Internet of Things Assisted Solid Biofuel Classification Using Sailfish Optimizer Hybrid Deep Learning Model for Smart Cities

Abstract

:1. Introduction

2. Related Works

3. The Proposed Model

3.1. Data Preprocessing

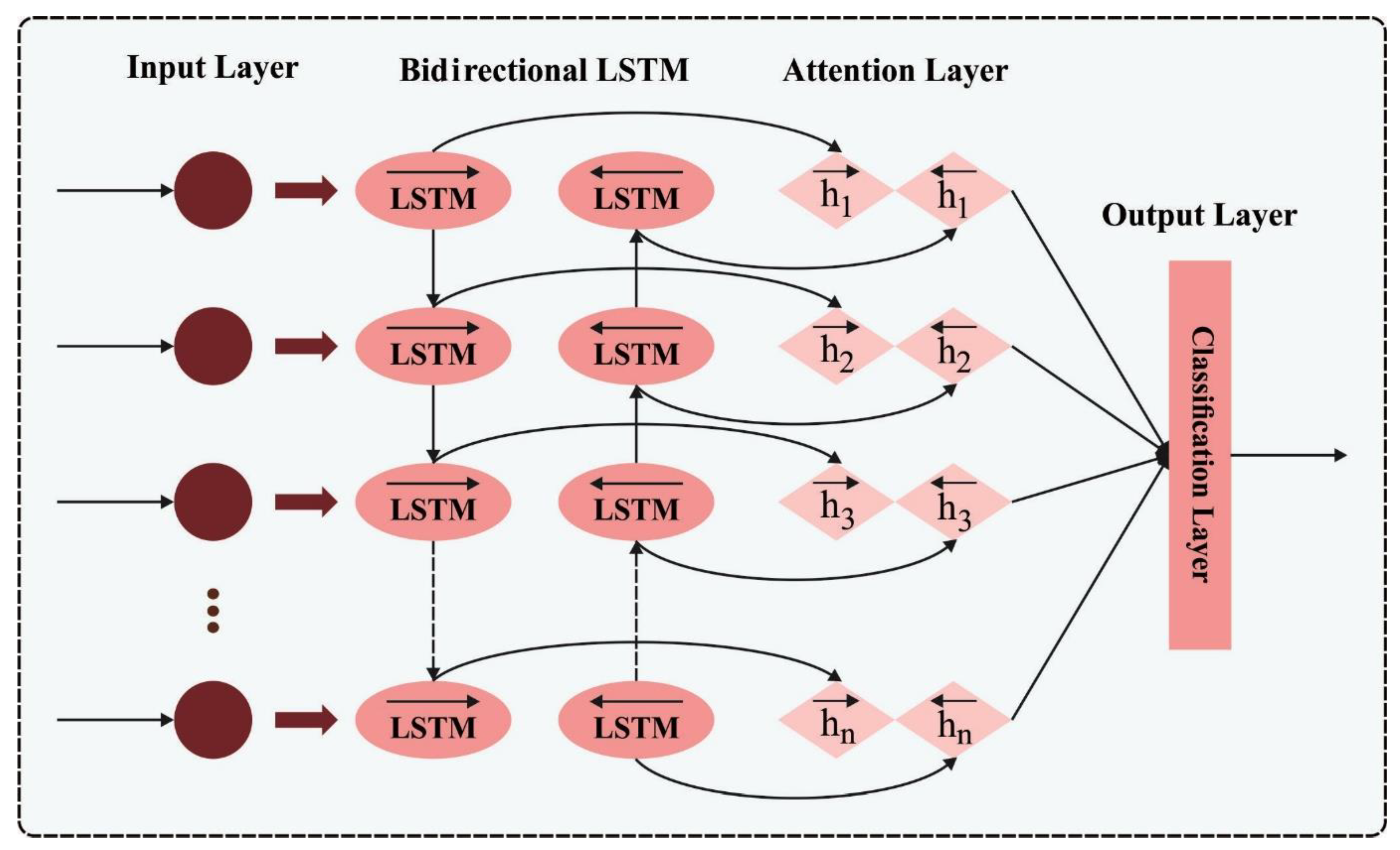

3.2. Solid Biofuel Classification

3.3. Hyperparameter Tuning Using SFO Algorithm

3.3.1. Initialization of Population

3.3.2. Mechanism and Evaluation of Elitism

3.3.3. Sailfish Position Updating

3.3.4. Sardine Position Update

| Algorithm 1 Pseudocode of SFO algorithm |

|

Begin The population of sailfish and sardine are arbitrarily initialized Set parameter Evaluate the fitness of sailfish and sardine Choose the better sailfish and sardine and define them as injured sardine and elite sailfish, correspondingly While the ending condition is not fulfilled For all the sailfishes Evaluate using based on Equation (19) Upgrade the position of the sailfish based on (18) End for Evaluate the attack power based on (22) Evaluate based on (23) Choose a set of sardines based on the value Upgrade the position of the selected sardine based on Equation (24) Else Upgrade the position of the sardine based on Equation (24) End if Evaluate each sardine fitness If the best solution for the sardine population Exchange the sailfish alongside the wounded sardine Remove the hunted sardine from the population Upgrade the better sailfish with sardine End if End while Return better sailfish obtained so far |

