Evaluating the Effect of Curing Time and Resting Time on Moisture Damage Resistance of Asphalt Mixtures Using the Pull-Off Tensile Strength (POTS) Test

Abstract

1. Introduction

2. Materials and Methods

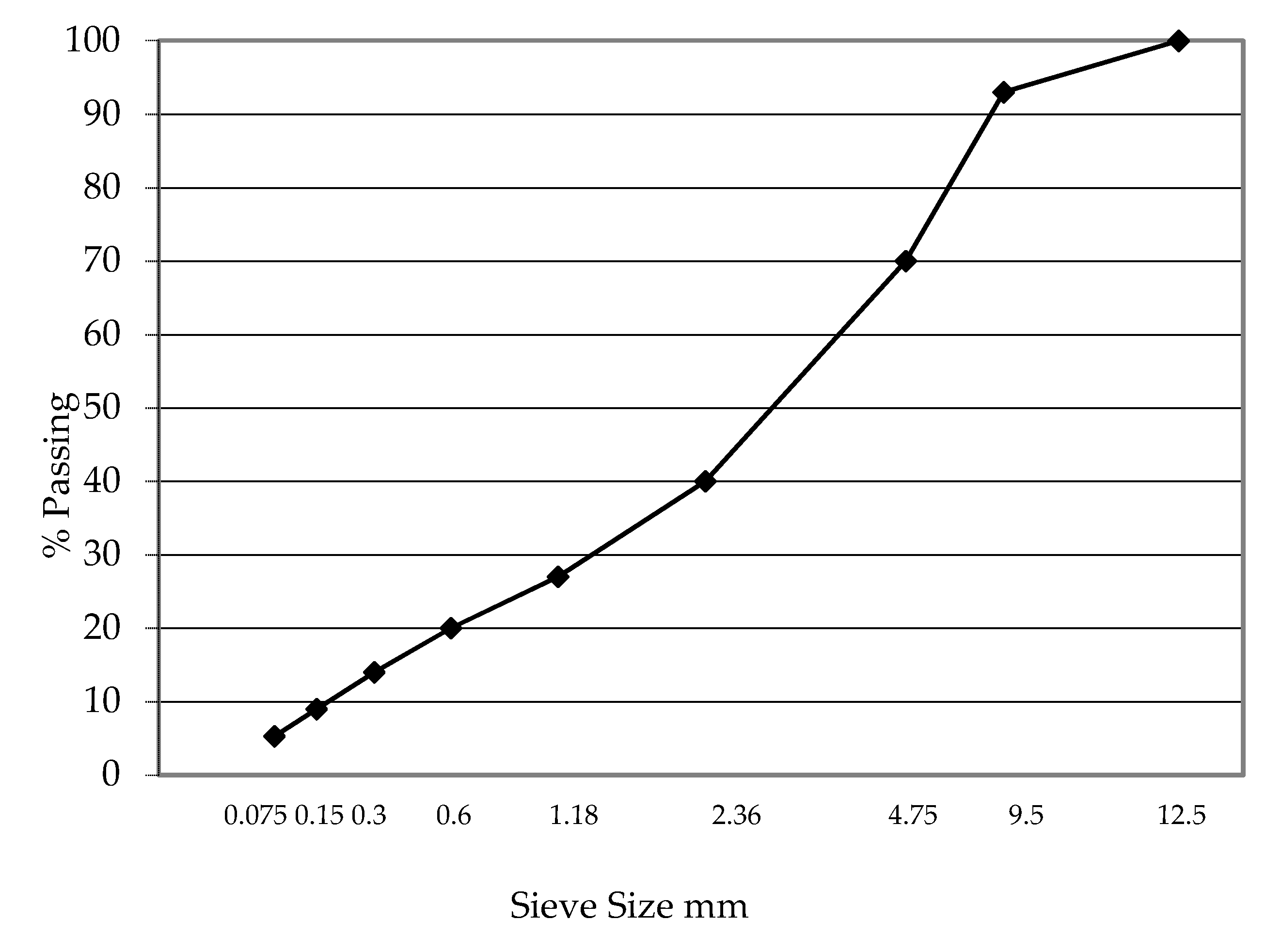

2.1. Materials

2.2. Asphalt Mixture Preparation

2.3. Experimental Methods

2.3.1. Indirect Tensile Strength Test

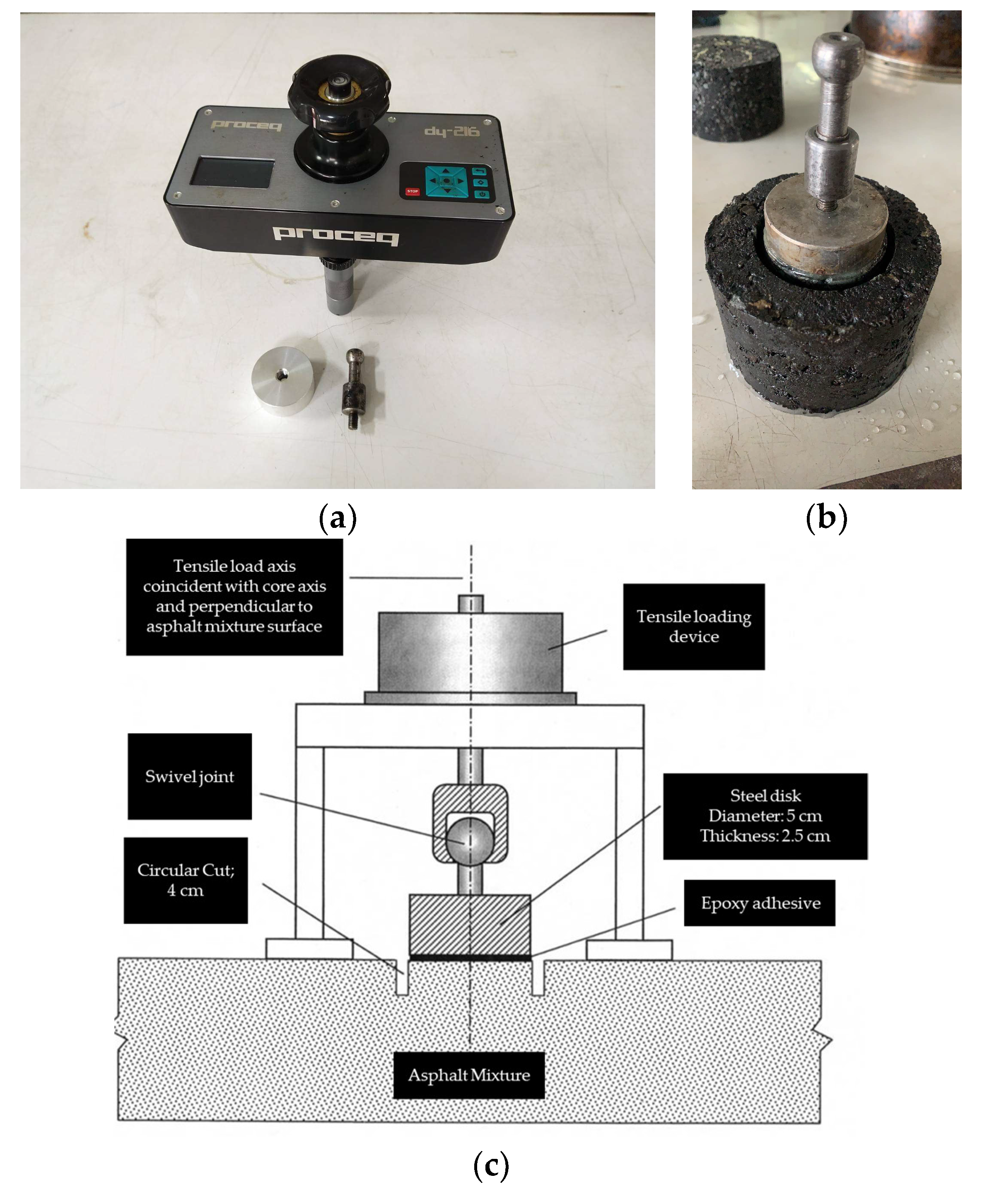

