Sustainable Performance Assessment towards Sustainable Consumption and Production: Evidence from the Indian Dairy Industry

Abstract

1. Introduction

Research Objectives (ROs)

2. Literature Review

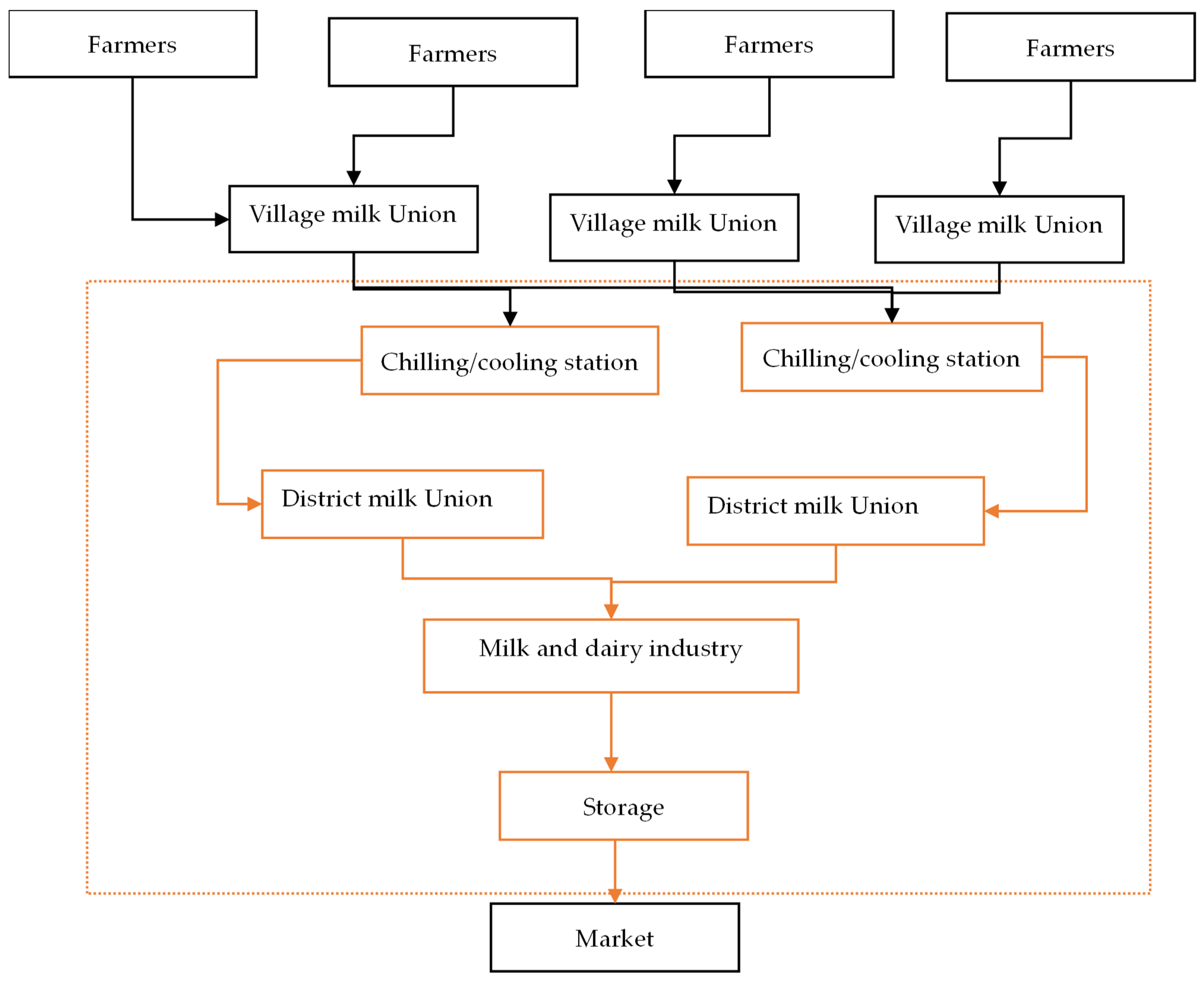

2.1. Sustainability in Dairy Supply Chain

2.2. Sustainable Performance Assessment in Dairy Supply Chain

2.3. Sustainability KPIs

2.4. Tools and Techniques

2.5. Research Gap

3. Methodology

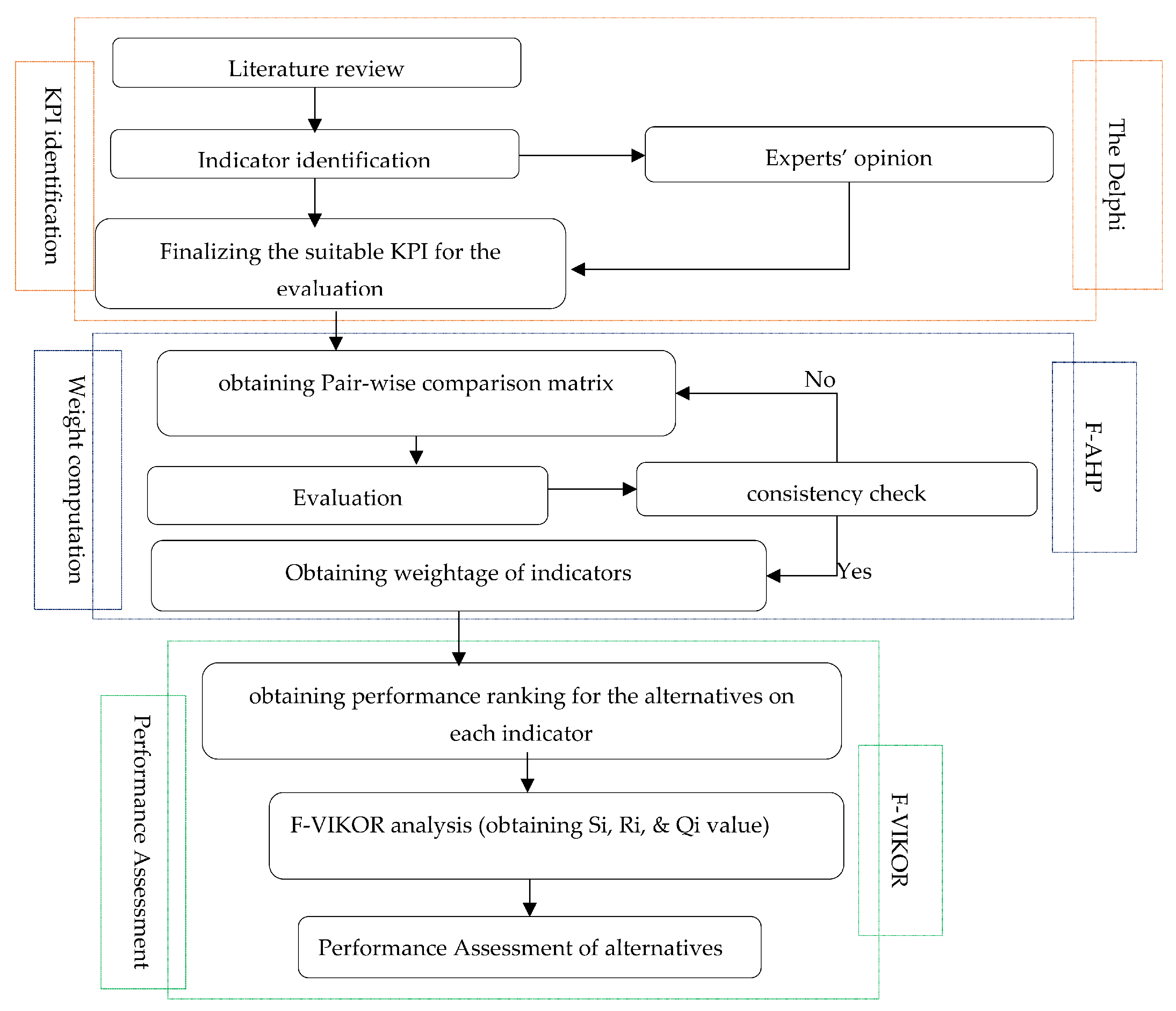

3.1. Research Methodology

The Methodological Steps

- In the first step, we identified 25 sustainable performance indicators from the literature and made a questionnaire to sort them. The questionnaire (shown in Appendix A.1) was circulated to collect the responses for the Delphi study to sort the PIs, and finally, 19 PIs were finalized.

- In the second step, we made a questionnaire to obtain pairwise importance weight for the computation of the weights of the indicators using the F-AHP methodology. Through conducting talks with three industrial and two academic professionals, we prepared the pairwise importance matrix. The AHP methodology provided by Kumar et al. [12] has been followed.

- In the last step, we utilized the fuzzy VIKOR methodology, which is provided by Vinodh et al. (2013). To simplify the calculation, we opted for different linguistic fuzzy numbers and scales [59]. Thus, we utilized a 5-point linguistic variable from very-poor to very-high performance, with a triangular fuzzy scale between 1 and 9; however, Ref. [59] used the same linguistic term but have a trapezoidal fuzzy number between 0 and 1. The fuzzy numbers of the linguistic scale are shown in Table 3.

3.2. Data Collection and Demographic Profile

4. Results

4.1. Sustainable Performance Assessment

4.1.1. Phase Ⅰ Identification of Sustainable KPIs: Delphi Study

4.1.2. Phase Ⅱ Criteria and Sub-Criteria Weight Computation Using F-AHP

4.1.3. Phase Ⅲ Sustainable Performance Assessment of the Dairy Industry

4.2. Sensitivity Analysis

5. Discussions

5.1. Discussions on Findings

5.2. Discussion on SDG and Dairy Industry

5.3. Research Implications

5.3.1. Theoretical Implications

5.3.2. Managerial Implications

6. Conclusions

Limitations and Future Research Direction

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FSC | Food supply chain |

