Sustainable Off-Site Construction in Desert Environments: Zero-Energy Houses as Case Studies

Abstract

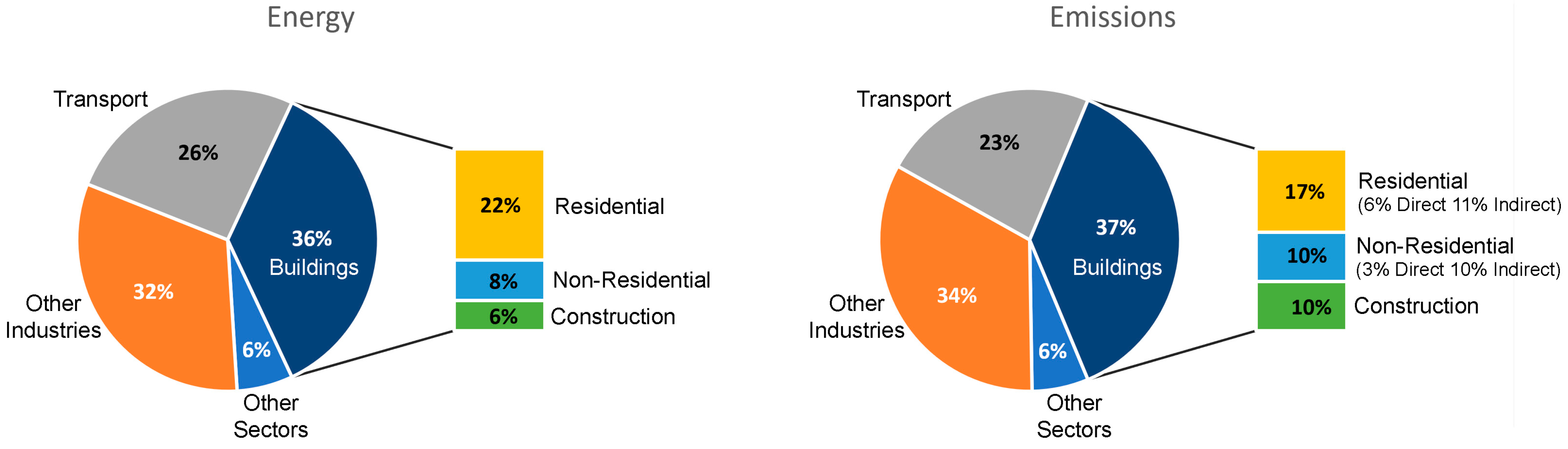

1. Introduction

2. Off-Site Construction

2.1. Off-Site Construction Classification

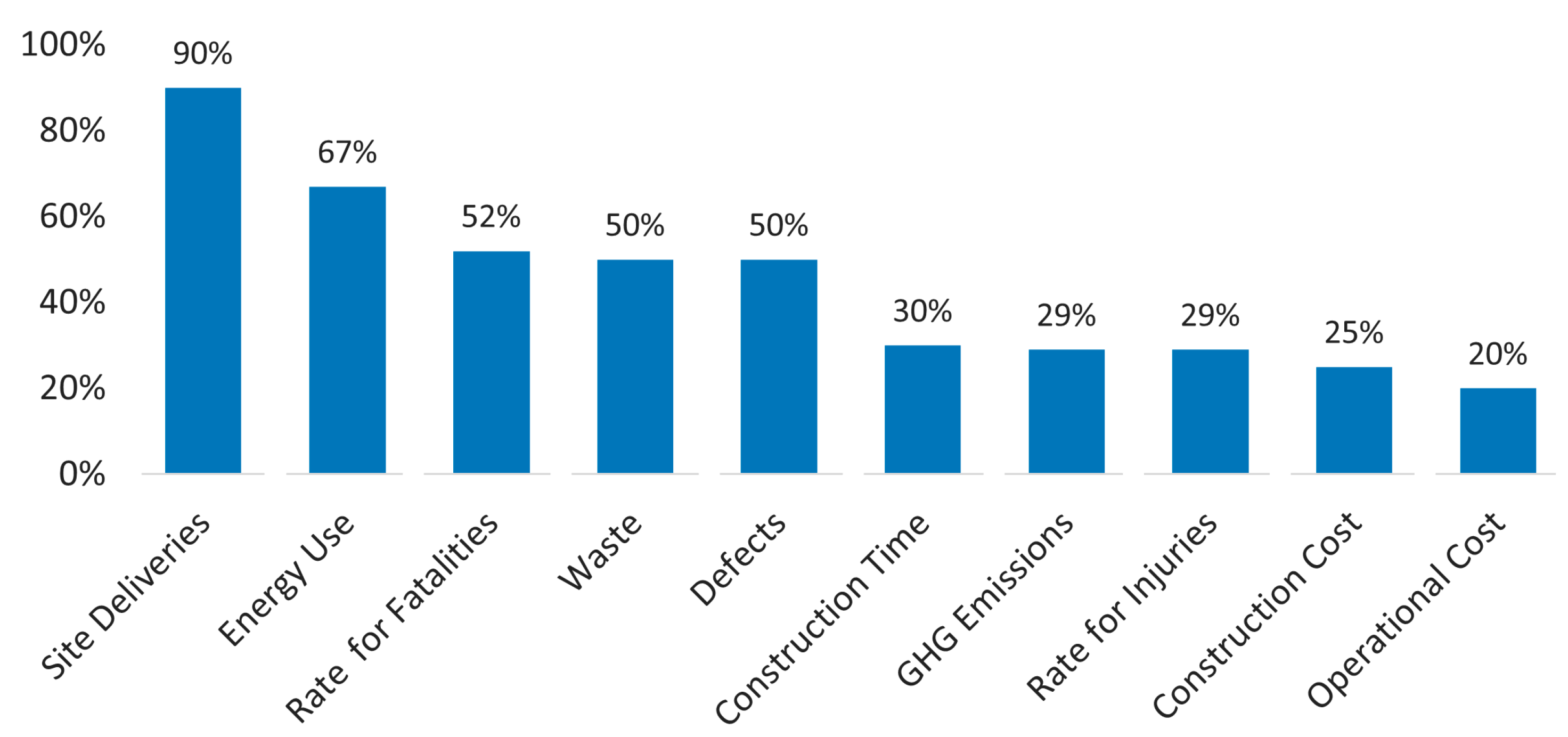

2.2. Benefits of Off-Site Construction Methods Related to Their Classification

2.3. Comparisons between Conventional and Off-Site Construction

3. Methods

- Selection of case studies. The case studies were chosen based on two criteria: First, the case had to be a zero-energy house that took part in the 2018 Solar Decathlon Middle East, and second, the project had to be pre-constructed and assembled utilizing off-site systems.

- Data collection. The authors studied the cases using the construction data from the participating teams, such as construction drawings and project manuals, in addition to photos, videos, and in-person observations during the houses’ assembly process.

- Classification of the cases. The authors developed a classification based on a literature review and organized the cases around it.

