Comparative Cradle-to-Grave Carbon Footprint of a CFRP-Grid Reinforced Concrete Façade Panel

Abstract

1. Introduction

2. State of the Art

2.1. Carbon Reinforced Concrete

2.2. Life Cycle Assessment

3. LCA Case Study: Façade Element

3.1. Goal and Scope

3.2. Technical Description

3.3. Life Cycle Inventory

3.3.1. Inventory Carbon Reinforced Concrete

Cradle-to-Gate

Use-Stage

End-of-Life

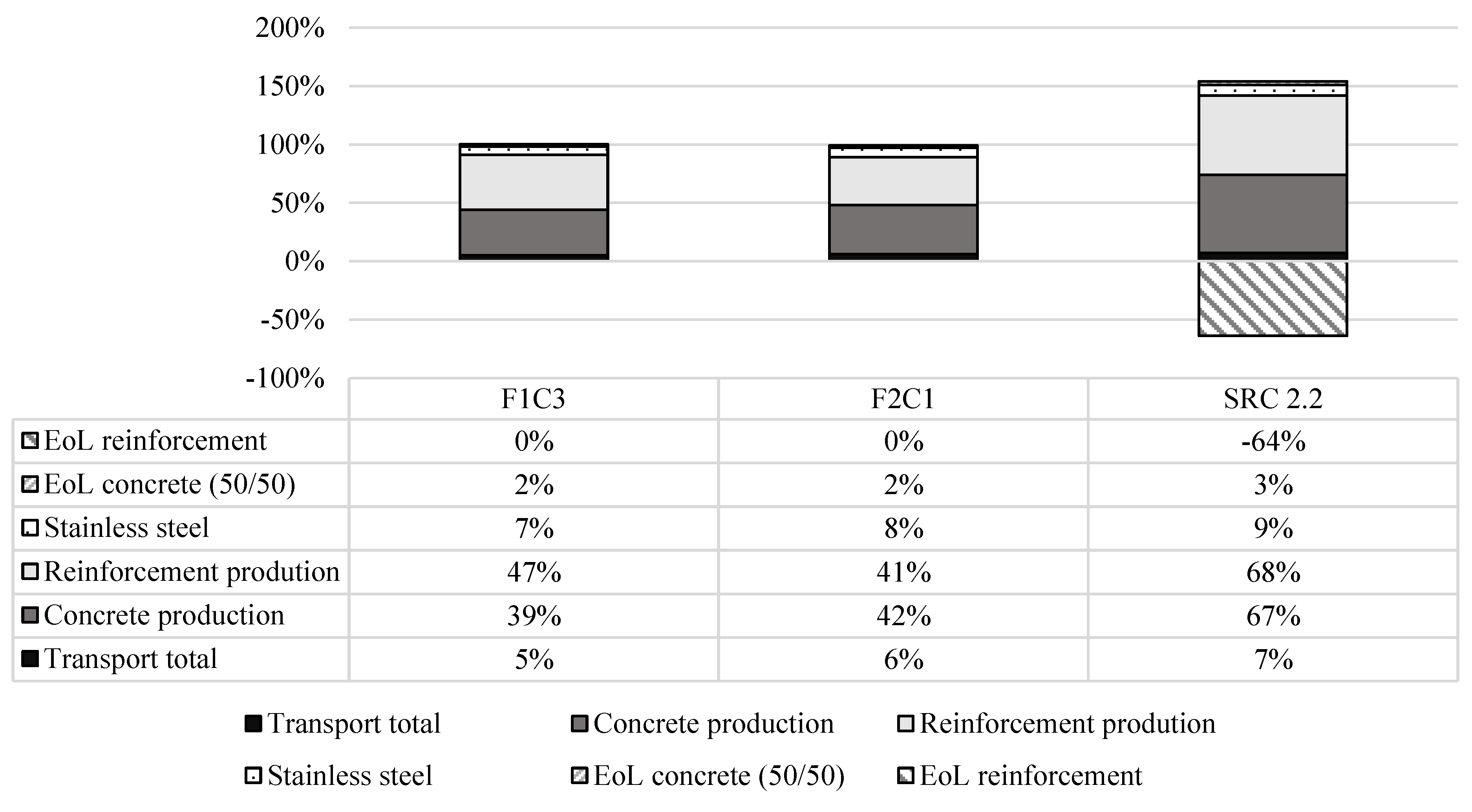

3.4. Life Cycle Impact Assessment and Interpretation

4. Discussion and Limitations

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| C | Concrete |

| CFRP | Carbon Fiber Reinforced Polymer |

| CO2e | Carbon Dioxide Equivalent |

| CRC | Carbon Reinforced Concrete |

| EoL | End-of-Life |

| EP | Epoxy Resin |

| FU | Functional Unit |

| F | Fiber |

| GWP | Global Warming Potential |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| PAN | Polyacrylonitrile |

| PE | Polyethylene |

| SBR | Styrene-Butadiene Rubber |

| SRC | Steel Reinforced Concrete |

| UHPC | Ultra-High-Performance Concrete |

References

- Onat, N.C.; Kucukvar, M.; Tatari, O. Integrating triple bottom line input-output analysis into life cycle sustainability assessment framework: The case for US buildings. Int. J. Life Cycle Assess. 2014, 19, 1488–1505. [Google Scholar] [CrossRef]

- Akhanova, G.; Nadeem, A.; Kim, J.R.; Azhar, S. A multi-criteria decision-making framework for building sustainability assessment in Kazakhstan. Sustain. Cities Soc. 2020, 52, 101842. [Google Scholar] [CrossRef]