| SSCM | Sustainable supply chain management |

| DSC | Dairy supply chain |

| KPI | Key performance indicator |

| PIs | Performance indicators |

| GHG | Greenhouse gas emission |

| DPI | Dairy Industry |

| AHP | Analytic hierarchy process |

| TOPSIS | Technique for order |

| VIKOR | VIseKriterijumska Optimizacija I Kompromisno Resenje (Multicriteria Optimization and Compromise Solution, with pronunciation) |

| SD | Sustainable development |

| SCP | Sustainable consumption and production |

| SDG | Sustainable development goal |

| SRPM | Supplier relationship and performance measurement |

| SCOR | Supply chain operations reference |

Appendix A

| RND | ASC | REG | UQS | TRA | GEQ | EGR | PSH | GSR | CCE | WMT | GHG | MEM | GRM | SRE | EBO | RCD | UOT | CUR | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RND | 1 | 1/2 | 1 | 1 | |||||||||||||||

| ASC | 2 | 1 | 1 | 2 | |||||||||||||||

| REG | 1 | 1 | 1 | 1/2 | |||||||||||||||

| UQS | 1 | 1/2 | 2 | 1 | |||||||||||||||

| TRA | 1 | 2 | 3 | 2 | |||||||||||||||

| GEQ | 1/2 | 1 | 1 | 2 | |||||||||||||||

| EGR | 1/3 | 1 | 1 | 1 | |||||||||||||||

| PSH | 1/2 | 1/2 | 1 | 1 | |||||||||||||||

| GSR | 1 | 2 | 1/3 | 1/2 | 1/3 | 1/2 | 1/4 | ||||||||||||

| CCE | 1/2 | 1 | 1 | 1/2 | 1 | 1/3 | 1/4 | ||||||||||||

| WMT | 3 | 1 | 1 | 1 | 2 | 1 | 1 | ||||||||||||

| GHG | 2 | 2 | 1 | 1 | 2 | 1 | 1 | ||||||||||||

| MEM | 3 | 1 | 1/2 | 1/2 | 1 | 1 | 1/4 | ||||||||||||

| GRM | 2 | 3 | 1 | 1 | 1 | 1 | 1 | ||||||||||||

| SRE | 4 | 4 | 1 | 1 | 4 | 1 | 1 | ||||||||||||

| EBO | 1 | 3 | 1 | 2 | |||||||||||||||

| RCD | 1/3 | 1 | 1/2 | 1/4 | |||||||||||||||

| UOT | 1 | 2 | 1 | 2 | |||||||||||||||

| CUR | 1/2 | 4 | 1/2 | 1 |

| EN1 | EN2 | EN3 | EN4 | EN5 | EN6 | EN7 | SO1 | SO2 | SO3 | SO4 | EC1 | EC2 | EC3 | EC4 | BO1 | BO2 | BO3 | BO4 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Expert 1 | DP1 | G. | VG | VP | G. | A | G. | VG | P | G. | P | G. | G. | VG | VP | A | G. | VG | P | A |

| DP2 | A | G. | VG | P | P | G. | VP | G. | VP | G. | VG | VP | G. | VP | G. | A | A | G | P | |

| DP3 | G. | VG | G. | A | A | VG | G. | VG | A | P | VG | G. | A | A | VG | G. | P | P | A | |

| Expert 2 | EN1 | EN2 | EN3 | EN4 | EN5 | EN6 | EN7 | SO1 | SO2 | SO3 | SO4 | EC1 | EC2 | EC3 | EC4 | BO1 | BO2 | BO3 | BO4 | |

