Assessment of the Effect of Different Loading Combinations Due to Truck Platooning and Autonomous Vehicles on the Performance of Asphalt Pavement

Abstract

1. Introduction

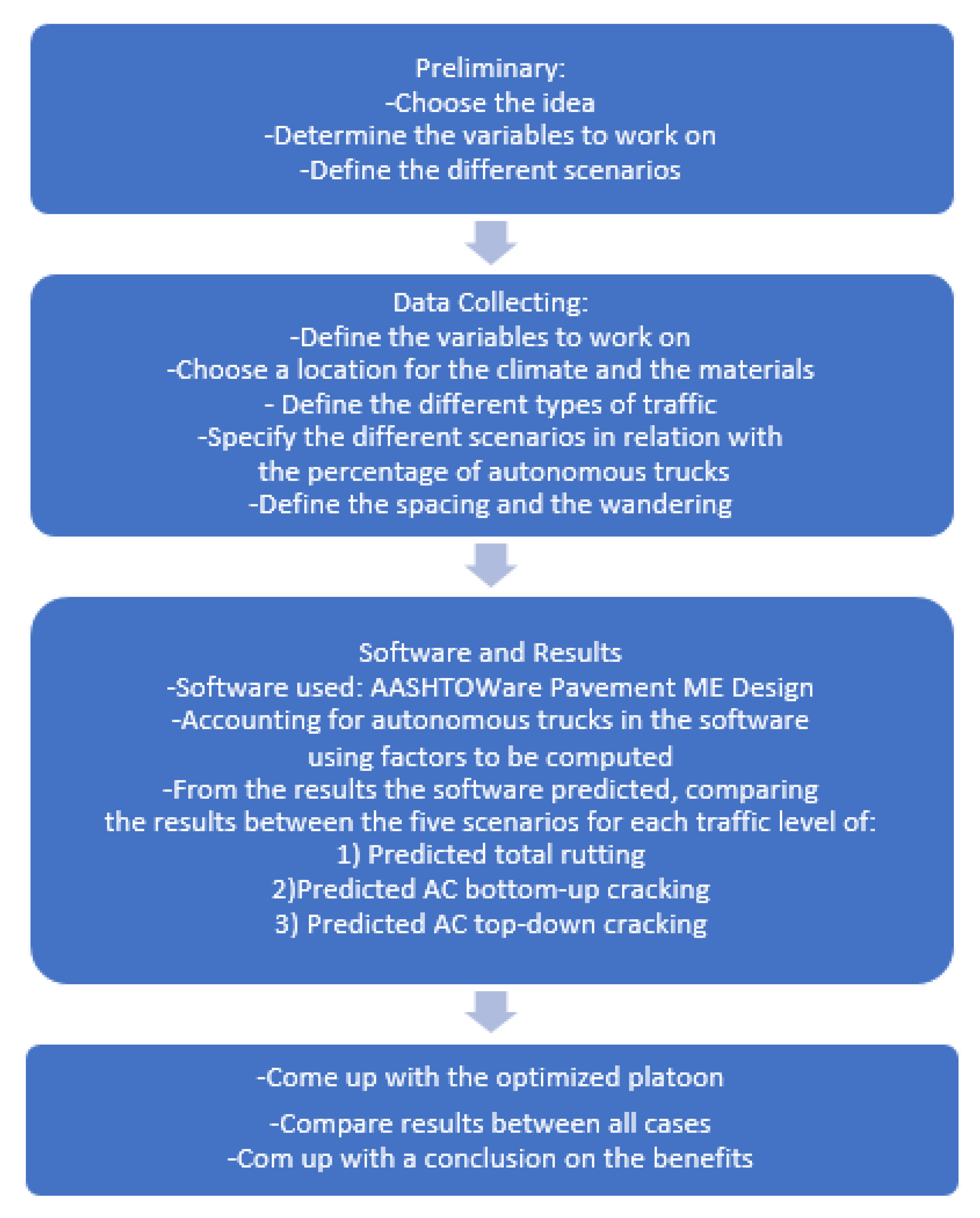

2. Scope and Objective

3. Methodology and Data

3.1. Software Used

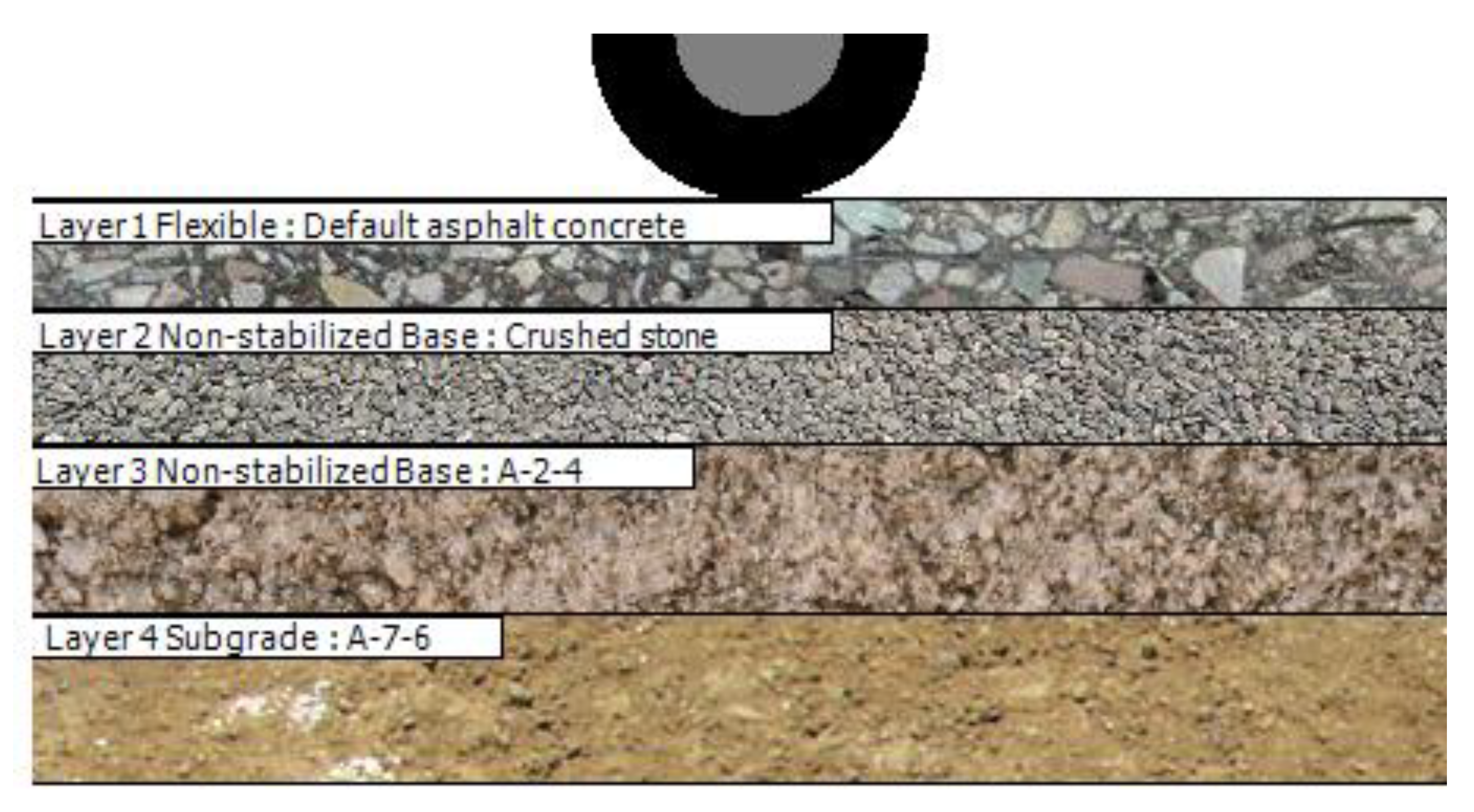

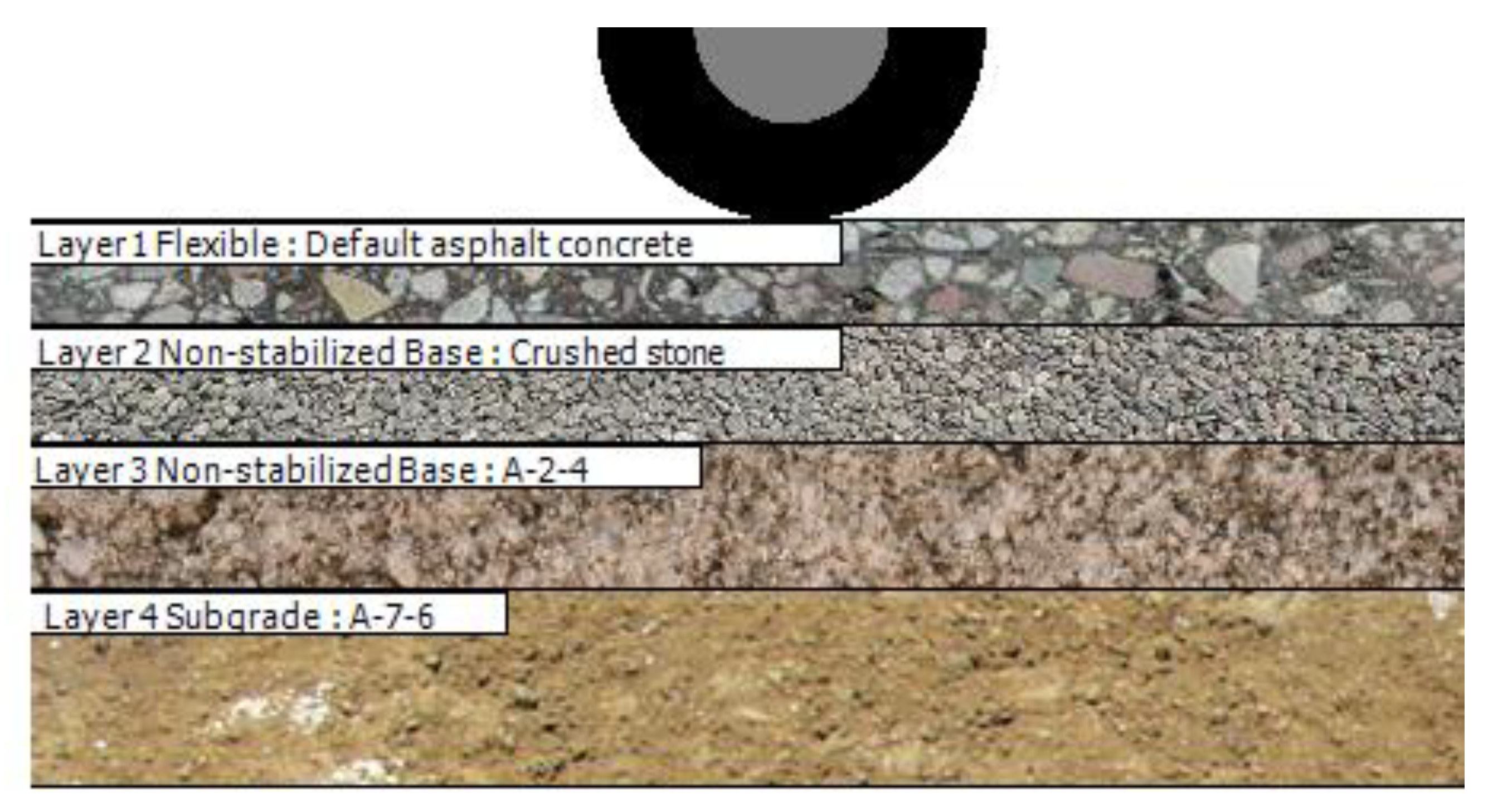

3.2. Climate and Material Properties

3.3. Types of Traffic

3.4. Percentage of Autonomous Trucks

3.5. Vehicle Positioning

3.6. Wander

3.7. Accounting for the Autonomous Trucks

4. Results and Discussion

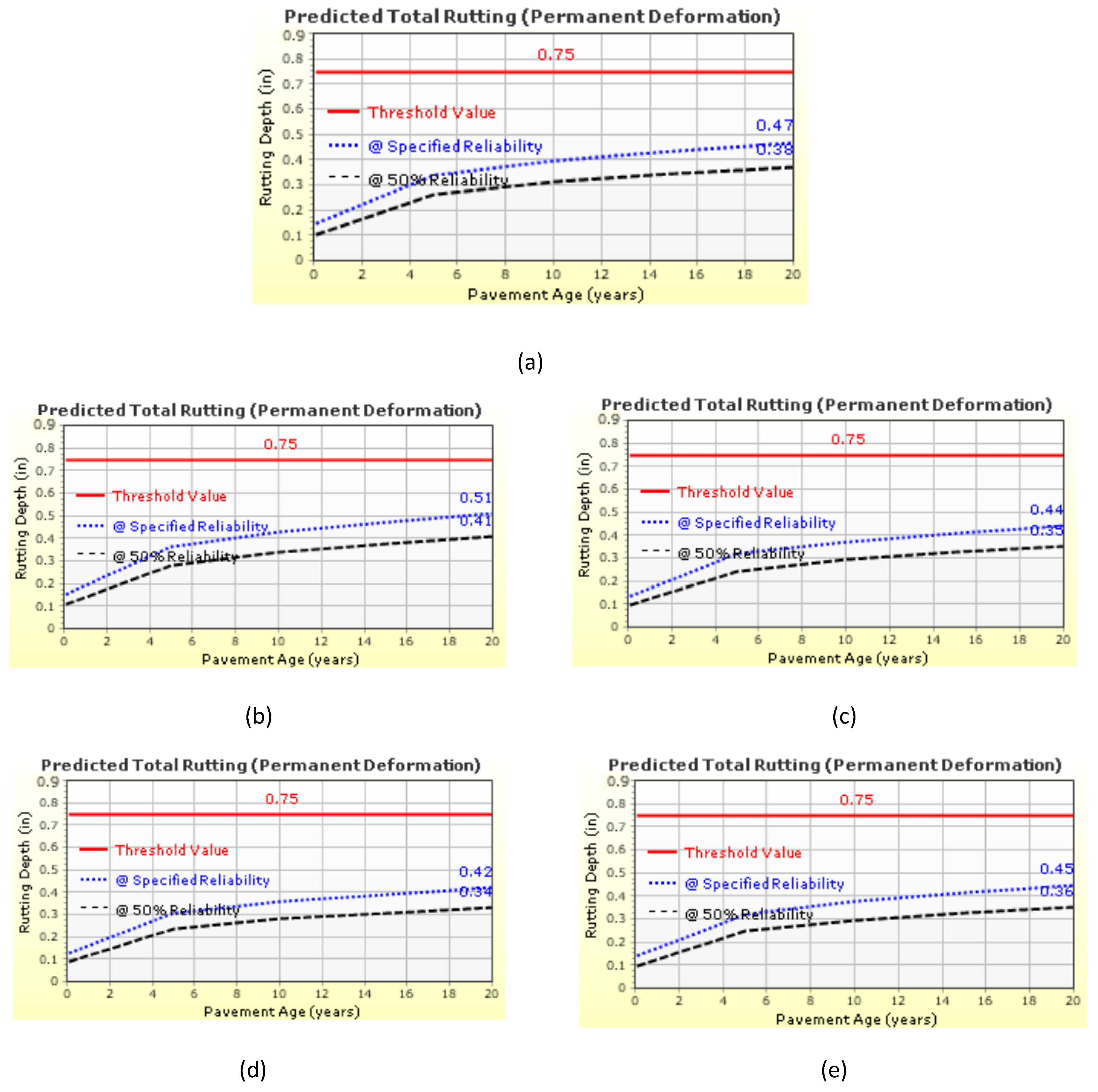

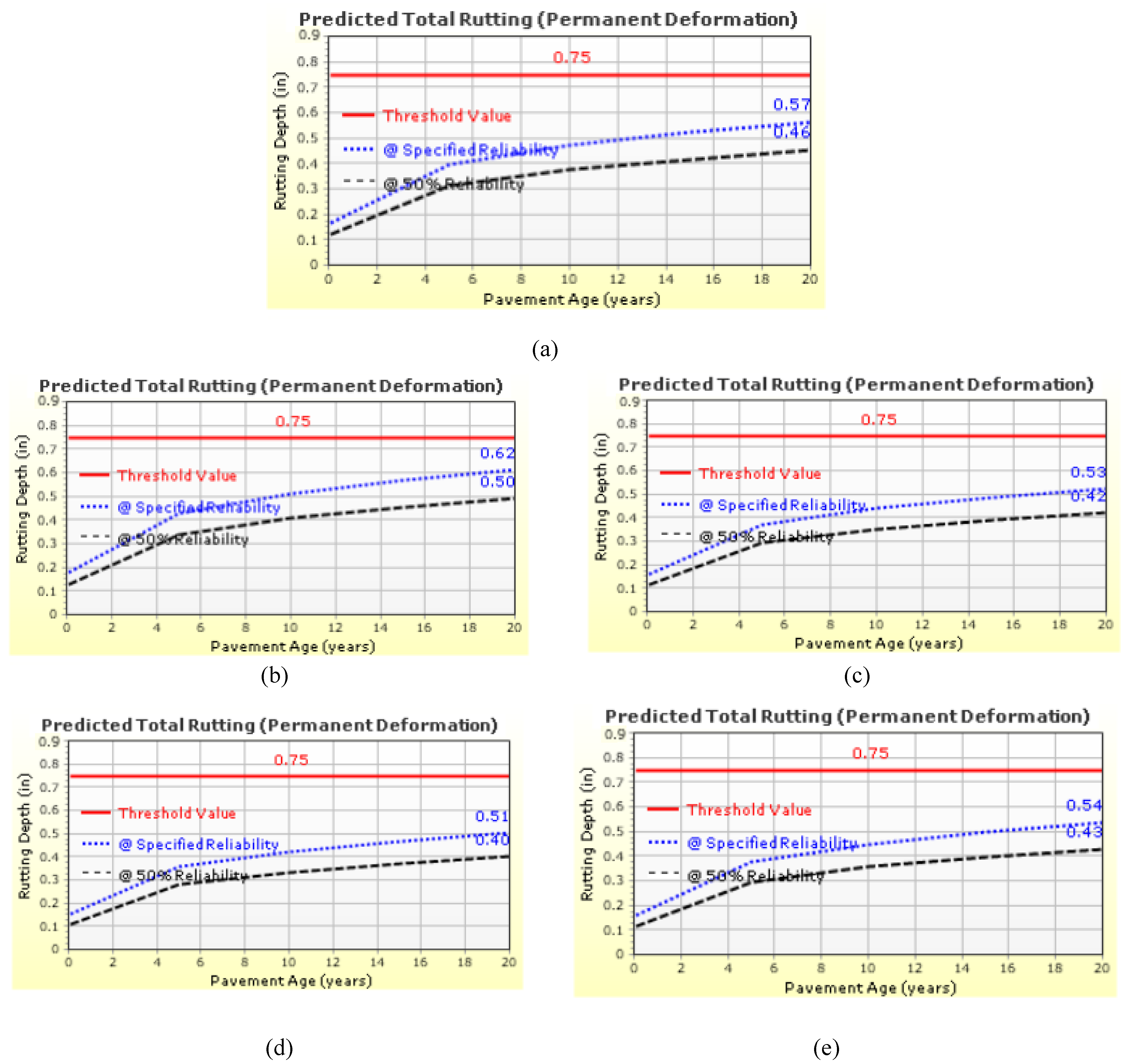

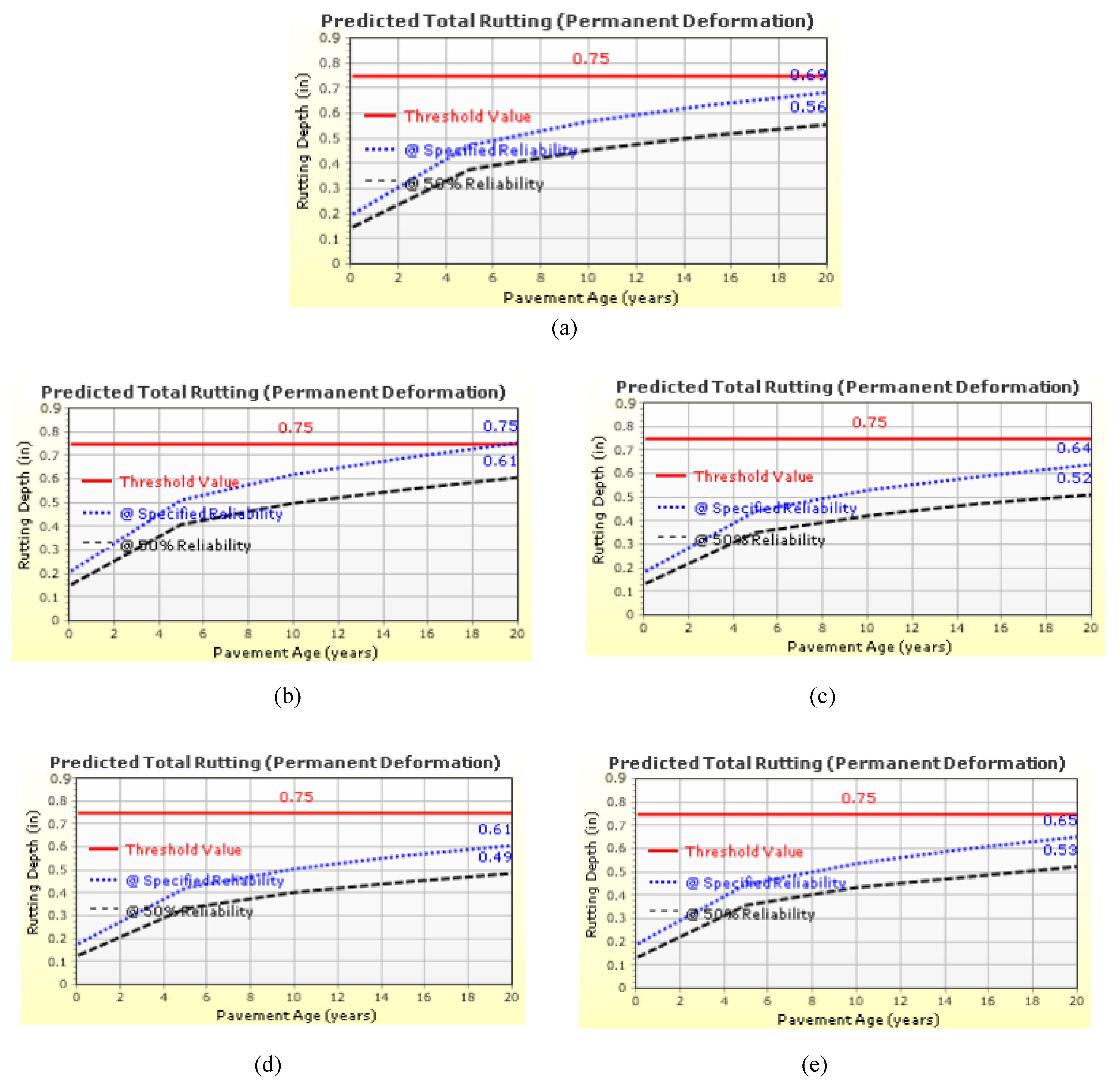

