Impact of Customer Predictive Ability on Sustainable Innovation in Customized Enterprises

Abstract

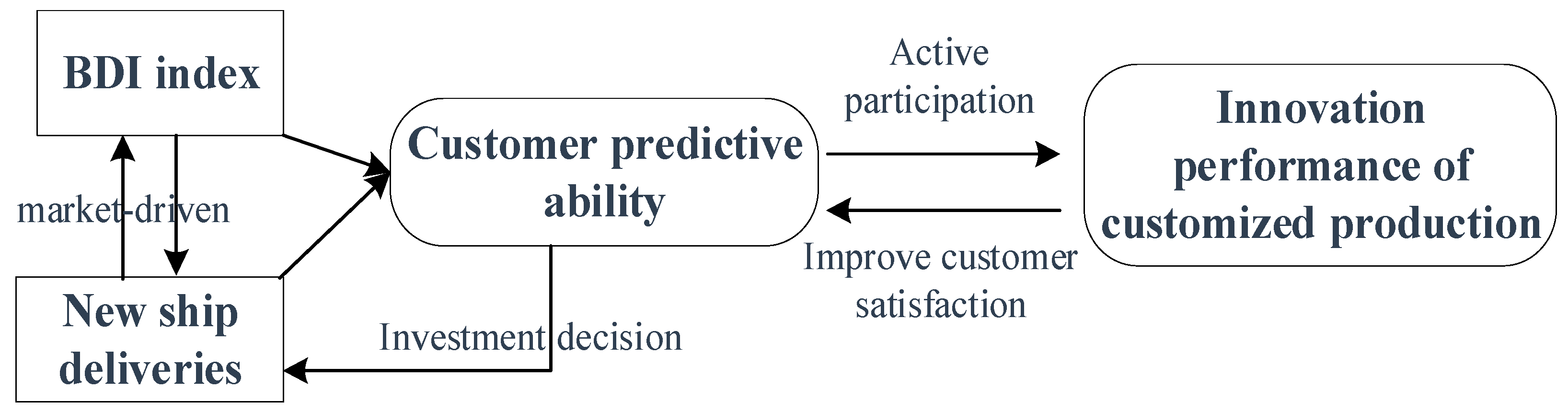

1. Introduction

2. Literature Review

2.1. Service Innovation

2.2. Predictive Ability

2.3. Innovation in Manufacturing

2.4. The Impact of Customers on Innovation

3. Empirical Study

3.1. Research Background

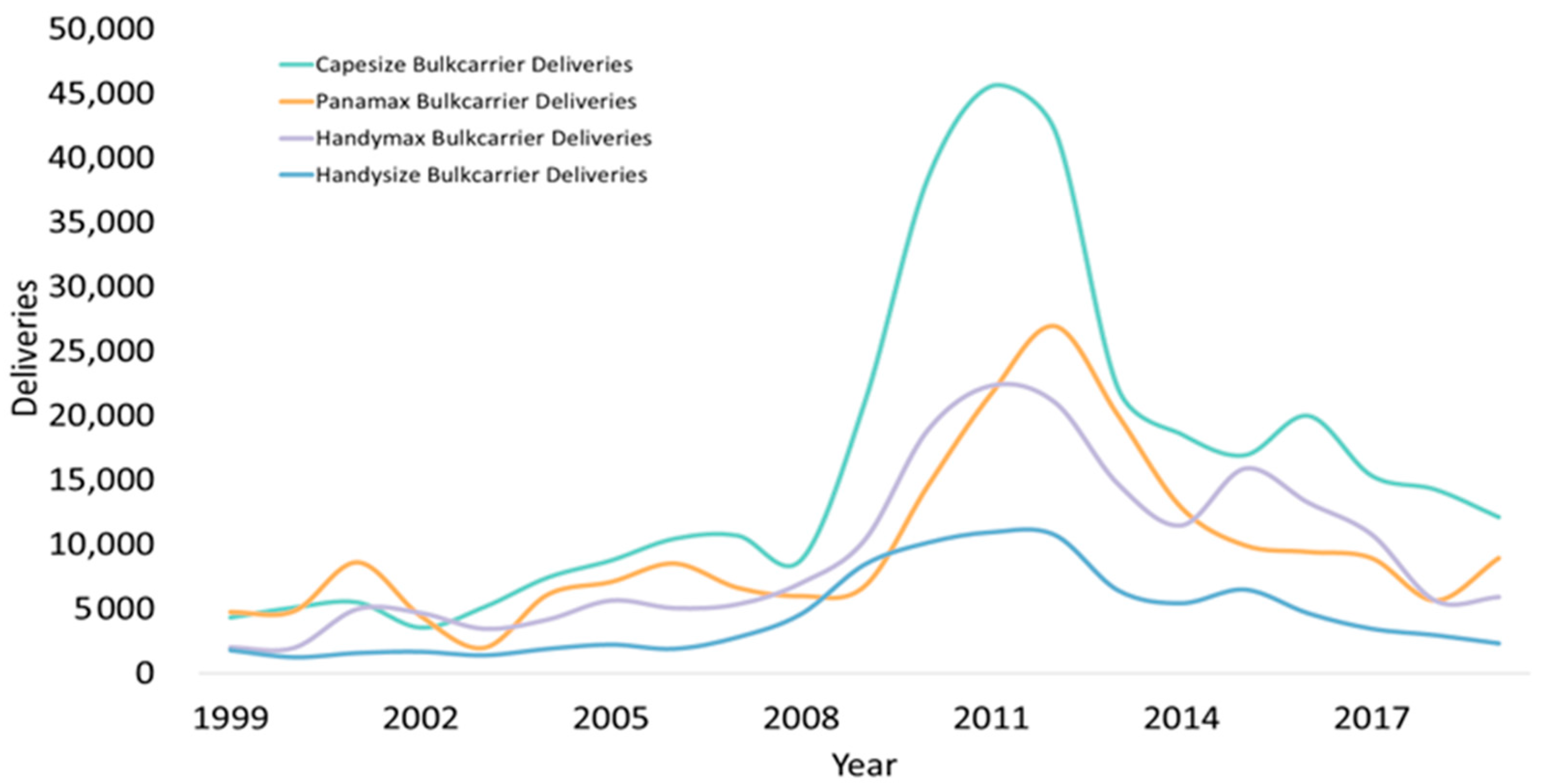

3.2. Data Source

3.3. Method

4. Results

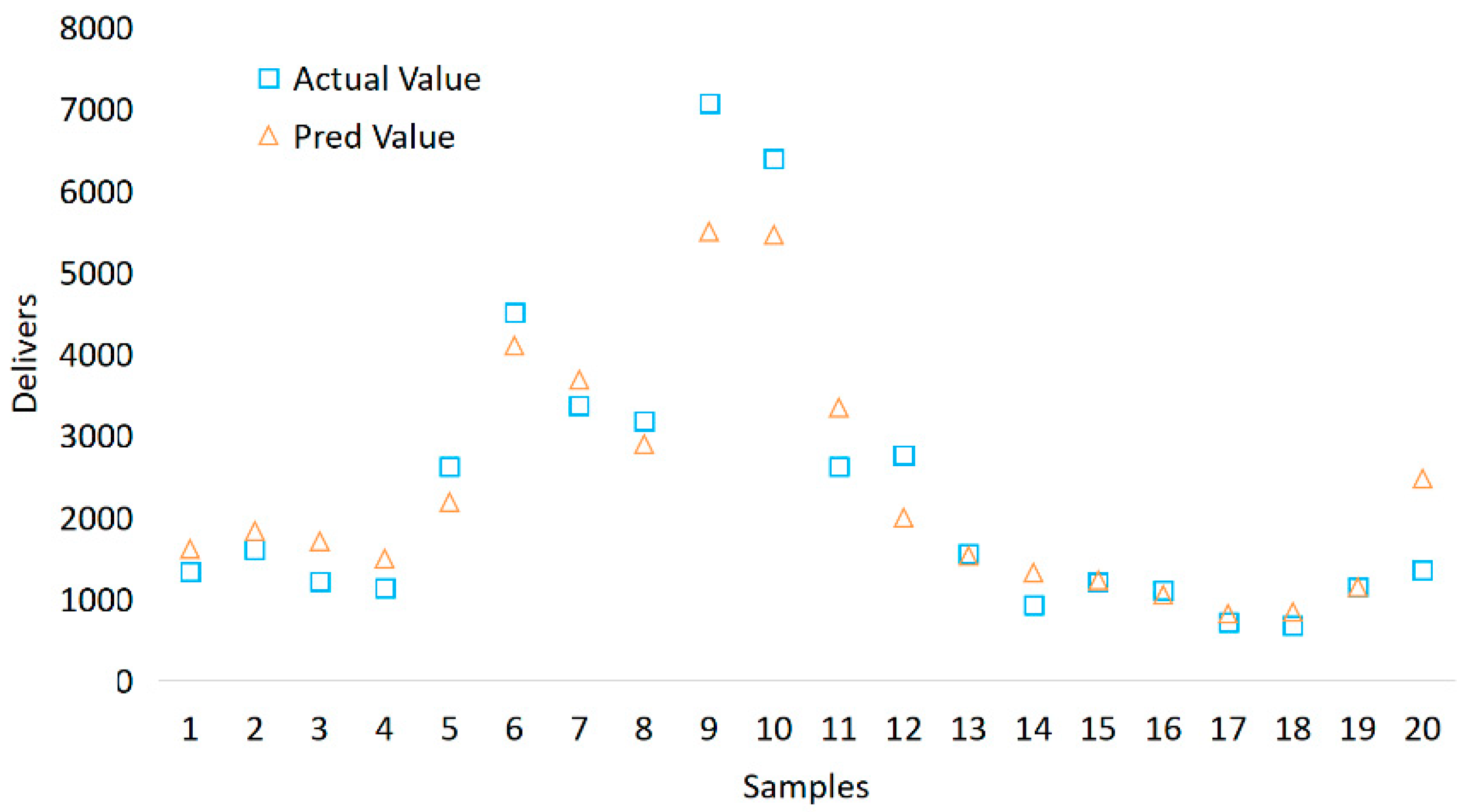