| DP1 | VG | G. | p | G. | G. | G. | VG | A | G. | A | G. | VG | G. | VP | P | G. | VG | A | G. | |

| DP2 | A | G. | G. | A | G. | VP | VP | G. | P | VG | G. | VP | G. | VP | G. | A | A | A | G. | |

| DP3 | G. | VG | VG | G. | VG | A | G. | VG | A | P | VG | G. | A | A | G. | G. | P | P | VG | |

| EN1 | EN2 | EN3 | EN4 | EN5 | EN6 | EN7 | SO1 | SO2 | SO3 | SO4 | EC1 | EC2 | EC3 | EC4 | BO1 | BO2 | BO3 | BO4 | ||

| Expert 3 | DP1 | VG | VG | A | A | VG | G. | VG | P | G. | G. | G. | G. | VG | G. | G. | G. | G | P | G. |

| DP2 | G. | G. | VG | P | VP | G. | P | G. | VP | G. | VG | G. | G. | G. | G. | A | A | P | VP | |

| DP3 | G. | VG | G. | A | G. | VG | G. | G. | A | G. | VG | A | P | A | VG | A | P | G | A |

| EN1 | EN2 | EN3 | EN4 | EN5 | EN6 | EN7 | SO1 | SO2 | SO3 | SO4 | EC1 | EC2 | EC3 | EC4 | BO1 | BO2 | BO3 | BO4 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DP1 | 7.89 | 7.89 | 3.33 | 7.11 | 6.67 | 7.00 | 8.67 | 3.78 | 7.00 | 5.00 | 7.00 | 7.44 | 7.89 | 1.33 | 5.00 | 7.00 | 6.67 | 3.78 | 6.22 |

| DP2 | 5.78 | 7.00 | 8.67 | 3.78 | 4.11 | 5.00 | 2.11 | 7.00 | 2.11 | 7.44 | 7.89 | 2.11 | 7.00 | 3.67 | 7.00 | 5.00 | 5.00 | 5.00 | 4.11 |

| DP3 | 7.00 | 8.67 | 7.44 | 5.78 | 6.67 | 7.11 | 5.00 | 7.89 | 5.78 | 4.56 | 8.67 | 6.22 | 4.22 | 5.00 | 7.89 | 6.22 | 3.00 | 4.56 | 6.22 |

| Xi+ | 7.89 | 8.67 | 8.67 | 7.11 | 6.67 | 7.11 | 8.67 | 3.78 | 7.00 | 7.44 | 8.67 | 7.44 | 7.89 | 5.00 | 7.89 | 7.00 | 6.67 | 5.00 | 6.22 |

| Xi- | 5.78 | 7.00 | 3.33 | 3.78 | 4.11 | 5.00 | 2.11 | 7.89 | 2.11 | 4.56 | 7.00 | 2.11 | 4.22 | 1.33 | 5.00 | 5.00 | 3.00 | 3.78 | 4.11 |

| Si | |||||||||||||||||||

| DP1 | 0.00 | 0.05 | 0.32 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.14 | 0.24 | 0.00 | 0.00 | 0.21 | 0.25 | 0.00 | 0.00 | 0.18 | 0.00 |

| DP2 | 0.34 | 0.10 | 0.00 | 0.23 | 0.07 | 0.08 | 0.17 | 0.13 | 0.11 | 0.00 | 0.11 | 0.20 | 0.08 | 0.08 | 0.08 | 0.43 | 0.11 | 0.00 | 0.16 |

| DP3 | 0.14 | 0.00 | 0.07 | 0.09 | 0.00 | 0.00 | 0.09 | 0.17 | 0.03 | 0.17 | 0.00 | 0.05 | 0.35 | 0.00 | 0.00 | 0.17 | 0.23 | 0.06 | 0.00 |

| Overall | BO | EC | SO | EN | |

|---|---|---|---|---|---|

| DP1 | 0.303 | 0.415 | 0.665 | 1.000 | 1.000 |

| DP2 | 0.750 | 1.000 | 0.000 | 0.293 | 0.269 |

| DP3 | 0.000 | 0.020 | 0.697 | 0.000 | 0.000 |

| Expertise | Designation | Experience | Gander | |

|---|---|---|---|---|

| Expert 1 | Supply chain management | Professor | 18 | Male |

| Expert 2 | Warehouse management | Production manager | 16 | Female |

| Expert 3 | Procurement | Procurement officer | 10 | Female |

| Expert 4 | Supply chain management | Professor | 17 | Male |

| Expert 5 | Marketing | Sales and marketing manager | 17 | Male |

| Expert 6 | Sustainable development | Professor | 15 | Male |

| Expert 7 | Waste management | Production engineer | 17 | Female |

| Expert 8 | Performance assessment | Professor | 17 | Female |

| Expert 9 * | Sustainable development | Production manager | 16 | Female |

| Expert 10 * | Waste management | Executive officer | 17 | Male |

| Expert 11 | Sustainable development | Professor | 18 | Male |

| Expert 12 | Procurement | Procurement officer | 13 | Male |

| Expert 13 | Supply chain management | Professor | 20 | Male |

| Expert 14 | Marketing | Sales and marketing manager | 13 | Male |

| Expert 15 | Human resource | Human resource manager | 17 | Female |

| Expert 16 | Waste management | Professor | 14 | Female |

| Expert 17 | Sustainable development | Professor | 14 | Female |

| Expert 18 | Supply chain management | Professor | 18 | Female |

| Expert 19 | Marketing | Sales and marketing manager | 18 | Male |

| Expert 20 * | Sustainable development | Executive officer | 16 | Male |

| Expert 21 | Production planning | Production manager | 12 | Female |

| Expert 22 | Quality management | Procurement officer | 14 | Female |

| Expert 23 | Supply chain management | Professor | 14 | Male |

| Expert 24 | Sustainable development | Professor | 18 | Female |

| Expert 25 | Waste management | Production manager | 14 | Male |

| Expert 26 | Supplier selection | Production manager | 15 | Male |

| Expert 27 # | Sustainable development | Cooperative member | 15 | Male |

| Expert 28 # | Production planning | Cooperative member | 12 | Male |

| Expert 29 # | Sustainable development | Cooperative member | 14 | Male |

| Blank Questionnaire Consent Form |

| Dear Sir/Madam, |

| Warm greetings of the day! We hope this message finds you well. We are reaching out to you to seek your valuable expertise and opinion on our questionnaire. Our research focuses on assessing the sustainable performance of the Indian dairy industry. We would like to share with you a list of sustainable key performance indicators (KPIs) that we have compiled for creating our performance assessment tool. |

| We greatly appreciate your expertise and kindly request your response to help us in this endeavor. Please rest assured that we will treat your personal details with the utmost confidentiality and they will never be shared with anyone. Your expertise opinion is of immense value to us, and we encourage you to provide your insights without any hesitation. |