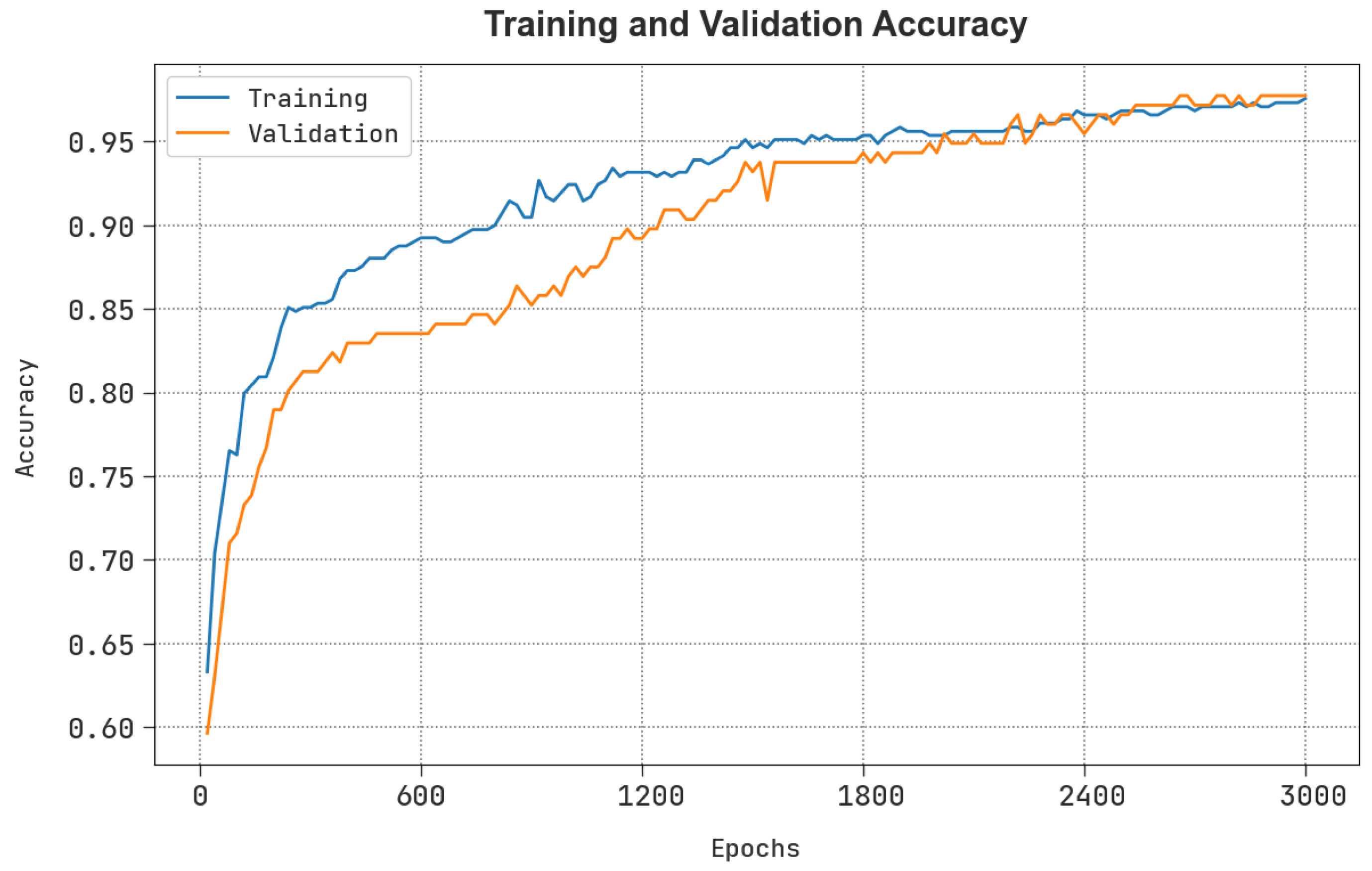

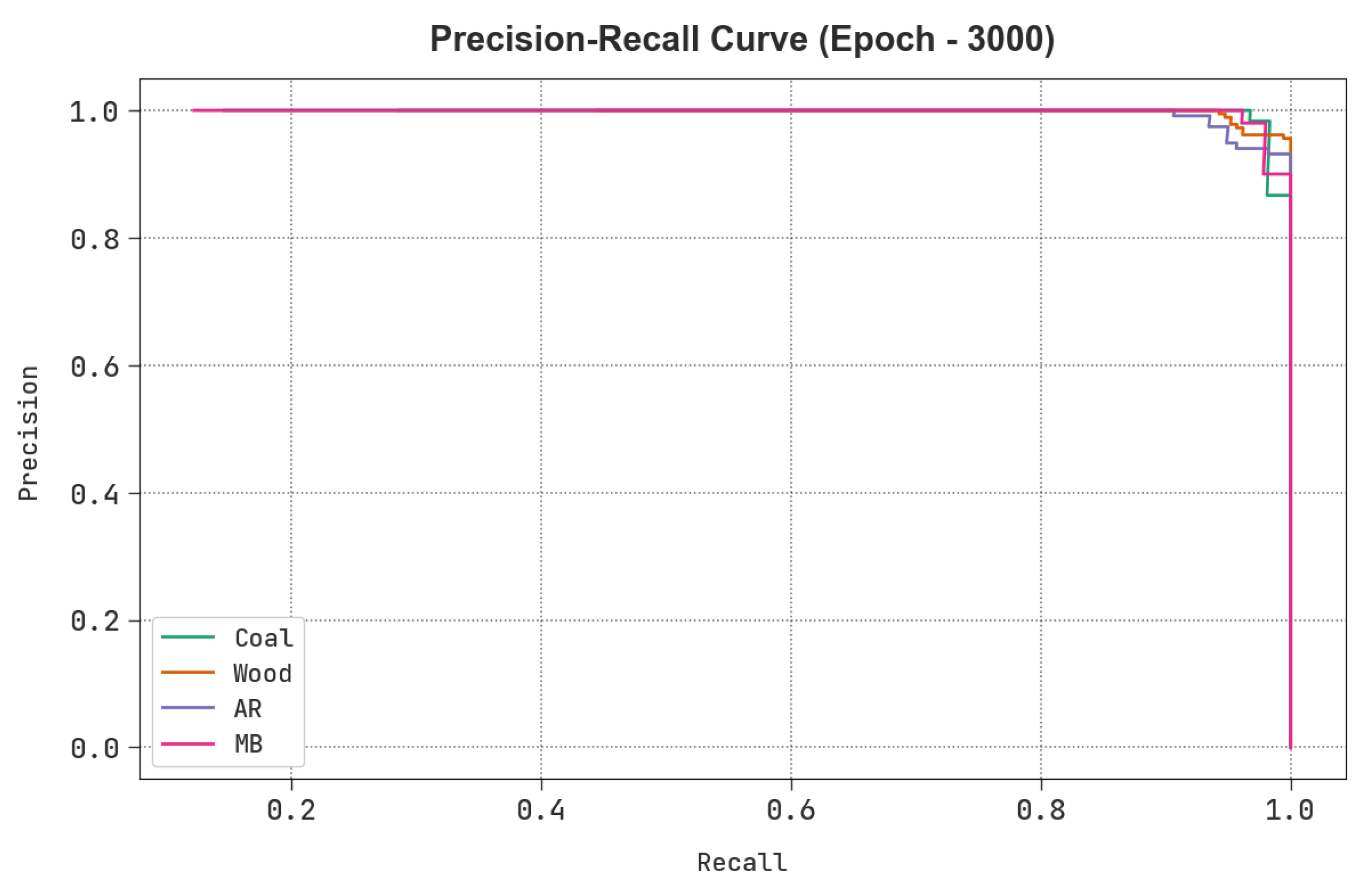

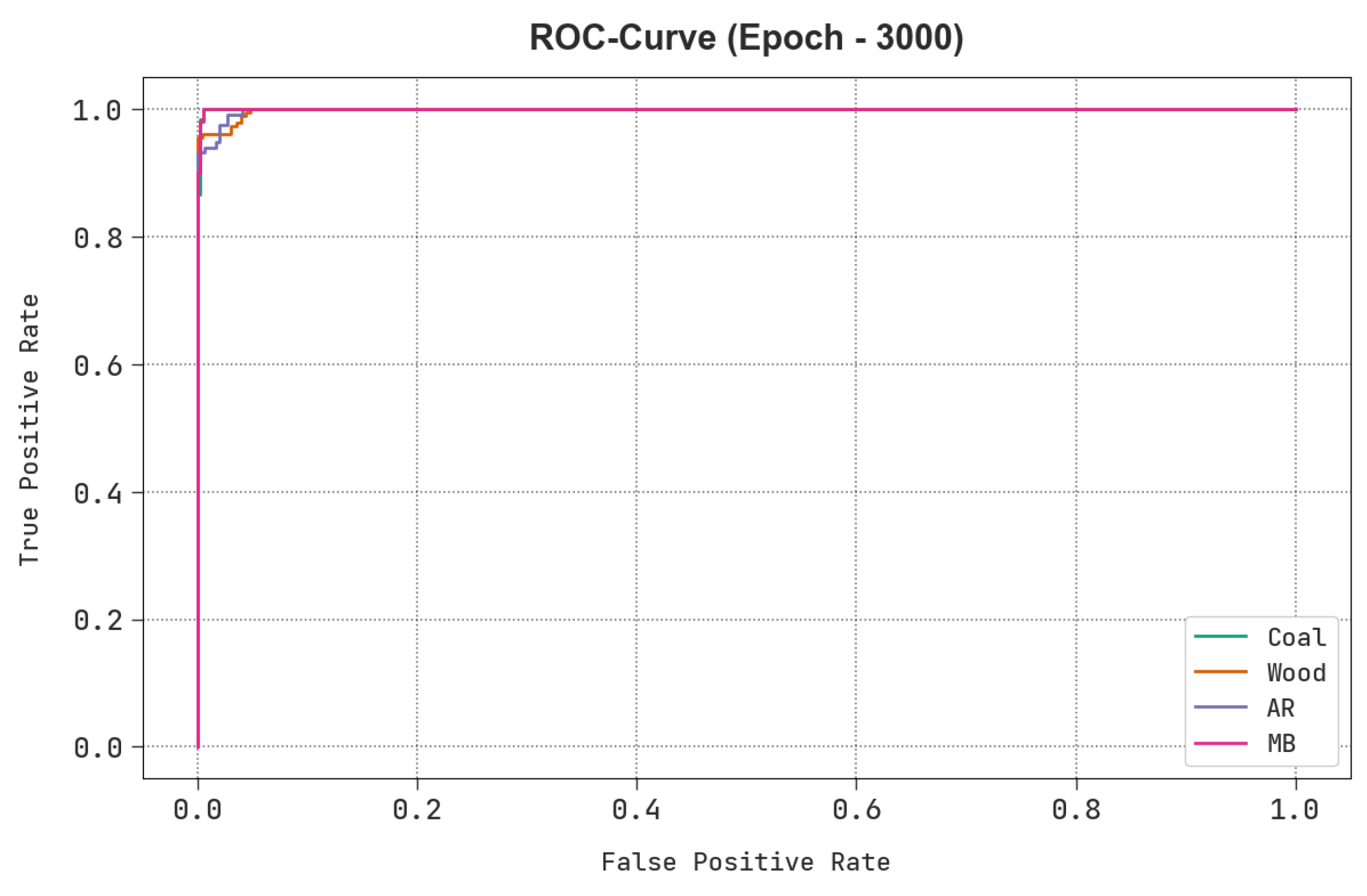

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, W.; Sadaghiani, O.K. An Analytical Review on the Utilization of Machine Learning in the Biomass Raw Materials, Their Evaluation, Storage, and Transportation. Arch. Comput. Methods Eng. 2023, 1–22. [Google Scholar] [CrossRef]

- Peng, W.; Sadaghiani, O.K. Enhancement of quality and quantity of woody biomass produced in forests using machine learning algorithms. Biomass Bioenergy 2023, 175, 106884. [Google Scholar] [CrossRef]

- Akram, S.V.; Rawat, B. The Smart Analysis of Hydropower Energy Measurement in Power Plants using Industrial Machine Learning Model. In Proceedings of the 2023 IEEE International Conference on Integrated Circuits and Communication Systems (ICICACS), Raichur, India, 24–25 February 2023; pp. 1–6. [Google Scholar]

- Barus, J.; Mustikawati, D.R.; Endriani, E.; Meithasari, D.; Ernawati, R.; Wardani, N.; Soraya, S.; Suretno, N.D.; Tambunan, R.D.; Silalahi, M. Evaluation of composting of several plant biomass wastes with different types of starters. Int. J. Recycl. Org. Waste Agric. 2023. [Google Scholar]