- Choi, J.H. Strategy for reducing carbon dioxide emissions from maintenance and rehabilitation of highway pavement. J. Clean. Prod. 2019, 209, 88–100. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Tam, V.W.Y.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- Sameer, H.; Bringezu, S. Life cycle input indicators of material resource use for enhancing sustainability assessment schemes of buildings. J. Build. Eng. 2018, 21, 230–242. [Google Scholar] [CrossRef]

- Dong, Y.H.; Ng, S.T. A modeling framework to evaluate sustainability of building construction based on LCSA. Int. J. Life Cycle Assess. 2016, 21, 555–568. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- BMI. ÖKOBAUDAT 2021. Available online: https://www.oekobaudat.de/ (accessed on 22 May 2023).

- Cembureau. 2021 Activity Report. 2022. Available online: www.cembureau.eu (accessed on 22 May 2023).

- Spelter, A.; Bergmann, S.; Bielak, J.; Hegger, J. Long-term durability of carbon-reinforced concrete: An overview and experimental investigations. Appl. Sci. 2019, 9, 1651. [Google Scholar] [CrossRef]

- Bielak, J.; Hegger, J. Enhancing shear capacity of thin slabs with CFRP shear reinforcement: Experimental study. Struct. Concr. 2021, 22, 3057–3073. [Google Scholar] [CrossRef]

- Beckmann, B.; Bielak, J.; Bosbach, S.; Scheerer, S.; Schmidt, C.; Hegger, J.; Curbach, M. Collaborative research on carbon reinforced concrete structures in the CRC/TRR 280 project. Civ. Eng. Des. 2021, 3, 99–109. [Google Scholar] [CrossRef]

- Bielak, J.; Adam, V.; Hegger, J.; Classen, M. Shear capacity of textile-reinforced concrete slabs without shear reinforcement. Appl. Sci. 2019, 9, 1382. [Google Scholar] [CrossRef]

- Kraft, R.; Kahnt, A.; Grauer, O.; Thieme, M.; Wolz, D.S.; Schlüter, D.; Tietze, M.; Curbach, M.; Holschemacher, K.; Jäger, H. Advanced Carbon Reinforced Concrete Technologies for Façade Elements of Nearly Zero-Energy Buildings. Materials 2022, 15, 1619. [Google Scholar] [CrossRef]