| Thank you in advance for considering our invitation, and we look forward to receiving your valuable input. |

| Best regards, |

| Authors’ Team |

Appendix A.1. Questionnaire for Performance Criteria Selection

| Sustainable KPIs for Dairy Industry | Question | Rate between 1–5 | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Effective business and operations (EBO) | Effective business and operation is an important indicators for sustainable performance assessment (SPA) of dairy industry | |||||

| Use of Quality standards and HACCP (UQS) | Use of Quality standards and HACCP is an important indicator for SPA of dairy industry | |||||

| Green supplier (GSR) | Green suppliers an important indicator for SPA of dairy industry | |||||

| Diversity of market | Diversity of market is an important indicator for SPA of dairy industry | |||||

| Cold chain effectiveness (CCE) | Cold chain effectiveness is an important indicator for SPA of dairy industry | |||||

| Responsiveness to customer demand (RCD) | Responsiveness to customer demand is an important indicator for SPA of dairy industry | |||||

| Use of Technology (UOT) | Use of Technology is an important indicator for SPA of dairy industry | |||||

| Waste management (WMT) | Waste management is an important indicator for SPA of dairy industry | |||||

| Research and development (RND) | Research and development is an important indicators for SPA of dairy industry | |||||

| Average wages per person per year | Average wages per person per year is an important indicator for SPA of dairy industry | |||||

| Average supply chain cost (ASC) | Average supply chain cost (ASC) | |||||

| Chilling Capacity | Chilling Capacity is an important indicator for SPA of dairy industry | |||||

| Capacity utilization rate (CUR) | Capacity utilization rate is an important indicator for SPA of dairy industry | |||||

| Effective number of Refrigerated carriers | Effective number of Refrigerated carriers is an important indicator for SPA of dairy industry | |||||

| Traceability (TRA) | Traceability is an important indicator for SPA of dairy industry | |||||

| GHG emission (GHG) | GHG emission is an important indicator for SPA of dairy industry | |||||

| Hazard substance exposure | Hazard substance exposure is an important indicator for SPA of dairy industry | |||||

| Gender equity (GEQ) | Gender equity is an important indicator for SPA of dairy industry | |||||

| Employment generation (EGR) | Employment generation is an important indicator for SPA of dairy industry | |||||

| Donation to charity (DC) | Donation to charity is an important indicator for SPA of dairy industry | |||||

| Utilization of modern environment management system (MEM) | Utilization of modern environment management system is an important indicator for SPA of dairy industry | |||||

| Utilization of green and recycled material (GER) | Utilization of green and recycled material is an important indicator for SPA of dairy industry | |||||

| workforce utilization | workforce utilization is an important indicator for SPA of dairy industry | |||||

| Share of renewable energy (SRE) | Share of renewable energy is an important indicator for SPA of dairy industry | |||||

| Profit sharing (PSH) | Profit sharing is an important indicator for SPA of dairy industry | |||||

| Revenue growth (REG) | Revenue growth is an important indicator for SPA of dairy industry | |||||

Appendix A.2. Questionnaire for Performance Criteria and Sub-Criteria Weight Evaluation

| 1 | Economic | Social | Business operations |

| Environmental criteria | |||

| 2 | Environmental criteria | Social | Business operations |

| Economic | |||

| 3 | Environmental criteria | Economic | Business operations |

| Social | |||

| 4 | Environmental criteria | Economic | Social |

| Business operations |

| Business operations | |||

| RCD | UOT | CUR | |

| EBO | |||

| EBO | UOT | CUR | |

| RCD | |||

| EBO | RCD | CUR | |

| UOT | |||

| EBO | RCD | UOT | |

| CUR |

| Environmental criteria | ||||||

| CCE | WMT | GHG | MEM | GRM | SRE | |

| GSR | ||||||

| GSR | WMT | GHG | MEM | GRM | SRE | |

| CCE | ||||||

| CCE | GSR | GHG | MEM | GRM | SRE | |

| WMT | ||||||

| CCE | WMT | GSR | MEM | GRM | SRE | |

| GHG | ||||||

| CCE | WMT | GHG | GSR | GRM | SRE | |

| MEM | ||||||

| CCE | WMT | GHG | MEM | GSR | SRE | |

| GRM | ||||||

| CCE | WMT | GHG | MEM | GRM | GSR | |

| SRE |

| Economic criteria | |||

| ASC | REG | UQS | |

| RND | |||

| RND | REG | UQS | |

| ASC | |||

| ASC | RND | UQS | |

| REG | |||

| ASC | REG | RND | |

| UQS |

| Social criteria | |||

| GEQ | EGR | PSH | |

| TRA | |||

| TRA | EGR | PSH | |

| GEQ | |||

| GEQ | GEQ | PSH | |

| EGR | |||

| GEQ | EGR | EGR | |

| PSH |

Appendix A.3. Questionnaire for Alternatives Selection through VIKOR

| VP | Very poor |

| P | Poor |

| A | Average |

| H | High |

| VH | Very high |

| Criteria | GSR | CCE | WMT | GHG | MEM | GRM | SRE | |

| Dairy Industries | DIA | |||||||

| DPB | ||||||||

| DPC |

| Criteria | TRA | GEQ | EGR | PSH | |

| Dairy Industries | DIA | ||||

| DPB | |||||

| DPC |

| Criteria | RND | ASC | REG | UQS | |

| Dairy Industries | DIA | ||||

| DPB | |||||

| DPC |

| Criteria | EBO | RCD | UOT | CUR | |

| Dairy Industries | DIA | ||||

| DPB | |||||

| DPC |

References

- Matthews, L.; Power, D.; Touboulic, A.; Marques, L. Building Bridges: Toward Alternative Theory of Sustainable Supply Chain Management. J. Supply Chain Manag. 2016, 52, 82–94. [Google Scholar] [CrossRef]

- Pagell, M.; Shevchenko, A. Why Research in Sustainable Supply Chain Management Should Have No Future. J. Supply Chain Manag. 2014, 50, 44–55. [Google Scholar] [CrossRef]

- Gayá, P.; Phillips, M. Imagining a Sustainable Future: Eschatology, Bateson’s Ecology of Mind and Arts-Based Practice. Organization 2016, 23, 803–824. [Google Scholar] [CrossRef]

- Prasad, P.; Elmes, M. In the Name of the Practical: Unearthing the Hegemony of Pragmatics in the Discourse of Environmental Management. J. Manag. Stud. 2005, 42, 845–867. [Google Scholar] [CrossRef]

- Cannas, V.G.; Ciccullo, F.; Pero, M.; Cigolini, R. Sustainable Innovation in the Dairy Supply Chain: Enabling Factors for Intermodal Transportation. Int. J. Prod. Res. 2020, 58, 7314–7333. [Google Scholar] [CrossRef]