4.1. Random Forest Experiment

4.1.1. Descriptive Statistical Analysis

4.1.2. Building A Random Forest Model

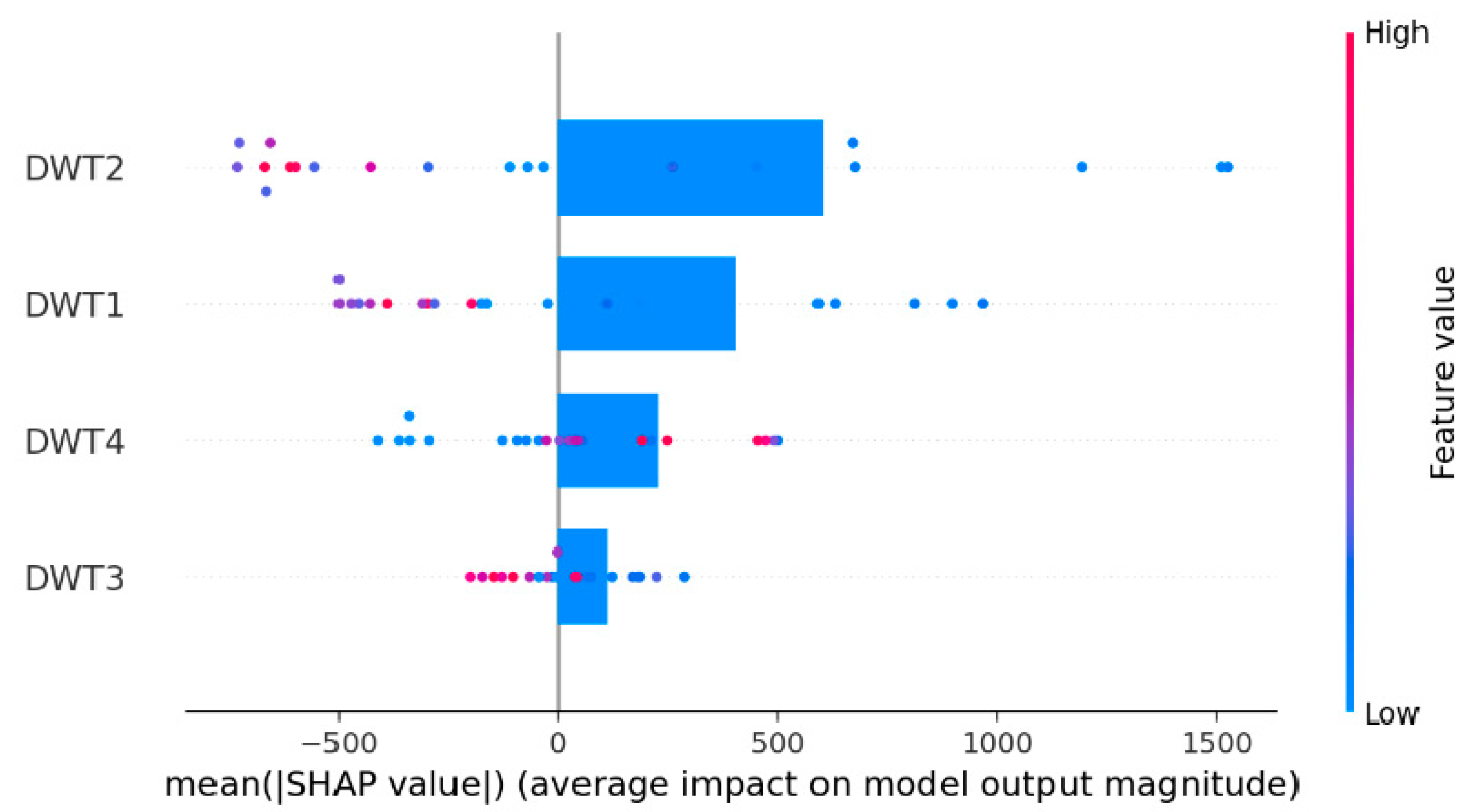

4.1.3. SHAP Values for Model Interpretation

Global SHAP Interpretation

Individual SHAP Explanation

4.2. Granger Causality Experiment

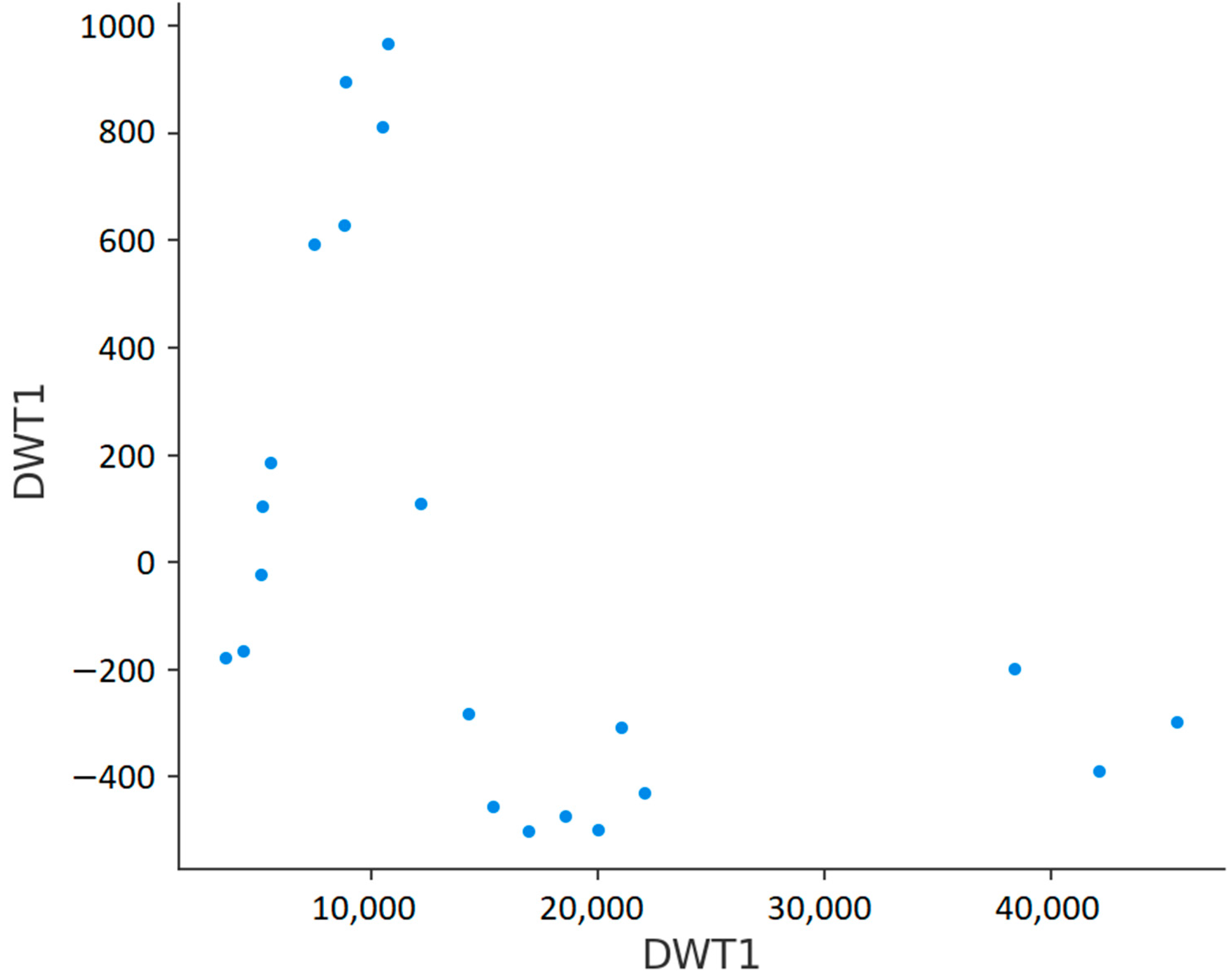

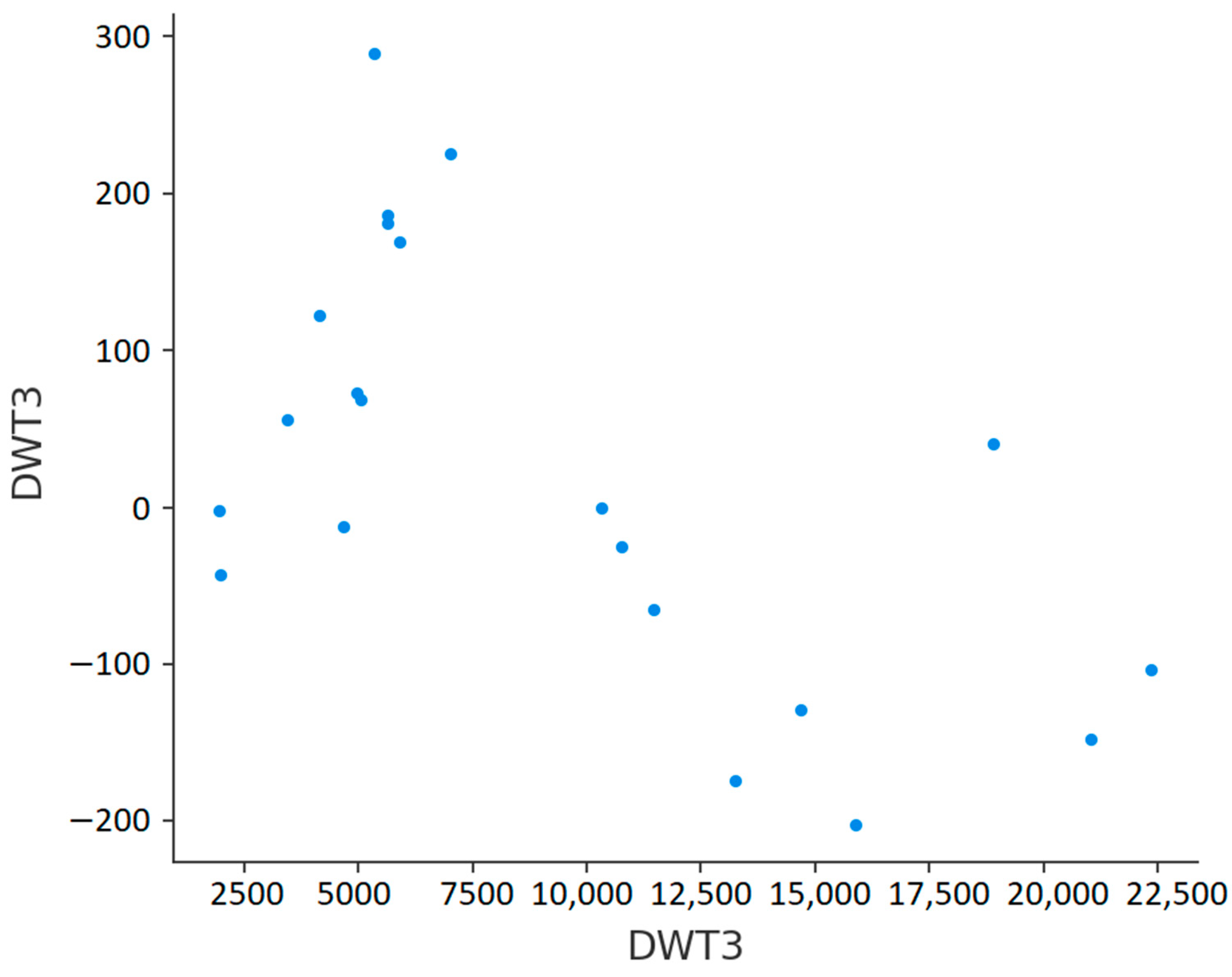

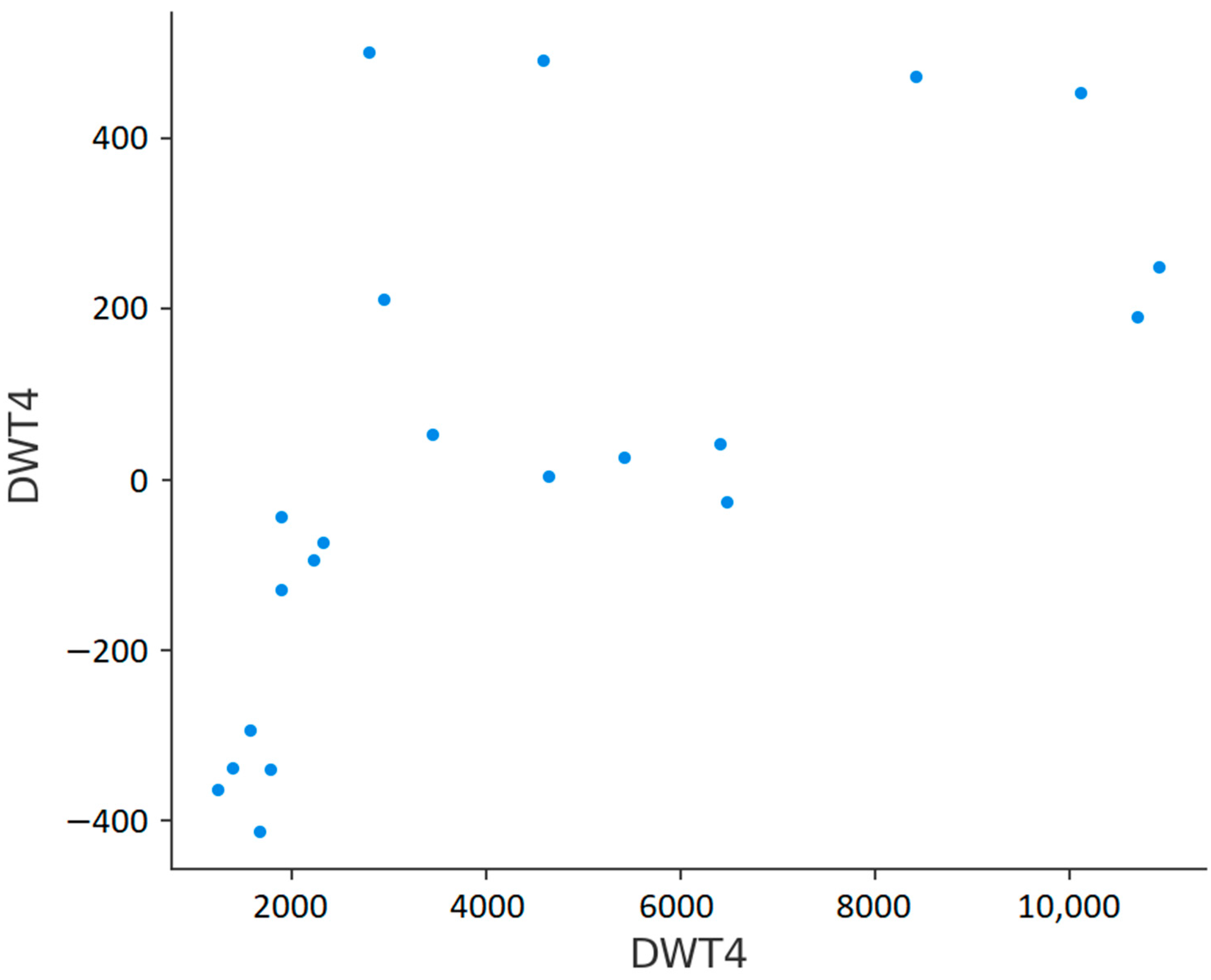

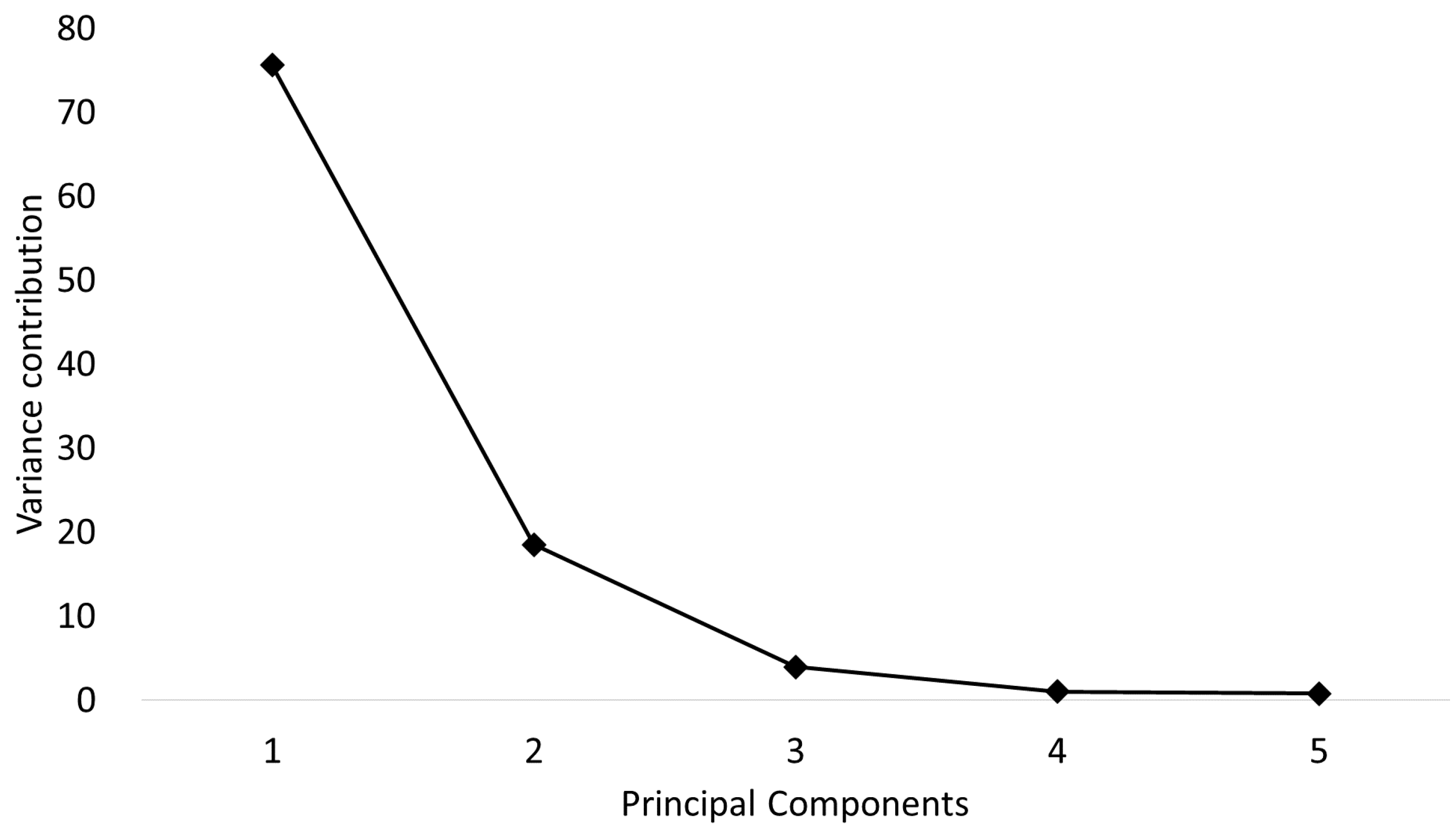

