Performance Evaluation of Open-Graded Bituminous Concrete Modified with Natural Fibers

Abstract

:1. Introduction

Motivation and Objectives

2. Methodology and Experimental Programme

2.1. Design of OGBC Mixtures

2.1.1. Aggregates

2.1.2. Binder

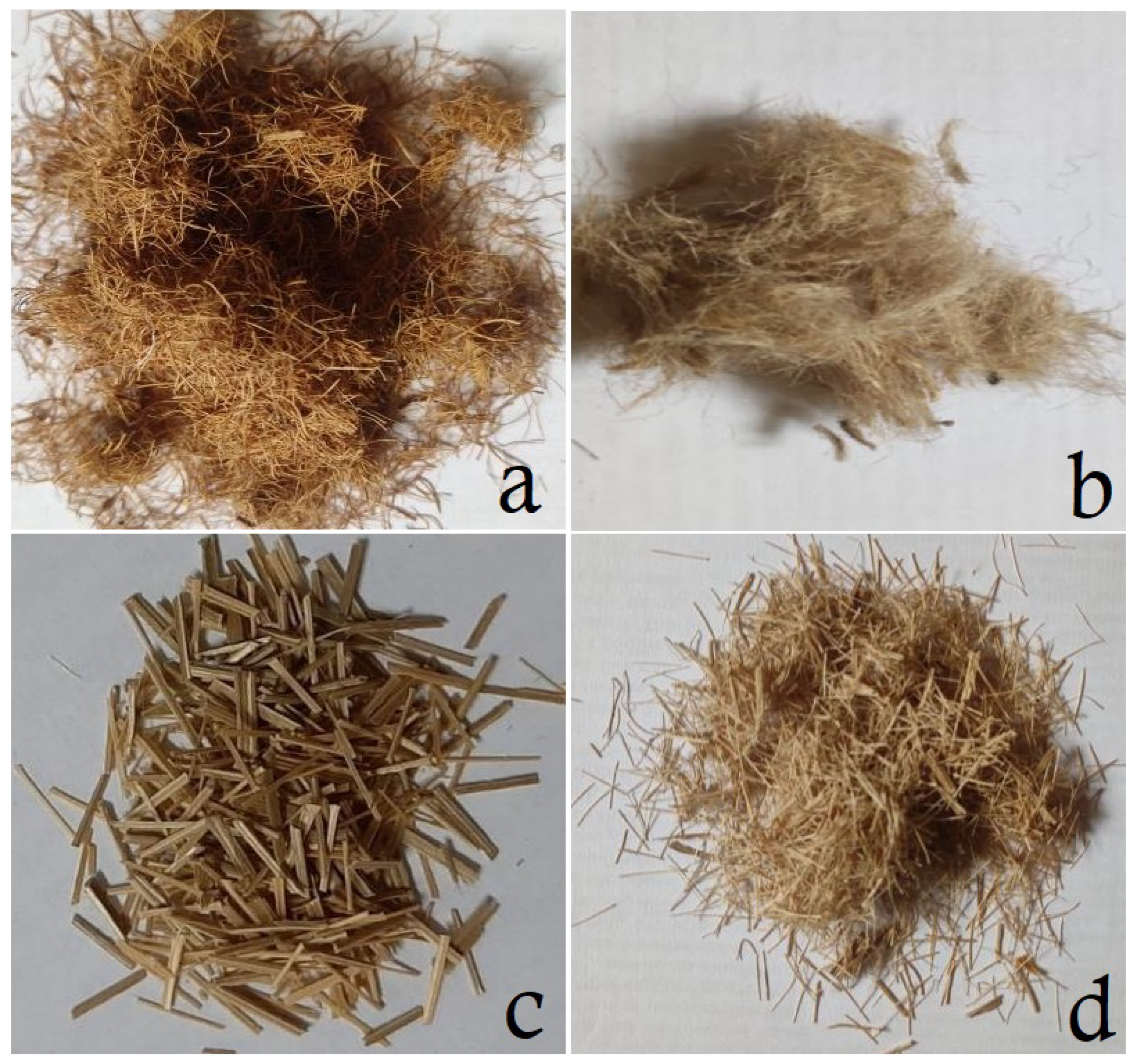