- Gerbens-Leenes, P.W.; Moll, H.C.; Schoot Uiterkamp, A.J.M. Design and Development of a Measuring Method for Environmental Sustainability in Food Production Systems. Ecol. Econ. 2003, 46, 231–248. [Google Scholar] [CrossRef]

- De Burgos Jiménez, J.; Céspedes, J.J. Environmental Performance as an Operations Objective. Int. J. Oper. Prod. Manag. 2001, 21, 1553–1572. [Google Scholar] [CrossRef]

- Ilbahar, E.; Kahraman, C.; Cebi, S. Evaluation of Sustainable Energy Planning Scenarios with a New Approach Based on FCM, WASPAS and Impact Effort Matrix. Environ. Dev. Sustain. 2022. [Google Scholar] [CrossRef]

- Sarkis, J. Manufacturing’s Role in Corporate Environmental Sustainability Concerns for the New Millennium. Int. J. Oper. Prod. Manag. 2001, 21, 666–686. [Google Scholar] [CrossRef]

- Angell, L.C.; Klassen, R.D. Integrating Environmental Issues into the Mainstream: An Agenda for Research in Operations Management. J. Oper. Manag. 1999, 17, 575–598. [Google Scholar] [CrossRef]

- Tasdemir, C.; Gazo, R.; Quesada, H.J. Sustainability Benchmarking Tool (SBT): Theoretical and Conceptual Model Proposition of a Composite Framework. Environ. Dev. Sustain. 2020, 22, 6755–6797. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, M.; Raut, R.D.; Mangla, S.K.; Choubey, V.K. Performance Assessment of Circular Driven Sustainable Agri-Food Supply Chain towards Achieving Sustainable Consumption and Production. J. Clean. Prod. 2022, 372, 133698. [Google Scholar] [CrossRef]

- Hendiani, S.; Sharifi, E.; Bagherpour, M.; Ghannadpour, S.F. A Multi-Criteria Sustainability Assessment Approach for Energy Systems Using Sustainability Triple Bottom Line Attributes and Linguistic Preferences. Environ. Dev. Sustain. 2020, 22, 7771–7805. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A Framework of Sustainable Supply Chain Management: Moving toward New Theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar Choubey, V.; Deepak, A.; Gedam, V.V.; Raut, R.D. Life Cycle Assessment (LCA) of Dairy Industry: A Case Study of North India. J. Clean. Prod. 2021, 326, 129331. [Google Scholar] [CrossRef]

- Aziz, E. The Impact of COVID-19 on Food and Agriculture in Asia and the Pacific and FAO’s Response. In Proceedings of the 35th Session of the Regional Conference for Asia and the Pacific, Virtual, 1–4 September 2020; pp. 1–16. [Google Scholar]

- Ladha-Sabur, A.; Bakalis, S.; Fryer, P.J.; Lopez-Quiroga, E. Mapping Energy Consumption in Food Manufacturing. Trends Food Sci. Technol. 2019, 86, 270–280. [Google Scholar] [CrossRef]

- Soetan, K.O.; Olaiya, C.O.; Oyewole, O.E. The Importance of Mineral Elements for Humans, Domestic Animals and Plants: A Review. African J. Food Sci. 2010, 4, 200–222. [Google Scholar]

- Gerosa, S.; Skoet, J. Milk Availability: Trends in Production and Demand and Medium-Term Outlook; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2012. [Google Scholar]

- OECD/FAO. Chapter 7. Dairy and Dairy Products. In OECD-FAO Agricultural Outlook 2018–2027; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2018. [Google Scholar]

- Lacour, C.; Seconda, L.; Allès, B.; Hercberg, S.; Langevin, B.; Pointereau, P.; Lairon, D.; Baudry, J.; Kesse-Guyot, E. Environmental Impacts of Plant-Based Diets: How Does Organic Food Consumption Contribute to Environmental Sustainability? Front. Nutr. 2018, 5, 8. [Google Scholar] [CrossRef]

- Fehér, A.; Gazdecki, M.; Véha, M.; Szakály, M.; Szakály, Z. A Comprehensive Review of the Benefits of and the Barriers to the Switch to a Plant-Based Diet. Sustainability 2020, 12, 4136. [Google Scholar] [CrossRef]

- Scarborough, P.; Appleby, P.N.; Mizdrak, A.; Briggs, A.D.M.; Travis, R.C.; Bradbury, K.E.; Key, T.J. Dietary Greenhouse Gas Emissions of Meat-Eaters, Fish-Eaters, Vegetarians and Vegans in the UK. Clim. Change 2014, 125, 179–192. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ekinci, E.; Mangla, S.K.; Sezer, M.D.; Kayikci, Y. Performance Evaluation of Reverse Logistics in Food Supply Chains in a Circular Economy Using System Dynamics. Bus. Strateg. Environ. 2020, 30, 71–91. [Google Scholar] [CrossRef]

- Ivo de Carvalho, M.; Relvas, S.; Barbosa-Póvoa, A.P. A Roadmap for Sustainability Performance Assessment in the Context of Agri-Food Supply Chain. Sustain. Prod. Consum. 2022, 34, 565–585. [Google Scholar] [CrossRef]

- Noya, L.I.; Vasilaki, V.; Stojceska, V.; González-García, S.; Kleynhans, C.; Tassou, S.; Moreira, M.T.; Katsou, E. An Environmental Evaluation of Food Supply Chain Using Life Cycle Assessment: A Case Study on Gluten Free Biscuit Products. J. Clean. Prod. 2018, 170, 451–461. [Google Scholar] [CrossRef]

- Cecchini, L.; Venanzi, S.; Pierri, A.; Chiorri, M. Environmental Efficiency Analysis and Estimation of CO2 Abatement Costs in Dairy Cattle Farms in Umbria (Italy): A SBM-DEA Model with Undesirable Output. J. Clean. Prod. 2018, 197, 895–907. [Google Scholar] [CrossRef]

- Houssard, C.; Maxime, D.; Benoit, S.; Pouliot, Y.; Margni, M. Comparative Life Cycle Assessment of Five Greek Yogurt Production Systems: A Perspective beyond the Plant Boundaries. Sustainability 2020, 12, 9141. [Google Scholar] [CrossRef]

- Mohammed, A.; Harris, I.; Govindan, K. A Hybrid MCDM-FMOO Approach for Sustainable Supplier Selection and Order Allocation. Int. J. Prod. Econ. 2019, 217, 171–184. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Yao, J.; Li, Y.; Yang, S. Socially Responsible Supplier Selection and Sustainable Supply Chain Development: A Combined Approach of Total Interpretive Structural Modeling and Fuzzy Analytic Network Process. Bus. Strateg. Environ. 2018, 27, 1708–1719. [Google Scholar] [CrossRef]

