Supply Chain in the Digital Age: A Scientometric–Thematic Literature Review

Abstract

1. Introduction

- Q1: What are the research directions related to the digitalization of supply chains over the last five years (2018–2022)?

- Q2: Which research areas are particularly interesting to the scientific community (high publication rate), and which are still in the early stages of development or less popular?

- Q3: Is there a research gap that should be analyzed due to recent economic and political changes?

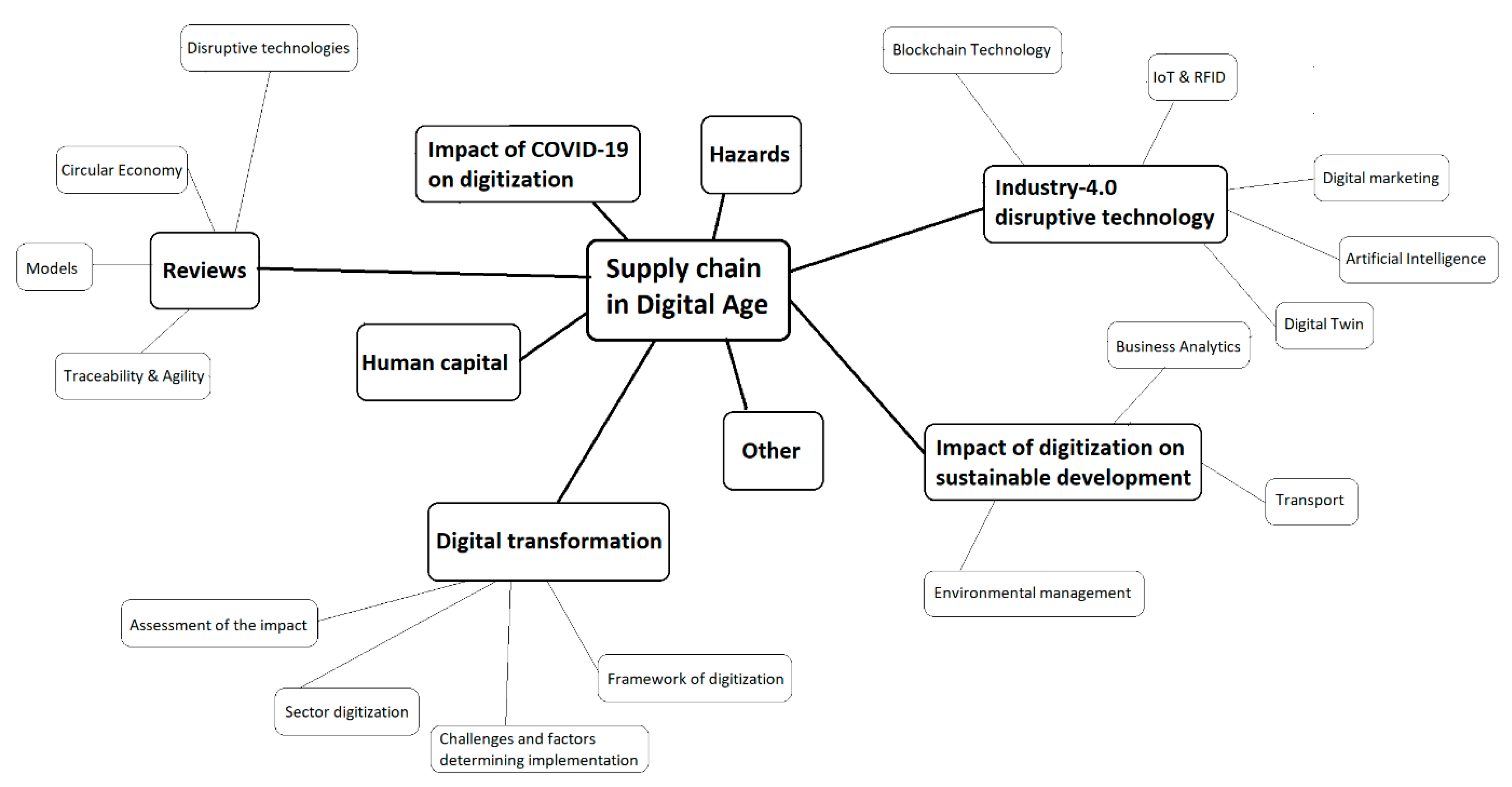

- Development of a two-level classification framework for research in the analyzed area according to the assumptions of the concept map;

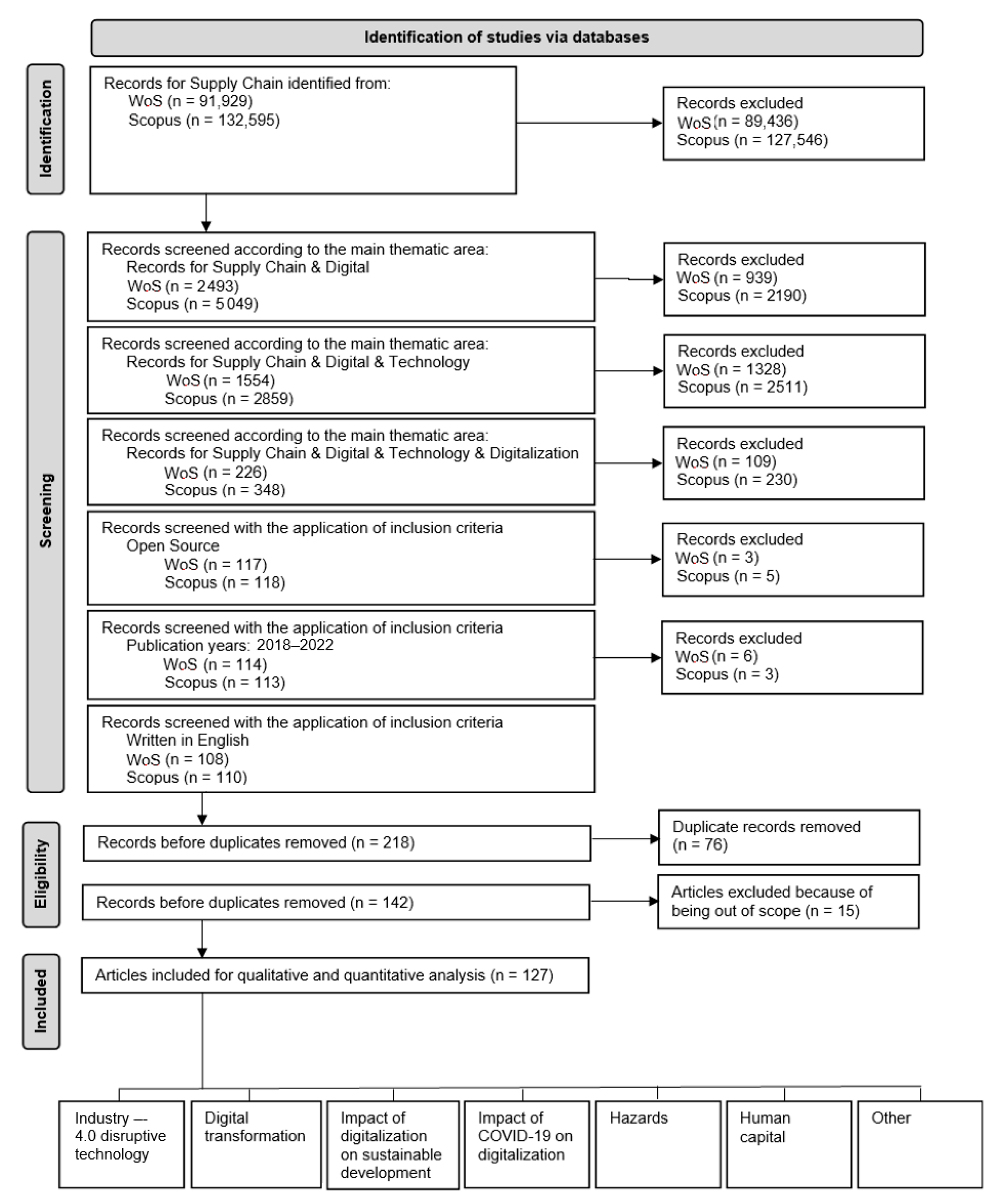

- Conducting the qualification procedure following the adopted distribution criteria based on the results of the literature research;

- Detailed characteristics of research on the digitalization of supply chains from the last five years.

