Comprehensive Research on the Near-Zero Energy Consumption of an Office Building in Hefei Based on a Photovoltaic Curtain Wall

Abstract

:1. Introduction

2. Model Analysis Process

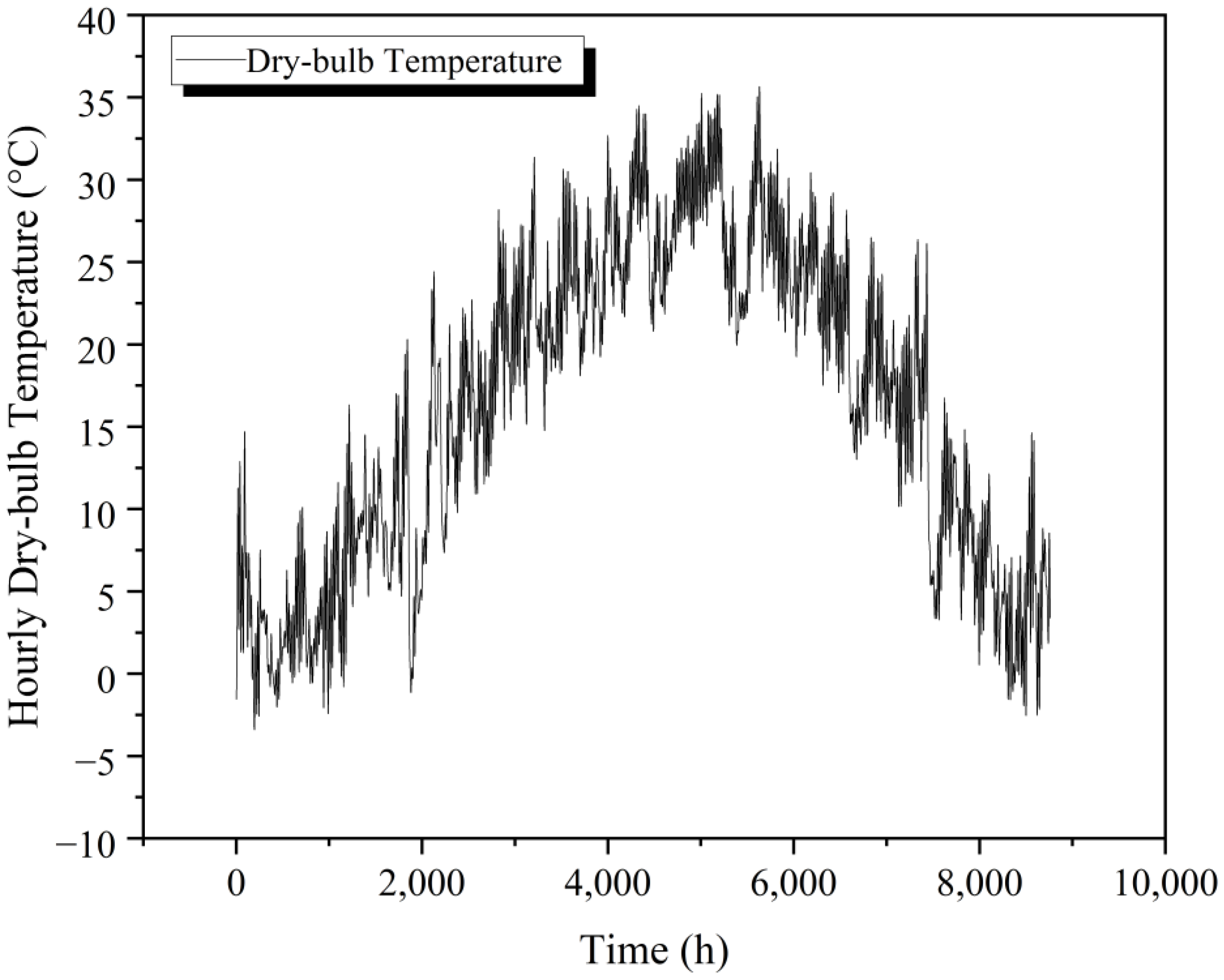

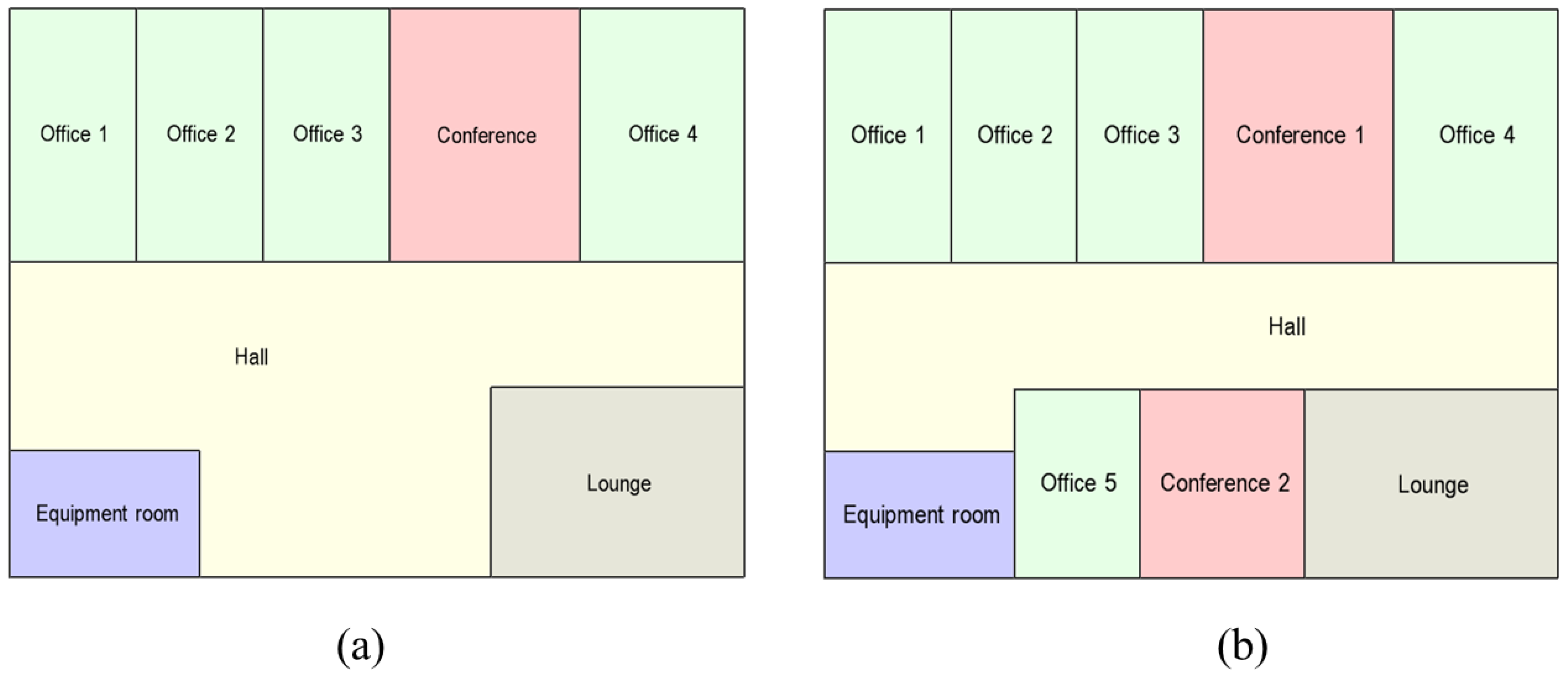

2.1. Overview of the Benchmark Building

2.2. Model Optimization Scheme

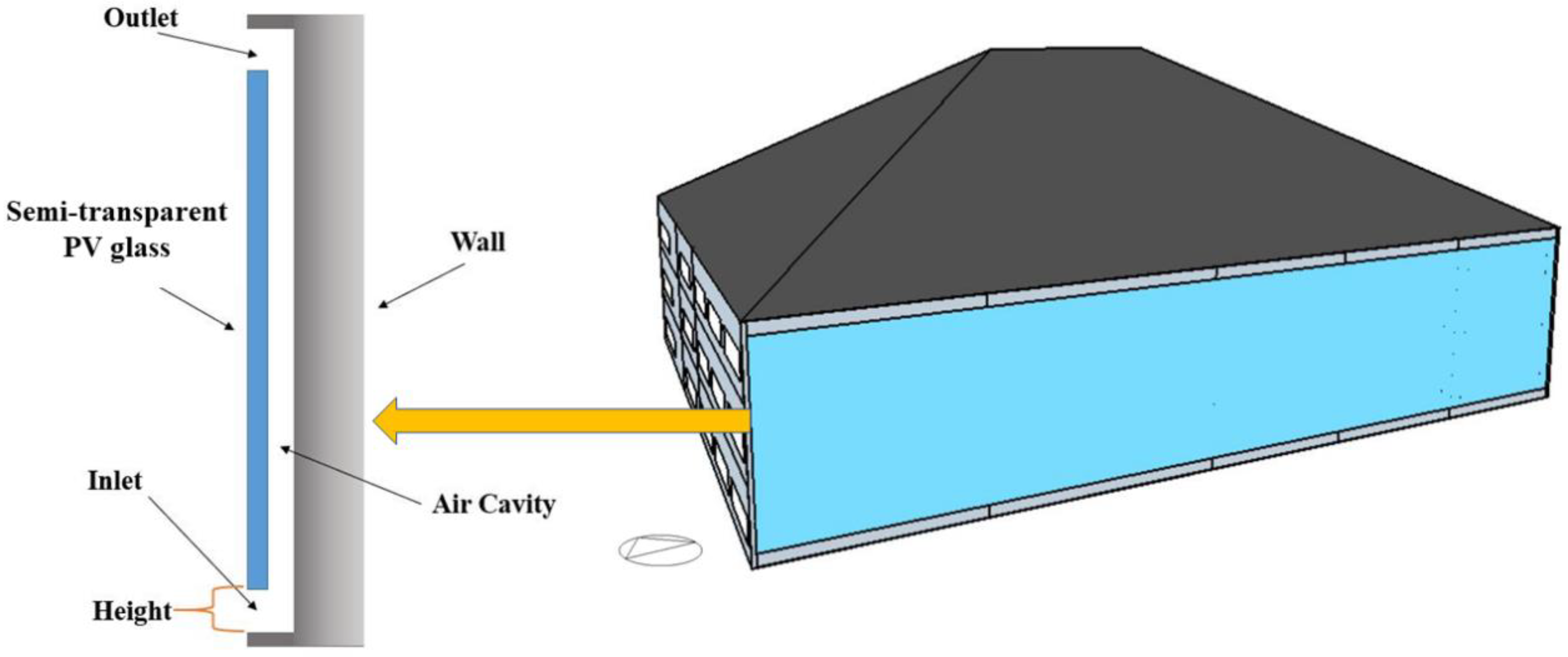

