Social, Environmental, and Governance Factors on Supply-Chain Performance with Mediating Technology Adoption

Abstract

1. Introduction

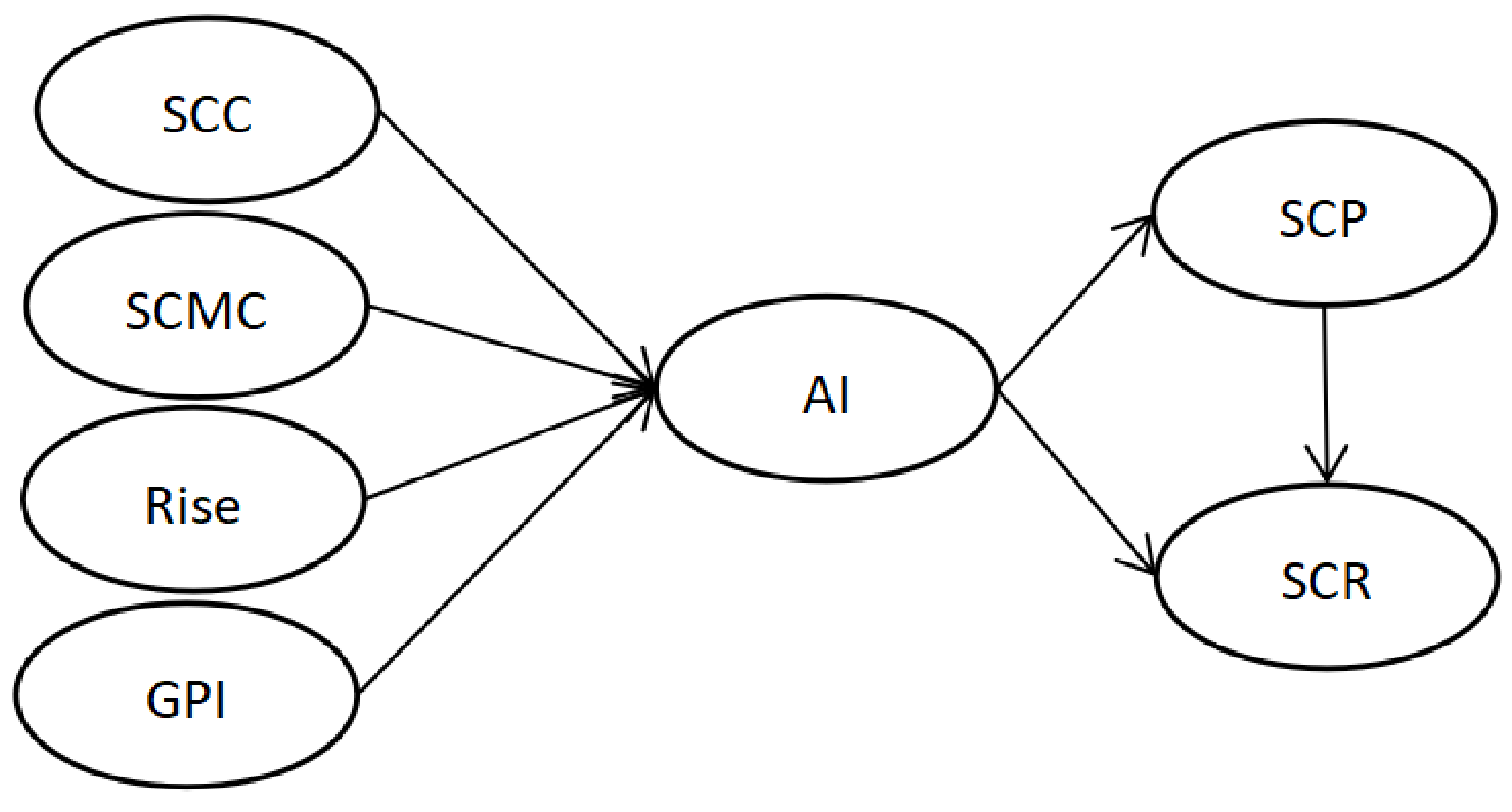

2. Literature Review and Hypotheses

2.1. Supply-Chain Collaboration and New Technology Adoption Intention

2.2. Supply-Chain Management Capabilities and New Technology Adoption Intention

2.3. Green-Product Innovation and New Technology Adoption Intention

2.4. Supply-Chain Risk and New Technology Adoption Intention

2.5. New Technology Adoption Intention and Supply-Chain Resilience/Performance

3. Methodology

3.1. Sampling and Data Collection

3.2. Measurement of Variables

4. Data Analysis and Results

4.1. Reliability Analysis and Validity Analysis

4.2. Correlation Analysis

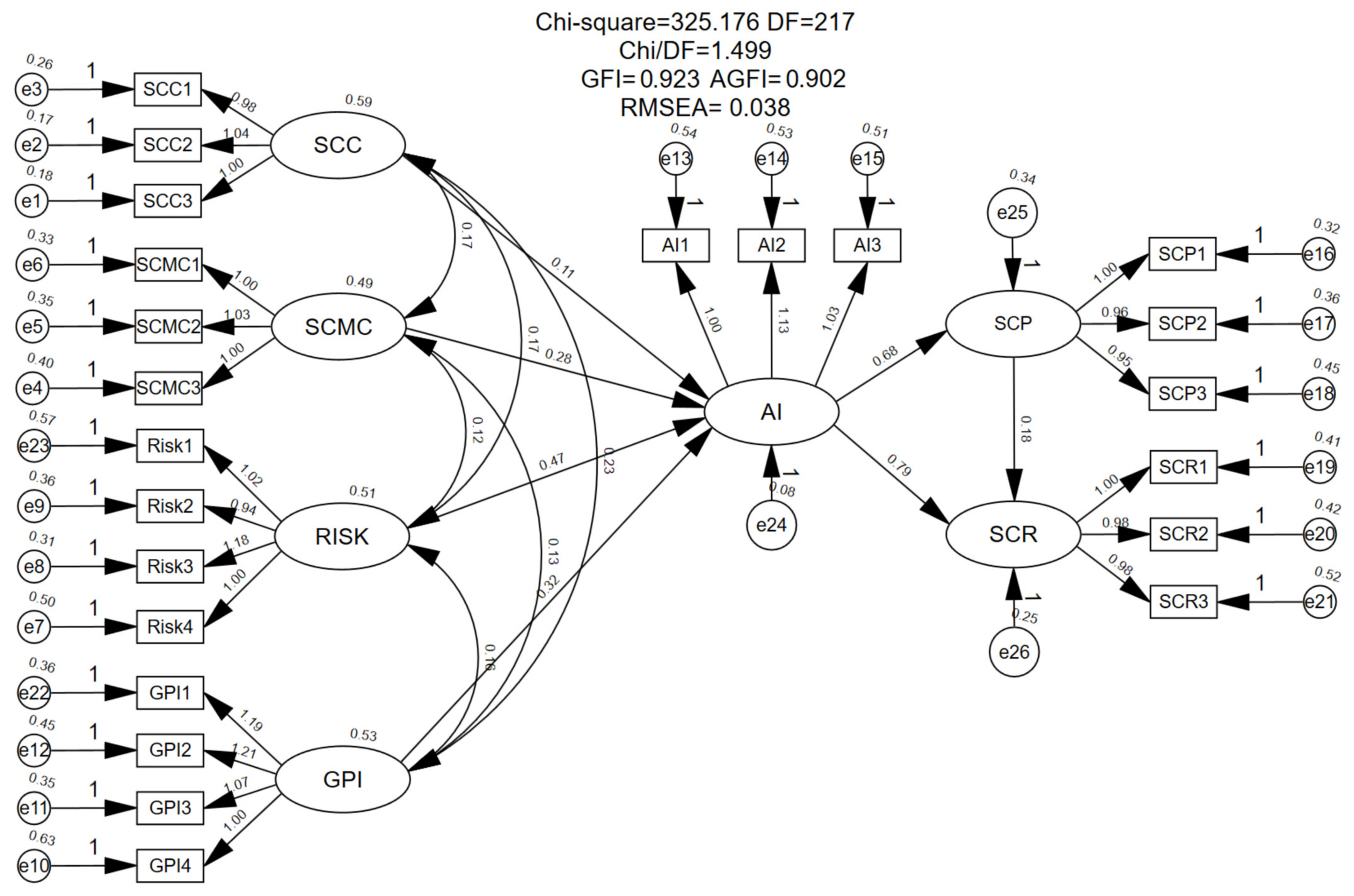

4.3. Hypothesis Test

4.4. Mediating Effect Analysis

5. Discussion and Conclusions

5.1. Conclusions

5.2. Implications

5.3. Research Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kleindorfer, P.R.; Saad, G.H. Managing disruption risks in supply chains. Prod. Oper. Manag. 2005, 14, 53–68. [Google Scholar] [CrossRef]

- Speier, C.; Whipple, J.M.; Closs, D.J.; Voss, M.D. Global supply chain design considerations: Mitigating product safety and security risks. J. Oper. Manag. 2011, 29, 721–736. [Google Scholar] [CrossRef]

