Mechanical Properties of Polyamide Fiber-Reinforced Lime–Cement Concrete

Abstract

1. Introduction

2. Raw Materials

3. Methodology, Sample Preparation, and Testing

4. Results and Discussion

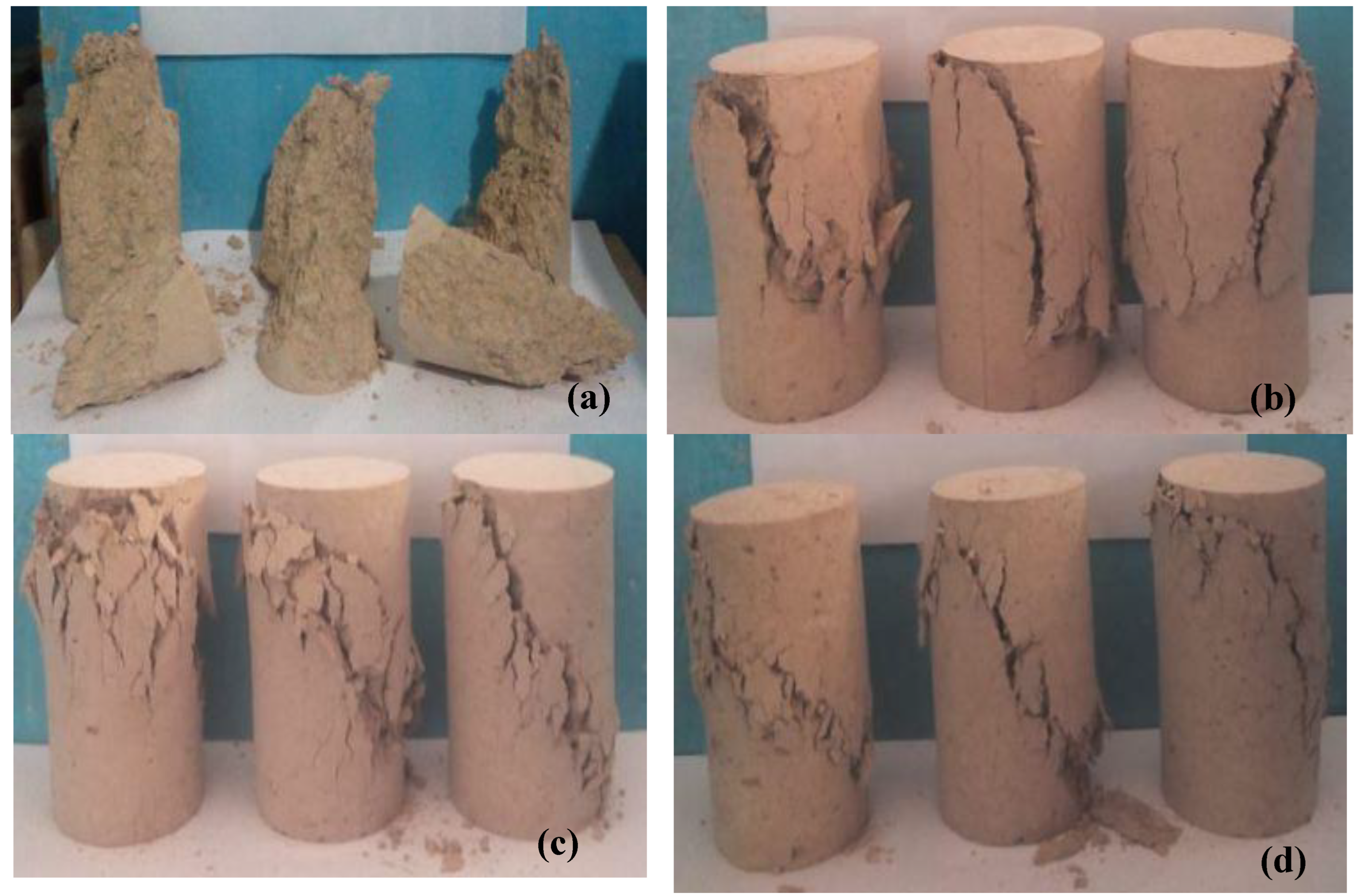

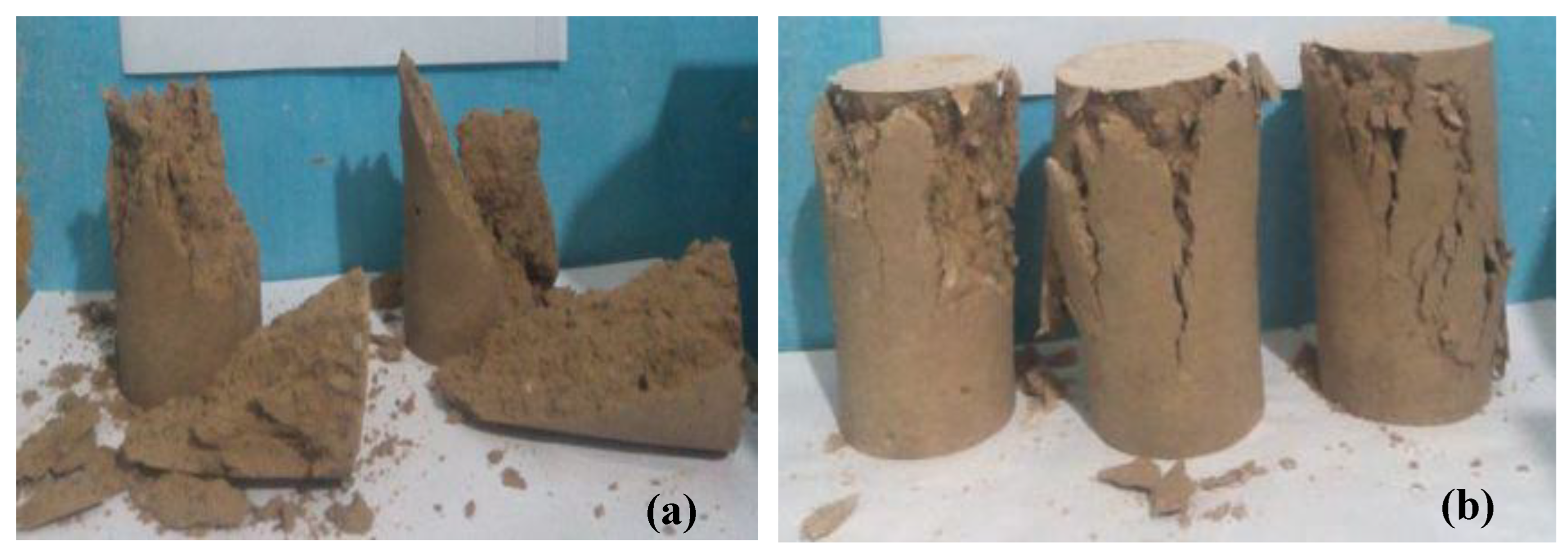

4.1. Failure Pattern

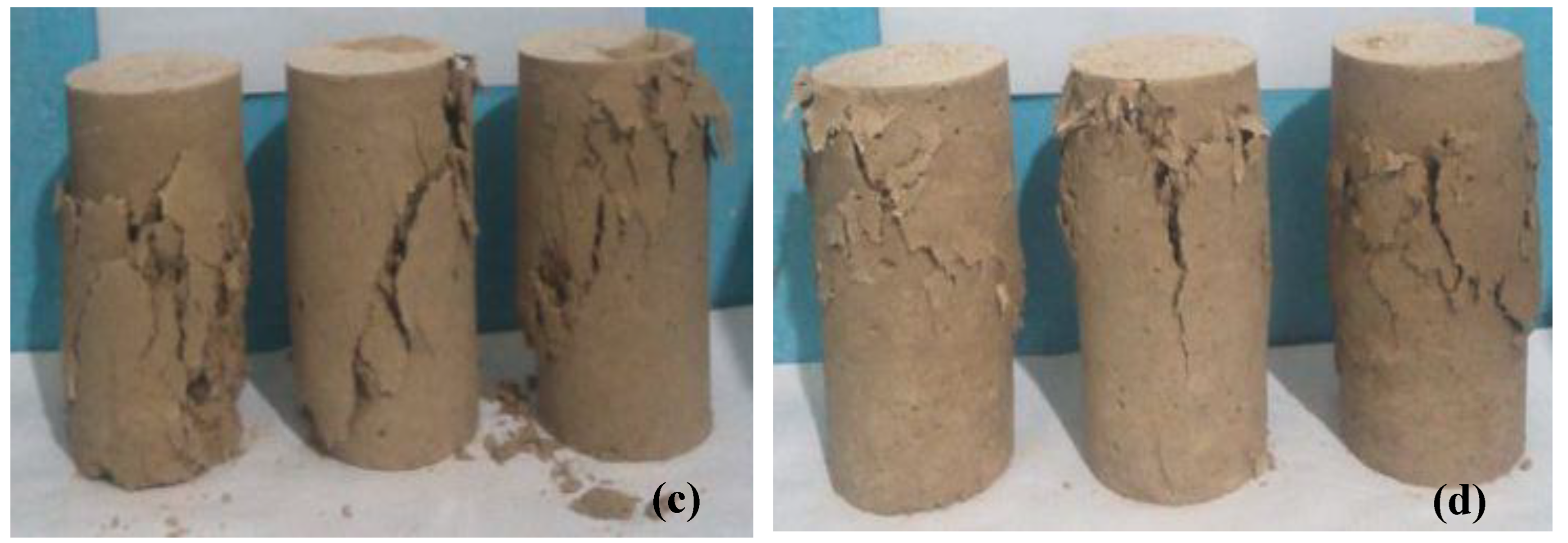

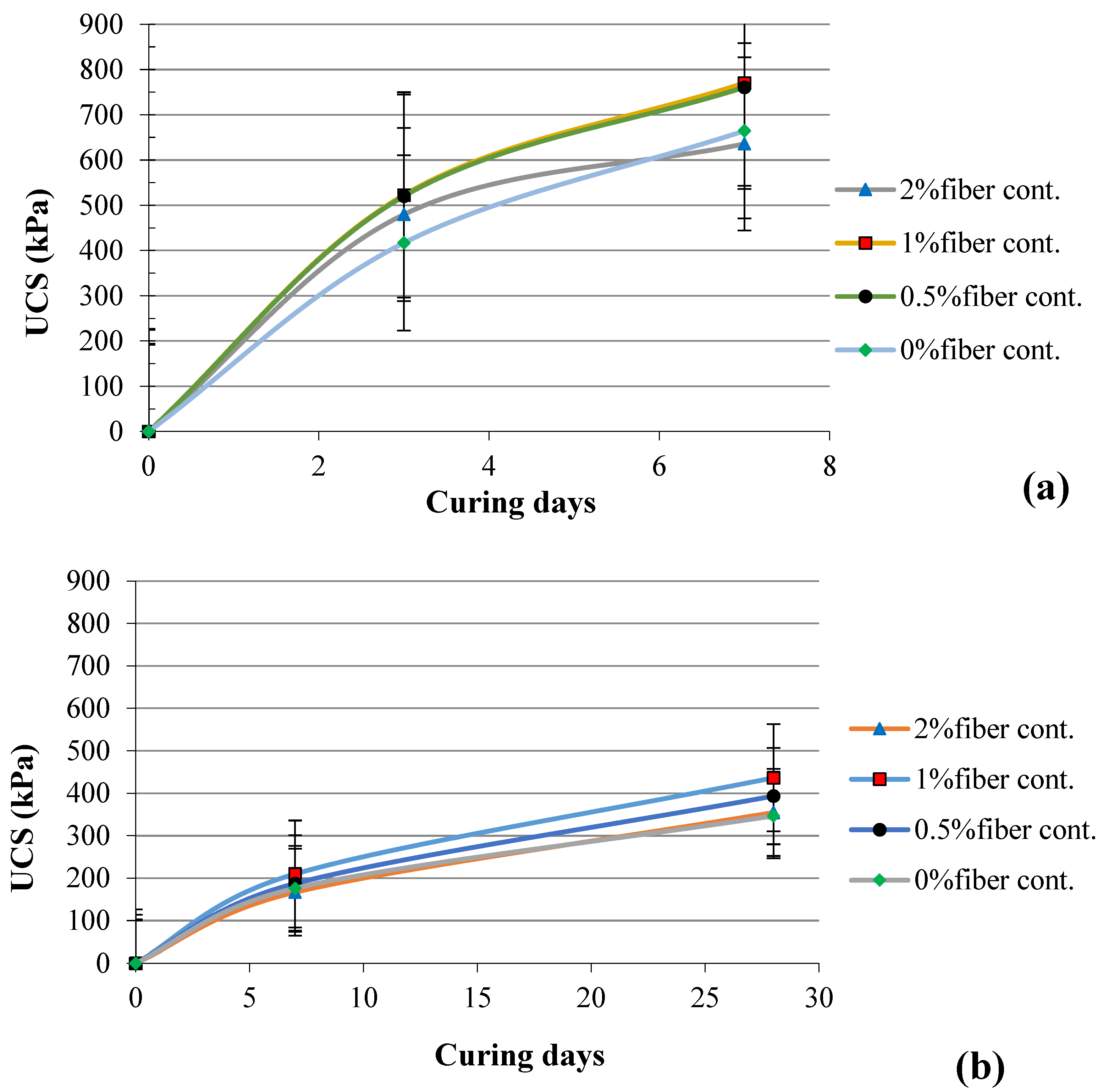

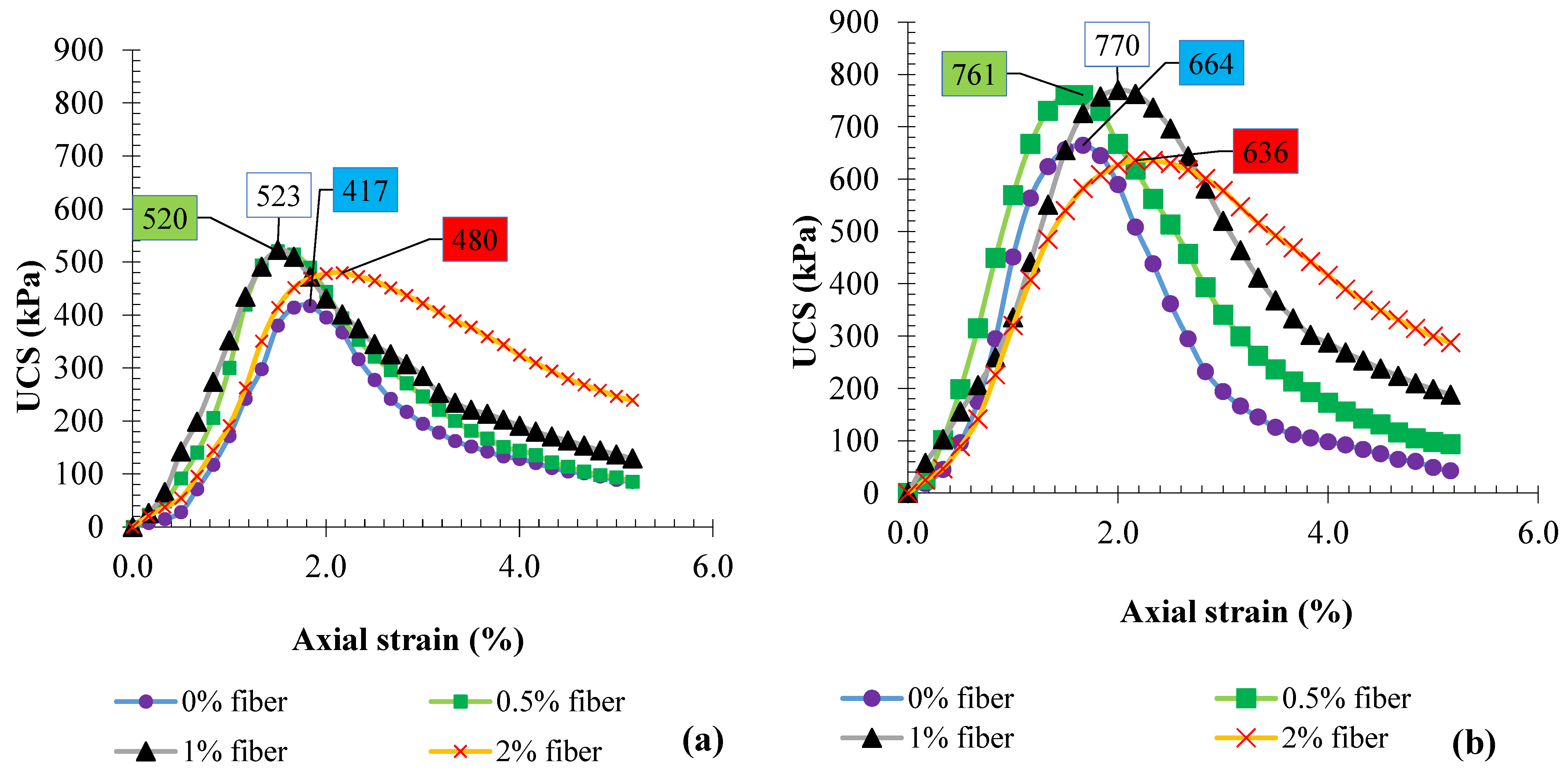

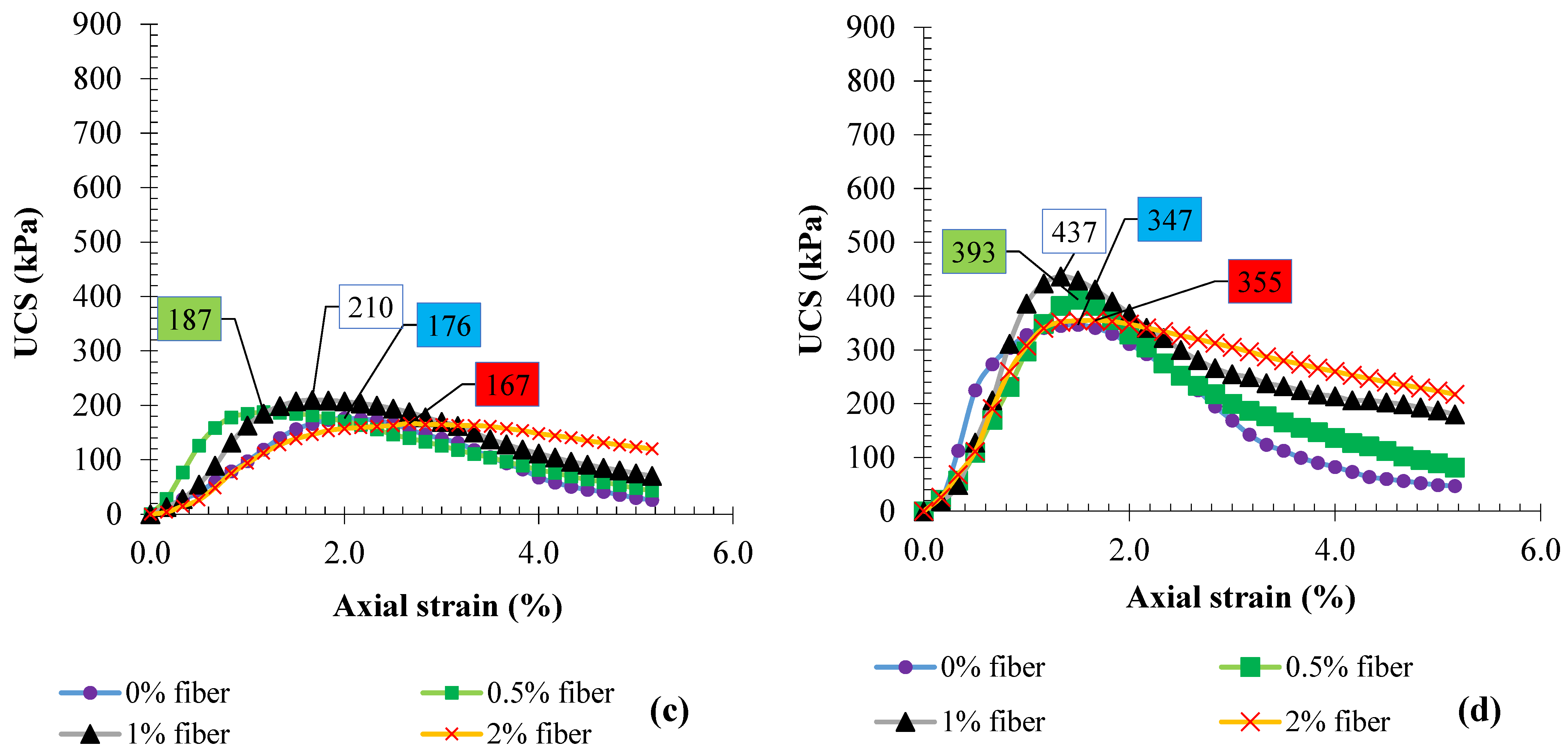

4.2. Unconfined Compressive Strength and Stress–Strain Properties of Lime–Cement Concrete

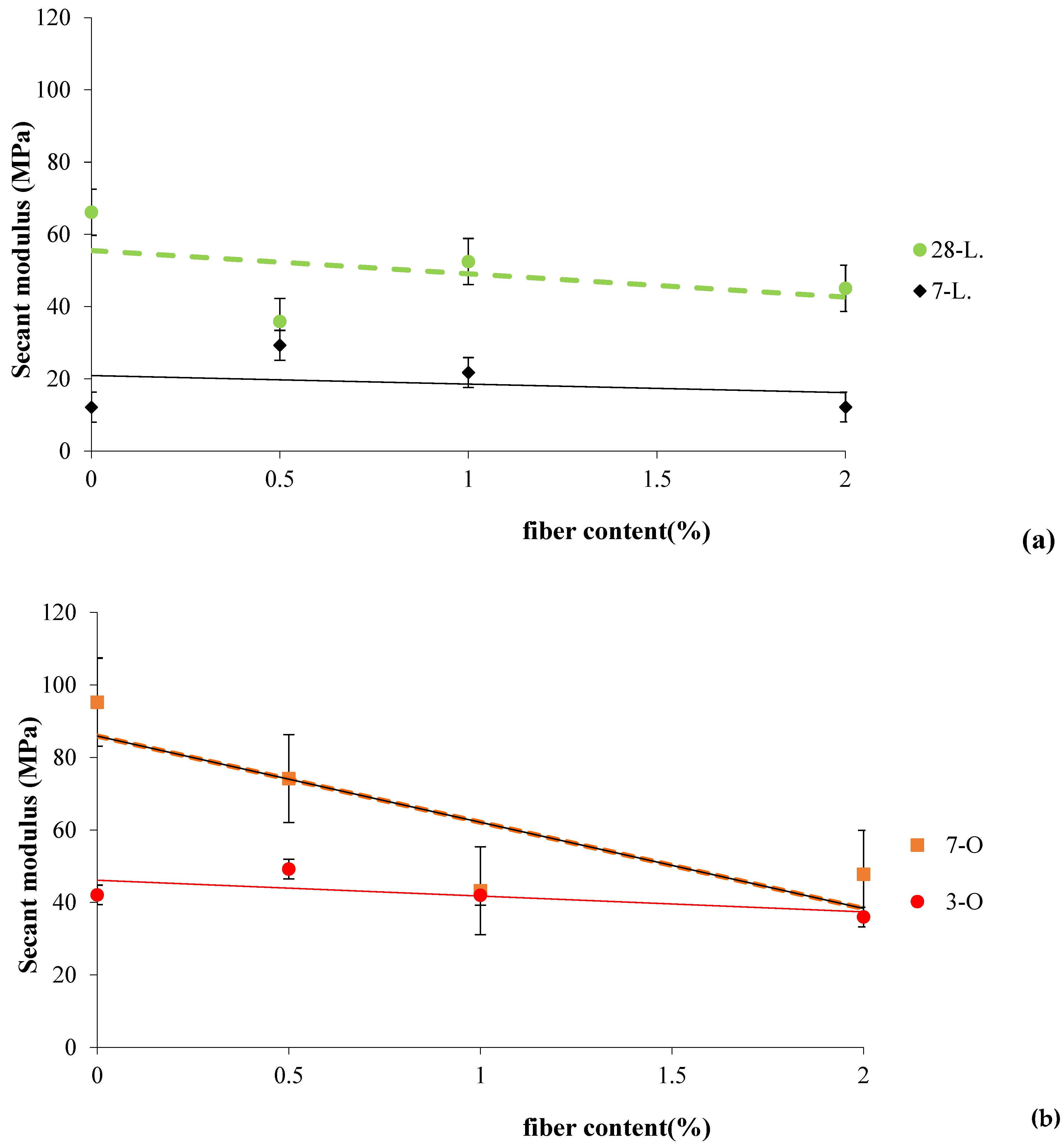

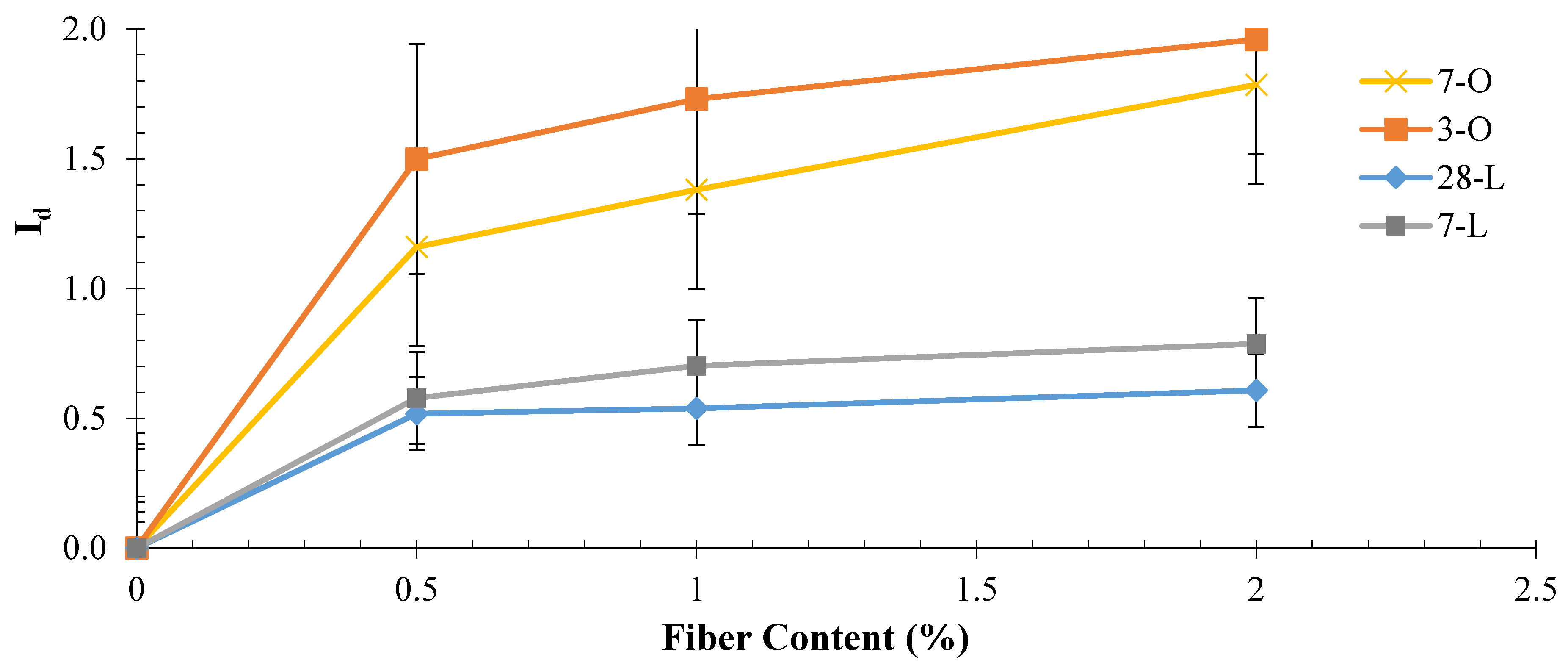