- Bielak, J.; Schmidt, M.; Hegger, J.; Jesse, F. Structural behavior of large-scale I-beams with combined textile and CFRP reinforcement. Appl. Sci. 2020, 10, 4625. [Google Scholar] [CrossRef]

- Bielak, J.; Will, N.; Hegger, J.; Bosbach, S. Shear capacity of TRC slabs: Modelling and examples from practice. Am Concr Institute. ACI Spec. Publ. 2021, SP-345, 16–31. [Google Scholar] [CrossRef]

- Stark, A.; Classen, M.; Knorrek, C.; Camps, B.; Hegger, J. Sandwich panels with folded plate and doubly curved UHPFRC facings. Struct. Concr. 2018, 19, 1851–1861. [Google Scholar] [CrossRef]

- Eamon, C.D.; Jensen, E.A.; Grace, N.F.; Shi, X. Life-Cycle Cost Analysis of Alternative Reinforcement Materials for Bridge Superstructures Considering Cost and Maintenance Uncertainties. J. Mater. Civ. Eng. 2012, 24, 373–380. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneve, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneve, Switzerland, 2018.

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Backes, J.G.; Traverso, M.; Horvath, A. Environmental assessment of a disruptive innovation: Comparative cradle-to-gate life cycle assessments of carbon-reinforced concrete building component. Int. J. Life Cycle Assess. 2022, 28, 16–37. [Google Scholar] [CrossRef]

- Preinstorfer, P.; Huber, T.; Reichenbach, S.; Lees, J.M.; Kromoser, B. Parametric Design Studies of Mass-Related Global Warming Potential and Construction Costs of FRP-Reinforced Concrete Infrastructure. Polymers 2022, 14, 2383. [Google Scholar] [CrossRef] [PubMed]

- Reichenbach, S.; Preinstorfer, P.; Hammerl, M.; Kromoser, B. A review on embedded fibre-reinforced polymer reinforcement in structural concrete in Europe. Constr. Build. Mater. 2021, 307, 124946. [Google Scholar] [CrossRef]

- Seifert, W.; Lieboldt, M. Ressourcenverbrauch im globalen Stahlbetonbau und Potenziale der Carbonbetonbauweise: Globale Herausforderungen des Bauwesens. Beton Stahlbetonbau 2020, 115, 469–478. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries 2020; U.S. Geological Survey: Reston, VA, USA, 2020. [Google Scholar]

- DIN EN 1992-1-1:2011-01; Eurocode 2: Bemessung und Konstruktion von Stahlbeton- und Spannbetontragwerken - Teil 1-1: Allgemeine Bemessungsregeln und Regeln für den Hochbau; Deutsche Fassung EN 1992-1-1:2004 + AC:2010. Beuth Verlag: Berlin, Germany, 2011.

- DIN EN 1992-1-1/NA:2013-04; Nationaler Anhang - National festgelegte Parameter - Eurocode 2: Bemessung und Konstruktion von Stahlbeton- und Spannbetontragwerken - Teil 1-1: Allgemeine Bemessungsregeln und Regeln für den Hochbau. Beuth Verlag: Berlin, Germany, 2013.

- Kortmann, J. Verfahrenstechnische Untersuchungen zur Recyclingfähigkeit von Carbonbeton; Springer Vieweg: Dresden, Germany, 2020. [Google Scholar] [CrossRef]

- Lunn, D.; Lucier, G.; Rizkalla, S.; Cleland, N.; Gleich, H. New generation of precast concrete double tees reinforced with carbon-fiber Reinforced Polymer Grid. PCI J. 2015, 60, 37–48. [Google Scholar] [CrossRef]

- Schumann, A.; Michler, H.; Schladitz, F.; Curbach, M. Parking slabs made of carbon reinforced concrete. Struct. Concr. 2018, 19, 647–655. [Google Scholar] [CrossRef]

