Social Sustainability of Raw Rubber Production: A Supply Chain Analysis under Sri Lankan Scenario

Abstract

1. Introduction

| Author (Year) | Area of Application | Scope | SLCA Database in Use | Content |

|---|---|---|---|---|

| Our study | Raw rubber production | Cradle-to-gate | SHDB | Our paper appraises the social footprint of three main raw rubber supply chains in Sri Lanka (i.e., crepe rubber, concentrated latex, and RSS), seeks hotspots, and evaluates the potential degree of improvement if those hotspots are addressed. |

| Arzoumanidis and D’Eusanio [27] (2023) | Accommodation Facility | Gate-togate | SHDB | This paper evaluates the social footprint of the supply chain of an Italian accommodation facility and identifies the hotspots. |

| Tragnone et al. [26] (2023) | Confetti production | Cradle-to-gate | PSILCA | This study compares the potential social risks of traditional almond-sugared confetti and Tenerelli-sugared almonds made by the same company in Italy. |

| Shi et al. [31] (2023) | Lithium iron phosphate battery production | Cradle-to-gate | SHDB | This study identifies the social profiles of three key Lithium iron phosphate battery production supply chains in China, Japan, and South Korea and avenues for their improvements. |

| Akhtar et al. [32] (2023) | Green hydrogen production via water electrolysis powered by renewable electricity from solar photovoltaic and wind farms | Cradle-to-gate | PSILCA | The study focused on Green hydrogen production in seven countries (the US, Chile, South Africa, Saudi Arabia, Oman, Australia, and China) to pinpoint social hotspots across respective value chains. |

| Iribarren et al. [33] (2022) | Green methanol and conventional fossil methanol production | Cradle-to-gate | PSILCA | This study identifies the most socially sound supply chain between Green and conventional fossil methanol supply chains (based in the US) by identifying social hotpots in respective supply chains. |

| Aranda et al. [34] (2021) | Meat production | Cradle-to-gate | PSILCA | This study quantifies the social footprint of a specific pork product supply chain based in Spain. |

| Martin and Herlaar [35] (2021) | Sweater production supply chains that use different types of wool | Cradle-to-gate | PSILCA | This study compares the social profiles of sweater production based on two waste wool supply chains in Europe to those of the same made of two conventional wool supply chains based in Australia and Uruguay. |

| Herrera Almanza et al. [36] (2020) | Textile production | Cradle-to-gate | PSILCA | This paper identifies the social hotpots of a value chain of a T-shirt retailed in the Netherlands. |

| Werker et al. [37] (2019) | Rare earth NdFeB permanent magnets production | Cradle-to-gate | PSILCA | This study investigates the potential social risks of rare earth permanent magnet production across three distinct production locations and their corresponding value chains. These locations include a fully Chinese-based operation, a chain consisting of Australian and Malaysian processes, and a third chain that combines processes in the United States and Japan. |

| Norris et al. [38] (2019) | Computer production | Cradle-to-gate | SHDB | This paper evaluates the social footprint of a computer manufactured in the US, considering its upstream supply chains, and seeks improvements. |

| Takeda et al. [39] (2019) | Renewable energy technologies | Cradle-to-gate | SHDB | This paper compares renewable technologies from a supply chain perspective and identifies their hotspots. |

| Schlör et al. [40] (2017) | Hydrogen production via alkaline water electrolysis | Cradle-to-gate | SHDB | This paper investigates the social footprints and hotspots of supply chains of three hydrogen production supply chains in Europe (i.e., Germany, Austria, and Spain). |

| Lenzo et al. [41] (2017) | Textile production | Cradle-to-gate | SHDB | This paper evaluates the social profile of a supply chain of a textile product based in Italy to identify hotspots. |