3. Photovoltaic Curtain Wall Size Analysis

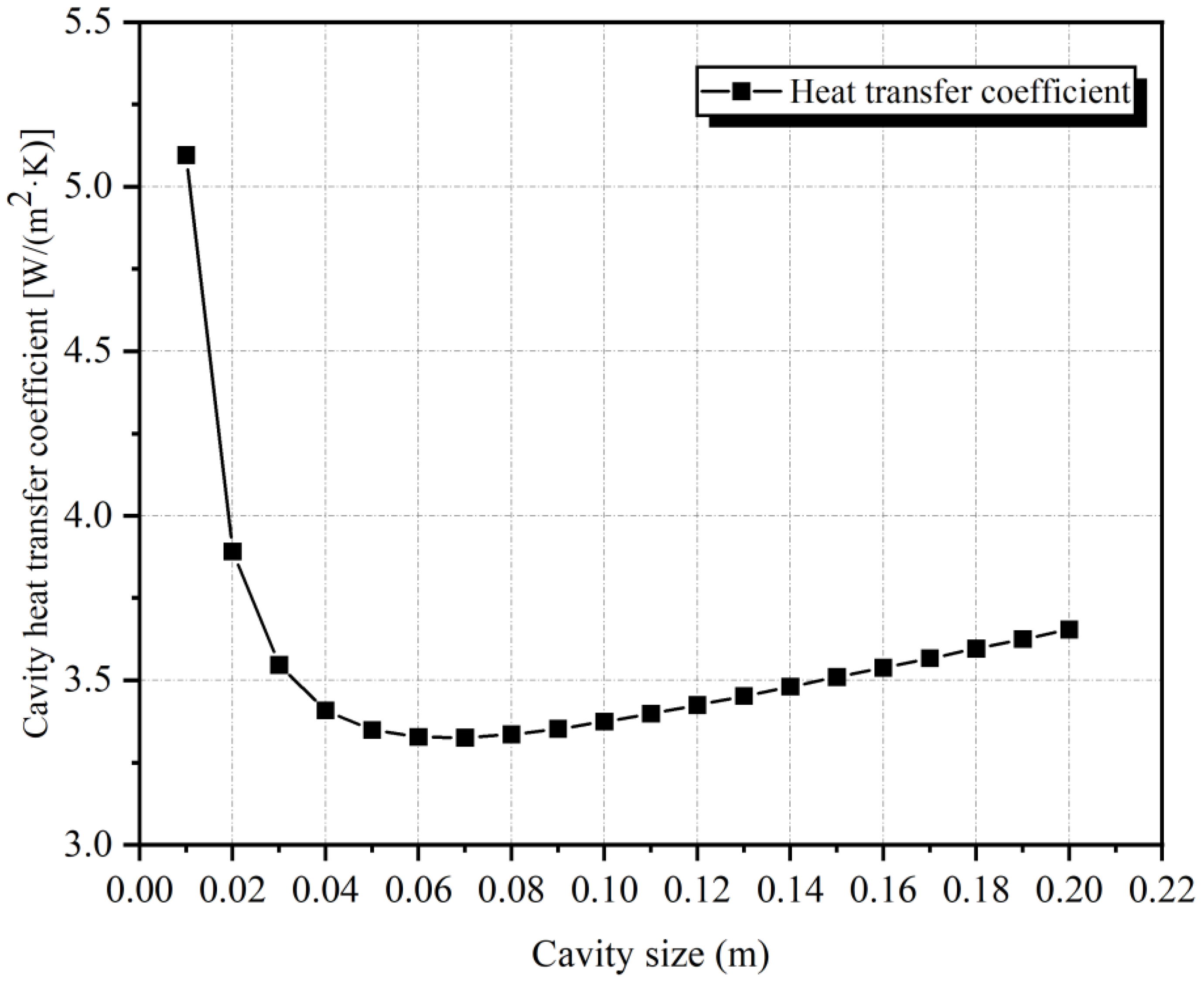

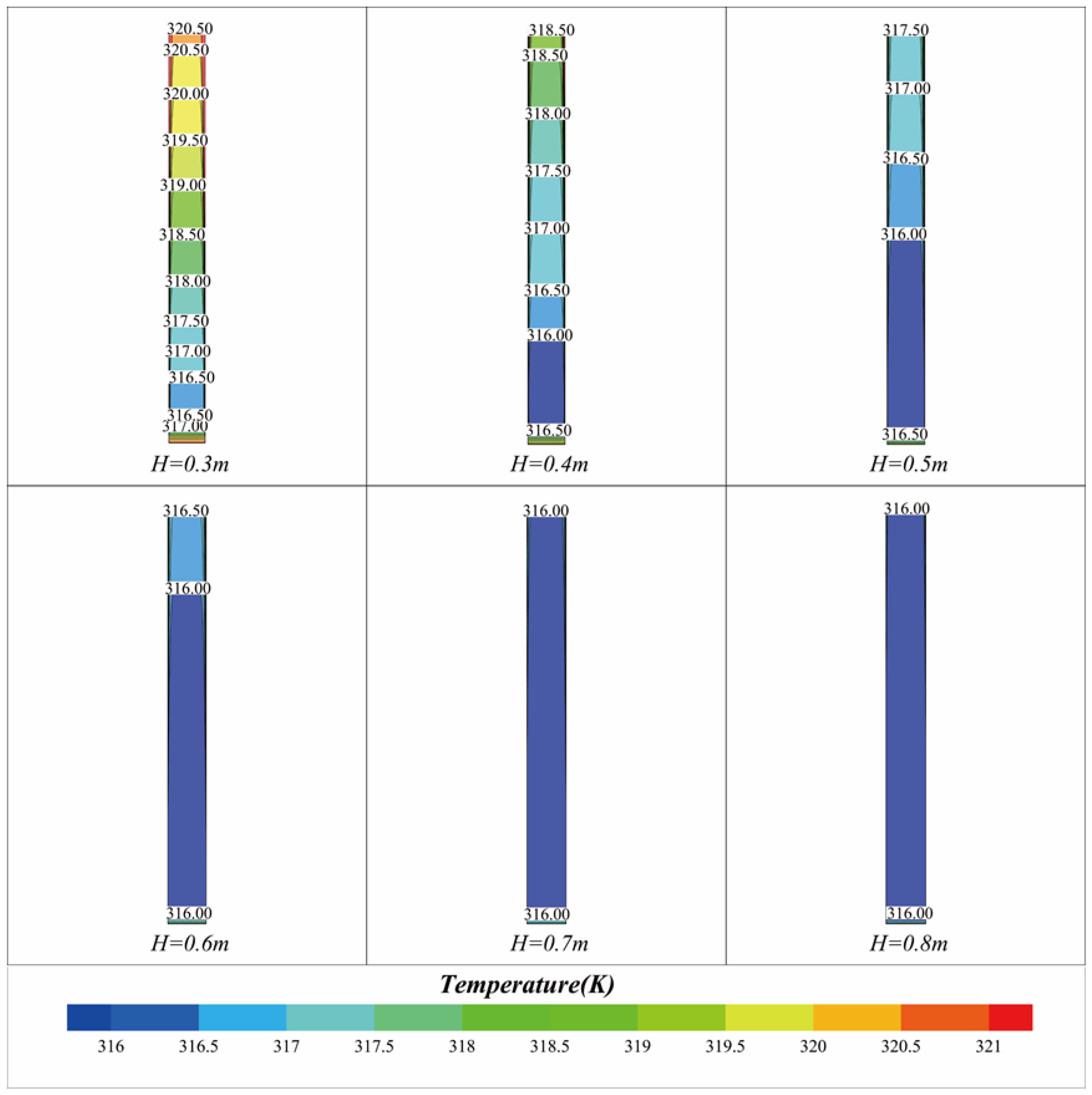

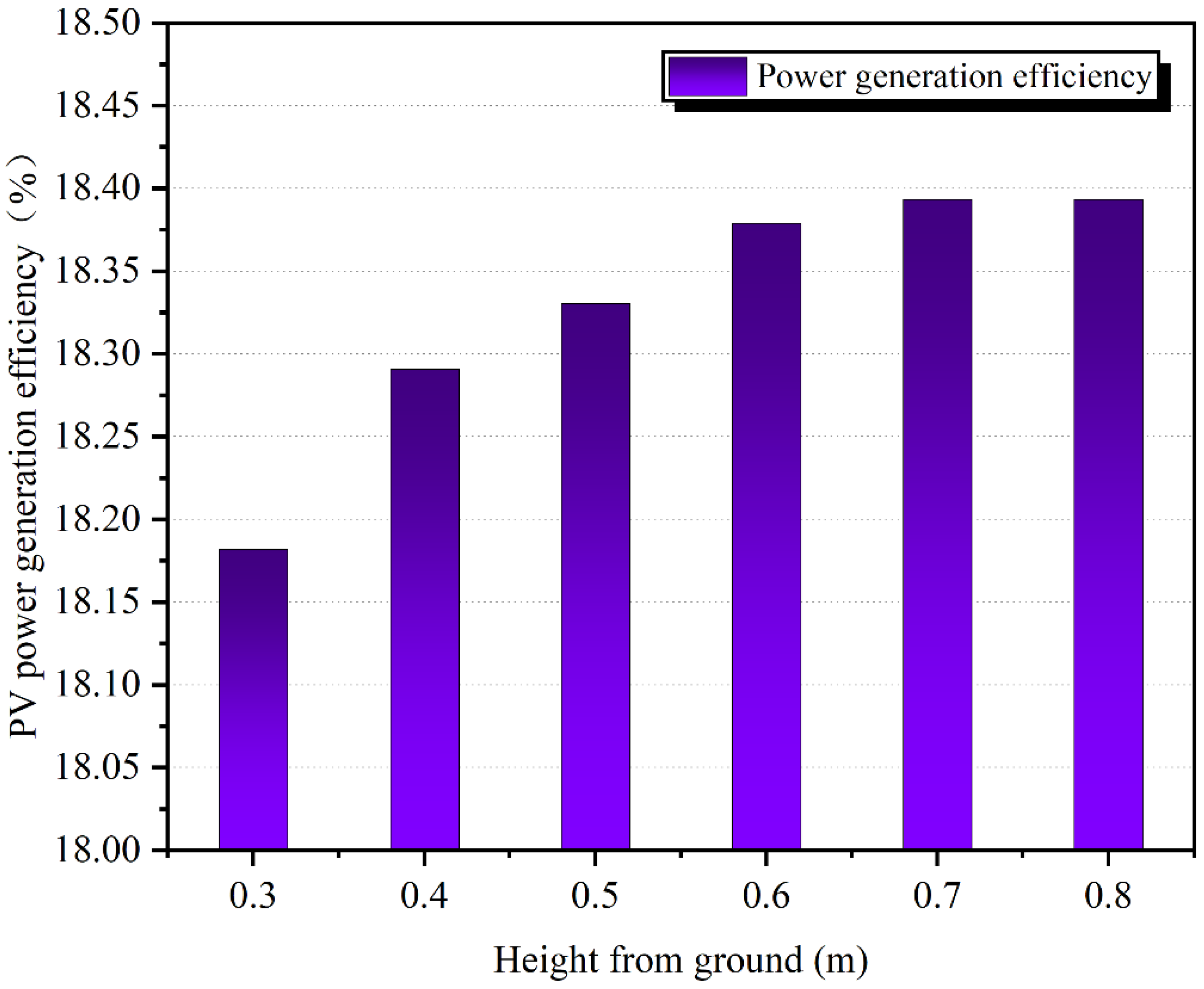

3.1. Photovoltaic Cavity Size

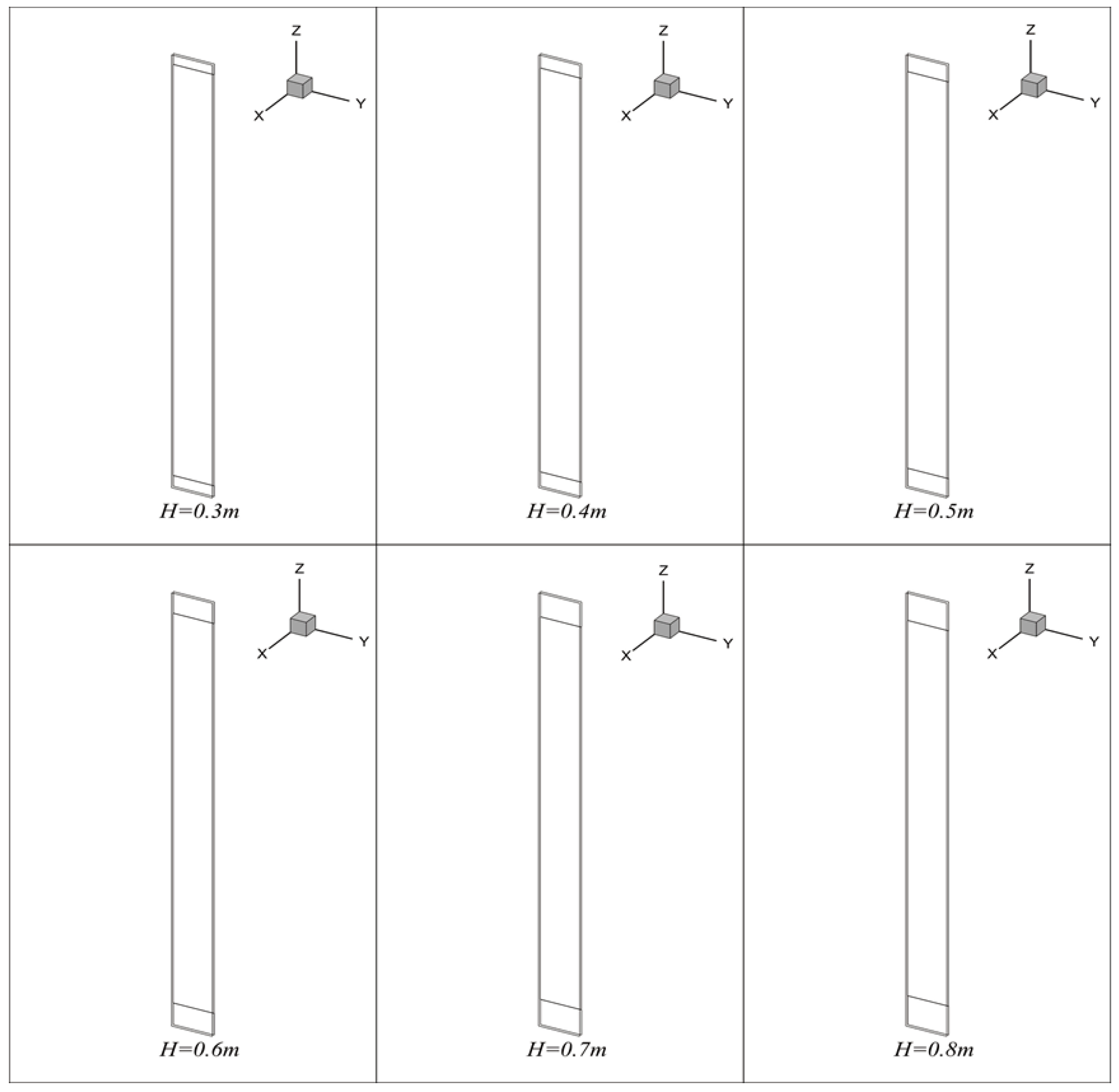

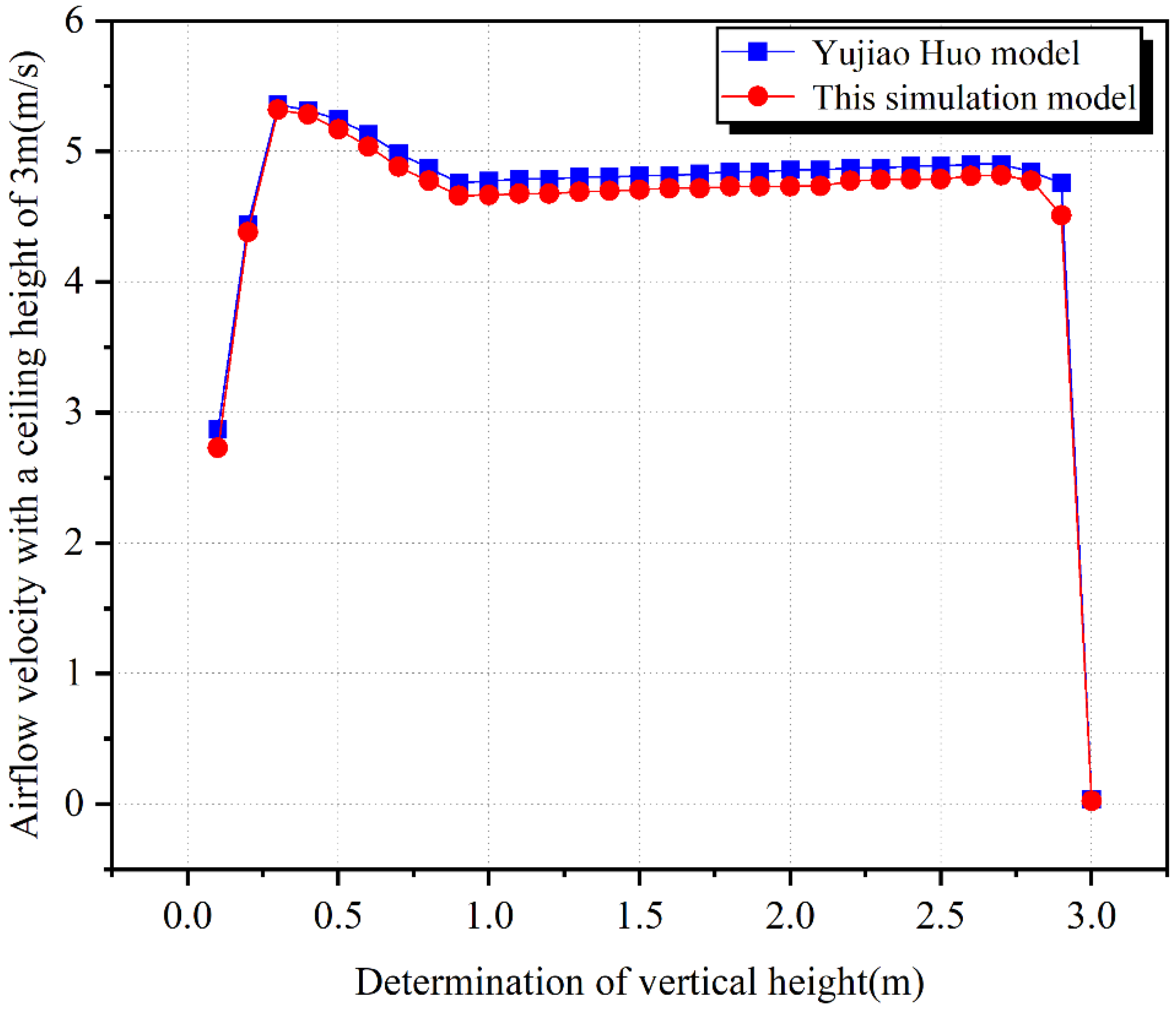

3.2. PV Curtain Wall Model Construction

3.3. Boundary Conditions and Numerical Processes

4. Results and Analysis