- Mondal, P.P.; Galodha, A.; Verma, V.K.; Singh, V.; Show, P.L.; Awasthi, M.K.; Lall, B.; Anees, S.; Pollmann, K.; Jain, R. Review on machine learning-based bioprocess optimization, monitoring, and control systems. Bioresour. Technol. 2022, 370, 128523. [Google Scholar] [CrossRef]

- Zheng, K.; Jia, X.; Chi, K.; Liu, X. DDPG-based joint time and energy management in ambient backscatter-assisted hybrid underlay CRNs. IEEE Trans. Commun. 2022, 71, 441–456. [Google Scholar] [CrossRef]

- Liu, X.; Xu, B.; Zheng, K.; Zheng, H. Throughput maximization of wireless-powered communication network with mobile access points. IEEE Trans. Wirel. Commun. 2022, 22, 4401–4415. [Google Scholar] [CrossRef]

- Zheng, K.; Jiang, G.; Liu, X.; Chi, K.; Yao, X.; Liu, J. DRL-Based Offloading for Computation Delay Minimization in Wireless-Powered Multi-Access Edge Computing. IEEE Trans. Commun. 2023, 71, 1755–1770. [Google Scholar] [CrossRef]

- Balachander, K.; Paulraj, D. RETRACTED ARTICLE: ANN and fuzzy based household energy consumption prediction with high accuracy. J. Ambient. Intell. Humaniz. Comput. 2021, 12, 7543–7557. [Google Scholar] [CrossRef]