2. Raw Rubber Production

2.1. Rubber Cultivation

2.2. Crepe Rubber Manufacture

2.3. Concentrated Latex Manufacture

2.4. Ribbed Smoked Sheets Manufacture

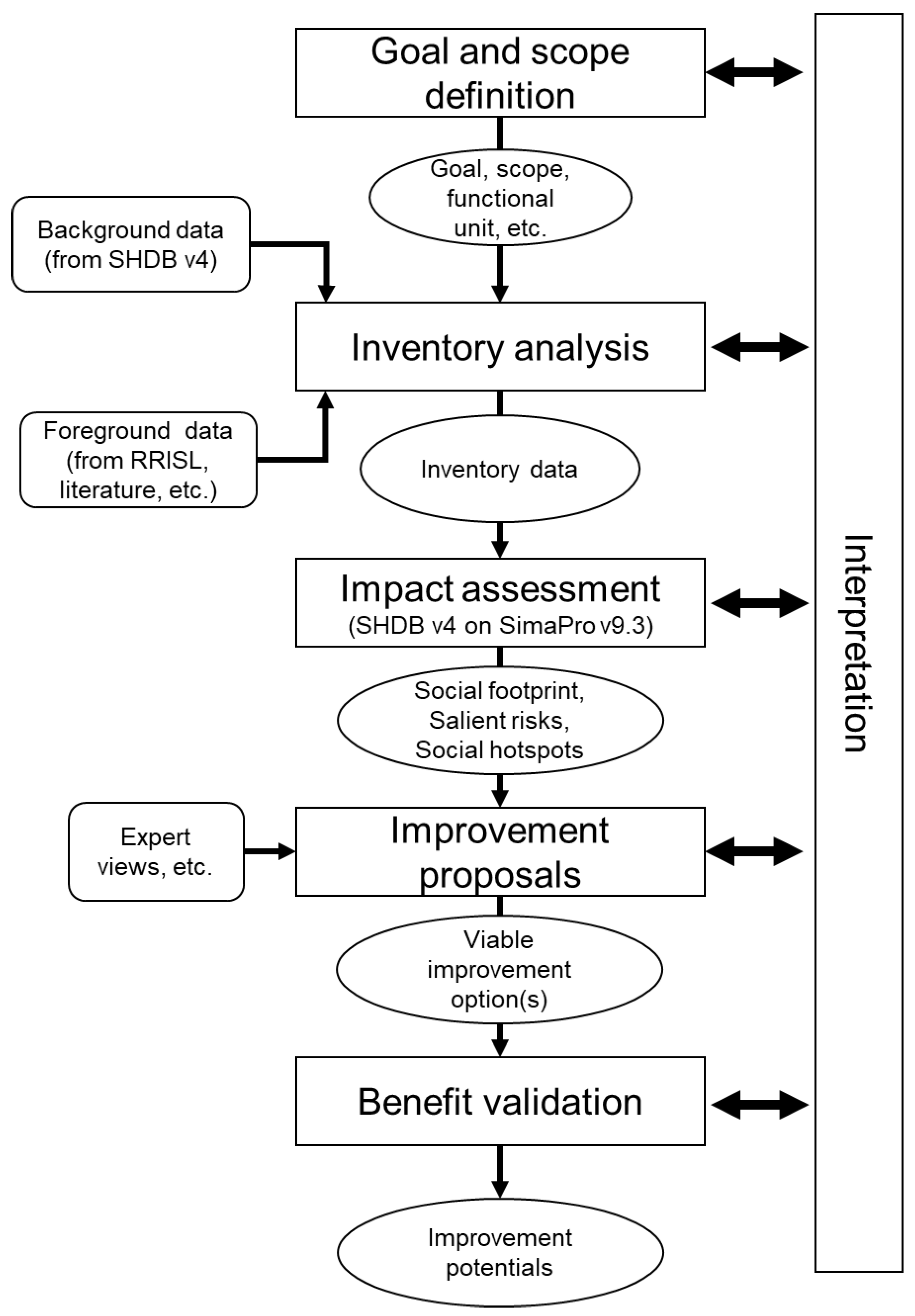

3. Methodology

3.1. Social Life Cycle Assessment

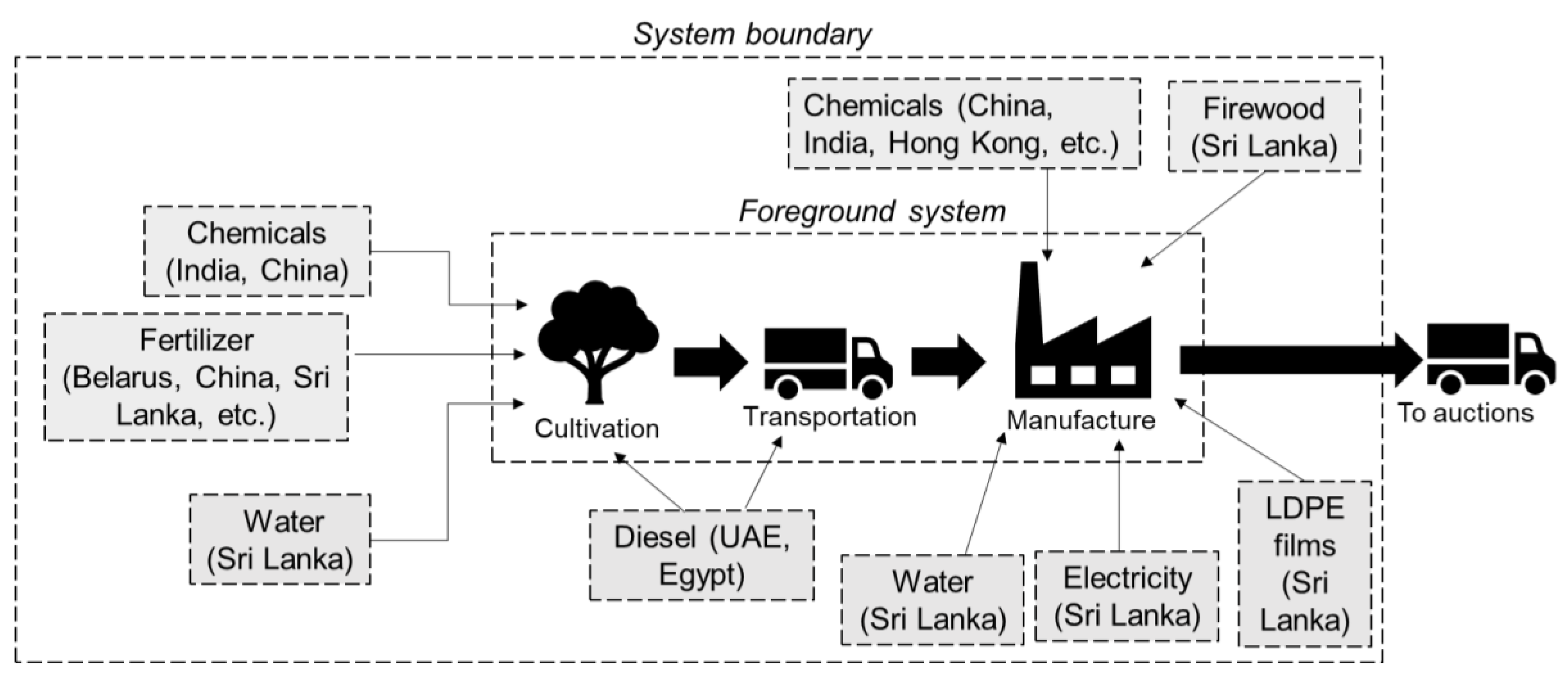

3.2. Goal and Scope Definition

3.3. Life Cycle Inventory Analysis

3.4. Life Cycle Impact Assessment

3.5. Improvement Proposals

3.6. Benefit Validation

3.7. Interpretation

4. Results and Discussion

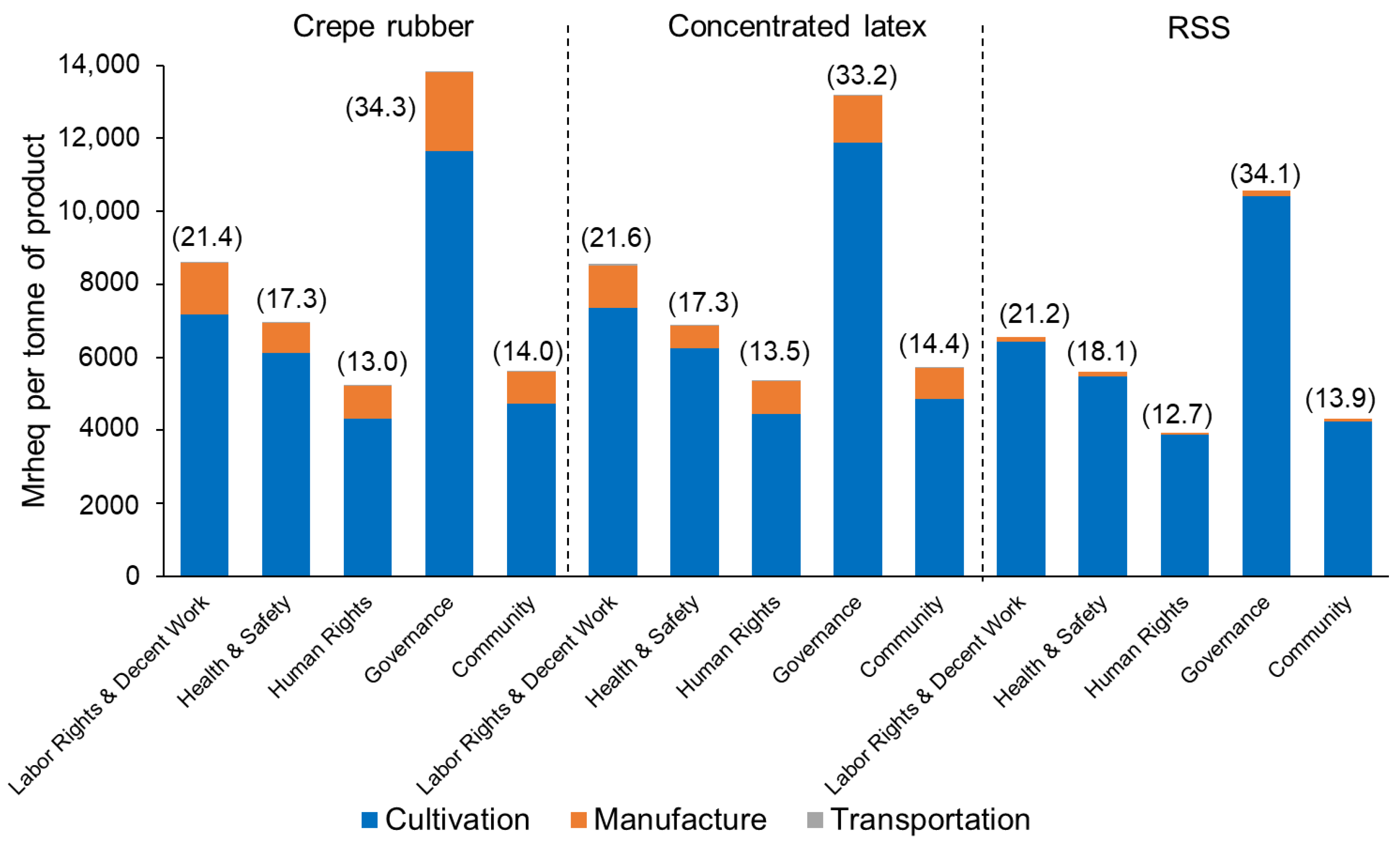

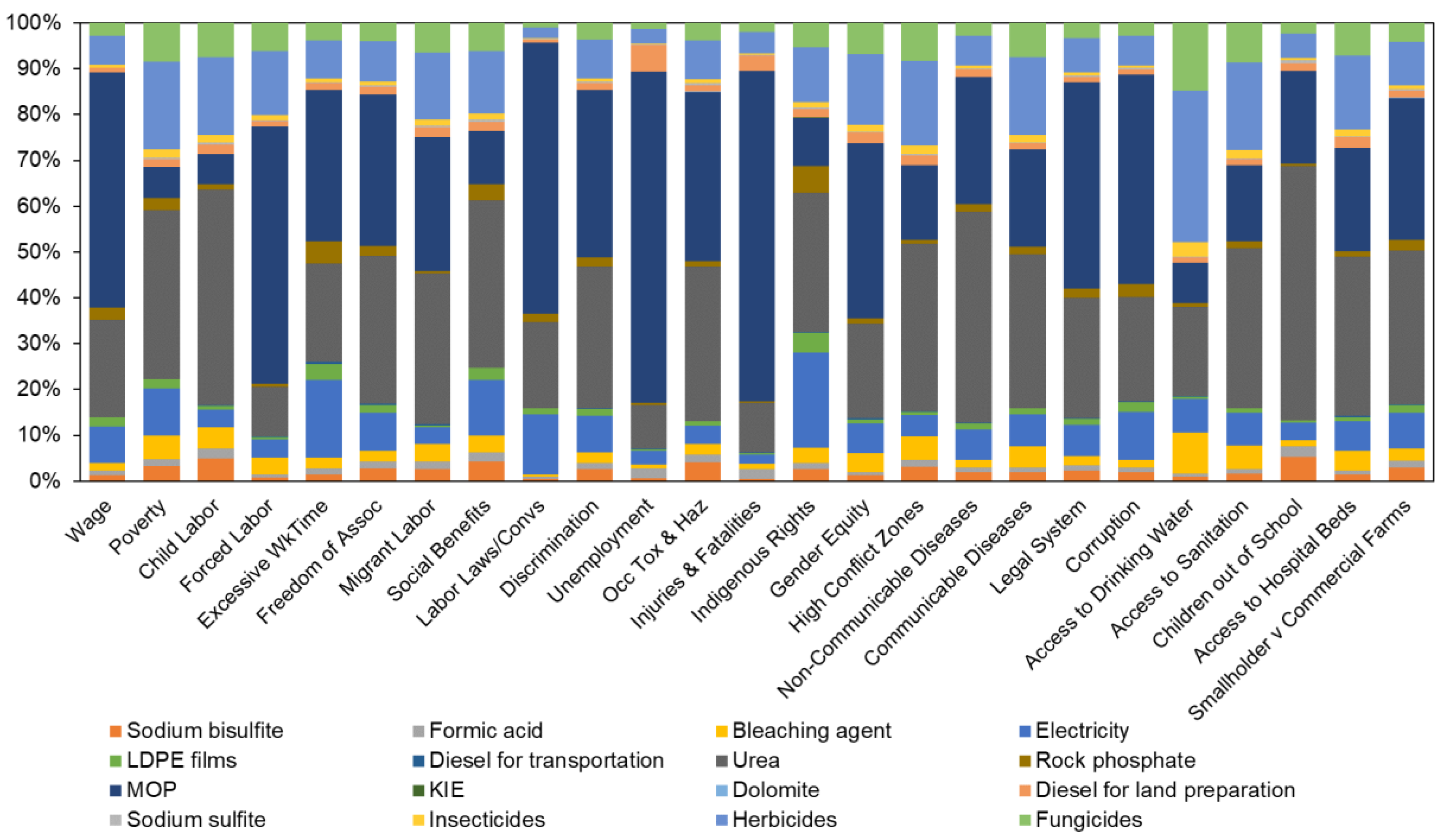

4.1. Social Footprints and Salient Risks in Supply Chains of Three Raw Rubber Types

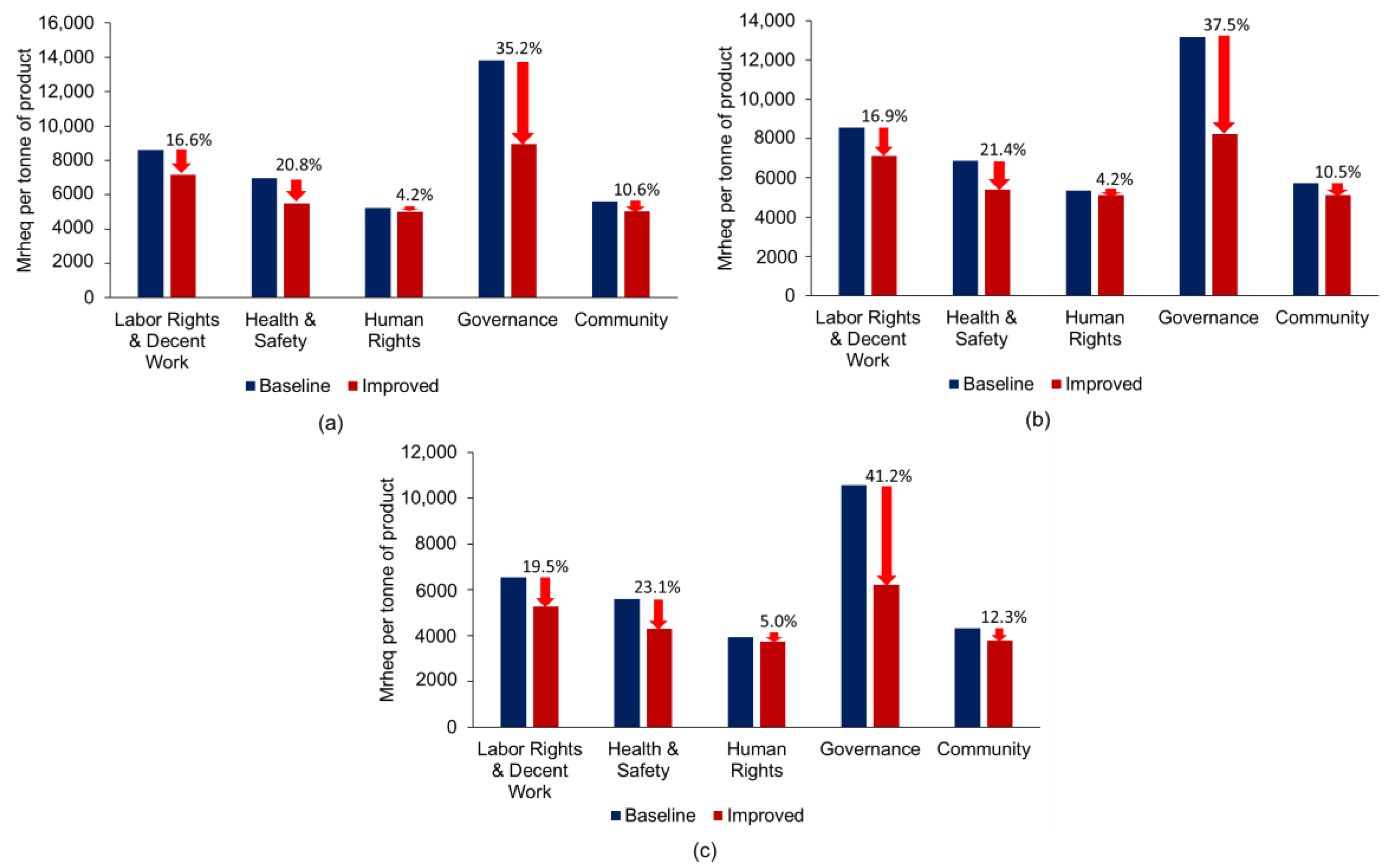

4.2. Improvement Proposals

4.3. Benefit Validation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dunuwila, P.; Rodrigo, V.H.L.; Goto, N. Improving Financial and Environmental Sustainability in Concentrated Latex Manufacture. J. Clean. Prod. 2020, 255, 120202. [Google Scholar] [CrossRef]