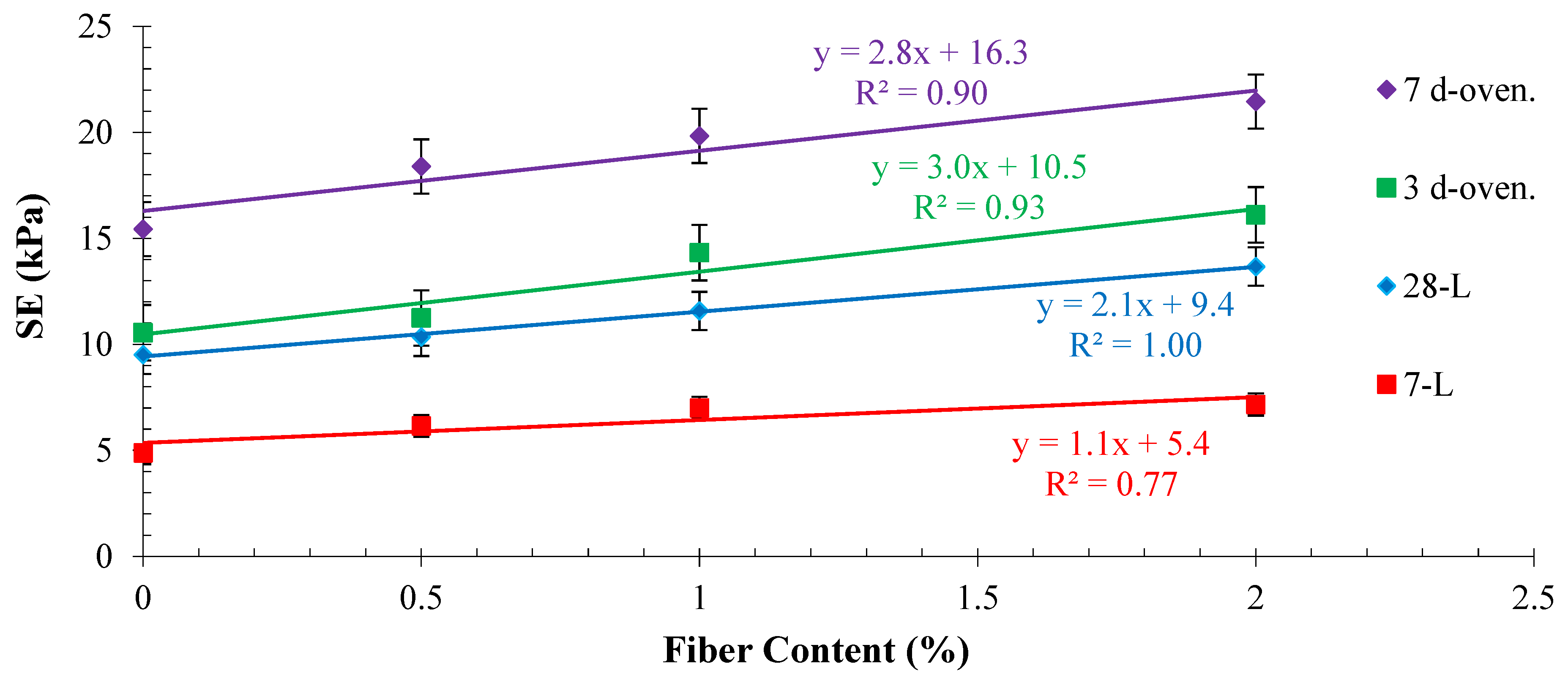

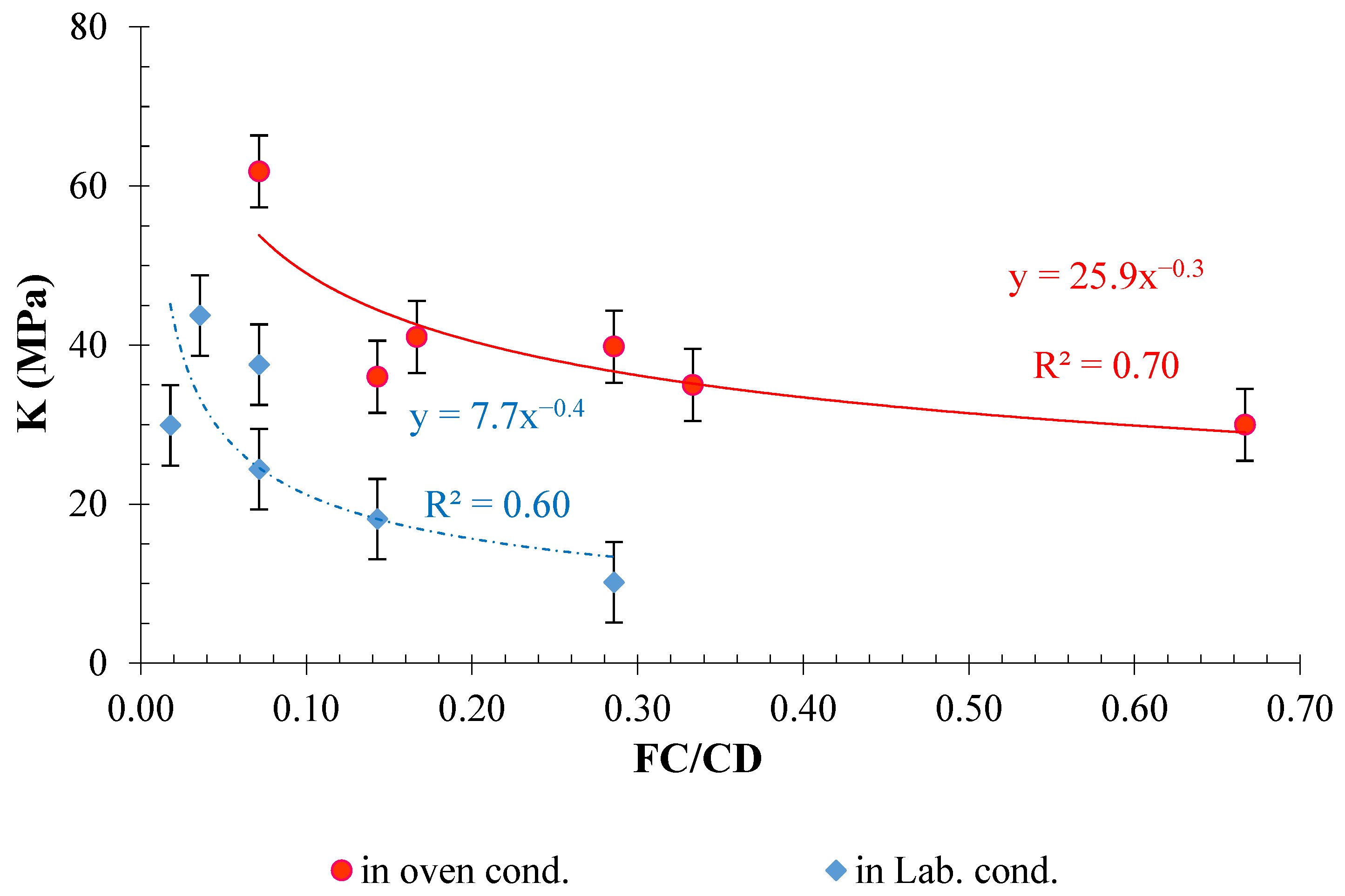

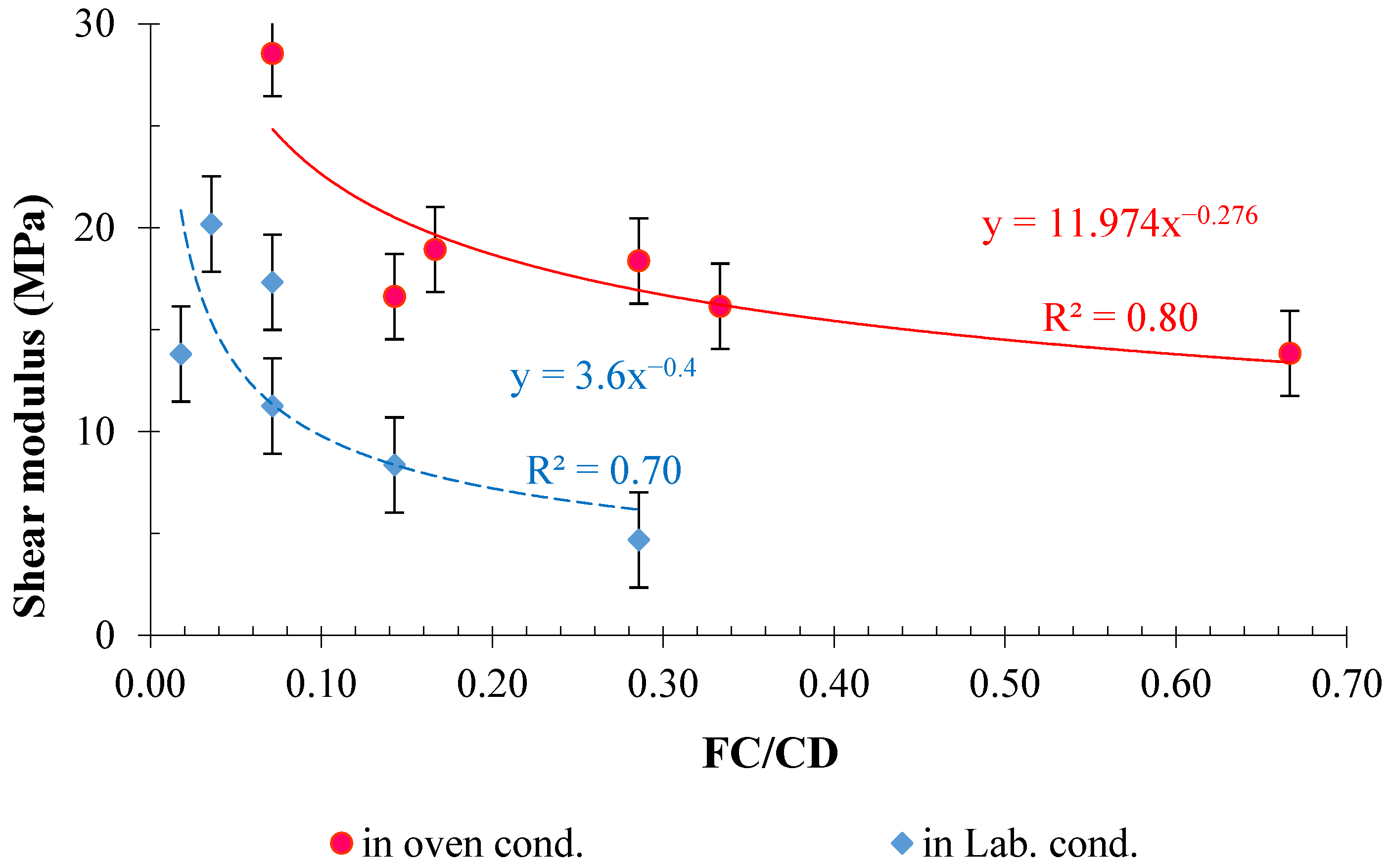

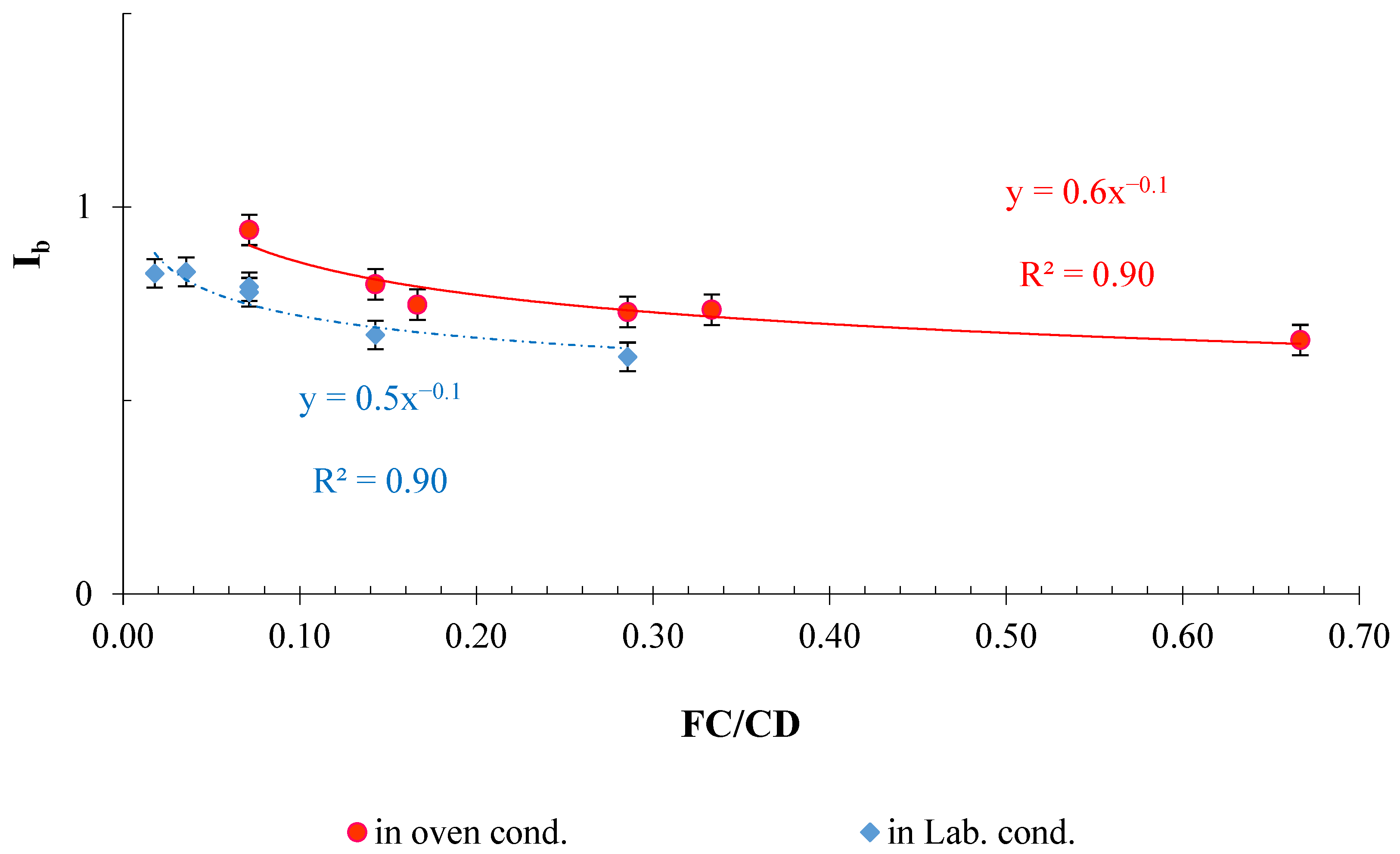

4.3. Mechanical Properties of Lime–Cement Concrete

5. Mathematical (Phenomenological) Model

6. Conclusions

- The optimum fiber content to increase the UCS of LCC is 1%. Increasing the fiber content from 1% to 2% led to a decrease in the UCS due to a reduction in cohesion;

- The energy absorption in LCC increased with increasing fiber content. In addition, LCC with a higher fiber content (i.e., over 1%) showed more ductile post-peak behavior compared to LCC with a lower fiber content;

