Advances in the Sustainable Use of Plastics in Horticulture—Perspectives, Innovations, Opportunities, and Limitations

Abstract

:1. Introduction

Why Plastics?

2. Materials and Methods

2.1. Source of Information

2.2. Sustainability Criteria

- ◦

- Reduce: plastic type, density, and longevity/lifespan;

- ◦

- Reuse: single-use or repeated use in the same or another year;

- ◦

- Recycle: degree and type of contamination;

- ▪

- plastic retrieval rate;

- ▪

- chance of recycling;

- ◦

- Replace: effective alternatives for the same purpose;

3. Results

3.1. Hail, Insect, and Shade Nets

3.2. Polytunnel

3.3. Irrigation Pipes

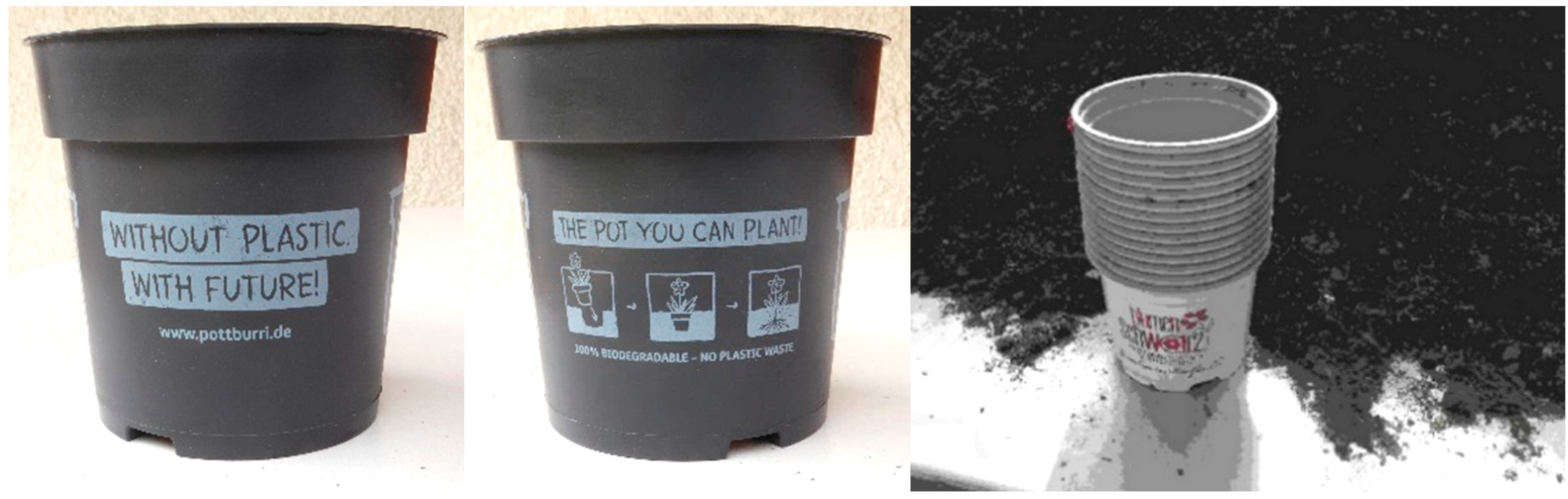

3.4. Flower Pots

3.5. Special Mulches

3.5.1. Fleeces

3.5.2. Solarisation and Soil Disinfection e.g. against SARD

3.5.3. Reflective White (or Silver) Mulches

3.5.4. Black Mulches in Nurseries

3.5.5. Asparagus Black/White Mulch

3.6. Black PE Mulch

Standard Black Mulch

4. Alternatives (Plastics) to Black Mulch-PE versus PLA

4.1. PLA–Biodegradable Plastic (Mulch)—A More Sustainable Option?: “Plough the Plastic”

4.2. LCA (Life Cycle Assessment) and GHG of Alternative (Biodegradable) Plastics

4.3. Hormonal and Endocrinal Activity—Beyond Sustainability

5. Outlook and Perspectives

5.1. Spray on Plastic Mulch from Renewable Sources

5.2. Microbial Plastic Digestion and Possibility of Upcycling Plastics

5.3. Organic Agri PV

5.4. Retrieval and Recycling—Part of the Solution at the End of Life

6. Towards a Sustainable Use of Plastics in Horticulture and Agriculture

6.1. Hail Net (HD-PE)

- (1)

- Prolonged use by careful rolling up over winter and minimising physical damage over, e.g., support poles and wires;

- (2)

- Careful net retrieval and collection (e.g., by like “ERDE”) for recycling.