- IHS Markit. Rubber, Natural—Chemical Economics Handbook. Available online: https://www.ihs.com/products/natural-rubber-chemical-economics-handbook.html (accessed on 18 December 2017).

- Rubber Research Institute of Sri Lanka. Handbook of Rubber; Rubber Research Institute of Sri Lanka: Agalawatta, Sri Lanka, 2003.

- Jawjit, W.; Kroeze, C.; Rattanapan, S. Greenhouse Gas Emissions from Rubber Industry in Thailand. J. Clean. Prod. 2010, 18, 403–411. [Google Scholar] [CrossRef]

- Dunuwila, P.; Rodrigo, V.H.L.; Goto, N. Financial and Environmental Sustainability in Manufacturing of Crepe Rubber in Terms of Material Flow Analysis, Material Flow Cost Accounting and Life Cycle Assessment. J. Clean. Prod. 2018, 182, 587–599. [Google Scholar] [CrossRef]

- Tillekeratne, L.M.K.; Nugawela, A.; Seneviratne, W.M.G. Handbook of Rubber; Vishva Lekha Printers: Ratmalana, Sri Lanka, 2003. [Google Scholar]

- EMR. Market Research Reports|Strong Industry Analysis|Expert Market Research. Available online: https://www.expertmarketresearch.com/about-us (accessed on 15 March 2023).

- Bengtsen, P. Behind the Rubber Label; DanWatch: Copenhagen, Denmark, 2013. [Google Scholar]

- Sri Lanka Rubber Secretariat. Sri Lanka Rubber Industry Development Master Plan 2017–2026; Ministry of Plantation Industries of Sri lanka: Battaramulla, Sri Lanka, 2017. [Google Scholar]

- Jawjit, W.; Pavasant, P.; Kroeze, C. Evaluating Environmental Performance of Concentrated Latex Production in Thailand. J. Clean. Prod. 2015, 98, 84–91. [Google Scholar] [CrossRef]

- Dunuwila, P.; Rodrigo, V.H.L.; Goto, N. Assessing the Financial and Environmental Sustainability in Raw Rubber Processing; a Case Study with Ribbed Smoked Sheet Manufacture in Sri Lanka. Indones. J. Life Cycle Assess. Sustain. 2018, 2, 1–7. [Google Scholar] [CrossRef]

- Fagbemi, E.A.; Audu, M.; Ayeke, P.; Ohifuemen, A. Ribbed Smoked Rubber Sheet Production—Review. Ribbed Smoked Rubber Sheet Prod. Rev. 2018, 3, 38–41. [Google Scholar]

- Cecil, J.; Mitchell, P. Processing of Natural Rubber; FAO: Rome, Italy, 2003. [Google Scholar]

- Dunuwila, P.; Rodrigo, V.H.L.; Daigo, I.; Goto, N. Social Impact Improving Model Based on a Novel Social Life Cycle Assessment for Raw Rubber Production: A Case of a Sri Lankan Rubber Estate. J. Clean. Prod. 2022, 338, 130555. [Google Scholar] [CrossRef]

- UNESCAP. Country Study on Sri Lanka Using Global Value Chain Analysis: The Industrial Rubber and Electronic Products Sectors; United Nations: New York, NY, USA, 2011. [Google Scholar]

- Tillekeratne, L.M.K. Strategies to Curb Declining Rubber Production. Sunday Times Sri Lanka, 27 August 2017.