2.3.2. Pull-Off Tensile Strength (POTS) Test

3. Results

3.1. Effect of Curing Time and Resting Time on Pull-off Tensile Strength

3.2. Sensitivity Analysis

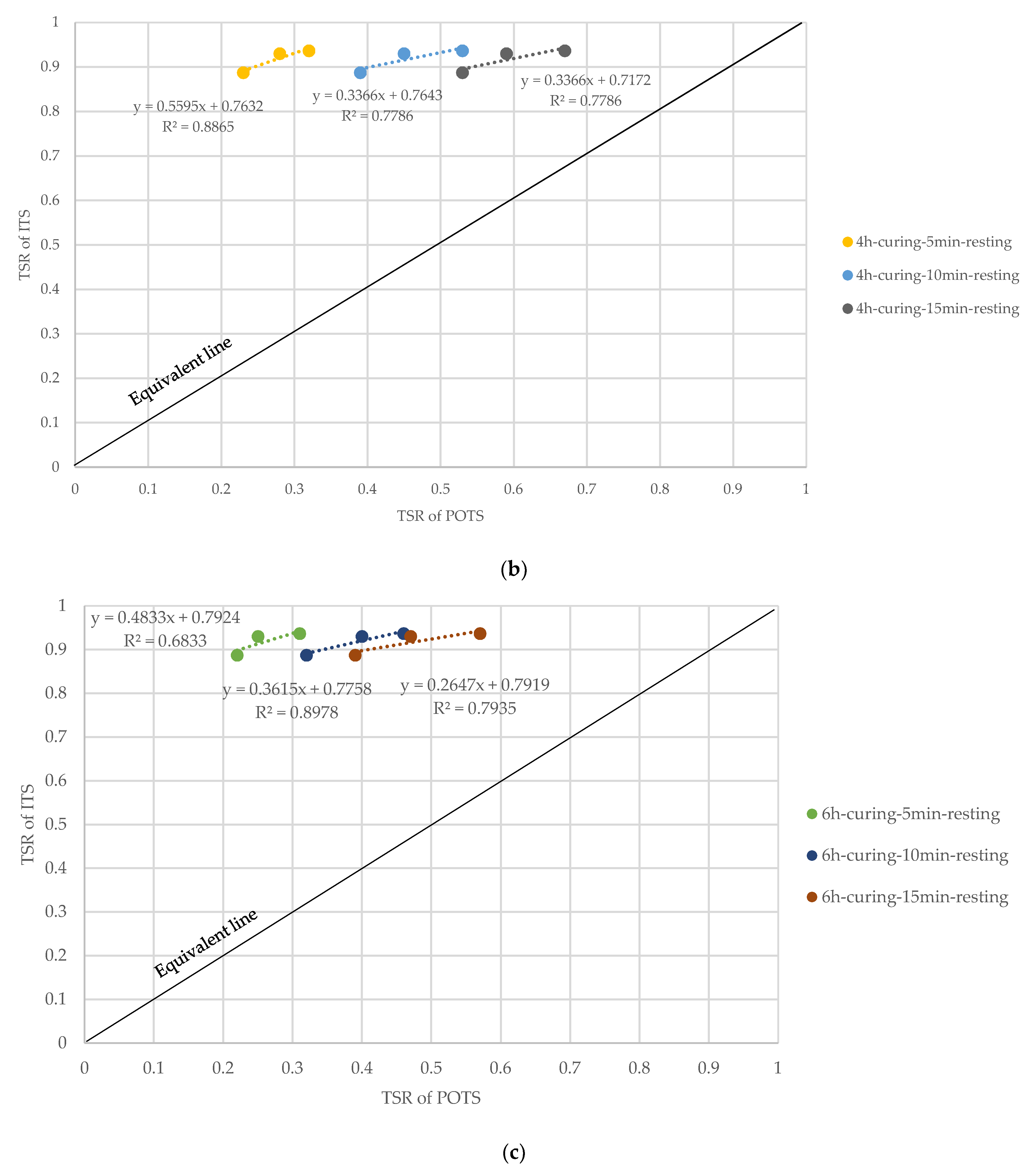

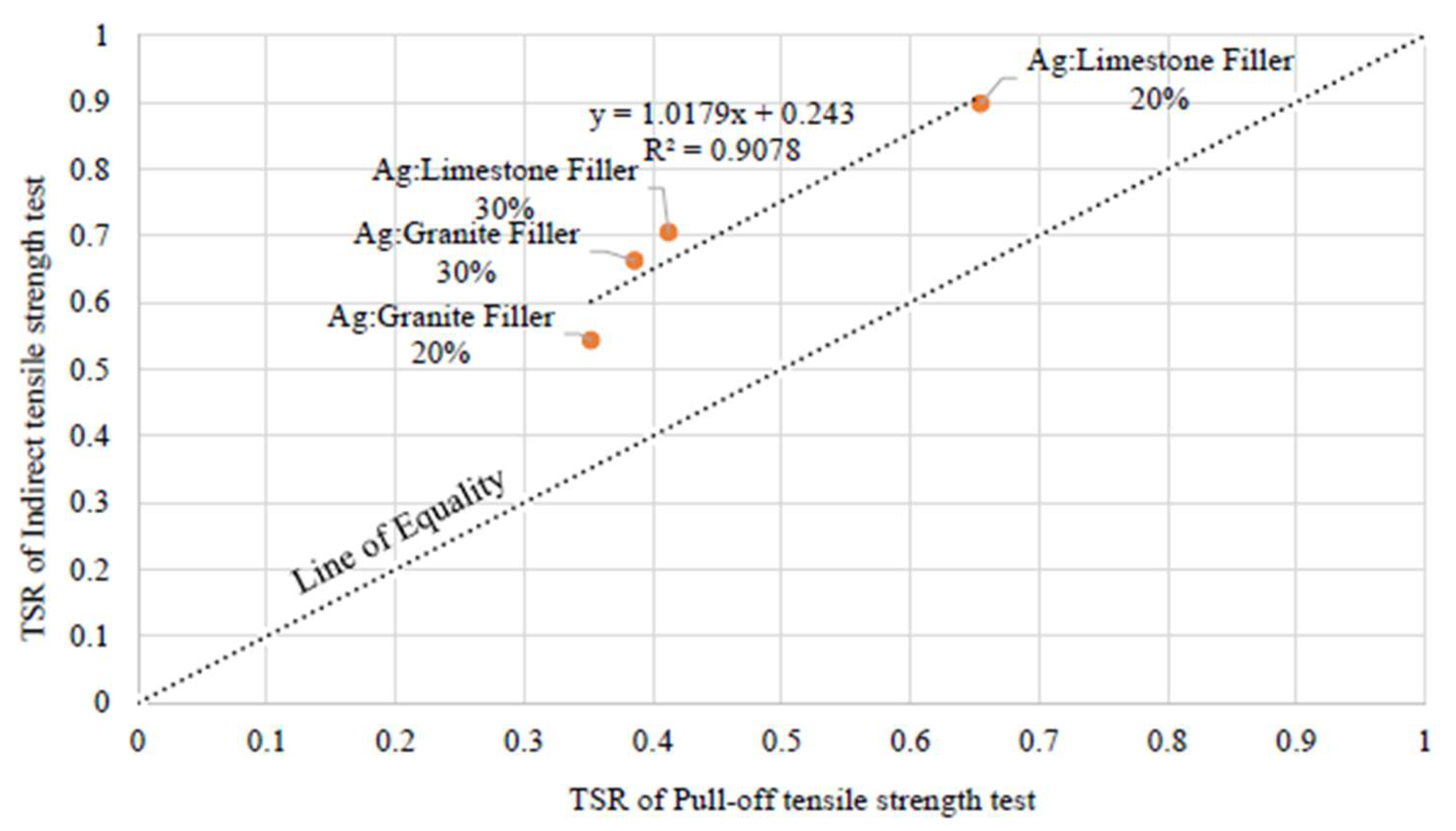

3.3. Correlation between TSR-POTS and TSR-ITS

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Terrel, R.L.; Al-Swailmi, S. Water Sensitivity of Asphalt-Aggregate Mixes: Test Selection; SHRP-A-403; Transportation Research Board: Washington, DC, USA, 1994. [Google Scholar]

- Al-Swailmi, S.; Terrel, R.L. Evaluation of Water Damage of Asphalt Concrete Mixtures Using the Environmental Conditioning. J. Assoc. Asph. Paving Technol. 1992, 61, 405–445. [Google Scholar]

- Airey, G.D.; Choi, C.S. State of the Art Report on Moisture Sensitivity Test Methods for Bituminous Pavement Materials. Road Mater. Pavement Des. 2002, 3, 355–372. [Google Scholar] [CrossRef]

- Diab, A.; You, Z. Development of a Realistic Conditioning and Evaluation System to Study Moisture Damage of Asphalt Materials. In Airfield and Highway Pavement Sustainable and Efficient Pavements; Kandhal, K.T., Thompson, M.R., Eds.; American Society of Civil Engineers: Reston, WV, USA, 2013; pp. 1008–1017. [Google Scholar]