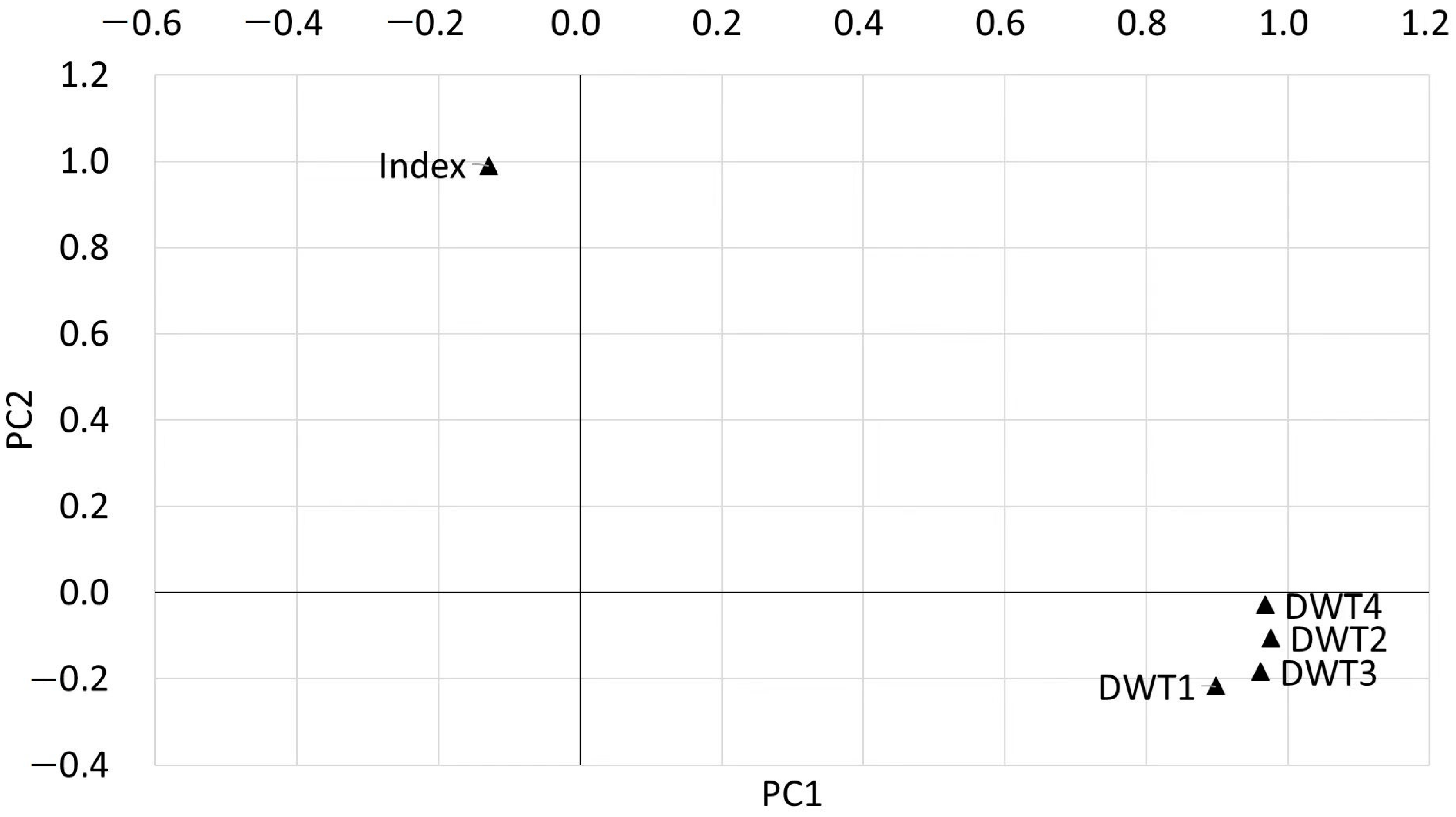

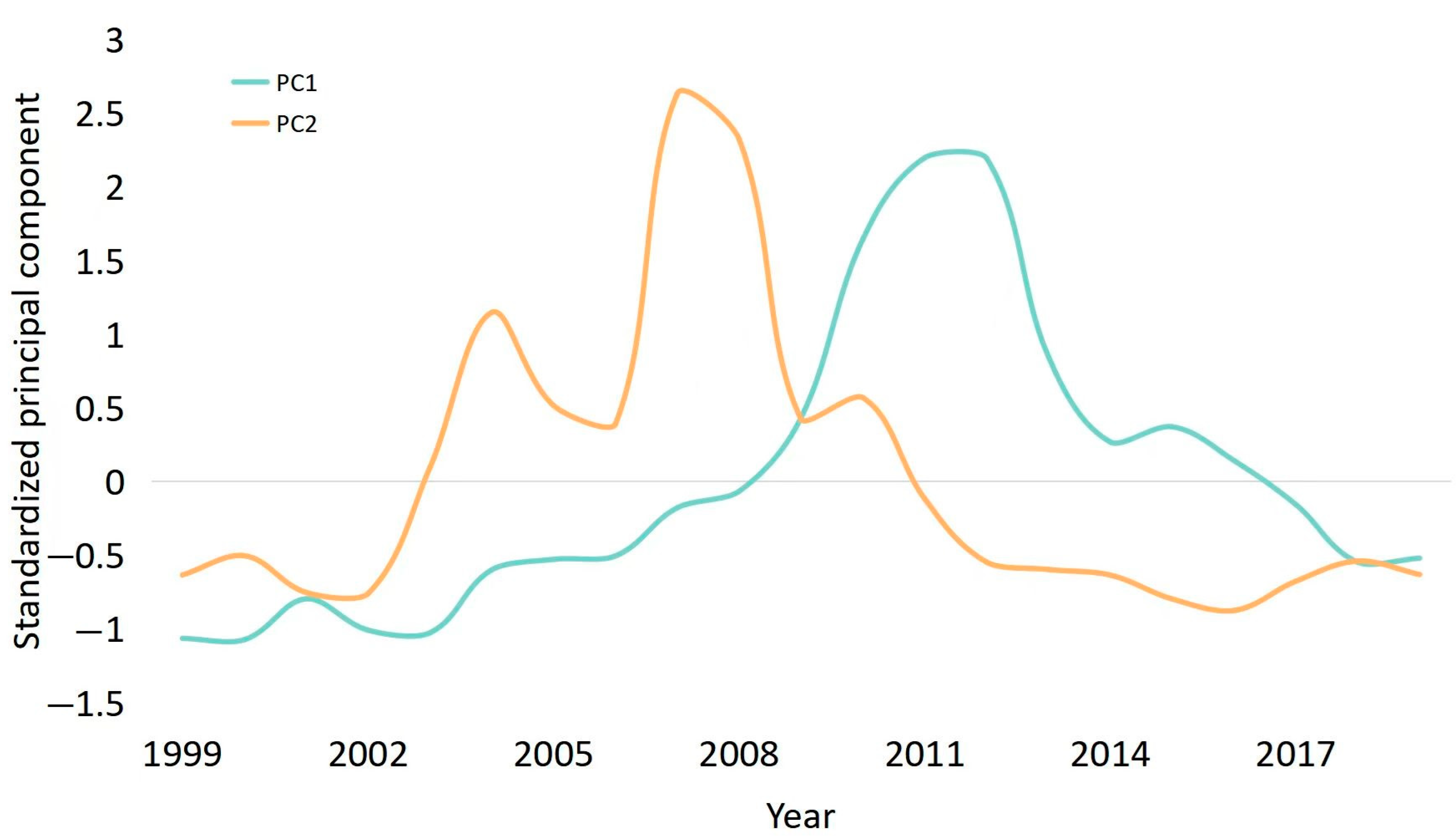

4.2.1. Principal Component Analysis

4.2.2. Granger Causality Test

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Daradkeh, F.M.; Hassan, T.H.; Palei, T.; Helal, M.Y.; Mabrouk, S.; Saleh, M.I.; Salem, A.E.; Elshawarbi, N.N. Enhancing Digital Presence for Maximizing Customer Value in Fast-Food Restaurants. Sustainability 2023, 15, 5690. [Google Scholar] [CrossRef]