- Heppes, O. Von der Idee zur Industriellen Produktion von Parkhausdeckenplatten mit Carbonbeton; Technische Universität Kaiserslautern: Kaiserslautern, Germany, 2021. [Google Scholar]

- Hentschel, M.; Schumann, A.; Ulrich, H.; Jentzsch, S. Sanierung der Hyparschale Magdeburg. Bautechnik 2019, 96, 25–30. [Google Scholar] [CrossRef]

- Steinbock, O.; Teworte, F.; Neis, B. Carbonbeton—Eine neue Verstärkungsmethode für Massivbrücken: Teil 3: Planung und Umsetzung der Verstärkungsmaßnahme mit Carbonbeton am Pilot-projekt “Brücken über die Nidda im Zuge der BAB A 648”. Beton Stahlbetonbau 2021, 116, 118–126. [Google Scholar] [CrossRef]

- Stark, A.; Hegger, J. A calculation approach for sandwich panels with facings made of UHPFRC and pre-tensioned CFRP reinforcement. Eng. Struct. 2021, 243, 112331. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Pan, B.-Z.; Fan, T.-H.; Zhuge, Y.; Liu, F.; Li, L.-J. Shear behavior of FRP-UHPC tubular beams. Compos. Struct. 2023, 307, 116576. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Mechtcherine, V.; Bellmann, C.; Michel, S. Tensile behavior of high-strength strain-hardening cement-based composites (HS-SHCC) made with high-performance polyethylene, aramid and PBO fibers. Cem. Concr. Res. 2017, 98, 71–81. [Google Scholar] [CrossRef]

- C3 carbon concrete composite. Stoffkreislauf Carbonbeton. 2021. Available online: https://www.bauen-neu-denken.de/stoffkreislauf-carbonbeton/ (accessed on 22 May 2023).

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Impacts of booming concrete production on water resources worldwide. Nat. Sustain. 2018, 1, 69–76. [Google Scholar] [CrossRef]

- Becke, A.; Reiners, J.; Sülun, C. Erläuterungen zu den Umweltproduktdeklarationen für Beton; InformationsZentrum Beton GmbH: Erkrath, Germany, 2014. [Google Scholar]

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent progress in recycling carbon fibre reinforced composites and dry carbon fibre wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Khalil, Y.F. Comparative environmental and human health evaluations of thermolysis and solvolysis recycling technologies of carbon fiber reinforced polymer waste. Waste Manag. 2018, 76, 767–778. [Google Scholar] [CrossRef] [PubMed]

- Howarth, J.; Mareddy, S.S.R.R.; Mativenga, P.T. Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite. J. Clean. Prod. 2014, 81, 46–50. [Google Scholar] [CrossRef]

- Limburg, M.; Quicker, P. Entsorgung von Carbonfasern—Probleme des Recyclings und Auswirkungen auf die Abfallverbrennung. Berl. Abfallwirtsch. Energ. 2016, 13, 135–144. [Google Scholar]

- Backes, J.G.; del Rosario, P.; Petrosa, D.; Traverso, M.; Hatzfeld, T.; Guenther, E. Building sector issues in about 100 years: End-of-Life scenarios of carbon-reinforced concrete presented in the context of a Life Cycle Assessment, focusing the Carbon Footprint. Processes 2022, 10, 1791. [Google Scholar] [CrossRef]

- Traverso, M.; Finkbeiner, M.; Jørgensen, A.; Schneider, L. Life Cycle Sustainability Dashboard. J. Ind. Ecol. 2012, 16, 680–688. [Google Scholar] [CrossRef]

- Weidema, B. Has ISO 14040/44 Failed Its Role as a Standard for Life Cycle Assessment? J. Ind. Ecol. 2014, 18, 324–326. [Google Scholar] [CrossRef]

- ISO 15686-5; International Standard ISO 15686-5. Buildings and Constructed Assets—Sercive Life Planning. Part 5: Life-Cycle Costing. ISO: Geneve, Switzerland, 2017.

