The Design and Performance Prediction Model of an Integrated Scheme of a Membrane Bioreactor and Anaerobic Digester for the Treatment of Domestic Wastewater and Biowaste

Abstract

1. Introduction

2. Materials and Methods

2.1. Integrated System

- An MBR treating the effluent of a primary settling tank of domestic wastewater from the wastewater treatment plant of Anthoupolis in Nicosia, Cyprus (primary effluent) and the liquid fraction of the digestate of an AD unit (liquid digestate).

- An AD unit treating biodegradable organic waste and sewage sludge from the MBR.

- A biogas treatment line for its purification and valorization via a cogeneration heat and power engine.

- A digestate treatment system, where its separation into liquid and solid fractions occurred. The solid digestate was led to a solar dryer, whereas the liquid one was recirculated to both bioprocesses as dilution water.

2.2. Model Structure

2.2.1. Aerobic Membrane Reactor

- The concentration of active biomass (XBH, XBA) and particulate substrate from cell decay (XP) in the influent and effluent of the MBR were neglected.

- Given that nitrite nitrogen (SNO) was not detected in steady-state conditions, it was assumed that the bioconversion of ammonia to nitrate occurred in a single step.

2.2.2. Anaerobic Digester

2.3. Objective Function—Optimisation Parameter

2.4. Model Efficiency

3. Results

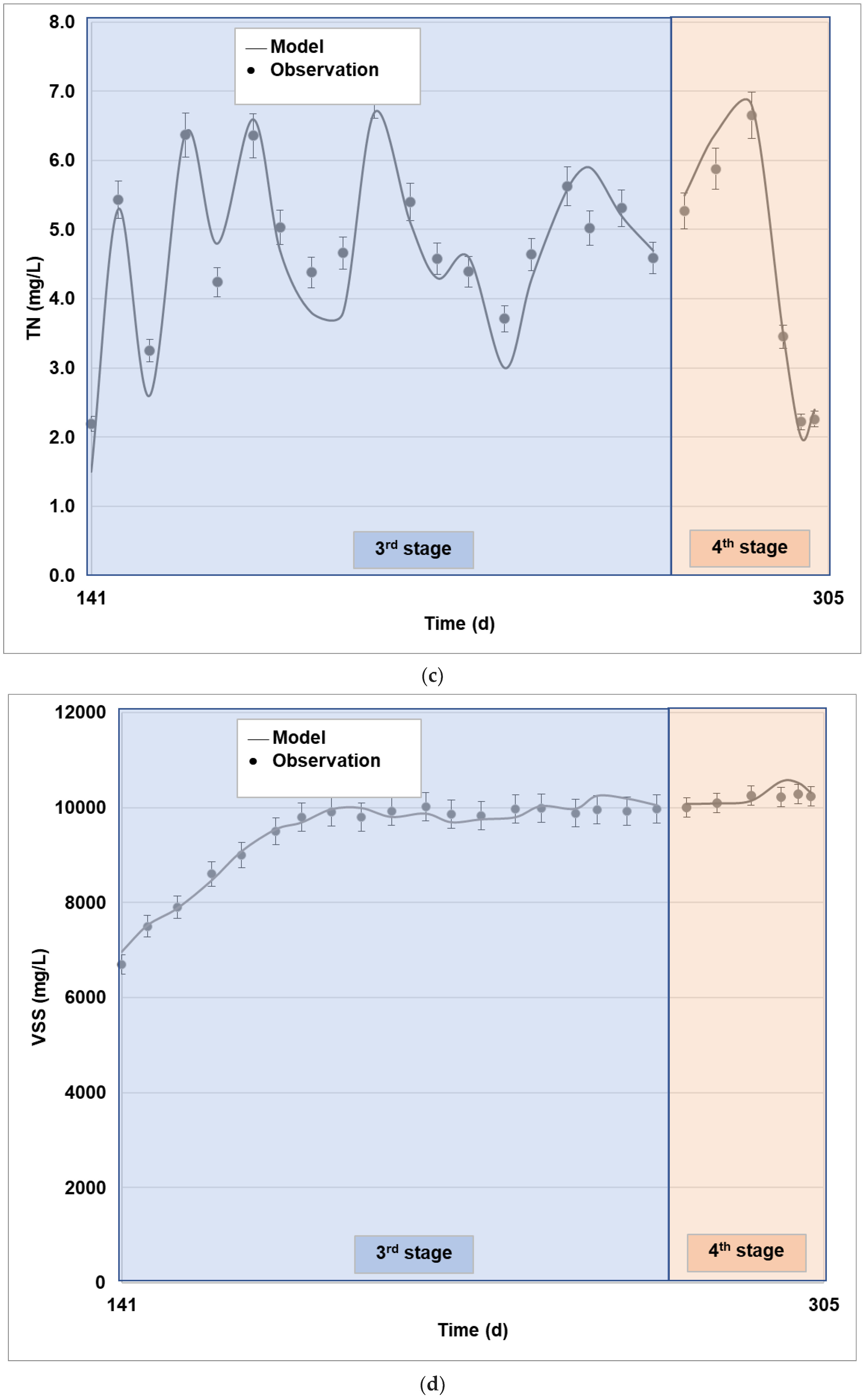

3.1. Aerobic Process

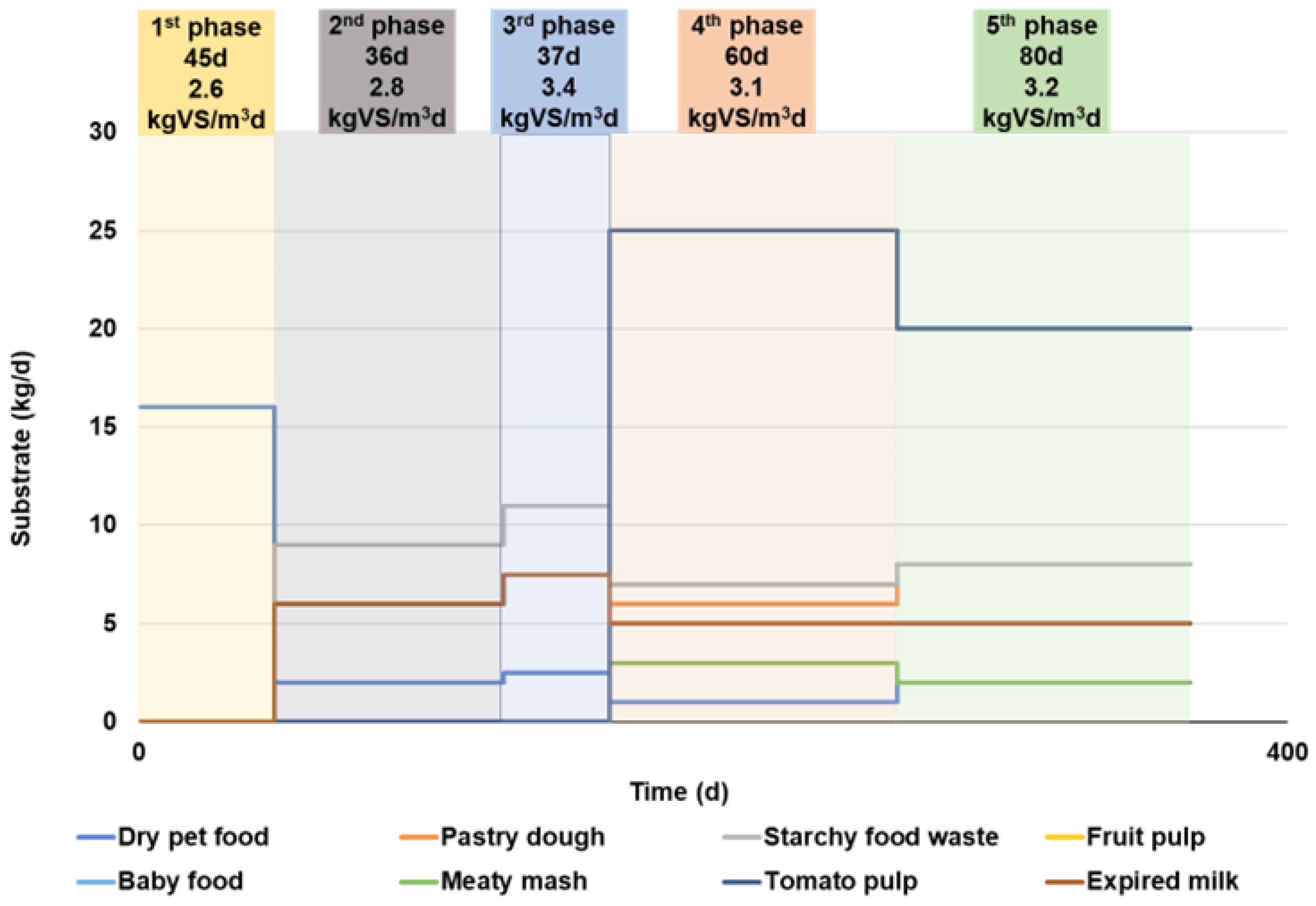

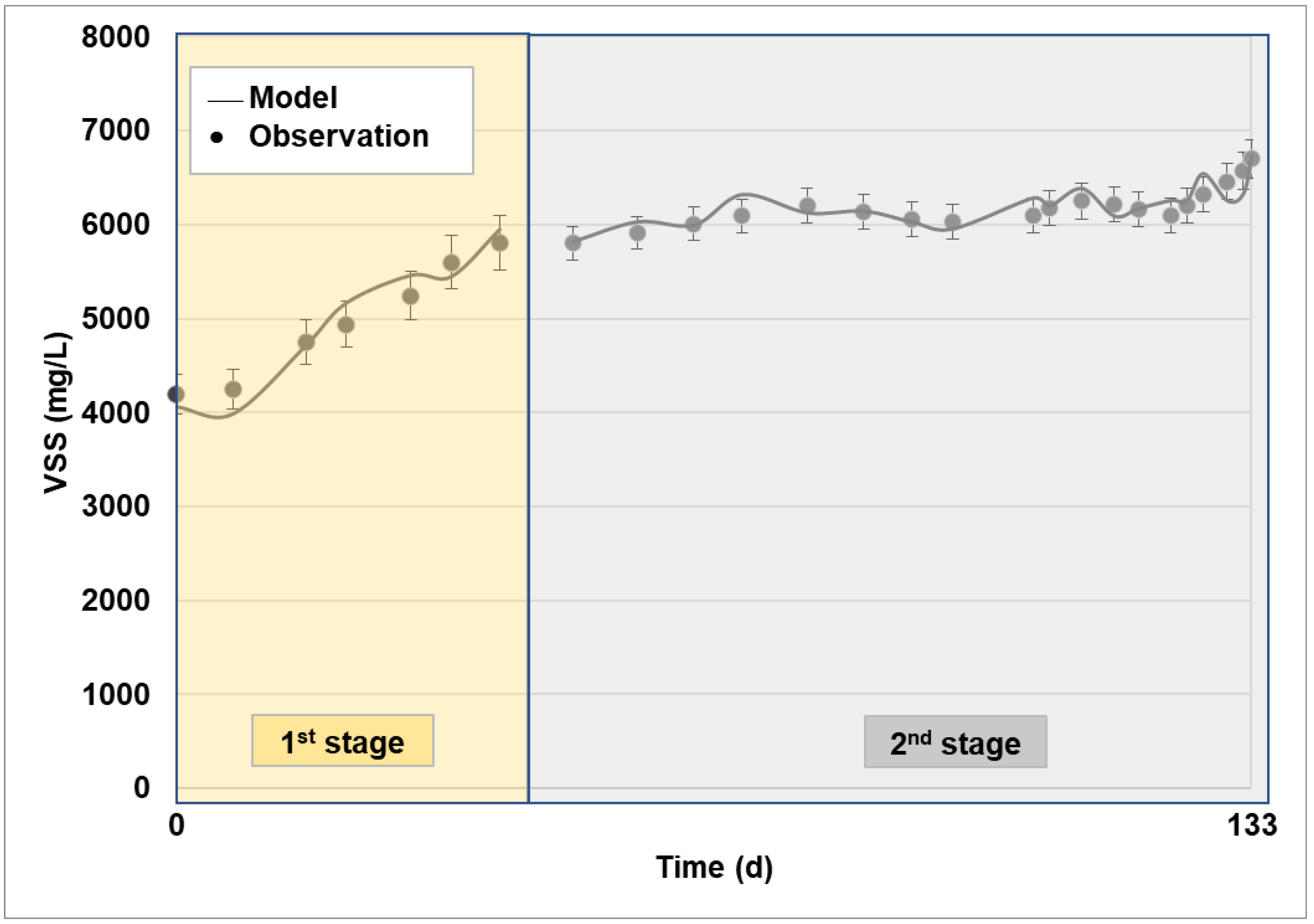

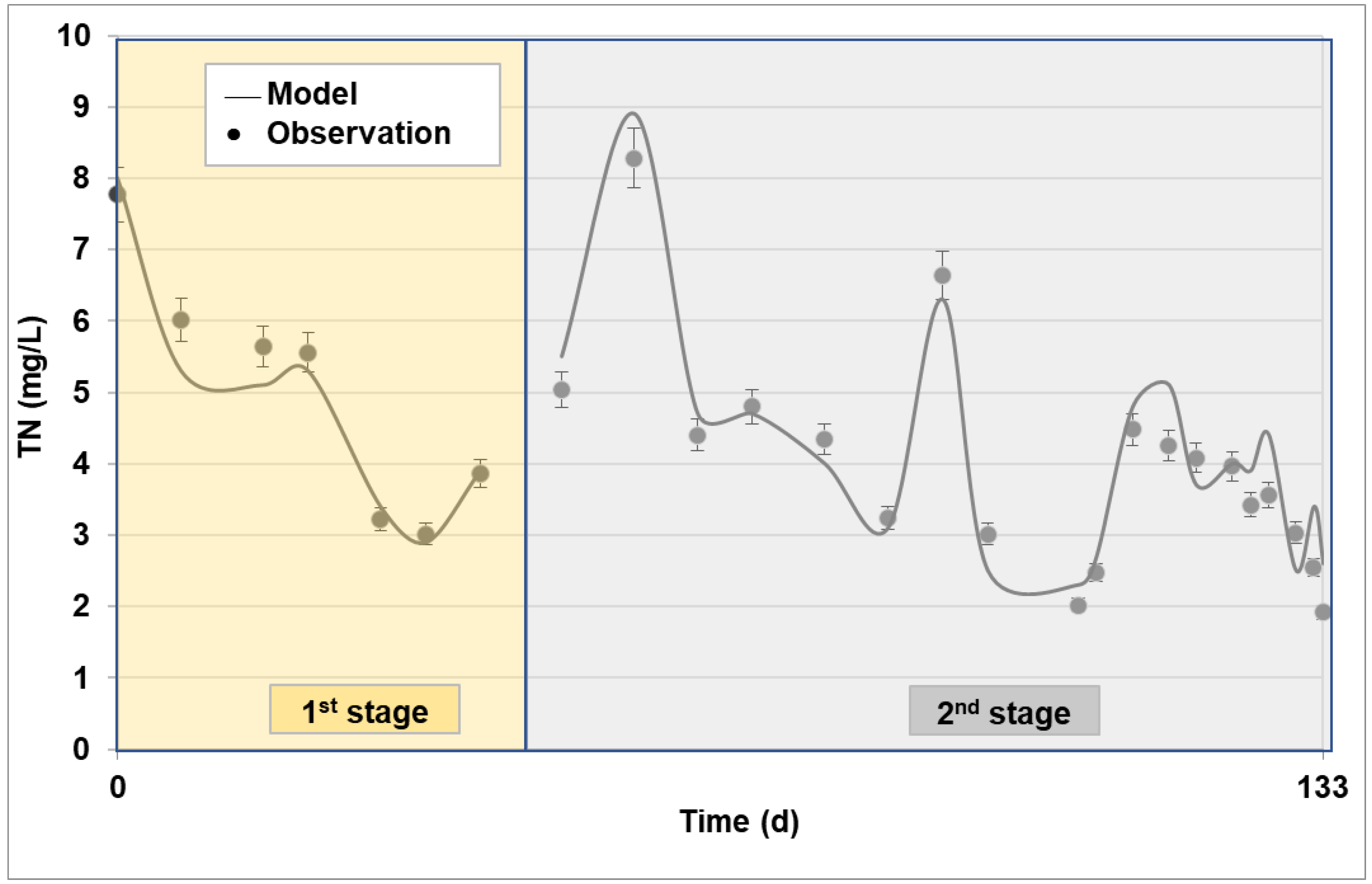

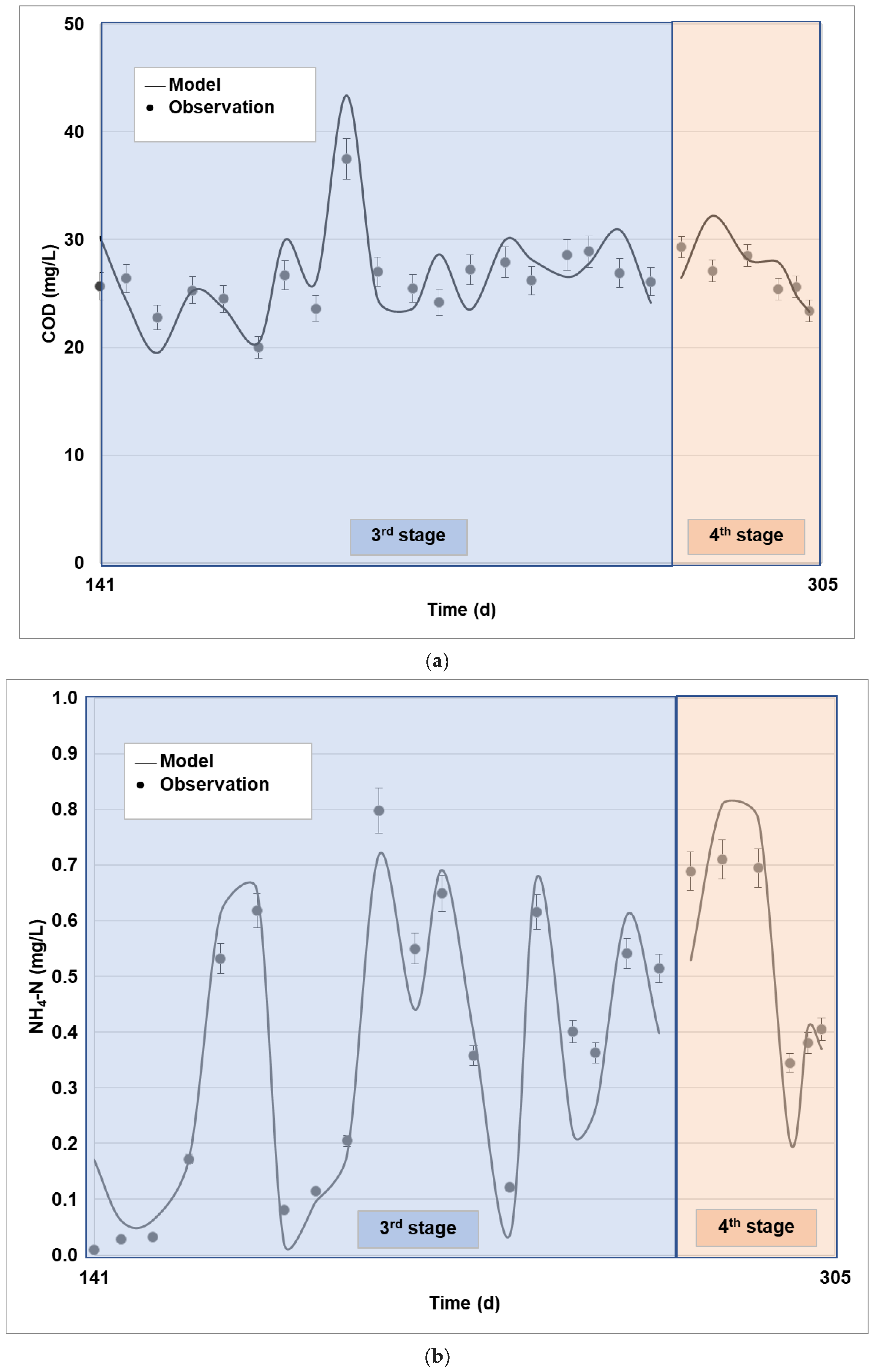

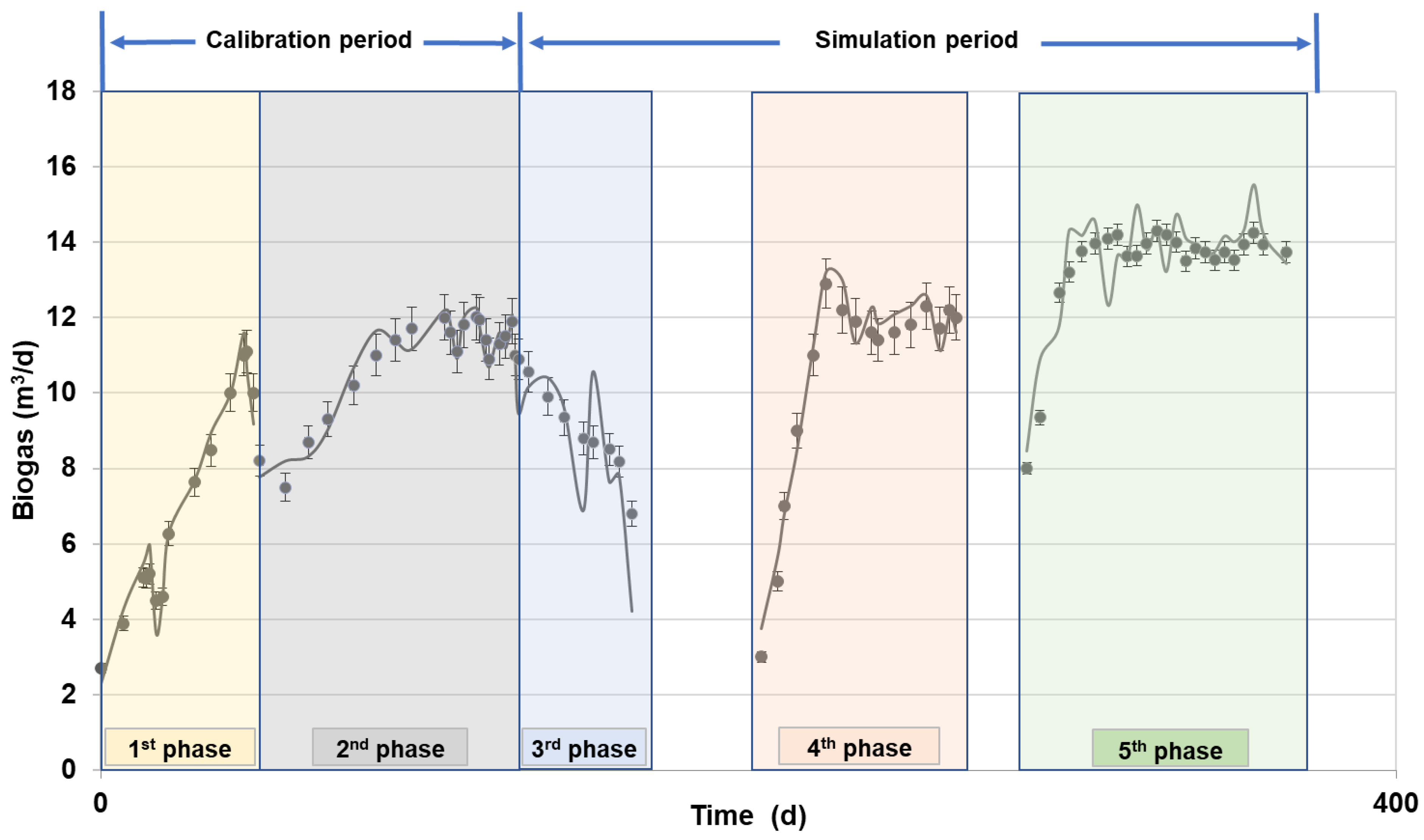

3.2. Anaerobic Process

4. Design of Full-Scale Implementation

- MBR feeding tank: for the collection of waste water to be treated by the MBR unit.

- MBR unit: for the biological treatment of the municipal wastewater using emerged membrane modules.

- AD feeding and mixing tank: for the collection and homogenization of sewage sludge from MBR and biowaste.