6.2. Black Mulch (PE and PP)

- (1)

- (2)

- Careful PE mulch retrieval and recycling using schemes such as PolieCo, MAPLA, or ERDE

- (3)

- Search for non-fossil alternatives with an efficient biodegradation rate.

7. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization. Assessment of Agricultural Plastics and Their Sustainability—A Call for Action; Food and Agriculture Organization: Rome, Italy, 2021; 160p. [Google Scholar]

- UBA. Implementation of Sustainability Citeria—Implementierung von Nachhaltigkeitskriterien für die Sdtoffliche Nutzung; Umweltbundesamt: Berlin, Germany, 2019; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2019-08-19_texte_88-2019_be_biomassenutzung_kunststoffe.pdf (accessed on 10 November 2022).

- Blanke, M. The micro- and microplastic situation in horticulture—[GKL Tagung zur Bestandesaufnahme von Mikro- und Makroplastik im Gartenbau]. Erwerbs-Obstbau 2020, 62, 489–497. [Google Scholar] [CrossRef]

- Blanke, M.; Burdick, B. Food (miles) for Thought—Energy Balance for Locally-grown versus Imported Apple Fruit. Environ. Sci. Pollut. Res. 2005, 12, 125–127. [Google Scholar] [CrossRef] [PubMed]

- Briassoulis, D.; Babou, E.; Hiskakis, M.; Scarascia-Mugnozza, G.; Picuno, P.; Guarde, D.; Dejean, C. Review, mapping and analysis of the agricultural plastic waste generation and consolidation in Europe. Waste Manag. Res. 2013, 31, 1262–1278. [Google Scholar] [CrossRef] [PubMed]

- Lamont, W.J. Chapter 3—Plastic mulches for the production of vegetable crops. In A Guide to the Manufacture, Performance, and Potential of Plastics in Agriculture; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Scarascia-Mugnozza, G.; Sica, C.; Russo, G. Plastic materials in European agriculture: Actual use and perspectives. J. Agric. Eng. 2012, 42, 15–28. [Google Scholar] [CrossRef]

- Vuković, M.; Jurić, S.; Bandić, L.M.; Levaj, B.; Fu, D.-Q.; Jemrić, T. Sustainable Fruit Production—A Review: Innovative Netting Concepts and Their Mode of Action on Fruit Crops. Sustainability 2022, 14, 9264. [Google Scholar] [CrossRef]

- Blanke, M.M.; Golombek, S.D. Innovative Strategy to Reduce Single-Use Plastics in Sustainable Horticulture by a Refund Strategy for Flowerpots. Sustainability 2021, 13, 8532. [Google Scholar] [CrossRef]

- Mählmann, J.; (GKL Workshop, Neustadt/Weinstrasse, Germany). Personal communication, 2022.

- Schaefer, F.; Blanke, M.; Fels, J. Comparison of CO2e emissions associated with regional, heated or imported Asparagus. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector (LCA Food 2014), San Francisco, CA, USA, 8–10 October 2014; Schenk, R., Huizen, D., Eds.; American Center for Life Cycle Assessment: Vashon, WA, USA, 2014; pp. 1210–1214, ISBN 978-0-9882145-7-6. [Google Scholar]

- Stapleton, J.J. Toward Sustainably Managed Tree Establishment in a Changing Mediterranean Climate: A Case Study in Citrus. Acad. Lett. 2021, 2, 946. [Google Scholar] [CrossRef]

- Funke, K.; Blanke, M. Spatial and temporal enhancement of colour development in apples subjected to reflective material in the Southern Hemisphere. Horticulturae 2021, 7, 2. [Google Scholar] [CrossRef]

- Hess, P.; Kunz, A.; Blanke, M.M. Innovative Strategies for the Use of Reflective Foils for Fruit Colouration to Reduce Plastic Use in Orchards. Sustainability 2021, 13, 73. [Google Scholar] [CrossRef]