- Curing times and conditions have significant effects on UCS values. Specimens cured in oven conditions showed higher UCS values compared to the ambient-cured specimens;

- The application of polyamide fibers, in general, showed a positive impact on improving the mechanical properties of LCC. However, the secant modulus of specimens for any curing condition and curing period decreased by increasing the fiber content;

- The deformability index of specimens for any curing condition and curing period increased by increasing the fiber content;

- Based on the laboratory test results, simple models were developed to predict the mechanical properties of LCC samples in relation to fiber content and curing days. Their prediction accuracy is reasonably good.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Islam, M.S.; Hashim, R. Bearing Capacity of Stabilised Tropical Peat by Deep Mixing Method. Aust. J. Basic Appl. Sci. 2009, 3, 682–688. [Google Scholar]

- Al-Swaidani, A.; Hammoud, I.; Meziab, A. Effect of Adding Natural Pozzolana on Geotechnical Properties of Lime-Stabilized Clayey Soil. J. Rock Mech. Geotech. Eng. 2016, 8, 714–725. [Google Scholar] [CrossRef]

- Umar, M.; Kassim, K.A.; Chiet, K.T.P. Biological Process of Soil Improvement in Civil Engineering: A Review. J. Rock Mech. Geotech. Eng. 2016, 8, 767–774. [Google Scholar] [CrossRef]

- Saberian, M.; Khabiri, M.M. Effect of Oil Pollution on Function of Sandy Soils in Protected Deserts and Investigation of Their Improvement Guidelines (case Study: Kalmand Area, Iran). Environ. Geochem. Health 2018, 40, 243–254. [Google Scholar] [CrossRef] [PubMed]

- Zainorabidin, A.; Wijeyesekera, D.C. Geotechnical Challenges with Malaysian Peat. 2007. Available online: https://repository.uel.ac.uk/download/41d7bd3a3df6b74d6069261c0817e0b8f3d7dad24a5ff57f5dc3af0e34011ad3/363072/Zainorabidin%2C%20A%20%282007%29%20AC%26T%20252-61.pdf (accessed on 13 April 2023).