- Anaerobic digester: for the anaerobic digestion of the mixture (TS~10%).

- Biogas production unit.

- CHP unit.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Description |

| AD | Anaerobic digestion |

| ADM1 | Anaerobic digestion model 1 |

| ASM1 | Activated sludge model |

| bA | Decay coefficient for autotrophic biomass |

| bH | Decay coefficient for heterotrophic biomass |

| COD | Chemical oxygen demand |

| CSTR | Continuously stirred tank reactor |

| fp | Fraction of biomass leading to particulate products |

| HRT | Hydraulic retention time |

| iXB | Mass of nitrogen per mass of COD in biomass |

| ixp | Mass of nitrogen per mass of COD in products from biomass |

| Jobj | Objective function |

| ka | Ammonification rate |

| kch | First-order hydrolysis constants for carbohydrates |

| kdec | Anaerobic microbial decay rate |

| kH | Maximum specific hydrolysis rate for slowly biodegradable COD |

| KH,ch4 | Henry’s law equilibrium constant for methane |

| KH,co2 | Henry’s law equilibrium constant for carbon dioxide |

| KLa | Gas–liquid transfer coefficient |

| kli | First-order hydrolysis constants for lipids |

| KNH | Ammonium half-saturation coefficient for nitrifying heterotrophic biomass |

| KNO | Nitrate half-saturation coefficient for denitrifying heterotrophic biomass |