2.1.3. Fibers

2.1.4. Experimental Programme

3. Results and Discussion

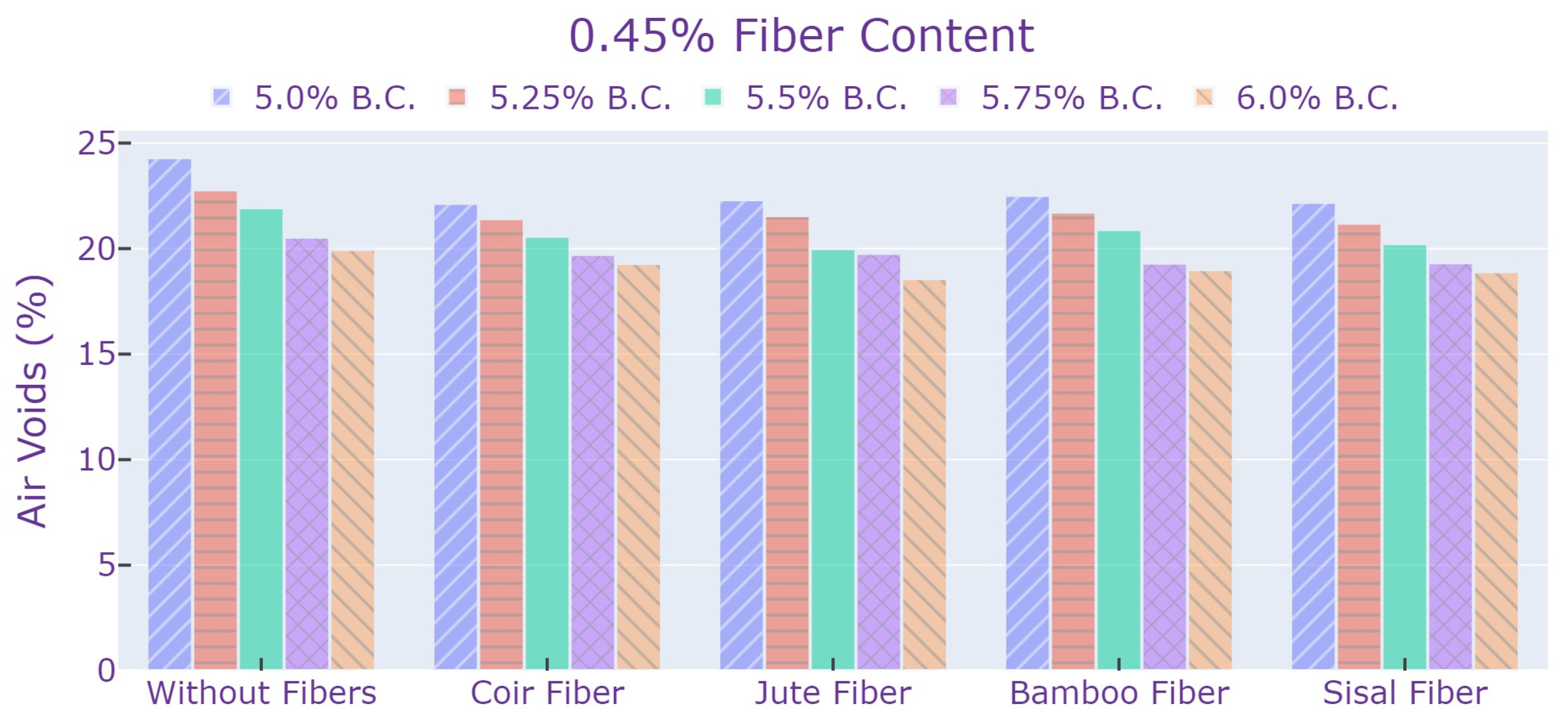

3.1. Air-Voids

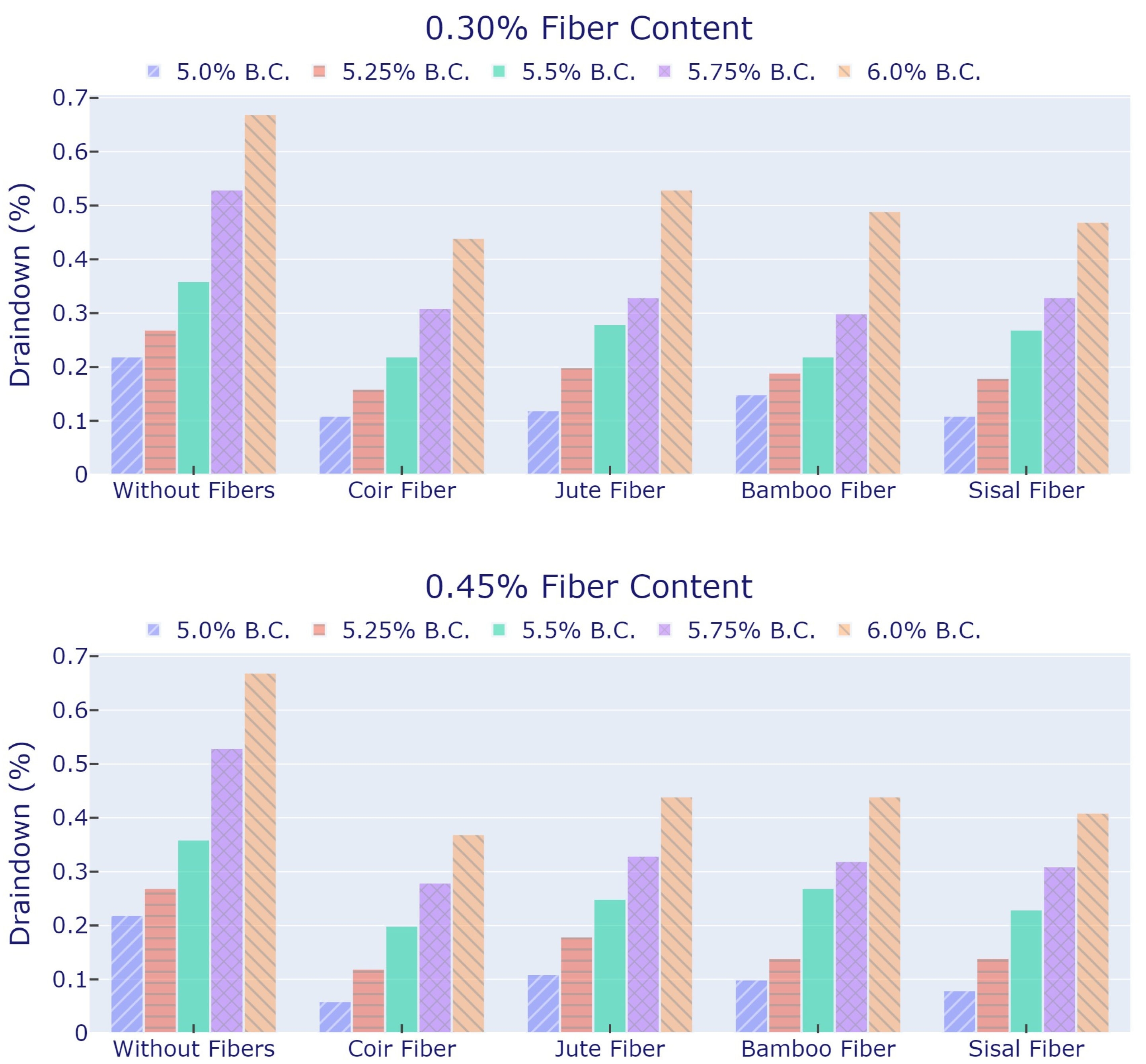

3.2. Draindown

3.3. Cantabro Loss

3.4. Determination of Optimum Binder Content (OBC)

3.5. Indirect Tensile Strength (ITS) and Tensile Strength Ratio (TSR)

4. Conclusions

- The addition of fibers slightly reduced the air void content when compared with the reference OGBC mix, but it satisfied the minimum air void content stipulated by IRC guidelines.