- Puppala, A.J.; Musenda, C. Effects of Fiber Reinforcement on Strength and Volume Change in Expansive Soils. Transp. Res. Rec. 2000, 1736, 134–140. [Google Scholar] [CrossRef]

- Saberian, M.; Rahgozar, M.A. Geotechnical Properties of Peat Soil Stabilised with Shredded Waste Tyre Chips in Combination with Gypsum, Lime or Cement. Mires Peat 2016, 18, 1–16. [Google Scholar] [CrossRef]

- Rogers, C.D.; Boardman, D.I.; Papadimitriou, G. Stress Path Testing of Realistically Cured Lime and Lime/cement Stabilized Clay. J. Mater. Civ. Eng. 2006, 18, 259–266. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Zodinsanga, S. Swell–shrink Behaviour of Lime Precipitation Treated Soil. Proc. Inst. Civ. Eng. Improv. 2014, 167, 260–273. [Google Scholar] [CrossRef]

- Jahandari, S. Laboratory Study of Moisture and Capillarity Impact on Lime Concrete Resistance due to the Increase of Ground Water Level; Faculty of Civil and Surveying Engineering, Department of Geotechnical Engineering, Graduate University of Advanced Technology: Kerman, Iran, 2015. [Google Scholar]

- Ameri, M.; Kalantari, B.; Jahandari, S. Laboratory Study of Determination of Optimum Amount of Water and Clay in Mortar Made with Lime and Fly Ash. In Proceedings of the International Conference on Research in Science and Technology, Kualalumpur, Malaysia, 14 December 2015. [Google Scholar]

- Jahandari, S.; Saberian, M.; Zivari, F.; Li, J.; Ghasemi, M.; Vali, R. Experimental Study of the Effects of Curing Time on Geotechnical Properties of Stabilized Clay with Lime and Geogrid. Int. J. Geotech. Eng. 2019, 13, 172–183. [Google Scholar] [CrossRef]

- Jahandari, S.; Toufigh, M.M.; Li, J.; Saberian, M. Laboratory Study of the Effect of Degrees of Saturation on Lime Concrete Resistance due to the Groundwater Level Increment. Geotech. Geol. Eng. 2018, 36, 413–424. [Google Scholar] [CrossRef]

- Jahandari, S.; Li, J.; Saberian, M.; Shahsavarigoughari, M. Experimental Study of the Effects of Geogrids on Elasticity Modulus, Brittleness, Strength, and Stress-Strain Behavior of Lime Stabilized Kaolinitic Clay. GeoResJ 2017, 13, 49–58. [Google Scholar] [CrossRef]

- Saberian, M.; Jahandari, S.; Li, J.; Zivari, F. Effect of Curing, Capillary Action, and Groundwater Level Increment on Geotechnical Properties of Lime Concrete: Experimental and Prediction Studies. J. Rock Mech. Geotech. Eng. 2017, 9, 638–647. [Google Scholar] [CrossRef]

- Firoozfar, A.; Khosroshiri, N. Kerman Clay Improvement by Lime and Bentonite to Be Used as Materials of Landfill Liner. Geotech. Geol. Eng. 2017, 35, 559–571. [Google Scholar] [CrossRef]

- Costigan, A.; Pavía, S.; Kinnane, O. An Experimental Evaluation of Prediction Models for the Mechanical Behavior of Unreinforced, Lime-Mortar Masonry under Compression. J. Build. Eng. 2015, 4, 283–294. [Google Scholar] [CrossRef]

- Pavlík, V.; Užáková, M. Effect of Curing Conditions on the Properties of Lime, Lime–metakaolin and Lime–zeolite Mortars. Constr. Build. Mater. 2016, 102, 14–25. [Google Scholar] [CrossRef]

- de Bruijn, P.B.; Jeppsson, K.-H.; Sandin, K.; Nilsson, C. Mechanical Properties of Lime–hemp Concrete Containing Shives and Fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Walker, R.; Pavia, S.; Mitchell, R. Mechanical Properties and Durability of Hemp-Lime Concretes. Constr. Build. Mater. 2014, 61, 340–348. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Samuel, Z.; Kumar, K.S.R. Relative Efficiencies of Electrolytes in Stabilization of an Expansive Soil. Int. J. Geotech. Eng. 2016, 10, 107–113. [Google Scholar] [CrossRef]

- Bartlett, S.; Farnsworth, C. Performance of Lime Cement-Stabilized Soils for the I-15 Reconstruction Project: Salt Lake City, Utah. Transp. Res. Rec. 2002, 1808, 58–66. [Google Scholar] [CrossRef]

- Chand, S.K.; Subbarao, C. Strength and Slake Durability of Lime Stabilized Pond Ash. J. Mater. Civ. Eng. 2007, 19, 601–608. [Google Scholar] [CrossRef]

- Malekpoor, M.; Toufigh, M. Laboratory Study of Soft Soil Improvement Using Lime Mortar-(well Graded) Soil Columns. Geotech. Test. J. 2010, 33, 225–235. [Google Scholar]

- Toohey, N.M.; Mooney, M.A.; Bearce, R.G. Stress-Strain-Strength Behavior of Lime-Stabilized Soils during Accelerated Curing. J. Mater. Civ. Eng. 2013, 25, 1880–1886. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Ozbakkaloglu, T. Synthetic Fibers for Cementitious Composites: A Critical and in-Depth Review of Recent Advances. Constr. Build. Mater. 2019, 207, 491–518. [Google Scholar] [CrossRef]

- Wang, L.; Tang, S. High-Performance Fiber-Reinforced Composites: Latest Advances and Prospects. Buildings 2023, 13, 1094. [Google Scholar] [CrossRef]

- Wang, L.; Tang, S.; Chen, T.E.; Li, W.; Gunasekara, C. Sustainable High-Performance Hydraulic Concrete. Sustainability 2022, 14, 695. [Google Scholar] [CrossRef]

- Wang, L.; Tang, S. High-Performance Construction Materials: Latest Advances and Prospects. Buildings 2022, 12, 928. [Google Scholar] [CrossRef]

- Maher, M.H.; Ho, Y.C. Behavior of Fiber-Reinforced Cemented Sand under Static and Cyclic Loads. Geotech. Test. J. 1993, 16, 330–338. [Google Scholar]

- Omine, K.; Ochiai, H.; Yasufuku, N.; Kato, T. Effect of Plastic Wastes in Improving Cement-Treated Soils. Proc. 2nd Int. Congr. Environ. Geotech. 1996, 875–880. [Google Scholar]

- Prabakar, J.; Sridhar, R.S. Effect of Random Inclusion of Sisal Fibre on Strength Behaviour of Soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Čermák, J. Triaxial Compression of Sand Reinforced with Fibers. J. Geotech. Geoenviron. Eng. 2003, 129, 125–136. [Google Scholar] [CrossRef]

- Cai, Y.; Shi, B.; Ng, C.W.W.; Tang, C.S. Effect of Polypropylene Fibre and Lime Admixture on Engineering Properties of Clayey Soil. Eng. Geol. 2006, 87, 230–240. [Google Scholar] [CrossRef]

- Miraftab, M.; Lickfold, A. Utilization of Carpet Waste in Reinforcement of Substandard Soils. J. Ind. Text. 2008, 38, 167–174. [Google Scholar] [CrossRef]

- Lovisa, J.; Shukla, S.K.; Sivakugan, N. Behaviour of Prestressed Geotextile-Reinforced Sand Bed Supporting a Loaded Circular Footing. Geotext. Geomembr. 2010, 28, 23–32. [Google Scholar] [CrossRef]

- Mandal, J.N.; Murthi, M.V.R. Potential Use of Natural Fibres in Geotechnical Engineering. In Proceedings of the International Workshops on Geo-Textiles, Bangalore, India, 22 November 1989; pp. 22–29. [Google Scholar]

- Sivakumar Babu, G.L.; Vasudevan, A.K. Strength and Stiffness Response of Coir Fiber-Reinforced Tropical Soil. J. Mater. Civ. Eng. 2008, 20, 571–577. [Google Scholar] [CrossRef]

- Dang, L.C.; Fatahi, B.; Khabbaz, H. Behaviour of Expansive Soils Stabilized with Hydrated Lime and Bagasse Fibres. Procedia Eng. 2016, 143, 658–665. [Google Scholar] [CrossRef]

- Kafodya, I.; Okonta, F. Effects of Natural Fiber Inclusions and Pre-Compression on the Strength Properties of Lime-Fly Ash Stabilised Soil. Constr. Build. Mater. 2018, 170, 737–746. [Google Scholar] [CrossRef]

- Yixian, W.; Panpan, G.; Shengbiao, S.; Haiping, Y.; Binxiang, Y. Study on Strength Influence Mechanism of Fiber-Reinforced Expansive Soil Using Jute. Geotech. Geol. Eng. 2016, 34, 1079–1088. [Google Scholar] [CrossRef]