| KOH | Oxygen half-saturation coefficient for heterotrophic biomass |

| kp | Pipe friction coefficient |

| kpr | First-order hydrolysis constants for proteins |

| Ks | Half-saturation coefficient for heterotrophic biomass |

| KX | Half-saturation coefficient for hydrolysis of slowly biodegradable substrate |

| KOA | Oxygen half-saturation coefficient for autotrophic biomass |

| MBR | Membrane aerobic bioprocess |

| MSE | Mean squared error |

| ng | Correction factor for μH under anoxic conditions |

| nH | Correction factor for hydrolysis under anoxic conditions |

| NH4-N | Ammonium nitrogen, charge +1 |

| NSE | Nash–Sutcliffe efficiency |

| NO3-N | Nitrate nitrogen, charge-1 |

| OLR | Organic loading rate |

| patm | Atmospheric pressure |

| pch4 | Methane gas phase partial pressure |

| pco2 | Carbon dioxide gas phase partial pressure |

| pgas | Pressure of biogas |

| ph2o | Partial pressure of water vapours |

| pj | Kinetic rate for process j |

| Qe | Flow rate of effluent wastewater |

| Qin | Flow rate of influent wastewater |

| Qw | Flow rate of excess sludge |

| R | Universal gas constant |

| Sch4 | Liquid methane concentration |

| Sch4,gas | Concentration of methane gas in headspace |

| Sco2,gas | Concentration of carbon dioxide gas in headspace |

| SI | Soluble inert COD concentration in wastewater |

| SIC | Concentration of inorganic carbon |

| SIN | Concentration of inorganic nitrogen |

| SND | Soluble biodegradable organic nitrogen concentration in wastewater |

| SNH | Soluble “ammonia” nitrogen concentration in wastewater |

| SNO | Soluble nitrate nitrogen (charge-1) concentration in wastewater |

| SO | Concentration of dissolved oxygen |

| SRT | Solid retention time |

| SS | Concentration of readily biodegradable COD in wastewater |

| T | Temperature |

| TN | Total nitrogen |

| TOC | Total organic carbon |

| TP | Total phosphorous concentration |

| TSs | Total solids |

| TSSs | Total suspended solids |

| Vgas | Head space volume |

| Vliq | Liquid volume |

| VSSs | Volatile suspended solids |

| XBA | Active autotrophic biomass |

| Xbac | Group of bacteria |

| XBH | Active heterotrophic biomass |

| Xch | Concentration of particulate carbohydrates |

| XI | Inert suspended organic matter concentration in wastewater |

| Xli | Concentration of particulate lipids |

| XND | Slowly biodegradable organic nitrogen concentration in wastewater |

| XP | Particulate products from cell decay |

| Xpr | Concentration of particulate proteins |

| XS | Slowly biodegradable organic matter concentration in wastewater |

| YA | Yield for autotrophic biomass |

| YH | Yield for heterotrophic biomass |

| μH | Maximum specific growth rate for heterotrophic biomass |

| μA | Maximum specific growth rate for autotrophic biomass |

References

- Adam, M.R.; Othman, M.H.D.; Kurniawan, T.A.; Puteh, M.H.; Ismail, A.F.; Khongnakorn, W.; Rahman, M.A.; Jaafar, J. Advances in adsorptive membrane technology for water treatment and resource recovery applications: A critical review. J. Environ. Chem. Eng. 2022, 10, 107633. [Google Scholar] [CrossRef]

- Lange, J.; Takors, R.; Blombach, B. Zero-growth bioprocesses: A challenge for microbial production strains and bioprocess engineering. Eng. Life Sci. 2017, 17, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.H.; Jeon, S.K.K.; Pagilla, K. Mathematical modeling of aerobic membrane bioreactor (MBR) using activated sludge model no. 1 (ASM1). J. Ind. Eng. Chem. 2009, 15, 835–840. [Google Scholar] [CrossRef]

- Shin, C.; Tilmans, S.H.; Chen, F.; Criddle, C.S. Anaerobic membrane bioreactor model for design and prediction of domestic wastewater treatment process performance. Chem. Eng. J. 2021, 426, 131912. [Google Scholar] [CrossRef]

- Weinrich, S.; Nelles, M. Systematic simplification of the Anaerobic Digestion Model No. 1 (ADM1)—Model development and stoichiometric analysis. Bioresour. Technol. 2021, 333, 125124. [Google Scholar] [CrossRef] [PubMed]

- Batstone, D.J.; Puyol, D.; Flores-Alsina, X.; Rodríguez, J. Mathematical modelling of anaerobic digestion processes: Applications and future needs. Rev. Environ. Sci. Biotechnol. 2015, 14, 595–613. [Google Scholar] [CrossRef]

- Jimenez, J.; Latrille, E.; Harmand, J.; Robles, A.; Ferrer, J.; Gaida, D.; Wolf, C.; Mairet, F.; Bernard, O.; Alcaraz-Gonzalez, V.; et al. Instrumentation and control of anaerobic digestion processes: A review and some research challenges. Rev. Environ. Sci. Bio/Technol. 2015, 14, 615–648. [Google Scholar] [CrossRef]