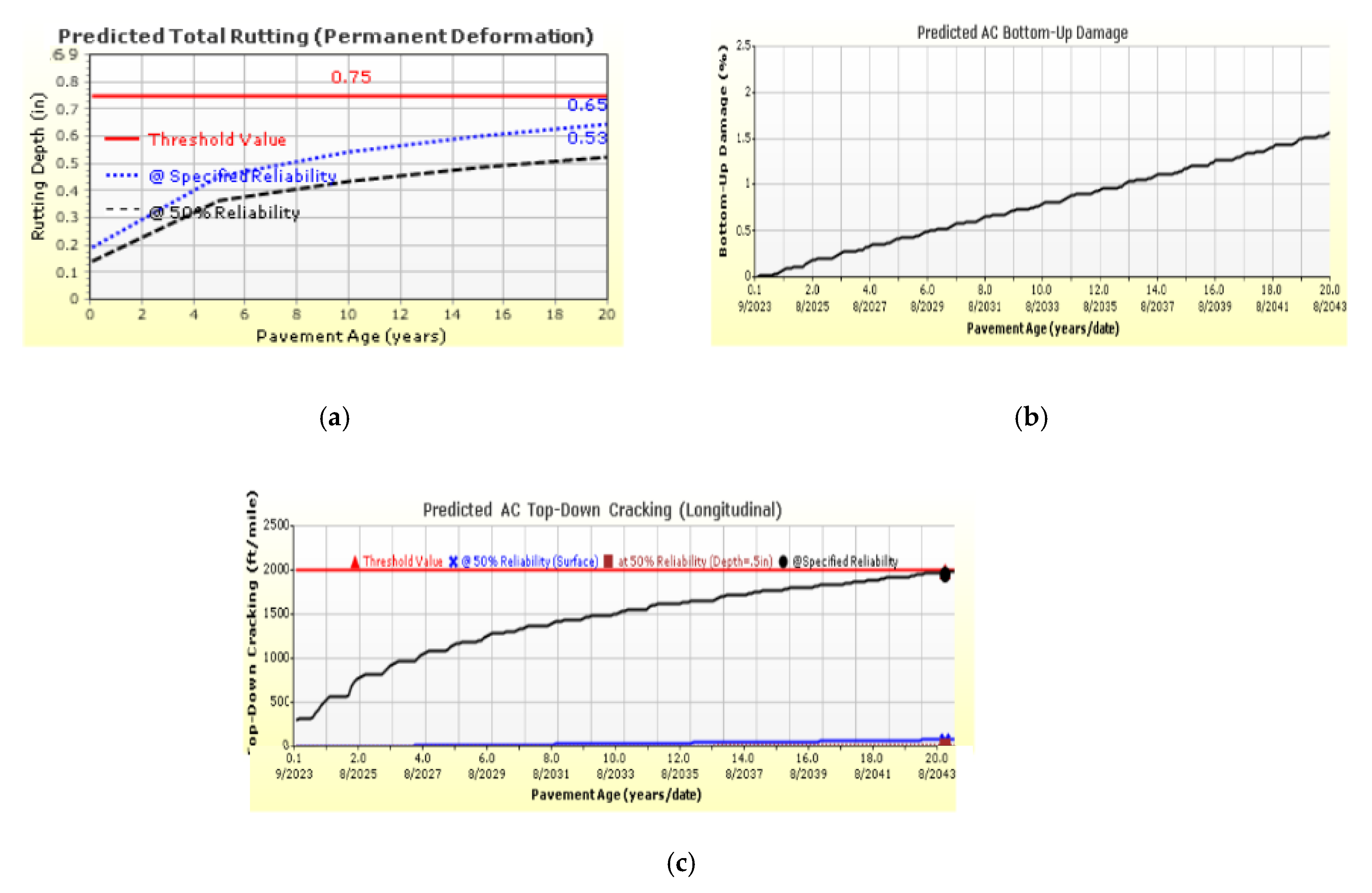

4.1. Predicted Total Rutting

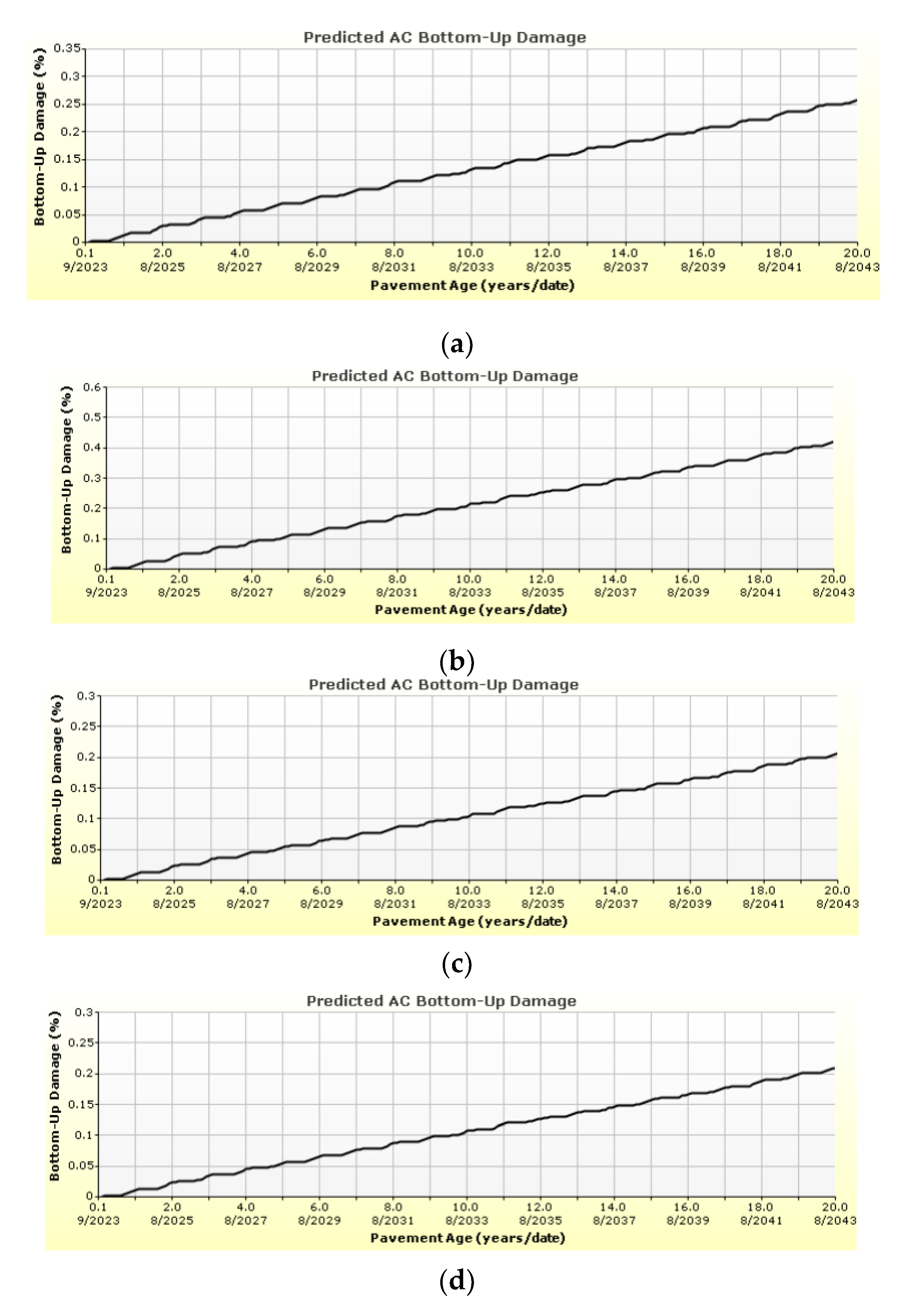

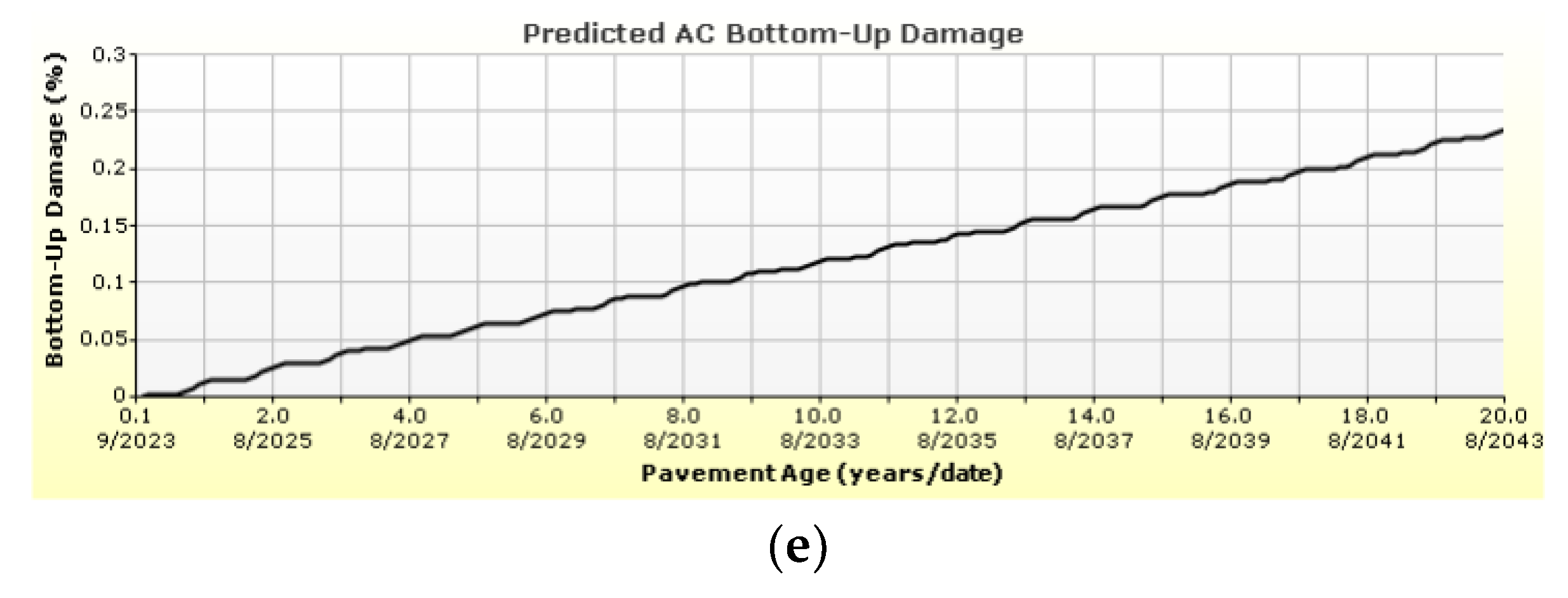

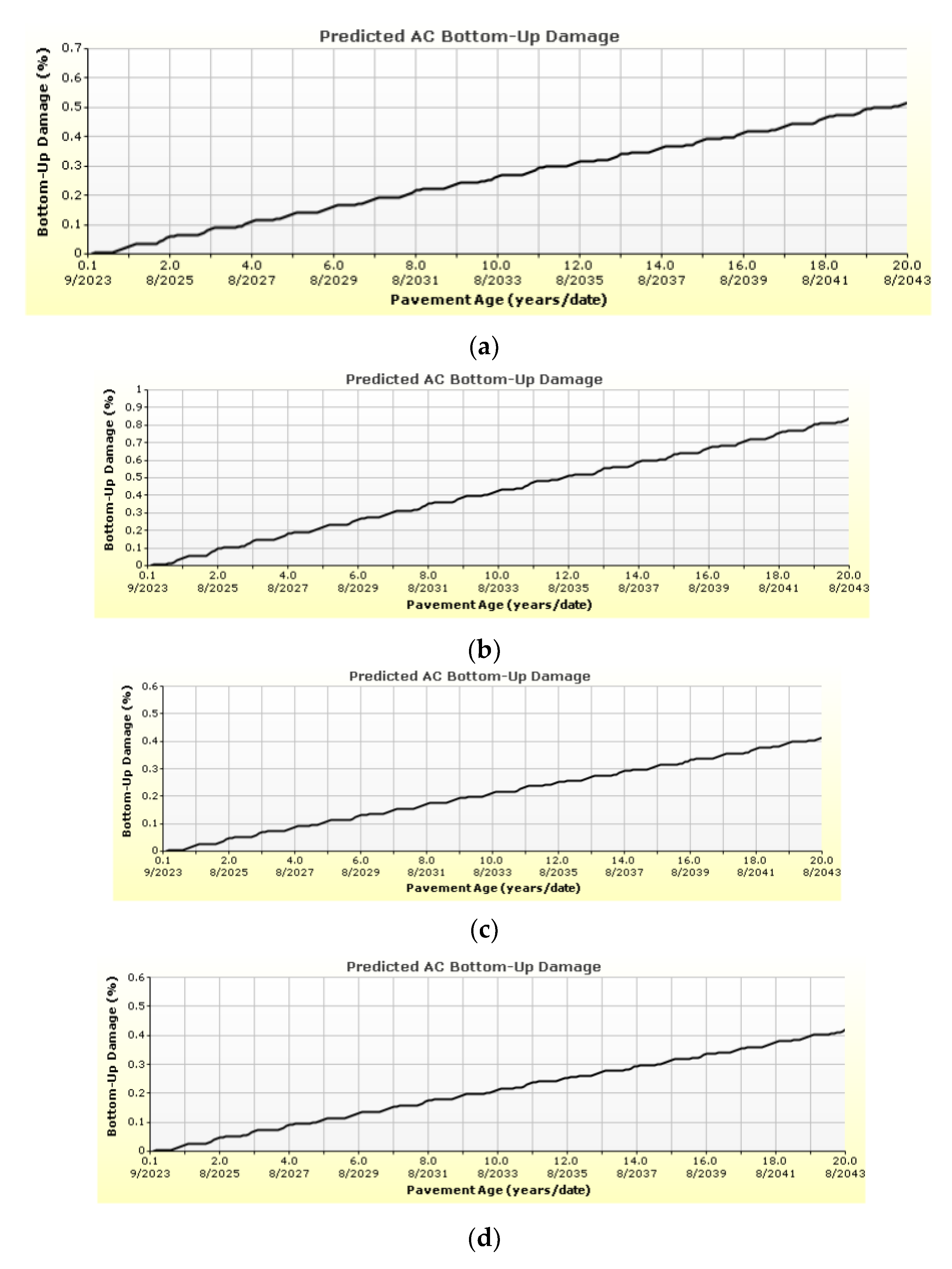

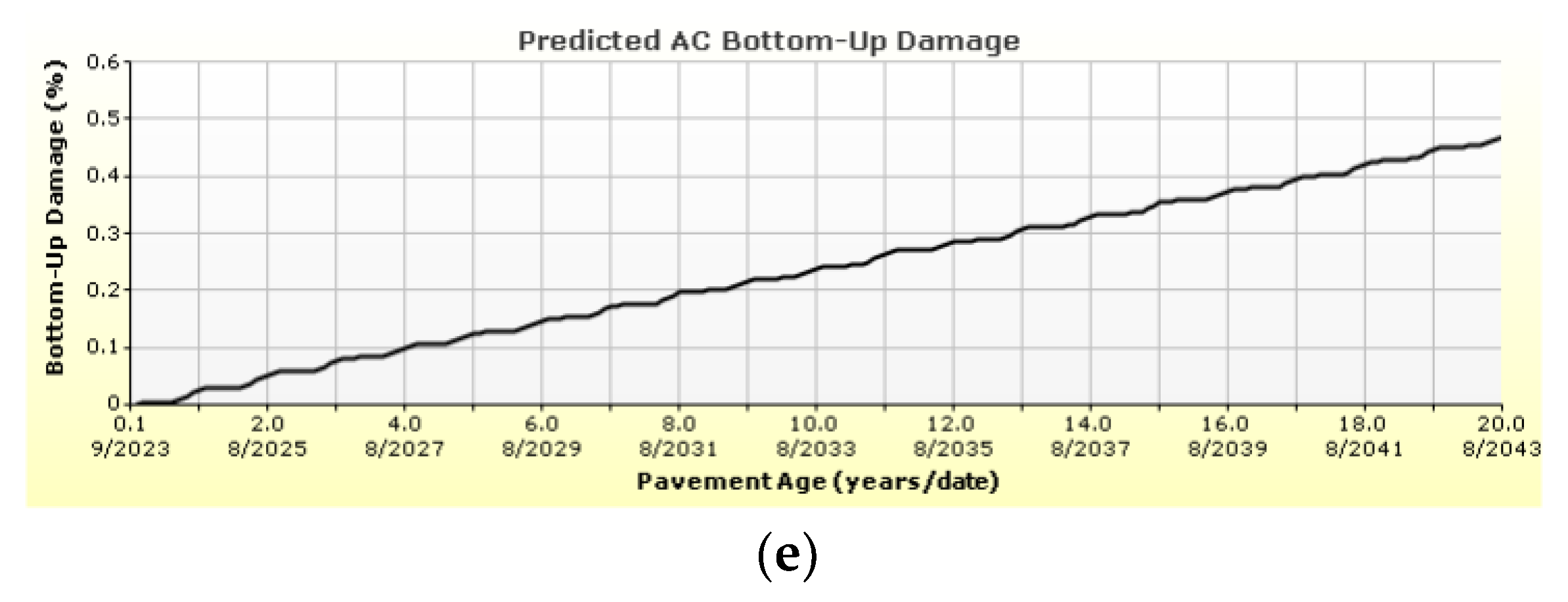

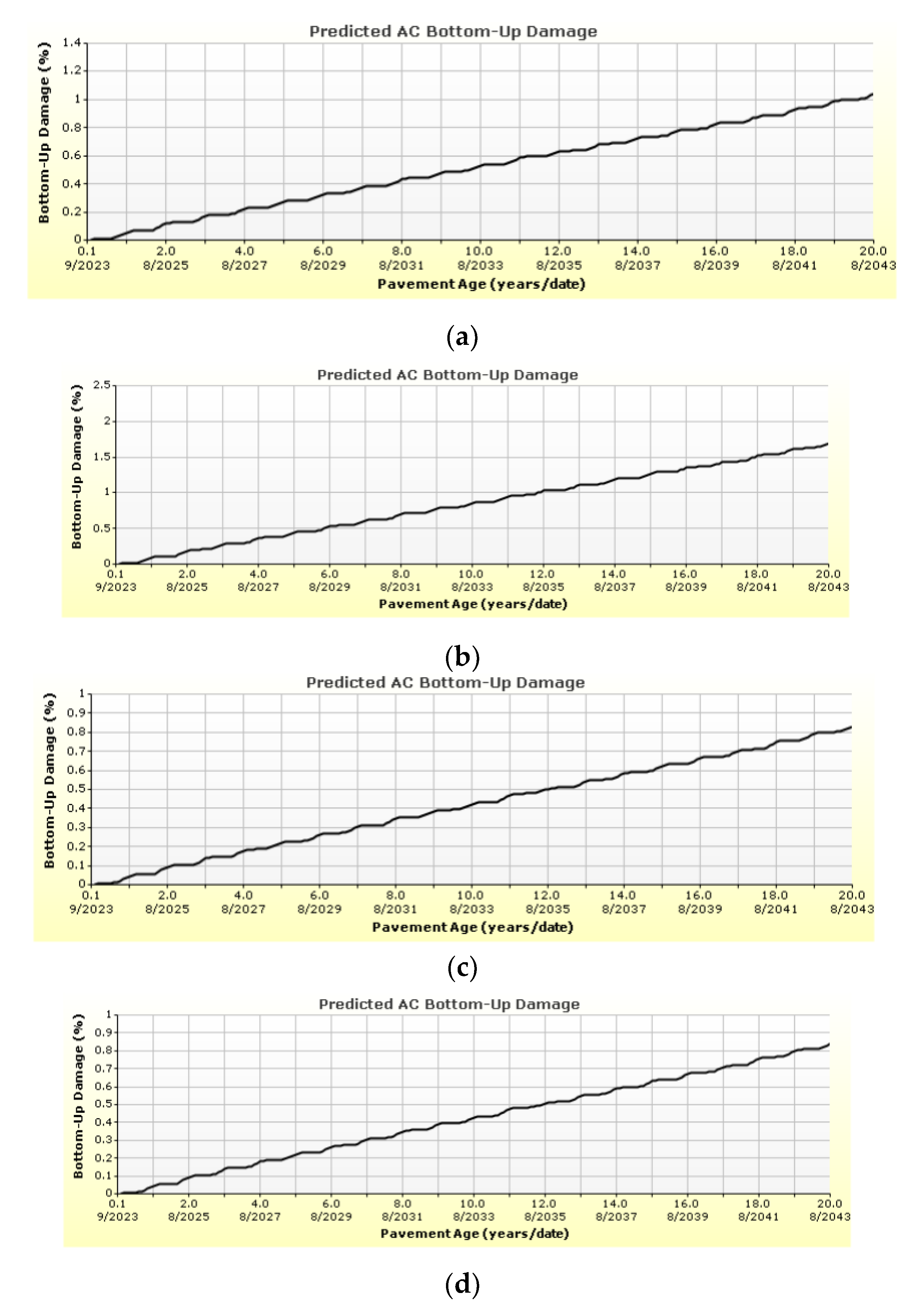

4.2. Predicted AC Bottum-Up Cracking

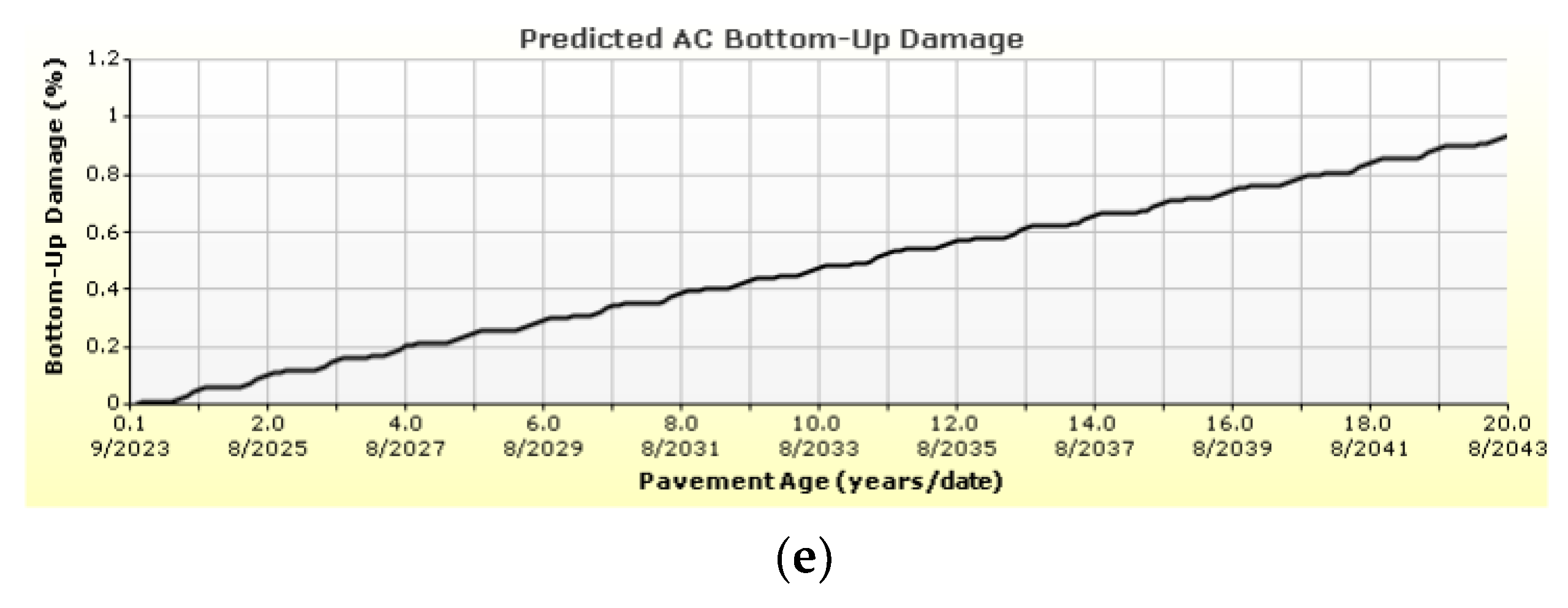

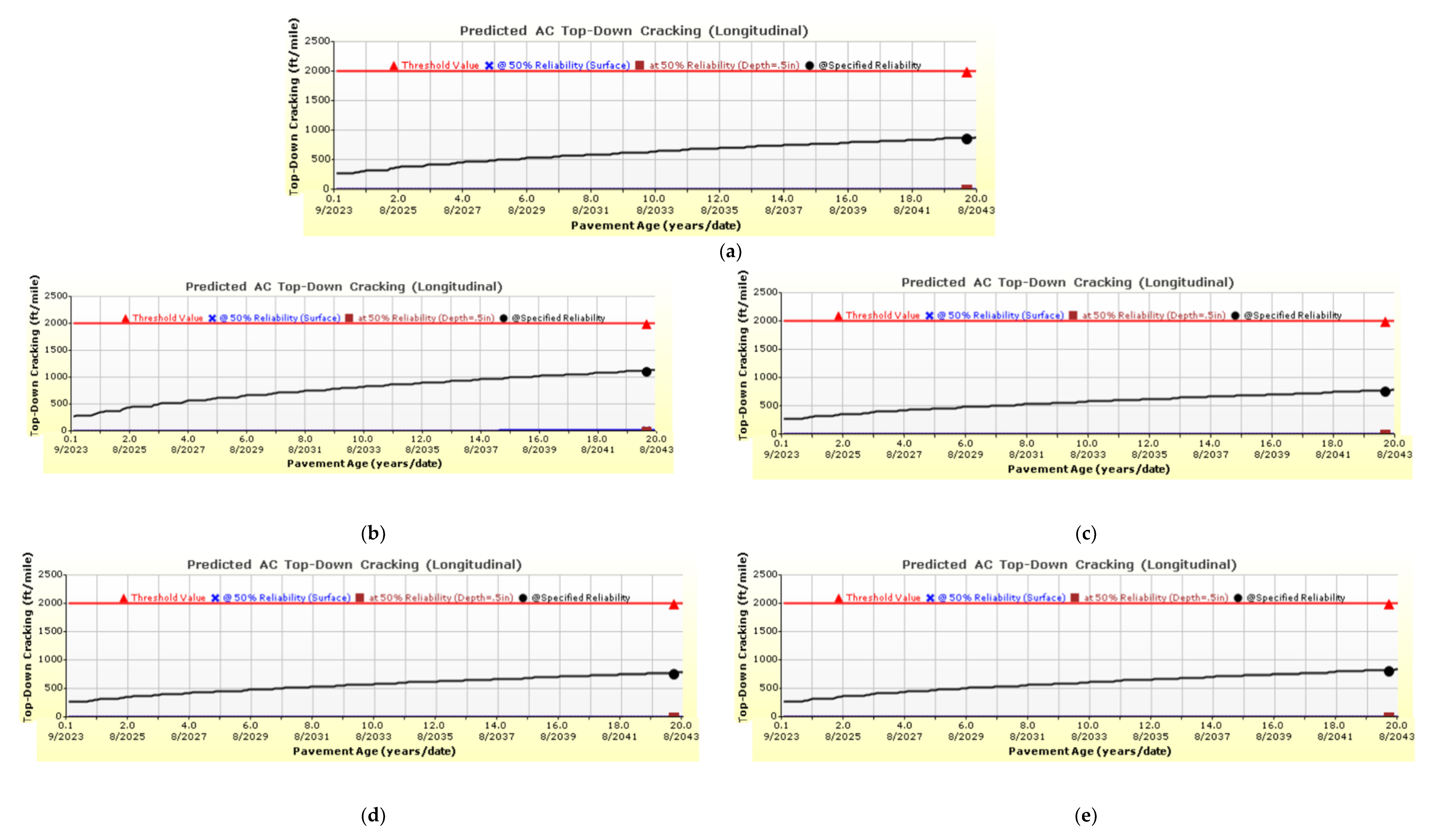

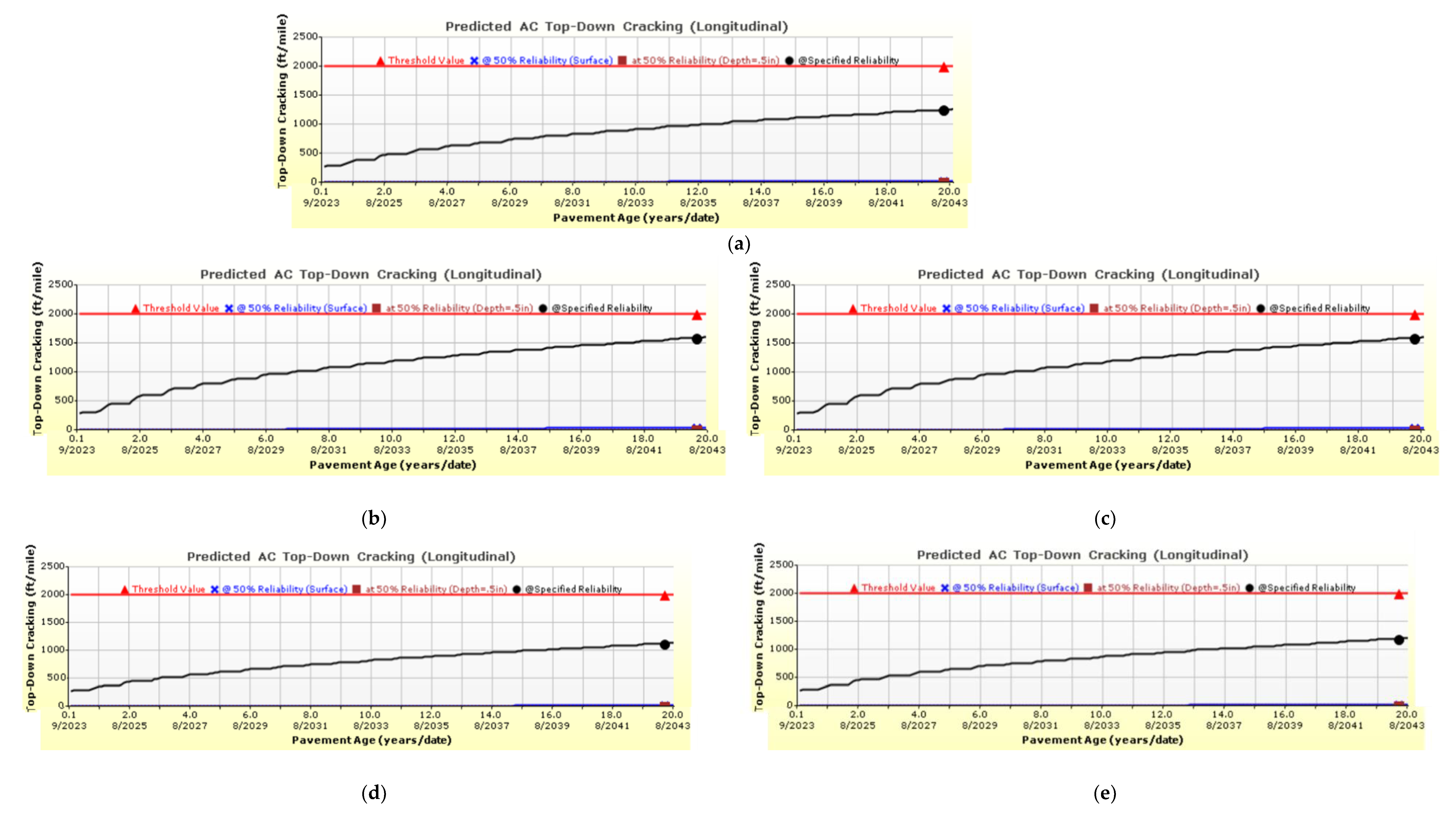

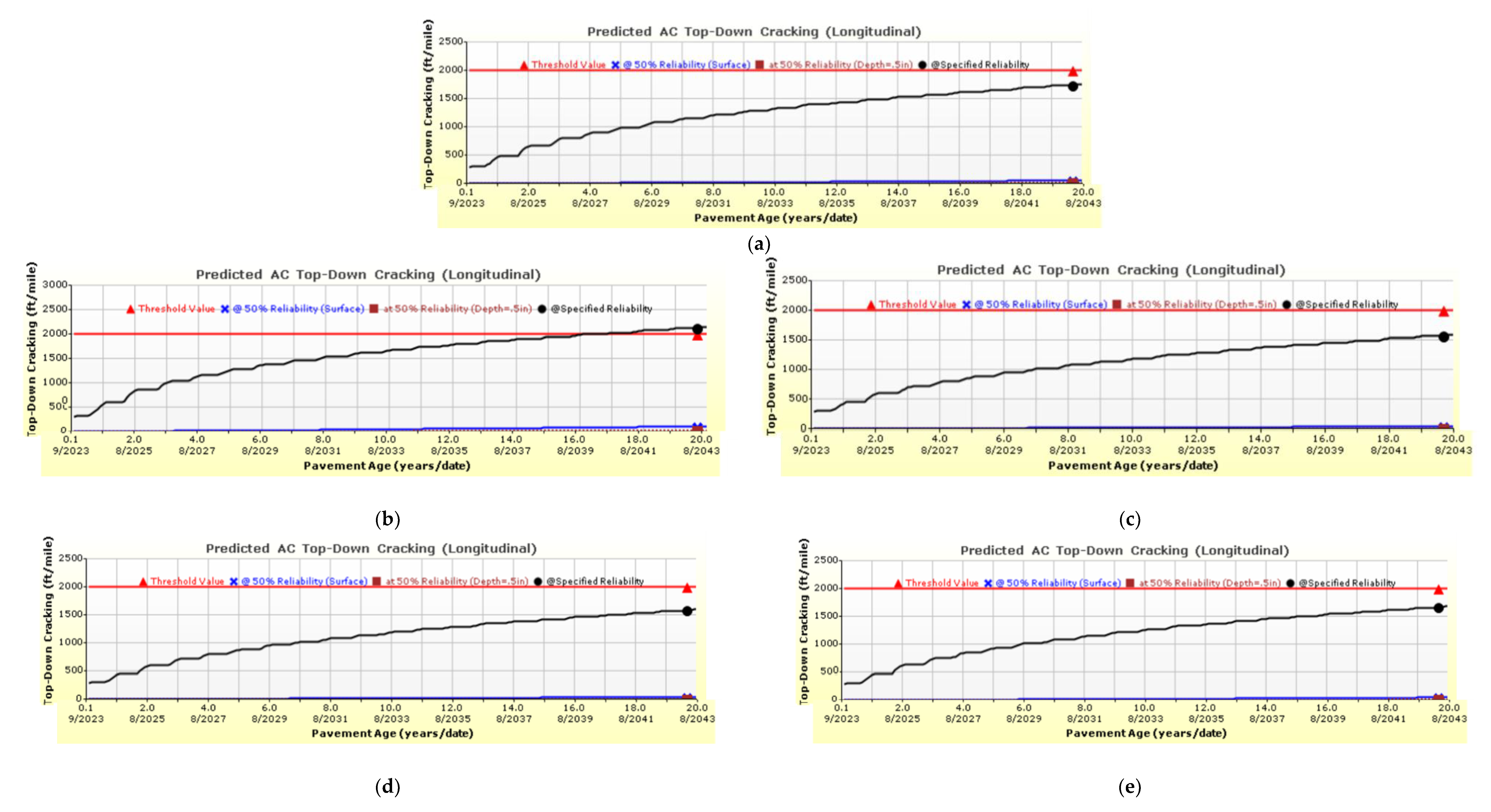

4.3. Predicted AC Top-Down Cracking

5. Optimum Spacing

5.1. Wandering

5.2. Improved Pavement Design

6. Conclusions