- Rajamoorthy, R.; Saraswathi, H.V.; Devaraj, J.; Kasinathan, P.; Elavarasan, R.M.; Arunachalam, G.; Mostafa, T.M.; Mihet-Popa, L. A Hybrid Sailfish Whale Optimization and Deep Long Short-Term Memory (SWO-DLSTM) Model for Energy Efficient Autonomy in India by 2048. Sustainability 2022, 14, 1355. [Google Scholar] [CrossRef]

- Sharma, A.K.; Ghodke, P.K.; Goyal, N.; Nethaji, S.; Chen, W.H. Machine learning technology in biohydrogen production from agriculture waste: Recent advances and future perspectives. Bioresour. Technol. 2022, 364, 128076. [Google Scholar] [CrossRef] [PubMed]

- Ning, H.; Li, R.; Zhou, T. Machine learning for microalgae detection and utilization. Front. Mar. Sci. 2022, 9, 947394. [Google Scholar] [CrossRef]

- Hai, A.; Bharath, G.; Patah, M.F.A.; Daud, W.M.A.W.; Rambabu, K.; Show, P.; Banat, F. Machine learning models for the prediction of total yield and specific surface area of biochar derived from agricultural biomass by pyrolysis. Environ. Technol. Innov. 2023, 30, 103071. [Google Scholar] [CrossRef]