- Knemeyer, A.M.; Zinn, W.; Eroglu, C. Proactive planning for catastrophic events in supply chains. J. Oper. Manag. 2009, 27, 141–153. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, C. Enterprise collaborative emergency strategies for responding to supply chain unexpected events risks. Bus. Econ. Manag. 2011, 3, 17–23. [Google Scholar]

- Spieske, A.; Birkel, H. Improving supply chain resilience through industry 4.0: A systematic literature review under the impressions of the COVID-19 pandemic. Comput. Ind. Eng. 2021, 158, 107452. [Google Scholar] [CrossRef]

- Grzybowska, K.; Tubis, A.A. Supply Chain Resilience in Reality VUCA—An International Delphi Study. Sustainability 2022, 14, 10711. [Google Scholar] [CrossRef]

- Chen, J.K.; Huang, T.Y. The Multi-Level Hierarchical Structure of the Enablers for Supply Chain Resilience Using Cloud Model-DEMATEL–ISM Method. Sustainability 2022, 14, 12116. [Google Scholar] [CrossRef]

- Lockamy, A., III; McCormack, K. Analysing risks in supply networks to facilitate outsourcing decisions. Int. J. Prod. Res. 2010, 48, 593–611. [Google Scholar] [CrossRef]

- Heckmann, I.; Comes, T.; Nickel, S. A critical review on supply chain risk–Definition, measure and modeling. Omega 2015, 52, 119–132. [Google Scholar] [CrossRef]

- Svensson, G. A conceptual framework for the analysis of vulnerability in supply chains. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 731–750. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring supply chain resilience: Development of a conceptual framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Falasca, M.; Zobel, C.W.; Cook, D. A decision support framework to assess supply chain resilience. In Proceedings of the 5th International ISCRAM Conference, Washington, DC, USA, 4 May 2008; pp. 596–605. [Google Scholar]

- Jüttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Peck, H. Drivers of supply chain vulnerability: An integrated framework. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 210–232. [Google Scholar] [CrossRef]

- Stewart, M.; Reid, G.; Mangham, C. Fostering children’s resilience. J. Pediatr. Nurs. 1997, 12, 21–31. [Google Scholar] [CrossRef] [PubMed]

- Arsovski, S.; Arsovski, Z.; Stefanović, M.; Tadić, D.; Aleksić, A. Organisational resilience in a cloud-based enterprise in a supply chain: A challenge for innovative SMEs. Int. J. Comput. Integr. Manuf. 2017, 30, 409–419. [Google Scholar] [CrossRef]

- Atkins, B. Demystifying ESG: Its History & Current Status; Forbes Markets: Jersey City, NJ, USA, 2020. [Google Scholar]