- The OGBC mixtures without any fibers exhibited higher draindown of binder in the range of 0.22–0.67%, whereas the mixtures with fibers showed reduced binder draindown property.

- The ideal fiber content was determined to be 0.30% for sisal, bamboo and coir fibers and 0.45% for jute fibers. At 0.3% dosage rate, sisal fibers impart the most desired qualities to the OGBC mix and are thus recommended as the most ideal fiber for OGBC mixes.

- Based on ITS criteria, the coir fibers provide OGBC with the highest level of strength qualities; however, the TSR of the OGBC made of sisal fibers showed increased resistance to moisture susceptibility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dhir, P.M. INDIA: An Asphalt Roads Country. In The Asphalt Yearbook 2000; Institute of Asphalt Technology: Surrey, UK, 2000; pp. 51–53. [Google Scholar]

- Singh, R.; Mondal, P.; Sharma, N.; Kumar, A.; Bhangale, U.D.; Tyagi, D. Effect of Rainfall and Wet Road Condition on Road Crashes: A Critical Analysis. In Proceedings of the SIAT 2011, Pune, India, 19–22 January 2011; The Automotive Research Association of India: Maharashtra, India, 2011; pp. 1–7. [Google Scholar] [CrossRef]

- Omar, H.A.; Yusoff, N.I.M.; Mubaraki, M.; Ceylan, H. Effects of moisture damage on asphalt mixtures. J. Traffic Transp. Eng. 2020, 7, 600–628. [Google Scholar] [CrossRef]

- Wu, H.; Yu, J.; Song, W.; Zou, J.; Song, Q.; Zhou, L. A critical state-of-the-art review of durability and functionality of open-graded friction course mixtures. Constr. Build. Mater. 2020, 237, 117759. [Google Scholar] [CrossRef]

- Gu, F.; Watson, D.; Moore, J.; Tran, N. Evaluation of the benefits of open graded friction course: Case study. Constr. Build. Mater. 2018, 189, 131–143. [Google Scholar] [CrossRef]

- IRC:129-2019; Specifications for Open-Graded Friction Course. Indian Standard, Indian Road Congress: New Delhi, India, 2019.

- Airey, G.D. State of the Art Report on Ageing Test Methods for Bituminous Pavement Materials. Int. J. Pavement Eng. 2003, 4, 165–176. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Ayatollahi, M. Fracture resistance of asphalt concrete under different loading modes and temperature conditions. Constr. Build. Mater. 2014, 53, 235–242. [Google Scholar] [CrossRef]

- Huber, G.A. Performance Survey on Open-Graded Friction Course Mixes, NCHRP Synthesis Report; Transportation Research Board: Washington, DC, USA, 2000; Volume 284, p. 44. [Google Scholar]

- NCHRP-Committee. Asphalt Additives and Modifiers. In Relationship Between Chemical Makeup of Binders and Engineering Performance; Daly, W.H., Ed.; The National Academies Press: Washington, DC, USA, 2017; Chapter 4; pp. 41–52. [Google Scholar] [CrossRef]

- Gan, X.; Zhang, W. Application of biochar from crop straw in asphalt modification. PLoS ONE 2021, 16, e0247390. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Rheological and adhesive properties of nanocomposite bitumen binders based on hydrophilic or hydrophobic silica and modified with bio-oil. Constr. Build. Mater. 2022, 342, 127946. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Ilyin, S.O. Bitumen improvement with bio-oil and natural or organomodified montmorillonite: Structure, rheology, and adhesion of composite asphalt binders. Constr. Build. Mater. 2023, 364, 129919. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete—A review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- Cooley, J.L.A.; Brown, E.R.; Watson, D.E. Evaluation of Open-Graded Friction Course Mixtures Containing Cellulose Fibers. Transp. Res. Rec. 2000, 1723, 19–25. [Google Scholar] [CrossRef]