- Adeleke, O.; Akinlabi, S.; Jen, T.C.; Adedeji, P.A.; Dunmade, I. Evolutionary-based neuro-fuzzy modelling of combustion enthalpy of municipal solid waste. Neural Comput. Appl. 2022, 34, 7419–7436. [Google Scholar] [CrossRef]

- Kaewpengkrow, P.R.; Atong, D.; Sricharoenchaikul, V. Bio-fuel production from catalytic fast pyrolysis of Jatropha wastes using pyroprobe GC/MS and drop tube pyrolyzer. J. Anal. Appl. Pyrolysis 2022, 165, 105574. [Google Scholar] [CrossRef]

- Al-Wesabi, F.N.; Malibari, A.A.; Hilal, A.M.; NEMRI, N.; Kumar, A.; Gupta, D. Intelligent ensemble of voting based solid fuel classification model for energy harvesting from agricultural residues. Sustain. Energy Technol. Assess. 2022, 52, 102040. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Niedzwiecki, L.; Sieradzka, M.; Mlonka-Mędrala, A.; Baranowski, M.; Serafin-Tkaczuk, M.; Magdziarz, A. Hydrothermal carbonization of agricultural and municipal solid waste digestates–Structure and energetic properties of the solid products. Fuel 2020, 275, 117837. [Google Scholar] [CrossRef]

- Zheng, J.; Wu, Z.; Sharma, R.; Lv, H. Adaptive decision model of product team organization pattern for extracting new energy from agricultural waste. Sustain. Energy Technol. Assess. 2022, 53, 102352. [Google Scholar] [CrossRef]

- Bot, B.V.; Axaopoulos, P.J.; Sakellariou, E.I.; Sosso, O.T.; Tamba, J.G. Energetic and economic analysis of biomass briquettes production from agricultural residues. Appl. Energy 2022, 321, 119430. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G.; Olsson, S.O. Traceability system for improved utilization of solid biofuel from agricultural prunings. Sustainability 2018, 10, 258. [Google Scholar] [CrossRef]

- Jifara, B.; Diriba, M.; Mengesha, A. Pelletization of mixed torrefied corn cob and khat stem to enhance the physicochemical and thermal properties of solid biofuel and parametric optimization. Biomass Convers. Biorefinery 2022, 1–15. [Google Scholar] [CrossRef]

- Samadi, S.H.; Ghobadian, B.; Nosrati, M. Prediction and estimation of biomass energy from agricultural residues using air gasification technology in Iran. Renew. Energy 2020, 149, 1077–1091. [Google Scholar] [CrossRef]

- Perez-Herrera, R.; de Souza, T.A.; Coronado, C.J.; do Nascimento, M.A.R.; Pinto, G.M. Numerical CFD Simulation of a Horizontal Cyclonic Combustion Chamber for Burning Pulverized Biomass Solid Fuels. Waste Biomass Valorization 2023, 14, 1979–2007. [Google Scholar] [CrossRef]

- Michal, H.; Jozef, J.; Miriam, N. Design of a wireless monitoring system with emission analysis integration for solid-fuel based heating devices in households of SmartCity. Wirel. Netw. 2022, 1–10. [Google Scholar] [CrossRef]

- Koval, S.; Vytisk, J.; Ruzickova, J.; Raclavska, H.; Skrobankova, H.; Hellebrandova, L. The Impact of Solid Fuel Residential Boilers Exchange on Particulate Matter Air Pollution. Appl. Sci. 2021, 11, 5400. [Google Scholar] [CrossRef]

- Akarsu, K.; Duman, G.; Yilmazer, A.; Keskin, T.; Azbar, N.; Yanik, J. Sustainable valorization of food wastes into solid fuel by hydrothermal carbonization. Bioresour. Technol. 2019, 292, 121959. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Chen, L.; Luo, Y.; Zhou, J. EEG-Based Emotion Recognition Using Convolutional Recurrent Neural Network with Multi-Head Self-Attention. Appl. Sci. 2022, 12, 11255. [Google Scholar] [CrossRef]

- Sailaja, C.; Maloji, S.; Mannepalli, K. A hybrid HXPLS-TMFCC parameterization and DCNN-SFO clustering based speaker diarization system. Concurr. Comput. Pract. Exp. 2022, 34, e6954. [Google Scholar] [CrossRef]

- Elmaz, F.; Büyükçakır, B.; Yücel, Ö.; Mutlu, A.Y. Hierarchical Classification Framework for Solid Fuel Classification. Available online: https://github.com/furkanelmaz/SolidFuelClassification (accessed on 12 June 2023).