- Copeland, A.R. Influence of Moisture on Bond Strength of Asphalt-Aggregate Systems. Ph.D. Thesis, Vanderbilt University, Nashville, TN, USA, 2007. [Google Scholar]

- Solaimanian, M.; Harvey, J.; Tahmoressi, M.; Tandon, V. Test Methods to Predict Moisture Sensitivity of Hot-Mix Asphalt Pavements. In The Moisture Sensitivity of Asphalt Pavements—A National Seminar, San Diego; Transportation Research Board: Washington, DC, USA, 2003. [Google Scholar]

- AASHTO T 165; Standard Method of Test for Effect of Water on Compressive Strength of Compacted Bituminous Mixtures. 2022 ed. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T 283; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. 2022 ed. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- ASTM D3625-96; Standard Practice for Effect of Water on Bituminous-Coated Aggregate Using Boiling Water. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM D4867/D4867M-09; Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures. ASTM International: West Conshohocken, PA, USA, 2014.

- AASHTO T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. 2022 ed. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Moraes, R.; Velasquez, R.; Bahia, H. Measuring Effect of Moisture on Asphalt Aggregate Bond with the Bitumen Bond Strength Test. J. Transp. Res. Board 2011, 2209, 70–81. [Google Scholar] [CrossRef]

- Chaturabong, P.; Bahia, H.U. Effect of Moisture on the Cohesion of Asphalt Mastics and Bonding with Surface of Aggregates. Road Mater. Pavement Des. 2016, 22, 741–753. [Google Scholar] [CrossRef]

- Bhasin, A.; Masad, E.; Little, D.; Lytton, R. Limits on Adhesive Bond Energy for Improved Resistance of Hot-Mix Asphalt to Moisture Damage. In Transportation Research Board; No. 1970; Transportation Research Board of the National Academies: Washington, DC, USA, 2006; pp. 3–13. [Google Scholar]

- Kanitpong, K.; Bahia, H.U. Role of Adhesion and Thin Film Tackiness of Asphalt Binders in Moisture Damage of HMA. Asph. Paving Technol. 2003, 72, 502–528. [Google Scholar]

- Caro, S.; Masad, E.; Bhasin, A.; Little, D.N. Moisture Susceptibility of Asphalt Mixtures, Part 1: Mechanisms. Int. J. Pavement Eng. 2008, 9, 81–98. [Google Scholar] [CrossRef]

- Kiggundu, B.M.; Roberts, F.L. Stripping in HMA Mixtures: State-of-the-Art and Critical Review of Test Methods; Report No. 88-2; National Center for Asphalt Technology: Auburn, AL, USA, 1988. [Google Scholar]

- Canestrari, F.; Cardone, F.; Graziani, A.; Santagata, F.; Bahia, H.U. Adhesive and Cohesive Properties of Asphalt-Aggregate Systems Subjected to Moisture Damage. Road Mater. Pavement Des. 2010, 11, 11–32. [Google Scholar] [CrossRef]

- Youtcheff, J.; Aurilio, V. Moisture Sensitivity of Asphalt Binders: Evaluation and Modeling of the Pneumatic Adhesion Test Results. In Proceedings of the 42nd Annual Conference of Canadian Technical Asphalt Association, Ottawa, ON, Canada, 1997; pp. 180–200. [Google Scholar]

- National Academies of Sciences, Engineering, and Medicine. Final Report for NCHRP RRD 316: Using Surface Energy Measurements to Select Materials for Asphalt Pavement; National Academies Press: Washington, DC, USA, 2017. [Google Scholar]

- Hefer, A.W.; Bhasin, A.; Little, D.N. Bitumen Surface Energy Characterization Using a Contact Angle Approach. J. Mater. Civ. Eng. 2006, 18, 759–767. [Google Scholar] [CrossRef]

- Arabani, M.; Hamedi, G.H. Using the Surface Free Energy Method to Evaluate the Effects of Liquid Antistrip Additives on Moisture Sensitivity in Hot Mix Asphalt. Int. J. Pavement Eng. 2014, 15, 66–78. [Google Scholar] [CrossRef]