- Hassan, H.F.; Al-Oraimi, S.; Taha, R. Evaluation of Open-Graded Friction Course Mixtures Containing Cellulose Fibers and Styrene Butadiene Rubber Polymer. J. Mater. Civ. Eng. 2005, 17, 416–422. [Google Scholar] [CrossRef]

- Hassan, H.F.; Al-Jabri, K.S. Effect of organic fibers on open-graded friction course mixture properties. Int. J. Pavement Eng. 2005, 6, 67–75. [Google Scholar] [CrossRef]

- Punith, V.S.; Veeraragavan, A. Characterization of OGFC Mixtures Containing Reclaimed Polyethylene Fibers. J. Mater. Civ. Eng. 2011, 23, 335–341. [Google Scholar] [CrossRef]

- Tanzadeh, J.; Shahrezagamasaei, R. Laboratory Assessment of Hybrid Fiber and Nano-silica on Reinforced Porous Asphalt Mixtures. Constr. Build. Mater. 2017, 144, 260–270. [Google Scholar] [CrossRef]

- Gupta, A.; Castro-Fresno, D.; Lastra-Gonzalez, P.; Rodriguez-Hernandez, J. Selection of fibers to improve porous asphalt mixtures using multi-criteria analysis. Constr. Build. Mater. 2021, 266, 121198. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, Y.; Nassiri, S.; Li, H.; Englund, K. Performance evaluation of porous asphalt mixture enhanced with high dosages of cured carbon fiber composite materials. Constr. Build. Mater. 2021, 274, 122066. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D. Laboratory assessment of porous asphalt mixtures reinforced with synthetic fibers. Constr. Build. Mater. 2020, 234, 117224. [Google Scholar] [CrossRef]

- Lyons, K.R.; Putman, B.J. Laboratory evaluation of stabilizing methods for porous asphalt mixtures. Constr. Build. Mater. 2013, 49, 772–780. [Google Scholar] [CrossRef]

- Wu, S.P.; Liu, G.; Mo, L.T.; Chen, Z.; Ye, Q.S. Effect of fiber types on relevant properties of porous asphalt. Trans. Nonferrous Met. Soc. China 2006, 16, s791–s795. [Google Scholar] [CrossRef]

- Ma, X.; Li, Q.; Cui, Y.C.; Ni, A.Q. Performance of porous asphalt mixture with various additives. Int. J. Pavement Eng. 2018, 19, 355–361. [Google Scholar] [CrossRef]

- Tanzadeh, R.; Tanzadeh, J.; honarmand, M.; Tahami, S.A. Experimental study on the effect of basalt and glass fibers on behavior of open-graded friction course asphalt modified with nano-silica. Constr. Build. Mater. 2019, 212, 467–475. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Silva-Rojas, I.M.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Multiple-response optimization of open graded friction course reinforced with fibers through CRITIC-WASPAS based on Taguchi methodology. Constr. Build. Mater. 2020, 233, 117274. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Zhang, Y.; Lv, Q.; Yan, C. Evaluating four typical fibers used for OGFC mixture modification regarding drainage, raveling, rutting and fatigue resistance. Constr. Build. Mater. 2020, 253, 119131. [Google Scholar] [CrossRef]

- Wu, M.; Zhao, J.; Cai, H.; Liang, J.; Qian, S.; Chen, H.; He, Q.; Zhang, Y. Effect of Fibers on the Performance of a Porous Friction Course. ACS Omega 2022, 7, 28324–28333. [Google Scholar] [CrossRef]

- Petroudy, S.R.D. Physical and mechanical properties of natural fibers. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Sawston, UK, 2017; Chapter 3; pp. 59–83. [Google Scholar] [CrossRef]

- IS:73-2013; Paving Bitumen–Specifications. Fourth Revision; Bureau of Indian Standards: New Delhi, India, 2013.

- IS:12269-2013; Ordinary Portland Cement, 53 Grade–Specifications. First Revision, Bureau of Indian Standards: New Delhi, India, 2013.