- DIN EN 15804:2012; Nachhaltigkeit von Bauwerken—Umweltproduktdeklarationen—Grundregeln für die Produktkategorie Bauprodukte. Beuth Verlag: Berlin, Germany, 2012.

- Hirai, T. Use of Continuous Fibers for Reinforcing Concrete. Concr. Int. 1992, 14, 58–60. [Google Scholar]

- von der Heid, A.C.; Grebe, R.; Will, N.; Hegger, J. Großformatige Sandwichelemente mit Deckschichten aus Textilbeton: Untersuchungen an Sandwichplattenstreifen. Beton Stahlbetonbau 2019, 114, 476–484. [Google Scholar] [CrossRef]

- Kulas, C.; Schneider, M.; Will, N.; Grebe, R. Hinterlüftete Vorhangfassaden aus Textilbeton: Tragverhalten und Ausführung. Bautechnik 2011, 88, 271–280. [Google Scholar] [CrossRef]

- Hegger, J.; Horstmann, M. Sandwichfassaden aus Textilbeton—Numerik und Ingenieurmodelle (Teil 2). Bautechnik 2011, 88, 373–384. [Google Scholar] [CrossRef]

- von der Heid, A.-C.; Grebe, R. Perforierte und vollflächige Fassadenplatten aus carbonbewehrtem Beton. Bauingenieur 2020, 95, 210–219. [Google Scholar] [CrossRef]

- Hering Bau GmbH & Co. KG. Allgemeine bauaufsichtliche Zulassung Z-10.3-723: Fassadenplatten “betoShell Neo 30” aus Textilbeton zur Verwendung bei vorgehängten hinterlüfteten Außenwandbekleidungen Z-10.3-723; Hering Bau GmbH & Co. KG: Berlin, Germany, 2017. [Google Scholar]

- Laiblová, L.; Pešta, J.; Kumar, A.; Hájek, P.; Fiala, C.; Vlach, T.; Kočí, V. Environmental impact of textile reinforced concrete facades compared to conventional solutions-lca case study. Materials 2019, 12, 3194. [Google Scholar] [CrossRef]

- Stoiber, N.; Hammerl, M.; Kromoser, B. Cradle-to-gate life cycle assessment of CFRP reinforcement for concrete structures: Calculation basis and exemplary application. J. Clean. Prod. 2021, 280, 124300. [Google Scholar] [CrossRef]

- Hülsmeier, F.; Kahnt, A.; Grauer, O.; Huth, S.; Kirmse, S.; Tietze, M. Vakutex Vakuumgedämmte Fassadenelemente aus Textilbeton Fraunhofer IRB Verlag; Fraunhofer IRB Verlag: Stuttgart, Germany, 2013. [Google Scholar]

- Roik, M.; Tietze, M.; Kahnt, A. A revival in façades: Textile reinforced concrete panels are light, safe and aethetically pleasing. Acta Polytech. CTU Proc. 2022, 33, 497–503. [Google Scholar] [CrossRef]

- DAfStb-Richtlinie. DAfStb-Richtlinie Betonbauteile mit Nichtmetallischer Bewehrung—Entwurf vom 06. September 2022. Berlin, Germany. 2022. Available online: https://www.beuth.de/de/technische-regel-entwurf/dafstb-betonbauteile-nichtmetallische-bewehrung/362887890 (accessed on 14 July 2023).

- CML—Department of Industrial Ecology. CML-IA Characterisation Factors. 2016. Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 14 July 2023).

- Backes, J.G.; Traverso, M. Life Cycle Sustainability Assessment in the construction sector—Actual application and future outlook. LCM 2021. [Google Scholar] [CrossRef]

- Backes, J.G.; Traverso, M. Application of Life Cycle Sustainability Assessment in the Construction Sector: A Systematic Literature Review. Processes 2021, 9, 1248. [Google Scholar] [CrossRef]

- Umweltbundesamt. Erneuerbare Energien in Deutschland—Daten zur Entwicklung 2020; Umweltbundesamt: Berlin/Bonn, Germany, 2021. [Google Scholar]

- DIN EN 206:2021-06; Beton - Festlegung, Eigenschaften, Herstellung und Konformität; Deutsche Fassung EN 206:2013+A2:2021. Beuth Verlag: Berlin, Germany, 2021.