- Moazzam, M.; Akhtar, P.; Garnevska, E.; Marr, N.E. Measuring Agri-Food Supply Chain Performance and Risk through a New Analytical Framework: A Case Study of New Zealand Dairy. Prod. Plan. Control 2018, 29, 1258–1274. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Sagnak, M.; Mangla, S.K.; Sezer, M.D.; Pala, M.O. A Fuzzy Based Hybrid Decision Framework to Circularity in Dairy Supply Chains through Big Data Solutions. Technol. Forecast. Soc. Change 2021, 170, 120927. [Google Scholar] [CrossRef]

- Gupta, H.; Kumar, A.; Wasan, P. Industry 4.0, Cleaner Production and Circular Economy: An Integrative Framework for Evaluating Ethical and Sustainable Business Performance of Manufacturing Organizations. J. Clean. Prod. 2021, 295, 126253. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Nayal, K.; Kraus, S.; Yadav, V.S.; Narkhede, B.E. To Identify Industry 4.0 and Circular Economy Adoption Barriers in the Agriculture Supply Chain by Using ISM-ANP. J. Clean. Prod. 2021, 293, 126023. [Google Scholar] [CrossRef]

- Sufiyan, M.; Haleem, A.; Khan, S.; Khan, M.I. Evaluating Food Supply Chain Performance Using Hybrid Fuzzy MCDM Technique. Sustain. Prod. Consum. 2019, 20, 40–57. [Google Scholar] [CrossRef]

- Bloemhof, J.M.; van der Vorst, J.G.A.J.; Bastl, M.; Allaoui, H. Sustainability Assessment of Food Chain Logistics. Int. J. Logist. Res. Appl. 2015, 18, 101–117. [Google Scholar] [CrossRef]

- Jouzdani, J.; Govindan, K. On the Sustainable Perishable Food Supply Chain Network Design: A Dairy Products Case to Achieve Sustainable Development Goals. J. Clean. Prod. 2021, 278, 123060. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating Sustainability and Resilience in the Supply Chain: A Systematic Literature Review and a Research Agenda. Bus. Strateg. Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Sharma, V.; Raut, R.D.; Mangla, S.K.; Narkhede, B.E.; Luthra, S.; Gokhale, R. A Systematic Literature Review to Integrate Lean, Agile, Resilient, Green and Sustainable Paradigms in the Supply Chain Management. Bus. Strateg. Environ. 2021, 30, 1191–1212. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and Circular Economy: Operational Excellence for Sustainable Reverse Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Miranda-Ackerman, M.A.; Azzaro-Pantel, C.; Aguilar-Lasserre, A.A.; Bueno-Solano, A.; Arredondo-Soto, K.C. Green Supplier Selection in the Agro-Food Industry with Contract Farming: A Multi-Objective Optimization Approach. Sustainability 2019, 11, 7017. [Google Scholar] [CrossRef]

- Kumar, A.; Mangla, S.K.; Kumar, P.; Karamperidis, S. Challenges in Perishable Food Supply Chains for Sustainability Management: A Developing Economy Perspective. Bus. Strateg. Environ. 2020, 29, 1809–1831. [Google Scholar] [CrossRef]

- Qorri, A.; Mujkić, Z.; Kraslawski, A. A Conceptual Framework for Measuring Sustainability Performance of Supply Chains. J. Clean. Prod. 2018, 189, 570–584. [Google Scholar] [CrossRef]

- Cicatiello, C.; Franco, S.; Pancino, B.; Blasi, E.; Falasconi, L. The Dark Side of Retail Food Waste: Evidences from in-Store Data. Resour. Conserv. Recycl. 2017, 125, 273–281. [Google Scholar] [CrossRef]

- Choubey, V.K.; Kumar, M. Modelling the Interaction among the Key Performance Indicators of Sustainable Supply Chain in Perspective of Perishable Food. Int. J. Logist. Syst. Manag. 2023, 45, 108–130. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A Fuzzy Multi Criteria Approach for Measuring Sustainability Performance of a Supplier Based on Triple Bottom Line Approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Kumar, M.; Choubey, V.K. Analysis of Sustainable Performance Indicators in Dairy Supply Chain Using Fuzzy-DEMATEL. Int. J. Logist. Syst. Manag. 2022, 1, 1. [Google Scholar] [CrossRef]

- Morrison-Saunders, A.; Pope, J. Conceptualising and Managing Trade-Offs in Sustainability Assessment. Environ. Impact Assess. Rev. 2013, 38, 54–63. [Google Scholar] [CrossRef]

- Waas, T.; Hugé, J.; Block, T.; Wright, T.; Benitez-Capistros, F.; Verbruggen, A. Sustainability Assessment and Indicators: Tools in a Decision-Making Strategy for Sustainable Development. Sustainability 2014, 6, 5512–5534. [Google Scholar] [CrossRef]

- Moldavska, A.; Welo, T. A Holistic Approach to Corporate Sustainability Assessment: Incorporating Sustainable Development Goals into Sustainable Manufacturing Performance Evaluation. J. Manuf. Syst. 2019, 50, 53–68. [Google Scholar] [CrossRef]

- Kumar, M.; Choubey, V.K.; Raut, R.D.; Jagtap, S. Enablers to Achieve Zero Hunger through IoT and Blockchain Technology and Transform the Green Food Supply Chain Systems. J. Clean. Prod. 2023, 405, 136894. [Google Scholar] [CrossRef]

- Uygun, Ö.; Dede, A. Performance Evaluation of Green Supply Chain Management Using Integrated Fuzzy Multi-Criteria Decision Making Techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Stohler, M.; Rebs, T.; Brandenburg, M. Toward the Integration of Sustainability Metrics into the Supply Chain Operations Reference (SCOR) Model. In Greening of Industry Networks Studies; Springer: Berlin/Heidelberg, Germany, 2018; Volume 5, pp. 49–60. [Google Scholar]

- Stranieri, S.; Riccardi, F.; Meuwissen, M.P.M.; Soregaroli, C. Exploring the Impact of Blockchain on the Performance of Agri-Food Supply Chains. Food Control 2021, 119, 107495. [Google Scholar] [CrossRef]

- Yontar, E.; Ersöz, S. Investigation of Food Supply Chain Sustainability Performance for Turkey’s Food Sector. Front. Sustain. Food Syst. 2020, 4, 68. [Google Scholar] [CrossRef]

- Gold, S.; Hahn, R.; Seuring, S. Sustainable Supply Chain Management in “Base of the Pyramid” Food Projects-A Path to Triple Bottom Line Approaches for Multinationals? Int. Bus. Rev. 2013, 22, 784–799. [Google Scholar] [CrossRef]

- Farrukh, A.; Mathrani, S.; Sajjad, A. A Natural Resource and Institutional Theory-Based View of Green-Lean-Six Sigma Drivers for Environmental Management. Bus. Strateg. Environ. 2022, 31, 1074–1090. [Google Scholar] [CrossRef]