- Gür, B.; Kunz, A.; Blanke, M. Reflexionsfolien, Entlaubung oder Biostimulanzien—Methoden zur Intensivierung der Deckfarbe beim Apfel der Sorte ‚Braeburn Hillwell’ im Vergleich. Erwerbs-Obstbau 2023, 64, 1–11. [Google Scholar] [CrossRef]

- Peerzada, A.M.; Chauhan, B.S. Thermal Weed Control: History, Mechanisms and Impact. Non-Chemical Weed Control 2018. Available online: https://www.sciencedirect.com/science/article/abs/pii/B9780128098813000024 (accessed on 10 November 2022).

- Sander, M. Biodegradation of Polymeric Mulch Films in Agricultural Soils: Concepts, Knowledge Gaps, and Future Research Directions. Environ. Sci. Technol. 2019, 53, 2304–2315. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Sadeghi, K.; Jang, J.; Seo, J. Mechanical, chemical, and bio-recycling of biodegradable plastics: A review. Sci. Total Environ. 2023, 882, 163446. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, E.; Giordano, M.; Fiorentino, N.; El-Nakhel, C.; Pannico, A.; Di Mola, I.; Mori, M.; Kyriacou, M.C.; Colla, G.; Rouphael, Y. Appraisal of Biodegradable Mulching Films and Vegetal-Derived Biostimulant Application as Eco-Sustainable Practices for Enhancing Lettuce Crop Performance and Nutritive Value. Agronomy 2020, 10, 427. [Google Scholar] [CrossRef] [Green Version]

- Morra, L.; Bilotto, M.; Cerrato, D.; Coppola, R.; Leone, V.; Mignoli, E.; Pasquariello, M.S.; Petriccione, M.; Cozzolino, E. The Mater-Bi® biodegradable film for strawberry (Fragaria × ananassa Duch.) mulching: Effects on fruit yield and quality. Ital. J. Agron. 2016, 11, 203–206. [Google Scholar] [CrossRef] [Green Version]

- EN 13432; Packaging. Requirements for Packaging Recoverable through Composting and Biodegradation. Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging. European Standards: Plzen, Czech Republic, 2002.

- Andrade, C.S.; Palha, M.D.G.; Duarte, E. Biodegradable mulch films performance for autumn-winter strawberry production. J. Berry Res. 2014, 4, 193–202. [Google Scholar] [CrossRef]

- Giordano, M.; Amoroso, C.G.; El-Nakhel, C.; Rouphael, Y.; De Pascale, S.; Cirillo, C. An Appraisal of Biodegradable Mulch Films with Respect to Strawberry Crop Performance and Fruit Quality. Horticulturae 2020, 6, 48. [Google Scholar] [CrossRef]

- Bertling, J.; Zimmermann, T. UMSICHT Study by Fraunhofer. 2019. Available online: https://www.umsicht.fraunhofer.de/de/forschung-fuer-den-markt/kunststoffe-in-der-umwelt (accessed on 12 December 2022).

- Imulch. IUTA Duisburg—Project Co-Funded by the EU Regional Development Fund EFRE. 2021. Available online: https://renewable-carbon.eu/news/?p=67195 (accessed on 22 November 2022).

- Chen, B.; Cui, J.; Dong, W.; Yan, C. Effects of Biodegradable Plastic Film on Carbon Footprint of Crop Production. Agriculture 2023, 13, 816. [Google Scholar] [CrossRef]

| Plastic Specs | Main Crop | Material | Specs | Longevity | CO2e * |

|---|---|---|---|---|---|

| High structures | |||||

| Hail net | Apple | HD-PE | 32 µm | 8–20 | 2 |

| Polytunnel | Cherry | Trans LD PE | 200 µm | 6–12 | 2 |

| Low structures; crop or ground covers | |||||

| Reflective mulches | Apple | PP white | 8–10 a | 2–4 | |

| Mulch textile | Nurseries | PP black | 8–10 a | 2–4 | |

| Mulches | Veg. straw. | LD-PE black | 1–2 a | 2 | |

| Solarisation mulch | Bare soil | LD PE trans | 1 a | 2 | |

| Fleece | Vegetables | PP | 16–24 µm | 2 a | 2–4 |

| Asparagus | Asparagus | LD-PE | 120 µm | 8–10 a | 2 |

| Cultivation | |||||

| Irrigation pipes | Misc. | PP black | n.a. | 8–10 a | 2–4 |

| Plant pots | Misc. | PP black | n.a. | once | 2–4 |

| Plastic Specs | Main Crop | Use | Alternative |

|---|---|---|---|

| High structures | |||

| Hail net | Apple | Protect from hail, prevent sunburn, save water | No |

| Polytunnel | Cherry, strawberry | Prevent cherry cracking, force cherries and strawberries | No |