- Dai, T.; Tang, C. Frontiers in Service Science: Integrating ESG Measures and Supply Chain Management: Research Opportunities in the Postpandemic Era. Serv. Sci. 2022, 14, 1–12. [Google Scholar] [CrossRef]

- Ziolo, M.; Filipiak, B.Z.; Bąk, I.; Cheba, K. How to design more sustainable financial systems: The roles of environmental, social, and governance factors in the decision-making process. Sustainability 2019, 11, 5604. [Google Scholar] [CrossRef]

- Sardanelli, D.; Bittucci, L.; Mirone, F.; Marzioni, S. An integrative framework for supply chain rating: From financial-based to ESG-based rating models. Total Qual. Manag. Bus. Excell. 2022, 20, 69557. [Google Scholar] [CrossRef]

- Rajesh, R. Exploring the sustainability performances of firms using environmental, social, and governance scores. J. Clean. Prod. 2020, 247, 119600. [Google Scholar] [CrossRef]

- Li, T.T.; Wang, K.; Sueyoshi, T.; Wang, D.D. ESG: Research progress and future prospects. Sustainability 2021, 13, 11663. [Google Scholar] [CrossRef]

- Soni, N.; Sharma, E.K.; Singh, N.; Kapoor, A. Artificial intelligence in business: From research and innovation to market deployment. Procedia Comput. Sci. 2020, 167, 2200–2210. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Leal-Millán, A.; Cepeda-Carrión, G. The antecedents of green innovation performance: A model of learning and capabilities. J. Bus. Res. 2016, 69, 4912–4917. [Google Scholar] [CrossRef]

- Chan, H.K.; Yee, R.W.; Dai, J.; Lim, M.K. The moderating effect of environmental dynamism on green product innovation and performance. Int. J. Prod. Econ. 2016, 181, 384–391. [Google Scholar] [CrossRef]

- Kaplan, A.; Haenlein, M. Siri, Siri, in my hand: Who’s the fairest in the land? On the interpretations, illustrations, and implications of artificial intelligence. Bus. Horiz. 2019, 62, 15–25. [Google Scholar] [CrossRef]

- Bowersox, D.J. The strategic benefits of logistics alliances. Harv. Bus. Rev. 1990, 68, 36–43. [Google Scholar]

- McIvor, R.; Humphreys, P.; McCurry, L. Electronic commerce: Supporting collaboration in the supply chain. J. Mater. Process. Technol. 2003, 139, 147–152. [Google Scholar] [CrossRef]

- Zhong, R.; Xu, X.; Wang, L. Food supply chain management: Systems, implementations, and future research. Ind. Manag. Data Syst. 2017, 17, 2085–2114. [Google Scholar] [CrossRef]

- Alzoubi, H.M.; Yanamandra, R. Investigating the mediating role of information sharing strategy on agile supply chain. Uncertain Supply Chain Manag. 2020, 8, 273–284. [Google Scholar] [CrossRef]

- Baah, C.; Agyeman, D.O.; Acquah, I.S.; Agyabeng-Mensah, Y.; Afum, E.; Issau, K.; Ofori, D.; Faibil, D. Effect of information sharing in supply chains: Understanding the roles of supply chain visibility, agility, collaboration on supply chain performance. Benchmark. Int. J. 2022, 29, 434–455. [Google Scholar] [CrossRef]

- Krasnikov, A.; Jayachandran, S. The relative impact of marketing, research-and-development, and operations capabilities on firm performance. J. Mark. 2008, 72, 1–11. [Google Scholar] [CrossRef]

- Sabry, A. The impact of supply-chain management capabilities on business performance in Egyptian industrial sector. Int. J. Bus. Manag. 2015, 10, 251. [Google Scholar] [CrossRef]

- Ramaswami, S.N.; Srivastava, R.K.; Bhargava, M. Market-based capabilities and financial performance of firms: Insights into marketing’s contribution to firm value. J. Acad. Mark. Sci. 2009, 37, 97–116. [Google Scholar] [CrossRef]