2. Materials and Methods

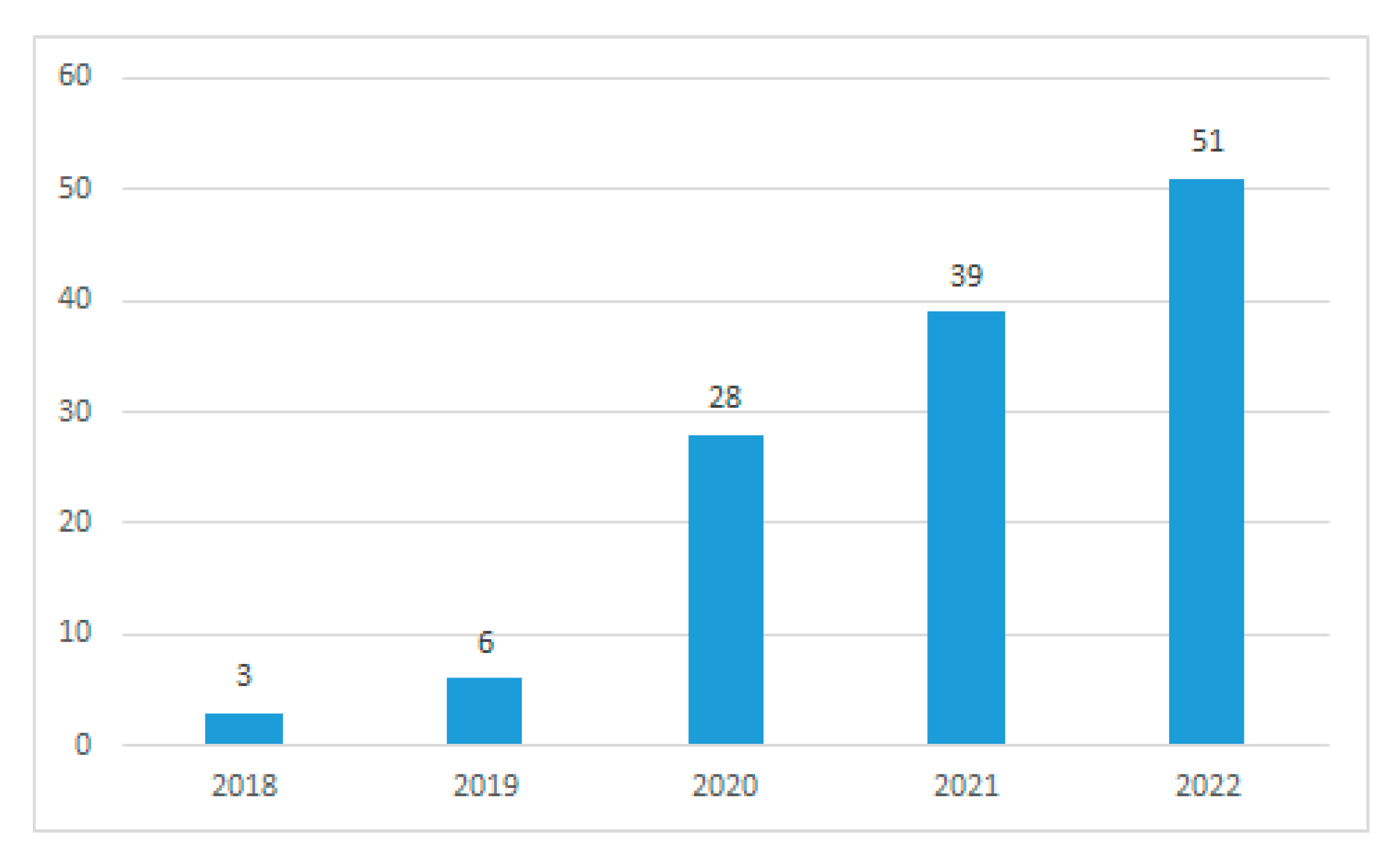

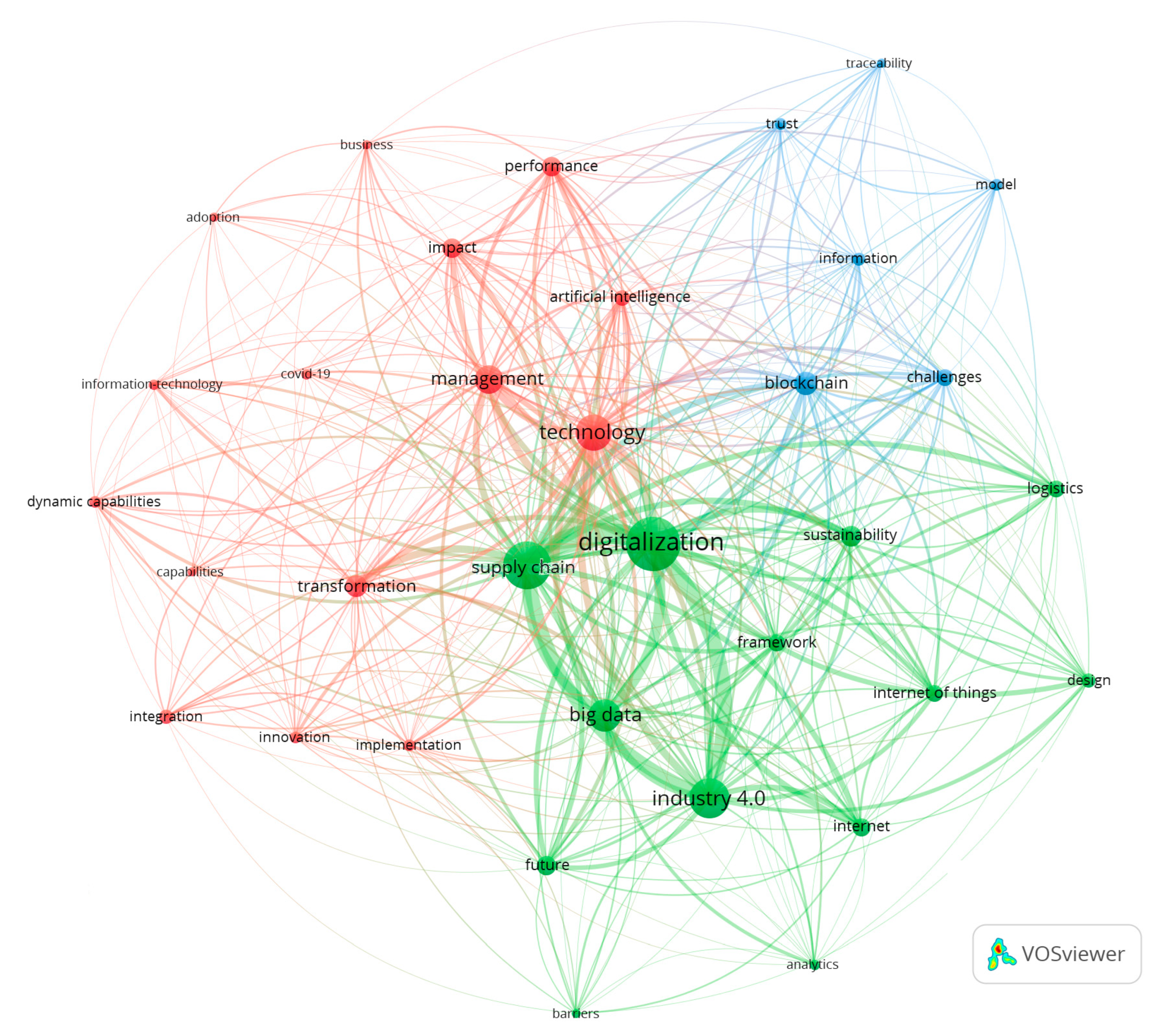

3. Bibliometric Analysis

4. Results

4.1. Literature Review

4.1.1. Circular Economy (CE)

4.1.2. Traceability and Agility

4.1.3. Disruptive Technologies

4.1.4. Models

4.2. Digital Transformation

4.2.1. Framework of Digitalization

4.2.2. Assessment of the Impact of Digitalization on the Functioning of SC

4.2.3. Identification of Challenges Related to Digitalization and Factors Determining Implementation

4.2.4. Digitalization in the Selected Sector

| Sector | Research Area | Authors |

|---|---|---|

| Agri-food | critical challenges related to the implementation of digitalization | [78] |

| improving food traceability and verifying its authenticity through digitalization | [79] | |

| creating digitization incubators | [80] | |

| the possibility of using digitalization to improve Agriculture 4.0 solutions | [81] | |

| building the resilience of short-food supply chain participants through digitalization | [65] | |

| implementation of digital transformation and automation in the meat industry | [82] | |

| Automotive | the impact of digital transformation on the integration of global value chains | [83] |

| differences in the use and impact of digital technologies between manufacturing subsidiaries and lead companies | [84] | |

| Fashion/Textile | using digitalization in creating interactive clothing design systems | [85] |

| implementation of an IoT-based solution for warehouse process management | [86] | |

| Wood | restructuring of business processes by implementing digital technologies | [87] |

| Metallurgical | tools used in the metallurgy in Poland on the way to full digitalization | [88] |

| Public services | modernization of processes by implementing blockchain technology | [89] |

| assessing different approaches to digital transformation in the public services sector | [90] | |

| Humanitarian supply chains | the impact of digitalization on fast, fair, and safe humanitarian logistics | [61] |

| configuration of the technology portfolio and overcoming barriers related to the implementation of digital technologies | [91] |

4.3. Industry 4.0—Disruptive Technology

4.3.1. Blockchain Technology

4.3.2. Digital Twin

4.3.3. IoT and RFID

4.3.4. Artificial Intelligence

4.3.5. Digital Marketing

4.4. Impact of Digitalization on Sustainable Development

4.4.1. Business Analytics

4.4.2. Environmental Management

4.4.3. Transport

4.5. Impact of COVID-19 on Digitalization

4.6. Hazards

4.7. Human Capital

4.8. Other

- Analysis of aspects related to business ethics in the light of implementing digital and mechatronic solutions [140].

- Digital transformation of a human-centric manual assembly process by implementing a multi-criteria algorithm [141].

- Development of digitization over the past 60 years in the logistics and supply chain sector [19].

- Equipment maintenance model by utilizing digitization and organizational integration [142].

- Using digitization to solve the information transmission problem between enterprises as part of project management [143].

5. Discussion

- Market challenges related to changes in business models, producer-customer relations, and the evolution of servitization.

- Organizational challenges relate primarily to knowledge management and increased access to information.

- Economic challenges refer to new digital paradigms’ impact on labor demand.