- In all scenarios, the integrated scenario where the autonomous trucks were disproportionally placed in one lane of the highway registered the worst results in both rutting and fatigue cracking analyses in the course of 2 years, registering AC top-down damage in high traffic during its service life.

- The integrated scenario, where the trucks are equally distributed among all lanes, and the segregated scenario registered better results than the reference scenario in all cases.

- For rutting, the segregated scenario, where the percentage of autonomous trucks is lower than 50%, developed the best results in all three types of traffic.

- Regarding fatigue cracking, the integrated scenario, where the autonomous trucks were equally distributed among all lanes, registered the best results. However, the segregated scenario, where the trucks occupy one lane, also registered very close results.

7. Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Noorvand, H.; Karnati, G.; Underwood, B.S. Autonomous vehicles: Assessment of the implications of truck positioning on flexible pavement performance and design. Transp. Res. Rec. 2017, 2640, 21–28. [Google Scholar] [CrossRef]

- Chen, F.; Song, M.; Ma, X.; Zhu, X. Assess the impacts of different autonomous trucks’ lateral control modes on asphalt pavement performance. Transp. Res. Part C Emerg. Technol. 2019, 103, 17–29. [Google Scholar] [CrossRef]

- Wang, Z.; Bian, Y.; Shladover, S.E.; Wu, G.; Li, S.E.; Barth, M.J. A survey on cooperative longitudinal motion control of multiple connected and automated vehicles. IEEE Intell. Transp. Syst. Mag. 2019, 12, 4–24. [Google Scholar] [CrossRef]

- Xia, X.; Meng, Z.; Han, X.; Li, H.; Tsukiji, T.; Xu, R.; Ma, J. An automated driving systems data acquisition and analytics platform. Transp. Res. Part C: Emerg. Technol. 2023, 151, 104120. [Google Scholar] [CrossRef]

- Xia, X.; Hashemi, E.; Xiong, L.; Khajepour, A. Autonomous Vehicle Kinematics and Dynamics Synthesis for Sideslip Angle Estimation Based on Consensus Kalman Filter. IEEE Trans. Control. Syst. Technol. 2022, 31, 179–192. [Google Scholar] [CrossRef]