- Mangla, S.K.; Sharma, Y.K.; Patil, P.P.; Yadav, G.; Xu, J. Logistics and Distribution Challenges to Managing Operations for Corporate Sustainability: Study on Leading Indian Diary Organizations. J. Clean. Prod. 2019, 238, 117620. [Google Scholar] [CrossRef]

- Vinodh, S.; Varadharajan, A.R.; Subramanian, A. Application of Fuzzy VIKOR for Concept Selection in an Agile Environment. Int. J. Adv. Manuf. Technol. 2013, 65, 825–832. [Google Scholar] [CrossRef]

- Kumar, M.; Raut, R.D.; Sharma, M.; Choubey, V.K.; Paul, S.K. Enablers for Resilience and Pandemic Preparedness in Food Supply Chain. Oper. Manag. Res. 2022, 15, 1198–1223. [Google Scholar] [CrossRef]

- Burksiene, V.; Dvorak, J.; Burbulyte-Tsiskarishvili, G. Sustainability and sustainability marketing in competing for the title of European Capital of Culture. Organizacija 2018, 51, 66–78. [Google Scholar] [CrossRef]

- Dvorak, J.; Razova, I. Empirical validation of blue ocean strategy sustainability in an international environment. Found. Manag. 2018, 10, 143–162. [Google Scholar] [CrossRef]

- Mills, D.; Pudney, S.; Pevcin, P.; Dvorak, J. Evidence-based public policy decision-making in smart cities: Does extant theory support achievement of city sustainability objectives? Sustainability 2021, 14, 3. [Google Scholar] [CrossRef]

| Stage | Risk Factor | Description |

|---|---|---|

| Farmer | Land Degradation | Farmland can become less sustainable over the long term due to soil erosion, deforestation, and excessive pesticide usage. |

| Climate Change | Climate change: The production and quality of milk can be impacted by more unpredictable weather patterns, such as droughts or floods. | |

| Animal Health | Infections and diseases that affect dairy animals might spread, resulting in lower productivity and more frequent usage of antibiotics. | |

| Milk Collection and Processing: | Energy Use | Poor methods for gathering and processing milk can result in higher energy use and greenhouse gas emissions. |

| Water Usage | During the production of milk, inefficient water management and excessive water use can put pressure on the local water supply. | |

| Food Safety | Mishandling or contamination of milk during collection and processing can endanger consumer health and tarnish the dairy industry’s reputation. | |

| Packaging and Transportation: | Packaging Waste | Packaging waste, such as plastic containers improperly disposed of, can cause environmental damage. |

| Carbon Footprint | Excessive long-distance shipping and ineffective transportation operations can raise greenhouse gas emissions and carbon footprint. | |

| Supply Chain Transparency | It may be challenging to maintain ethical and sustainable practices throughout the supply chain in the absence of traceability and monitoring tools. | |

| Consumer and Retail: | Food Waste: | Dairy products that are improperly handled, stored, or that have expired can produce a lot of food waste. |

| Consumer Awareness | Consumer demand for sustainable goods may be impacted by consumers’ ignorance or indifference to sustainable dairy producing processes. | |

| Pricing Pressure | Market dynamics and price pressures may force businesses to slash costs in ways that undermine sustainability initiatives. |

| Performance Indicators PIs | Description | Source |

|---|---|---|

| Effective business and operations (EBO) | Business effectiveness and operations play a significant role in achieving a balance among the sustainable triple bottom-line approach. Optimal business operations help the environment, society, and economy. | [45] |

| Use of Quality standards and HACCP (UQS) | The use of high-quality standards and HACCP standards in the food system helps to lower food wastage along with high satisfaction to the consumer. | [12] |

| Green supplier (GSR) | The selection of green suppliers is a crucial step in reaching the objective of sustainable development since it helps to minimize emissions from the very beginning of the supply chain. | [46] |

| Cold chain effectiveness (CCE) | The efficacy of the cold chain plays a vital role in the supply chain for dairy products since it gives the product longer shelf life, ensures optimum emissions from refrigerated vehicles, and reduces waste of transportation. | [12] |

| Responsiveness to customer demand (RCD) | Responsiveness to customer demand helps to create long-lasting relationships with customers, timely delivery of a product, and an increase in demand. | [46] |

| Use of Technology (UOT) | The dairy industry has recently realized the importance of applying technology to automate production, maintain hygienic standards, fulfil orders from customers, deliver products on time, and monitor emissions in real time. | [12,46] |

| Waste management (WMT) | Waste management metrics measure how well SC’s waste management practices dispose of hazardous and chemical waste for SCP, aiding in the achievement of SDG 12.4. | [12] |

| Research and development (RND) | Nowadays, sustainable growth is absolutely necessary inside the company to produce an eco-friendly product to maintain our ecosystem by reducing environmental effects and harmful food ingredients, so research and development will play a significant role. | [12,46] |

| Average supply chain cost (ASC) | Total supply chain costs are the leading indicator of any supply chain performance. Various costs are associated with the supply chain cost, such as procurement cost, holding cost, shortage cost, and transportation cost. Need to use sustainable procurement and transportation network. | [47] |

| Capacity utilization rate (CUR) | Proper use of the company’s warehouse, shop floor, delivery vans, and other facilities within the firm is important. | [47] |

| Traceability (TRA) | Traceability is a cutting-edge technology that is often used for monitoring and tracking to improve product security and safety. It allows the consumer to track their order details and delivery of the product. | [46] |

| GHG emission (GHG) | By calculating equivalent carbon emissions, greenhouse gas emissions are the key indicator for monitoring and mitigating environmental damage. | [12] |

| Gender equity (GEQ) | Gender equity in the business organization is recommended to take advantage of experience from a diverse set of people. With gender equity, a firm’s social performance is improved. | [46] |

| Employment generation (EGR) | Employment generation is an important social measurement that is used to assess a firm’s social performance based on its ability to generate employment. | [12] |

| Utilization of modern environment management system (MEM) | Another strategy for tracking and managing the environmental impact/emissions generated by the firm is to use a modern environment management system. The MEM system enables real-time monitoring of the firm’s environmental emissions, which can then be readily managed and used to develop reduction strategies to improve environmental performance. | [47] |

| Utilization of green and recycled material (GER) | The use of green and recyclable materials in the dairy industry, particularly packaging materials, helps to reduce waste and GHG emissions, hence improving environmental performance. | [47] |

| Share of renewable energy (SRE) | The utilization of renewable energy in the dairy firm is important to lower GHG emissions. | [12] |

| Profit sharing (PSH) | Profit sharing among farmers and suppliers is a key factor in improving the social performance of the dairy business. Because the dairy sector is so reliant on farmers and vice versa, maximal profit sharing is critical to improving social performance. | [12] |