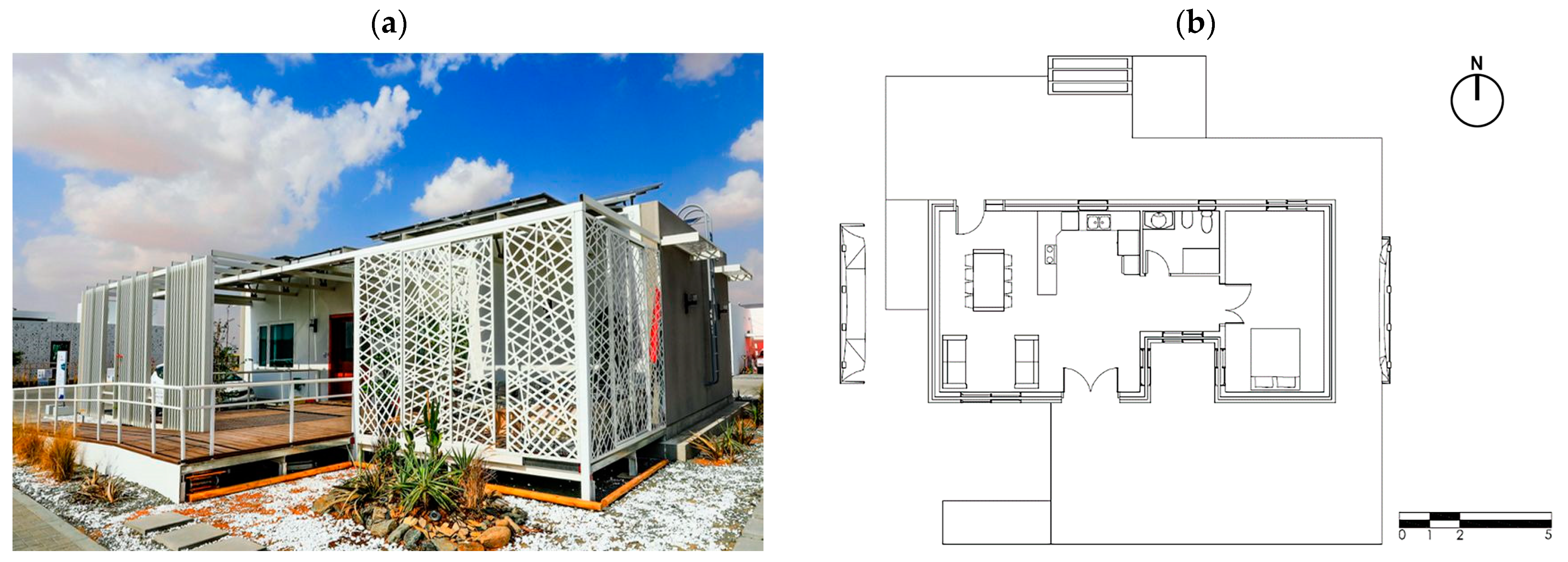

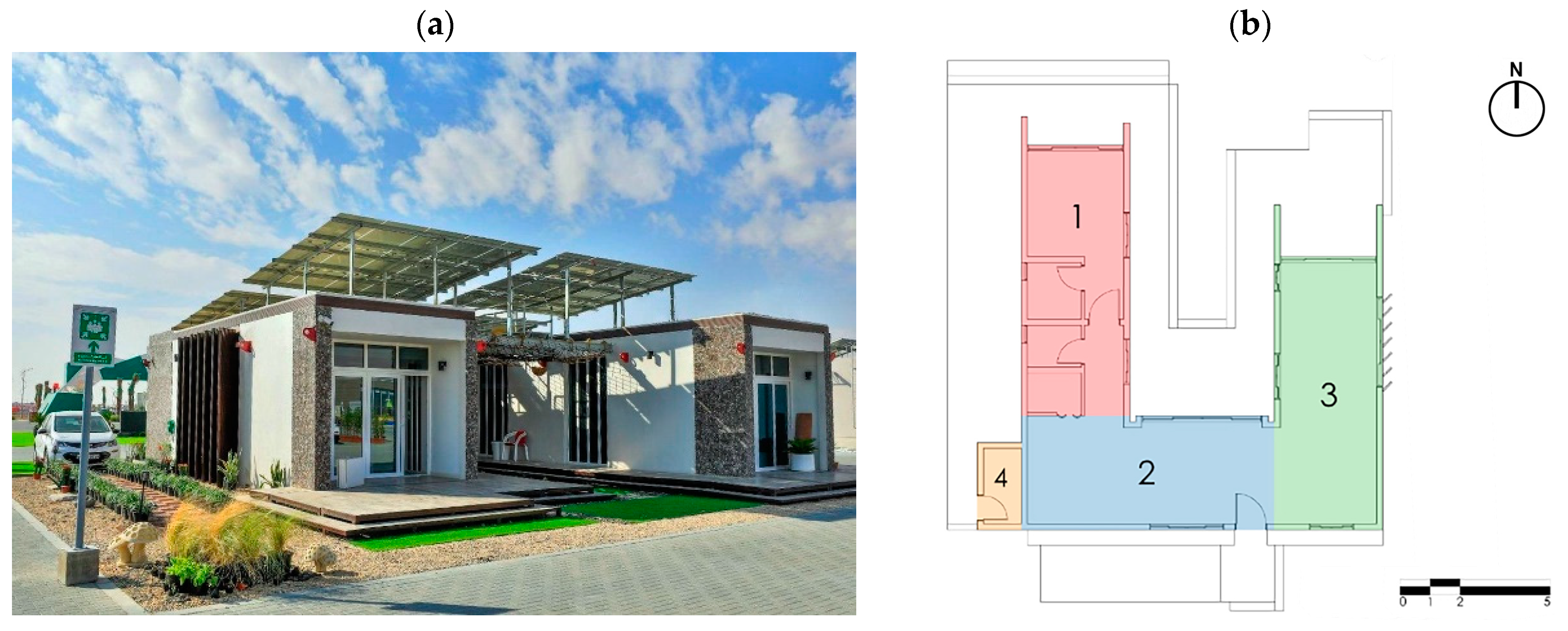

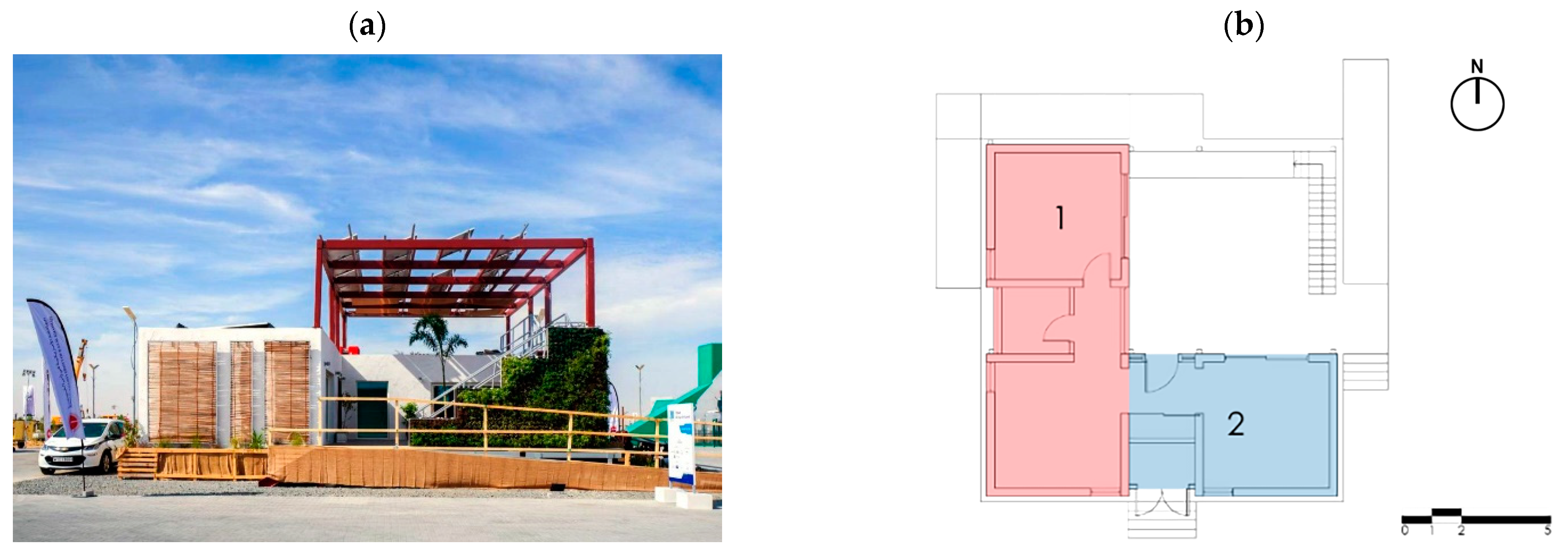

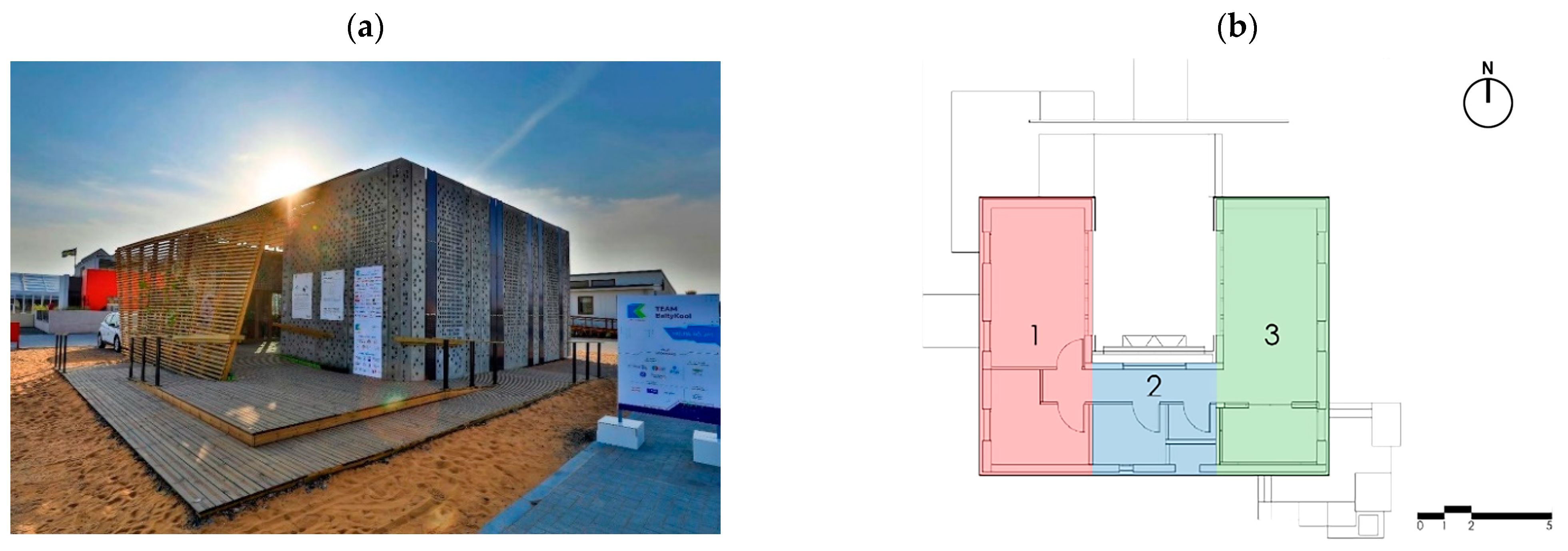

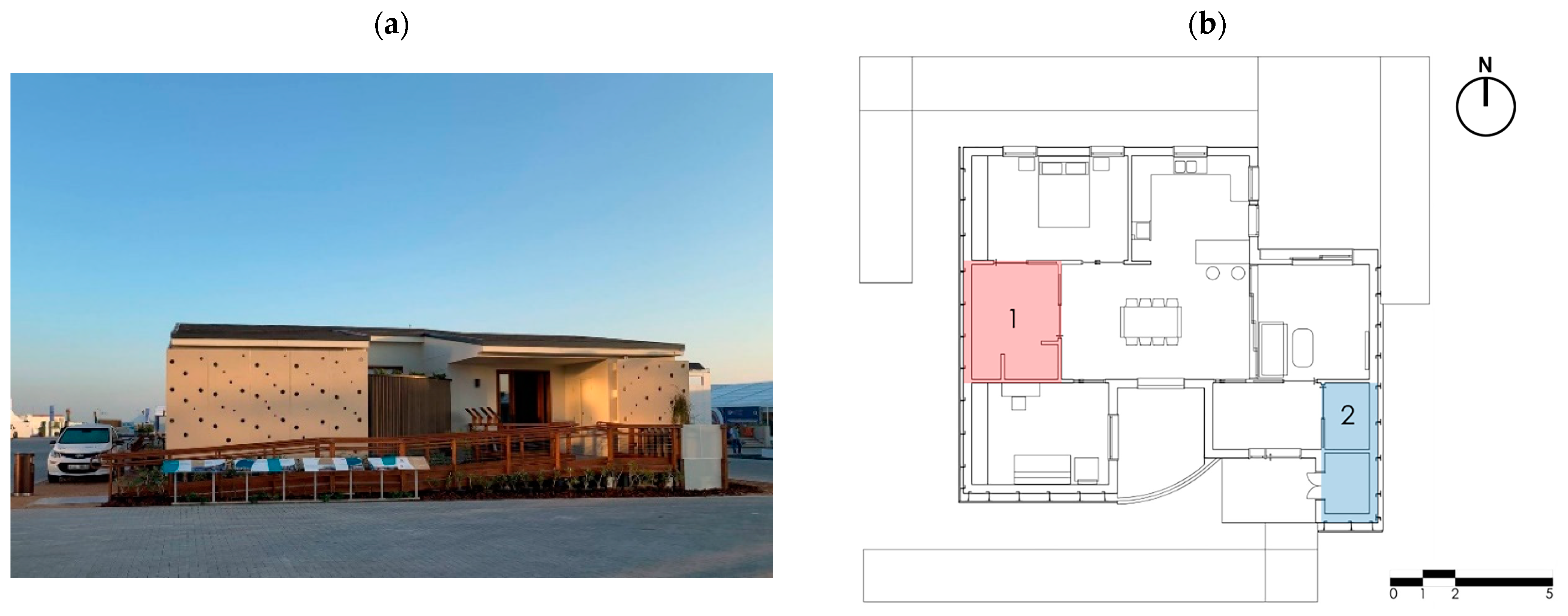

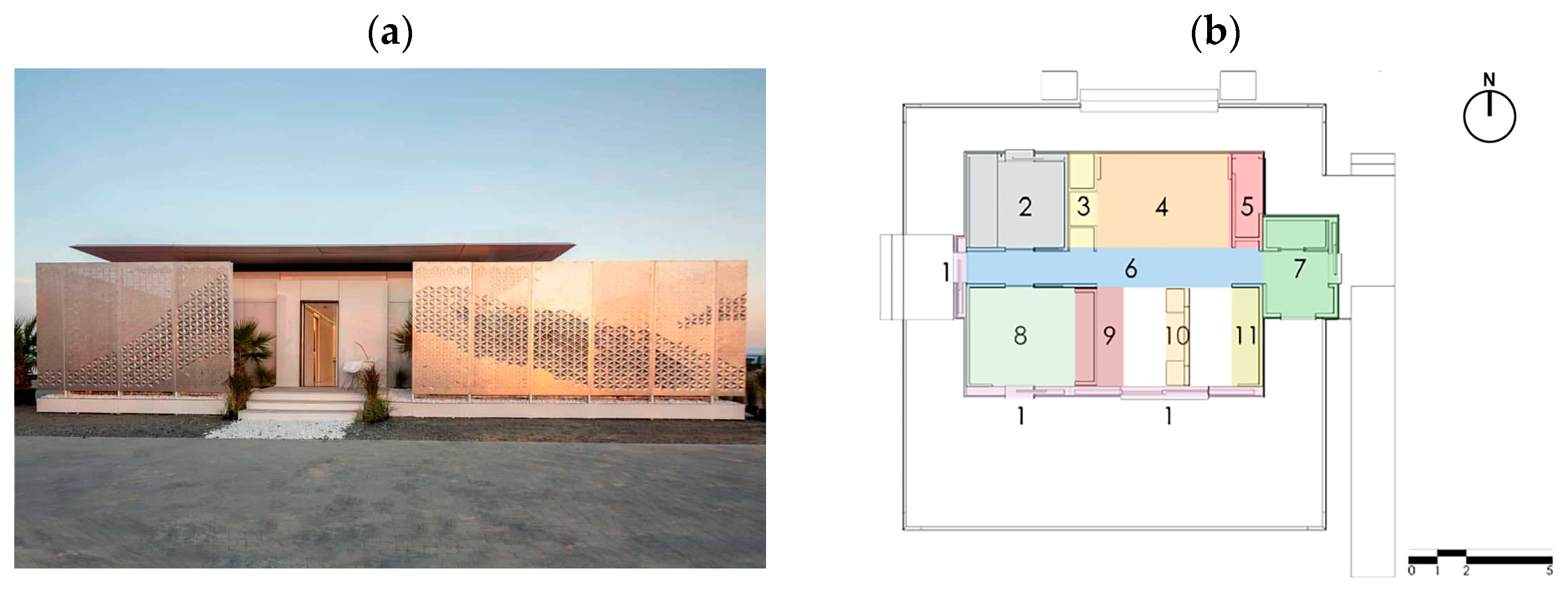

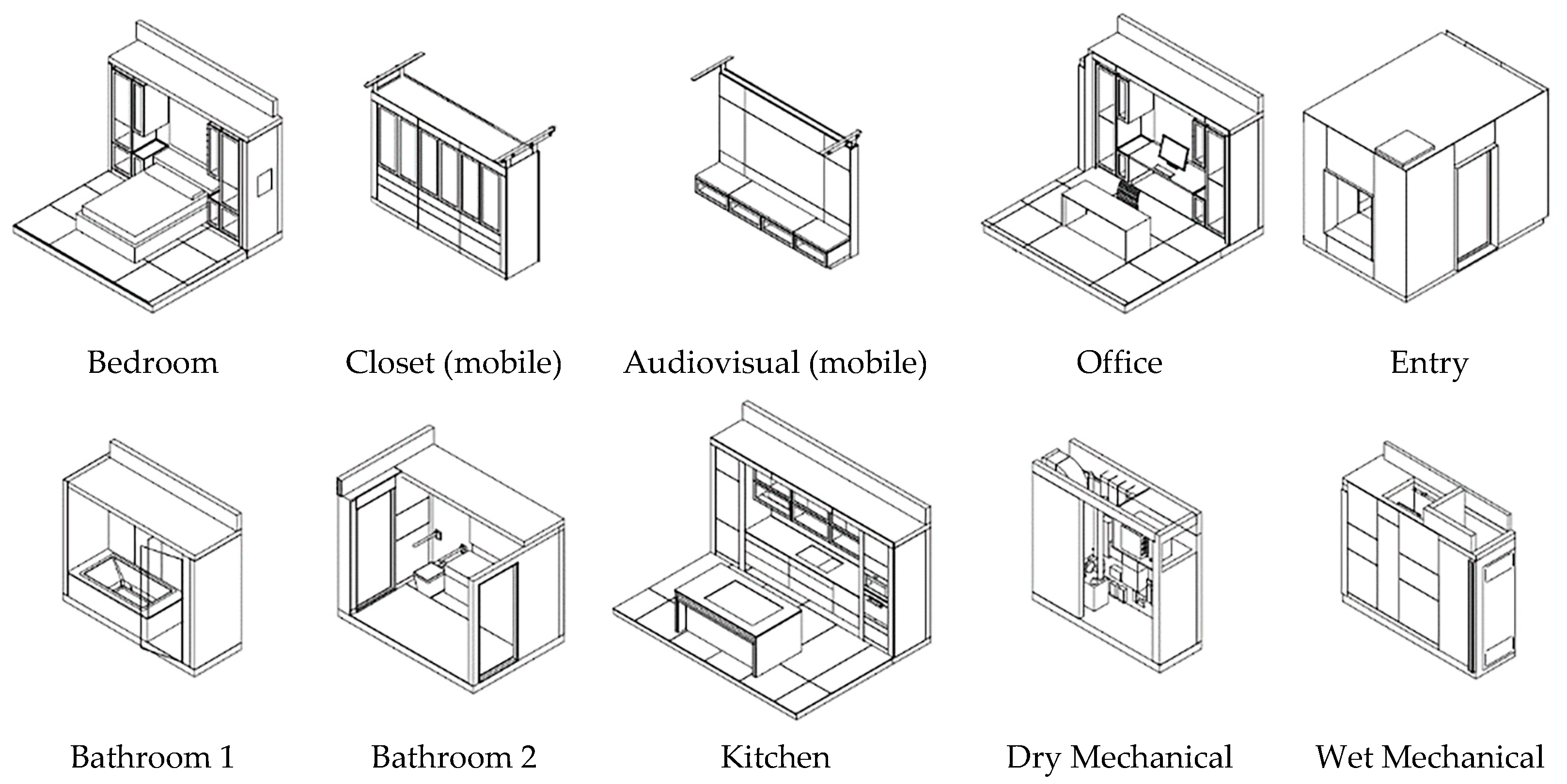

- Case analysis. The authors analyzed each house independently, including the off-site construction system types and categories, architectural concepts, structure, façade system, materials, and how the teams assembled their houses. To illustrate the houses’ design, interior distribution, and off-site construction elements, the authors drew the floor plan in AutoCAD for each of the cases, as well as some of their construction details. In the case of houses constructed using 3D modules and hybrid solutions, the volumetric units (modules, pods, and cartridges) were color-coded in the floor plans.

- Comparison and discussion. The case studies were compared and discussed based on their categories, solutions, structural materials, and how these choices relate to the transportation method used in each case. Also, the façade types and building materials were examined. Lastly, the cases were compared in relation to the applicable Dubai building regulation and two early adopters of sustainable zero-energy houses.