- Meng, Z.; Xia, X.; Xu, R.; Liu, W.; Ma, J. HYDRO-3D: Hybrid Object Detection and Tracking for Cooperative Perception Using 3D LiDAR. IEEE Trans. Intell. Veh. 2023, 1–13. [Google Scholar] [CrossRef]

- Gkartzonikas, C.; Gkritza, K. What have we learned? A review of stated preference and choice studies on autonomous vehicles. Transp. Res. Part C Emerg. Technol. 2019, 98, 323–337. [Google Scholar] [CrossRef]

- Leiva-Padilla, P.; Blanc, J.; Hammoum, F.; Salgado, A.; Chailleux, E.; Mateos, A.; Hornych, P. The impact of truck platooning action on asphalt pavement: A parametric study. Int. J. Pavement Eng. 2022, 1–11. [Google Scholar] [CrossRef]

- Neubauer, M.; Schauer, O.; Schildorfer, W. A scenario-based investigation of truck platooning acceptance. In Advances in Human Factors of Transportation, Proceedings of the AHFE 2019 International Conference on Human Factors in Transportation, Washington DC, USA, 24–28 July 2019; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 453–461. [Google Scholar] [CrossRef]

- Doan, T.L.; Nguyen, T.G. Dynamic Analysis of the Laminated Composite Plate Resting on Two-Parameter Elastic Foundation Subjected to Moving Mass Using Finite Element Method. J. Sci. Tech. 2019, 14. [Google Scholar] [CrossRef]

- Mallik, R.B.; El-Korchi, T. (Eds.) Pavement Engineering: Principles and Practice, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar] [CrossRef]