4.1. Analysis of Photovoltaic Curtain Wall Layout

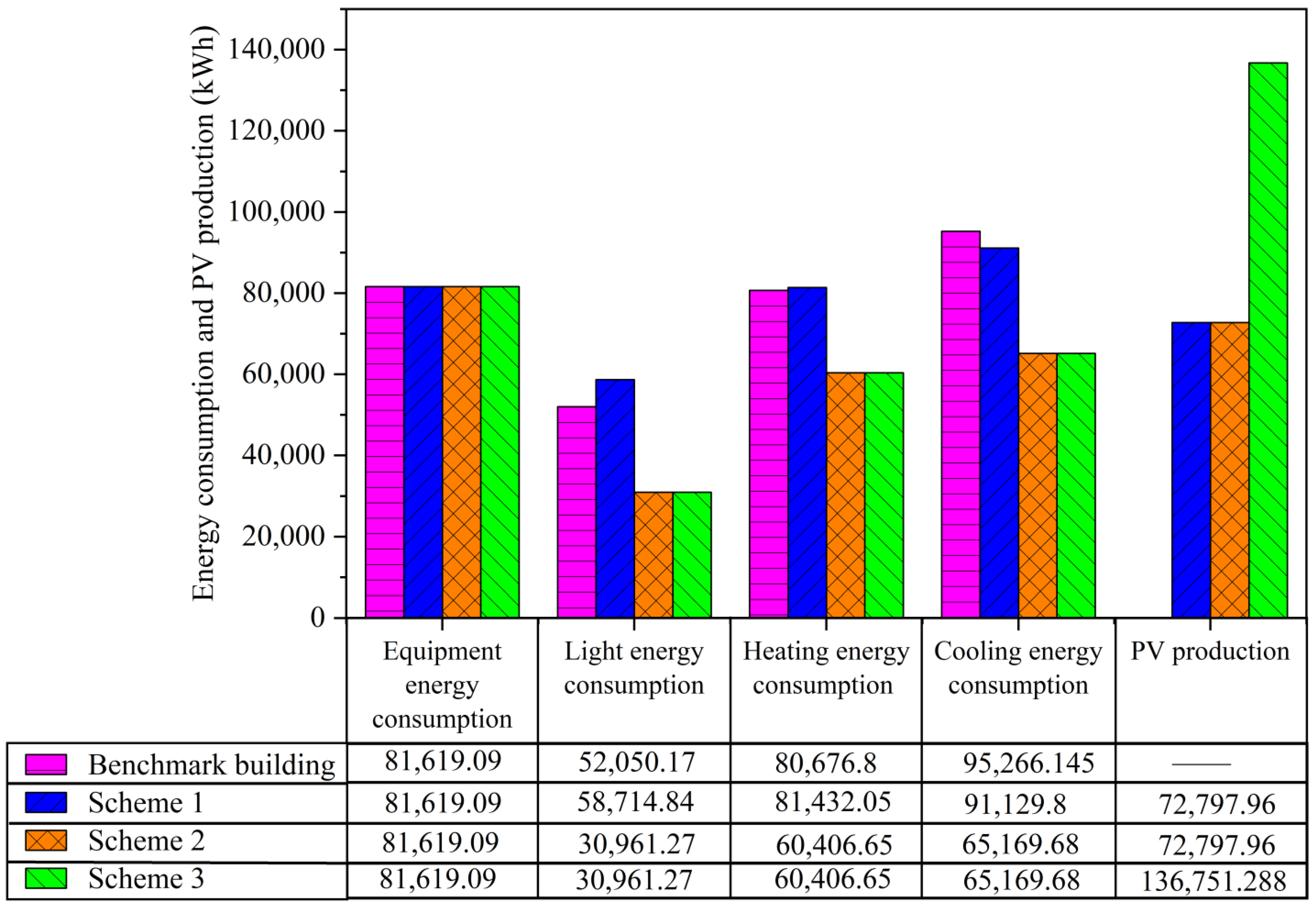

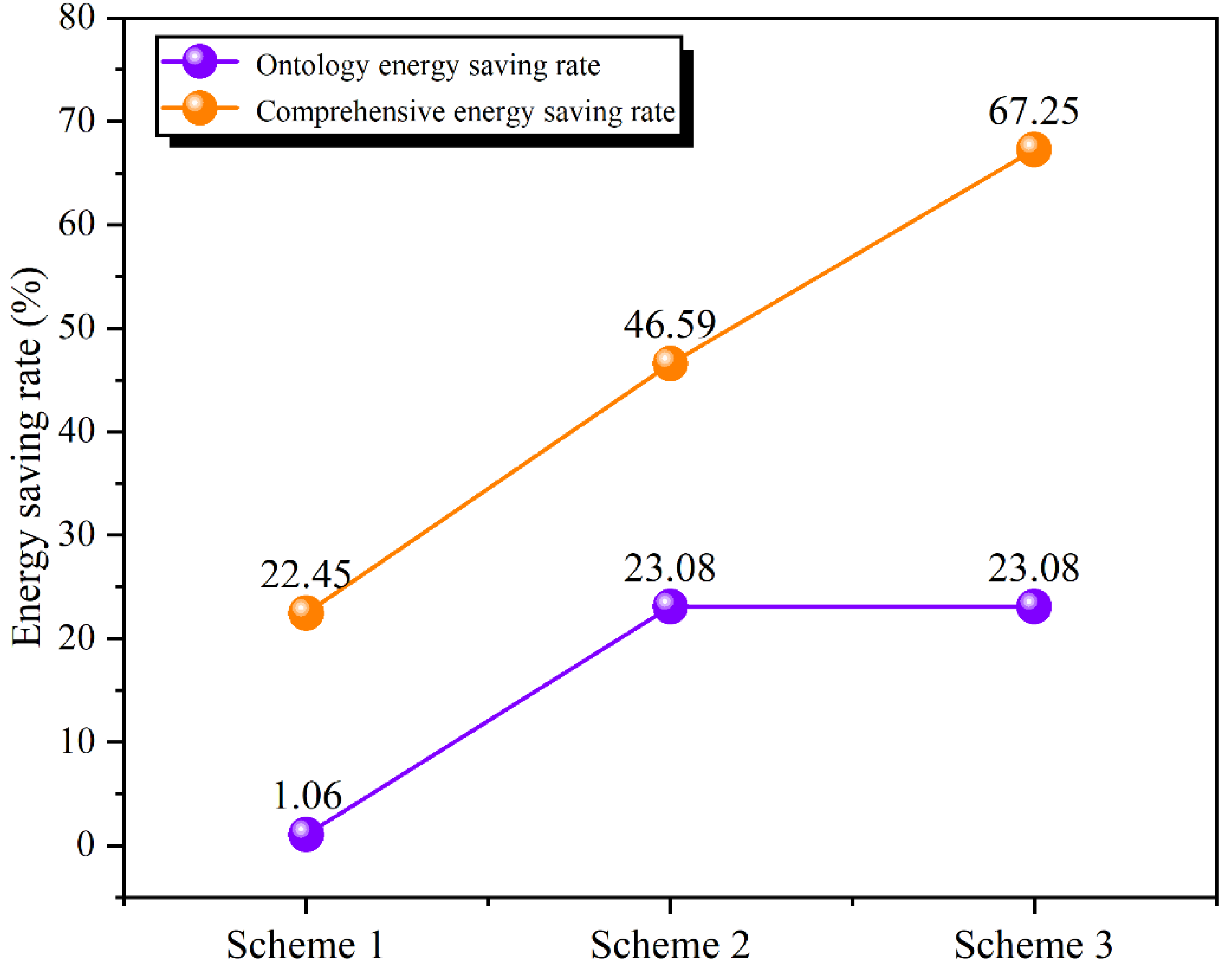

4.2. Comparison of Energy Consumption Results of Each Scheme

5. Conclusions

- (1)

- When the cavity size of the photovoltaic curtain wall in Hefei is 70 mm, the cavity heat transfer coefficient is the lowest and the heat insulation performance of the building is the best. For 12-m high public buildings, when the height is 0.7 m from the ground, the surface temperature of the photovoltaic curtain wall is the lowest and the temperature has the least impact on the efficiency of photovoltaic power generation;

- (2)

- The best installation position of the single-façade photovoltaic curtain wall is on the south façade of the building and the installation of a single façade wall will have a shading effect on the building, increasing the heating energy consumption of the building by 1.07% and reducing the cooling energy consumption by 4.34%;

- (3)

- The use of a single-façade photovoltaic curtain wall cannot meet the energy efficiency indicators of near-zero energy buildings, and it is necessary to cooperate with efficient air conditioning systems and lighting systems and install photovoltaic roofs. Only then can an energy-saving rate of not less than 20% and the comprehensive energy saving rate of no less than 60%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- GB/T51350-2019; Technical Standard for near Zero Energy Buildings. China Building Industry Press: Beijing, China, 2019.