- Fang, E.; Zou, S. Antecedents and consequences of marketing dynamic capabilities in international joint ventures. J. Int. Bus. Stud. 2009, 40, 742–761. [Google Scholar] [CrossRef]

- Zhao, X.D.; Xie, J.X. Several basic concepts of modern supply chain management. Nankai Bus. Rev. 1999, 1, 62–66. [Google Scholar]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to green innovation initiatives among manufacturers: The Malaysian case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Kong, T.; Feng, T.; Ye, C. Advanced manufacturing technologies and green innovation: The role of internal environmental collaboration. Sustainability 2016, 8, 1056. [Google Scholar] [CrossRef]

- OECD. The Measurement of Scientific and Technical Activities, 3rd ed.; OECD Publishing: Paris, France, 2005. [Google Scholar]

- Jian, L. Research on the organization innovation: Conditions methods. China Soft Sci. 2011, S1, 225–231. [Google Scholar]

- Singh, S.K.; Del Giudice, M.; Chierici, R.; Graziano, D. Green innovation and environmental performance: The role of green transformational leadership and green human resource management. Technol. Forecast. Soc. Change 2020, 150, 119762. [Google Scholar] [CrossRef]

- Shen, H.C.; Tao, Q.; Chen, Y.B. Theory and methods of supply chain management. China Manag. Sci. 2012, 1, 105–128. [Google Scholar]

- Yu, H.S.; Long, Y.H. Coordination and Resilience; Science Press: Beijing, China, 2012. [Google Scholar]

- Hohenstein, N.O.; Feisel, E.; Hartmann, E.; Giunipero, L. Research on the phenomenon of supply chain resilience: A systematic review and paths for further investigation. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 90–117. [Google Scholar] [CrossRef]

- Ali, A.; Mahfouz, A.; Arisha, A. Analysing supply chain resilience: Integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 16–39. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M. Supply chain readiness, response and recovery for resilience. Supply Chain. Manag. Int. J. 2016, 21, 709–731. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Sahebjamnia, N.; Torabi, S.A.; Mansouri, S.A. Building organizational resilience in the face of multiple disruptions. Int. J. Prod. Econ. 2018, 197, 63–83. [Google Scholar] [CrossRef]

- Liu, C.L.; Shang, K.C.; Lirn, T.C.; Lai, K.H.; Lun, Y.V. Supply chain resilience, firm performance, and management policies in the liner shipping industry. Transp. Res. Part A Policy Pract. 2018, 110, 202–219. [Google Scholar] [CrossRef]

- Gunessee, S.; Subramanian, N.; Ning, K. Natural disasters, PC supply chain and corporate performance. Int. J. Oper. Prod. Manag. 2018, 38, 1796–1814. [Google Scholar] [CrossRef]

- Li, X.; Wu, Q.; Holsapple, C.W.; Goldsby, T. An empirical examination of firm financial performance along dimensions of supply chain resilience. Manag. Res. Rev. 2017, 40, 254–269. [Google Scholar] [CrossRef]

- Soni, U.; Jain, V.; Kumar, S. Measuring supply chain resilience using a deterministic modeling approach. Comput. Ind. Eng. 2014, 74, 11–25. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Patel, C.; Tirtiroglu, E. Performance measures and metrics in a supply chain environment. Int. J. Oper. Prod. Manag. 2001, 21, 71–87. [Google Scholar] [CrossRef]

- Simatupang, T.M.; Sridharan, R. A benchmarking scheme for supply chain collaboration. Benchmarking Int. J. 2004, 11, 9–30. [Google Scholar] [CrossRef]

- Chen, Y.S. The driver of green innovation and green image–green core competence. J. Bus. Ethics 2008, 81, 531–543. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Chiou, T.Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Manuj, I.; Mentzer, J.T. Global supply chain risk management. J. Bus. Logist. 2008, 29, 133–156. [Google Scholar] [CrossRef]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Venkatesh, V.; Zhang, X. Unified theory of acceptance and use of technology: US vs. China. J. Glob. Inf. Technol. Manag. 2010, 13, 5–27. [Google Scholar] [CrossRef]