- Societal challenges deal with the impact of environmental sustainability, notably resource efficiency and energy consumption.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Koh, L.; Orzes, G.; Jia, F. The Fourth Industrial Revolution (Industry 4.0): Technologies Disruption on Operations and Supply Chain Management. Int. J. Oper. Prod. Manag. 2019, 39, 817–828. [Google Scholar] [CrossRef]

- Savastano, M.; Amendola, C.; Bellini, F.; D’Ascenzo, F. Contextual Impacts on Industrial Processes Brought by the Digital Transformation of Manufacturing: A Systematic Review. Sustainability 2019, 11, 891. [Google Scholar] [CrossRef]

- Matt, D.T.; Pedrini, G.; Bonfanti, A.; Orzes, G. Industrial Digitalization. A Systematic Literature Review and Research Agenda. Eur. Manag. J. 2022, 41, 47–78. [Google Scholar] [CrossRef]

- Legner, C.; Eymann, T.; Hess, T.; Matt, C.; Böhmann, T.; Drews, P.; Mädche, A.; Urbach, N.; Ahlemann, F. Digitalization: Opportunity and Challenge for the Business and Information Systems Engineering Community. Bus. Inf. Syst. Eng. 2017, 59, 301–308. [Google Scholar] [CrossRef]

- Alsufyani, N.; Gill, A.Q. Digitalisation Performance Assessment: A Systematic Review. Technol. Soc. 2022, 68, 101894. [Google Scholar] [CrossRef]

- Abdallah, Y.O.; Shehab, E.; Al-Ashaab, A. Developing a Digital Transformation Process in the Manufacturing Sector: Egyptian Case Study. Inf. Syst. E-Bus. Manag. 2022, 20, 613–630. [Google Scholar] [CrossRef]

- George, G.; Schillebeeckx, S.J.D. Digital Transformation, Sustainability, and Purpose in the Multinational Enterprise. J. World Bus. 2022, 57, 101326. [Google Scholar] [CrossRef]

- Peng, Y.; Tao, C. Can Digital Transformation Promote Enterprise Performance? —From the Perspective of Public Policy and Innovation. J. Innov. Knowl. 2022, 7, 100198. [Google Scholar] [CrossRef]

- Meng, F.; Wang, W. Research on the Mechanism of Digitalization to the Improvement of Manufacturing Enterprises Performance Based on Mediating Effect. In Proceedings of the 2020 6th International Conference on Information Management (ICIM), London, UK, 27–29 March 2020; IEEE: Piscataway, NJ, USA; pp. 122–126. [Google Scholar]

- Dhanpat, N.; Buthelezi, Z.P.; Joe, M.R.; Maphela, T.V.; Shongwe, N. Industry 4.0: The Role of Human Resource Professionals. SA J. Hum. Resour. Manag. 2020, 18, a1302. [Google Scholar] [CrossRef]

- Giang, N.T.H.; Hai, P.T.T.; Tu, N.T.T.; Tan, P.X. Exploring the Readiness for Digital Transformation in a Higher Education Institution towards Industrial Revolution 4.0. Int. J. Eng. Pedagog. 2021, 11, 4. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R.; Bozan, K. Designing Value Chains for Industry 4.0 and a Circular Economy: A Review of the Literature. Sustainability 2022, 14, 7084. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Jabbour, A.B.L.d.S.; Sarkis, J.; Filho, M.G. Unlocking the Circular Economy through New Business Models Based on Large-Scale Data: An Integrative Framework and Research Agenda. Technol. Forecast. Soc. Chang. 2019, 144, 546–552. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A Review of Internet of Things (IoT) Embedded Sustainable Supply Chain for Industry 4.0 Requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Atif, S.; Ahmed, S.; Wasim, M.; Zeb, B.; Pervez, Z.; Quinn, L. Towards a Conceptual Development of Industry 4.0, Servitisation, and Circular Economy: A Systematic Literature Review. Sustainability 2021, 13, 6501. [Google Scholar] [CrossRef]