- ISO 10406-1:2008; Fibre-reinforced polymer (FRP) reinforcement of concrete — Test methods — Part 1: FRP bars and grids. ISO: Geneve, Switzerland, 2008.

- DIN EN 1990:2021-10; Eurocode: Grundlagen der Tragwerksplanung; Deutsche Fassung EN 1990:2002 + A1:2005 + A1:2005/AC:2010. Beuth Verlag: Berlin, Germany, 2021.

- Halfen. HALFEN FPA-SL30 SYSTEM Produktinformation Technik. 2020. Available online: https://www.halfen.com/PDF-Dateien/Druckschriften/Technische%20Produktinformationen/FPA-SL30_Leviat_19.pdf (accessed on 14 July 2023).

- Bielak, J. Shear in Slabs With Non-Metallic Reinforcement; RWTH Aachen University: Aachen, Germany, 2021. [Google Scholar]

- Dorer, C.; Hahn, J. Energetische Optimierung der Betonherstellung im Transportbetonwerk. Bestandsaufnahme Ableitung Von Optim. 2015, 79. Available online: https://www.transportbeton.org/fileadmin/user_upload/Abschlussbericht_Energetische_Optimierung-2015-03-06-.pdf (accessed on 14 July 2023).

- Sjunnesson, J. Life cycle assessment of concrete. Environ. Energy Syst. Stud. 2005, 61. Available online: https://lup.lub.lu.se/luur/download?fileOId=4469176&func=downloadFile&recordOId=4468239 (accessed on 14 July 2023).

- Hohmann, A. Ökobilanzielle Untersuchung von Herstellungsverfahren für CFK-Strukturen zur Identifikation von Optimierungspotentialen. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2019. [Google Scholar]

- Backes, J.G.; Suer, J.; Pauliks, N.; Neugebauer, S.; Traverso, M. Life Cycle Assessment of an Integrated Steel Mill Using Primary Manufacturing Data: Actual Environmental Profile. Sustainability 2021, 13, 3443. [Google Scholar] [CrossRef]

- Suer, J.; Ahrenhold, F.; Traverso, M. Integration of direct reduction plants into classical basic oxygen furnace production sites—Carbon footprint and energy transformation analysis towards sustainable primary steel production. J. Sustain. Metall. 2022, 8, 1532–1545. [Google Scholar] [CrossRef]

- Backes, J.G.; Del Rosario, P.; Luthin, A.; Traverso, M. Comparative Life Cycle Assessment of End-of-Life Scenarios of Carbon-Reinforced Concrete: A Case Study. Appl. Sci. 2022, 12, 9255. [Google Scholar] [CrossRef]

- Sphera. Description of the CML 2001 Method 2020. Available online: www.gabi-software.com/support/gabi/gabi-lcia-documentation/cml-2001/%0D (accessed on 11 August 2020).

- Hatzfeld, T.; Backes, J.G.; Scope, C.; Guenther, E.; Traverso, M. Environmental Assessment of Carbon Reinforced Concrete Recycling Options. fib Conf. 2022, Oslo, Fédération Internationale du Béton—International Federation for Structural Concrete. 2022, pp. 892–900. Available online: https://www.fib-international.org/publications/fib-proceedings/6th-i-fib-i-international-congress-in-oslo,-norway-2022-proceedings-em-pdf-em-detail.html (accessed on 14 July 2023).