- Chokshi, S.; Parmar, V.; Gohil, P.; Chaudhary, V. Chemical Composition and Mechanical Properties of Natural Fibers. J. Nat. Fibers 2022, 19, 3942–3953. [Google Scholar] [CrossRef]

| Property | Coir | Jute | Bamboo | Sisal |

|---|---|---|---|---|

| Diameter (microns) | 100–400 | 14–180 | 10–30 | 120–140 |

| Density (g/cc) | 1.1–1.3 | 1.4–1.6 | 0.54–0.80 | 1.2–1.5 |

| Tenacity (g/tex) | 09–12 | 22–34 | 20–60 | 45–58 |

| Breaking Elongation (%) | 30 | 1–3 | 20–25 | 3–6 |

| Tensile strength (MPa) | 100–500 | 120–600 | 600–850 | 400–700 |

| Young’s Modulus (GPa) | 2–8 | 15–25 | 35–45 | 20–40 |

| OGBC Mix | Fiber Content | VCADRC (%) | VCAMIX (%) | ||||

|---|---|---|---|---|---|---|---|

| Binder Content | |||||||

| 5.0% | 5.25% | 5.50% | 5.75% | 6.0% | |||

| Without Fibers | 55.9 | 53.50 | 52.83 | 52.58 | 52.01 | 51.91 | |

| Coir Fiber | 0.15% | 55.9 | 52.89 | 52.83 | 52.57 | 52.01 | 51.78 |

| 0.30% | 55.9 | 52.36 | 52.34 | 51.78 | 51.80 | 51.46 | |

| 0.45% | 55.9 | 52.17 | 51.99 | 51.76 | 51.51 | 51.52 | |

| Jute Fiber | 0.15% | 55.9 | 52.80 | 52.51 | 52.42 | 51.81 | 51.81 |

| 0.30% | 55.9 | 52.45 | 52.33 | 51.84 | 51.64 | 51.68 | |

| 0.45% | 55.9 | 52.27 | 52.08 | 51.41 | 51.54 | 51.09 | |

| Bamboo Fiber | 0.15% | 55.9 | 53.31 | 52.76 | 52.22 | 52.23 | 51.39 |

| 0.30% | 55.9 | 52.94 | 52.56 | 52.12 | 51.75 | 51.78 | |

| 0.45% | 55.9 | 52.40 | 52.19 | 51.95 | 51.26 | 51.34 | |

| Sisal Fiber | 0.15% | 55.9 | 52.85 | 52.79 | 51.95 | 52.01 | 51.40 |

| 0.30% | 55.9 | 52.31 | 52.31 | 51.77 | 51.66 | 51.73 | |

| 0.45% | 55.9 | 52.20 | 51.87 | 51.55 | 51.27 | 51.29 | |

| OGBC Mix | Fiber Content | VMA % | ||||

|---|---|---|---|---|---|---|

| Binder Content | ||||||

| 5.0% | 5.25% | 5.5% | 5.75% | 6.0% | ||

| Without Fibers | 33.37 | 32.42 | 32.06 | 31.23 | 31.10 | |

| Coir Fiber | 0.15% | 32.50 | 32.41 | 32.04 | 31.24 | 30.91 |

| 0.30% | 31.75 | 31.72 | 30.91 | 30.94 | 30.45 | |

| 0.45% | 31.47 | 31.22 | 30.88 | 30.53 | 30.54 | |

| Jute Fiber | 0.15% | 32.37 | 31.96 | 31.82 | 30.95 | 30.96 |

| 0.30% | 31.87 | 31.70 | 30.99 | 30.71 | 30.77 | |

| 0.45% | 31.62 | 31.34 | 30.37 | 30.57 | 29.92 | |

| Bamboo Fiber | 0.15% | 33.11 | 32.31 | 31.53 | 31.56 | 30.36 |

| 0.30% | 32.57 | 32.02 | 31.39 | 30.09 | 30.90 | |

| 0.45% | 31.80 | 31.49 | 31.15 | 30.17 | 30.28 | |

| Sisal Fiber | 0.15% | 32.44 | 32.36 | 31.15 | 31.23 | 30.37 |

| 0.30% | 31.60 | 31.66 | 30.90 | 30.74 | 30.84 | |

| 0.45% | 31.51 | 31.04 | 30.58 | 30.18 | 30.20 | |

| Fiber | Fiber | Binder Content | Air Voids | Draindown | Abrasion Loss (%) | OBC (%) | |