- Darter, M.I.; Titus-Gl, O.L.; Von Quintus, H.; Bhattacharya, B.B.; Jagannath, M. Calibration and Implementation of the AASHTO Mechanistic-Empirical Pavement Design Guide in Arizona (No. FHWA-AZ-14-606); The Arizona Transportation Research Center: Phoenix, AZ, USA, 2014. [Google Scholar]

- Litman, T. Autonomous Vehicle Implementation Predictions; Victoria Transport Policy Institute: Victoria, BC, Canada, 2017; p. 28. [Google Scholar]

- Gungor, O.E.; Al-Qadi, I.L. All for one: Centralized optimization of truck platoons to improve roadway infrastructure sustainability. Transp. Res. Part C Emerg. Technol. 2020, 114, 84–98. [Google Scholar] [CrossRef]

- Browand, F.; McArthur, J.; Radovich, C. Fuel Saving Achieved in the Field Test of Two Tandem Trucks; Report No. UCB-ITS-PRR-2004-20. California Path Research Report; University of Soutehrn California: Los Angeles, CA, USA, 2004. [Google Scholar]

- Gungor, O.E.; She, R.; Al-Qadi, I.L.; Ouyang, Y. One for all: Decentralized optimization of lateral position of autonomous trucks in a platoon to improve roadway infrastructure sustainability. Transp. Res. Part C Emerg. Technol. 2020, 120, 102783. [Google Scholar] [CrossRef]

- Fagnant, D.J.; Kockelman, K. Preparing a nation for autonomous vehicles: Opportunities, barriers and policy recommendations. Transp. Res. Part A Policy Pract. 2015, 77, 167–181. [Google Scholar] [CrossRef]

- Kawa, I.; Zhang, Z.; Hudson, W.R. Evaluation of the AASHTO 18-Kip Load Equivalency Concept; Center for Transportation Research, Bureau of Engineering Research, University of Texas at Austin: Austin, TX, USA, 1998; Volume 7. [Google Scholar]

- Gungor, O.E.; Al-Qadi, I.L. Wander 2D: A flexible pavement design framework for autonomous and connected trucks. Int. J. Pavement Eng. 2022, 23, 121–136. [Google Scholar] [CrossRef]

- Ahammed, M.A.; Kass, S.; Hilderman, S. Implementing the AASHTOWare pavement ME design guide: Manitoba issues and proposed approaches. In Proceedings of the 2013 Conference and Exhibition of the Transportation Association of Canada-Transportation: Better-Faster-Safer, Ottawa, ON, Canada, 22–25 September 2013. [Google Scholar]

- Rana, M.M.; Hossain, K. Simulation of autonomous truck for minimizing asphalt pavement distresses. Road Mater. Pavement Des. 2022, 23, 1266–1286. [Google Scholar] [CrossRef]

- Kassem, H.A.; Chehab, G.R.; Najjar, S.S. Quantification of the inherent uncertainty in the relaxation modulus and creep compliance of asphalt mixes. Mech. Time-Depend. Mater. 2018, 22, 331–350. [Google Scholar] [CrossRef]

- Bose, A.; Ioannou, P.A. Analysis of traffic flow with mixed manual and semiautomated vehicles. IEEE Trans. Intell. Transp. Syst. 2003, 4, 173–188. [Google Scholar] [CrossRef]

- Hamdar, Y.; Kassem, H.; Srour, I.; Chehab, G. Performance-based specifications for sustainable pavements: A lean engineering analysis. Energy Procedia 2015, 74, 453–461. [Google Scholar] [CrossRef]

- Joumblat, R.; Al Basiouni Al Masri, Z.; Al Khateeb, G.; Elkordi, A.; El Tallis, A.R.; Absi, J. State-of-the-Art Review on Permanent Deformation Characterization of Asphalt Concrete Pavements. Sustainability 2023, 15, 1166. [Google Scholar] [CrossRef]

- Pierce, L.M.; McGovern, G. Implementation of the AASHTO Mechanistic-Empirical Pavement Design Guide and Software; No. Project 20-05, Topic 44-06; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2014. [Google Scholar]

- Gungor, O.E. Final Report: A Literature Review on Wheel Wander; Illinois Asphalt Pavement Association: Springfield, IL, USA, 2018. [Google Scholar]

| Properties | Asphalt Binder | Cement Mix | Base | Sub-Base |

|---|---|---|---|---|

| Type of the Materials | Nominal Maximum Aggregate size = ¾″ Fines % in the mix = 4 Air Voids Content (%) = 5 Asphalt Content (%) = 10 | ¾″ maximum limestone aggregate size | ¾″ maximum size of crushed limestone | 1½″ maximum size of gravel |

| Physical Properties | Performance Graded PG 58-34 | 28-day compressive strength = 32 MPa | Resilient Modulus of 140 MPa | Resilient Modulus of 120 MPa |

| Strength Properties (acc. to AASHTO 1993) | layer coefficient = 0.42 | layer coefficient = 0.14 | layer coefficient = 0.12 | |

| Design Lane Width= 4.3 | ||||

| Subgrade Type and Resilient Modulus | Design (20-Year) ESALs × 106 (Truck Factor = 3.25) | Bituminous Layer Thickness (Inches) | Granular A Base Thickness (Inches) | Granular C Base Thickness (Inches) |

|---|---|---|---|---|

| Fine Sand (A-2-4), Mr = 150 MPa | 28.8 | 6.5 | 8 | 10 |

| Vehicle Class | Distribution (%) | Growth Rate (%) |

|---|---|---|

| Class 4 | 3.3 | 1 |

| Class 5 | 34 | 1 |

| Class 6 | 11.7 | 1 |

| Class 7 | 1.6 | 1 |

| Class 8 | 9.9 | 1 |

| Class 9 | 36.2 | 1 |

| Class 10 | 1 | 1 |

| Class 11 | 1.8 | 1 |

| Class 12 | 0.2 | 1 |

| Class 13 | 0.3 | 1 |

| Reference Scenario (a) | Integrated Scenario (b) | Segregated Scenario (c) | ||

|---|---|---|---|---|

| Only non-autonomous trucks use the highway | (AT) and (NAT) share the same lanes simultaneously. Both operate in the same way following the same traffic rules. | (AT) and (NAT) use a dedicated lane. When the (AT) volume is >50%, it is allocated to two lanes, whereas when the (AT) volume is <50%, it is allocated to only a single lane. | ||

| b-1 | b-2 | c-1 | c-2 | |

| The rules of lane distribution for (NAT) are applied to (AT), e.g., (AT) would disproportionately position themselves in one lane of the highway. | (AT) will equally distribute themselves across all lanes of the road. Analysis proposes distributing (AT) across all lanes; in this way, it could significantly smooth traffic during congestion [19]. | The lane distribution of (AT) is the same as the lane distribution of (NAT). | When the (AT) occupy more than one lane, they are equally split across lanes, which is the case only when (AT) volume is higher than 50%. | |

| a | b-1 | b-2 | c-1 | c-2 | |

|---|---|---|---|---|---|

| AT < 50% | AT > 50% | ||||

| Lane Distribution | 70% | 70% for AT | 33.3% for AT | 100% | 50% |

| NAT < 50% | NAT > 50% | ||||

| 100% | 90% | ||||

| Scenarios AADTT | Reference (a) | Integrated (b) | Segregated (c) | |||

|---|---|---|---|---|---|---|

| b-1 | b-2 | c-1 | c-2 | |||

| 500 trucks/day | 500 | Fatigue | 811 | 400 | 405 | 452 |

| Rutting | 680 | 387 | 325 | 412 | ||

| 1000 trucks/day | 1000 | Fatigue | 1623 | 801 | 810 | 905 |

| Rutting | 1361 | 775.65 | 650 | 825 | ||

| 2000 trucks/day | 2000 | Fatigue | 3246 | 1603 | 1620 | 1810 |

| Rutting | 2723 | 1551 | 1300 | 1650 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merhebi, G.H.; Joumblat, R.; Elkordi, A. Assessment of the Effect of Different Loading Combinations Due to Truck Platooning and Autonomous Vehicles on the Performance of Asphalt Pavement. Sustainability 2023, 15, 10805. https://doi.org/10.3390/su151410805

Merhebi GH, Joumblat R, Elkordi A. Assessment of the Effect of Different Loading Combinations Due to Truck Platooning and Autonomous Vehicles on the Performance of Asphalt Pavement. Sustainability. 2023; 15(14):10805. https://doi.org/10.3390/su151410805

Chicago/Turabian StyleMerhebi, Ghina H., Rouba Joumblat, and Adel Elkordi. 2023. "Assessment of the Effect of Different Loading Combinations Due to Truck Platooning and Autonomous Vehicles on the Performance of Asphalt Pavement" Sustainability 15, no. 14: 10805. https://doi.org/10.3390/su151410805

APA StyleMerhebi, G. H., Joumblat, R., & Elkordi, A. (2023). Assessment of the Effect of Different Loading Combinations Due to Truck Platooning and Autonomous Vehicles on the Performance of Asphalt Pavement. Sustainability, 15(14), 10805. https://doi.org/10.3390/su151410805