- Azadegan, O.; Kaffash, E.A.; Yaghoubi, M.J.; Pourebrahim, G.R. Laboratory Study on the Swelling, Cracking and Mechanical Characteristics of the Palm Fiber Reinforced Clay. Electron. J. Geotech. Eng. 2012, 17, 47–54. [Google Scholar]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of Clayey Soils Using Scrap Tire Rubber and Synthetic Fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- Consoli, N.C.; Montardo, J.P.; Donato, M.; Prietto, P.D. Effect of Material Properties on the Behaviour of Sand—Cement—Fibre Composites. Proc. Inst. Civ. Eng. Improv. 2004, 8, 77–90. [Google Scholar] [CrossRef]

- Chaduvula, U.; Viswanadham, B.V.S.; Kodikara, J. A Study on Desiccation Cracking Behavior of Polyester Fiber-Reinforced Expansive Clay. Appl. Clay Sci. 2017, 142, 163–172. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.; Ulbrich, L.A. Influence of Fiber and Cement Addition on Behavior of Sandy Soil. J. Geotech. Geoenviron. Eng. 1998, 124, 1211–1214. [Google Scholar] [CrossRef]

- Mukherjee, K.; Mishra, A.K. Hydro-Mechanical Properties of Sand-Bentonite-Glass Fiber Composite for Landfill Application. KSCE J. Civ. Eng. 2019, 23, 4631–4640. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, B. Strength and Deformation Behavior of Fiber-Reinforced Cohesive Soil under Varying Moisture and Compaction States. Geotech. Geol. Eng. 2017, 35, 1767–1781. [Google Scholar] [CrossRef]

- Gao, L.; Zhou, Q.; Yu, X.; Wu, K.; Mahfouz, A.H. Experimental Study on the Unconfined Compressive Strength of Carbon Fiber Reinforced Clay Soil. Mar. Georesources Geotechnol. 2017, 35, 143–148. [Google Scholar] [CrossRef]

- Cui, H.; Jin, Z.; Bao, X.; Tang, W.; Dong, B. Effect of Carbon Fiber and Nanosilica on Shear Properties of Silty Soil and the Mechanisms. Constr. Build. Mater. 2018, 189, 286–295. [Google Scholar] [CrossRef]

- Fatahi, B.; Khabbaz, H.; Fatahi, B. Mechanical Characteristics of Soft Clay Treated with Fibre and Cement. Geosynth. Int. 2012, 19, 252–262. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A Simple Review of Soil Reinforcement by Using Natural and Synthetic Fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Valipour, M.; Shourijeh, P.T.; Mohammadinia, A. Application of Recycled Tire Polymer Fibers and Glass Fibers for Clay Reinforcement. Transp. Geotech. 2021, 27, 100474. [Google Scholar] [CrossRef]

- Jiang, H.; Cai, Y.; Liu, J. Engineering Properties of Soils Reinforced by Short Discrete Polypropylene Fiber. J. Mater. Civ. Eng. 2010, 22, 1315–1322. [Google Scholar] [CrossRef]

- Consoli, N.C.; Vendruscolo, M.A.; Prietto, P.D.M. Behavior of Plate Load Tests on Soil Layers Improved with Cement and Fiber. J. Geotech. Geoenviron. Eng. 2003, 129, 96–101. [Google Scholar] [CrossRef]

- Zaimoglu, A.S. Freezing–thawing Behavior of Fine-Grained Soils Reinforced with Polypropylene Fibers. Cold Reg. Sci. Technol. 2010, 60, 63–65. [Google Scholar] [CrossRef]

- Miller, C.J.; Rifai, S. Fiber Reinforcement for Waste Containment Soil Liners. J. Env. Eng. 2004, 130, 891–895. [Google Scholar] [CrossRef]

- Papayianni, I.; Stefanidou, M.; Pachta, V. Plastering the Prehistory: Marl as a unique material to cover, maintain and decorate the Neolithic walls of Catalhöyük. In Proceedings of the 4th Historic Mortars Conference HMC2016, Santorini, Greece, 10–12 October 2016. [Google Scholar]

- Almerich-Chulia, A.; Fenollosa, E.; Martin, P. Reinforced Lime Concrete with FRP: An Alternative in the Restoration of Architectural Heritage. Appl. Mech. Mater. 2016, 851, 751–756. [Google Scholar] [CrossRef]

- ASTM C 618-19; Standard Specification for Mortar for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- Sirivitmaitrie, C.; Puppala, A.J.; Saride, S.; Hoyos, L. Combined Lime–cement Stabilization for Longer Life of Low-Volume Roads. Transp. Res. Rec. 2011, 2204, 140–147. [Google Scholar] [CrossRef]

- ASTM D 2487-06; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil). ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D422-63; Standard Method for Particle-Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM-D424-54; Standard Method of Test for Plastic Limit. ASTM International: West Conshohocken, PA, USA, 1982.

- ASTM D423-66; Standard Test Method for Liquid Limit of Soils. ASTM International: West Conshohocken, PA, USA, 1982.

- Das, B.M. Advanced Soil Mechanics; CRC press: Boca Raton, FL, USA, 2019; ISBN 1351215167. [Google Scholar]

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System) 1. ASTM International: West Conshohocken, PA, USA, 2017.

- AASHTO T 180-10; Standard Method of Test for Moisture-Density Relations of Soils Using a 4.54-Kg (10-Lb) Rammer and a 457-Mm (18-In.) Drop. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2010.

- ASTM D 854-1; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D 2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- Piro, N.S.; Mohammed, A.; Hamad, S.M.; Kurda, R. Artificial Neural Networks (ANN), MARS, and Adaptive Network-Based Fuzzy Inference System (ANFIS) to Predict the Stress at the Failure of Concrete with Waste Steel Slag Coarse Aggregate Replacement. Neural Comput. Appl. 2023, 35, 13293–13319. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, J. Mechanical Properties, Failure Mode, and Microstructure of Soil-Cement Modified with Fly Ash and Polypropylene Fiber. Adv. Mater. Sci. Eng. 2019, 2019, 9561794. [Google Scholar] [CrossRef]

- Elkhadiri, I.; Palacios, M.; Puertas, F. Effect of Curing Temperatura on Hydration Process of Different Cement; Czech Academy of Sciences: Staré Město, Czech Republic, 2009. [Google Scholar]

- Price, W.H. Factors Influencing Concrete Strength. J. Proc. 1951, 47, 417–432. [Google Scholar] [CrossRef]

- Escalante-Garcıa, J.I.; Sharp, J.H. The Microstructure and Mechanical Properties of Blended Cements Hydrated at Various Temperatures. Cem. Concr. Res. 2001, 31, 695–702. [Google Scholar] [CrossRef]

- Lothenbach, B.; Winnefeld, F.; Alder, C.; Wieland, E.; Lunk, P. Effect of Temperature on the Pore Solution, Microstructure and Hydration Products of Portland Cement Pastes. Cem. Concr. Res. 2007, 37, 483–491. [Google Scholar] [CrossRef]

- Ballester, P.; Hidalgo, A.; Mármol, I.; Morales, J.; Sánchez, L. Effect of Brief Heat-Curing on Microstructure and Mechanical Properties in Fresh Cement Based Mortars. Cem. Concr. Res. 2009, 39, 573–579. [Google Scholar] [CrossRef]

- Jahandari, S.; Saberian, M.; Tao, Z.; Mojtahedi, S.F.; Li, J.; Ghasemi, M.; Rezvani, S.S.; Li, W. Effects of Saturation Degrees, Freezing-Thawing, and Curing on Geotechnical Properties of Lime and Lime-Cement Concretes. Cold Reg. Sci. Technol. 2019, 160, 242–251. [Google Scholar] [CrossRef]

- Tang, L.; Cong, S.; Geng, L.; Ling, X.; Gan, F. The Effect of Freeze-Thaw Cycling on the Mechanical Properties of Expansive Soils. Cold Reg. Sci. Technol. 2018, 145, 197–207. [Google Scholar] [CrossRef]

- Duncan, J.M.; Bursey, A. Soil Modulus Correlations. In Foundation Engineering in the Face of Uncertainty: Honoring Fred H. Kulhawy; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 321–336. [Google Scholar]

- Hobbs, D.W. The Dependence of the Bulk Modulus, Young’s Modulus, Creep, Shrinkage and Thermal Expansion of Concrete upon Aggregate Volume Concentration. Matériaux Constr. 1971, 4, 107–114. [Google Scholar] [CrossRef]

- Selvadurai, A.P.S.; Katebi, A. Mindlin’s Problem for an Incompressible Elastic Half-Space with an Exponential Variation in the Linear Elastic Shear Modulus. Int. J. Eng. Sci. 2013, 65, 9–21. [Google Scholar] [CrossRef]

- Ostadan, F.; Ostadan, F.; Arango, I. Energy-Based Method for Liquefaction Potential Evaluation, Phase I-Feasibility Study; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 1996.