|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | Unaged | Aged | ||

| Sisal | 0.15 | 5 | 23.25 | 0.16 | 29.60 | 38.8 | 5.5 |

| 5.25 | 22.72 | 0.24 | 25.00 | 28.6 | |||

| 5.5 | 20.90 | 0.30 | 18.10 | 24.9 | |||

| 5.75 | 20.55 | 0.40 | 17.50 | 22.6 | |||

| 6 | 19.09 | 0.51 | 15.40 | 20.3 | |||

| 0.3 | 5 | 22.38 | 0.11 | 28.9 | 36.8 | 5.6 | |

| 5.25 | 21.93 | 0.18 | 26 | 27.2 | |||

| 5.5 | 20.60 | 0.27 | 17 | 23.6 | |||

| 5.75 | 19.98 | 0.33 | 11.3 | 21.8 | |||

| 6 | 19.65 | 0.47 | 7.7 | 18.3 | |||

| 0.45 | 5 | 22.19 | 0.08 | 30.5 | 39.2 | 5.7 | |

| 5.25 | 21.21 | 0.14 | 26.3 | 30.6 | |||

| 5.5 | 20.24 | 0.23 | 20.3 | 26.4 | |||

| 5.75 | 19.33 | 0.31 | 12.5 | 23.8 | |||

| 6 | 18.91 | 0.41 | 9.5 | 21.1 | |||

| Jute | 0.15 | 5 | 23.17 | 0.18 | 25.07 | 36.15 | 5.45 |

| 5.25 | 22.26 | 0.26 | 20.85 | 31.97 | |||

| 5.5 | 21.67 | 0.32 | 11.97 | 30.76 | |||

| 5.75 | 20.21 | 0.44 | 10.32 | 23.03 | |||

| 6 | 19.78 | 0.55 | 7.58 | 22.07 | |||

| 0.3 | 5 | 22.6 | 0.12 | 27.91 | 39.17 | 5.6 | |

| 5.25 | 21.97 | 0.2 | 22.23 | 36.23 | |||

| 5.5 | 20.71 | 0.28 | 20.12 | 32.24 | |||

| 5.75 | 19.94 | 0.33 | 11.51 | 29.24 | |||

| 6 | 19.57 | 0.53 | 9.11 | 23.47 | |||

| 0.45 | 5 | 22.32 | 0.11 | 29.17 | 41.65 | 5.65 | |

| 5.25 | 21.56 | 0.18 | 26.06 | 33.9 | |||

| 5.5 | 20 | 0.25 | 20.8 | 30.02 | |||

| 5.75 | 19.78 | 0.33 | 16.14 | 23.02 | |||

| 6 | 18.58 | 0.44 | 10.69 | 20.36 | |||

| Bamboo | 0.15 | 5 | 24.01 | 0.19 | 25.1 | 34.45 | 5.35 |

| 5.25 | 22.67 | 0.28 | 21.95 | 31.83 | |||

| 5.5 | 21.34 | 0.35 | 19.58 | 29.03 | |||

| 5.75 | 20.92 | 0.48 | 9.64 | 24.43 | |||

| 6 | 19.08 | 0.56 | 7.7 | 22.28 | |||

| 0.3 | 5 | 23.4 | 0.15 | 26.61 | 37.2 | 5.60 | |

| 5.25 | 22.34 | 0.19 | 23.26 | 32.15 | |||

| 5.5 | 21.18 | 0.22 | 20.97 | 29.55 | |||

| 5.75 | 20.12 | 0.3 | 11.32 | 25.17 | |||

| 6 | 19.72 | 0.49 | 8.21 | 22.96 | |||

| 0.45 | 5 | 22.52 | 0.1 | 29.02 | 36.47 | 5.65 | |

| 5.25 | 21.73 | 0.17 | 26.22 | 31.51 | |||

| 5.5 | 20.9 | 0.27 | 22.69 | 26.65 | |||

| 5.75 | 19.31 | 0.32 | 20.39 | 22.3 | |||

| 6 | 19 | 0.44 | 9.51 | 20.34 | |||

| Coir | 0.15 | 5 | 23.32 | 0.14 | 24.86 | 35.55 | 5.55 |

| 5.25 | 22.78 | 0.23 | 21 | 33.39 | |||

| 5.5 | 21.91 | 0.29 | 19.26 | 29.77 | |||