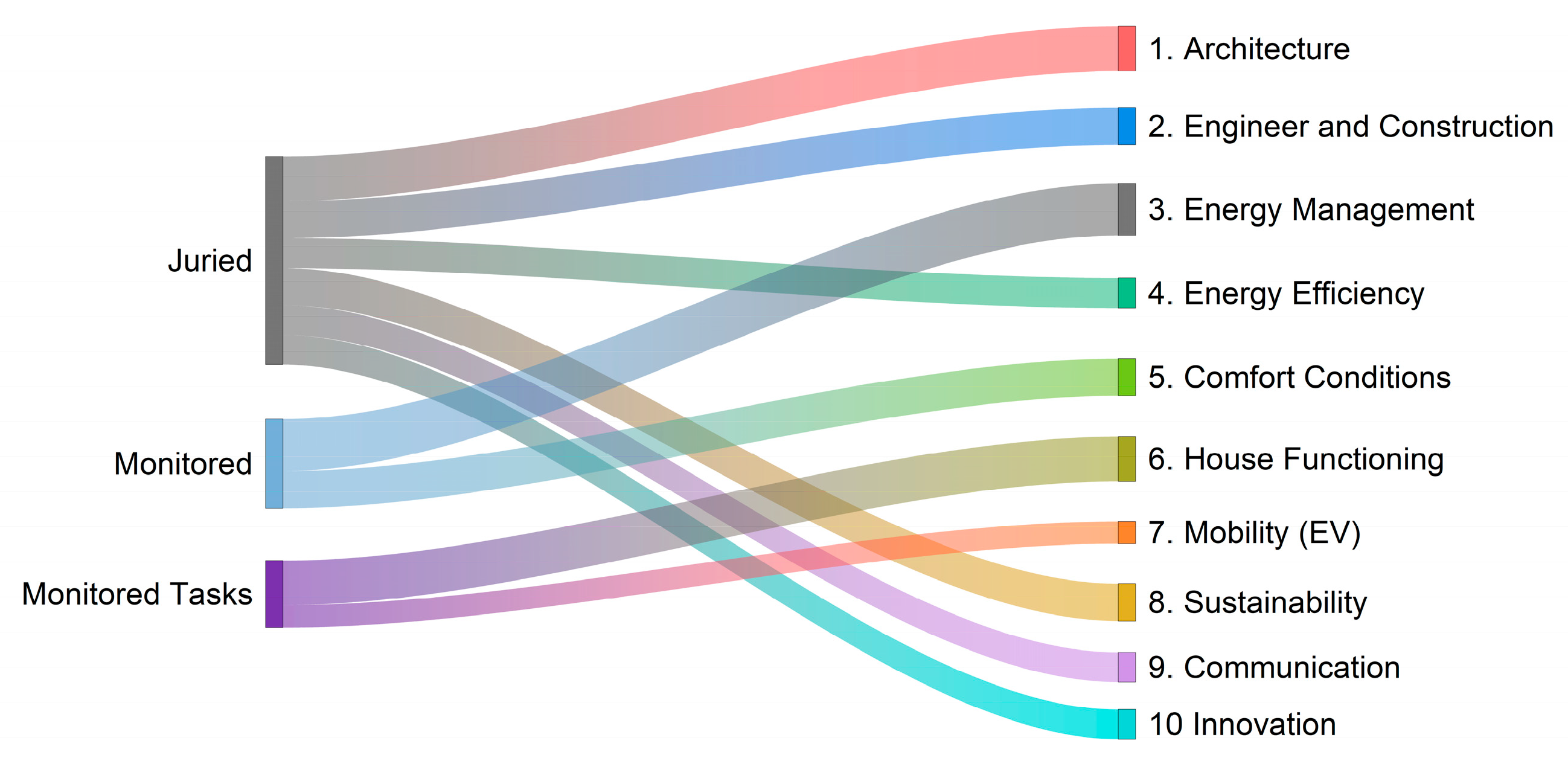

3.1. Solar Decathlon Middle East

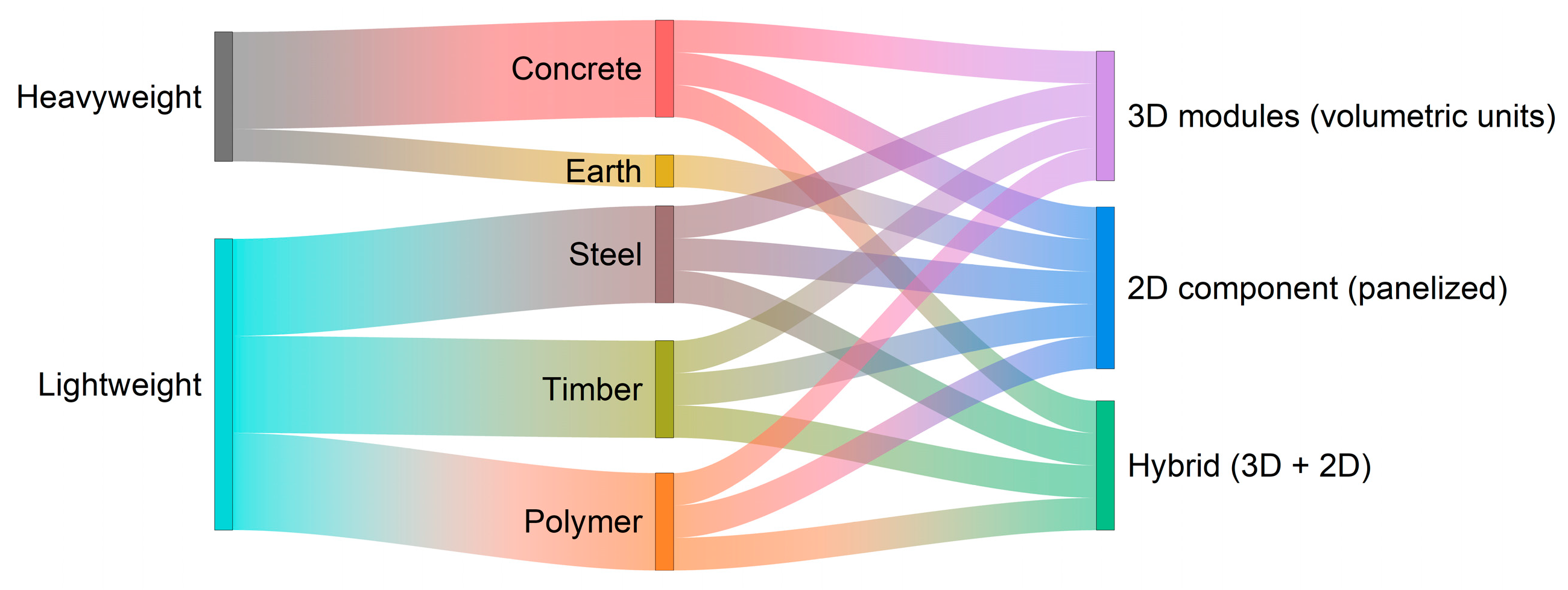

3.2. Off-Site Construction Classification

4. Case Characteristics and Classifications

4.1. Cases’ General Characteristics

4.2. Classification of the Cases

5. Case Details

5.1. Solutions 2D

Team Aqua Green

5.2. 3D Solutions

5.2.1. Team KSU

5.2.2. Team AURAK

5.2.3. Team Baity Kool

5.3. Hybrid Solutions

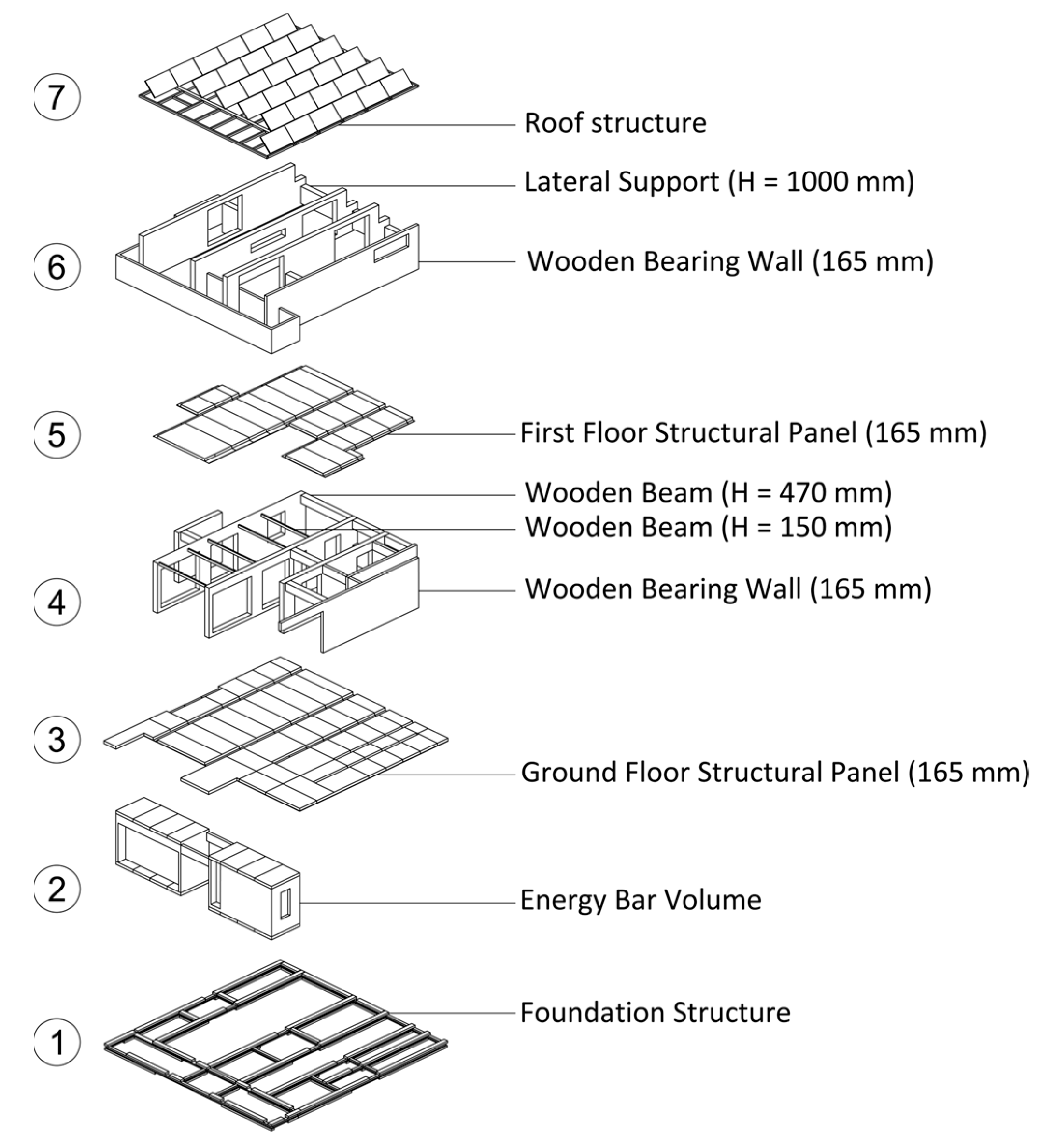

5.3.1. Team UOW

5.3.2. Team Virginia Tech

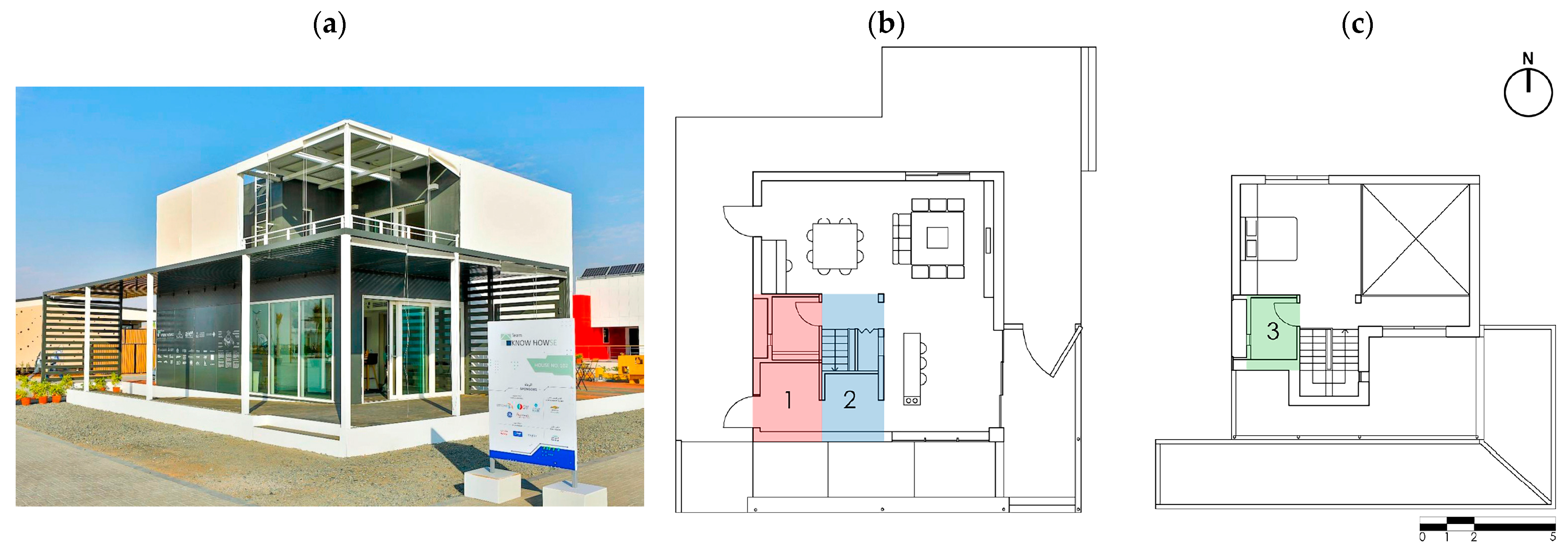

5.3.3. Team KNOW HOWse

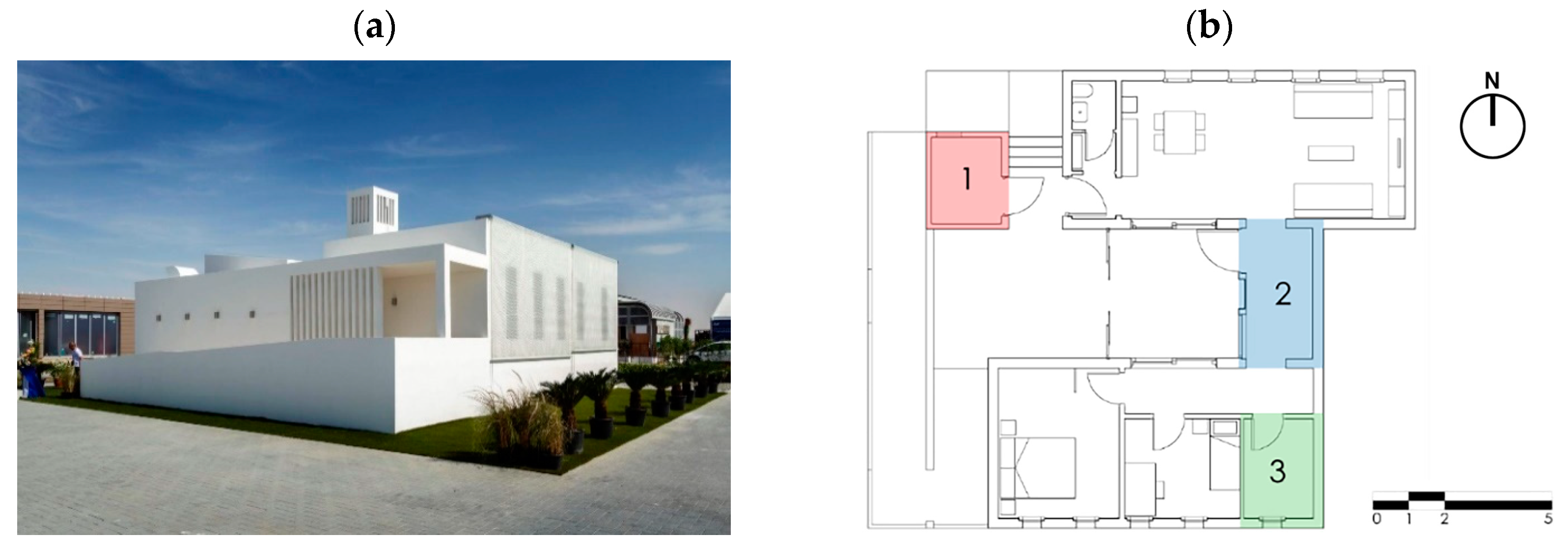

5.3.4. Team Sapienza

5.3.5. Team TDIS

5.3.6. Team EFDEN

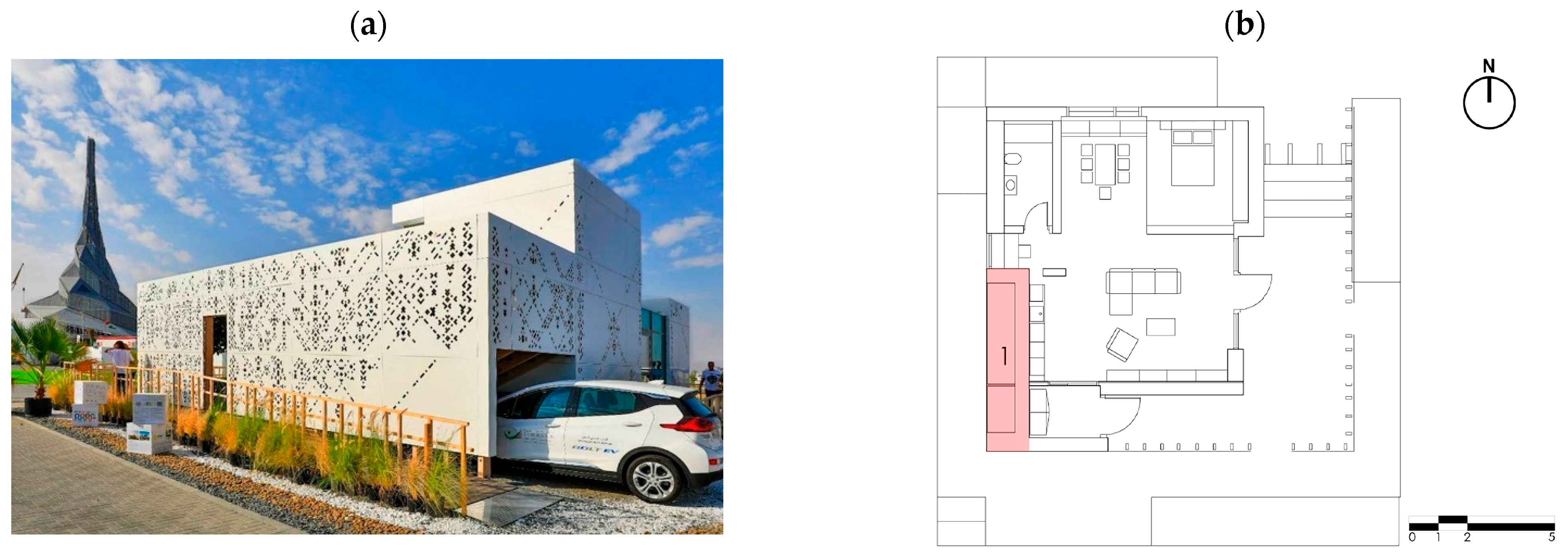

5.3.7. Team Virtue

6. Discussion

6.1. Category, Type of Solution, and Primary Structural Material

6.2. Projects’ Passive Strategies, Thermal Envelopes, and Materials

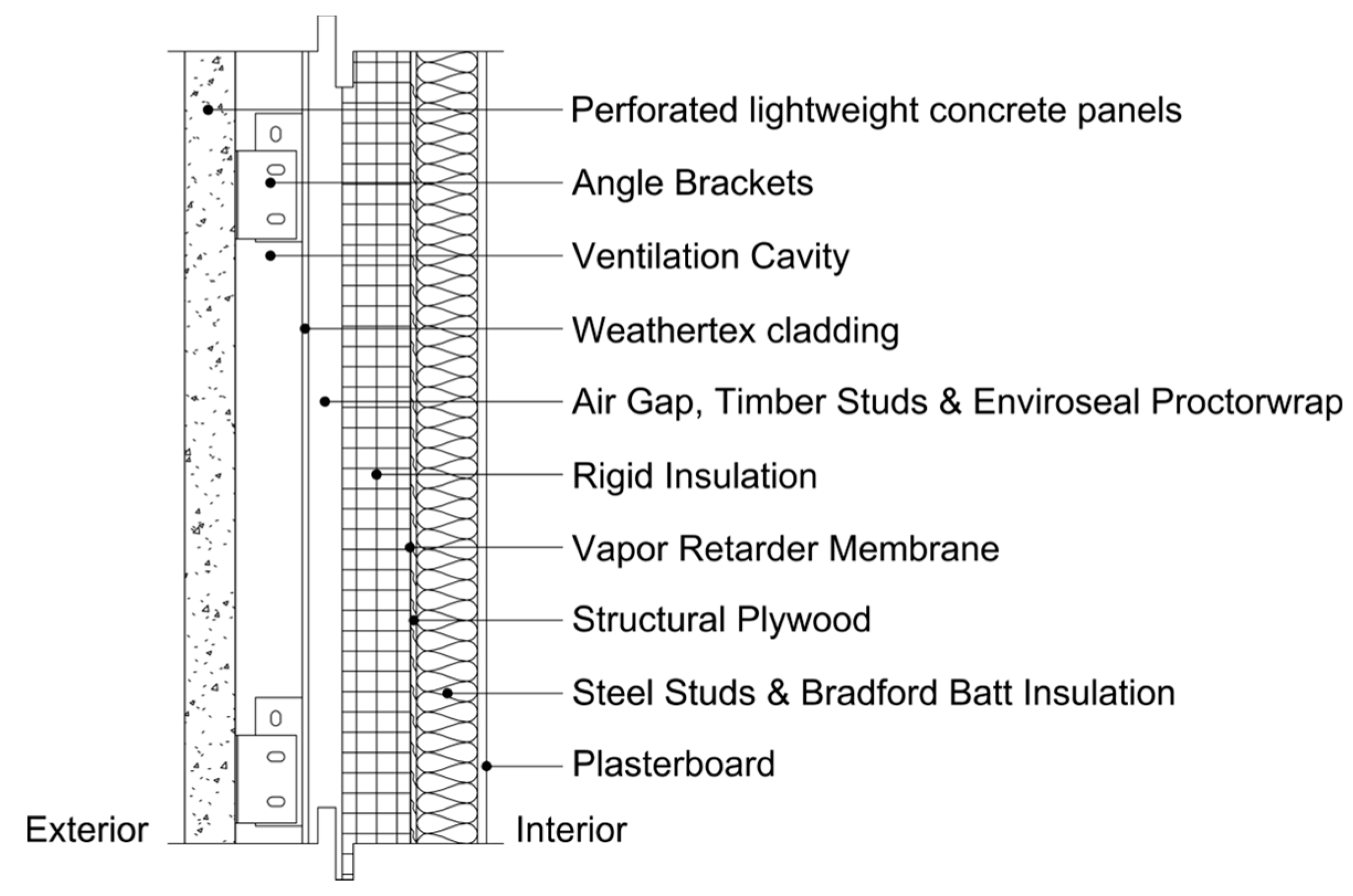

6.2.1. Façades Types and Exterior Wall Materials

6.2.2. Bio-Composite and Natural Materials

6.2.3. High-Performance Insulation Materials

6.2.4. Phase Change Materials

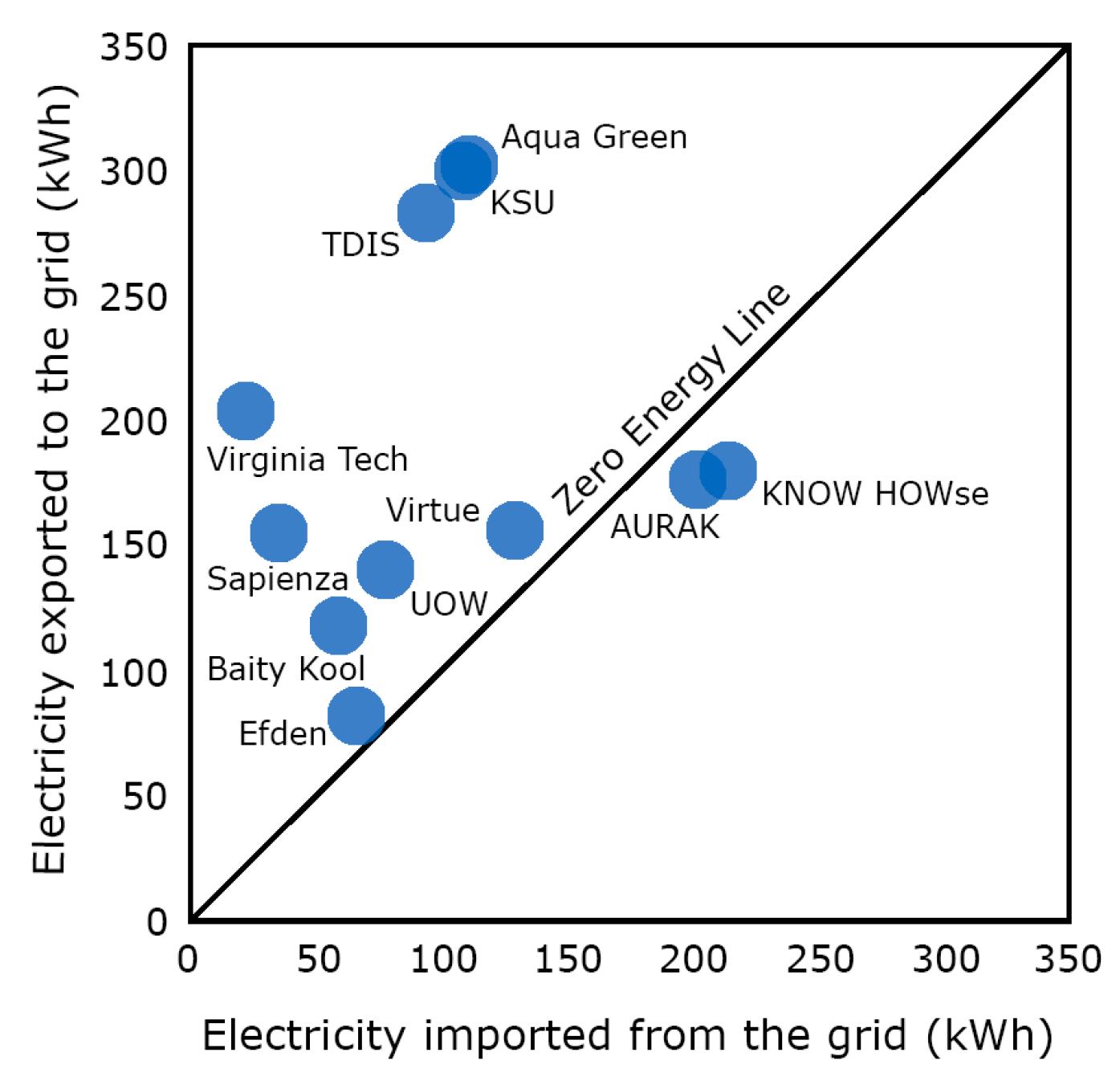

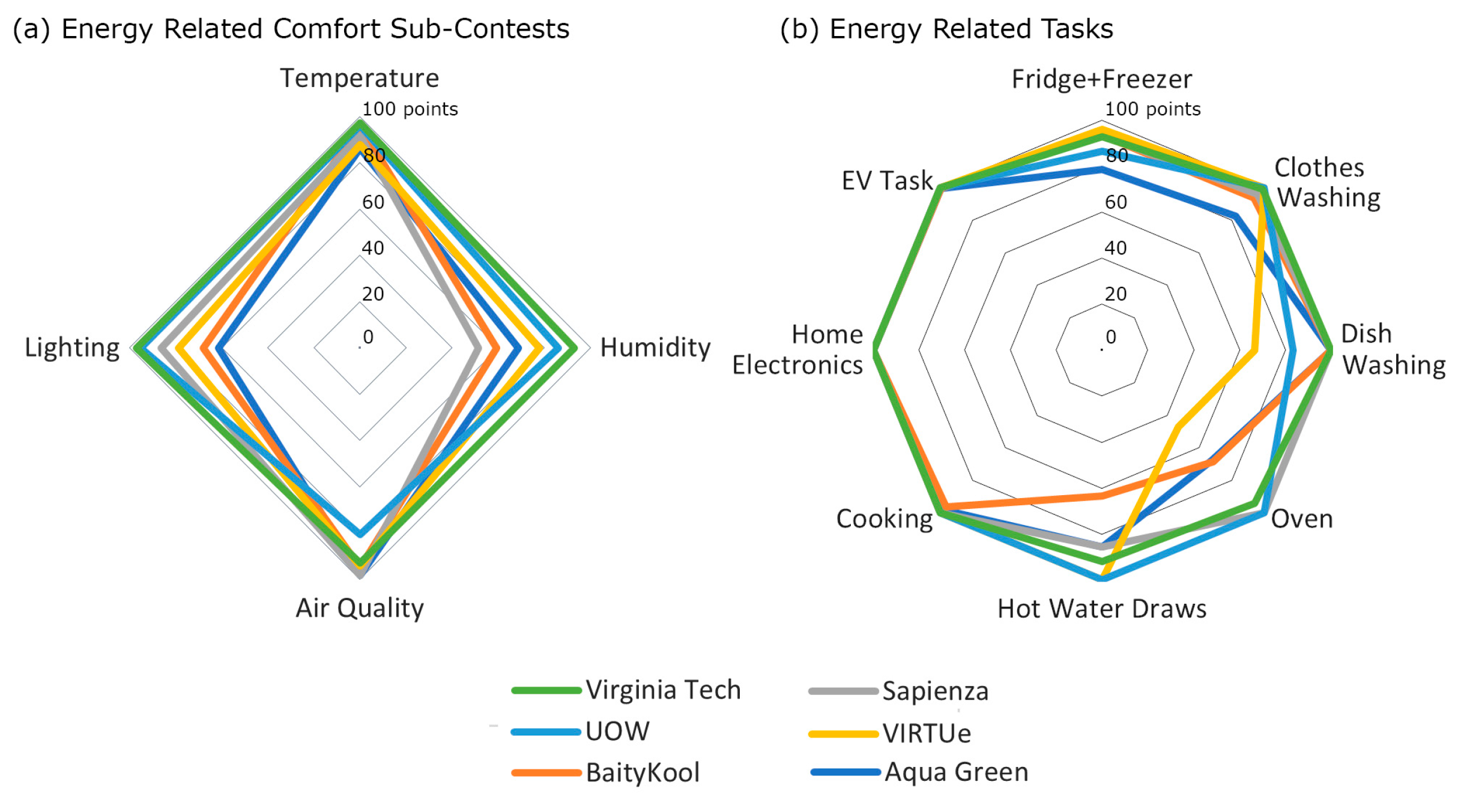

6.3. Energy Performance During the Competition

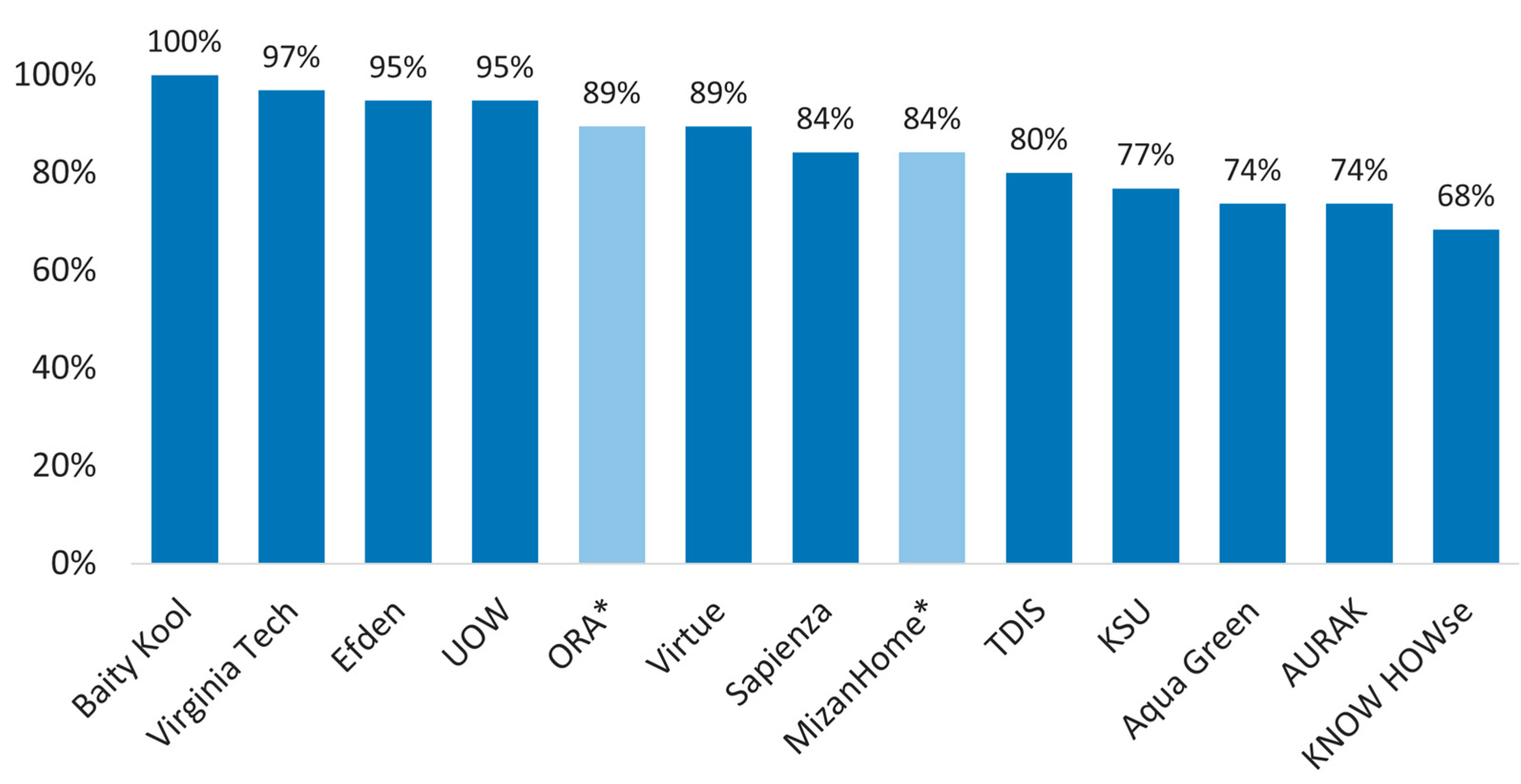

6.4. Sustainability Evaluation during the Competition

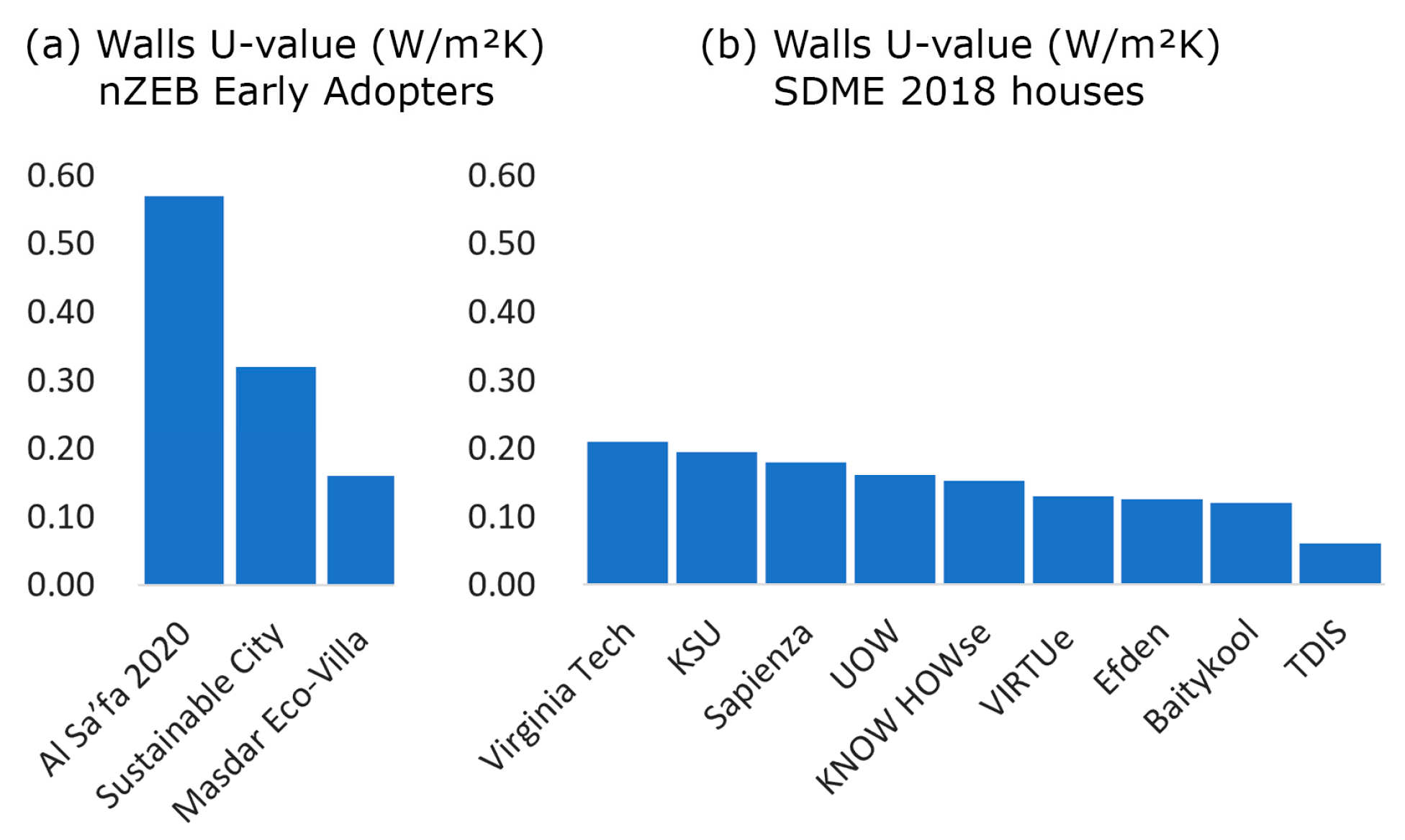

6.5. Comparison between SDME 2018 Houses, Nearly Zero Energy Early Adopters in the UAE, and the Dubai Green Building Regulations

6.6. Additional Solutions to Those Utilized by the SDME 2018 Houses

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. SDME 2018 Houses Occupancy and Energy-Related Tasks

| Teams’ Tasks and Responsibilities | During the Competition (10 days) | Weekly Average |

|---|---|---|

| Maintain temperature, humidity, CO2, and lighting levels | 240 h | 168 h |

| Use of TV and other house entertainment equipment | 69 h (min) | 48 h (min) |

| Use of computers | 69 h (min) | 48 h (min) |

| Maintain fridge and freezer temperature | 240 h | 168 h |

| Cooking tasks | 7 times | 5 times |

| Oven tasks | 6 times | 4 times |

| Special dinners for eight people | 3 times | 2 times |

| Loads of dishwashing machines | 6 times | 4 times |

| Hot water for showers 50 L | 700 L (min) | 490 L (min) |

| Loads of washing machine (using hot water) | 7 times | 5 times |

| Clothes drying | 7 times | 5 times |

| Turn on all artificial lights (interior and exterior) | 33 h (min) | 23 h (min) |

| Drive and charge an electric vehicle (EV) | 430 km (min) | 301 km (min) |

Appendix B. SDME 2018 Houses PV Solar Systems

| Team | Module Type | Modules Location | Orientation | System Size (kWp) |

|---|---|---|---|---|

| Virginia | Mono & polycrystalline Silicon | Roof & entryway window 1 | Top & South (vertical) | 13.55 |