- Gaida, D.; Wolf, C.; Bongards, M. Feed control of anaerobic digestion processes for renewable energy production: A review. Renew. Sustain. Energy Rev. 2017, 68, 869–875. [Google Scholar] [CrossRef]

- Loizidou, M.; Malamis, D.; Stamatoglou, A.; Solomou, N. Integrated system for the treatment of municipal wastewater and biodegradable solid waste. In Proceedings of the Fourth International Symposium on Energy from Biomass and Waste, Venice, Italy, 12–15 November 2012; pp. 1–9. [Google Scholar]

- Solomou, N.; Stamatoglou, A.; Malamis, S.; Katsou, E.; Costa, C.N.; Loizidou, M. An integrated solution to wastewater and biodegradable organic waste management by applying anaerobic digestion and membrane bioreactor processes. Water Pract. Technol. 2014, 9, 464–474. [Google Scholar] [CrossRef]

- Sari Erkan, H.; Bakaraki Turan, N.; Önkal Engin, G. Membrane Bioreactors for Wastewater Treatment. Compr. Anal. Chem. 2018, 81, 151–200. [Google Scholar] [CrossRef]

- Henze, M.; Gujer, W.; Mino, T.; van Loosedrecht, M. Activated Sludge Model No.1; IAWPRC: London, UK, 1987. [Google Scholar]

- Lahdhiri, A.; Lesage, G.; Hannachi, A.; Heran, M. Steady-state methodology for activated sludge model 1 (ASM1) state variable calculation in MBR. Water 2020, 12, 3220. [Google Scholar] [CrossRef]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.M.; Siegrist, H.; Vavilin, V.A. Anaerobic digestion model no. 1 (ADM1), IWA task group for mathematical modelling of anaerobic digestion processes. Water Res. 2002, 41, 4085–4096. [Google Scholar]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.; Siegrist, H.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1 (ADM1). Water Sci. Technol. 2002, 45, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Weinrich, S.; Mauky, E.; Schmidt, T.; Krebs, C.; Liebetrau, J.; Nelles, M. Systematic simplification of the Anaerobic Digestion Model No. 1 (ADM1)—Laboratory experiments and model application. Bioresour. Technol. 2021, 333, 125104. [Google Scholar] [CrossRef] [PubMed]

- Donoso-Bravo, A.; Mailier, J.; Martin, C.; Rodrìguez, J.; Aceves-Lara, C.A.; Wouwer, A.V. Model selection, identification and validation in anaerobic digestion: A review. Water Res. 2011, 45, 5347–5364. [Google Scholar] [CrossRef] [PubMed]

- Pavlostathis, S.G.; Giraldo-Gomez, E. Kinetics of Anaerobic Treatment: A Critical Review. Crit. Rev. Environ. Control 1991, 21, 411–490. [Google Scholar] [CrossRef]

- Dubois, V.; Falipou, E.; Boutin, C. Quantification and qualification of the urban domestic pollution discharged per household and per resident. Water Sci. Technol. 2022, 85, 1484–1499. [Google Scholar] [CrossRef] [PubMed]

- Eurostat Statistics Explained Translate Food Waste and Food Waste Prevention—Estimates. Eurostat. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Food_waste_and_food_waste_prevention_-_estimates (accessed on 12 March 2023).

- Barampouti, E.M.; Mai, S.; Malamis, D.; Moustakas, K.; Loizidou, M. Liquid biofuels from the organic fraction of municipal solid waste: A review. Renew. Sustain. Energy Rev. 2019, 110, 298–314. [Google Scholar] [CrossRef]

| Parameter | 1st Stage | 2nd Stage | 3rd Stage | 4th Stage |

|---|---|---|---|---|

| Operating period (d) | 45 | 89 | 131 | 34 |

| Type of feedstock | Primary effluent | Primary effluent and liquid digestate | Primary effluent and liquid digestate | Primary effluent and liquid digestate |

| Qin (m3/d) | 1.5 | 1.5 | 1.5 | 3.0 |

| SRT (d) | 20 | 30 | 40 | 40 |

| HRT (h) | 24 | 24 | 24 | 12 |

| Component ij Process | 1 (SI) | 2 (Ss) | 3 (XI) | 4 (XS) | 5 (XBH) | 6 (XBA) | 7 (XP) | 8 (SQ) | 9 (SNO) | 10 (SNH) | 11 (SND) | 12 (XND) | Process Rate (pj) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Aerobic growth of heterotrophs | 1 | iXB | iXBfpiXP | ||||||||||

| 2. Anoxic growth of heterotrophs | 1 | iXB | |||||||||||

| 3. Aerobic growth of autotrophs | 1 | iXB | |||||||||||

| 4. Decay of heterotrophs | 1fp | 1 | fp | iXBfpiXP | bHXBH | ||||||||

| 5. Decay of autotrophs | 1fp | 1 | fp | bAXBA | |||||||||

| 6. Ammonification of soluble organic nitrogen | 1 | 1 | kaSNDXBH | ||||||||||

| 7. Hydrolysis of entrapped organics | 1 | 1 | |||||||||||

| 8. Hydrolysis of entrapped organic nitrogen | 1 | 1 | |||||||||||

| 9. Sludge removal | XI | XS | XBH | XBA | XP | −XND |

| Component i → | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| j Process ↓ | Sch4 | SIC | Sin | Sh2o | Xch | Xpr | Xli | Xbac | Sch4,gas | Sco2,gas | Process Rate pj |