- Chen, X.; Despeisse, M.; Johansson, B. Environmental Sustainability of Digitalization in Manufacturing: A Review. Sustainability 2020, 12, 10298. [Google Scholar] [CrossRef]

- Chen, Q.; García de Soto, B.; Adey, B.T. Supplier-Contractor Coordination Approach to Managing Demand Fluctuations of Ready-Mix Concrete. Autom. Constr. 2021, 121, 103423. [Google Scholar] [CrossRef]

- Kayapinar Kaya, S.; Aycin, E. An Integrated Interval Type 2 Fuzzy AHP and COPRAS-G Methodologies for Supplier Selection in the Era of Industry 4.0. Neural Comput. Appl. 2021, 33, 10515–10535. [Google Scholar] [CrossRef]

- Herold, D.M.; Ćwiklicki, M.; Pilch, K.; Mikl, J. The Emergence and Adoption of Digitalization in the Logistics and Supply Chain Industry: An Institutional Perspective. J. Enterp. Inf. Manag. 2021, 34, 1917–1938. [Google Scholar] [CrossRef]

- Booth, A.; Sutton, A.; Clowes, M.; Martyn-St James, M. Systematic Approaches to a Successful Literature Review; Sage Publications: Thousand Oaks, CA, USA, 2021. [Google Scholar]

- van Eck, N.J.; Waltman, L. Visualizing Bibliometric Networks. In Measuring Scholarly Impact; Ding, Y., Rousseau, R., Wolfram, D., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 285–320. [Google Scholar]

- Kerin, M.; Pham, D.T. Smart Remanufacturing: A Review and Research Framework. J. Manuf. Technol. Manag. 2020, 31, 1205–1235. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Azevedo, B.D.; de Mattos Nascimento, D.L.; Quelhas, O.L.G. Challenges and Benefits of Sustainable Industry 4.0 for Operations and Supply Chain Management—A Framework Headed toward the 2030 Agenda. Sustainability 2022, 14, 830. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Pigosso, D.C.A.; Parida, V. Towards the Smart Circular Economy Paradigm: A Definition, Conceptualization, and Research Agenda. Sustainability 2022, 14, 4960. [Google Scholar] [CrossRef]

- Tavana, M.; Shaabani, A.; Raeesi Vanani, I.; Kumar Gangadhari, R. A Review of Digital Transformation on Supply Chain Process Management Using Text Mining. Processes 2022, 10, 842. [Google Scholar] [CrossRef]

- Gharaibeh, L.; Eriksson, K.M.; Lantz, B.; Matarneh, S.; Elghaish, F. Toward Digital Construction Supply Chain-Based Industry 4.0 Solutions: Scientometric-Thematic Analysis. Smart Sustain. Built Environ. 2022. [Google Scholar] [CrossRef]

- Chang, S.E.; Chen, Y. When Blockchain Meets Supply Chain: A Systematic Literature Review on Current Development and Potential Applications. IEEE Access 2020, 8, 62478–62494. [Google Scholar] [CrossRef]

- Seyedghorban, Z.; Tahernejad, H.; Meriton, R.; Graham, G. Supply Chain Digitalization: Past, Present and Future. Prod. Plan. Control 2020, 31, 96–114. [Google Scholar] [CrossRef]

- Ciampi, F.; Faraoni, M.; Ballerini, J.; Meli, F. The Co-Evolutionary Relationship between Digitalization and Organizational Agility: Ongoing Debates, Theoretical Developments and Future Research Perspectives. Technol. Forecast. Soc. Chang. 2022, 176, 121383. [Google Scholar] [CrossRef]

- Amentae, T.K.; Gebresenbet, G. Digitalization and Future Agro-Food Supply Chain Management: A Literature-Based Implications. Sustainability 2021, 13, 12181. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Abdollahi, A.; Zailani, S.; Iranmanesh, M.; Ghobakhloo, M. Digitalization in Food Supply Chains: A Bibliometric Review and Key-Route Main Path Analysis. Sustainability 2021, 14, 83. [Google Scholar] [CrossRef]

- Ancín, M.; Pindado, E.; Sánchez, M. New Trends in the Global Digital Transformation Process of the Agri-Food Sector: An Exploratory Study Based on Twitter. Agric. Syst. 2022, 203, 103520. [Google Scholar] [CrossRef]

- Park, A.; Li, H. The Effect of Blockchain Technology on Supply Chain Sustainability Performances. Sustainability 2021, 13, 1726. [Google Scholar] [CrossRef]

- Felsberger, A.; Reiner, G. Sustainable Industry 4.0 in Production and Operations Management: A Systematic Literature Review. Sustainability 2020, 12, 7982. [Google Scholar] [CrossRef]

- Rad, F.F.; Oghazi, P.; Palmié, M.; Chirumalla, K.; Pashkevich, N.; Patel, P.C.; Sattari, S. Industry 4.0 and Supply Chain Performance: A Systematic Literature Review of the Benefits, Challenges, and Critical Success Factors of 11 Core Technologies. Ind. Mark. Manag. 2022, 105, 268–293. [Google Scholar] [CrossRef]

- Dethine, B.; Enjolras, M.; Monticolo, D. Digitalization and SMEs’ Export Management: Impacts on Resources and Capabilities. Technol. Innov. Manag. Rev. 2020, 10, 18–34. [Google Scholar] [CrossRef]

- Cricelli, L.; Strazzullo, S. The Economic Aspect of Digital Sustainability: A Systematic Review. Sustainability 2021, 13, 8241. [Google Scholar] [CrossRef]

- Hänninen, M.; Kwan, S.K.; Mitronen, L. From the Store to Omnichannel Retail: Looking Back over Three Decades of Research. Int. Rev. Retail Distrib. Consum. Res. 2021, 31, 1–35. [Google Scholar] [CrossRef]

- Mthimkhulu, A.; Jokonya, O. Exploring the Factors Affecting the Adoption of Blockchain Technology in the Supply Chain and Logistic Industry. J. Transp. Supply Chain Manag. 2022, 16, 9. [Google Scholar] [CrossRef]

- Chen, C.; Feng, Y.; Shen, B. Managing Labor Sustainability in Digitalized Supply Chains: A Systematic Literature Review. Sustainability 2022, 14, 3895. [Google Scholar] [CrossRef]

- Malacina, I.; Teplov, R. Supply Chain Innovation Research: A Bibliometric Network Analysis and Literature Review. Int. J. Prod. Econ. 2022, 251, 108540. [Google Scholar] [CrossRef]

- Samoggia, A.; Monticone, F.; Bertazzoli, A. Innovative Digital Technologies for Purchasing and Consumption in Urban and Regional Agro-Food Systems: A Systematic Review. Foods 2021, 10, 208. [Google Scholar] [CrossRef]

- Li, J.; Kassem, M. Applications of Distributed Ledger Technology (DLT) and Blockchain-Enabled Smart Contracts in Construction. Autom. Constr. 2021, 132, 103955. [Google Scholar] [CrossRef]

- Hellweg, F.; Lechtenberg, S.; Hellingrath, B.; Thomé, A.M.T. Literature Review on Maturity Models for Digital Supply Chains. Braz. J. Oper. Prod. Manag. 2021, 18, 1–12. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Fosso Wamba, S.; Chiappetta Jabbour, C.J.; Lopes de Sousa Jabbour, A.B.; Machado, M.C. Adoption of Industry 4.0 Technologies by Organizations: A Maturity Levels Perspective. Ann. Oper. Res. 2022. [Google Scholar] [CrossRef] [PubMed]