| UOW | Monocrystalline Silicon | South facing part of the roof 2 | Top (South tilted) | 10.4 |

| BaityKool | Polycrystalline Silicon | Façades 1 (S, E, and W) & patio shading 1 | S, E, and W (vert.) & S (tilted) | 7.34 |

| EFdeN | Polycrystalline Silicon | Roof | Top | 8.96 |

| Sapienza | Mono HIT | Roof 1 | Top (South tilted) | 10.56 |

| VIRTUe | Thin Film (CIGS) | Roof 2 | Top (South tilted) | 7.77 |

| TDIS | Monocrystalline Silicon | Roof terrace canopy 1 | Top (adjustable tilt) | 9.36 |

| KNOW HOWse | Monocrystalline Silicon | Roof | Top | 9.6 |

| Aqua Green | Polycrystalline Silicon | Roof and terrace shading 1 | Top (south tilted) | 9.6 |

| KSU | Monocrystalline Silicon | Roof and patio shading 1 | Top (South tilted) | 17.4 |

| AURAK | Monocrystalline Silicon | Roof and patio shading 1 | Top (South tilted) | 11.4 |

Appendix C. HVAC Systems of the SDME 2018

| Team | Cooling Only | Heat Pump | Centralized | Decentralized | ERV | HRV | R32 | R410A | R134a | Air/Water | Air/Air | Single OD Units | Multiple OD Units | Non-Ducted System | Ducted Network | Chilled Water Network |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aqua Green | █ | █ | █ | █ | █ | █ | ||||||||||

| AURAK | █ | █ | █ | █ | █ | █ | █ | |||||||||

| KNOW HOWse | █ | █ | █ | █ | █ | █ | ||||||||||

| EFdeN | █ | █ | █ | █ | █ | █ | █ | |||||||||

| TDIS | █ | █ | █ | █ | █ | █ | █ | |||||||||

| KSU | █ | █ | █ | █ | █ | █ | █ | |||||||||

| Virginia Tech | █ | █ | █ | █ | █ | █ | █ | |||||||||

| Baity Kool | █ | █ | █ | █ | █ | █ | █ | |||||||||

| VIRTUe | █ | █ | █ | █ | █ | █ | █ | |||||||||

| UOW | █ | █ | █ | █ | █ | █ | █ | |||||||||

| Sapienza | █ | █ | █ | █ | █ | █ | █ |

Appendix D. SDME 2018 Instrumentation and Monitoring

| Image | Type | Accuracy | Location |

|---|---|---|---|

| Globe temperature (PT1000) Range (−5 to 60 °C) | Class B (DIN EN 60751) PT1000 ±0.3° C | Living room and bedroom (tripod) |

| Relative humidity and temp. sensor (temperature-compensated digital output) | RH 1.5% (typ.) Temp. ± 0.1 (typ. 20 °C to 60 °C) | Living room and bedroom (tripod) |

| Multi-parameter ambient sensor CO2 range 0–10,000 ppm Temp. range: −40 °C to 120 °C RH range: 0 to 100% | CO2 ±30 ppm ±3% Temp. ±0.5 °C, RH ±2% | Living room, kitchen, and bedroom (tripod) |

| Ambient light sensor (with high-precision human-eye response) | <0.2% (typ. matching between ranges) | Living room and kitchen |

| Insulated thermocouples Type J (exposed junction) | Class 1 (EN 60584-2) | Inside oven, fridge, freezer, clothes washing, and dishwashing machines |

| Smart bidirectional energy meter Rated current: 63 A Frequency: 50 and 60 Hz | Class B (EN 50470) Class 1 (IEC 61557-12) Class 1 (IEC 62053-21) | SDME Monitoring Box (3 units) Houses electrical panels (2 units) |