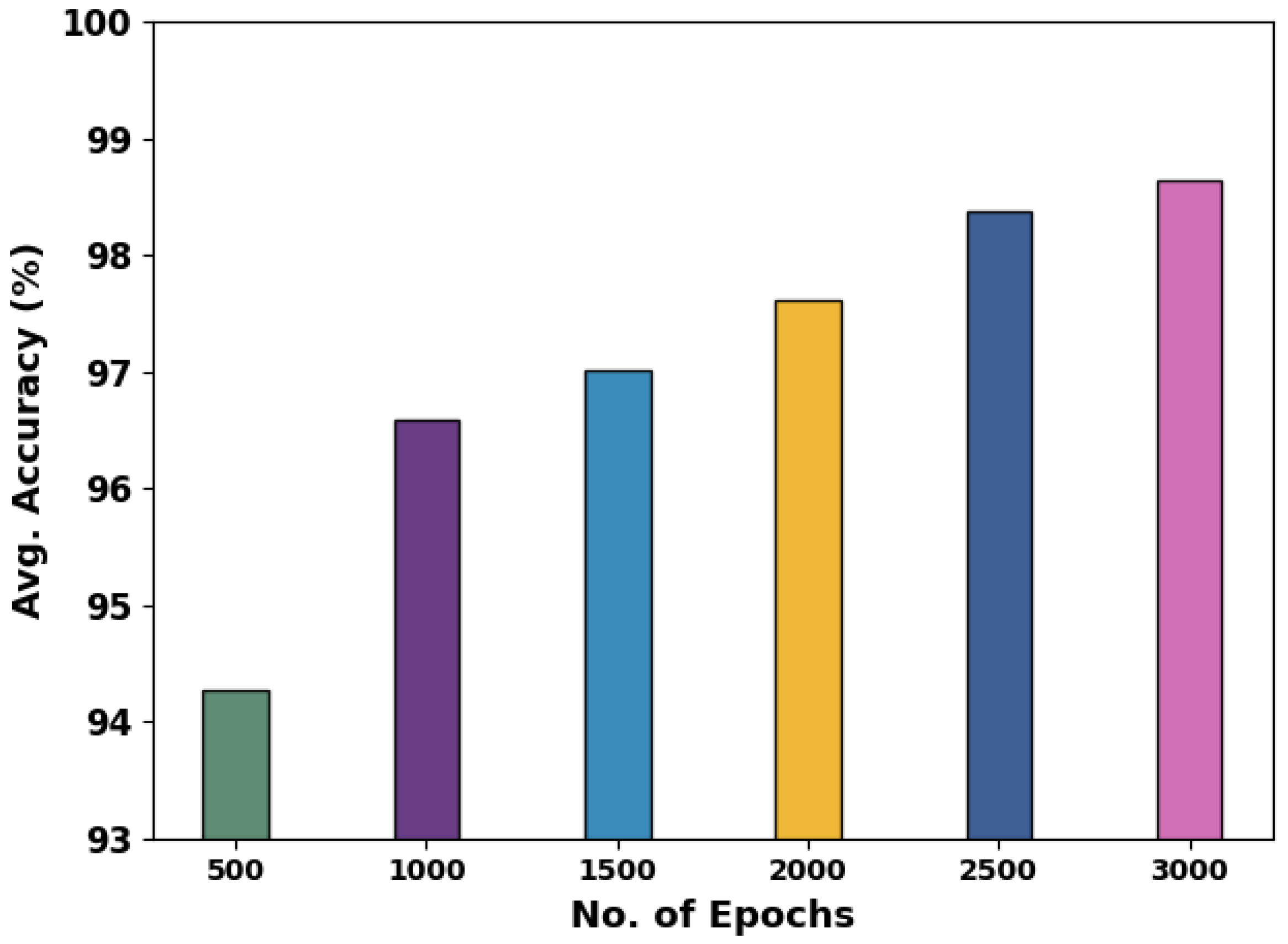

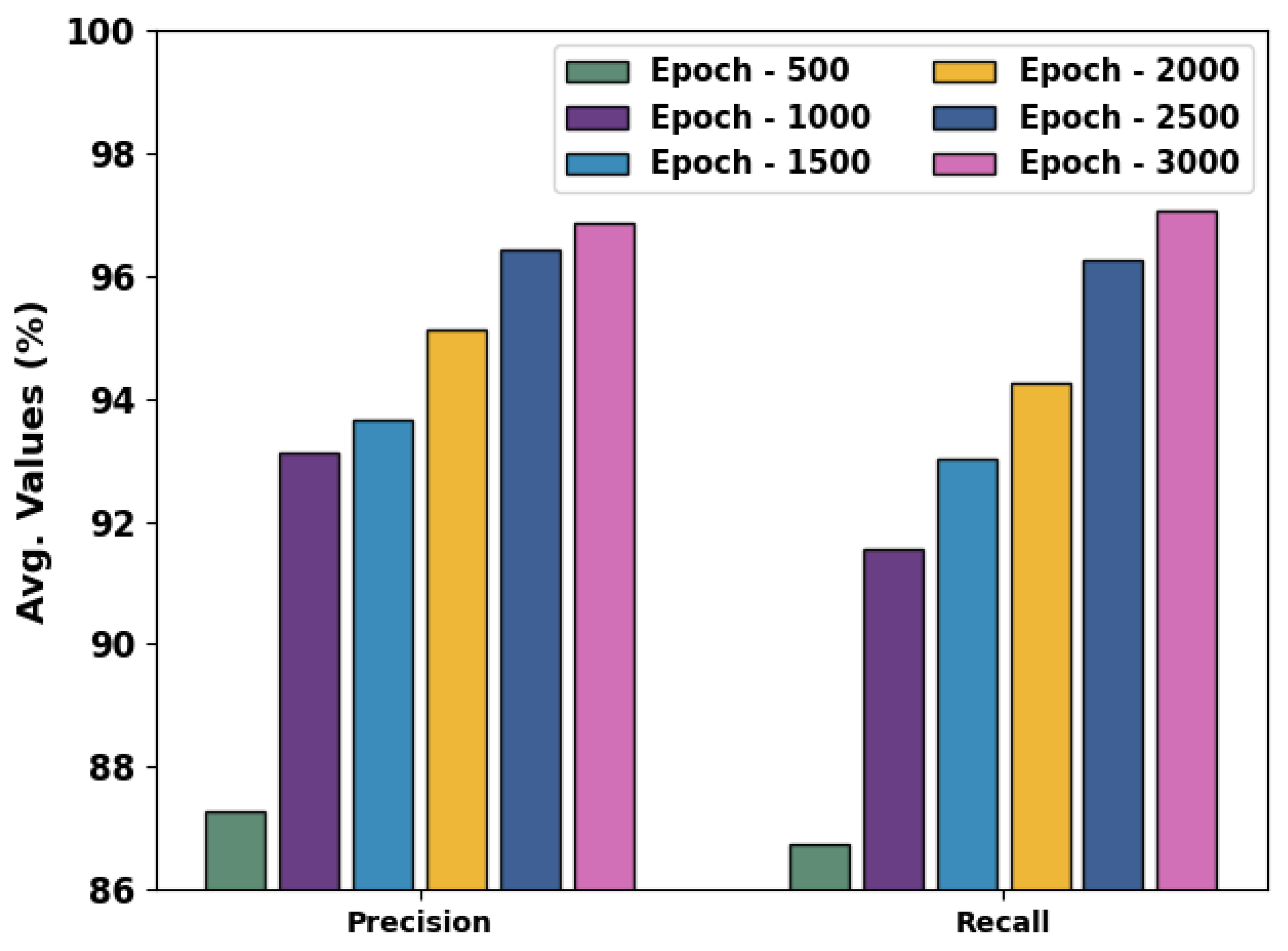

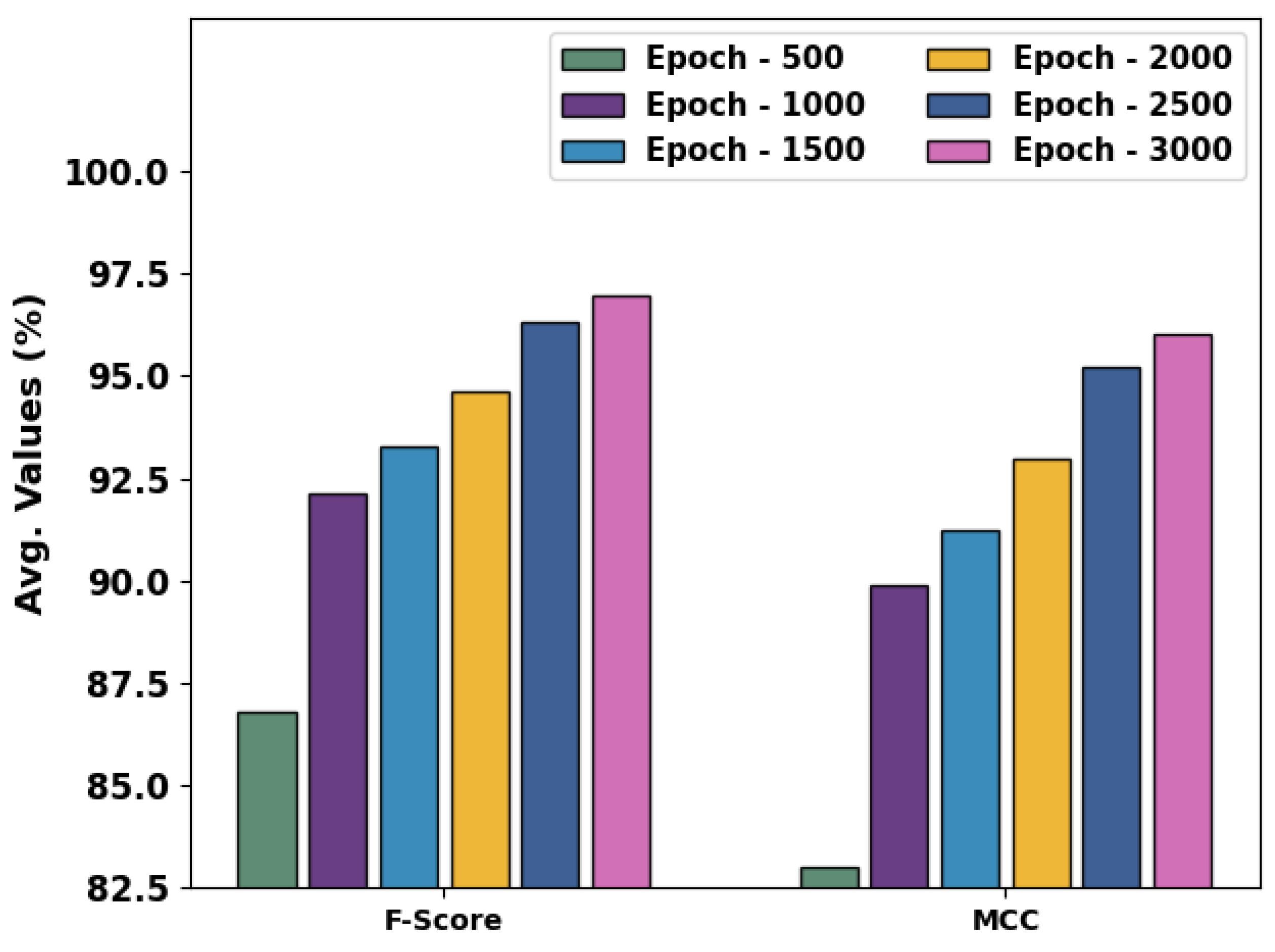

| No. of Epochs | Classes | MCC | ||||

|---|---|---|---|---|---|---|

| Epoch 500 | Coal | 92.82 | 82.50 | 70.21 | 75.86 | 72.00 |

| Wood | 95.04 | 96.25 | 92.03 | 94.09 | 89.89 | |

| AR | 91.45 | 80.95 | 91.62 | 85.96 | 80.16 | |

| MB | 97.78 | 89.47 | 93.15 | 91.28 | 90.03 | |

| Average | 94.27 | 87.29 | 86.75 | 86.80 | 83.02 | |

| Epoch 1000 | Coal | 95.73 | 93.67 | 78.72 | 85.55 | 83.50 |

| Wood | 97.09 | 96.80 | 96.41 | 96.61 | 94.07 | |

| AR | 94.70 | 87.36 | 95.21 | 91.12 | 87.52 | |

| MB | 98.80 | 94.59 | 95.89 | 95.24 | 94.56 | |

| Average | 96.58 | 93.11 | 91.56 | 92.13 | 89.91 | |

| Epoch 1500 | Coal | 96.41 | 92.94 | 84.04 | 88.27 | 86.31 |

| Wood | 97.26 | 96.81 | 96.81 | 96.81 | 94.42 | |

| AR | 95.38 | 90.23 | 94.01 | 92.08 | 88.86 | |

| MB | 98.97 | 94.67 | 97.26 | 95.95 | 95.37 | |

| Average | 97.01 | 93.66 | 93.03 | 93.28 | 91.24 | |

| Epoch 2000 | Coal | 97.09 | 95.29 | 86.17 | 90.50 | 88.95 |

| Wood | 97.61 | 97.21 | 97.21 | 97.21 | 95.12 | |