- dos Santos Ferreira, G.; dos Santos, D.M.; Avila, S.L.; Albani, V.V.L.; Orsi, G.C.; Vieira, P.C.C.; Rodrigues, R.N. Short- and long-term forecasting for building energy consumption considering IPMVP recommendations, WEO and COP27 scenarios. Appl. Energy 2023, 339, 120980. [Google Scholar] [CrossRef]

- Research Report on Building Energy Consumption and Carbon Emissions in China (2022). Building 2023, 57–69. Available online: https://kns-cnki-net-443.webvpn.ahjzu.edu.cn/kcms/detail/detail.aspx?FileName=JANZ202302051&DbName=CJFQ2023 (accessed on 20 July 2023).

- Amaripadath, D.; Rahif, R.; Zuo, W.; Velickovic, M.; Voglaire, C.; Attia, S. Climate change sensitive sizing and design for nearly zero-energy office building systems in Brussels. Energy Build. 2023, 286, 112971. [Google Scholar] [CrossRef]

- Ahmed, A.; Ge, T.; Peng, J.; Yan, W.-C.; Tee, B.T.; You, S. Assessment of the renewable energy generation towards net-zero energy buildings: A review. Energy Build. 2022, 256, 111755. [Google Scholar] [CrossRef]

- D’Agostino, D.; Parker, D.; Epifani, I.; Crawley, D.; Lawrie, L. How will future climate impact the design and performance of nearly zero energy buildings (NZEBs)? Energy 2022, 240, 122479. [Google Scholar] [CrossRef]

- Jaysawal, R.K.; Chakraborty, S.; Elangovan, D.; Padmanaban, S. Concept of net zero energy buildings (NZEB)-A literature review. Clean. Eng. Technol. 2022, 11, 100582. [Google Scholar] [CrossRef]

- Sobhani, H.; Shahmoradi, F.; Sajadi, B. Optimization of the renewable energy system for nearly zero energy buildings: A future-oriented approach. Energy Convers. Manag. 2020, 224, 113370. [Google Scholar] [CrossRef]

- Jin, X.; Sun, Z.; Wang, D. Research on Detection and Evaluation Methods for Nearly Zero Energy Building. Build. Sci. 2022, 38, 1–10. [Google Scholar] [CrossRef]

- Dehwah, A.H.; Haredy, A.; Krarti, M. Retrofit analysis of historical buildings to net-zero energy: Case study of the Ain village, Saudi Arabia. Energy Build. 2022, 258, 111826. [Google Scholar] [CrossRef]

- Qi, H.; Huang, X.; Sheeraz, M. Green financing for renewable energy development: Driving the attainment of zero-emission targets. Renew. Energy 2023, 213, 30–37. [Google Scholar] [CrossRef]

- Liao, X.; Wang, W.; Zhou, Y. Investigating the Energy-Saving Effectiveness of Envelope Retrofits and Photovoltaic Systems: A Case Study of a Hotel in Urumqi. Sustainability 2023, 15, 9926. [Google Scholar] [CrossRef]

- Capizzi, G.; Sciuto, G.L.; Cammarata, G.; Cammarata, M. Thermal transients simulations of a building by a dynamic model based on thermal-electrical analogy: Evaluation and implementation issue. Appl. Energy 2017, 199, 323–334. [Google Scholar] [CrossRef]

- Kciuk, M.; Bijok, T.; Sciuto, G.L. Design and Modeling of Intelligent Building Office and Thermal Comfort Based on Probabilistic Neural Network. SN Comput. Sci. 2022, 3, 6. [Google Scholar] [CrossRef]

- Hachem-Vermette, C. Role of solar energy in achieving net zero energy neighborhoods. Sol. Energy Adv. 2022, 2, 100018. [Google Scholar] [CrossRef]

- Vassiliades, C.; Agathokleous, R.; Barone, G.; Forzano, C.; Giuzio, G.; Palombo, A.; Buonomano, A.; Kalogirou, S. Building integration of active solar energy systems: A review of geometrical and architectural characteristics. Renew. Sustain. Energy Rev. 2022, 164, 112482. [Google Scholar] [CrossRef]

- Kou, F.; Gong, Q.; Zou, Y.; Mo, J.; Wang, X. Solar application potential and thermal property optimization of a novel zero-carbon heating building. Energy Build. 2023, 279, 112688. [Google Scholar] [CrossRef]

- Panicker, K.; Anand, P.; George, A. Assessment of building energy performance integrated with solar PV: Towards a net zero energy residential campus in India. Energy Build. 2023, 281, 2244042. [Google Scholar]

- Tan, Y.; Peng, J.; Luo, Y.; Li, H.; Wang, M.; Zhang, F.; Ji, J.; Song, A. Daylight-electrical-thermal coupling model for real-time zero-energy potential analysis of vacuum-photovoltaic glazing. Renew. Energy 2023, 205, 1040–1056. [Google Scholar] [CrossRef]

- Wang, Q. Study on The Power Generation Performance of a Photovoltaic Curtain Wall System in Yunnan. Sol. Energy 2019, 5, 65–69. [Google Scholar]

- Shen, J. Application and Prospect of Building Integrated Photovoltaic Technology. Energy Energy Conserv. 2023, 49–52. [Google Scholar] [CrossRef]

- Hao, G.; Zhang, R.; Li, H.; Liu, C.; Yuan, X.; Ye, X.; Li, S.; Yang, N.; Zhang, J. Thermal Performance of Photovoltaic Skin Facades. Build. Sci. 2017, 33, 65–71, 88. [Google Scholar] [CrossRef]

- Reffat, R.M.; Ezzat, R. Impacts of design configurations and movements of PV attached to building facades on increasing generated renewable energy. Sol. Energy 2023, 252, 50–71. [Google Scholar] [CrossRef]