- Green, R.A.; Mitchell, J.K.; Polito, C.P. An Energy-Based Excess Pore Pressure Generation Model for Cohesionless Soils. In Proceedings of the John Booker Memorial Symposium, Sydney, Australia; AA Balkema Publishers: Rotterdam, The Netherlands, 2000; Volume 3. [Google Scholar]

- Ding, M.; Zhang, F.; Ling, X.; Lin, B. Effects of Freeze-Thaw Cycles on Mechanical Properties of Polypropylene Fiber and Cement Stabilized Clay. Cold Reg. Sci. Technol. 2018, 154, 155–165. [Google Scholar] [CrossRef]

- Li, L.; Shao, W.; Li, Y.; Cetin, B. Effects of Climatic Factors on Mechanical Properties of Cement and Fiber Reinforced Clays. Geotech. Geol. Eng. 2015, 33, 537–548. [Google Scholar] [CrossRef]

- Cong, M.; Longzhu, C.; Bing, C. Analysis of Strength Development in Soft Clay Stabilized with Cement-Based Stabilizer. Constr. Build. Mater. 2014, 71, 354–362. [Google Scholar] [CrossRef]

| Characteristics | Results | Used Standards |

|---|---|---|

| Coarse aggregates type | SW-SM | ASTM 2487-11 [62] |

| D10 | 0.11 | ASTM D422-63 [63] |

| Cu | 33 | ASTM D422-63 [63] |

| Cc | 1.86 | ASTM D422-63 [63] |

| PL | 21% | ASTM D424-54 [64] |

| LL | 26% | ASTM D423-66 [65] |

| PI | 5% | Das 2019 [66] |

| Fine aggregates type | Cay (CL) | ASTM 2487-11 [67] |

| Mineral | Kaolinite | Das 2019 [66] |

| Activity degree | 0.48 | Das 2019 [66] |

| D10 | 0.0016 | ASTM D422-63 [63] |

| Cu | 18 | ASTM D422-63 [63] |

| CC | 0.40 | ASTM D422-63 [63] |

| PL | 23% | ASTM D424-54 [64] |

| LL | 33% | ASTM D423-66 [65] |

| PI | 10% | Das 2019 [66] |

| Optimum moisture | 15% | AASHTO T180 [68] |

| Maximum specific weight | 18.76 kN/m3 | AASHTO T180 [68] |

| Specific gravity (Gs) | 2.46 | ASTM D854-10 [69] |

| UCS | 111.33 kPa | ASTM D2166 [70] |

| Component Oxides | Clay Composition (%) | Lime Composition (%) | Cement Composition (%) |

|---|---|---|---|

| Calcium oxide (CaO) | 13.20 | 73.70 | 63.41 |

| Silica (SiO2) | 41.75 | 1.15 | 21.66 |

| Alumina (Al2O3) | 15.15 | 0.11 | 4.21 |

| Iron oxide (Fe2O3) | 5.20 | 0.24 | 3.10 |

| Magnesium oxide (MgO) | 5.13 | 1.619 | 2.82 |

| Sulfur trioxide (SO3) | 3.48 | 0.015 | 2.61 |

| Chloride as NaCl | 0.08 | 0.011 | - |

| Manganese (Mn) | - | 0.005 | - |

| Loss on ignition | 12.58 | 23.15 | 0.81 |

| Specimen | Clay Content (%) | Lime Content (%) | Cement Content (%) | Water Content (%) | Fiber Content (%) | Curing Temp. (°C) | Curing Time (Days) | Number of Samples | Curing Condition |

|---|---|---|---|---|---|---|---|---|---|

| * F0-7-L | 23 | 3 | 4 | 24.04 | 0 | 20 | 7 | 3 | Lab |

| F0.5-7-L | 23 | 3 | 4 | 24.04 | 0.5 | 20 | 7 | 3 | Lab |

| F1-7-L | 23 | 3 | 4 | 24.04 | 1 | 20 | 7 | 3 | Lab |

| F2-7-L | 23 | 3 | 4 | 24.04 | 2 | 20 | 7 | 3 | Lab |

| F0-28-L | 23 | 3 | 4 | 24.04 | 0 | 20 | 28 | 3 | Lab |

| F0.5-28-L | 23 | 3 | 4 | 24.04 | 0.5 | 20 | 28 | 3 | Lab |

| F1-28-L | 23 | 3 | 4 | 24.04 | 1 | 20 | 28 | 3 | Lab |

| F2-28-L | 23 | 3 | 4 | 24.04 | 2 | 20 | 28 | 3 | Lab |

| F0-3-O | 23 | 3 | 4 | 24.04 | 0 | 50 | 3 | 3 | Oven |

| F0.5-3-O | 23 | 3 | 4 | 24.04 | 0.5 | 50 | 3 | 3 | Oven |

| F1-3-O | 23 | 3 | 4 | 24.04 | 1 | 50 | 3 | 3 | Oven |

| F2-3-O | 23 | 3 | 4 | 24.04 | 2 | 50 | 3 | 3 | Oven |

| F0-7-O | 23 | 3 | 4 | 24.04 | 0 | 50 | 7 | 3 | Oven |

| F0.5-7-O | 23 | 3 | 4 | 24.04 | 0.5 | 50 | 7 | 3 | Oven |

| F1-7-O | 23 | 3 | 4 | 24.04 | 1 | 50 | 7 | 3 | Oven |

| F2-7-O | 23 | 3 | 4 | 24.04 | 2 | 50 | 7 | 3 | Oven |

| FC (%) | Curing Days | UCS (kPa) | ℇf (%) | Es (MPa) | Id | Ib | SE (kPa) | K (MPa) | Gs (MPa) | Mr (MPa) | Rqu | REu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 3 | 417 | 0.87 | 42 | 1.00 | 1.00 | 11 | 35 | 16 | 120 | 1.00 | 1.00 |

| 0.5 | 3 | 520 | 1.30 | 49 | 1.50 | 0.75 | 11 | 41 | 19 | 133 | 1.25 | 1.17 |

| 1 | 3 | 523 | 1.50 | 42 | 1.73 | 0.73 | 14 | 35 | 16 | 134 | 1.25 | 1.00 |

| 2 | 3 | 480 | 1.70 | 36 | 1.96 | 0.66 | 16 | 30 | 14 | 128 | 1.15 | 0.86 |

| 0 | 7 | 664 | 1.12 | 95 | 1.00 | 1.00 | 15 | 79 | 37 | 151 | 1.00 | 1.00 |

| 0.5 | 7 | 761 | 1.30 | 74 | 1.16 | 0.94 | 18 | 62 | 26 | 163 | 1.14 | 1.16 |

| 1 | 7 | 770 | 1.55 | 43 | 1.38 | 0.80 | 20 | 36 | 17 | 164 | 1.16 | 1.38 |

| 2 | 7 | 636 | 2.00 | 48 | 1.79 | 0.73 | 21 | 40 | 18 | 148 | 0.96 | 1.79 |

| FC (%) | Curing Days | UCS (kPa) | ℇf (%) | Es (MPa) | Id | Ib | SE (kPa) | K (MPa) | Gs (MPa) | Mr (MPa) | Rqu | REu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 7 | 176 | 1.83 | 12.14 | 1.00 | 1.00 | 4.87 | 10.12 | 5 | 91 | 1.00 | 1.00 |

| 0.5 | 7 | 187 | 1.06 | 29.26 | 0.58 | 0.78 | 6.15 | 24.38 | 11 | 92 | 1.06 | 2.41 |

| 1 | 7 | 210 | 1.29 | 21.73 | 0.70 | 0.67 | 7.00 | 18.11 | 8 | 95 | 1.19 | 1.79 |

| 2 | 7 | 167 | 1.44 | 12.18 | 0.79 | 0.61 | 7.16 | 10.15 | 5 | 89 | 0.95 | 1.00 |

| 0 | 28 | 347 | 1.92 | 66.13 | 1.00 | 1.00 | 9.51 | 55.11 | 25 | 112 | 1.00 | 1.00 |

| 0.5 | 28 | 393 | 1.00 | 35.89 | 0.52 | 0.83 | 10.35 | 29.91 | 14 | 118 | 1.14 | 0.54 |

| 1 | 28 | 437 | 1.03 | 52.46 | 0.54 | 0.83 | 11.57 | 43.72 | 20 | 123 | 1.26 | 0.79 |

| 2 | 28 | 355 | 1.17 | 45.04 | 0.61 | 0.79 | 13.67 | 37.53 | 17 | 113 | 1.02 | 0.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafari, M.M.; Jahandari, S.; Ozbakkaloglu, T.; Rasekh, H.; Jahed Armaghani, D.; Rahmani, A. Mechanical Properties of Polyamide Fiber-Reinforced Lime–Cement Concrete. Sustainability 2023, 15, 11484. https://doi.org/10.3390/su151511484

Jafari MM, Jahandari S, Ozbakkaloglu T, Rasekh H, Jahed Armaghani D, Rahmani A. Mechanical Properties of Polyamide Fiber-Reinforced Lime–Cement Concrete. Sustainability. 2023; 15(15):11484. https://doi.org/10.3390/su151511484

Chicago/Turabian StyleJafari, Mohammad Mostafa, Soheil Jahandari, Togay Ozbakkaloglu, Haleh Rasekh, Danial Jahed Armaghani, and Aida Rahmani. 2023. "Mechanical Properties of Polyamide Fiber-Reinforced Lime–Cement Concrete" Sustainability 15, no. 15: 11484. https://doi.org/10.3390/su151511484

APA StyleJafari, M. M., Jahandari, S., Ozbakkaloglu, T., Rasekh, H., Jahed Armaghani, D., & Rahmani, A. (2023). Mechanical Properties of Polyamide Fiber-Reinforced Lime–Cement Concrete. Sustainability, 15(15), 11484. https://doi.org/10.3390/su151511484