| AR | 96.58 | 92.00 | 96.41 | 94.15 | 91.79 | |

| MB | 99.15 | 95.95 | 97.26 | 96.60 | 96.11 | |

| Average | 97.61 | 95.11 | 94.26 | 94.62 | 92.99 | |

| Epoch 2500 | Coal | 98.29 | 96.67 | 92.55 | 94.57 | 93.58 |

| Wood | 98.29 | 98.39 | 97.61 | 98.00 | 96.51 | |

| AR | 97.78 | 94.77 | 97.60 | 96.17 | 94.62 | |

| MB | 99.15 | 95.95 | 97.26 | 96.60 | 96.11 | |

| Average | 98.38 | 96.44 | 96.26 | 96.33 | 95.21 | |

| Epoch 3000 | Coal | 98.80 | 96.77 | 95.74 | 96.26 | 95.55 |

| Wood | 98.46 | 98.79 | 97.61 | 98.20 | 96.86 | |

| AR | 98.12 | 95.88 | 97.60 | 96.74 | 95.42 | |

| MB | 99.15 | 95.95 | 97.26 | 96.60 | 96.11 | |

| Average | 98.63 | 96.85 | 97.05 | 96.95 | 95.99 |

| Methods | ||||

|---|---|---|---|---|

| SBFC-SFOHDL | 96.85 | 97.05 | 98.63 | 96.95 |

| SVM | 89.61 | 85.45 | 94.54 | 86.88 |

| KNN | 91.90 | 86.59 | 95.48 | 88.84 |

| Flat Classifier | 90.49 | 84.22 | 94.02 | 86.80 |

| Hierarchical Classifier | 91.33 | 90.37 | 95.24 | 90.97 |