- Venkatesh, V.; Morris, M.G.; Davis, G.B.; Davis, F.D. User acceptance of information technology: Toward a unified view. MIS Q. 2003, 27, 425–478. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. Ensuring supply chain resilience: Development and implementation of an assessment tool. J. Bus. Logist. 2013, 34, 46–76. [Google Scholar] [CrossRef]

- Beamon, B.M. Measuring supply chain performance. Int. J. Oper. Prod. Manag. 1999, 19, 275–292. [Google Scholar] [CrossRef]

- Preacher, K.J.; Hayes, A.F. SPSS and SAS procedures for estimating indirect effects in simple mediation models. Behav. Res. Methods Instrum. Comput. 2004, 36, 717–731. [Google Scholar] [CrossRef] [PubMed]

- Preacher, K.J.; Hayes, A.F. Asymptotic and resampling strategies for assessing and comparing indirect effects in multiple mediator models. Behav. Res. Methods 2008, 40, 879–891. [Google Scholar] [CrossRef] [PubMed]

| The Variable | Measurement Dimension | Reference |

|---|---|---|

| Supply-chain collaboration | “Information sharing”, “Decision synchronization”, “Incentive alignment”. | Simatupang and Sridharan (2004) [55] |

| Supply-chain management capabilities | “Outward-in process capability”, “Inward-out process capability”, “Cross-process capability”. | Sabry (2015) [33] |

| Green-product innovation | “Using less or non-polluting/toxic materials”, “Improving and designing environmentally friendly packaging”, “Recovery of company end-of-life products and recycling”, “Using eco-labeling”. | Chen et al., (2006); Chen (2008); Chiou et al., (2011) [56,57,58] |

| Supply-chain risk | “Supply risk”, “operational risk”, “demand risk”, “security risk”. | Manuj and Mentzer (2008) [59] |

| Adopt intention | “Willingness to Use”, “Willingness to Pay”, “Willingness to Recommend”. | Davis (1989); Venkatesh et al., (2003); Venkatesh and Zhang (2010) [60,61,62] |

| Supply-chain resilience | “Absorption capacity”, “recovery capacity”, “adaption capacity”. | Pettit et al., (2013) [63] |

| Supply-chain performance | “Resource measurement”, “output measurement”, “flexibility”. | Beamon (1999) [64] |

| Construct | Code | Loadings | Cronbach’s Alpha | AVE (Average Variance Extracted) | CR (Composite Reliability) |

