eng. 2023, 76, 107314. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R. Adding aluminum oxide to improve the repairing effect of cracks based on bio-remediation. J. Adv. Concr. Technol. 2019, 17, 177–187. [Google Scholar] [CrossRef]

- Wang, X.; Nackenhorst, U. A coupled bio-chemo-hydraulic model to predict porosity and permeability reduction during microbially induced calcite precipitation. Adv. Water Resour. 2020, 140, 103563. [Google Scholar] [CrossRef]

- Konstantinou, C.; Wang, Y.; Biscontin, G. A systematic study on the influence of grain characteristics on hydraulic and mechanical performance of MICP-treated porous media. Transp. Porous Media 2023, 147, 305–330. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R.; Wang, H.; Wu, L. A revised porous media model of microbially induced carbonate precipitation for loess solidification. J. Geotech. Geoenviron. Eng. 2023, 149, 04023031. [Google Scholar] [CrossRef]

- Kurz, D.L.; Secchi, E.; Stocker, R.; Jimenez-Martinez, J. Morphogenesis of biofilms in porous media and control on hydrodynamics. Environ. Sci. Technol. 2023, 57, 5666–5677. [Google Scholar] [CrossRef]

- Peszynska, M.; Trykozko, A.; Iltis, G.; Schlueter, S.; Wildenschild, D. Biofilm growth in porous media: Experiments, computational modeling at the porescale, and upscaling. Adv. Water Resour. 2016, 95, 288–301. [Google Scholar] [CrossRef]

- Markale, I.; Carrel, M.; Kurz, D.L.; Morales, V.L.; Holzner, M.; Jiménez-Martínez, J. Internal Biofilm Heterogeneities Enhance Solute Mixing and Chemical Reactions in Porous Media. Environ. Sci. Technol. 2023, 57, 8065–8074. [Google Scholar] [CrossRef]

- Medina Boyd, I. Effects of Stress in the Growth of Microbial Biofilms. Master’s Thesis, Pontificia University, Santiago, Chile, 2023. Available online: https://repositorio.uc.cl/handle/11534/66418 (accessed on 26 July 2023).

- Shi, W.; Wang, M.; Wu, L.; Xie, X.; Wang, M.; Lu, T. Study of Concrete Crack Repair using Bacillus megaterium. Adv. Mater. Sci. Eng. 2022, 2022, 6188680. [Google Scholar] [CrossRef]

- Gao, R.; Ma, J.; Liu, G.; Chen, H.; Wen, J.; Wang, J. Optimization of deposition process for a productive and cohesive bio-CaCO3 to repair concrete existing cracks. Appl. Microbiol. Biotechnol. 2023, 107, 3479–3494. [Google Scholar] [CrossRef]

- Bilgic, A.; Cimen, A. Synthesis, characterisation, adsorption studies and comparison of superparamagnetic iron oxide nanoparticles (SPION) with three different amine groups functionalised with BODIPY for the removal of Cr (VI) metal ions from aqueous solutions. Int. J. Environ. Anal. Chem. 2023, 103, 1866–1891. [Google Scholar] [CrossRef]

- Hossain, M.R.; Sultana, R.; Patwary, M.M.; Khunga, N.; Sharma, P.; Shaker, S.J. Self-healing concrete for sustainable buildings. A review. Environ. Chem. Lett. 2022, 20, 1265–1273. [Google Scholar] [CrossRef]

- Algaifi, H.A.; Bakar, S.A.; Sam, A.R.M.; Ismail, M.; Abidin, A.R.Z.; Shahir, S.; Altowayti, W.A.H. Insight into the role of microbial calcium carbonate and the factors involved in self-healing concrete. Constr. Build. Mater. 2020, 254, 119258. [Google Scholar] [CrossRef]

- Landa-Marbán, D.; Tveit, S.; Kumar, K.; Gasda, S.E. Practical approaches to study microbially induced calcite precipitation at the field scale. Int. J. Greenh. Gas Control 2021, 106, 103256. [Google Scholar] [CrossRef]