- Claßen, M.; Kurz, W. Zum Trag-und Verformungsverhalten von Verbundträgern mit Verbunddübelleisten und großen Stegöffnungen. Lehrstuhl Inst. Für Massivbau 2017. [Google Scholar] [CrossRef]

- Claßen, M.; Dressen, T. Experimental investigations on prestressed concrete beams with openings. ACI Struct. J. 2015, 112, 221. [Google Scholar] [CrossRef]

- Reissen, K.; Classen, M.; Hegger, J. Shear in reinforced concrete slabs—Experimental investigations in the effective shear width of one-way slabs under concentrated loads and with different degrees of rotational restraint. Struct. Concr. 2018, 19, 36–48. [Google Scholar] [CrossRef]

- Classen, M.; Gallwoszus, J.; Hegger, J.; Papakosta, A.; Kuhnhenne, M. Nachhaltigkeitsbewertung von Deckensystemen mit großen Spannweiten. Bauingenieur 2014, 89, 125–133. [Google Scholar]

| Material | Unit | Input | GaBi Process |

|---|---|---|---|

| CEM I 42.5 | kg/m3 | 300 | DE: Cement (CEM I 42.5) Portland cement (economically allocated binders) |

| Gravel 8 mm | 1274 | DE: Gravel (Grain size 2/32) | |

| Superplasticizer PCE | 1.2 | DE: Concrete admixtures—plasticizer and superplasticizer—Deutsche bauchemie e.V. (DBC) | |

| Sand 0/2 (dried) | 772 | DE: Sand (grain size 0/2) dried | |

| Water | 105 | DE: Tap water from surface water | |

| Truck | km | 100 | GLO: Truck, euro4, 28–32 t gross weight/22 t payload capacity |

| Concrete Mixing | kWh/m3 | 9.2 | DE: Electricity grid mix (2020) |

| Material | Unit | Input | GaBi Process |

|---|---|---|---|

| CEM I 52.5 | kg/m3 | 300 | DE: Cement (CEM I 52,5) (burden-free binders) |

| Gravel 8 mm | 1240 | DE: Gravel (Grain size 2/32) | |

| Superplasticizer PCE | 0.6 | DE: Concrete admixtures—plasticizer and superplasticizer—Deutsche bauchemie e.V. (DBC) | |

| Sand 0/2 (dried) | 750 | DE: Sand (grain size 0/2) dried | |

| Water | 126 | DE: Tap water from surface water | |

| Truck | km | 100 | GLO: Truck, euro4, 28–32 t gross weight/22 t payload capacity |

| Concrete Mixing | kWh/m3 | 9.2 | DE: Electricity grid mix (2020) |

| Material | Unit | Input | GaBi Process |

|---|---|---|---|

| Impregnated yarn (PAN bases, Epoxy Resin) | kg/m2 | 0.592 | DE: Carbon fiber reinforced plastic part—63—(CFRP. CF: GLO, P: DE) |

| Truck | km | 100 | GLO: Truck, euro4, 28–32 t gross weight/22 t payload capacity |

| Production of carbon grid | kWh | 0.05 | DE: Electricity grid mix (2020) |

| Material | Unit | Input | GaBi Process |

|---|---|---|---|

| Impregnated fiber (PAN bases, Epoxy Resin) | kg/m2 | 0.592 | DE: Carbon fiber reinforced plastic part—65—(CFRP. CF: GLO, P: DE) [optimized energy] |

| Truck | km | 100 | GLO: Truck, euro4, 28–32 t gross weight/22 t payload capacity |

| Production of carbon grid | kWh | 0.05 | DE: Electricity grid mix (2020) |

| Material | Unit | Input | GaBi Process |

|---|---|---|---|

| Raw fiber | kg/m2 | 0.342 | DE: Carbon fiber reinforced plastic part—8 |

| Epoxy resin | kg/m2 | 0.218 | DE: Epoxy Resin (EP) Mix |

| Credit blend raw fiber | kg/m2 | 0.02 | EU-28: Textile Landfill |

| Truck | km | 100 | GLO: Truck, euro4, 28–32 t gross weight/22 t payload capacity |