- Terziovski, M. Innovation practice and its performance implications in small and medium enterprises (SMEs) in the manufacturing sector: A resource-based view. Strateg. Manag. J. 2010, 31, 892–902. [Google Scholar] [CrossRef]

- Martínez-Olvera, C. An Entropy-Based Formulation for Assessing the Complexity Level of a Mass Customization Industry 4.0 Environment. Math. Probl. Eng. 2020, 2020, 6376010. [Google Scholar] [CrossRef]

- Cui, A.S.; Wu, F. Utilizing Customer Knowledge in Innovation: Antecedents and Impact of Customer Involvement on New Product Performance. J. Acad. Mark. Sci. 2016, 44, 516–538. [Google Scholar] [CrossRef]

- Nambisan, S. Designing virtual customer environments for new product development: Toward a theory. Acad. Manag. Rev. 2002, 27, 392–413. [Google Scholar] [CrossRef]

- Remy, E.; Kopel, S. Social linking and human service sector. Serv. Ind. J. 2002, 22, 35–55. [Google Scholar] [CrossRef]

- Nordin, F.; Kowalkowski, C. Solutions Offerings: A Critical Review and Reconceptualization. J. Serv. Manag. 2010, 21, 441–459. [Google Scholar] [CrossRef]

- Cooper, R.G.; Kleinschmidt, E.J. New product performance: Keys to success, profitability & cycle time reduction. J. Mark. Manag. 1995, 11, 315–337. [Google Scholar]

- Dean, J.W., Jr.; Bowen, D.E. Management theory and total quality: Improving research and practice through theory development. Acad. Manag. Rev. 1994, 19, 392–418. [Google Scholar] [CrossRef]