| Smart static ultrasonic water meter | Class 2—T30, T50: ±2% (range Q2 ≤ Q ≤ Q4) | Outside of the houses |

References

- Aoul, K.A.T.; Akhozheya, B.; Karaouzene, R.; Hagi, R.; Abdelghani, R.; Syam, M. The Existing Residential Building Stock in UAE: Energy efficiency and retrofitting opportunities. In Proceedings of the 6th Annual International Conference on Architecture and Civil Engineering, Singapore, 14–15 May 2018. [Google Scholar]

- Parrish, K. Lean and Green Construction: Lessons Learned from Design and Construction of a Modular Leed® Gold Building. In Proceedings of the IGLC 2012—20th Conference of the International Group for Lean Construction, Diego, CA, USA, 17–22 July 2012. [Google Scholar]

- United Nations Environment Programme. 2021 Global Status Report for Buildings and Construction—Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; Global Alliance for Buildings and Construction: Nairobi, Kenya, 2021. [Google Scholar]

- Dixon, W. The Impacts of Construction and the Built Environment Introduction Energy Use, Global Warming, Climate Change; Willmott Dixon: Letchworth Garden City, UK, 2010. [Google Scholar]

- Elhacham, E.; Alpert, P. Temperature Patterns along an Arid Coastline Experiencing Extreme and Rapid Urbanization, Case Study: Dubai. Sci. Total Environ. 2021, 784, 147168. [Google Scholar] [CrossRef]

- European Parliament; Council of the European Union. Directive (EU) 2018/844 of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Off. J. Eur. Union 2018, 19, 75–91. [Google Scholar]

- Fowler, K.M.; Demirkanli, D.I.; Hostick, D.J.; McMordie Stoughton, K.L.; Solana, A.E.; Sullivan, R.S. Federal New Buildings Handbook for Net Zero Energy, Water, and Waste; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2017. [Google Scholar]

- Asif, M. Growth and Sustainability Trends in the Buildings Sector in the GCC Region with Particular Reference to the KSA and UAE. Renew. Sustain. Energy Rev. 2016, 55, 1267–1273. [Google Scholar] [CrossRef]

- Rodriguez-Ubinas, E.; Alzarouni, S.; Alhammadi, N.; Alantali, M.; Behzad, F.; Sgouridis, S. Sustainability through Energy Conservation Building Codes: Comperatie Analysis of Green Building Regulations in the Middle East. WIT Trans. Ecol. Environ. 2020, 249, 85–100. [Google Scholar]

- IEA. 2019 Global Status Report for Buildings and Construction towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; IEA: Paris, France, 2019; ISBN 9789280737684. [Google Scholar]

- Masdar City. Masdar City Eco-Villa Net-Zero Energy; Masdar City: Abu Dhabi, United Arab Emirates, 2018. [Google Scholar]

- Trichakis, P.; Carter, N.; Tudhope, S.; Patel, I.; Sgouridis, S.; Griffiths, S. Enabling the UAE’s Energy Transition—Top Ten Priority Areas for Renewable Energy Policymakers; Ministry of Energy and Industry: Abu Dhabi, United Arab Emirates, 2018.