| IEVB-SFC | 94.71 | 92.56 | 96.63 | 93.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ragab, M.; Khadidos, A.O.; Alshareef, A.M.; Alyoubi, K.H.; Hamed, D.; Khadidos, A.O. Internet of Things Assisted Solid Biofuel Classification Using Sailfish Optimizer Hybrid Deep Learning Model for Smart Cities. Sustainability 2023, 15, 12523. https://doi.org/10.3390/su151612523

Ragab M, Khadidos AO, Alshareef AM, Alyoubi KH, Hamed D, Khadidos AO. Internet of Things Assisted Solid Biofuel Classification Using Sailfish Optimizer Hybrid Deep Learning Model for Smart Cities. Sustainability. 2023; 15(16):12523. https://doi.org/10.3390/su151612523

Chicago/Turabian StyleRagab, Mahmoud, Adil O. Khadidos, Abdulrhman M. Alshareef, Khaled H. Alyoubi, Diaa Hamed, and Alaa O. Khadidos. 2023. "Internet of Things Assisted Solid Biofuel Classification Using Sailfish Optimizer Hybrid Deep Learning Model for Smart Cities" Sustainability 15, no. 16: 12523. https://doi.org/10.3390/su151612523

APA StyleRagab, M., Khadidos, A. O., Alshareef, A. M., Alyoubi, K. H., Hamed, D., & Khadidos, A. O. (2023). Internet of Things Assisted Solid Biofuel Classification Using Sailfish Optimizer Hybrid Deep Learning Model for Smart Cities. Sustainability, 15(16), 12523. https://doi.org/10.3390/su151612523