- Edirisinghe, J. Community Pressure and Environmental Compliance: Case of Rubber Processing in Sri Lanka. J. Environ. Prof. Sri Lanka 2013, 1, 14–23. [Google Scholar] [CrossRef]

- Leong, S.T.; Muttamara, S.; Laortanakul, P. Reutilization of Wastewater in a Rubber-Based Processing Factory: A Case Study in Southern Thailand. Resour. Conserv. Recycl. 2003, 37, 159–172. [Google Scholar] [CrossRef]

- Massoudinejad, M.; Mehdipour-Rabori, M.; Dehghani, M.H. Treatment of Natural Rubber Industry Wastewater through a Combination of Physicochemical and Ozonation Processes Citation: Massoudinejad M, Mehdipour-Rabori M, Dehghani MH. Treatment of Natural Rubber Industry Wastewater through a Combination of Physicoch. J. Adv. Environ. Health Res. 2015, 3, 242–249. [Google Scholar]

- Kumara, P.R.; Munasinghe, E.S.; Rodrigo, V.H.L.; Karunaratna, A.S. Carbon Footprint of Rubber/Sugarcane Intercropping System in Sri Lanka: A Case Study. Procedia Food Sci. 2016, 6, 298–302. [Google Scholar] [CrossRef]

- Tekasakul, P.; Tekasakul, S. Environmental Problems Related to Natural Rubber Production in Thailand. J. Aerosol Res. 2006, 21, 122–129. [Google Scholar]

- Tekasakul, S.; Tantichaowanan, M.; Otani, Y.; Kuruhongsa, P.; Tekasakul, P. Removal of Soot Particles in Rubber Smoking Chamber by Electrostatic Precipitator to Improve Rubber Sheet Color. Aerosol Air Qual. Res. 2006, 6, 1–14. [Google Scholar] [CrossRef]

- Rathnayake, W. Efficiency Study of a Single Day Smoke Dryer. Master’s Thesis, University of Moratuwa, Moratuwa, Sri Lanka, 2010. [Google Scholar]

- Dunuwila, P.; Rodrigo, V.H.L.; Goto, N. Sustainability of Natural Rubber Processing Can Be Improved: A Case Study with Crepe Rubber Manufacturing in Sri Lanka. Resour. Conserv. Recycl. 2018, 133, 417–427. [Google Scholar] [CrossRef]

- Pollok, L.; Spierling, S.; Endres, H.J.; Grote, U. Social Life Cycle Assessments: A Review on Past Development, Advances and Methodological Challenges. Sustainability 2021, 13, 10286. [Google Scholar] [CrossRef]

- Tragnone, B.M.; Serreli, M.; Arzoumanidis, I.; Pelino, C.A.; Petti, L. Using the Product Social Impact Life Cycle Assessment (PSILCA) Database for Product Comparison: Confetti Case Study. Int. J. Life Cycle Assess. 2023, 1, 1031–1053. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; D’Eusanio, M. Tourism Sector: The Supply Chain Social Footprint of an Italian Accommodation Facility. Sustainability 2023, 15, 9793. [Google Scholar] [CrossRef]

- Sri Lanka Export Development Board. Industry Capability of Sri Lankan Rubber & Rubber Products Sector. Available online: https://www.srilankabusiness.com/rubber/about/industry-capability.html (accessed on 15 March 2023).

- Dunuwila, P. Integration of Process Analysis and Decision-Making Tools for the Sustainability Improvements in Raw Rubber Manufacture. Ph.D. Thesis, Toyohashi University of Technology, Toyohashi, Japan, 2019. [Google Scholar]

- Rubber Research Institute of Sri Lanka. Available online: http://www.rrisl.lk/sub_pags/statistics.html (accessed on 10 May 2016).

- Shi, Y.; Chen, X.; Jiang, T.; Jin, Q. Social Life Cycle Assessment of Lithium Iron Phosphate Battery Production in China, Japan and South Korea Based on External Supply Materials. Sustain. Prod. Consum. 2023, 35, 525–538. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Khan, H.; Liu, J.J.; Na, J. Green Hydrogen and Sustainable Development—A Social LCA Perspective Highlighting Social Hotspots and Geopolitical Implications of the Future Hydrogen Economy. J. Clean. Prod. 2023, 395, 136438. [Google Scholar] [CrossRef]

- Iribarren, D.; Calvo-Serrano, R.; Martín-Gamboa, M.; Galán-Martín, Á.; Guillén-Gosálbez, G. Social Life Cycle Assessment of Green Methanol and Benchmarking against Conventional Fossil Methanol. Sci. Total Environ. 2022, 824, 153840. [Google Scholar] [CrossRef]

- Aranda, J.; Zambrana-Vásquez, D.; Del-Busto, F.; Círez, F. Social Impact Analysis of Products under a Holistic Approach: A Case Study in the Meat Product Supply Chain. Sustainability 2021, 13, 12163. [Google Scholar] [CrossRef]

- Martin, M.; Herlaar, S. Sustainable Production and Consumption Environmental and Social Performance of Valorizing Waste Wool for Sweater Production. Sustain. Prod. Consum. 2021, 25, 425–438. [Google Scholar] [CrossRef]

- Herrera Almanza, A.M.; Corona, B. Using Social Life Cycle Assessment to Analyze the Contribution of Products to the Sustainable Development Goals: A Case Study in the Textile Sector. Int. J. Life Cycle Assess. 2020, 25, 1833–1845. [Google Scholar] [CrossRef]

- Werker, J.; Wulf, C.; Zapp, P.; Schreiber, A.; Marx, J. Social LCA for Rare Earth NdFeB Permanent Magnets. Sustain. Prod. Consum. 2019, 19, 257–269. [Google Scholar] [CrossRef]

- Norris, C.B.; Norris, G.A.; Azuero, L.; Pflueger, J. Creating Social Handprints: Method and Case Study in the Electronic Computer Manufacturing Industry. Resources 2019, 8, 176. [Google Scholar] [CrossRef]

- Takeda, S.; Keeley, A.R.; Sakurai, S.; Managi, S.; Norris, C.B. Are Renewables as Friendly to Humans as to the Environment?: A Social Life Cycle Assessment of Renewable Electricity. Sustainability 2019, 11, 1370. [Google Scholar] [CrossRef]