- Nitsche, A.-M.; Kusturica, W. Modelling Advanced Technology Integration for Supply Chains. In Proceedings of the 24th International Conference on Enterprise Information Systems, Online, 25–27 April 2022; SCITEPRESS—Science and Technology Publications: Setúbal, Portugal, 2022; pp. 397–407. [Google Scholar]

- Emmanouilidis, C.; Bakalis, S. Digital Technology Enablers for Resilient and Customer Driven Food Value Chains. In Advances in Production Management Systems. Towards Smart and Digital Manufacturing. APMS 2020. IFIP Advances in Information and Communication Technology; Lalic, B., Majstorovic, V., Marjanovic, U., von Cieminski, G., Romero, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 592, pp. 649–657. [Google Scholar]

- Abdallah, Y.O.; Shehab, E.; Al-Ashaab, A. Towards Managing Digital Transformation in Manufacturing Industry: Theoretical Framework. Adv. Transdiscipl. Eng. 2021, 15, 21–26. [Google Scholar] [CrossRef]

- Hallikas, J.; Immonen, M.; Brax, S. Digitalizing Procurement: The Impact of Data Analytics on Supply Chain Performance. Supply Chain Manag. Int. J. 2021, 26, 629–646. [Google Scholar] [CrossRef]

- Sjodin, D.; Kamalaldin, A.; Parida, V.; Islam, N. Procurement 4.0: How Industrial Customers Transform Procurement Processes to Capitalize on Digital Servitization. IEEE Trans. Eng. Manag. 2022, 1–16. [Google Scholar] [CrossRef]

- Ho, W.R.; Tsolakis, N.; Dawes, T.; Dora, M.; Kumar, M. A Digital Strategy Development Framework for Supply Chains. IEEE Trans. Eng. Manag. 2022, 70, 2493–2506. [Google Scholar] [CrossRef]

- Sjøbakk, B. The Strategic Landscape of Industry 4.0. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0. APMS 2018. IFIP Advances in Information and Communication Technology; Moon, I., Lee, G., Park, J., Kiritsis, D., von Cieminski, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; Volume 536, pp. 122–127. [Google Scholar]

- Deepu, T.S.; Ravi, V. A Conceptual Framework for Supply Chain Digitalization Using Integrated Systems Model Approach and DIKW Hierarchy. Intell. Syst. Appl. 2021, 10–11, 200048. [Google Scholar] [CrossRef]

- Zaki, M.; Theodoulidis, B.; Shapira, P.; Neely, A.; Tepel, M.F. Redistributed Manufacturing and the Impact of Big Data: A Consumer Goods Perspective. Prod. Plan. Control 2019, 30, 568–581. [Google Scholar] [CrossRef]

- Ehie, I.; Ferreira, L.M.D.F. Conceptual Development of Supply Chain Digitalization Framework. IFAC-PapersOnLine 2019, 52, 2338–2342. [Google Scholar] [CrossRef]

- Pekarčíková, M.; Trebuňa, P.; Kliment, M.; Edl, M.; Rosocha, L. Transformation the Logistics to Digital Logistics: Theoretical Approach. Acta Logist. 2020, 7, 217–223. [Google Scholar] [CrossRef]

- Genzorova, T.; Corejova, T.; Stalmasekova, N. How Digital Transformation Can Influence Business Model, Case Study for Transport Industry. Transp. Res. Procedia 2019, 40, 1053–1058. [Google Scholar] [CrossRef]

- Belli, L.; Davoli, L.; Medioli, A.; Marchini, P.L.; Ferrari, G. Toward Industry 4.0 With IoT: Optimizing Business Processes in an Evolving Manufacturing Factory. Front. ICT 2019, 6, 17. [Google Scholar] [CrossRef]

- Chen, Q.; Adey, B.T.; Haas, C.T.; Hall, D.M. Exploiting Digitalization for the Coordination of Required Changes to Improve Engineer-to-Order Materials Flow Management. Constr. Innov. 2022, 22, 76–100. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Sokolov, B. Reconfigurable Supply Chain: The X-Network. Int. J. Prod. Res. 2020, 58, 4138–4163. [Google Scholar] [CrossRef]

- Khan, M.; Khan, M.; Ali, A.; Khan, M.I.; Ullah, I.; Iqbal, M. Digitalization for Fast, Fair, and Safe Humanitarian Logistics. Logistics 2022, 6, 31. [Google Scholar] [CrossRef]

- Lee, K.L.; Azmi, N.A.N.; Hanaysha, J.R.; Alzoubi, H.M.; Alshurideh, M.T. The Effect of Digital Supply Chain on Organizational Performance: An Empirical Study in Malaysia Manufacturing Industry. Uncertain Supply Chain Manag. 2022, 10, 495–510. [Google Scholar] [CrossRef]

- Gviliya, N.; Parfyonov, A.; Shulzhenko, T. Managing Integrated Interorganizational Logistic Systems in the Digital Economy. Upravlenets 2019, 10, 40–51. [Google Scholar] [CrossRef]

- Zouari, D.; Ruel, S.; Viale, L. Does Digitalising the Supply Chain Contribute to Its Resilience? Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 149–180. [Google Scholar] [CrossRef]

- Michel-Villarreal, R.; Vilalta-Perdomo, E.L.; Canavari, M.; Hingley, M. Resilience and Digitalization in Short Food Supply Chains: A Case Study Approach. Sustainability 2021, 13, 5913. [Google Scholar] [CrossRef]

- Pasqualino, R.; Demartini, M.; Bagheri, F. Digital Transformation and Sustainable Oriented Innovation: A System Transition Model for Socio-Economic Scenario Analysis. Sustainability 2021, 13, 11564. [Google Scholar] [CrossRef]

- Rymarczyk, J. Technologies, Opportunities and Challenges of the Industrial Revolution 4.0: Theoretical Considerations. Entrep. Bus. Econ. Rev. 2020, 8, 185–198. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, C.W. Relationships among Healthcare Digitalization, Social Capital, and Supply Chain Performance in the Healthcare Manufacturing Industry. Int. J. Environ. Res. Public Health 2021, 18, 1417. [Google Scholar] [CrossRef]

- Wehrle, M.; Lechler, S.; von der Gracht, H.A.; Hartmann, E. Digitalization and Its Impact on the Future Role of SCM Executives in Talent Management—An International Cross-Industry Delphi Study. J. Bus. Logist. 2020, 41, 356–383. [Google Scholar] [CrossRef]

- Koh, L.Y.; Li, X.; Wang, X.; Yuen, K.F. Key Knowledge Domains for Maritime Shipping Executives in the Digital Era: A Knowledge-Based View Approach. Technol. Anal. Strat. Manag. 2022, 11, 1–18. [Google Scholar] [CrossRef]

- Hodorog, A.; Petri, I.; Rezgui, Y.; Hippolyte, J.-L. Building Information Modelling Knowledge Harvesting for Energy Efficiency in the Construction Industry. Clean Technol. Environ. Policy 2021, 23, 1215–1231. [Google Scholar] [CrossRef]

- Song, D. A Literature Review, Container Shipping Supply Chain: Planning Problems and Research Opportunities. Logistics 2021, 5, 41. [Google Scholar] [CrossRef]

- Rugiubei, R.; Pînzaru, F. The Digitalization of Supply Chain Management in Romanian Companies: An Introductive Research. Proc. Int. Conf. Bus. Excell. 2022, 16, 1295–1305. [Google Scholar] [CrossRef]