- Xiao, R.; Ding, Y.; Polaczyk, P.; Ma, Y.; Jiang, X.; Huang, B. Moisture Damage Mechanism and Material Selection of HMA with Amine Antistripping Agent. Mater. Des. 2022, 220, 110797. [Google Scholar] [CrossRef]

- Ali, S.A.; Zaman, M.; Ghabchi, R.; Rahman, M.A.; Ghos, S.; Rani, S. Effect of Additives and Aging on Moisture-Induced Damage Potential of Asphalt Mixes Using Surface Free Energy and Laboratory-Based Performance Tests. Int. J. Pavement Eng. 2022, 23, 285–296. [Google Scholar] [CrossRef]

- Al Basiouni Al Masri, Z.; Alarab, A.; Chehab, G.; Tehrani-Bagha, A. Assessing Moisture Damage of Asphalt-Aggregate Systems Using Principles of Thermodynamics: Effects of Recycled Materials and Binder Aging. J. Mater. Civ. Eng. 2019, 31, 04019190. [Google Scholar] [CrossRef]

- Howson, J.; Masad, E.; Bhasin, A.; Little, D.; Lytton, R. Comprehensive Analysis of Surface Free Energy of Asphalts and Aggregates and the Effects of Changes in PH. Constr. Build. Mater. 2011, 25, 2554–2564. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, B. Moisture Damage Mechanism and Thermodynamic Properties of Hot-Mix Asphalt under Aging Conditions. ACS Sustain. Chem. Eng. 2022, 10, 14865–14887. [Google Scholar] [CrossRef]

- Rachabut, K.; Chaturabong, P. Evaluation of Using of Natural Fillers to Improve Moisture Damage Resistance and the Use of Pull-off Tensile Test in Determining Moisture Damage Resistance in Asphalt. Appl. Sci. 2020, 10, 4318. [Google Scholar] [CrossRef]

- Long, A.E.; Murray, A. The Pull-Off Partially Destructive Test for Concrete. In In-Situ Non-Destructive Testing of Concrete, SP-82; American Concrete Institute: Detroit, MI, YSA, 1984. [Google Scholar]

- Gonçalves, A.F. Novos Ensaios Não Destrutivos Para a Determinação da Resistência do Betão Nas Estruturas; Laboratório Nacional de Engenharia Civil: Lisboa, Portugal, 1986. [Google Scholar]

- Testing concrete. In Recommendations for the Assessment of Concrete Strength by Near-to-Surface Tests; BS 1881, Part 207; British Standards Institution: London, UK, 1992.

- Chaturabong, P.; Bahia, H.U. Mechanisms of Asphalt Mixture Rutting in the Dry Hamburg Wheel Tracking Test and the Potential to be Alternative Test in Measuring Rutting Resistance. Constr. Build. Mater. 2017, 146, 175–182. [Google Scholar] [CrossRef]