- Schlör, H.; Jan, K.; Petra, Z.; Andrea, S.; Jürgen-Friedrich, H. The Social Footprint of Hydrogen Production-A Social Life Cycle Assessment (S-LCA) of Alkaline Water Electrolysis Selection and/or Peer-Review under Responsibility of ICAE. Energy Procedia 2017, 105, 3038–3044. [Google Scholar] [CrossRef]

- Lenzo, P.; Traverso, M.; Salomone, R.; Ioppolo, G. Social Life Cycle Assessment in the Textile Sector: An Italian Case Study. Sustainability 2017, 9, 2092. [Google Scholar] [CrossRef]

- Birnbach, M.; Lehmann, A.; Naranjo, E.; Finkbeiner, M. A Condom’s Footprint—Life Cycle Assessment of a Natural Rubber Condom. Int. J. Life Cycle Assess. 2020, 25, 964–979. [Google Scholar] [CrossRef]

- Jawjit, W.; Pavasant, P.; Kroeze, C.; Tuffey, J. Evaluation of the Potential Environmental Impacts of Condom Production in Thailand. J. Integr. Environ. Sci. 2021, 18, 89–114. [Google Scholar] [CrossRef]

- Rubber Research Institute of Sri Lanka. Production of Budded Plants; Rubber Research Institute of Sri Lanka: Agalawatta, Sri Lanka, 2016.

- Rubber Research Institute of Sri Lanka. Fertilizer for Rubber; Rubber Research Institute of Sri Lanka: Agalawatta, Sri Lanka, 2016.

- Ekener, E.; Hansson, J.; Gustavsson, M. Addressing Positive Impacts in Social LCA—Discussing Current and New Approaches Exemplified by the Case of Vehicle Fuels. Int. J. Life Cycle Assess. 2018, 23, 556–568. [Google Scholar] [CrossRef]

- Zheng, X.; Easa, S.M.; Ji, T.; Jiang, Z. Modeling Life-Cycle Social Assessment in Sustainable Pavement Management at Project Level. Int. J. Life Cycle Assess. 2020, 25, 1106–1118. [Google Scholar] [CrossRef]

- The International Organization for Standardization (ISO). International Standard ISO 14040; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Benoît Norris, C.; Traverso, M.; Neugebauer, S.; Ekener, E.; Schaubroeck, T.; Russo Garrido, S.; Berger, M.; Valdivia, S.; Lehmann, A.; Finkbeiner, M.; et al. Guidelines for Social Life Cycle Assessment of Products and Organisations 2020; UNEP: Nairobi, Kenya, 2020. [Google Scholar]

- Andrews, E.S.; Barthel, L.-P.; Tabea, B.; Benoît, C.; Ciroth, A.; Cucuzzella, C.; Gensch, C.-O.; Hébert, J.; Lesage, P.; Manhart, A.; et al. Guidelines for Social Life Cycle Assessment of Products; UNEP: Nairobi, Kenya, 2009. [Google Scholar]

- Hossain, M.U.; Poon, C.S.; Dong, Y.H.; Lo, I.M.C.; Cheng, J.C.P. Development of Social Sustainability Assessment Method and a Comparative Case Study on Assessing Recycled Construction Materials. Int. J. Life Cycle Assess. 2018, 23, 1654–1674. [Google Scholar] [CrossRef]

- Benoît-Norris, C.; Vickery-Niederman, G.; Valdivia, S.; Franze, J.; Traverso, M.; Ciroth, A.; Mazijn, B. Introducing the UNEP/SETAC Methodological Sheets for Subcategories of Social LCA. Int. J. Life Cycle Assess. 2011, 16, 682–690. [Google Scholar] [CrossRef]

- NewEarth B SHDB. Available online: http://www.socialhotspot.org/ (accessed on 31 October 2021).

- Saling, P.; Morris, D.; Florea, A.; Visser, D.; Morao, A.; Musoke-Flores, E.; Alvarado, C.; Rawat, I.; Schenker, U.; Goedkoop, M.; et al. Handbook for Product Social Impact Assessment; PRé Sustainability: Amersfoort, The Netherlands, 2020. [Google Scholar]

- Hannouf, M.; Assefa, G. Subcategory Assessment Method for Social Life Cycle Assessment: A Case Study of High-Density Polyethylene Production in Alberta, Canada. Int. J. Life Cycle Assess. 2018, 23, 116–132. [Google Scholar] [CrossRef]

- Santos, A.; Benoît Norris, C.; Barbosa-Póvoa, A.; Carvalho, A. Social Life Cycle Assessment of Pulp and Paper Production—A Portuguese Case Study. Comput. Aided Chem. Eng. 2020, 48, 15–20. [Google Scholar] [CrossRef]

- Center for Global Trade Analysis. Global Trade Analysis Project (GTAP). Available online: https://www.gtap.agecon.purdue.edu/ (accessed on 15 March 2023).

- Benoît Norris, C.; Norris, G. The Social Hotspots Database Context of the SHDB. In The Sustainability Practitioner’s Guide to Social Analysis and Assessment; Murray, J., McBain, D., Wiedmann, T., Eds.; Common Ground Publishing: Champaign, IL, USA, 2015. [Google Scholar]

- IndiaMART IndiaMART. Available online: https://www.indiamart.com/ (accessed on 16 March 2023).

- U.S. Bureau of Labor Statistics CPI Inflation Calculator. Available online: https://www.bls.gov/data/inflation_calculator.htm (accessed on 16 March 2023).