- Kamali Saraji, M.; Streimikiene, D.; Kyriakopoulos, G.L. Fermatean Fuzzy CRITIC-COPRAS Method for Evaluating the Challenges to Industry 4.0 Adoption for a Sustainable Digital Transformation. Sustainability 2021, 13, 9577. [Google Scholar] [CrossRef]

- Omrani, N.; Rejeb, N.; Maalaoui, A.; Dabic, M.; Kraus, S. Drivers of Digital Transformation in SMEs. IEEE Trans. Eng. Manag. 2022, 1–14. [Google Scholar] [CrossRef]

- Ahi, A.A.; Sinkovics, N.; Shildibekov, Y.; Sinkovics, R.R.; Mehandjiev, N. Advanced Technologies and International Business: A Multidisciplinary Analysis of the Literature. Int. Bus. Rev. 2022, 31, 101967. [Google Scholar] [CrossRef]

- Suleiman, Z.; Shaikholla, S.; Dikhanbayeva, D.; Shehab, E.; Turkyilmaz, A. Industry 4.0: Clustering of Concepts and Characteristics. Cogent Eng. 2022, 9, 2034264. [Google Scholar] [CrossRef]

- Anastasiadis, F.; Tsolakis, N.; Srai, J. Digital Technologies Towards Resource Efficiency in the Agrifood Sector: Key Challenges in Developing Countries. Sustainability 2018, 10, 4850. [Google Scholar] [CrossRef]

- McVey, C.; Elliott, C.T.; Cannavan, A.; Kelly, S.D.; Petchkongkaew, A.; Haughey, S.A. Portable Spectroscopy for High Throughput Food Authenticity Screening: Advancements in Technology and Integration into Digital Traceability Systems. Trends Food Sci. Technol. 2021, 118, 777–790. [Google Scholar] [CrossRef]

- D’Oronzio, M.A.; Sica, C. Innovation in Basilicata Agriculture: From Tradition to Digital. Econ. Agro-Aliment. 2021, 23, 1–18. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Enhancing Smart Farming through the Applications of Agriculture 4.0 Technologies. Int. J. Intell. Netw. 2022, 3, 150–164. [Google Scholar] [CrossRef]

- Echegaray, N.; Hassoun, A.; Jagtap, S.; Tetteh-Caesar, M.; Kumar, M.; Tomasevic, I.; Goksen, G.; Lorenzo, J.M. Meat 4.0: Principles and Applications of Industry 4.0 Technologies in the Meat Industry. Appl. Sci. 2022, 12, 6986. [Google Scholar] [CrossRef]

- Szalavetz, A. Digital Transformation—Enabling Factory Economy Actors’ Entrepreneurial Integration in Global Value Chains? Postcommunist Econ. 2020, 32, 771–792. [Google Scholar] [CrossRef]

- Szalavetz, A. Digitalisation, Automation and Upgrading in Global Value Chains—Factory Economy Actors versus Lead Companies. Postcommunist Econ. 2019, 31, 646–670. [Google Scholar] [CrossRef]

- Sharma, S.; Koehl, L.; Bruniaux, P.; Zeng, X.; Wang, Z. Development of an Intelligent Data-Driven System to Recommend Personalized Fashion Design Solutions. Sensors 2021, 21, 4239. [Google Scholar] [CrossRef]

- Khan, M.G.; Huda, N.U.; Zaman, U.K.U. Smart Warehouse Management System: Architecture, Real-Time Implementation and Prototype Design. Machines 2022, 10, 150. [Google Scholar] [CrossRef]

- Labelle, E.R.; Kemmerer, J. Business Process Reengineering of a Large-Scale Public Forest Enterprise Through Harvester Data Integration. Croat. J. For. Eng. 2022, 43, 13–27. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R. Digitalisation and Innovation in the Steel Industry in Poland—Selected Tools of ICT in an Analysis of Statistical Data and a Case Study. Energies 2021, 14, 3034. [Google Scholar] [CrossRef]

- Doguchaeva, S.; Zubkova, S.; Katrashova, Y. Blockchain in Public Supply Chain Management: Advantages and Risks. Transp. Res. Procedia 2022, 63, 2172–2178. [Google Scholar] [CrossRef]

- Seepma, A.P.; de Blok, C.; Van Donk, D.P. Designing Digital Public Service Supply Chains: Four Country-Based Cases in Criminal Justice. Supply Chain Manag. Int. J. 2021, 26, 418–446. [Google Scholar] [CrossRef]

- Marić, J.; Galera-Zarco, C.; Opazo-Basáez, M. The Emergent Role of Digital Technologies in the Context of Humanitarian Supply Chains: A Systematic Literature Review. Ann. Oper. Res. 2022, 319, 1003–1044. [Google Scholar] [CrossRef] [PubMed]

- Bigliardi, B.; Filippelli, S.; Petroni, A.; Tagliente, L. The Digitalization of Supply Chain: A Review. Procedia Comput. Sci. 2022, 200, 1806–1815. [Google Scholar] [CrossRef]

- Amoozad Mahdiraji, H.; Yaftiyan, F.; Abbasi-Kamardi, A.; Garza-Reyes, J.A. Investigating Potential Interventions on Disruptive Impacts of Industry 4.0 Technologies in Circular Supply Chains: Evidence from SMEs of an Emerging Economy. Comput. Ind. Eng. 2022, 174, 108753. [Google Scholar] [CrossRef]

- Pekarcikova, M.; Trebuna, P.; Kliment, M.; Rosocha, L. Material Flow Optimization through E-Kanban System Simulation. Int. J. Simul. Model. 2020, 19, 243–254. [Google Scholar] [CrossRef]

- Tsolakis, N.; Schumacher, R.; Dora, M.; Kumar, M. Artificial Intelligence and Blockchain Implementation in Supply Chains: A Pathway to Sustainability and Data Monetisation? Ann. Oper. Res. 2022, 327, 157–210. [Google Scholar] [CrossRef]

- Sorger, M.; Ralph, B.J.; Hartl, K.; Woschank, M.; Stockinger, M. Big Data in the Metal Processing Value Chain: A Systematic Digitalization Approach under Special Consideration of Standardization and SMEs. Appl. Sci. 2021, 11, 9021. [Google Scholar] [CrossRef]

- Hassoun, A.; Boukid, F.; Pasqualone, A.; Bryant, C.J.; García, G.G.; Parra-López, C.; Jagtap, S.; Trollman, H.; Cropotova, J.; Barba, F.J. Emerging Trends in the Agri-Food Sector: Digitalisation and Shift to Plant-Based Diets. Curr. Res. Food Sci. 2022, 5, 2261–2269. [Google Scholar] [CrossRef] [PubMed]

- Rana, S.K.; Kim, H.-C.; Pani, S.K.; Rana, S.K.; Joo, M.-I.; Rana, A.K.; Aich, S. Blockchain-Based Model to Improve the Performance of the Next-Generation Digital Supply Chain. Sustainability 2021, 13, 10008. [Google Scholar] [CrossRef]

- Durack, C.F.; Blesik, T.; Düring, M.; Bick, M. Blockchain Applications in Supply Chain Transactions. J. Bus. Logist. 2021, 42, 7–24. [Google Scholar] [CrossRef]

- Joannou, D.; Kalawsky, R.; Martínez-García, M.; Fowler, C.; Fowler, K. Realizing the Role of Permissioned Blockchains in a Systems Engineering Lifecycle. Systems 2020, 8, 41. [Google Scholar] [CrossRef]