| Type of Asphalt Binder | Performance Grade |

|---|---|

| AC60-70 | PG58 |

| AC60-70 + Carbon black | PG76 |

| PMA | PG76 |

| Factor | Descriptions |

|---|---|

| Aggregate type | Limestone |

| Filler types | Limestone |

| Mixture types | Dense |

| Binder types | AC60-70, AC6070 + carbon black, and PMA |

| Replication | 3 |

| Curing Time | Resting Time (Minutes) | Tensile Strength (MPa) | |||||

|---|---|---|---|---|---|---|---|

| AC60-70 | CV (%) | AC60-70 + Carbon Black | CV (%) | PMA | CV (%) | ||

| Dry | 0.92 | 1.7 | 0.66 | 0.8 | 1.05 | 0.3 | |

| Wet-2 h | 5 | 0.32 | 1.6 | 0.21 | 1.9 | 0.42 | 1.7 |

| 10 | 0.54 | 2.5 | 0.30 | 1.8 | 0.71 | 1.6 | |

| 15 | 0.65 | 1.5 | 0.40 | 1.7 | 0.83 | 5.6 | |

| Wet-4 h | 5 | 0.26 | 2.3 | 0.15 | 3.6 | 0.34 | 1.5 |

| 10 | 0.41 | 5.9 | 0.26 | 4.2 | 0.55 | 0.5 | |

| 15 | 0.54 | 6.3 | 0.35 | 5.5 | 0.70 | 0.6 | |

| Wet-6 h | 5 | 0.23 | 1.2 | 0.14 | 2.3 | 0.33 | 1.0 |

| 10 | 0.37 | 1.9 | 0.21 | 2.3 | 0.48 | 4.4 | |

| 15 | 0.43 | 1.3 | 0.26 | 2.4 | 0.60 | 5.4 | |

| Curing Time | Resting Time (Minutes) | TSR | |||||

|---|---|---|---|---|---|---|---|

| AC60-70 | CV (%) | AC60-70 + Carbon Black | CV (%) | PMA | CV (%) | ||

| Wet-2 h | 5 | 0.35 | 4.2 | 0.32 | 2.5 | 0.40 | 3.2 |

| 10 | 0.59 | 3.5 | 0.45 | 7.2 | 0.68 | 5.6 | |

| 15 | 0.70 | 4.5 | 0.61 | 8.7 | 0.79 | 8.5 | |

| Wet-4 h | 5 | 0.28 | 3.2 | 0.23 | 2.5 | 0.32 | 5.5 |

| 10 | 0.45 | 2.9 | 0.39 | 0.8 | 0.53 | 0.5 | |

| 15 | 0.59 | 6.1 | 0.53 | 3.5 | 0.67 | 3.2 | |

| Wet-6 h | 5 | 0.25 | 7.2 | 0.22 | 3.2 | 0.31 | 2.4 |

| 10 | 0.40 | 1.3 | 0.32 | 4.5 | 0.46 | 1.5 | |

| 15 | 0.47 | 2.3 | 0.39 | 5.4 | 0.57 | 1.1 | |

| Asphalt Type | TSR | ||||

|---|---|---|---|---|---|

| Resting Time (Minutes) | |||||

| 5 | %Diff (5–10) | 10 | %Diff (10–15) | 15 | |

| 2 h curing time | |||||

| AC60/70 | 0.35 | 42% | 0.59 | 16% | 0.70 |

| AC60-70 + Carbon black | 0.32 | 29% | 0.45 | 26% | 0.61 |

| PMA | 0.40 | 41% | 0.68 | 14% | 0.79 |

| 4 h curing time | |||||

| AC60/70 | 0.28 | 37% | 0.45 | 24% | 0.59 |

| AC60-70 + Carbon black | 0.23 | 41% | 0.39 | 25% | 0.53 |

| PMA | 0.32 | 38% | 0.53 | 21% | 0.67 |

| 6 h curing time | |||||

| AC60/70 | 0.25 | 38% | 0.40 | 13% | 0.47 |

| AC60-70 + Carbon black | 0.22 | 32% | 0.32 | 18% | 0.39 |

| PMA | 0.31 | 32% | 0.46 | 20% | 0.57 |

| Condition | Tensile Strength (MPa) | |||||

|---|---|---|---|---|---|---|

| AC60-70 | CV (%) | AC60-70 + Carbon Black | CV (%) | PMA | CV (%) | |

| Dry | 1041.34 | 4.3 | 727.02 | 10.0 | 1060.18 | 4.5 |

| Wet | 968.73 | 5.7 | 645.10 | 9.1 | 992.83 | 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nimsanor, A.; Chaturabong, P. Evaluating the Effect of Curing Time and Resting Time on Moisture Damage Resistance of Asphalt Mixtures Using the Pull-Off Tensile Strength (POTS) Test. Sustainability 2023, 15, 6760. https://doi.org/10.3390/su15086760

Nimsanor A, Chaturabong P. Evaluating the Effect of Curing Time and Resting Time on Moisture Damage Resistance of Asphalt Mixtures Using the Pull-Off Tensile Strength (POTS) Test. Sustainability. 2023; 15(8):6760. https://doi.org/10.3390/su15086760

Chicago/Turabian StyleNimsanor, Adulwit, and Preeda Chaturabong. 2023. "Evaluating the Effect of Curing Time and Resting Time on Moisture Damage Resistance of Asphalt Mixtures Using the Pull-Off Tensile Strength (POTS) Test" Sustainability 15, no. 8: 6760. https://doi.org/10.3390/su15086760

APA StyleNimsanor, A., & Chaturabong, P. (2023). Evaluating the Effect of Curing Time and Resting Time on Moisture Damage Resistance of Asphalt Mixtures Using the Pull-Off Tensile Strength (POTS) Test. Sustainability, 15(8), 6760. https://doi.org/10.3390/su15086760