- Ali, K.A.; Ahmad, M.I.; Yusup, Y. Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Albus, J.; Drexler, H. Prefab Housing. Untersuchung von Produktionsprozessen im Hinblick auf Effizensteigerung und Kostensenkung für Bedarfsgerechten Wohnraum; Fraunhofer IRB: Stuttgart, Germany, 2020. [Google Scholar]

- Mohamed, B.E.; Elkaftangui, M.; Zureikat, R. Towards Rethinking the Precast Concrete Industry in the UAE. In Learning Prototyping and Adapting, Proceedings of the 23rd International Conference on Computer-Aided Architectural Design Research in Asia (CAADRIA), Beijing, China, 17–19 May 2018; Fukuda, T., Huang, W., Eds.; Association for Computer-Aided Architectural Design Research in Asia (CAADRIA): Hong Kong, China, 2018; pp. 287–296. [Google Scholar]

- Smith, R.E. Off-Site Construction Implementation Resource: Off-Site and Modular Construction Explained; National Institute of Building Sciences: Washington, DC, USA, 2014; pp. 1–6. [Google Scholar]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Oti-Sarpong, K.; Wuni, I.Y.; Tetteh, M.O. Systematic Review on the Integration of Building Information Modelling and Prefabrication Construction for Low-Carbon Building Delivery. Build. Res. Inf. 2023, 51, 279–300. [Google Scholar] [CrossRef]

- Anane, W.; Iordanova, I.; Ouellet-Plamondon, C. BIM-Driven Computational Design for Robotic Manufacturing in off-Site Construction: An Integrated Design-to-Manufacturing (DtM) Approach. Autom. Constr. 2023, 150, 104782. [Google Scholar] [CrossRef]

- Meuser, P.; Albus, J.; Belov, A.; Kuznetsov, S. Construction and Design Manual: Prefabricated Housing, 2nd ed.; Construction and Design manual; DOM Publishers: Berlin, Germany, 2020; ISBN 978-3-86922-021-5. [Google Scholar]

- Albus, J. Prefabrication and Automated Processes in Residential Construction; DOM Publishers: Berlin, Germany, 2018; ISBN 9783869226118. [Google Scholar]

- Lawson, M.; Ogden, R.; Goodier, C. Design in Modular Construction; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9780203870785. [Google Scholar]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New Advancements, Challenges and Opportunities of Multi-Storey Modular Buildings—A State-of-the-Art Review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus Modular Construction Methods: A Comparative Cradle-to-Gate LCA for Residential Buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A Holistic Review of Off-Site Construction Literature Published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.H.; Kim, J.T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Thai, H.T.; Ngo, T.; Uy, B. A Review on Modular Construction for High-Rise Buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Wilson, J. The Potential of Prefab: How Modular Construction Can Be Green. Building Green Spotlight Report. Build. Green 2019, 1–21. [Google Scholar]

- Meehleis, M.W. Difficulties Posed and Overcoming Challenges in Modular Construction: A Case Study. 2009. Available online: https://digitalcommons.calpoly.edu/cgi/viewcontent.cgi?article=1424&context=cmsp (accessed on 5 July 2023).

- Krug, D.; Miles, J. Offsite Construction: Sustainability Characteristics; Buildoffsite: London, UK, 2013. [Google Scholar]

- Dollard, T. Off-Site Construction. In Designed to Perform; RIBA Publishing: London, UK, 2019; pp. 101–113. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-adaway, I.H. Modular Construction: Determining Decision-Making Factors and Future Research Needs. J. Manag. Eng. 2020, 36, 04020085. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life Cycle Performance of Modular Buildings: A Critical Review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- John, Q.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction Matters: Comparing Environmental Impacts of Building Modular and Conventional Homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar]

- Jayawardana, J.; Kulatunga, A.K.; Jayasinghe, J.A.S.C.; Sandanayake, M. Environmental Sustainability of Off-Site Construction in Developed and Developing Regions: A Systematic Review. J. Archit. Eng. 2023, 29, 04023008. [Google Scholar] [CrossRef]

- Samuel, A.K.; Mohanan, V.; Sempey, A.; Garcia, F.Y.; Lagiere, P.; Bruneau, D.; Mahanta, N. A Sustainable Approach for a Climate Responsive House in UAE: Case Study of SDME 2018 BAITYKOOL Project. In Proceedings of the 2019 International Conference on Computational Intelligence and Knowledge Economy, ICCIKE, Dubai, United Arab Emirates, 11–12 December 2019; pp. 816–823. [Google Scholar] [CrossRef]

- Belpoliti, V.; Said, Z.; Hachicha, A.A.; Altan, H. Simulated and Monitored Electrical Energy Balance in a Solar House in Dubai, UAE. Archit. Eng. Des. Manag. 2023, 1–18. [Google Scholar] [CrossRef]

- Casini, M. A Positive Energy Building for the Middle East Climate: ReStart4Smart Solar House at Solar Decathlon Middle East 2018. Renew Energy 2020, 159, 1269–1296. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M.; Spišáková, M. The Benefits of Modern Method of Construction Based on Wood in the Context of Sustainability. Int. J. Environ. Sci. Technol. 2017, 14, 1591–1602. [Google Scholar] [CrossRef]

- Hill, C.; Zimmer, K. The Environmental Impacts of Wood Compared to Other Building Materials; Norwegian Institute of Bioeconomy Research: As, Norway, 2018; Volume 4, ISBN 9788217020905. [Google Scholar]

- Trepci, E.; Rodriguez-Ubinas, E.; Alshikh, Z.; Sgouridis, S. Passive Design Strategies for Zero Energy Houses in Desert Environments: The Case of Solar Decathlon Middle East 2021, Proceedings of the WIT Transactions on Ecology and the Environment, Rome, Italy, 10–12 October 2022; WIT Press: Billerica, MA, USA, 2022; Volume 258, pp. 139–151. [Google Scholar]

- Ibañez-Puy, M.; Vidaurre-Arbizu, M.; Sacristán-Fernández, J.A.; Martín-Gómez, C. Opaque Ventilated Façades: Thermal and Energy Performance Review. Renew. Sustain. Energy Rev. 2017, 79, 180–191. [Google Scholar] [CrossRef]

- Shareef, S.; Mushtaha, E.S.; Abu Dabous, S.; Alsyouf, I. Holistic Analysis for the Efficiency of the Thermal Mass Performance of Precast Concrete Panels in Hot Climate Zones. Eng. Constr. Archit. Manag. 2023. [Google Scholar] [CrossRef]

- Derakhtenjani, A.S.; Barbosa, J.D.; Rodriguez-Ubinas, E. Evaluation of Energy Flexibility Potential of a Typical Thermal Zone in Dubai. Int. J. Energy Prod. Manag. 2022, 7, 265–275. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA Based Biocomposites for Sustainable Products: A Review. Adv. Ind. Eng. Polym. Res. 2023; in press. [Google Scholar] [CrossRef]

- Raddadi, N.; Fava, F. Biodegradation of Oil-Based Plastics in the Environment: Existing Knowledge and Needs of Research and Innovation. Sci. Total Environ. 2019, 679, 148–158. [Google Scholar] [CrossRef] [PubMed]

- Belhous, M.; Boumhaout, M.; Oukach, S.; Hamdi, H. Effect of a Material Based on Date Palm Fibers on the Thermal Behavior of a Residential Building in the Atlantic Climate of Morocco. Sustainability 2023, 15, 6314. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, Q. Application of Vacuum Insulation Panels (VIPs) in Buildings; Springer International Publishing: Cham, Germany, 2022; pp. 289–346. [Google Scholar]

- Rodriguez-Ubiñas, E.; Ruiz-Valero, L.; Vega, S.; Neila, J. Applications of Phase Change Material in Highly Energy-Efficient Houses. Energy Build. 2012, 50, 49–62. [Google Scholar] [CrossRef]

- Kośny, J. PCM-Enhanced Building Components: An Application of Phase Change Materials in Building Envelopes and Internal Structures; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Dubai Municipality. AlSafat—Dubai Green Building Evaluation System; Government of Dubai: Dubai, United Arab Emirates, 2020.

- Dubai Municipality. Dubai Building Code; Government of Dubai: Dubai, United Arab Emirates, 2021.

| Parameters | The Expected Level of Benefits |

|---|---|

| Time on site | 3D < Hybrid < 2D |

| Crane size | 2D < Hybrid < 3D |

| Use of crane and auxiliary equipment | 3D < Hybrid < 2D |

| Auxiliary equipment time of use | 3D < Hybrid < 2D |

| Free space around the building | 2D < Hybrid < 3D |

| Effort and number of workers on site | 3D < Hybrid < 2D |

| Site deliveries cost | 2D < Hybrid < 3D |

| Parameters | Sustainability Benefits | |||

|---|---|---|---|---|

| J. Wilson [27] | D. Krug and J. Miles [29] | Economic | Environmental | Social |

| More efficient process | █ | |||

| Better quality control | Reduction in snagging and defects | █ | █ | |

| Faster construction | █ | █ | ||

| Improvement in the cash-flow | █ | |||

| Reduction in material waste | Reduction in waste | █ | █ | █ |

| Construction cost saving | █ | |||

| Reduction in energy use for construction | Reduction in energy used on site | █ | █ | |

| Reduction in life-cycle embodied energy and carbon | Reduction in energy use | █ | █ | █ |

| Reduction in operational impacts | █ | █ | ||

| Reduction in transportation-related impacts | Reduction in road traffic movements | █ | █ | █ |

| Support for adaptation, reuse, and recycling | █ | █ | ||

| Reduction in disruption to the surrounding community | █ | █ | ||

| Support for resilience | █ | █ | ||

| Reduction in indoor environmental quality issues | █ | █ | ||

| Health and safety | █ | █ | ||

| Improved working conditions | █ | |||

| Contribution towards affordable housing shortage | █ | |||

| Potential Drawbacks | Brief Explanation |

|---|---|

| Higher initial cost | They can often be more expensive than traditional materials, especially when they are first introduced to the market. They may require more specialized manufacturing processes or be produced in smaller quantities. |

| Limited availability | They may not be as widely available as traditional materials, especially in certain regions. This can make it more difficult to find contractors and suppliers who are familiar with working with them. |

| Performance | They may not always perform as well as traditional materials in terms of strength, durability, or fire resistance. |

| Lack of research | There is still a lack of research on the long-term performance of some sustainable materials. This can make it difficult to assess their true environmental impact and durability. |

| Acceptance | There may be some resistance to using sustainable materials from contractors, builders, or building owners unfamiliar with them. |

| House | ID | Team Name | Participating Universities and Countries | Unique Features | Floor Area (m2) |

|---|---|---|---|---|---|

| H01 | AST | Aqua Green |

| 84.0 | |

| H02 | KSU | KSU |

| 101.4 | |

| H03 | AURAK |

| Roof terrace | 92.6 | |

| H04 | BX | Baity Kool |

| 105.5 | |

| H05 | UOW | UOW |

| 120.0 | |

| H06 | VT | Virginia Tech |

| 99.1 | |

| H07 | UOS | KNOW HOWse |

| Two floors | 120.0 |

| H08 | SUR | Sapienza |

| 103.1 | |

| H09 | NCT | TDIS |

| Roof terrace | 75.9 |

| H10 | BU | Efden |

| 97.1 | |

| H11 | TUE | Virtue |

| Apartment | 82.5 |

| House # | Team Name | Category | Solution | Structural Material |

|---|---|---|---|---|

| H01 | Aqua Green | Heavyweight | 2D (panelized) | Concrete |

| H02 | KSU | Heavyweight | 3D (volumetric units) | Steel 1 |

| H03 | AURAK | Lightweight | 3D (volumetric units) | Steel |

| H04 | Baity Kool | Lightweight | 3D (volumetric units) | Timber |

| H05 | UOW | Lightweight | Hybrid | Light Steel Frame |

| H06 | Virginia Tech | Lightweight | Hybrid 2 | Timber |

| H07 | KNOW HOWse | Lightweight | Hybrid | Timber |

| H08 | Sapienza | Lightweight | Hybrid | Timber |

| H09 | TDIS | Lightweight | Hybrid | Timber |

| H10 | Efden | Lightweight | Hybrid | Timber |

| H11 | Virtue | Lightweight | Hybrid | Timber |

| House | Team Name | Country of Off-Site Preparation | Transportation | Category | Solution | Structural Material |

|---|---|---|---|---|---|---|

| H01 | Aqua Green | UAE | Land | Heavyweight | 2D (panelized) | Concrete |

| H02 | KSU | Saudi Arabia | Land | Heavyweight | 3D (volumetric units) | Steel 1 |

| H03 | AURAK | UAE | Land | Lightweight | 3D (volumetric units) | Steel |

| H04 | Baity Kool | France and UAE | Land 2 | Lightweight | 3D (volumetric units) | Timber |

| H05 | UOW | Australia | Maritime and Land | Lightweight | Hybrid | Light Steel Frame |

| H06 | Virginia Tech | US | Maritime and Land | Lightweight | Hybrid 3 | Timber |

| H07 | KNOW HOWse | Italy and UAE | Land 4 | Lightweight | Hybrid | Timber |

| H08 | Sapienza | Italy | Maritime and Land | Lightweight | Hybrid | Timber |

| H09 | TDIS | Taiwan | Maritime and Land | Lightweight | Hybrid | Timber |

| H10 | Efden | Romania | Maritime and Land | Lightweight | Hybrid | Timber |

| H11 | Virtue | Netherlands | Maritime and Land | Lightweight | Hybrid | Timber |

| SDME 2018 Houses Passive Strategies | Aqua Green | KSU | AURAK | Baity Kool | UOW | Virginia Tech | KNOW HOWse | Sapienza | TDIS | Efden | Virtue |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume and geometric | |||||||||||

| Compact | █ | █ | █ | █ | |||||||

| Around or next to a covered patio | █ | █ | █ | █ | █ | ||||||

| Elongated along east–west axis (with south protected by a covered open space) | █ | █ | |||||||||