- Ebigbo, A.; Phillips, A.; Gerlach, R.; Helmig, R.; Cunningham, A.B.; Class, H.; Spangler, L.H. Darcy-scale modeling of microbially induced carbonate mineral precipitation in sand columns. Water Resour. Res. 2012, 48, 1–17. [Google Scholar] [CrossRef]

- Lauchnor, E.G.; Topp, D.; Parker, A.; Gerlach, R. Whole cell kinetics of ureolysis by Sporosarcina pasteurii. J. Appl. Microbiol. 2015, 118, 1321–1332. [Google Scholar] [CrossRef]

- Liu, Y.; Ali, A.; Su, J.-F.; Li, K.; Hu, R.-Z.; Wang, Z. Microbial-induced calcium carbonate precipitation: Influencing factors, nucleation pathways, and application in waste water remediation. Sci. Total Environ. 2023, 860, 160439. [Google Scholar] [CrossRef]

- Dai, Q.; Wang, W.; Xu, F.; Zhao, Y.; Zhou, L.; Wang, L.; Jiang, R. Study on the Combined Behaviour of Montmorillonite and Carbonate Mineralizing Bacteria on Lead Retention and Fixation. Minerals 2023, 13, 763. [Google Scholar] [CrossRef]

- Du, W.; Qian, C. Revealing the effect mechanism of calcareous aggregate and silica aggregate on the strength of ordinary concrete: Experiments, microscopic characterization, and molecular simulation. J. Build. Eng. 2023, 72, 106646. [Google Scholar] [CrossRef]

- Fu, Q.; Liu, M.; Zhang, S.; Lu, L.; Fang, N.; Chen, J.; Shama, S.; Wang, J. Growth and mineralization characteristics of Bacillus subtilis isolated from marine aquaculture wastewater and its application in coastal self-healing concrete. Mater. Today Commun. 2023, 35, 105654. [Google Scholar] [CrossRef]

- Barton, N.; Choubey, V. The shear strength of rock joints in theory and practice. Rock Mech. 1977, 10, 1–54. [Google Scholar] [CrossRef]

- Ma, L.; Pang, A.-P.; Luo, Y.; Lu, X.; Lin, F. Beneficial factors for biomineralization by ureolytic bacterium Sporosarcina pasteurii. Microb. Cell Factories 2020, 19, 12. [Google Scholar] [CrossRef]

- Snow, D.T. Anisotropie permeability of fractured media. Water Resour. Res. 1969, 5, 1273–1289. [Google Scholar] [CrossRef]

- Qin, Y.; Li, M.; Li, Y.; Ma, W.; Xu, Z.; Chai, J.; Zhou, H. Effects of nylon fiber and nylon fiber fabric on the permeability of cracked concrete. Constr. Build. Mater. 2021, 274, 121786. [Google Scholar] [CrossRef]

- Li, M.; Chai, J.; Zhang, X.; Qin, Y.; Ma, W.; Duan, M.; Zhou, H. Quantifying the recycled nylon fibers influence on geometry of crack and seepage behavior of cracked concrete. Constr. Build. Mater. 2023, 373, 130853. [Google Scholar] [CrossRef]

- Dharmabiksham, B.; Murali, K. Experimental investigation on the strength and durability aspect of bacterial self-healing concrete with GGBS and dolomite powder. Mater. Today Proc. 2022, 66, 1156–1161. [Google Scholar] [CrossRef]

- Albuhairi, D.; Di Sarno, L. Low-carbon self-healing concrete: State-of-the-art, challenges and opportunities. Buildings 2022, 12, 1196. [Google Scholar] [CrossRef]

- Li, H.-F.; Yu, Q.-Q.; Zhang, K.; Wang, X.-Y.; Liu, Y.; Zhang, G.-Z. Effect of types of curing environments on the self-healing capacity of mortars incorporating crystalline admixture. Case Stud. Constr. Mater. 2023, 18, e01713. [Google Scholar] [CrossRef]