- Gonçalves, J.E.; Montazeri, H.; van Hooff, T.; Saelens, D. Performance of building integrated photovoltaic facades: Impact of exterior convective heat transfer. Appl. Energy 2021, 287, 116538. [Google Scholar] [CrossRef]

- Zhu, J.; He, G. Heat transfer coefficients of double skin facade windows. Sci.Technol. Built Environ. 2019, 25, 1143–1151. [Google Scholar] [CrossRef]

- Shukla, S.; Lee, E.; Lunt, R.R.; Anctil, A. Net energy and cost benefit of phthalocyanine and heptamethine transparent photovoltaics in commercial buildings. Sustain. Energy Technol. Assess. 2022, 53, 102631. [Google Scholar] [CrossRef]

- Qiu, C.; Yang, H. Daylighting and overall energy performance of a novel semi-transparent photovoltaic vacuum glazing in different climate zones. Appl. Energy 2020, 276, 115414. [Google Scholar]

- Huo, Y. Research on Daylight Environment and Energy Performance of Building Integrated See-Through Thin Film Photovoltaic Curtain Wall. Ph.D. Thesis, Tianjin University, Tianjin, China, 2016. [Google Scholar]

- Siddique, M.; Shahzad, N.; Umar, S.; Waqas, A.; Shakir, S.; Janjua, A.K. Performance assessment of Trombe wall and south façade as applications of building integrated photovoltaic systems. Sustain. Energy Technol. Assess. 2023, 57, 103141. [Google Scholar] [CrossRef]

- Cheng, Y.; Lu, X.; Feng, G.; Huang, K.; Wang, T. Heat Exchange Optimization of Photovoltaic Curtain Wall System in Near Zero Energy Building. J. Shenyang Jianzhu Univ. (Nat. Sci. Ed.) 2023, 39, 314–322. [Google Scholar]

- Kotarela, F.; Kyritsis, A.; Agathokleous, R.; Papanikolaou, N. On the exploitation of dynamic simulations for the design of buildings energy systems. Energy 2023, 271, 127002. [Google Scholar] [CrossRef]

- Hyun, J.Y.; Park, B.R.; Kim, N.H.; Moon, J.W. Building energy performance of DSSC BIPV windows in accordance with the lighting control methods and climate zones. Sol. Energy 2022, 244, 279–288. [Google Scholar]

- GB 50736-2012; Code for Design of Heating, Ventilation and Air Conditioning of Civil Buildings. Issued by the Ministry of Housing and Urban-Rural Development. China Architecture and Construction Press: Beijing, China, 2012.

- GB 50189-2015; Energy Saving Design Standard for Public Buildings. China Academy of Building Research; China Building Industry Press: Beijing, China, 2015.

- Jia, Y. Research on Building Intelligent Lighting Control System. Master’s Thesis, Hebei University of Science and Technology, Shijiazhuang, China, 2020. [Google Scholar] [CrossRef]

- Wang, F. Computational Fluid Dynamics Analysis; Tsinghua University Press: Beijing, China, 2004. [Google Scholar]

- Liu, R. Application of Photovoltaic Curtain Wall in Office Building. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2020. [Google Scholar] [CrossRef]

| Functional Partitions | Floor Space Per Capita (m2) | Occupancy Rate | Equipment Power Density (W/m2) | Device Usage | Lighting Power Density (W/m2) | Lighting Duration (h/Month) |

|---|---|---|---|---|---|---|

| Office | 10 | 32.7% | 13 | 32.7% | 9 | 240 |

| Conference | 3.33 | 16.7% | 5 | 61.8% | 9 | 180 |

| Lounge | 3.33 | 16.7% | 0 | 0.0% | 5 | 150 |

| Hall | 20 | 33.3% | 0 | 0.0% | 5 | 270 |

| Equipment room | 0 | 0.0% | 0 | 0.0% | 5 | 0 |

| Tm/°C | 20 | 30 | 40 |

| λa/W·(m·K)−1 | 0.0259 | 0.0267 | 0.0276 |

| Density kg/m³ | Specific Heat Capacity J/(kg·K) | Thermal Conductivity W/(m·K) | Viscosity Coefficient kg/(m·s) | Coefficient of Expansion 1/K |

|---|---|---|---|---|

| 1.2 | 1006.43 | 0.0242 | 1.78 × 10−5 | 3.19 × 10−3 |

| Material Name | Density kg/m3 | Specific Heat Capacity J/(kg·K) | Thermal Conductivity W/(m·K) | Absorptivity |

|---|---|---|---|---|

| PV glass | 2330 | 712 | 1.48 | 0.9 |

| Building walls | 1990 | 1880 | 1.75 | —— |

| Equipment kWh | Lighting kWh | Heating kWh | Cooling kWh | Total kWh | |

|---|---|---|---|---|---|

| Basic orientation | 81,619.09 | 51,495.98 | 80,564.98 | 92,159.73 | 305,839.78 |

| Rotate 90° | 81,619.09 | 52,812.79 | 81,168.06 | 97,844.07 | 313,444.01 |

| Rotate 180° | 81,619.09 | 51,934.13 | 80,425.95 | 92,913.83 | 306,893.00 |

| Rotate 270° | 81,619.09 | 51,957.78 | 80,548.21 | 98,146.95 | 312,272.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wu, F.; Lu, N.; Zhai, J. Comprehensive Research on the Near-Zero Energy Consumption of an Office Building in Hefei Based on a Photovoltaic Curtain Wall. Sustainability 2023, 15, 11701. https://doi.org/10.3390/su151511701

Wang H, Wu F, Lu N, Zhai J. Comprehensive Research on the Near-Zero Energy Consumption of an Office Building in Hefei Based on a Photovoltaic Curtain Wall. Sustainability. 2023; 15(15):11701. https://doi.org/10.3390/su151511701

Chicago/Turabian StyleWang, Haitao, Fanghao Wu, Ning Lu, and Jianfeng Zhai. 2023. "Comprehensive Research on the Near-Zero Energy Consumption of an Office Building in Hefei Based on a Photovoltaic Curtain Wall" Sustainability 15, no. 15: 11701. https://doi.org/10.3390/su151511701

APA StyleWang, H., Wu, F., Lu, N., & Zhai, J. (2023). Comprehensive Research on the Near-Zero Energy Consumption of an Office Building in Hefei Based on a Photovoltaic Curtain Wall. Sustainability, 15(15), 11701. https://doi.org/10.3390/su151511701