| Production of carbon grid | kWh | 1.05 | DE: Electricity grid mix (2020) |

| Impregnation | kWh | 0.44 | DE: Electricity grid mix (2020) |

| Abbreviation | Explanation—Related to Life Cycle Inventory |

|---|---|

| F1C1 | fiber impregnated, conventional energy, and CEM I 42.5 |

| F1C2 | fiber impregnated, conventional energy, and CEM I 52.5 |

| F1C3 | fiber impregnated, conventional energy, and C50/60 |

| F2C1 | fiber-impregnated, optimized energy, and CEM I 42.5 |

| F2C2 | fiber-impregnated, optimized energy, and CEM I 52.5 |

| F2C3 | fiber-impregnated, optimized energy, and C50/60 |

| F3C1 | fiber own model and CEM I 42.5 |

| F3C2 | fiber own model and CEM I 52.5 |

| F3C3 | fiber own model and C50/60 |

| SRC1 | steel, blast furnace (2.2 kg CO2e/kg), and C35/45 |

| SRC2 | steel, electric arc furnace (0.9 kg CO2e/kg), and C35/45 |

| SRC3 | Steel, recycling steel/electric arc furnace (0.5 kg CO2e/kg), and C35/45 |

| In kg CO2e | F1C3 * (Worst) | F2C1 * (Best) | F1C3 † (Worst) | F2C1 † (Best) | SRC 2.2 * |

|---|---|---|---|---|---|

| Cradle-to-gate | 467 | 382 | 467 | 382 | 733 |

| in % of total | 94% | 93% | 88% | 86% | 149% |

| Use phase (transport) | 29 | 29 | 29 | 29 | 59 |

| in % of total | 6% | 7% | 6% | 7% | 12% |

| EoL | 0.2 | 0.2 | 31.5 | 31.5 | −299,9 |

| in % of total | 0% | 0% | 6% | 7% | −61% |

| Total | 496 | 411 | 527 | 442 | 492 |

| EoL-Scenario for Both Façade Panels | ||||

|---|---|---|---|---|

| GWP in kg CO2e/ Façade Panel/Lifetime | Assumed Lifetime in Years | GWP in kg CO2e/ Façade Panel/Lifetime | Assumed Lifetime in Years | |

| F1C3 | 4.96 | 100 | 4.96 | 100 |

| F1C3 100% LF | 5.27 | 5.27 | ||

| F2C1 | 4.11 | 100 | 4.11 | 100 |

| F2C1 100% LF | 4.42 | 4.42 | ||

| SRC1 (2.2) | 9.84 | 50 | 6.15 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Backes, J.G.; Schmidt, L.; Bielak, J.; Del Rosario, P.; Traverso, M.; Claßen, M. Comparative Cradle-to-Grave Carbon Footprint of a CFRP-Grid Reinforced Concrete Façade Panel. Sustainability 2023, 15, 11548. https://doi.org/10.3390/su151511548

Backes JG, Schmidt L, Bielak J, Del Rosario P, Traverso M, Claßen M. Comparative Cradle-to-Grave Carbon Footprint of a CFRP-Grid Reinforced Concrete Façade Panel. Sustainability. 2023; 15(15):11548. https://doi.org/10.3390/su151511548

Chicago/Turabian StyleBackes, Jana Gerta, Laura Schmidt, Jan Bielak, Pamela Del Rosario, Marzia Traverso, and Martin Claßen. 2023. "Comparative Cradle-to-Grave Carbon Footprint of a CFRP-Grid Reinforced Concrete Façade Panel" Sustainability 15, no. 15: 11548. https://doi.org/10.3390/su151511548

APA StyleBackes, J. G., Schmidt, L., Bielak, J., Del Rosario, P., Traverso, M., & Claßen, M. (2023). Comparative Cradle-to-Grave Carbon Footprint of a CFRP-Grid Reinforced Concrete Façade Panel. Sustainability, 15(15), 11548. https://doi.org/10.3390/su151511548