| 1 Fermentation Xch | 0.2482 | 0.6809 | −0.0207 | −0.0456 | 1 | 0.1372 | kch Xch | ||||

| 2 Fermentation Xpr | 0.3221 | 0.7954 | 0.1689 | −0.4588 | 1 | 0.1723 | kpr Xpr | ||||

| 3 Fermentation Xli | 0.6393 | 0.5817 | −0.0344 | −0.4152 | 1 | 0.2286 | kli Xli | ||||

| 4 Decay Xbac | 0.3247 | 0.7641 | 0.1246 | −0.3822 | 0.18 | 0.77 | 0.05 | 1 | kdec Xbac | ||

| 5 Phase transition Sch4 | 1 | KLa (Sch416KH,ch4 pch4) | |||||||||

| 6 Phase transition Sic | 1 | KLa (SIC44KH,co2 pco2) | |||||||||

| Algebraic equations | |||||||||||

| Phase | |||||

|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | |

| TS (%) | 9.69 | 10.18 | 12.49 | 10.29 | 11.62 |

| VS (%TS) | 90.61 | 94.05 | 94.03 | 93.08 | 93.25 |

| Ash (%TS) | 9.39 | 5.95 | 5.97 | 6.92 | 6.75 |

| Carbohydrates (%TS) | 4.10 | 65.52 | 65.43 | 60.22 | 60.61 |

| Proteins (%TS) | 2.41 | 12.35 | 12.38 | 13.51 | 13.32 |

| Lipids (%TS) | 1.92 | 22.10 | 22.07 | 18.14 | 19.85 |

| NH4-N (mg/L) | 0.57 | 0.27 | 0.14 | 0.29 | 0.52 |

| Parameters | Typical Values at 20 °C [12] | Values Suggested by Baek et al. [3] | Calibrated Values |

|---|---|---|---|

| bA | 0.05 | 0.048 | 0.05 |

| bH | 0.22 | 0.22 | 0.20 |

| fP | 0.08 | 0.08 | 0.08 |

| iXB | 0.086 | 0.088 | 0.088 |

| ixp | 0.06 | 0.06 | 0.06 |

| ka | 0.08 | 0.082 | 0.075 |

| kH | 3 | 3 | 3.4 |

| KNH | 1 | 0.94 | 1.03 |

| KNO | 0.5 | 0.45 | 0.55 |

| KOA | 0.4 | 0.1 | 0.4 |

| KOH | 0.2 | 0.19 | 0.25 |

| KS | 20 | 20.3 | 18 |

| KX | 0.03 | 0.04 | 0.04 |

| YA | 0.24 | 0.28 | 0.17 |

| YH | 0.67 | 0.69 | 0.71 |

| ng | 0.9 | 0.9 | 0.9 |

| nH | 0.4 | 0.4 | 0.4 |

| μA | 0.8 | 0.67 | 0.83 |

| μH | 6 | 6.9 | 7.2 |

| Kinetic Parameters | Calibrated Values | ADM1 Mesophilic High Rate [14] | ADM1 Mesophilic Solids [14] | ADM1 Thermophilic Solids [14] | ADM1-R4 [5] |

|---|---|---|---|---|---|

| kch (d−1) | 0.41 | 0.25 | 10 | 10 | 0.25 |

| kpr (d−1) | 0.25 | 0.2 | 10 | 10 | 0.2 |

| kli (d−1) | 0.09 | 0.1 | 10 | 10 | 0.1 |

| kdec (d−1) | 0.02 | 0.02 | 0.02 | 0.04 | 0.02 |

| KLa (d−1) | 180 | 200 | 200 | 200 | 200 |

| Experimental Phases | |||||

|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | |

| Methane content (%v/v) | 56 | 58 | 56 | 59 | 59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solomou, N.; Malamis, D.; Barampouti, E.M.; Mai, S.; Loizidou, M. The Design and Performance Prediction Model of an Integrated Scheme of a Membrane Bioreactor and Anaerobic Digester for the Treatment of Domestic Wastewater and Biowaste. Sustainability 2023, 15, 11455. https://doi.org/10.3390/su151411455

Solomou N, Malamis D, Barampouti EM, Mai S, Loizidou M. The Design and Performance Prediction Model of an Integrated Scheme of a Membrane Bioreactor and Anaerobic Digester for the Treatment of Domestic Wastewater and Biowaste. Sustainability. 2023; 15(14):11455. https://doi.org/10.3390/su151411455

Chicago/Turabian StyleSolomou, Nicos, Dimitris Malamis, Elli Maria Barampouti, Sofia Mai, and Maria Loizidou. 2023. "The Design and Performance Prediction Model of an Integrated Scheme of a Membrane Bioreactor and Anaerobic Digester for the Treatment of Domestic Wastewater and Biowaste" Sustainability 15, no. 14: 11455. https://doi.org/10.3390/su151411455

APA StyleSolomou, N., Malamis, D., Barampouti, E. M., Mai, S., & Loizidou, M. (2023). The Design and Performance Prediction Model of an Integrated Scheme of a Membrane Bioreactor and Anaerobic Digester for the Treatment of Domestic Wastewater and Biowaste. Sustainability, 15(14), 11455. https://doi.org/10.3390/su151411455