- Weerakoon, H.D.; Chandanie, H. Analysis of Feasibility of Blockchain Technology For International Trade Related to Sri Lankan Construction Industry. In Proceedings of the 9th World Construction Symposium 2021 on Reshaping Construction: Strategic, Structural and Cultural Transformations towards the “Next Normal”, virtually, 9–10 July 2021; The Ceylon Institute of Builders: Colombo, Sri Lanka, 2021; pp. 75–85. [Google Scholar]

- Qian, X.; Papadonikolaki, E. Shifting Trust in Construction Supply Chains through Blockchain Technology. Eng. Constr. Arch. Manag. 2020, 28, 584–602. [Google Scholar] [CrossRef]

- Ramkumar, G.; Kasat, K.; Khader, P.R.A.; Muhammed, P.K.N.; Raghu, T.; Chhabra, S. Quality Enhanced Framework through Integration of Blockchain with Supply Chain Management. Meas. Sens. 2022, 24, 100462. [Google Scholar] [CrossRef]

- Semenov, Y.; Semenova, O.; Kuvataev, I. Solutions for Digitalization of the Coal Industry Implemented in UC Kuzbassrazrezugol. E3S Web Conf. 2020, 174, 01042. [Google Scholar] [CrossRef]

- Moder, P.; Ehm, H.; Jofer, E. A Holistic Digital Twin Based on Semantic Web Technologies to Accelerate Digitalization. In Digital Transformation in Semiconductor Manufacturing. EADTC EADTC 2018 2019. Lecture Notes in Electrical Engineering; Keil, S., Lasch, R., Lindner, F., Lohmer, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 670, pp. 3–13. [Google Scholar]

- Moder, P.; Ehm, H.; Ramzy, N. Digital Twin for Plan and Make Using Semantic Web Technologies—Extending the JESSI/SEMATECH MIMAC Standard to the Digital Reference. In Digital Transformation in Semiconductor Manufacturing. EADTC EADTC 2018 2019. Lecture Notes in Electrical Engineering; Keil, S., Lasch, R., Lindner, F., Lohmer, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 670, pp. 24–32. [Google Scholar]

- Sermuksnyte-Alesiuniene, K.; Simanaviciene, Z.; Bickauske, D.; Mosiiuk, S.; Belova, I. Increasing the Effectiveness of Food Supply Chain Logistics through Digital Transformation. Indep. J. Manag. Prod. 2021, 12, s677–s701. [Google Scholar] [CrossRef]

- Beliatis, M.J.; Jensen, K.; Ellegaard, L.; Aagaard, A.; Presser, M. Next Generation Industrial IoT Digitalization for Traceability in Metal Manufacturing Industry: A Case Study of Industry 4.0. Electronics 2021, 10, 628. [Google Scholar] [CrossRef]

- Ben, K.; Feng, Z.; Cao, Y. Exploration and Practice of Intelligent Manufacturing of Electronic Information Equipment. IOP Conf. Ser. Mater. Sci. Eng. 2020, 892, 012056. [Google Scholar] [CrossRef]

- Mahlamäki, T.; Storbacka, K.; Pylkkönen, S.; Ojala, M. Adoption of Digital Sales Force Automation Tools in Supply Chain: Customers’ Acceptance of Sales Configurators. Ind. Mark. Manag. 2020, 91, 162–173. [Google Scholar] [CrossRef]

- Agnihotri, R.; Kalra, A.; Chen, H.; Daugherty, P.J. Utilizing Social Media in a Supply Chain B2B Setting: A Knowledge Perspective. J. Bus. Logist. 2022, 43, 189–208. [Google Scholar] [CrossRef]

- Liu, Z.; Sampaio, P.; Pishchulov, G.; Mehandjiev, N.; Cisneros-Cabrera, S.; Schirrmann, A.; Jiru, F.; Bnouhanna, N. The Architectural Design and Implementation of a Digital Platform for Industry 4.0 SME Collaboration. Comput. Ind. 2022, 138, 103623. [Google Scholar] [CrossRef]

- Rusch, M.; Schöggl, J.; Baumgartner, R.J. Application of Digital Technologies for Sustainable Product Management in a Circular Economy: A Review. Bus. Strategy Environ. 2022, 32, 1159–1174. [Google Scholar] [CrossRef]

- Ebinger, F.; Omondi, B. Leveraging Digital Approaches for Transparency in Sustainable Supply Chains: A Conceptual Paper. Sustainability 2020, 12, 6129. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Mikalef, P.; Blomsma, F.; Li, J. The Effects of Business Analytics Capability on Circular Economy Implementation, Resource Orchestration Capability, and Firm Performance. Int. J. Prod. Econ. 2021, 239, 108205. [Google Scholar] [CrossRef]

- Kunkel, S.; Matthess, M.; Xue, B.; Beier, G. Industry 4.0 in Sustainable Supply Chain Collaboration: Insights from an Interview Study with International Buying Firms and Chinese Suppliers in the Electronics Industry. Resour. Conserv. Recycl. 2022, 182, 106274. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Gunasekaran, A.; Sethuraman, K. Reflecting on an Empirical Study of the Digitalization Initiatives for Sustainability on Logistics: The Concept of Sustainable Logistics 4.0. Clean. Logist. Supply Chain 2022, 4, 100058. [Google Scholar] [CrossRef]

- Lee, S.-Y. Sustainable Supply Chain Management, Digital-Based Supply Chain Integration, and Firm Performance: A Cross-Country Empirical Comparison between South Korea and Vietnam. Sustainability 2021, 13, 7315. [Google Scholar] [CrossRef]

- Brinken, J.; Pabsch, C.; Behrendt, F. Decarbonization Potential of Logistic 4.0 Technologies in Apple Supply Chains. Procedia Comput. Sci. 2022, 200, 461–470. [Google Scholar] [CrossRef]

- Beier, G.; Matthess, M.; Guan, T.; Grudzien, D.I.d.O.P.; Xue, B.; de Lima, E.P.; Chen, L. Impact of Industry 4.0 on Corporate Environmental Sustainability: Comparing Practitioners’ Perceptions from China, Brazil and Germany. Sustain. Prod. Consum. 2022, 31, 287–300. [Google Scholar] [CrossRef]

- Matthess, M.; Kunkel, S.; Xue, B.; Beier, G. Supplier Sustainability Assessment in the Age of Industry 4.0—Insights from the Electronics Industry. Clean. Logist. Supply Chain 2022, 4, 100038. [Google Scholar] [CrossRef]

- Bahn, R.A.; Yehya, A.A.K.; Zurayk, R. Digitalization for Sustainable Agri-Food Systems: Potential, Status, and Risks for the MENA Region. Sustainability 2021, 13, 3223. [Google Scholar] [CrossRef]

- Kayikci, Y. Sustainability Impact of Digitization in Logistics. Procedia Manuf. 2018, 21, 782–789. [Google Scholar] [CrossRef]

- Brinken, J.; Trojahn, S.; Behrendt, F. Sufficiency, Consistency, and Efficiency as a Base for Systemizing Sustainability Measures in Food Supply Chains. Sustainability 2022, 14, 6742. [Google Scholar] [CrossRef]

- Gerhátová, Z.; Zitrický, V.; Klapita, V. Industry 4.0 Implementation Options in Railway Transport. Transp. Res. Procedia 2021, 53, 23–30. [Google Scholar] [CrossRef]

- Akram, U.; Fülöp, M.T.; Tiron-Tudor, A.; Topor, D.I.; Căpușneanu, S. Impact of Digitalization on Customers’ Well-Being in the Pandemic Period: Challenges and Opportunities for the Retail Industry. Int. J. Environ Res. Public Health 2021, 18, 7533. [Google Scholar] [CrossRef]