- Ahmad, S.S.; Elmahdy, M.A.; ELShami, A.; Yousry, E.-S.M. Bacterial sustainable concrete for repair and rehabilitation of structural cracks. J. Sustain. Cem.-Based Mater. 2023, 12, 627–646. [Google Scholar] [CrossRef]

- Sportelli, M.C.; Kranz, C.; Mizaikoff, B.; Cioffi, N. Recent advances on the spectroscopic characterization of microbial biofilms: A critical review. Anal. Chim. Acta 2022, 1195, 339433. [Google Scholar] [CrossRef]

- Kumar, S.; Nguyen, A.T.; Goswami, S.; Ferracane, J.; Koley, D. Real-time monitoring of biofilm formation using a noninvasive impedance-based method. Sens. Actuators B Chem. 2023, 376, 133034. [Google Scholar] [CrossRef] [PubMed]

- Ryparova, P.; Prošek, Z.; Schreiberova, H.; Bílý, P.; Tesarek, P. The role of bacterially induced calcite precipitation in self-healing of cement paste. J. Build. Eng. 2021, 39, 102299. [Google Scholar] [CrossRef]

- Zheng, T.; Qian, C. Self-healing of later-age cracks in cement-based materials by encapsulation-based bacteria. J. Mater. Civ. Eng. 2020, 32, 04020341. [Google Scholar] [CrossRef]

| Component | Water | Cement | Gravel | Sand | Coal Ash | Water Reducer |

|---|---|---|---|---|---|---|

| content | 160 | 330 | 990 | 845 | 85 | 8 |

| Crack No. | Joint Profile | JRC | S0 (m2) |

|---|---|---|---|

| 4 |  | 6.7 | 0.1027 |

| 6 |  | 10.8 | 0.1025 |

| 10 |  | 18.7 | 0.1086 |

| Crack No. | Volume of Cementation Solution (mL) | Concentration of Cementation Solution (M) | Repairing Period (Day) | Theoretical Producing Mass (g) | Practical Producing Mass (g) | Productive Rates for CaCO3 |

|---|---|---|---|---|---|---|

| 4# | 20 | 0.5 | 21 | 16.181 | 11.65 | 72% |

| 20 | 0.5 | 21 | 16.181 | 12.143 | 75% | |

| 20 | 0.5 | 21 | 16.181 | 11.165 | 69% | |

| 6# | 20 | 0.5 | 21 | 16.144 | 10.978 | 68% |

| 20 | 0.5 | 21 | 16.144 | 11.785 | 73% | |

| 20 | 0.5 | 21 | 16.144 | 12.754 | 79% | |

| 10# | 20 | 0.5 | 21 | 17.106 | 12.83 | 75% |

| 20 | 0.5 | 21 | 17.106 | 13.685 | 80% | |

| 20 | 0.5 | 21 | 17.106 | 13.856 | 81% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Wang, S.; Ahmed, Z.; Zhao, X. A Novel Mathematical Model for Repairing Rough Cracks Using the Microbially Induced Carbonate Precipitation (MICP). Sustainability 2023, 15, 13122. https://doi.org/10.3390/su151713122

Zhang S, Wang S, Ahmed Z, Zhao X. A Novel Mathematical Model for Repairing Rough Cracks Using the Microbially Induced Carbonate Precipitation (MICP). Sustainability. 2023; 15(17):13122. https://doi.org/10.3390/su151713122

Chicago/Turabian StyleZhang, Simiao, Shuhong Wang, Zulkifl Ahmed, and Xin Zhao. 2023. "A Novel Mathematical Model for Repairing Rough Cracks Using the Microbially Induced Carbonate Precipitation (MICP)" Sustainability 15, no. 17: 13122. https://doi.org/10.3390/su151713122

APA StyleZhang, S., Wang, S., Ahmed, Z., & Zhao, X. (2023). A Novel Mathematical Model for Repairing Rough Cracks Using the Microbially Induced Carbonate Precipitation (MICP). Sustainability, 15(17), 13122. https://doi.org/10.3390/su151713122