| 5.75 | 20.56 | 0.33 | 15.55 | 23.71 | |||

| 6 | 19.73 | 0.49 | 13.54 | 21.73 | |||

| 0.3 | 5 | 22.46 | 0.11 | 23.04 | 33.06 | 5.7 | |

| 5.25 | 21.99 | 0.16 | 20.32 | 30.04 | |||

| 5.5 | 20.62 | 0.22 | 16.4 | 28.12 | |||

| 5.75 | 20.2 | 0.31 | 11.61 | 22.14 | |||

| 6 | 19.19 | 0.44 | 8.51 | 20.8 | |||

| 0.45 | 5 | 22.15 | 0.06 | 28.28 | 34.37 | 5.75 | |

| 5.25 | 21.42 | 0.12 | 25.12 | 31.89 | |||

| 5.5 | 20.58 | 0.2 | 20.32 | 29.01 | |||

| 5.75 | 19.73 | 0.28 | 16.21 | 25.57 | |||

| 6 | 19.3 | 0.37 | 9.73 | 21.46 | |||

| Fiber | Fiber (%) | Optimum Binder Content (%) | Air Voids (%) | Draindown (%) | Abrasion Loss (%) | |

|---|---|---|---|---|---|---|

| Unaged | Aged | |||||

| Sisal | 0.15 | 5.50 | 20.90 | 0.30 | 18.10 | 24.90 |

| 0.30 | 5.60 | 20.35 | 0.29 | 14.72 | 22.88 | |

| 0.45 | 5.70 | 19.51 | 0.29 | 14.05 | 24.32 | |

| Jute | 0.15 | 5.45 | 21.79 | 0.30 | 13.75 | 31.00 |

| 0.30 | 5.60 | 20.40 | 0.30 | 16.68 | 31.00 | |

| 0.45 | 5.65 | 19.86 | 0.30 | 18.00 | 25.82 | |

| Bamboo | 0.15 | 5.35 | 22.13 | 0.30 | 21.00 | 30.70 |

| 0.30 | 5.60 | 20.76 | 0.25 | 17.11 | 27.80 | |

| 0.45 | 5.65 | 19.95 | 0.30 | 21.31 | 24.04 | |

| Coir | 0.15 | 5.55 | 21.64 | 0.30 | 18.52 | 28.56 |

| 0.30 | 5.70 | 20.28 | 0.29 | 12.57 | 23.34 | |

| 0.45 | 5.75 | 19.73 | 0.28 | 16.21 | 25.57 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balreddy, M.S.; Nethra, P.; Naganna, S.R. Performance Evaluation of Open-Graded Bituminous Concrete Modified with Natural Fibers. Sustainability 2023, 15, 11952. https://doi.org/10.3390/su151511952

Balreddy MS, Nethra P, Naganna SR. Performance Evaluation of Open-Graded Bituminous Concrete Modified with Natural Fibers. Sustainability. 2023; 15(15):11952. https://doi.org/10.3390/su151511952

Chicago/Turabian StyleBalreddy, Muttana S., Pamisetty Nethra, and Sujay Raghavendra Naganna. 2023. "Performance Evaluation of Open-Graded Bituminous Concrete Modified with Natural Fibers" Sustainability 15, no. 15: 11952. https://doi.org/10.3390/su151511952

APA StyleBalreddy, M. S., Nethra, P., & Naganna, S. R. (2023). Performance Evaluation of Open-Graded Bituminous Concrete Modified with Natural Fibers. Sustainability, 15(15), 11952. https://doi.org/10.3390/su151511952