- Datawheel. The Observatory of Economic Complexity|OEC—The Observatory of Economic Complexity. Available online: https://oec.world/ (accessed on 16 March 2023).

- Volza Volza.Com—Global Export Import Trade Data of 209 Countries. Available online: https://www.volza.com/ (accessed on 16 March 2023).

- PRé Sustainability about SimaPro—SimaPro. Available online: https://simapro.com/about/ (accessed on 16 March 2023).

- Economynext Sri Lanka Opens Floodgates for Corruption in Power Sector: Harsha|EconomyNext. Available online: https://economynext.com/sri-lanka-opens-floodgates-for-corruption-in-power-sector-harsha-95565/ (accessed on 16 March 2023).

- ILO. 8.Freedom of Association and Collective Bargaining. Available online: https://www.ilo.org/global/topics/dw4sd/themes/freedom-of-association/lang--en/index.htm (accessed on 16 March 2023).

- Dunuwila, P.; Hamada, K.; Takeyama, K.; Panasiuk, D.; Hoshino, T.; Morimoto, S.; Tahara, K.; Daigo, I. Influence of Different Allocation Methods for Recycling and Dynamic Inventory on CO2 Savings and Payback Times of Light-Weighted Vehicles Computed under Product- and Fleet-Based Analyses: A Case of Internal Combustion Engine Vehicles. Sustainability 2021, 13, 13935. [Google Scholar] [CrossRef]

| Impact Category | Subcategory | Crepe Rubber | CL | RSS |

|---|---|---|---|---|

| Labor rights and decent work | Wage | 262.9 (2.8) | 253.1 (2.7) | 205.2 (2.8) |

| Poverty | 417.3 (4.4) | 454.3 (4.8) | 317.7 (4.4) | |

| Child Labor | 446.6 (4.7) | 433.3 (4.6) | 319.3 (4.4) | |

| Forced Labor | 614.9 (6.5) | 655.6 (6.9) | 498.4 (6.8) | |

| Excessive WkTime | 206.6 (2.2) | 185.4 (2.0) | 140.3 (1.9) | |

| Freedom of Assoc | 1027.1 (10.8) | 990.9 (10.4) | 780.0 (10.7) | |

| Migrant Labor | 611.0 (6.4) | 645.2 (6.8) | 487.1 (6.7) | |

| Social Benefits | 326.0 (3.4) | 307.2 (3.2) | 225.9 (3.1) | |

| Labor Laws/Convs | 215.5 (2.3) | 197.0 (2.1) | 163.0 (2.2) | |

| Discrimination | 564.8 (5.9) | 554.1 (5.8) | 439.0 (6.0) | |

| Unemployment | 31.9 (0.3) | 31.6 (0.3) | 27.2 (0.4) | |

| Health & safety | Occ Tox & Haz | 572.8 (6.0) | 555.1 (5.9) | 448.1 (6.2) |

| Injuries & Fatalities | 130.0 (1.4) | 131.5 (1.4) | 111.9 (1.5) | |

| Human rights | Indigenous Rights | 156.6 (1.6) | 164.6 (1.7) | 117.7 (1.6) |

| Gender Equity | 283.6 (3.0) | 301.7 (3.2) | 221.1 (3.1) | |

| High Conflict Zones | 461.2 (4.8) | 493.0 (5.2) | 356.2 (4.9) | |

| Non-Communicable Diseases | 188.2 (2.0) | 153.0 (1.6) | 123.8 (1.7) | |

| Communicable Diseases | 215.7 (2.3) | 226.4 (2.4) | 164.7 (2.3) | |

| Governance | Legal System | 609.7 (6.4) | 598.6 (6.3) | 481.5 (6.6) |

| Corruption | 767.0 (8.1) | 718.6 (7.6) | 575.5 (7.9) | |

| Community | Access to Drinking Water | 128.0 (1.3) | 152.5 (1.6) | 94.3 (1.3) |

| Access to Sanitation | 224.2 (2.4) | 240.6 (2.5) | 170.8 (2.3) | |

| Children out of School | 270.3 (2.8) | 256.3 (2.7) | 214.8 (2.9) | |

| Access to Hospital Beds | 278.3 (2.9) | 296.1 (3.1) | 216.0 (3.0) | |

| Smallholder v Commercial Farms | 502.8 (5.3) | 487.5 (5.1) | 382.6 (5.3) | |

| Total | 9513.0 | 9483.1 | 7281.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dunuwila, P.; Rodrigo, V.H.L.; Daigo, I.; Goto, N. Social Sustainability of Raw Rubber Production: A Supply Chain Analysis under Sri Lankan Scenario. Sustainability 2023, 15, 11623. https://doi.org/10.3390/su151511623

Dunuwila P, Rodrigo VHL, Daigo I, Goto N. Social Sustainability of Raw Rubber Production: A Supply Chain Analysis under Sri Lankan Scenario. Sustainability. 2023; 15(15):11623. https://doi.org/10.3390/su151511623

Chicago/Turabian StyleDunuwila, Pasan, V. H. L. Rodrigo, Ichiro Daigo, and Naohiro Goto. 2023. "Social Sustainability of Raw Rubber Production: A Supply Chain Analysis under Sri Lankan Scenario" Sustainability 15, no. 15: 11623. https://doi.org/10.3390/su151511623

APA StyleDunuwila, P., Rodrigo, V. H. L., Daigo, I., & Goto, N. (2023). Social Sustainability of Raw Rubber Production: A Supply Chain Analysis under Sri Lankan Scenario. Sustainability, 15(15), 11623. https://doi.org/10.3390/su151511623