| Envelope | |||||||||||

| Ventilated Façade | █ | █ | █ | █ | █ | █ | █ | ||||

| Wall U-value (60% or lower than the code) | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ |

| Roof U-value (30% or lower than the code) | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ |

| High-performance glazing | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ |

| No windows in the east or west | █ | █ | █ | █ | █ | █ | █ | ||||

| Fully (parallel) protected east or west windows | █ | █ | █ | █ | |||||||

| Green roof | █ | █ | █ | █ | |||||||

| Green wall | █ | █ | █ | █ | █ | █ | |||||

| Cool roof and high reflective walls | █ | █ | █ | ||||||||

| Passive Cooling | |||||||||||

| Fixed solar shading | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ |

| Operable solar shading | █ | █ | █ | ||||||||

| Shaded roof | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ |

| Covered roof terrace | █ | █ | |||||||||

| Natural ventilation | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ |

| Night ventilation (natural night cooling) | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ | █ |

| Ventilation (Ventury or stack effect) | █ | █ | █ | ||||||||

| Passive space planning | |||||||||||

| Foyer or entrance vestibule | █ | █ | █ | █ | |||||||

| Living areas north- or south-oriented | █ | █ | █ | █ | █ | ||||||

| Living areas open to covered patio | █ | █ | █ | ||||||||

| Interior buffer zones | █ | █ | █ | ||||||||

| Attached covered spaces (terraces, porches) | █ | █ | █ | █ | █ | █ | |||||

| Thermal Energy Storage (TES) | |||||||||||

| Sensible thermal mass | █ | █ | █ | █ | █ | █ | |||||

| Passive latent TES |

| Passive Strategies in SDME 2018 Houses | Aqua Green | KSU | AURAK | Baity Kool | UOW | Virginia Tech | KNOW HOWse | Sapienza | TDIS | Efden | Virtue |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Motorized solar shading | █ | █ | █ | ||||||||

| Ventilation with heat recovery | █ | █ | █ | ||||||||

| Ventilation with energy recovery | █ | █ | █ | █ | █ | █ | |||||

| Evaporative cooling | █ | █ | |||||||||

| Radiant cooling | █ | █ | █ | █ | █ | █ | |||||

| Night or day sky radiation | █ | █ | |||||||||

| HVAC buffer tank (sensible) | █ | █ | |||||||||

| HVAC with PCM | █ | █ |

| Type | ID | Team | Façade Materials: Exterior Finishing | Façade Materials: Insulation Type | Insulation Location | Indoor Finishing Mat. |

|---|---|---|---|---|---|---|

| Non-ventilated Façade | H01 | Aqua Green 1 | Precast concrete | Extruded polystyrene | Wall core | Concrete |

| H02 | KSU | Cement board w/coated glass fiber mesh | Date palm tree surface fibers | Wall core | Gypsum board | |

| H03 | AURAK | Cement–mortar layer (applied over three-dimension welded wire mesh with insulation panel at the core) | Rigid insulation panels and semi-rigid wood fiber insulation | Exterior | Shotcrete | |

| H08 | Sapienza 2 | Cement board with coated glass fiber mesh | Fiber-reinforced aerogel blankets | Ext. and Int. | Gypsum board | |

| Opaque Ventilated Façade | H04 | UOW | Foamed concrete mixed with recycled crushed glass and carbon fiber mesh reinforcement | Extruded polystyrene insulation Board (closed cells) and insulation batts (recycled glass and natural organic binders) | Ext. and Int. | Gypsum board |

| H05 | Baity Kool | Cement mortar precast panels | Expanded polystyrene insulation (EPS) | Wall core | Raw clay bricks | |

| H06 | Virginia Tech | Glass rainscreen | Polyurethane foam | Wall core | Glass panels | |

| H07 | KNOW HOWse | Tensile fabric | Polyurethane foam | Interior | Magnesium board | |

| H11 | Virtue | Tridimensional cladding (Bio-composite materials) | Biofoam | Wall core | MDF wall panels | |

| H09 | TDIS | Rainscreen composite panels (resins reinforced cellulose fiber) | Extruded polystyrene insulation board (closed cells) and vacuum insulation panels (VIP) | Wall core | Glass–fiber–wood laminated panels | |

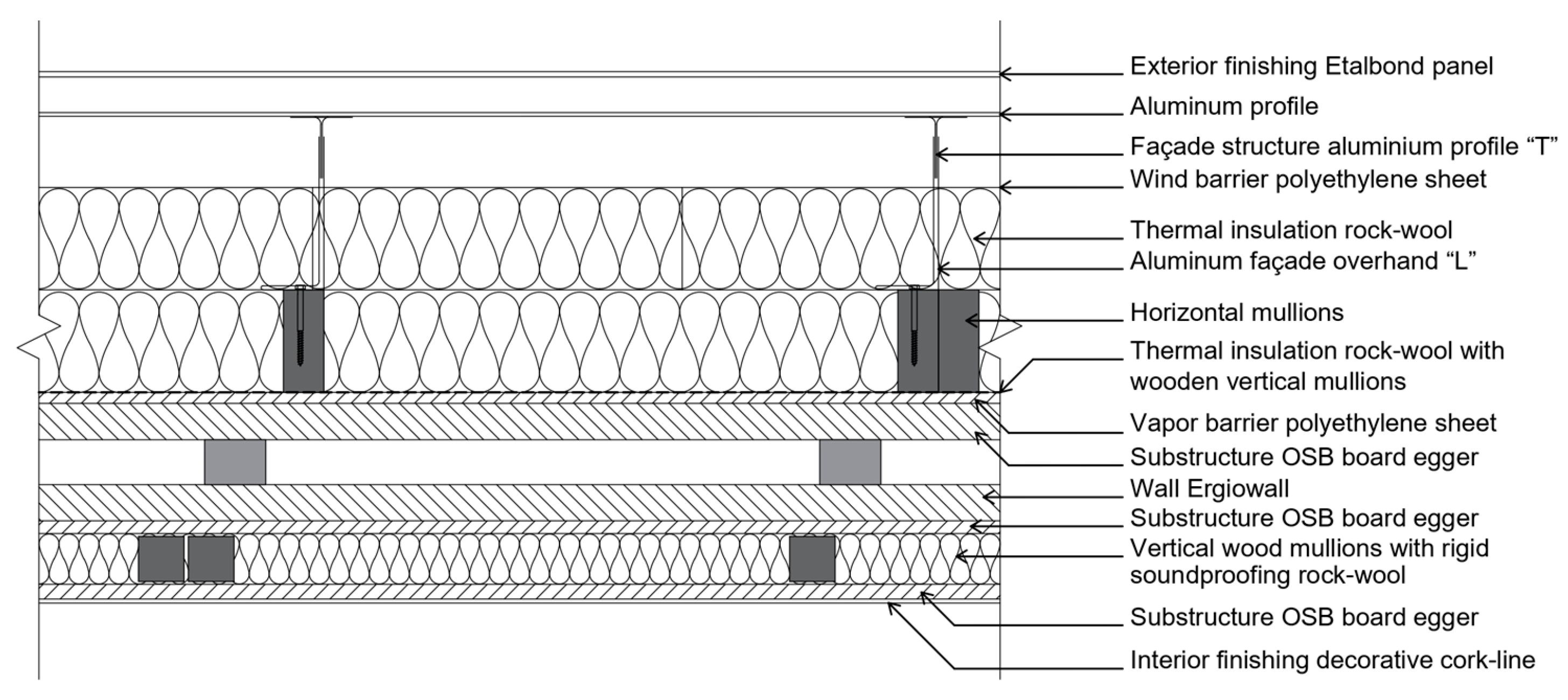

| H10 | Efden | Aluminum (Etalbond) | Rock-based mineral fiber insulation | Ext. and Int. | OSB with cork panels |

| Criteria | Description | |

|---|---|---|

| 1 | Sustainability and the project concept | Relationship between the general concepts of the house and sustainability, assessing the team’s understanding of the sustainable built environment and how this understanding is incorporated into their project. |

| 2 | Construction system | Sustainability merits of the selected system, considering aspects such as water use, solid waste, time, recyclability, and health and safety. |

| 3 | Materials | Sourcing and the environmental impact of selected materials, also considering their content and possibilities for reuse or recycling, embodied energy, durability, and maintenance requirements. |

| 4 | Bioclimatic strategies | Application of passive design strategies to maintain a healthy and comfortable indoor environment, minimizing energy requirements. |

| 5 | Active systems | Selection of equipment, HVAC, and lighting systems that effectively maintain a healthy, functional, and comfortable indoor environment while minimizing environmental impact. |

| 6 | Solar systems | Evaluation of the thermal solar, PV, and energy storage systems, including their environmental benefits and impacts, as well as their energy recovery time, CO2 emissions reduction, and durability. |

| 7 | Water | House and landscaping water conservation strategies, including low-flow or water-saving fixtures, high-efficiency irrigation solutions, greywater systems, water treatment, and water reuse. |

| 8 | Vegetation | Use of native and low-water-use locally adapted plants and low-maintenance solutions, as well as the use of plants, green walls, or roofs, to reduce the surrounding heat and the house’s energy demand. |

| 9 | Waste | Waste reduction, collection, and management, as well as its reuse or recycling possibilities, during the project’s construction, use, and end-of-life phases. |

| U-Value | (W/m2k) | |||||

|---|---|---|---|---|---|---|

| Name | Opaque | Transparency | SHGC | |||

| Wall | Roof | Floor | ||||

| Dubai Green Building Regulations | Al Sa’fat | 0.570 | 0.300 | - | 2.100/1.900 | 0.350/0.280/0.220 |

| Sustainable nZEB | The Sustainable City | 0.320 | 0.200 | 1.300 | 1.300 | - |

| Early Adopter | Masdar City Eco-Villa | 0.160 | - | - | - | - |

| Viginia Tech | 0.210 | 0.100 | 0.140 | - | - | |

| KNOW HOWse | 0.153 | 0.169 | 0.309 | 1.666 | 0.450 | |

| KSU | 0.195/0.192 | - | - | 1.533 | 0.270 | |

| Sapienza | 0.180 | 0.130 | 0.280 | 1.000 | - | |

| SDME 2018 | UOW | 0.161 | 0.200/0.164 a | 0.163 | 1.400 | - |

| Virtue | 0.133/0.127 b | 0.127 | 0.131 | - | - | |

| Efden | 0.126/0.133 | 0.126 | 0.193 | 1.000 | 0.280 | |

| Baity Kool | 0.120 | 0.140 | 0.160 | - | - | |

| TDIS | 0.060 | 0.075 | 0.072 | - | - |

| Category | Solutions |

|---|---|

| Responsive shading | Integrated into the 3D volumes and 2D wall panels are responsive shutters and solar protection devices that move, change, or adjust themselves as required. Use of dynamic solutions inspired by nature—biomimicry building envelopes. |

| Interior finishing | Integrate phase change materials (PCM) into the indoor boards to add dynamic thermal mass. Reduce the CO2 levels of the interior spaces, including CO2 adsorption materials as well as super-porous materials. The prefabricated elements can also utilize natural materials with humidity-control capabilities. |

| Advanced insulation | In addition to vacuum insulation panels (VIP) and insulation with aerogel utilized by SDME 2018 houses, prefabricated envelope elements can use other high-performance insulation, such as gas-filled panels (GFP). They can also use insulation enhanced with nanomaterials. For example, lightweight and highly effective insulation materials can be created using carbon nanotubes. |

| Dynamic glazing | Integrate photochromic or electrochromic glazing into the prefabricated panels and modules. Also, PCM, or polymer-filled glazing, can be integrated. |

| Renewables integration | Seamless integration of photovoltaic (PV), solar thermal, photovoltaic thermal (PVT), as well as daytime and night radiative cooling technology into prefabricated walls, roofs, or 3D modules. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshikh, Z.; Trepci, E.; Rodriguez-Ubinas, E. Sustainable Off-Site Construction in Desert Environments: Zero-Energy Houses as Case Studies. Sustainability 2023, 15, 11909. https://doi.org/10.3390/su151511909

Alshikh Z, Trepci E, Rodriguez-Ubinas E. Sustainable Off-Site Construction in Desert Environments: Zero-Energy Houses as Case Studies. Sustainability. 2023; 15(15):11909. https://doi.org/10.3390/su151511909

Chicago/Turabian StyleAlshikh, Zahraa, Esra Trepci, and Edwin Rodriguez-Ubinas. 2023. "Sustainable Off-Site Construction in Desert Environments: Zero-Energy Houses as Case Studies" Sustainability 15, no. 15: 11909. https://doi.org/10.3390/su151511909

APA StyleAlshikh, Z., Trepci, E., & Rodriguez-Ubinas, E. (2023). Sustainable Off-Site Construction in Desert Environments: Zero-Energy Houses as Case Studies. Sustainability, 15(15), 11909. https://doi.org/10.3390/su151511909