- Ahmad, T.; Van Looy, A. Development and Testing of an Explorative BPM Acceptance Model: Insights from the COVID-19 Pandemic. PLoS ONE 2021, 16, e0259226. [Google Scholar] [CrossRef]

- Koh, L.Y.; Yuen, K.F. Emerging Competencies for Logistics Professionals in the Digital Era: A Literature Review. Front. Psychol. 2022, 13, 965748. [Google Scholar] [CrossRef]

- Srinivasan, N.; Eden, L. Going Digital Multinationals: Navigating Economic and Social Imperatives in a Post-Pandemic World. J. Int. Bus. Policy 2021, 4, 228–243. [Google Scholar] [CrossRef]

- Kumar, R.; Ganapathy, L.; Gokhale, R.; Tiwari, M.K. Scaling up the Digitalization of the Public Distribution System: A COVID-19 Pandemic Impetus. IFAC-PapersOnLine 2022, 55, 55–60. [Google Scholar] [CrossRef]

- Sridhar, A.; Balakrishnan, A.; Jacob, M.M.; Sillanpää, M.; Dayanandan, N. Global Impact of COVID-19 on Agriculture: Role of Sustainable Agriculture and Digital Farming. Environ. Sci. Pollut. Res. 2022, 30, 42509–42525. [Google Scholar] [CrossRef] [PubMed]

- Son, B.-G.; Kim, H.; Hur, D.; Subramanian, N. The Dark Side of Supply Chain Digitalisation: Supplier-Perceived Digital Capability Asymmetry, Buyer Opportunism and Governance. Int. J. Oper. Prod. Manag. 2021, 41, 1220–1247. [Google Scholar] [CrossRef]

- Bekmurzaev, I.; Kurbanov, A.; Kurbanov, T.; Plotnikov, V.; Ushakova, E. Digital Technologies of Marketing Logistics and Risks of Their Implementation in Supply Chain. IOP Conf. Ser. Mater. Sci. Eng. 2020, 940, 012064. [Google Scholar] [CrossRef]

- Heim, H. Digital Fashion Revolutions: Supply Chain Transparency, Digitalization and the Non-Disclosure Paradox. Fash. Pract. 2022, 14, 329–351. [Google Scholar] [CrossRef]

- Kessler, M.; Arlinghaus, J.C.; Rosca, E.; Zimmermann, M. Curse or Blessing? Exploring Risk Factors of Digital Technologies in Industrial Operations. Int. J. Prod. Econ. 2022, 243, 108323. [Google Scholar] [CrossRef]

- Girrbach, P. Corporate Responsibility in the Context of Digitalization. Teh. Glas. 2021, 15, 422–428. [Google Scholar] [CrossRef]

- Kuteyi, D.; Winkler, H. Logistics Challenges in Sub-Saharan Africa and Opportunities for Digitalization. Sustainability 2022, 14, 2399. [Google Scholar] [CrossRef]

- Marinas, M.; Dinu, M.; Socol, A.G.; Socol, C. The Technological Transition of European Manufacturing Companies to Industry 4.0. Is the Human Resource Ready for Advanced Digital Technologies? The Case of Romania. Econ. Comput. Econ. Cybern. Stud. Res. 2021, 55, 23–41. [Google Scholar] [CrossRef]

- Meyer, C.; Gerlitz, L.; Henesey, L. Cross-Border Capacity-Building for Port Ecosystems in Small and Medium-Sized Baltic Ports. TalTech J. Eur. Stud. 2021, 11, 113–132. [Google Scholar] [CrossRef]

- Ludin, D.; Wellbrock, W.; Müller, E.; Gerstlberger, W.; Gray, L.; Salat, S. Robotics in the Modern World of Work—Results From an Empirical Study Regarding Business Ethics. Teh. Glas. 2021, 15, 242–249. [Google Scholar] [CrossRef]

- Turk, M.; Šimic, M.; Pipan, M.; Herakovič, N. Multi-Criterial Algorithm for the Efficient and Ergonomic Manual Assembly Process. Int. J. Environ. Res. Public Health 2022, 19, 3496. [Google Scholar] [CrossRef]

- Grijalvo Martín, M.; Pacios Álvarez, A.; Ordieres-Meré, J.; Villalba-Díez, J.; Morales-Alonso, G. New Business Models from Prescriptive Maintenance Strategies Aligned with Sustainable Development Goals. Sustainability 2020, 13, 216. [Google Scholar] [CrossRef]

- Zhao, L.; Deng, J.; Ma, Y.; Zhu, Y. Design of Digital Business Center of Enterprise Project Management System Based on Information Technology. J. Phys. Conf. Ser. 2021, 1744, 022010. [Google Scholar] [CrossRef]

- Brunetti, F.; Matt, D.T.; Bonfanti, A.; De Longhi, A.; Pedrini, G.; Orzes, G. Digital Transformation Challenges: Strategies Emerging from a Multi-Stakeholder Approach. TQM J. 2020, 32, 697–724. [Google Scholar] [CrossRef]

| Research Areas | Record Count | % of 127 |

|---|---|---|

| Business Economics | 39 | 30.7% |

| Engineering | 35 | 27.5% |

| Environmental Sciences: Ecology | 33 | 25.9% |

| Science, Technology, and Other Topics | 27 | 21.2% |

| Operations Research, Management Science | 15 | 11.8% |

| Computer Science | 13 | 10.2% |

| Publication Titles | Record Count | % of 127 |

|---|---|---|

| Sustainability | 21 | 17% |

| International Journal of Environmental Research and Public Health | 4 | 3% |

| Annals of Operations Research | 3 | 2% |

| IFIP Advances in Information and Communication Technology | 3 | 2% |

| International Journal of Production Economics | 3 | 2% |

| Journal of Business Logistics | 3 | 2% |

| Publishers | Record Count | % of 127 |

|---|---|---|

| MDPI | 38 | 29.92% |

| Elsevier | 25 | 19.68% |

| Emerald Group Publishing | 11 | 8.66% |

| Springer Nature | 11 | 8.66% |

| Cluster 1 | Cluster 2 | Cluster 3 |

|---|---|---|

| Adaptation | Analytics | Blockchain |

| Artificial Intelligence | Barriers | Challenges |

| Business | Big Data | Information |

| Capabilities | Design | Model |

| COVID-19 | Digitalization | Traceability |

| Dynamic capabilities | Framework | Trust |

| Impact | Future | |

| Implementation | Industry 4.0 | |

| Information technology | Internet | |

| Innovation | Internet of Thing | |

| Integration | Logistics | |

| Management | Supply chain | |

| Performance | Sustainability | |

| Technology | ||

| Transformation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tubis, A.A.; Grzybowska, K.; Król, B. Supply Chain in the Digital Age: A Scientometric–Thematic Literature Review. Sustainability 2023, 15, 11391. https://doi.org/10.3390/su151411391

Tubis AA, Grzybowska K, Król B. Supply Chain in the Digital Age: A Scientometric–Thematic Literature Review. Sustainability. 2023; 15(14):11391. https://doi.org/10.3390/su151411391

Chicago/Turabian StyleTubis, Agnieszka A., Katarzyna Grzybowska, and Bartosz Król. 2023. "Supply Chain in the Digital Age: A Scientometric–Thematic Literature Review" Sustainability 15, no. 14: 11391. https://doi.org/10.3390/su151411391

APA StyleTubis, A. A., Grzybowska, K., & Król, B. (2023). Supply Chain in the Digital Age: A Scientometric–Thematic Literature Review. Sustainability, 15(14), 11391. https://doi.org/10.3390/su151411391