- Jang, Y.-J.; Kim, E. Social and Personal Norms in Shaping Customers’ Environmentally Sustainable Behavior in Restaurants’ Social Media Communities. Sustainability 2023, 15, 6410. [Google Scholar] [CrossRef]

- Martínez-Torres, M. Customer preferences versus managerial decision-making in open innovation communities: The case of Starbucks. Technol. Anal. Strateg. Manag. 2015, 27, 1226–1238. [Google Scholar] [CrossRef]

- Lengnick-Hall, C.A. Customer contributions to quality: A different customer-oriented firm. Acad. Manag. Rev. 1996, 2l, 791–824. [Google Scholar] [CrossRef]

- Beibei, D.; Kenneth, R.E.; Zou, S. The effects of customer participation in co-created service recovery. Orig. Empir. Res. 2008, 36, 123–137. [Google Scholar]

- Auh, S.; Simon, J.B.; Colin, S.M.; Shih, E. Co-production and customer loyalty in financial services. J. Retail. 2007, 83, 359–370. [Google Scholar] [CrossRef]

- Chervonnaya, O. Customer Role and Skill Trajectories in Services. Int. J. Serv. Ind. Manag. 2003, 14, 347–363. [Google Scholar] [CrossRef]

- De Haan, E.; Verhoef, P.C.; Wiesel, T. The predictive ability of different customer feedback metrics for retention. Int. J. Res. Mark. 2015, 32, 195–206. [Google Scholar] [CrossRef]

- Stopford, M. Maritime Economics 3e; Routledge: London, UK, 2009. [Google Scholar]

- Pine, B.J. Mass Customization: The New Frontier in Business Competition; Harvard Business Press: Brighton, MA, USA, 1993. [Google Scholar]

- Alptekin, U.; Gabrijela, P.; Pavle, R.; Dragisa, S.; Darjan, K. A new hybrid fuzzy psi-piprecia-cocoso mcdm based approach to solving the transportation company selection problem. Technol. Econ. Dev. Econ. 2021, 27, 1227–1249. [Google Scholar]

- Enz, C.A. Strategies for the implementation of service innovations. Cornell Hosp. Q. 2012, 53, 187–195. [Google Scholar] [CrossRef]

- Liu, L. Research on the Driving Factors of Interaction Orientation and the Mechanism of Its Effect on Enterprise Service Innovation Performance. Ph.D. Thesis, Jilin University, Changchun, China, 2022. [Google Scholar]

- Kindström, D.; Kowalkowski, C.; Sandberg, E. Enabling service innovation: A dynamic capabilities approach. J. Bus. Res. 2013, 66, 1063–1073. [Google Scholar] [CrossRef]

- Rubalcaba, L.; Michel, S.; Sundbo, J.; Brown, S.W.; Reynoso, J. Shaping, organizing, and rethinking service innovation: A multidimensional framework. J. Serv. Manag. 2012, 23, 696–715. [Google Scholar] [CrossRef]

- Witell, L.; Snyder, H.; Gustafsson, A. Defining service innovation: A review and synthesis. J. Bus. Res. 2016, 69, 2863–2872. [Google Scholar] [CrossRef]

- Day, G.S. The capabilities of market driven organizations. J. Mark. 1994, 58, 37–52. [Google Scholar] [CrossRef]

- Meng, P. A Multi-Level Research on the Impact of Employee-Customer Value Co-Creation on Service Innovation. Ph.D. Thesis, Jilin University, Changchun, China, 2020. [Google Scholar]

- Ostrom, A.L.; Bitner, M.J.; Brown, S.W. Moving forward and making a difference: Research priorities for the science of service. J. Serv. Res. 2010, 13, 4–36. [Google Scholar] [CrossRef]

- Chamlibers, J.C.; Mullick, S.K.; Smith, D.D. How to Choose the right forecasting technique. Harv. Bus. Rev. 1971, 49, 45–74. [Google Scholar]

- Boucher, T.O.; Yalçin, A. Introduction. In Design of Industrial Information Systems; Academic Press: Cambridge, MA, USA, 2006; pp. 1–25. [Google Scholar]

- Rexer, K.; De Veaux, R.; Britton, G.; Taylor, J. Endorsements for Practical Text Mining & Statistical Analysis for Non-structured Text Data Applications; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Makridakis, S.; Wheelwrighlt, S. Forecasting: Methods and Applications; Wiley: New York, NY, USA, 1978. [Google Scholar]

- Bunn, D. Forecasting with more than one model. J. Forecast. 1989, 8, 161–166. [Google Scholar] [CrossRef]

- Tidd, J.; Bessant, J.; Pavitt, K. Managing Innovation; Integrating Technological, Market and Organizational Change; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Moore, W.L.; Tushman, M.L. Managing Innovation over the product life cycle. In Readings in the Management of Innovation; Harpercollins: New York, NY, USA, 1982; pp. 131–150. [Google Scholar]

- Roger, G.S.; Gary, D.S.; Dawn, R.E. Innovation in manufacturing. J. Oper. Manag. 1989, 8, 1–15. [Google Scholar]

- Wong, H.; Huang, C.-Y. Innovation in production research. Int. J. Prod. Econ. 2014, 147, 1–2. [Google Scholar] [CrossRef]

- Chae, B. An evolutionary framework for service innovation: Insights of complexity theory for service science. Int. J. Prod. Econ. 2012, 135, 813–822. [Google Scholar] [CrossRef]

- John, E.E.; Stephen, R.R. Service innovation in manufacturing. J. Serv. Manag. 2012, 23, 440–454. [Google Scholar]

- MacCarthy, B.; Brabazon, P.G.; Bramham, J. Fundamental modes of operation for mass customization. Int. J. Prod. Econ. 2003, 85, 289–304. [Google Scholar] [CrossRef]

- Caputo, A.; Marzi, G.; Pellegrini, M.M. The Internet of Things in manufacturing innovation processes. Bus. Process Manag. J. 2016, 22, 383–402. [Google Scholar] [CrossRef]

- Shepherd, C.; Ahmed, P.K. From product innovation to solutions innovation: A new paradigm for competitive advantage. Eur. J. Innov. Manag. 2000, 3, 100–106. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Li, Q.; Maggitti, P.G.; Smith, K.G.; Tesluk, P.E.; Katila, R. Top management attention to innovation: The role of search selection and intensity in new products introduction. Acad. Manag. J. 2013, 56, 893–916. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Y.; Sun, G. Research on Recommendation System from the Perspective of Consumers. J. Cent. Univ. Financ. Econ. 2016, 9, 79–85. [Google Scholar]