|---|---|---|---|---|---|

| GPI | GPI3 | 0.833 | 0.854 | 0.599 | 0.856 |

| GPI4 | 0.782 | ||||

| GPI2 | 0.77 | ||||

| GPI1 | 0.765 | ||||

| Risk | Risk3 | 0.824 | 0.832 | 0.562 | 0.836 |

| Risk1 | 0.802 | ||||

| Risk2 | 0.739 | ||||

| Risk4 | 0.696 | ||||

| SCC | SCC3 | 0.875 | 0.897 | 0.745 | 0.898 |

| SCC1 | 0.86 | ||||

| SCC2 | 0.858 | ||||

| SCMC | SCMC3 | 0.825 | 0.809 | 0.586 | 0.809 |

| SCMC1 | 0.821 | ||||

| SCMC2 | 0.798 | ||||

| SCP | SCP3 | 0.786 | 0.802 | 0.576 | 0.803 |

| SCP1 | 0.763 | ||||

| SCP2 | 0.756 | ||||

| AI | SCR3 | 0.782 | 0.793 | 0.561 | 0.793 |

| SCR2 | 0.728 | ||||

| SCR1 | 0.713 | ||||

| SCR | AI1 | 0.797 | 0.801 | 0.574 | 0.802 |

| AI3 | 0.721 | ||||

| AI2 | 0.655 | ||||

| Kaiser–Meyer–Olkin Measure of Sampling Adequacy. | 0.895 | ||||

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 3911.907 | |||

| df | 253 | ||||

| Sig. | 0.000 | ||||

| SCMC | SCC | Risk | GPI | AI | SCP | SCR | |

|---|---|---|---|---|---|---|---|

| SCMC | 0.861 | ||||||

| SCC | 0.267 ** | 0.757 | |||||

| Risk | 0.195 ** | 0.282 ** | 0.752 | ||||

| GPI | 0.208 ** | 0.359 ** | 0.256 ** | 0.785 | |||

| AI | 0.379 ** | 0.399 ** | 0.527 ** | 0.429 ** | 0.760 | ||

| SCP | 0.414 ** | 0.393 ** | 0.384 ** | 0.408 ** | 0.327 ** | 0.778 | |

| SCR | 0.333 ** | 0.312 ** | 0.489 ** | 0.476 ** | 0.515 ** | 0.452 ** | 0.771 |

| The Revised Index | CMIN/DF | GFI | AGFI | CFI | NFI | TLI | RMSEA |

|---|---|---|---|---|---|---|---|

| Ideal results | <3 and >1 | >0.8 | >0.8 | >0.9 | >0.9 | >0.9 | <0.08 |

| The fitting results | 1.499 | 0.923 | 0.902 | 0.971 | 0.919 | 0.966 | 0.038 |

| Estimate | S.E. | C.R. | p | Hypothesis | Conclusion | |

|---|---|---|---|---|---|---|

| SCC → AI | 0.114 | 0.042 | 2.692 | 0.007 ** | H1 | Support |

| SCMC → AI | 0.283 | 0.05 | 5.703 | *** | H3 | Support |

| Risk → AI | 0.398 | 0.045 | 8.763 | *** | H5 | Support |

| GPI → AI | 0.317 | 0.051 | 6.191 | *** | H7 | Support |

| AI → SCP | 0.677 | 0.079 | 8.518 | *** | H9 | Support |

| AI → SCR | 0.787 | 0.101 | 7.793 | *** | H10 | Support |

| SCP → SCR | 0.179 | 0.077 | 2.324 | 0.02 * | H11 | Support |

| Path | Effects | Boot SE | Bia-Corrected 95%CI | Hypothesis | Results | |

|---|---|---|---|---|---|---|

| Lower | Upper | |||||

| SCC → AI → SCR | 0.077 | 0.03 | 0.02 | 0.14 | H2 | Support |

| SCMC → AI → SCR | 0.191 | 0.042 | 0.117 | 0.285 | H4 | Support |

| Risk → AI → SCR | 0.269 | 0.04 | 0.193 | 0.351 | H6 | Support |

| GPI → AI → SCR | 0.215 | 0.046 | 0.131 | 0.313 | H8 | Support |

| SCC → AI → SCP | 0.104 | 0.039 | 0.025 | 0.18 | H2 | Support |

| SCMC → AI → SCP | 0.257 | 0.046 | 0.174 | 0.356 | H4 | Support |

| Risk → AI → SCP | 0.362 | 0.043 | 0.283 | 0.453 | H6 | Support |

| GPI → AI → SCP | 0.288 | 0.054 | 0.186 | 0.398 | H8 | Support |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Liu, Z. Social, Environmental, and Governance Factors on Supply-Chain Performance with Mediating Technology Adoption. Sustainability 2023, 15, 10865. https://doi.org/10.3390/su151410865

Li W, Liu Z. Social, Environmental, and Governance Factors on Supply-Chain Performance with Mediating Technology Adoption. Sustainability. 2023; 15(14):10865. https://doi.org/10.3390/su151410865

Chicago/Turabian StyleLi, Weijia, and Ziyang Liu. 2023. "Social, Environmental, and Governance Factors on Supply-Chain Performance with Mediating Technology Adoption" Sustainability 15, no. 14: 10865. https://doi.org/10.3390/su151410865

APA StyleLi, W., & Liu, Z. (2023). Social, Environmental, and Governance Factors on Supply-Chain Performance with Mediating Technology Adoption. Sustainability, 15(14), 10865. https://doi.org/10.3390/su151410865