| Low structures/crop or ground covers | |||

| Reflective mulches | Apple | Produce the required fruit colouration, save mulching | Yes |

| Mulches | Veg. strawberry | Prevent weeds, save water and herbicides, and prevent soil erosion | Yes |

| Fleece | Vegetables | Protect from frost | Yes |

| Forcing | Asparagus | Force crop, prevent weeds, save herbicides, and prevent soil erosion | No |

| Cultivation | |||

| Irrigation pipes | All | Supply and save water | No |

| Solarisation | No | Disinfect and maintain moisture | Yes |

| Flower pots | Misc. | Physical plant protection | Yes |

| Clips | All | Tie young fruit trees/branches | Yes |

| Land Use | PE (30 µm PE/m2) | PLA/PBAT (10 µm/m2) |

|---|---|---|

| Strawberry | <1 µg MP/g | <0.1 µg MP/g soil |

| Asparagus | <1 µg MP/g | <0.1 µg MP/g soil |

| Grass meadow | <1 µg MP/g | <0.1 µg MP/g soil |

| Project Acronym | Topic | P I | Website |

|---|---|---|---|

| Alternatives to (fossil-based) plastic mulches | |||

| ABOW MuNaRo | Two-component sprayable mulch | TFZ Bavaria, Austria, Italy (South Tyrol) | https://www.tfz.bayern.de/ |

| Imulch (intelligent mulch) | PLA/PBAT as substitutes for PE mulch Umsicht, Fraunhofer | Carmen Wolf EU regional development fund ERDF | http://imulch.eu/ |

| Projects/studies involving bacterial breakdown of plastics | |||

| ENSURE | Bacterial breeding for digestion of plastics | Marc Kreutzbruck Stuttgart-EU horizon | http://www.project-ensure.eu/ |

| RECOVER | Biofermenter | EU horizon | https://recover-bbi.eu/project/ |

| Upcycling of retrieved plastics | |||

| Mix-Up | Bacterial breakdown for upcycling plastics | Lars Blank, RWTH Aachen | https://www.mix-up.eu/rwth-aachen-university |

| Plastic | Use | Reuse | Alternative | Sustainability |

|---|---|---|---|---|

| HD-PE | Hail shade, insect net | Yes (longevity) | No | |

| LD-PE | Polytunnel | Yes (longevity) | No | |

| LD-PE b/w | Asparagus | Yes (longevity) | No | |

| LD-PE transp | Solarisation | Yes | Maybe | |

| LD-PE black | Ground mulch | No | Maybe | |

| PP Black | Flower pots | No | Refund | |

| PP Black | Nursery | Yes | No | |

| PP white | Light reflection | Yes | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanke, M.M. Advances in the Sustainable Use of Plastics in Horticulture—Perspectives, Innovations, Opportunities, and Limitations. Sustainability 2023, 15, 11629. https://doi.org/10.3390/su151511629

Blanke MM. Advances in the Sustainable Use of Plastics in Horticulture—Perspectives, Innovations, Opportunities, and Limitations. Sustainability. 2023; 15(15):11629. https://doi.org/10.3390/su151511629

Chicago/Turabian StyleBlanke, Michael M. 2023. "Advances in the Sustainable Use of Plastics in Horticulture—Perspectives, Innovations, Opportunities, and Limitations" Sustainability 15, no. 15: 11629. https://doi.org/10.3390/su151511629

APA StyleBlanke, M. M. (2023). Advances in the Sustainable Use of Plastics in Horticulture—Perspectives, Innovations, Opportunities, and Limitations. Sustainability, 15(15), 11629. https://doi.org/10.3390/su151511629