- Blecker, T.; Abdelkafi, N. Mass Customization: State-of-the-Art and Challenges; International Series in Operations Research & Management Science; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1–25. [Google Scholar]

- Li, J.; Lin, Z.; Zhang, X. The Study on the Effectiveness of Sustainable Customer Relationship Management: Evidence from the Online Shopping Industry. Sustainability 2023, 15, 5911. [Google Scholar] [CrossRef]

- Almunawar, M.N.; Anshari, M. Digital enabler and value integration: Revealing the expansion engine of digital marketplace. Technol. Anal. Strateg. Manag. 2021, 34, 847–857. [Google Scholar] [CrossRef]

- Yuliansyah, Y.; Rammal, H.G. Organizational learning, innovativeness and performance of financial service firms in an emerging market: Examining the mediation effects of customer-focused strategy. Bus. Process Manag. J. 2021, 27, 1126–1141. [Google Scholar] [CrossRef]

- Von Hippel, E. Lead-Users: A Source of Novel Product Concepts. Manag. Sci. 1986, 32, 791–805. [Google Scholar] [CrossRef]

- Lilien, G.; Morrison, P.D.; Searls, K.; Sonnack, M.; von Hippel, E. Performance Assessment of the Lead User Generation Process for New Product Development. Manag. Sci. 2002, 48, 1042–1059. [Google Scholar] [CrossRef]

- Urban, G.; von Hippel, E. Lead User Analyses for the Development of New Industrial Products. Manag. Sci. 1988, 35, 569–582. [Google Scholar] [CrossRef]

- Odei, S.A.; Stejskal, J. Firms pursuit of innovations through internationalization: A treatment effect estimation. Technol. Econ. Dev. Econ. 2020, 26, 837–866. [Google Scholar] [CrossRef]

- Christensen, C.M.; Bower, J.L. Customer Power, Strategic Investment and the Failure of Leading Firms. Strateg. Manag. J. 1996, 17, 197–218. [Google Scholar] [CrossRef]

- Gavetti, G.; Levinthal, D. Looking forward and looking backward: Cognitive and experiential search. Adm. Sci. Q. 2000, 45, 113–137. [Google Scholar] [CrossRef]

- Hsu, G.; Kovács, B.; Koçak, Ö. Experientially diverse customers and organizational adaptation in changing demand landscapes: A study of US cannabis markets, 2014–2016. Strateg. Manag. J. 2019, 40, 2214–2241. [Google Scholar] [CrossRef]

- Hughes, C. Ship Performance; LLP: London, UK, 1996. [Google Scholar]

- Gu, J. Standards in the eyes of shipowners. Shanghai Shipbuild. 2006, 16, 10–11+15. [Google Scholar]

- Schautschick, P.; Greenhalgh, C. Empirical studies of trade marks—The existing economic literature. Econ. Innov. New Technol. 2016, 25, 358–390. [Google Scholar] [CrossRef]

- Kim, B.; Gazzola, G.; Yang, J.; Lee, J.-M.; Coh, B.-Y.; Jeong, M.K.; Jeong, Y.-S. Two-phase edge outlier detection method for technology opportunity discovery. Scientometrics 2017, 113, 1–16. [Google Scholar] [CrossRef]

- Chen, L.; Luo, M. Comparative study on technological innovation ability of colleges and universities from the perspective of patent trend analysis. Libr. Inf. Res. 2023, 16, 114–123. [Google Scholar]

| Rename | Variable |

|---|---|

| DWT1 | Capesize Bulkcarrier Deliveries |

| DWT2 | Panamax Bulkcarrier Deliveries |

| DWT3 | Handymax Bulkcarrier Deliveries |

| DWT4 | Handysize Bulkcarrier Deliveries |

| Variables | Level | 1st Differenced | ADF |

|---|---|---|---|

| PC1 | −1.311 | −2.608 ** | YES |

| PC2 | −1.792 | −4.298 *** | YES |

| SP1 | 1.770 | −2.514 ** | YES |

| SP2 | 0.332 | −5.156 *** | YES |

| SP3 | 1.081 | −3.25 *** | YES |

| SP4(SP1 + SP2 + SP3) | 1.362 | −2.958 *** | YES |

| Serial Number | Null Hypothesis | chi-Square Test | p |

|---|---|---|---|

| 1 | PC1 is the Granger cause of SP4 | 1016.68 | 0 |

| 2 | PC2 is the Granger cause of SP4 | 21.24 | 0.0007 |

| 3 | PC1 is the Granger cause of SP3 | 1003.02 | 0 |

| 4 | PC2 is the Granger cause of SP3 | 373.69 | 0 |

| 5 | PC1 is the Granger cause of SP1 | 2.30 × 105 | 0 |

| 6 | PC2 is the Granger cause of SP1 | 26.18 | 0.0001 |

| 7 | PC1 is the Granger cause of SP2 | 463.86 | 0 |

| 8 | PC2 is the Granger cause of SP2 | 20.64 | 0.0009 |

| 9 | SP4 is the Granger cause of PC1 | 5.91 | 0.3154 |

| 10 | SP3 is the Granger cause of PC1 | 4.1 | 0.5352 |

| 11 | SP1 is the Granger cause of PC1 | 2.97 | 0.7039 |

| 12 | SP2 is the Granger cause of PC1 | 8.97 | 0.1103 |

| 13 | SP4 is the Granger cause of PC2 | 37.94 | 0 |

| 14 | SP3 is the Granger cause of PC2 | 989.9 | 0 |

| 15 | SP1 is the Granger cause of PC2 | 70 | 0 |

| 16 | SP2 is the Granger cause of PC2 | 28.81 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, H.; Ou, Z.; Bi, K.; Gao, Y. Impact of Customer Predictive Ability on Sustainable Innovation in Customized Enterprises. Sustainability 2023, 15, 10699. https://doi.org/10.3390/su151310699

Shen H, Ou Z, Bi K, Gao Y. Impact of Customer Predictive Ability on Sustainable Innovation in Customized Enterprises. Sustainability. 2023; 15(13):10699. https://doi.org/10.3390/su151310699

Chicago/Turabian StyleShen, Huayan, Zhiyong Ou, Kexin Bi, and Yu Gao. 2023. "Impact of Customer Predictive Ability on Sustainable Innovation in Customized Enterprises" Sustainability 15, no. 13: 10699. https://doi.org/10.3390/su151310699

APA StyleShen, H., Ou, Z., Bi, K., & Gao, Y. (2023). Impact of Customer Predictive Ability on Sustainable Innovation in Customized Enterprises. Sustainability, 15(13), 10699. https://doi.org/10.3390/su151310699