| Revenue growth (REG) | Continuous revenue expansion is also an important component of dairy enterprises in order to increase economic performance. | [12] |

| Scale | L | M | U | Reciprocal | L | M | U |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | ||||

| 2 | 1 | 2 | 3 | 1/2 | 1/3 | 1/2 | 1 |

| 3 | 2 | 3 | 4 | 1/3 | 1/4 | 1/3 | 1/2 |

| 4 | 3 | 4 | 5 | 1/4 | 1/5 | 1/4 | 1/3 |

| 5 | 4 | 5 | 6 | 1/5 | 1/6 | 1/5 | 1/4 |

| 6 | 5 | 6 | 7 | 1/6 | 1/7 | 1/6 | 1/5 |

| 7 | 6 | 7 | 8 | 1/7 | 1/8 | 1/7 | 1/6 |

| 8 | 7 | 8 | 9 | 1/8 | 1/9 | 1/8 | 1/7 |

| 9 | 9 | 9 | 9 | 1/9 | 1/9 | 1/9 | 1/9 |

| Lower (L) | Medium (M) | Upper (U) | |

|---|---|---|---|

| Very poor (VP) | 1 | 1 | 3 |

| Poor (P) | 1 | 3 | 5 |

| Average (A) | 3 | 5 | 7 |

| Good (H) | 5 | 7 | 9 |

| Very good (VH) | 7 | 9 | 9 |

| Performance Indicators | Symbol | Average Score | Decision |

|---|---|---|---|

| Effective business and operations | EBO | 3.1 | A |

| Use of quality standards and HACCP | UQS | 3.1 | A |

| Green supplier | GSR | 3.3 | A |

| Diversity of market | MD | 2.4 | R |

| Cold chain effectiveness | CCE | 3.1 | A |

| Responsiveness to customer demand | RCD | 3.3 | A |

| Use of technology | UOT | 3.55 | A |

| Waste management | WMT | 3.1 | A |

| Research and development | RND | 3.2 | A |

| Average wages per person per year | WPP | 2.7 | R |

| Average supply chain cost | ASC | 3.05 | A |

| Chilling capacity | CC | 2.75 | R * |

| Capacity utilization rate | CUR | 3.35 | A |

| Effective number of refrigerated carriers | ERC | 2.75 | R * |

| Traceability | TRA | 3.1 | A |

| GHG emission | GHG | 3.15 | A |

| Hazard substance exposure | HSE | 2.7 | R |

| Gender equity | GEQ | 3.15 | A |

| Employment generation | EGR | 3.25 | A |

| Donation to charity (DC) | EMS | 2.7 | R |

| Utilization of modern environment management system | MEM | 3.05 | A |

| Utilization of green and recycled material | GRM | 3.05 | A |

| Workforce utilization | CR23 | 2.7 | R |

| Share of renewable energy | SRE | 3.1 | A |

| Profit sharing | PSH | 3.95 | A |

| Revenue growth | REG | 3.25 | A |

| Indicators | Sub Criteria | Sub-Criteria Local Weight | Sub-Criteria Local Rank | Criteria | Criteria Rank | Sub-Criteria Global Weight | Sub-Criteria Global Rank | Eigenvalue (λ) | CI |

|---|---|---|---|---|---|---|---|---|---|

| Effective business and operations | EBO | 0.340 | 1 | 0.069 | 4 | 4.20 | 0.08 | ||

| Capacity utilization rate | CUR | 0.108 | 4 | Business operations (BO) | 0.022 | 19 | |||

| Use of technology | UOT | 0.307 | 2 | 0.204 | 0.063 | 8 | |||

| Responsiveness to customer demand | RCD | 0.245 | 3 | 0.050 | 12 | ||||

| Green supplier | GSR | 0.078 | 7 | 0.026 | 18 | 8.47 | 0.05 | ||

| Cold chain effectiveness | CCE | 0.080 | 6 | 0.026 | 17 | ||||

| Waste management | WMT | 0.165 | 3 | Environment (EN) | 0.330 | 0.054 | 10 | ||

| GHG emission | GHG | 0.172 | 2 | 0.057 | 9 | ||||

| Utilization of modern environment management system | MEM | 0.108 | 5 | 0.036 | 14 | ||||

| Utilization of green and recycled material | GRM | 0.164 | 4 | 0.054 | 11 | ||||

| Share of renewable energy | SRE | 0.232 | 1 | 0.077 | 2 | ||||

| Research and development | RND | 0.207 | 4 | 0.063 | 6 | 4.18 | 0.07 | ||

| Average supply chain cost | ASC | 0.336 | 1 | EC Economic (EC) | 0.103 | 1 | |||

| Revenue growth | REG | 0.207 | 3 | 0.306 | 0.063 | 6 | |||

| Use of quality standards and HACCP | UQS | 0.250 | 2 | 0.076 | 3 | ||||

| Traceability | TRA | 0.423 | 1 | 0.068 | 5 | 4.08 | 0.03 | ||

| Gender equity | GEQ | 0.234 | 2 | Social (SO) | 0.160 | 0.037 | 13 | ||

| Employment generation | EGR | 0.170 | 4 | 0.027 | 16 | ||||

| Profit sharing | PSH | 0.174 | 3 | 0.028 | 15 |

| Si | Ri | Qi (@ μ = 0.5) | Rank | |

|---|---|---|---|---|

| DPI1 | 1.811333 | 0.319 | 0.26965 | 2 |

| DPI2 | 2.071883 | 0.428 | 0.75 | 3 |

| DPI3 | 1.506332 | 0.345 | 0.059633 | 1 |

| S*, R* | 1.506332 | 0.319 | ||

| S-, R- | 2.071883 | 0.428 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, M.; Choubey, V.K. Sustainable Performance Assessment towards Sustainable Consumption and Production: Evidence from the Indian Dairy Industry. Sustainability 2023, 15, 11555. https://doi.org/10.3390/su151511555

Kumar M, Choubey VK. Sustainable Performance Assessment towards Sustainable Consumption and Production: Evidence from the Indian Dairy Industry. Sustainability. 2023; 15(15):11555. https://doi.org/10.3390/su151511555

Chicago/Turabian StyleKumar, Mukesh, and Vikas Kumar Choubey. 2023. "Sustainable Performance Assessment towards Sustainable Consumption and Production: Evidence from the Indian Dairy Industry" Sustainability 15, no. 15: 11555. https://doi.org/10.3390/su151511555

APA StyleKumar, M., & Choubey, V. K. (2023). Sustainable Performance Assessment towards Sustainable Consumption and Production: Evidence from the Indian Dairy Industry. Sustainability, 15(15), 11555. https://doi.org/10.3390/su151511555